The Combination of Building Greenery and Photovoltaic Energy Production—A Discussion of Challenges and Opportunities in Design

Abstract

1. Introduction

2. Method

2.1. Step 1: Literature Review

2.2. Step 2: Selection of Discussed Objects

2.3. Step 3: Matrix of Opportunities and Challenges

2.4. Step 4: Summarizing of Main Findings and Discussion

3. Background and Technical Terms

3.1. Building Greenery (BG)

3.1.1. Green Roofs (GR)

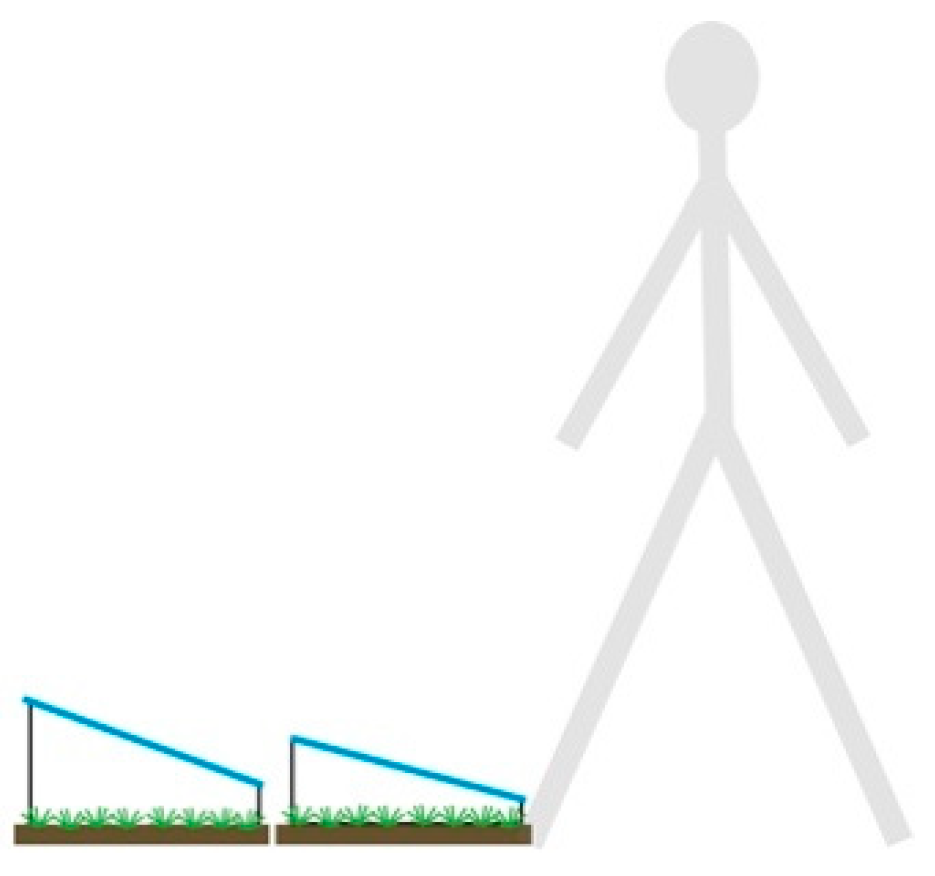

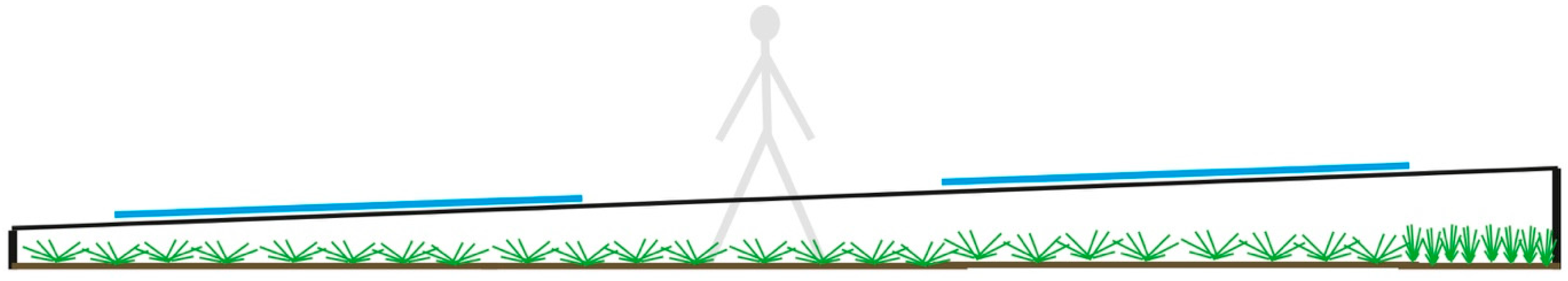

- Extensive green roofs have a low construction height below 15 cm. They only need to be maintained once a year and do not require additional watering. Typical plant communities are sedum, sedum-herb communities, or sedum-herb-grass communities. Furthermore, small shrubs can be planted. This type of roof greening is not designed for regular access of people.

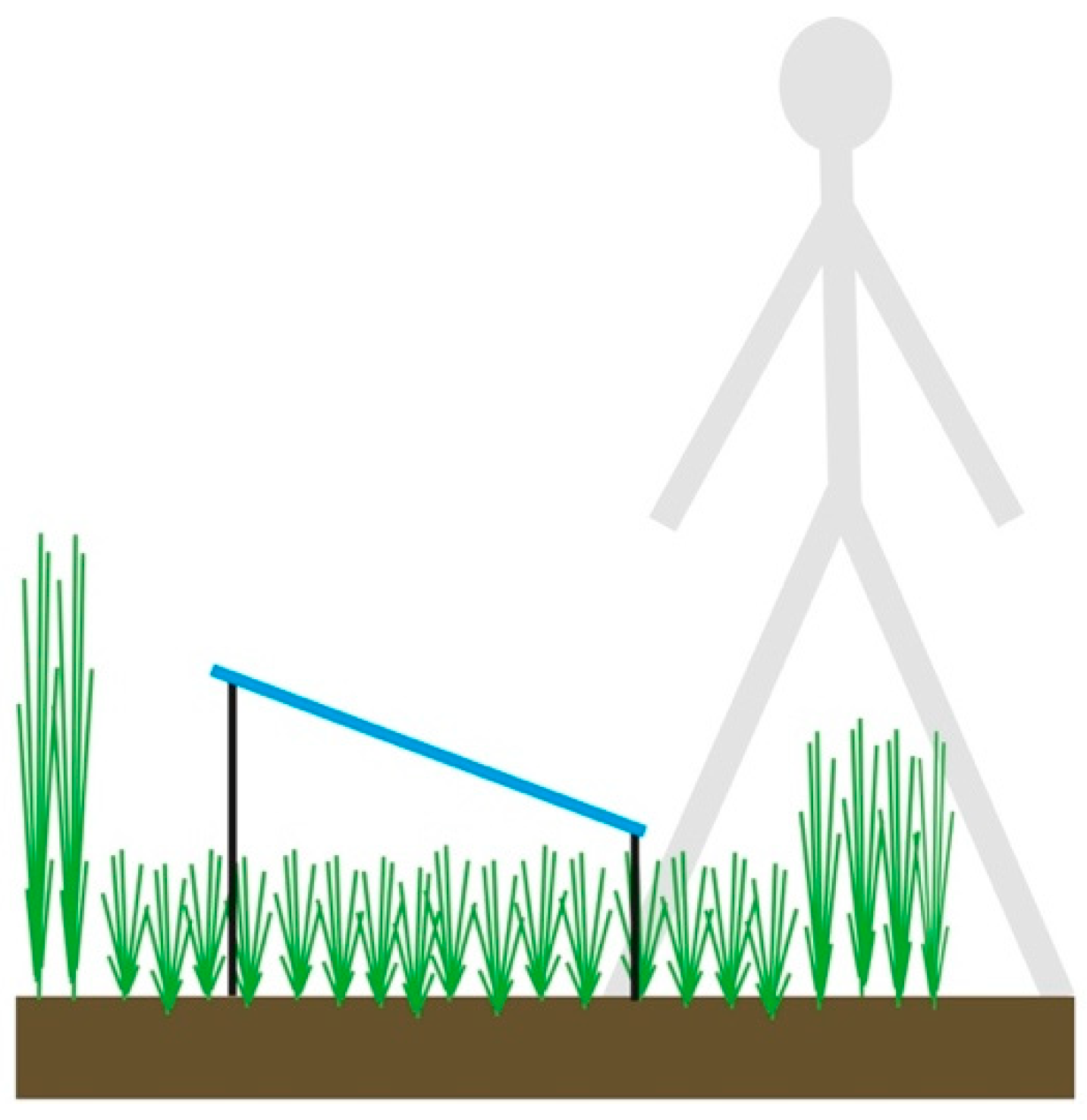

- Semi-intensive green roofs are constructed with a height between 16 and 20 cm. It is also possible to incorporate higher plants such as grasses, shrubs and perennials. Limited watering and maintenance are required. It is possible for people to access.

- Intensive green roofs and roof gardens need high maintenance and regular watering. All types of plants, even trees or edible plants, can be included. The design can be remarkably diverse, according to its purpose, from representative green, to recreation or even for urban gardening, or moreover urban farming.

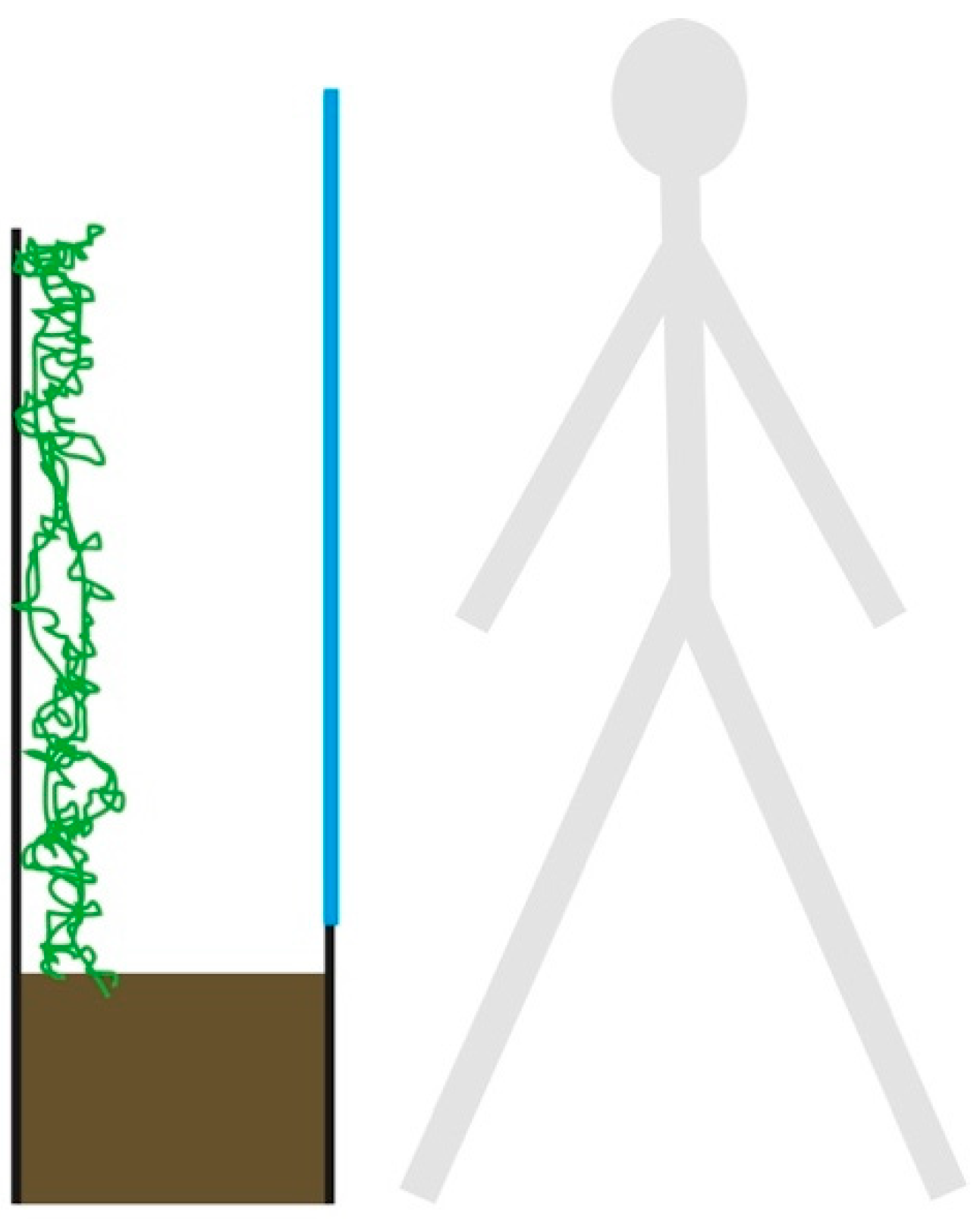

3.1.2. Vertical Green (VG)

- Living walls refer to vegetation in systems applied directly on the façade [23,24]. Within the last few years, there can be found a broad range of living wall systems on the market, differing in material and design (in turn leading to different water demands and ecological footprints of such systems [25]). The vegetation consists of annuals, perennials, grasses and small shrubs.

3.2. Photovoltaic (PV) Energy Production

- Monocrystalline silicon cells were the first PV cells on the market. They have the highest efficiency, are durable and expensive. Their colour is black or deep blue. Polycrystalline silicon cells are less expensive, have lower efficiency, and there is a broader range of colours available.

- Transparent thin-film cells are less durable, less expensive and have lower efficiencies, but allow flexible installation, even on curved surfaces.

- In the third generation, there are many new inventions of various technologies. For example, a polymer-based system of dye-sensitized solar cells or Perovskite-Si tandem cells [29]. New designs of cells are cells with laser-cut holes for shading effects or transparent effects when installed in a certain distance to the eye [30].

- type of photovoltaic cells (as mentioned above, each cell has a different capacity; this does not depend only on the type, but also on factors such as the difference in production within each cell of the same type);

- type of inverter (transforming direct current (DC) in alternating current (AC));

- inclination of module and system;

- shade and reflections from the surroundings (built or natural elements [29]);

- a fixed installation or tracking system that moves with the sun;

- local climate (air temperature, wind, radiation, direct influence of rain, as well as annual differences in climate factors);

- temperature of the cell (optimum around 20 °C [29]) and therefore surface materials below the panel; and

- frequent maintenance of the whole system.

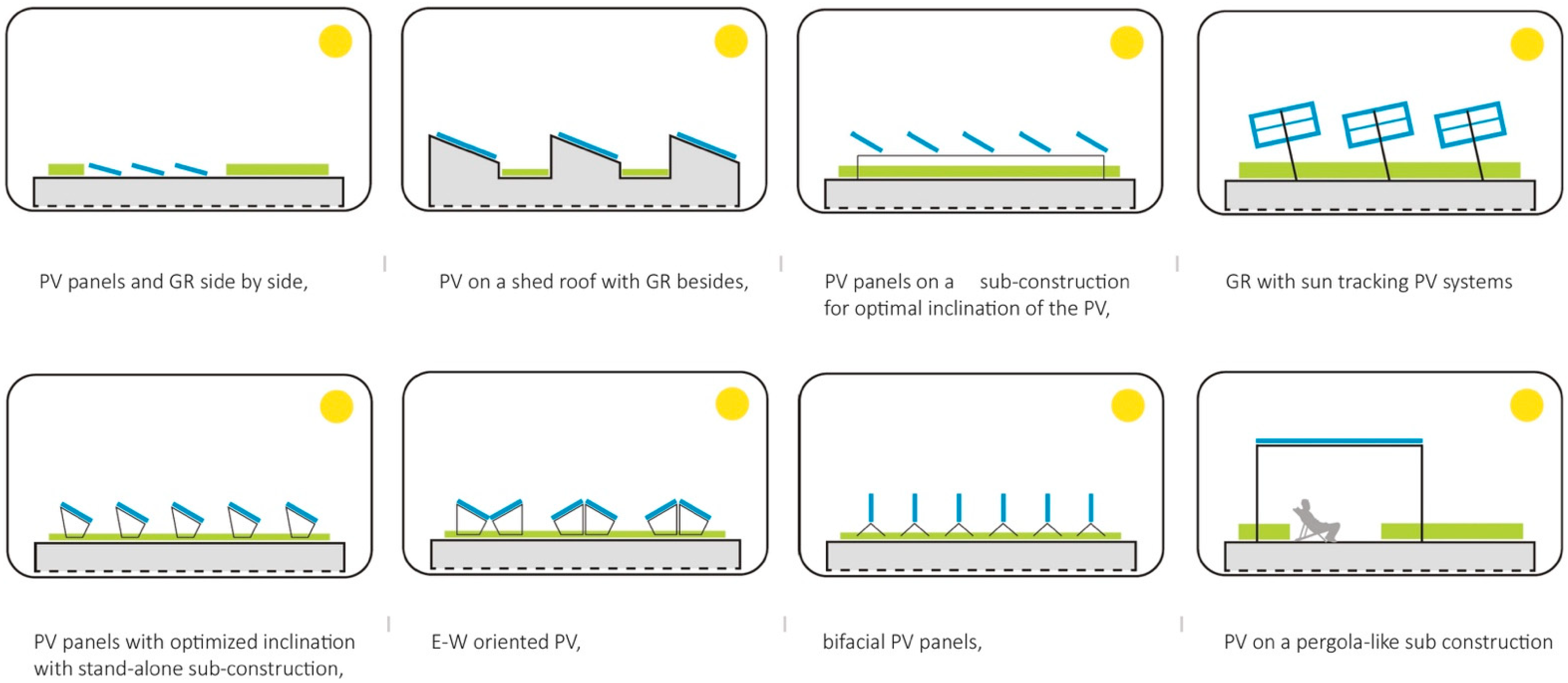

3.3. Combination of Building Greenery and Photovoltaic Energy Production

- Renewable energy production on the building is possible [34].

- Plant growth and further development of plants, as well as species richness, are enhanced due to the shading effect of the PV [35].

- Plants under the PV panels are protected from the cold in winter [34].

- Positive synergy between substrate/plants and PV panels is documented. A cooling effect occurs due to evapotranspiration. Moreover, there is an albedo effect of the plants, leading to increased energy efficiency (depending on plants, substrate and climatic conditions) [34].

- Reduced energy consumption for cooling buildings (depending on climate conditions and insulation of the building) [34].

- Improved utilization of the available roof space is possible [34].

- Potential for carbon sequestration is given (avoiding carbon production because of green energy production and carbon sequestration by soil/plant layer) [7].

- Potential for urban agriculture is given [7].

- PV panels work as a nurse object, helping plants to survive under harsh climate conditions of an extensive GR, because the soil moisture content is higher for a longer period under PV panels [7].

- Check for the possibility of funding;

- Calculate maintenance efforts;

- Obtain approvals;

- Calculate statics (wind load and load on the roof-construction);

- Investigate the shading of surrounding buildings, vegetation or installations;

- Allow accessibility to the roof for maintenance and transport of material;

- Secure water runoff (and water supply);

- Coordinate the different technical crews;

- Select the ideal combination of substrate height, plant community and sub-construction.

4. Examples of Practical Approaches for the Combination of Building Greenery (BG) and Photovoltaics (PV)

- Type of GR/VG: This criterion defines the height and material of the vegetation layer of the green roof or the vertical greening system. Moreover, information about the selected plant species is given.

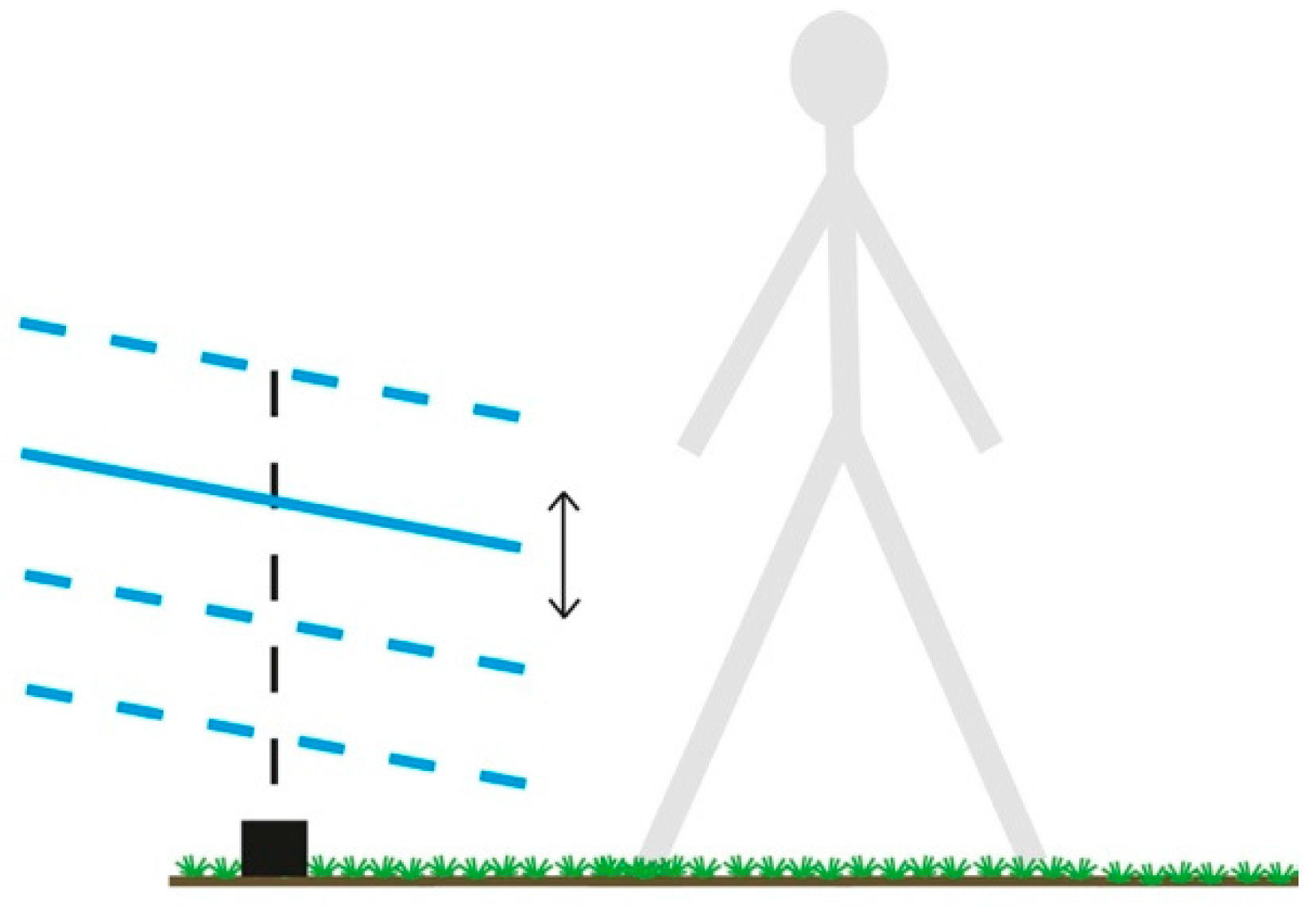

- PV-type and mounting: The sub-construction (material, distance from substrate surface to the lowest edge of the PV-panel and mounting) is described in this section. Inclination and orientation of the PV, as well as panel size and cell material, is given if available.

- Plant development influenced by PV: Information about plant growth, vitality, and flowering success of species or plants in total is collected here.

- Maintenance: Information about needed services for the PV system or cutting the vegetation and removing unwanted species is noted in this section.

- (Estimated) energy output/thermal behaviour: Information about the harvested energy yield is collected. The measured temperature of surfaces (panel, different roof type etc.) that influences the performance of the PV module is listed.

4.1. Test Facility 1 in Winterthur (Switzerland)

4.2. Science Research and Teaching Center (SRTC) Building at Portland State University (PSU) in Portland (USA, Oregon)

4.3. Examination Site at the University of Haifa in Haifa (Israel)

4.4. Test Facility 2 in Winterthur (Switzerland)

4.5. Testing Station “Öko-Prüfstand” of the TU Wien in Vienna (Austria)

4.6. System 1 on a School Building in Vienna (Austria)

4.7. System 2 on a School Building in Vienna (Austria)

4.8. Test Site of the Universidad Industrial de Santander in Bucaramanga (Colombia)

4.9. GR and PV Combination on ufaFabrik in Berlin (Germany)

4.10. Building on the Downtown Located St. George Campus of the University of Toronto in Toronto (Canada)

4.11. U.S. EPA Region 8 Headquarters Building in Denver (USA, Colorado)

4.12. PV Rooftop Garden Prototype at the University of Natural Resources and Life Science, Vienna in Vienna (Austria)

5. Results and Discussion

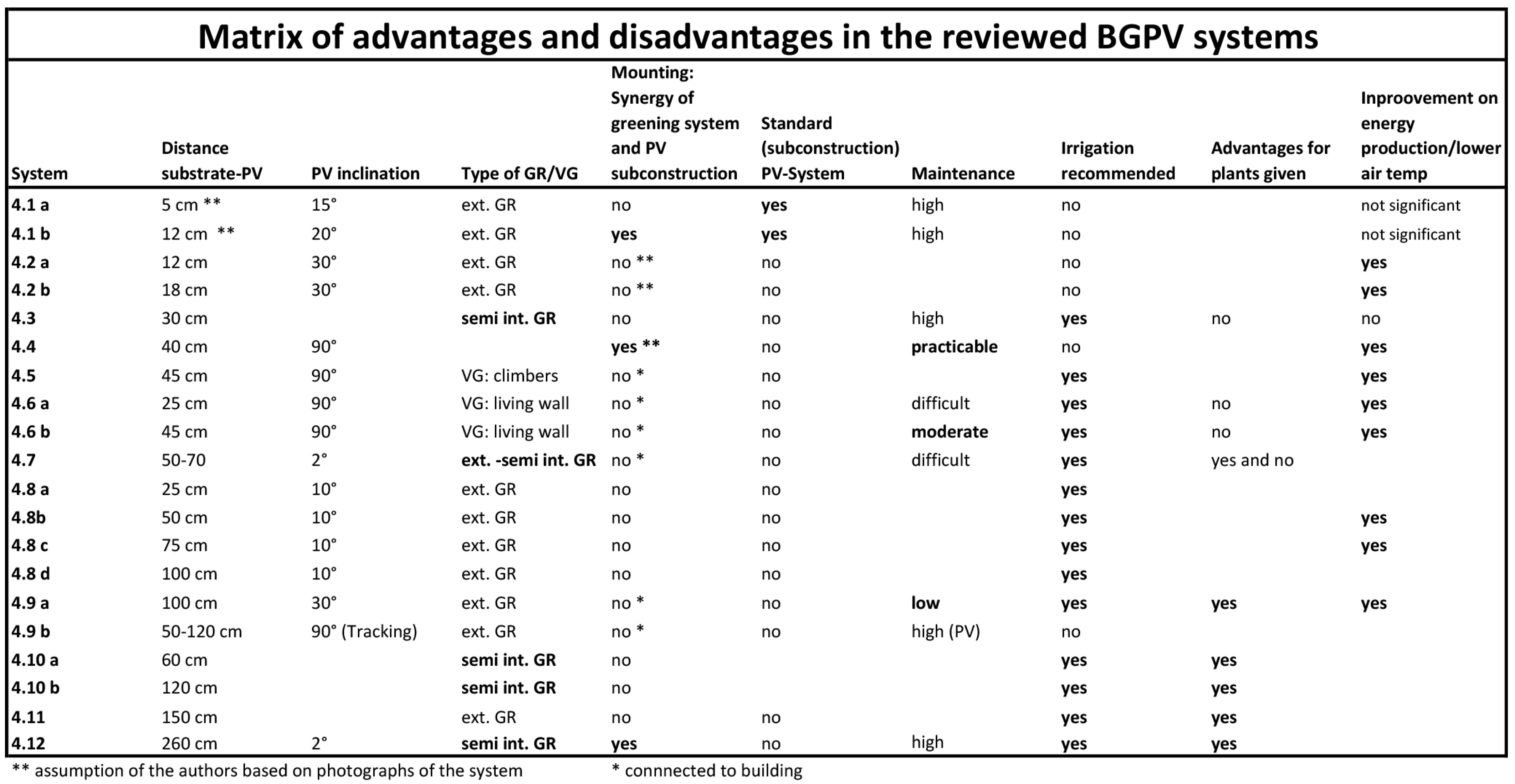

- Distance substrate (surface) to (lower) PV panel (side): This criterion shows the “air space” between the PV panel and vegetation layer. Plant height is not taken into account.

- PV-inclination: The angle of the PV panel is also listed. Both criteria (distance and PV inclination) allow a quick description of the system interactions.

- Type of green roof (GR) and vertical green (VG): The construction height of GR defines the different categories for green roofs according to the definition given in Section 3.1.1. For better understanding, extensive GR are presented in regular font, semi-intensive GR were marked bold, due to their higher environmental background. The evaluation of vertical green is done similarly: more shallow systems are described in regular font, systems with a substrate layer higher than 15 mm are marked in bold.

- Synergy of greening system and PV: This point considers whether the substrate is used as an additional weight as a ballast for the PV panels against wind loads, to avoid the need of extra weight or roof penetration to fix the PV system to the building. Furthermore, according to this, the sub-construction for VG (climbing aids or living wall systems) could be used instead of an extra sub-construction for the PV panels. If material could be reduced because of the synergy of both systems (BG and PV), it is highlighted in bold font.

- Standard (sub-construction) PV system: The systems, those that are already (prefabricated) available on the market, are highlighted bold, and customized systems are shown in regular font.

- Maintenance: Information about the maintenance of BG and PV are given in this section. If the maintenance was labelled as low or practicable, the findings are marked in a bold font. If there was a high maintenance effort necessary, or the access for maintenance work was difficult, the text is written in regular font.

- Irrigation recommended: Projects that were irrigated or would recommend irrigation are highlighted bold, not-irrigated projects are described in regular font.

- Advantages for plants given: If benefits for the plants due to the protecting effects of the PV were mentioned in the analysed publication, data are highlighted bold, if there were disadvantages, a regular font is used.

- Improvement on energy production/lower air (or PV-panel) temperatures: Positive interactions of BG and PV leading to increased energy production (compared to a PV system without plants) were highlighted in bold, negative effects are marked in regular font.

5.1. Design of Greening System and Selection of Plants

5.2. Interaction between Construction and Maintenance Efforts

5.3. Improvement in Energy Production

5.4. Key Findings for the Planning of Combined Building Greenery and Photovoltaic Systems

- BG and PV systems with low sub-construction heights require shallow substrates and low growing plants to avoid shade on the panels. The substrate can also be modelled to a lower height in front of the panel and to a higher one behind it.

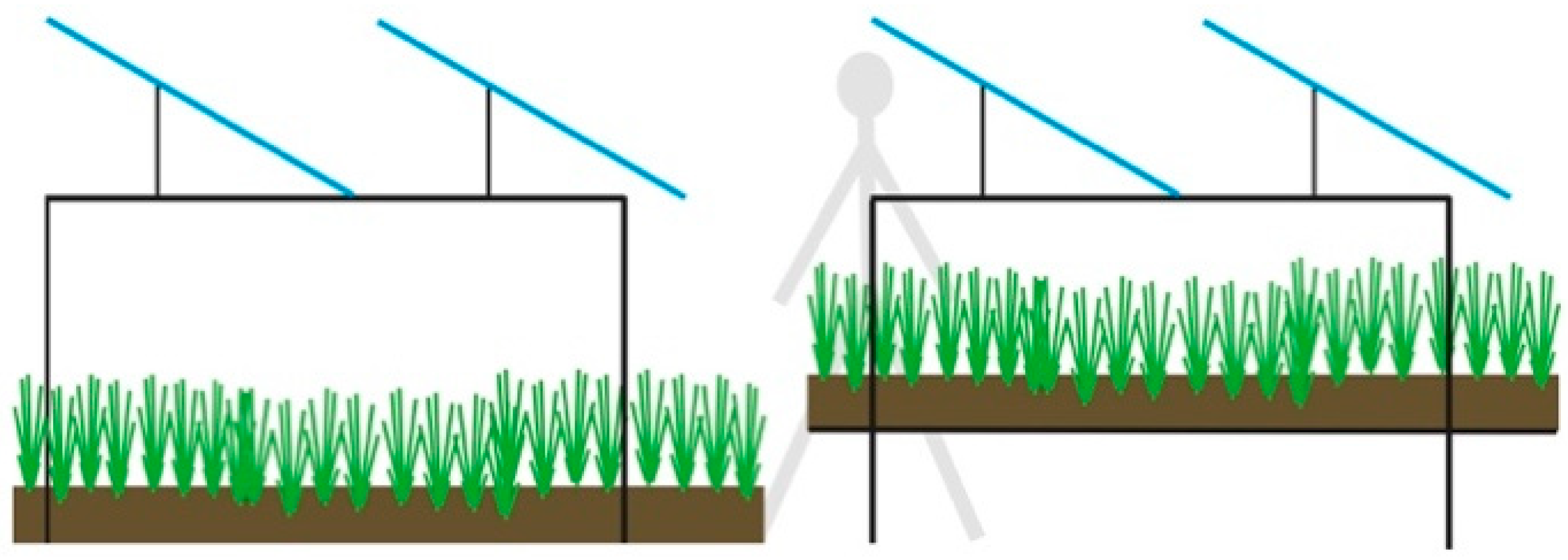

- In the case of the combination of a semi-intensive GR, a distance of 60 cm in minimum is recommended (or else high maintenance should be expected). With intensive GR-PV systems, the use of a broad range of plants is possible (depending on user needs); however, this is limited due to the gradient of shading of PV panels and the height of sub-construction.

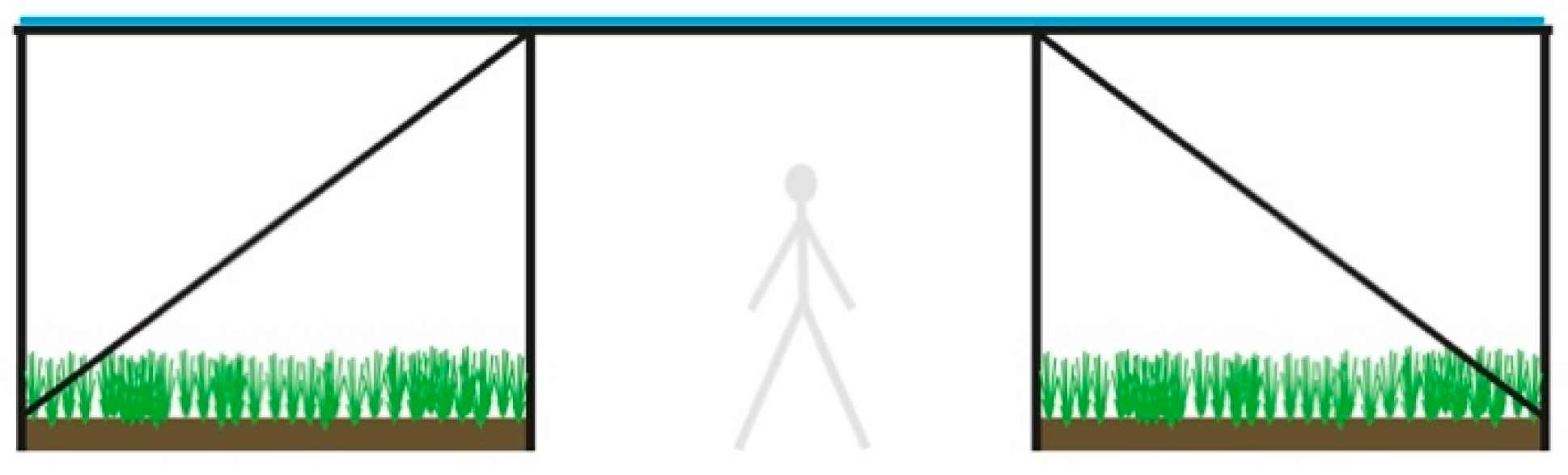

- Pergola-like sub-constructions can improve the sojourn quality on the roof for the user.

- Maintenance must be considered in the design of sub-construction. Cables must be installed properly. Mobile parts of the construction need more maintenance than fixed installations.

- To avoid penetration of the roof membrane, GR substrates can be used to secure PV panels against wind loads. Statics of the roof and wind load must be calculated with regards to the height of the building as well as local conditions.

- A combined sub-construction for PV and VG systems would be effective for minimizing anchor points in the façade. Furthermore, accessibility, in order to maintain plants under PV panels, must be considered.

- Intensive GR-PV combinations and living wall systems require irrigation. Semi-intensive and extensive GR-PV systems could consider additional watering to create more optimal conditions for plants as well as enhancement of the evapotranspiration process.

- The cooling effect of an extensive GR stops at a distance of around 75–100 cm.

- The cooling strongly depends on air velocity under the panel: Narrow system heights do not allow good air velocity and therefore store more hot air under PV panels.

- If the substrate is dry, there is no evapotranspiration and therefore no cooling. In hot and dry climate zones irrigation of the system should be considered, in order to enhance PV performance as well as cooling of the building below. Alternative water resources (rainwater, greywater) can be used to save drinking water resources.

5.5. Future Research Directions

- Development of standardized sub constructions adapted for semi-intensive and intensive GR.

- Observation of systems for the integration of alternative water resources (rain water/greywater) for an enhancement of the PV production, cooling effects and plant development.

- More research in the deployment of substrate material: there is the need for a lightweight substrate for (industrial) buildings with little weight load capacity. Moreover, the focus should go to recycled and local substrate components.

- The interaction of the shade of the PV-panels with different plant species (especially for agricultural applications) needs more investigation.

6. Conclusions

- BG and PV systems with low sub-construction heights require shallow substrates/low growing plants, whereas in the case of the combination of (a semi)-intensive GR system, a distance of a minimum 60 cm between the substrate surface and the lower panel edge is recommended; in case of an accessible roof garden, pergola-like sub-construction improve the quality of perception and comfort of users. The cooling effect of the greenery depends on the distance between the PV and the air velocity;

- If the substrate is dry, there is no evapotranspiration and therefore no cooling effect;

- There is a spectrum of different PV systems, sub-constructions, and plants for the combination of BG and PV, which are suitable for different applications shown within the publication.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schwaiger, H.N.B.D.; Gallaun, H.; Zuvela-Aloise, M.; Andre, K. Reduktion staedtischer Waermeinseln durch Verbesserung der Abstrahleigenschaften von Gebaeuden und Quartieren (KELVIN). In Berichte aus Energie- und Umweltforschung, I.u.T; Bundesministerium fuer Verkehr; Federal Ministry Republic of Austria: Vienna, Austria, 2018; p. 95. [Google Scholar]

- Brandenburg, C.; Damyanovic, D.; Reinwald, F.; Allex, B.; Gantner, B.; Czachs; Morawetz, U.; Kömle, D.; Kniepert, M. Urban Heat Islands Strategieplan; Municipal Department 22—Environmental Protection in Vienna (MA 22): Vienna, Austria, 2015. [Google Scholar]

- Scharf, B.; Zluwa, I. Case study investigation of the building physical properties of seven different green roof systems. Energy Build. 2017, 151, 564–573. [Google Scholar] [CrossRef]

- Tudiwer, D.; Korjenic, A. The effect of living wall systems on the thermal resistance of the façade. Energy Build. 2016, 135, 10–19. [Google Scholar] [CrossRef]

- Nations, U. Paris Agreement; United Nations: Paris, France, 2015. [Google Scholar]

- Baumann, T.; Nussbaumer, H.; Klenk, M.; Dreisiebner, A.; Carigiet, F.; Baumgartner, F. Photovoltaic systems with vertically mounted bifacial PV modules in combination with green roofs. Sol. Energy 2019, 190, 139–146. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. A critical analysis of factors affecting photovoltaic-green roof performance. Renew. Sustain. Energy Rev. 2015, 43, 264–280. [Google Scholar] [CrossRef]

- Korjenic, A.; Tudiwer, D.; Penaranda Moren, M.S.; Hollands, J.; Salonen, T.; Mitterböck, M.; Pitha, U.; Zluwa, I.; Stangl, R.; Kräftner, J.; et al. Hocheffiziente Fassaden- und Dachbegrünung mit Photovoltaik- Kombination. Optimale Lösung für die Energieeffizienz in gesamtökologischer Betrachtung; Federal Ministry Republic of Austria: Vienna, Austria, 2018 2019; Available online: https://nachhaltigwirtschaften.at/de/sdz/projekte/gruenplusschule-ballungszentrum-hocheffiziente-fassaden-und-dachbegruenung-mit-photovoltaik-kombination-optimale-loesung-fuer-die-energieeffizienz-in-gesamtoekologischer-betrachtung.php (accessed on 20 January 2021).

- Osma-Pinto, G.; Ordóñez-Plata, G. Measuring factors influencing performance of rooftop PV panels in warm tropical climates. Sol. Energy 2019, 185, 112–123. [Google Scholar] [CrossRef]

- Jahanfar, A.; Drake, J.; Sleep, B.; Margolis, L. Evaluating the shading effect of photovoltaic panels on green roof discharge reduction and plant growth. J. Hydrol. 2019, 568, 919–928. [Google Scholar] [CrossRef]

- Belčáková, I.; Świąder, M.; Bartyna-Zielińska, M. The Green Infrastructure in Cities as A Tool for Climate Change Adaptation and Mitigation: Slovakian and Polish Experiences. Atmosphere 2019, 10, 552. [Google Scholar] [CrossRef]

- Scharf, B.; Kraus, F. Green Roofs and Greenpass. Buildings 2019, 9, 205. [Google Scholar] [CrossRef]

- Wootton-Beard, P.C.; Xing, Y.; Prabhakaran, R.T.D.; Robson, P.; Bosch, M.; Thornton, J.M.; Ormondroyd, G.A.; Jones, P.; Donnison, I. Review: Improving the Impact of Plant Science on Urban Planning and Design. Buildings 2016, 6, 48. [Google Scholar] [CrossRef]

- What is a Green Roof? 2020. Available online: https://www.nps.gov/tps/sustainability/new-technology/green-roofs/define.htm (accessed on 4 April 2020).

- Cascone, S. Green Roof Design: State of the Art on Technology and Materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef]

- Köhler, M.; Ansel, W. Handbuch Bauwerksbegrünung: Planung, Konstruktion; Müller: Köln, Germany, 2012. [Google Scholar]

- Austrian Standards Institute. ÖNORM L 1131 Gartengestaltung und Landschaftsbau—Begrünung von Dächern und Decken auf Bauwerken; Wien, Austria, 2010; p. 59. [Google Scholar]

- Snodgrass, E.C.; McIntyre, L. The Green Roof Manual: A Professional Guide to Design, Installation, and Maintenance; Timber Press: London, UK; Portland, OR, USA, 2010. [Google Scholar]

- Wong, N.; Cheong, D.; Yan, H.; Soh, J.; Ong, C.; Sia, A. The effects of rooftop garden on energy consumption of a commercial building in Singapore. Energy Build. 2003, 35, 353–364. [Google Scholar] [CrossRef]

- Castleton, H.; Stovin, V.; Beck, S.B.; Davison, B. Green roofs; building energy savings and the potential for retrofit. Energy Build. 2010, 42, 1582–1591. [Google Scholar] [CrossRef]

- Jaffal, I.; Ouldboukhitine, S.-E.; Belarbi, R. A comprehensive study of the impact of green roofs on building energy performance. Renew. Energy 2012, 43, 157–164. [Google Scholar] [CrossRef]

- Medl, A.; Stangl, R.; Florineth, F. Vertical greening systems—A review on recent technologies and research advancement. Build. Environ. 2017, 125, 239. [Google Scholar] [CrossRef]

- Bustami, R.A.; Belusko, M.; Ward, J.; Beecham, S. Vertical greenery systems: A systematic review of research trends. Build. Environ. 2018, 146, 226–237. [Google Scholar] [CrossRef]

- Riley, B. The state of the art of living walls: Lessons learned. Build. Environ. 2017, 114, 219–232. [Google Scholar] [CrossRef]

- Ottelé, M.; Perini, K.; Fraaij, A.; Haas, E.; Raiteri, R. Comparative life cycle analysis for green façades and living wall systems. Energy Build. 2011, 43, 3419–3429. [Google Scholar] [CrossRef]

- Medl, A.; Florineth, F.; Kikuta, S.B.; Mayr, S. Irrigation of ‘Green walls’ is necessary to avoid drought stress of grass vegetation (Phleum pratense L.). Ecol. Eng. 2018, 113, 21–26. [Google Scholar] [CrossRef]

- Tudiwer, D.; Teichmann, F.; Korjenic, A. Thermal bridges of living wall systems. Energy Build. 2019, 205, 109522. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar Energy Engineering; Academic Press: London, UK, 2013. [Google Scholar]

- Celadyn, W.; Filipek, P. Investigation of the Effective Use of Photovoltaic Modules in Architecture. Buildings 2020, 10, 145. [Google Scholar] [CrossRef]

- Design Trifft Funktion. Ertex Solar GmbH. Available online: https://www.ertex-solar.at/fuer-architekten/ (accessed on 26 September 2020).

- Pearsall, N.M. Introduction to photovoltaic system performance. In The Performance of Photovoltaic (PV) Systems; Woodhead Publishing: Newcastle upon Tyne, UK, 2017. [Google Scholar]

- Köhler, M.; Wiartalla, W.; Feige, R. Interaction between PV-systems and extensive green roofs. In Proceedings of the Fifth Greening Rooftops for Sustainable Communities Conference, Minneapolis, MN, USA, 29 April–1 May 2007. [Google Scholar]

- Sattler, S.; Zluwa, I.; Österreicher, D. The “PV Rooftop Garden”: Providing Recreational Green Roofs and Renewable Energy as a Multifunctional System within One Surface Area. Appl. Sci. 2020, 10, 1791. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Photovoltaic-green roofs: A life cycle assessment approach with emphasis on warm months of Mediterranean climate. J. Clean. Prod. 2014, 72, 57–75. [Google Scholar] [CrossRef]

- Schindler, B.Y.; Blank, L.; Levy, S.; Kadas, G.; Pearlmutter, D.; Blaustein, L. Integration of photovoltaic panels and green roofs: Review and predictions of effects on electricity production and plant communities. Isr. J. Ecol. Evol. 2016, 62, 68–73. [Google Scholar] [CrossRef]

- Planungshilfe Solarenergie und Dachbegrünung. 2013. Available online: https://www.zinco.de/sites/default/files/2016-02/Solarenergie_Dachbegruenung.pdf (accessed on 23 September 2020).

- Solar Green Roof. Available online: https://www.optigreen.co.uk/system-solutions/solar-green-roof/system-build-up/ (accessed on 23 October 2020).

- Pfoser, N. Photovoltaik und Gebäudebegrünung—Lösungen und Vorteile. Neue Landsch. 2019, 11, 44–45. [Google Scholar]

- Pfoser, N. Gebäude, Begrünung, Energie: Potenziale und Wechselwirkungen. 1. Ausg. ed. FLL-Schriftenreihe Forschungsvorhaben: 2014, 1; FLL: Bonn, Germany, 2014. [Google Scholar]

- Baumann, T.; Schär, D.; Carigiet, F.; Dreisiebner, A.; Baumgartner, F. Performance Analysis of PV Green Roof Systems. In Proceedings of the 23nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 30 May–3 June 2016. [Google Scholar]

- UFA-Kräuter Solardach CH. Available online: https://www.ufasamen.ch/files/ufa-product-document/Kraeuter-Solardach-CH.pdf (accessed on 27 January 2021).

- Ogaili, H. Measuring the Effect of Vegetated Roofs on the Performance of Photovoltaic Panels in Combined Systems. Master’s Thesis, Portland State University, Portland, OR, USA, 2015. [Google Scholar]

- Ogaili, H.; Sailor, D.J. Measuring the Effect of Vegetated Roofs on the Performance of Photovoltaic Panels in a Combined System. J. Sol. Energy Eng. 2016, 138, 061009. [Google Scholar] [CrossRef]

- Schindler, B.Y.; Blaustein, L.; Lotan, R.; Shalom, H.; Kadas, G.J.; Seifan, M. Green roof and photovoltaic panel integration: Effects on plant and arthropod diversity and electricity production. J. Environ. Manag. 2018, 225, 288–299. [Google Scholar] [CrossRef] [PubMed]

- Moren, M.S.P.; Korjenic, A. Green buffer space influences on the temperature of photovoltaic modules: Multifunctional system: Building greening and photovoltaic. Energy Build. 2017, 146, 364–382. [Google Scholar] [CrossRef]

- Penaranda Moren, M.S.; Korjenic, A. Hotter and colder—How Do Photovoltaics and Greening Impact Exterior Facade Temperatures: The synergies of a Multifunctional System. Energy Build. 2017, 147, 123–141. [Google Scholar] [CrossRef]

- Stria, F. Pflanzenentwicklung in Gebäudebegrünungssystemen bei Kombination mit Photovoltaik: Am Standort GRG7 in Wien. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2019. [Google Scholar]

- Moren, M.S.P.; Korjenic, A. Untersuchungen zum ganzjährigen Wärmeschutz an Varianten eines kombinierten Dachaufbaus mit Photovoltaik und Begrünung. Bauphysik 2018, 40, 131–142. [Google Scholar] [CrossRef]

- Nusser, C. Die Etablierung Pannonischer Vegetation auf Extensiven Dachbegrünungen. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2019. [Google Scholar]

- Wiartalla, W.; Zluwa, I.; (University of Natural Resources and Life Sciences, Vienna, Austria). Personal communication, 2020.

- Bousselot, J.; Slabe, T.; Klett, J.; Koski, R. Environmental Protection Agency Photovoltaic Array Influences the Growth of Green Roof Plants. J. Living Arch. 2017, 4, 9–18. [Google Scholar] [CrossRef]

- Utzer, K.; König, J. Dachgärten in Verbindung mit Photovoltaik: Untersuchung unterschiedlicher Photovoltaikmodule über einem Dachgarten. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2014. [Google Scholar]

- Kremer, A. Pflanzen unter Lichtdurchlässigen Photovoltaikmodulen: Untersuchung des Einflusses Unterschiedlicher Beschattungen Durch Lichtdurchlässige Photovoltaikmodule auf Indikatorpflanzen. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2015. [Google Scholar]

- Buchart, A. Gemüse am Dach: Entwicklung von Gemüsepflanzen und Kräuterpflanzen im Photovoltaik-Dachgarten. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2018. [Google Scholar]

- Macher, M. Intensive Dachbegrünung in Kombination mit Photovoltaik. Untersuchung des Einflusses von lichtdurchlässigen Photovoltaikmodulen auf mehrjährige Pflanzen am Beispiel PV-Dachgarten BOKU. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2016. [Google Scholar]

- Weixelbaumer, V.; Zluwa, I.; Weihs, P.P. Roof shelter living environment: An experimental study about increasing thermal comfort on a rooftop terrace by combining photovoltaic energy production and greenroofs. In E-Nova; Leykam: Pinkafeld, Austria, 2018. [Google Scholar]

- Weixelbaumer, V. Mikroklimatische Verhältnisse im Photovoltaik-Dachgärten: Aufenthaltsqualität in einem Dachgarten mit Überdachung aus lichtdurchlässigen Photovoltaikmodulen. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2015. [Google Scholar]

- Zluwa, I.; University of Natural Resources and Life Sciences, Vienna, Austria. Unpublished work. 2018.

- Becker, G.; Leitner, B.; Stelzenhammer, O.; Absam, Austria. Report about the Energy Output in the PV-Roofgarden from 2017–2020. Unpublished work. 2020. [Google Scholar]

- Brenneisen, S. Naturschutz auf Dachbegrünungen in Verbindung mit Solaranlagen; Baudepartement des Kantons Basel-Stadt Amt für Umwelt und Energie Stadtgärtnerei und Friedhöfe: Basel, Switzerland, 2014. [Google Scholar]

- Shafique, M.; Luo, X.; Zuo, J. Photovoltaic-green roofs: A review of benefits, limitations, and trends. Sol. Energy 2020, 202, 485–497. [Google Scholar] [CrossRef]

- Pearlmutter, D.; Theochari, D.; Nehls, T.; Pinho, P.; Piro, P.; Korolova, A.; Papaefthimiou, S.; Mateo, M.C.G.; Calheiros, C.; Zluwa, I. Enhancing the circular economy with nature-based solutions in the built urban environment: Green building materials, systems and sites. Blue-Green Syst. 2019, 2, 46–72. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zluwa, I.; Pitha, U. The Combination of Building Greenery and Photovoltaic Energy Production—A Discussion of Challenges and Opportunities in Design. Sustainability 2021, 13, 1537. https://doi.org/10.3390/su13031537

Zluwa I, Pitha U. The Combination of Building Greenery and Photovoltaic Energy Production—A Discussion of Challenges and Opportunities in Design. Sustainability. 2021; 13(3):1537. https://doi.org/10.3390/su13031537

Chicago/Turabian StyleZluwa, Irene, and Ulrike Pitha. 2021. "The Combination of Building Greenery and Photovoltaic Energy Production—A Discussion of Challenges and Opportunities in Design" Sustainability 13, no. 3: 1537. https://doi.org/10.3390/su13031537

APA StyleZluwa, I., & Pitha, U. (2021). The Combination of Building Greenery and Photovoltaic Energy Production—A Discussion of Challenges and Opportunities in Design. Sustainability, 13(3), 1537. https://doi.org/10.3390/su13031537