1. Introduction

Industrial Symbiosis (IS) is commonly associated to Industrial Ecology (IE) and constitutes a strategy to promote circular economy, as it replicates or mimics nature in an industrial environment or industrial ecosystem [

1]. This business model recreates an ecosystem where the elements or industrial actors actively share resources and wastes. One of the most accepted definitions establishes IS as the use by one company or sector of underutilised resources broadly defined (waste, by-products, residues, energy, water, logistics, capacity, expertise, equipment, and materials) from another, with the result of keeping resources in productive use for longer [

2]. The firms involved in these kinds of synergies through these exchanges achieve economic, environmental and social benefits [

3]. In practice, the companies may benefit from reduced operational costs [

4], reduced taxes [

5,

6], job creation [

7] and reduced emissions of CO

2 [

8]. Among the various successful implementation cases, the Kalundborg Eco-Industrial park (EIP) is one of the best-known examples in the world [

9], since it has been establishing exchanges and industrial cooperation for over 50 years, involving nine partners and 25 stream exchanges [

10].

The circumstances that promote IS initiatives is a subject that has been widely addressed in last 20 years [

11]. Most of these studies were intended to understand the generic conditions, benefits and factors driving the IS emerging processes, and are especially focused on the early stage [

12,

13,

14,

15]. Several studies [

3,

12] have highlighted that in the IS implementation cases there are “key factors” that end up being crucial for the emerging process of synergies. Commonly, these key factors have been categorized as enablers, barriers, challenges and triggers [

3,

15,

16,

17], and the main objective of this categorization is to discern between factors that allow, ignite or enable IS implementation and factors that obstruct or threaten this process.

These factors cross-cut different dimensions—namely, policy, social, economic, intermediaries, geographical, and technological [

3]—although it is recognized that the relation and behaviour between these factors and the economic sectors has not been appropriately analysed, especially regarding enablers and barriers [

15,

16,

17,

18,

19]. In fact, these factors do not behave in the same manner for different economic sectors. For instance, while some authors defend the idea that geographical proximity is a fundamental enabler for promotion of synergies [

20,

21,

22,

23], other authors defend a contrary position [

24], but a more detailed analysis shows that this divergence can be related with the economic sector’s nature, exchange streams and materials. In this context, the purpose of this paper is to advance in the understanding of the barriers and enablers behaviour in the IS emerging process, considering the specificities of different economic sectors, by answer the following research questions:

1. What are the key enablers and barriers in the implementation cases analysed?

2. How do the enablers and barriers function according to its economic sector?

3. What are the generic recommendations for promoting IS in the economic sectors analysed?

This paper is structured as follows: Section I is an introductory section discussing the scope of the paper and motivations of the paper. Section II typifies IS, its context approaches. Section III describes the methodology adopted and section IV promotes a better understanding on the role of the enablers and barriers in the different economic sectors. A critical discussion is carried out in section V. The conclusions are drawn in the last section.

2. Typifying Industrial Symbiosis

Industrial Ecology (IE) and its concepts emerged in the literature of the 1970s [

25]. IE is an interdisciplinary study field that cover interrelated study areas of industrial ecosystem, industrial symbiosis, industrial metabolism, legislation and regulations for IE development and applications [

26]. Nevertheless, before the IS existed as a fairly established concept, there were cases of companies that established synergies, mainly of wastes and resources. These first IS initiatives occurred typically in Europe [

9,

27]. The approaches were diverse, but both internal and external synergies could be identified, improving the productive processes through the increase of resource and, in particular, energy efficiency [

27]. Currently, these industrial ecosystems have spread throughout the world, mostly in countries with strong production activities, such as Australia [

28,

29,

30,

31,

32], China [

8,

33,

34,

35,

36,

37,

38,

39,

40], and United States [

41,

42,

43,

44,

45].

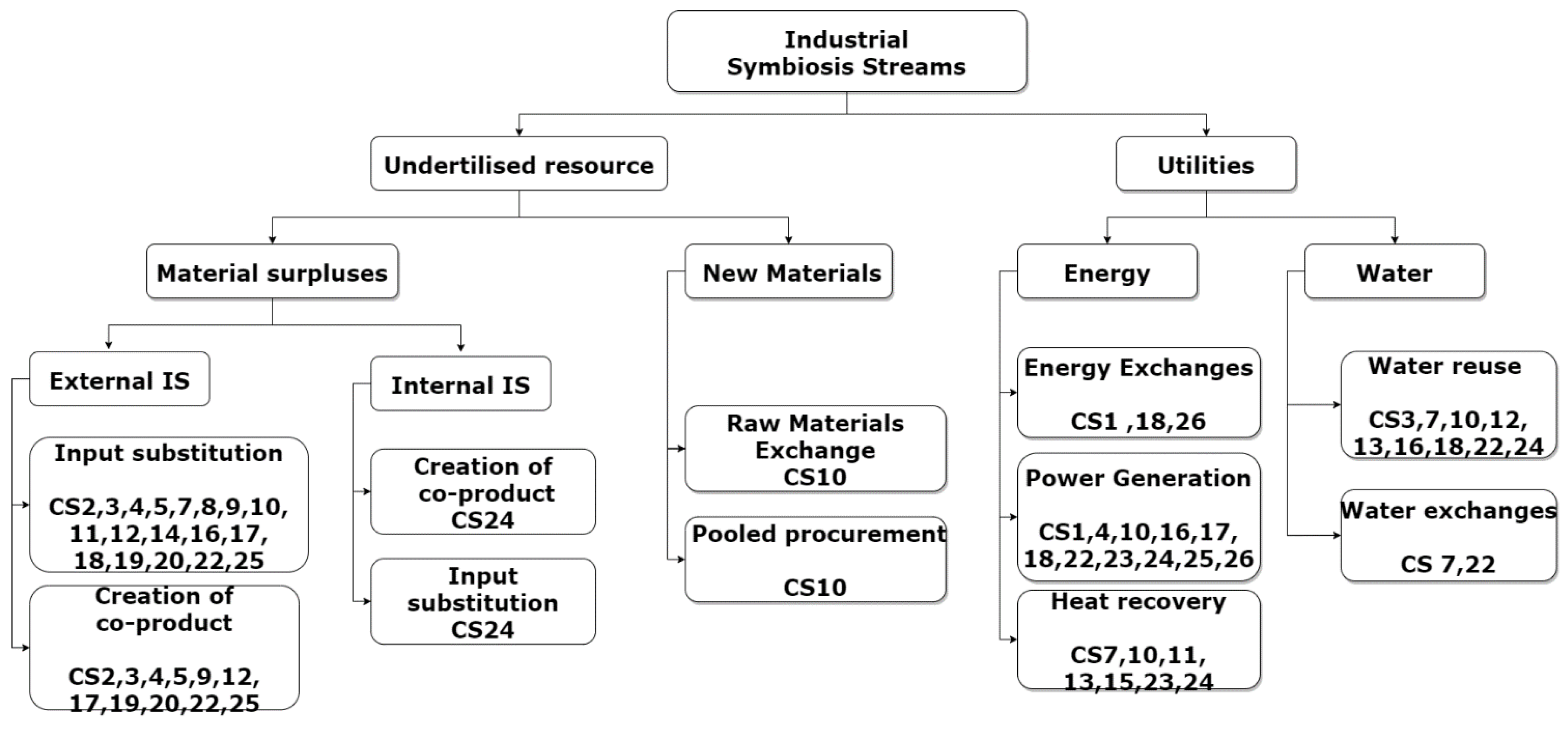

Considering IS as a collaborative approach concerning physical exchange among different companies [

1], it is natural that there are several business scenarios that provide the context for companies to perform these symbiotic exchanges [

46,

47]. The nature of these exchanges is directly related to the company operations, its environment, resources and wastes. The literature suggests that there are four types of approaches to perform these exchanges, namely:

Internal exchange: This approach refers to companies that develop synergies within the boundaries of one organization [

27].The principle is that companies can use wastes produced by their own production processes to replace inputs in other production processes within the company boundaries [

46]. Since this business model does not require strategic partnerships, the relationships will be confined to the internal boundaries, not requiring interdependences in complex networks [

47]. As a consequence, companies have to adapt their usual business model by changing the production chain to enable the synergies. The implementation of internal IS allows for adding value through lower production costs, in the form of lower virgin input purchase costs, and additional revenues [

46].

External exchange: In the external exchanges approach, instead of using the wastes produced within the company boundaries, they can send or receive wastes to/from other companies, which will use them in their production processes [

46]. In this model, the value is captured in two perspectives: the sender through the sale of the waste that is used by other companies (or at least to avoid the cost associated to waste disposal) and the receiver through lower production cost. The companies that participate in this model are highly dependent on each other to develop the streams exchanges [

47].

Eco Industrial Park: An EIP is represented by an industrial park where the local companies cooperate with each other in order to reduce the waste and pollution trough the symbiotic exchanges [

20,

48]. The main goal of this collaboration is to reduce economic costs and engage in sustainable production practices [

49]. In this approach, a central authority may design and manage the stream exchanges that will take place in the EIP [

47,

50]. The value is captured through material exchanges (by-products, wastes, resources or real-value products), operational cost reduction and non-direct revenues like stakeholder contributions and tax benefits [

46,

51,

52].

Urban Industrial Symbiosis: This approach can be described as a network of community and industrial actors bridging local needs to improve resource utilization [

53], by exploring synergies in urban and industrial areas, namely by using municipal solid waste into industrial companies, and meanwhile, applying industries as providers for living resources [

8]. In this approach, the government usually facilitates the wastes exchanges and interaction between companies and community, and, therefore, this approach is characterized by a high level of centralization [

47].

4. Enablers and Barriers: Uncovering Industrial Symbiosis in Each Economic Sector

The nomenclature given to the key symbiosis factors in the literature can diverge: drivers, enablers, incentives, barriers, and challenges [

14,

15,

81]. However, in general terms, all the studies that were analysed have the same purpose: to propose a categorization of these factors. This division of factors is intended to categorize or group them into two groups: factors that can unlock, facilitate and support the consolidation of synergies (enablers, drivers, triggers), and factors that can block or hinder the concretization of an initiative (barriers, challenges). As a consequence, we have focused on the assessment of enablers and barriers, which are amply discussed in the literature [

15,

16,

17,

18,

19], and therefore, two concepts that limit the boundaries were defined:

Enabler: A factor that facilitates and supports the concretization of symbiotic synergies.

Barrier: A factor that hinders or obstructs the development of symbiotic synergies.

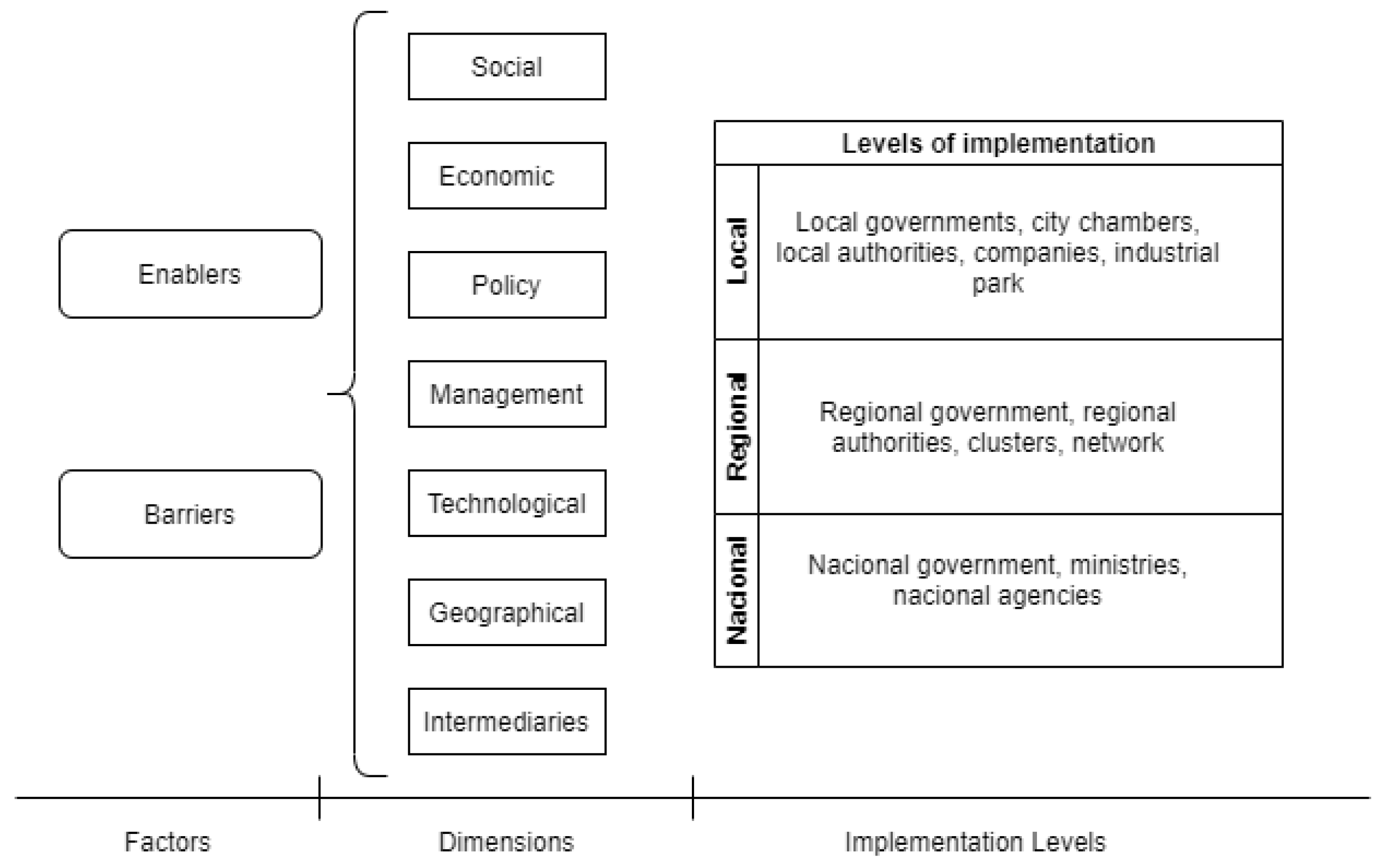

Enablers and barriers can be presented in various dimensions and levels [

3,

16,

19,

22,

82,

83,

84,

85,

86] and we suggest seven fundamental dimensions to be considered, namely social, economic, policy, management, technological, geographical and intermediaries. Any of these dimensions can be relevant in three levels of implementation [

7,

80,

87,

88]: (1) a local level that involves the most direct and close to industrial agents such as chambers, industrial park and local government; (2) a level of regional perspective that involves regional government and authorities; and (3) a national level that involves macro elements such as general government, agencies and others.

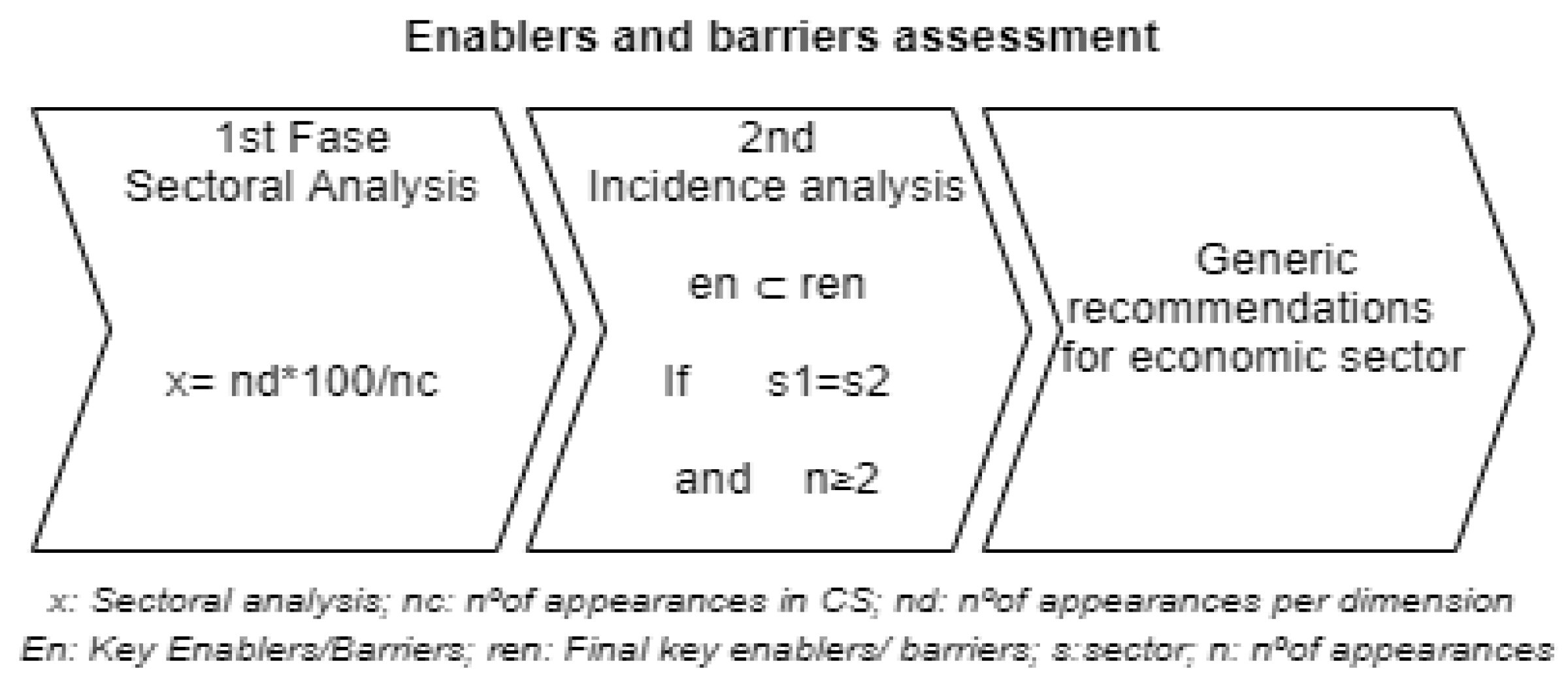

Figure 4 represents the identification framework developed for processing the enablers and barriers.

The identification of enablers and barriers was developed through a critical analysis of each paper in order to identify which were the enablers and barriers associated to each of the case study. It was possible to conclude that the majority of the studies identify the factors that had helped to overcome obstacles (enablers). However, the barriers identification was not so straightforward, but the analysis allowed for the identification of descriptors that can be used to describe the key enablers and barriers. This is presented in

Table 4 and

Table 5, where the descriptors are grouped by dimensions. The abbreviations are defined as follows: social (S); economic (E); policy (P); management (M); technological (T); geographical (G) and intermediaries (I).

4.1. Enablers and Barriers Assessment

The identification of the most important enablers and barriers in each economic sector was performed in two phases. A first phase (sectoral analysis) evaluates the dimension’s relevance (social, economic, policy, management, technological, geographical, and intermediaries) in the economic sectors. The second phase (incidence analysis), consists of the individual evaluation of barriers and enablers in each economic sector.

Figure 5 represents this two-phase approach.

The first phase (sectoral analysis) aims to identify which dimensions are more relevant in the economic sectors. For the design of the sectoral analysis, the number of cases with the same economic sector (nc) was correlated with the number of presences per dimensions (nd). The final results are presented in a heat diagram that allows for the visualization of the most important dimensions in each sector. In the second phase (incidence analysis), the barriers and enablers were separated of their dimensions, in order to evaluate the prevalence of each barrier/enabler individually. This separation of the factors dimensions is due to the fact that the first phase only allows us to obtain the overview by sector, and the second phase allows us to verify the individual behaviour of the enablers and barriers per sector.

4.1.1. Phase 1: Sectoral Analysis

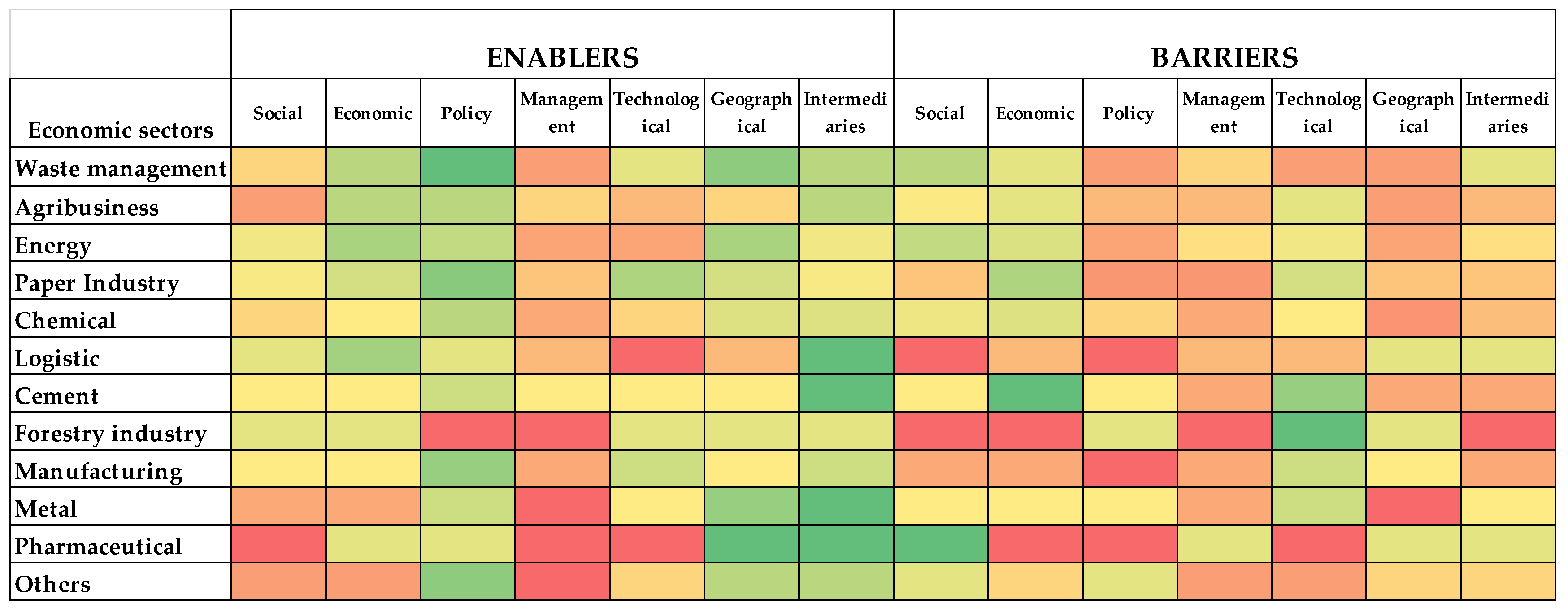

For the purpose of the phase 1, the enablers and barriers relevance are represented on a matrix basis. This heat diagram allows for the visualization of barriers and enablers relevance by economic sector. In this sense, darkest green represents the dimension with the highest presence ranging in colour degraded until darkest red, that represent those with no presence.

Figure 6 shows the heat diagram obtained for the purpose of the first phase of the factor’s assessment.

Regarding the enablers, the most relevant dimensions are the policy and intermediaries, followed by geographical and economic enablers. Concerning the barriers identification, social, technological and economic barriers are the ones that are represented with higher relevance in this first phase of the final sample.

4.1.2. Phase 2: Incidence Analysis

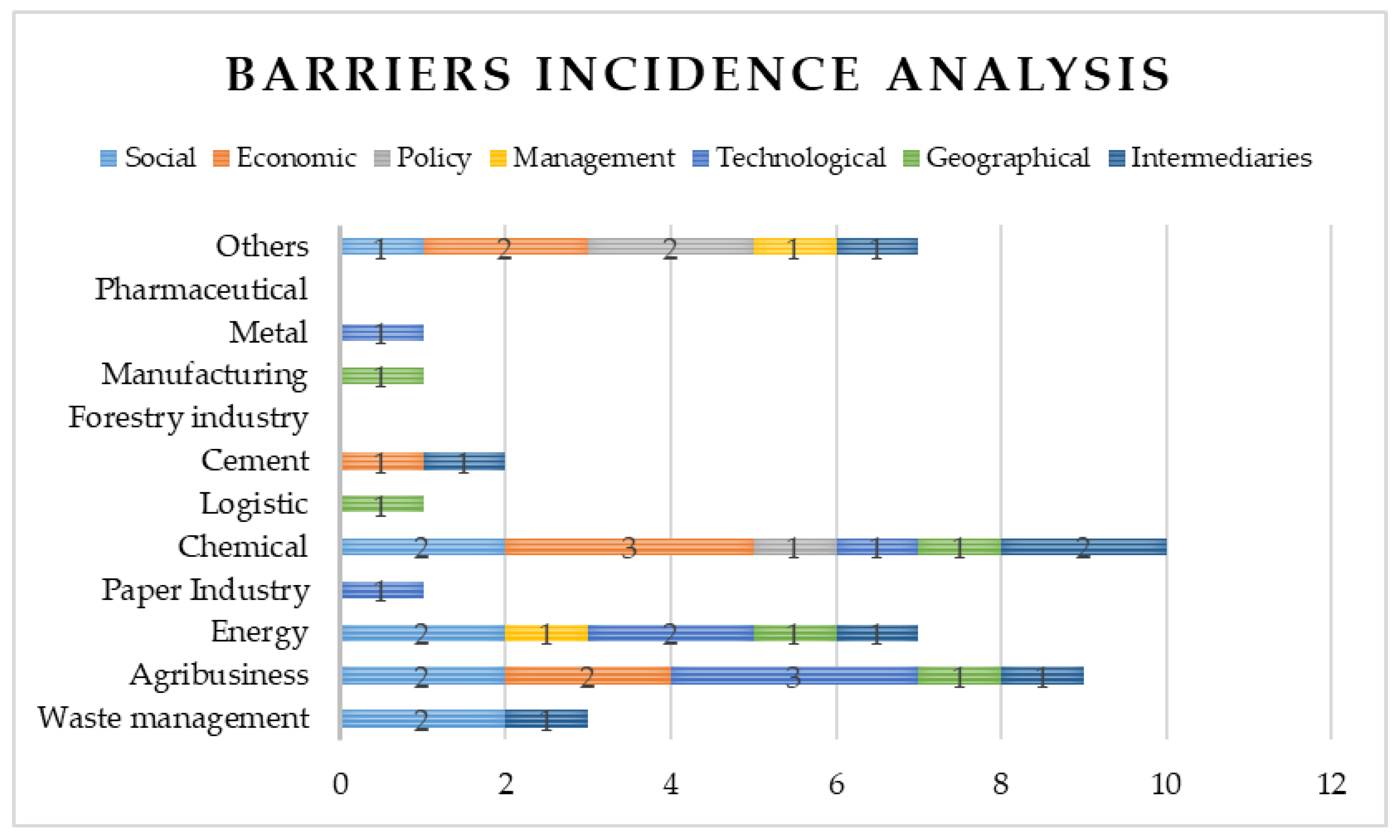

In phase 2, the incidence analysis was performed to identify the enablers and barriers with the highest prevalence and represent their importance in each sector.

Figure 7 and

Figure 8 represent the results of the second phase regarding the enablers and barriers.

Appendix A shows the final key enablers and barriers considered to the incidence analysis.

In the enablers incidence analysis, the sectors with the highest number of enablers are energy, waste management, and chemical. The main reason for these high number of enablers on the mentioned sectors is that they are highly developed sectors, with advanced processes, regulations, and technologies, such as CS 7, 10, 18. The agribusiness sector also has an important representation. A possible explanation for this important number of enablers, can deal with the fact that it is a sector with modest profit margins and, therefore, it is a sector that is quite receptive to any opportunities to create new profits [

23], such as the incorporation of synergies that can increase profits and reduce costs. This situation is presented in CS 17, 19. The cement sector is one of the best represented in existing symbiotic exchanges [

89,

90] and one of the sectors with the greatest potential for IS implementation [

91,

92], due to the fact that this sector can process diverse wastes as substitute for raw material [

89]. However, predominant enablers that met the phase 2 criteria of our analysis were not identified.

The enablers related to geographical and intermediaries’ dimensions were the ones with the greatest incidence in general terms, mostly in sectors such as wastes management, agribusiness and energy. Those sectors frequently process wastes with relatively low prices (waste management and agribusiness), and therefore, significant transport costs could make synergies unfeasible [

80]. Another premise is related to thermal losses associated to synergies on those sectors, that impose geographical proximity. This was a fact verified in energy synergies (e.g., steam and heat exchange) where the long distances could make the synergies technically and economically feasible [

93].

In regard to the enablers with less representation, in general terms, they were management and technological. This result is due to the fact that both enablers usually stand at the bottom of implementation priorities. Frequently, the implementation of management strategies or technology optimization for synergies is supported by intermediaries with strong background in IS implementation (knowledge and historical background in the development of synergies). In fact, this was confirmed in CS 23 where aspects, such as protocols for implementation of I4.0, were promoted by intermediaries with strong background [

62].

Regarding the barriers incidence analysis, the sectors with the highest representation are the agribusiness and chemical. Concerning the agribusiness sector, the technological limitations (due to the nature of the activities), social factors and reduced profit margins end up causing this great number of barriers. In the chemical sector, factors such as financial unviability due to lack of commercially viable technologies, lack of intermediaries, and social barriers have placed it as the sector with the highest characterization of barriers.

In regard to the individual incidence of barriers in the economic sectors, those that had the greatest presence were the technological and economic barriers. On the other hand, the economic barriers appeared in sectors such as agribusiness because it usually has modest profit margins. The barriers with the lowest representation were the policies and management. It is important to note that the lack of policies and a legal framework for IS is often seen as a problem [

15,

68,

94]. Even though an exception to this statement was found in CS17 [

23,

69], where firms use this absence to take advantage of the ambiguity and have flexibility to build up an incentive to promote synergies.

There are also other factors that have been represented transversally in some studies [

3,

15] and have also been identified in this analysis, reinforcing the importance of these factors. For instance, the lack of intermediaries (knowledge agents, consultancy, and companies) was represented in almost all economic sectors of the sample.

Additionally, the geographical factors re-emerge as a great barrier, especially geographical proximity. As previously mentioned, this barrier has a greater impact in low-value wastes or cases with technical specificities that require close proximity, for instance, heat and steam recovery synergies [

93]. It is important to highlight that for waste with low commercial value, the purchase of raw material often ends up being more economically viable for companies, since the distance travelled will affect the economic value of a synergy (logistics and transport) [

95]. For wastes with greater market value, proximity might not be a relevant factor [

24].

4.2. Generic Recommendations for IS per Economic Sector

The generic recommendations for symbiosis implementation are based on the key points and results of the factors’ assessment. For its promotion, has been performed a triangulation methodology in which the results of the two phases (Sectoral analysis and incidence analysis) and the literature review were triangulated in order to obtain the recommendations. This allows the main findings by means of data crosschecking from the different analysis considered to be unveiled. Hence, the generic recommendations of this study are obtained through our own methodology and results.

These recommendations are provided in order to reinforce the emerging synergies process and to help overcome the barriers identified in this study.

Table 6 present the generic recommendations for symbiosis implementation per economic sector.

5. Results Discussion

Considering the first question that refers to the enablers and barriers with greatest presence, the main output about this point was the extensive characterization of the barriers and enablers.

In general terms, this study suggests that the most important enablers dimensions are: intermediaries, geographical and policy dimensions. Concerning the intermediaries, government involvement [

35,

55,

63] and regional/national entities promoting synergies are the most prominent in this dimension [

28,

29,

60,

70].

In policy terms, the most relevant enabler is the promotion of framework supporting IS [

3,

9,

15,

16,

41,

96]. In various cases of the sample, the availability of a framework to promote industrial symbiosis was a defining factor for the realization of synergies, namely CS5, CS7, and CS22. The literature suggests that there are diverse levels of frameworks supporting IS: Macro (e.g., Waste Framework Directive [

97], Circular Economy Package [

98], Nationals plan for EC [

99]); meso (e.g., UK NISP [

88], ENEA Italy [

62]) and micro (e.g., Relvão Eco Park [

60]). Regardless of the level of governance, the framework should focus on strategic investment, promote regulatory instruments, promote incentives for IS, and increase the awareness on IS benefits and opportunities.

The taxation instruments also had an important role in this dimension, they can be separated into two main approaches: those that penalize environmental pollution or excessive and inefficient use of resources, and those taxes that promote the use of alternative methods with less environmental impact. Another important dimension consists on the economic enablers, and we specifically refer to funding and access to finance support in order to tackle economic barriers, such as co-funding investment [

7,

81], R&D projects [

100], and the local and regional funding for IS [

7]. Lastly, the geographical enablers, such as the proximity and availability of logistic networks [

20,

21,

22,

23], end up being the most prominent in this dimension.

On the other hand, the most important barriers dimensions are: technological, social, intermediaries, and geographical dimensions. Regarding intermediaries and social barriers, the conflict of interest [

22,

67,

68], the lack of trust environment [

28,

64] are the most important barriers in this dimension. In technological terms, the lack of appropriate investment and technical integration problems ended up being the most relevant in this dimension [

54,

55,

72,

75]. In social terms, the lack of interest and trust is a key barrier for IS implementation [

22,

76,

101]. Lastly, the presence of long distances is the most important geographical barrier [

9,

33].

Answering to the second question about the behaviour of the barriers and enablers according to its economic sector, there is no transversal answer, since the behaviour of the enablers and barriers will depend on the nature of each sector, streams exchanges, resources, and materials. Nevertheless, it can be concluded that primary sectors such as agribusiness, mineral extraction, and processing tend to have preference for the implementation direct exchanges of surpluses (raw material substitution) that allow to complement their operations and reduce operational costs. Secondary sectors such as manufacturing industry, steel, and wastes management, usually are characterized by high development levels, processes and regulations clearly stipulated. For this reason, those sectors tend to favour more ambitious and complex actions such as diversification of the business model, generation of new products and alteration of regulations.

In relation to the third question that refers to the recommendations for the economic sectors, it is concluded that each economic sector has different realities, priorities and interests, and, generic recommendations for each sector could be identified. It can be highlighted that we could identify as well some key aspects to promote industrial symbiosis. In this sense, the recommendations were addressed in order to reinforce these aspects (policy, economic, and social).

In policy terms, the promotion of an industrial wastes framework that effectively supports the long-term IS implementation was recommended. This framework should incentivize synergies creation through strategic investment, policy promotion and raising awareness. In economic terms, the attribution funds for synergies implementation, which will support overcoming cost barriers and uncertainties, was highlighted since many of the companies do not have the required funds to implement synergies, especially for purchase of infrastructure and utilities [

60,

68]. In the social aspect, the actions were directed in order to reinforce critical aspects such as government participation as a driving agent [

35,

55,

63], creation of collaborative approach [

60,

85] trust environment [

16,

22,

68,

76,

101], and reinforcing of strategic partnership.