Measuring the Effects of Automatic Replenishment on Product Availability in Retail Stores

Abstract

1. Introduction

2. Review of the Scientific Literature

2.1. Drivers of Retail Stock-Outs

2.2. Automation of Ordering Process

2.3. Impact of Automated Ordering on Product Availability

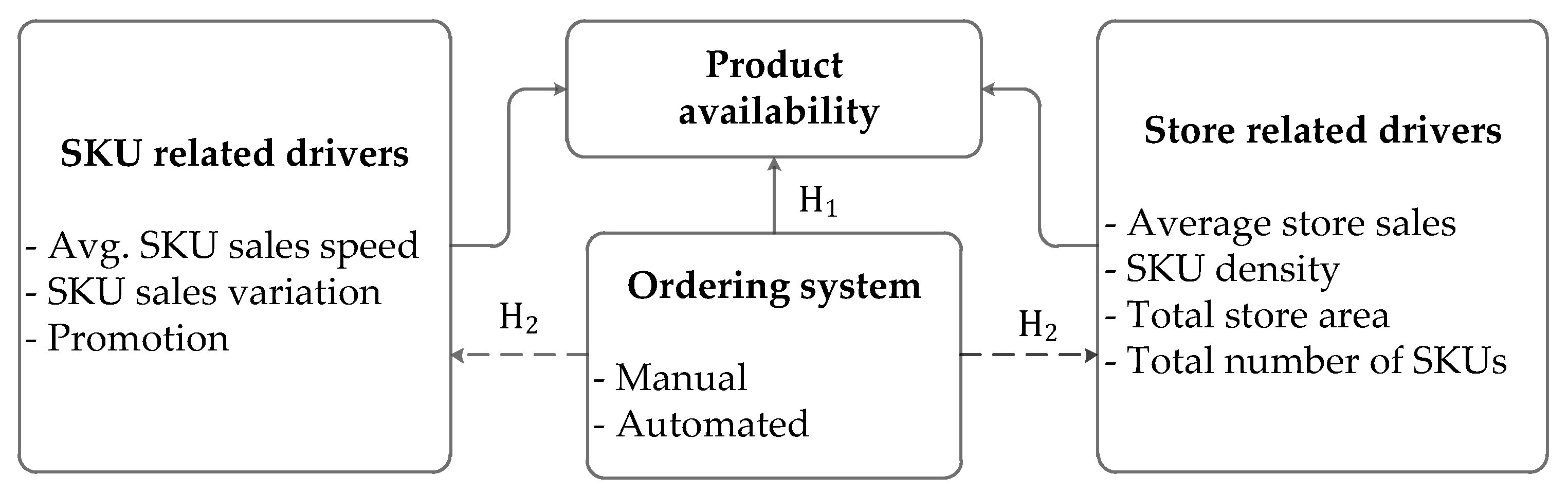

2.4. Conceptual Model and Hypotheses Development

3. Research Methodology

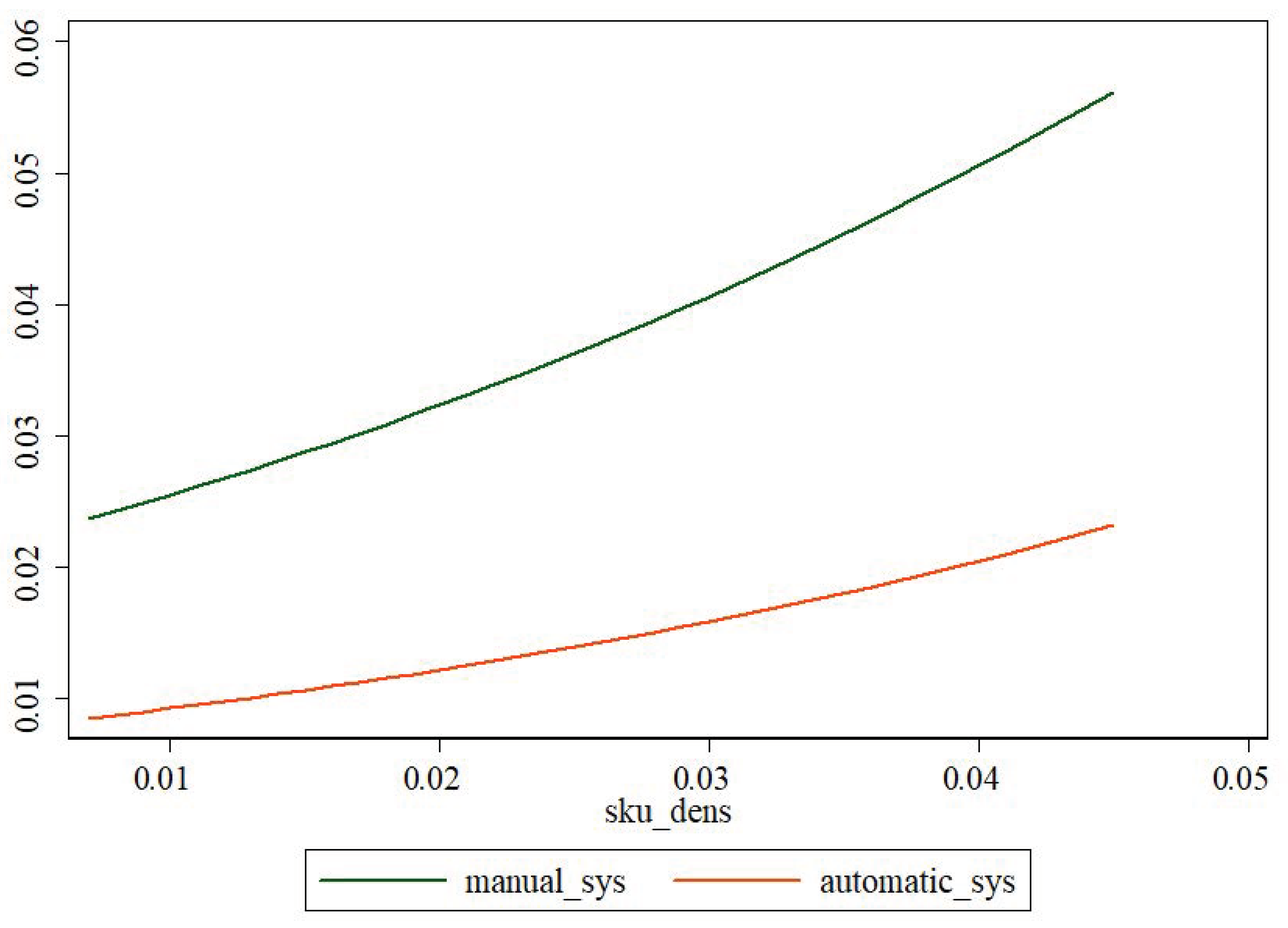

4. Results

5. Discussion

6. Managerial Insights

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lysenko-Ryba, K.; Zimon, D. Customer Behavioral Reactions to Negative Experiences during the Product Return. Sustainability 2021, 13, 448. [Google Scholar] [CrossRef]

- Wei, A.-P.; Peng, C.-L.; Huang, H.-C.; Yeh, S.-P. Effects of Corporate Social Responsibility on Firm Performance: Does Customer Satisfaction Matter? Sustainability 2020, 12, 7545. [Google Scholar] [CrossRef]

- Sakoda, G.; Takayasu, H.; Takayasu, M. Data Science Solutions for Retail Strategy to Reduce Waste Keeping High Profit. Sustainability 2019, 11, 3589. [Google Scholar] [CrossRef]

- Ronald Berger. Full-Shelf Satisfaction: Reducing Out-of-Stocks in the Grocery Channel; Grocery Manufacturers of America: Washington, DC, USA, 2002. [Google Scholar]

- Aastrup, J.; Kotzab, H. Forty years of out-of-stock research—And shelves are still empty. Int. Rev. Retail Distrib. Consum. Res. 2010, 20, 147–164. [Google Scholar] [CrossRef]

- Corsten, D.; Gruen, T. Desperately seeking shelf availability: An examination of the extent, the causes, and the efforts to address retail out-of-stocks. Int. J. Retail Distrib. Manag. 2003, 31, 605–617. [Google Scholar] [CrossRef]

- Seok, H.; Nof, S.Y.; Filip, F.G. Sustainability decision support system based on collaborative control theory. Annu. Rev. Control 2012, 36, 85–100. [Google Scholar] [CrossRef]

- Ronald Berger. Optimal Shelf Availability—Increasing Shopper Satisfaction at the Moment of Truth; ECR Europe and Roland Berger: Kontich, Belgium, 2003. [Google Scholar]

- Costantino, F.; Di Gravio, G.; Shaban, A.; Tronci, M. The impact of information sharing on ordering policies to improve supply chain performances. Comput. Ind. Eng. 2015, 82, 127–142. [Google Scholar] [CrossRef]

- Kelepouris, T.; Miliotis, P.; Pramatari, K. The impact of replenishment parameters and information sharing on the bullwhip effect: A computational study. Rev. Comput. Oper. Res. 2008, 35, 3657–3670. [Google Scholar] [CrossRef]

- Titah, R.; Shuraida, S.; Rekik, Y. Integration Breach: Investigating the Effect of Internal and External Information Sharing and Coordination on Firm Profit. Rev. Int. J. Prod. Econ. 2016, 181, 34–47. [Google Scholar] [CrossRef]

- Gajewska, T.; Zimon, D.; Kaczor, G.; Madzík, P. The impact of the level of customer satisfaction on the quality of e-commerce services. Int. J. Product. Perform. Manag. 2019, 69, 666–684. [Google Scholar] [CrossRef]

- Križo, P.; Madzík, P.; Vilgová, Z.; Sirotiaková, M. Evaluation of the Most Frequented Forms of Customer Feedback Acquisition and Analysis. In Proceedings of the International Conference on Knowledge Management in Organizations, Žilina, Slovakia, 6–10 August 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 562–573. [Google Scholar] [CrossRef]

- Capgemini Research Institute. Automation in Retail Stores Research; Consumer Survey; Capgemini Research Institute: Paris, France, 2019. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. Rev. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Sarkar, B.; Omair, M.; Choi, S.-B. A Multi-Objective Optimization of Energy, Economic, and Carbon Emission in a Production Model under Sustainable Supply Chain Management. Appl. Sci. 2018, 8, 1744. [Google Scholar] [CrossRef]

- Ehrenthal, J.C.; Stölzle, W. An examination of the causes for retail stockouts. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 54–69. [Google Scholar] [CrossRef]

- Avlijas, G.; Simicevic, A.; Avlijas, R.; Prodanovic, M. Measuring the impact of stock-keeping unit attributes on retail stock-out performance. Oper. Manag. Res. 2015, 8, 131–141. [Google Scholar] [CrossRef]

- Angerer, A. The Impact of Automatic Store Replenishment Systems on Retail: Technologies and Concepts for the Out-of-Stocks Problem; Deutscher Universitatsverlag: Wiesbaden, Germany, 2006. [Google Scholar]

- Usman, K. Determination of Drivers of Stock-out Performance of Retail Stores Using Data Mining Techniques. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2008. Available online: https://dspace.mit.edu/handle/1721.1/45246 (accessed on 7 October 2020).

- Grubor, A.; Milicevic, N. The Analysis of FMCG Product Availability in Retail Stores. Eng. Econ. 2015, 26, 67–74. [Google Scholar] [CrossRef]

- Avlijas, G.; Milicevic, N.; Golijanin, D. Influence of store characteristics on product availability in retail business. Ekon. Manag. 2018, 21, 195–206. [Google Scholar] [CrossRef]

- Milicevic, N.; Grubor, A.; Djokic, N.; Avlijas, G. Retail Out-of-stocks in the Context of Centralized and Direct Delivery. Promet Traffic Transp. 2018, 30, 105–114. [Google Scholar] [CrossRef]

- Moussaoui, I.; Williams, B.; Hofer, C.; Aloysius, J.A.; Waller, M. Drivers of retail on-shelf availability: Systematic review, critical assessment, and reflections on the road ahead. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 516–535. [Google Scholar] [CrossRef]

- Gruen, T.W.; Corsten, D.S.; Bharadwaj, S. Retail Out-of-Stocks: A Worldwide Examination of Extent, Causes and Consumer Responses; Grocery Manufacturers of America: Washington, DC, USA, 2002. [Google Scholar]

- Mattsson, S.A. Inventory control in environments with seasonal demand. Oper. Manag. Res. 2010, 3, 138–145. [Google Scholar] [CrossRef]

- Ettouzani, Y.; Yates, N.; Mena, C. Examining retail on shelf availability: Promotional impact and a call for research. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 213–243. [Google Scholar] [CrossRef]

- Van Donselaar, K.H.; Gaur, V.; Van Woensel, T.; Broekmeulen, R.A.; Fransoo, J.C. Ordering behavior in retail stores and implications for automated replenishment. Manag. Sci. 2010, 56, 766–784. [Google Scholar] [CrossRef]

- DeHoratius, N.; Raman, A. Inventory record inaccuracy: An empirical analysis. Manag. Sci. 2008, 54, 627–641. [Google Scholar] [CrossRef]

- Grubor, A.; Milicevic, N.; Djokic, N. The effect of inventory level on product availability and sale. Prague Econ. Pap. 2016, 25, 221–233. [Google Scholar] [CrossRef]

- Milicevic, N.; Grubor, A. The effect of backroom size on retail product availability—Operational and technological solutions. Amfiteatru Econ. J. 2015, 17, 661–675. [Google Scholar]

- Daugherty, P.J.; Myers, M.B.; Autry, C.W. Automatic replenishment programs: An empirical examination. Rev. J. Bus. Logist. 1999, 20, 63–82. [Google Scholar] [CrossRef]

- Yao, Y.; Dresner, M. The inventory value of information sharing, continuous replenishment, and vendor-managed inventory. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 361–378. [Google Scholar] [CrossRef]

- Arshinder, A.K.; Deshmukh, S.G. Supply chain coordination: Perspectives, empirical studies and research directions. Rev. Int. J. Prod. Econ. 2008, 115, 316–335. [Google Scholar] [CrossRef]

- Sabath, R.E.; Autry, C.W.; Daugherty, P.J. Automatic replenishment programs: The impact of organizational structure. Rev. J. Bus. Logist. 2001, 22, 91–105. [Google Scholar] [CrossRef]

- Van Donselaar, K.; Van Woensel, T.; Broekmeulen, R.; Fransoo, J. Inventory control of perishables in supermarkets. Rev. Int. J. Prod. Econ. 2006, 104, 462–472. [Google Scholar] [CrossRef]

- Kuhn, H.; Sternbeck, M. Integrative Retail Logistics: An Exploratory Study. Oper. Manag. Res. 2013, 6, 2–18. [Google Scholar] [CrossRef]

- Ehrenthal, J.; Honhon, D.; Woensel, T.V. Demand Seasonality in Retail Inventory Management. Eur. J. Oper. Res. 2014, 238, 527–539. [Google Scholar] [CrossRef]

- Jonsson, P.; Mattsson, S.A. The Value of Sharing Planning Information in Supply Chains. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 282–299. [Google Scholar] [CrossRef]

- Byrne, P.; Heavy, C. The Impact of Information Sharing and Forecasting in Capacitated Industrial Supply Chains: A Case Study. Int. J. Prod. Econ. 2006, 103, 420–437. [Google Scholar] [CrossRef]

- Noh, J.S.; Kim, J.S.; Sarkar, B. Stochastic joint replenishment problem with quantity discounts and minimum order constraints. Oper. Res. 2019, 19, 151–178. [Google Scholar] [CrossRef]

- Van Woensel, T.; Van Donselaar, K.; Broekmeulen, R.; Fransoo, J. Consumer responses to shelf out-of-stocks of perishable products. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 704–718. [Google Scholar] [CrossRef]

- Bakker, M.; Jan Riezebos, J.; Teunter, R.H. Review of inventory systems with deterioration since 2001. Rev. Eur. J. Oper. Res. 2012, 221, 275–284. [Google Scholar] [CrossRef]

- Broekmeulen, R.; Van Donselaar, K.H. A heuristic to manage perishable inventory with batch ordering, positive lead-times, and time-varying demand. Rev. Comput. Oper. Res. 2009, 36, 3013–3018. [Google Scholar] [CrossRef]

- Ferguson, M.; Ketzenberg, M.E. Information sharing to improve retail product freshness of perishables. Rev. Prod. Oper. Manag. 2006, 15, 57–73. [Google Scholar] [CrossRef]

- Huber, J.; Gossmann, A.; Stuckenschmidt, H. Cluster-based hierarchical demand forecasting for perishable goods. Expert Syst. Appl. 2017, 76, 140–151. [Google Scholar] [CrossRef]

- Ahvonen, O. Retail Store Replenishment: Understanding the Improvement Areas in Automated Ordering Processes. Master’s Thesis, Aalto University, Espoo, Finland, 2018. Available online: https://aaltodoc.aalto.fi/handle/123456789/34733 (accessed on 2 November 2020).

- Bourlakis, M.; Maglaras, G.; Gallear, D.; Fotopoulos, C. Examining sustainability performance in the supply chain: The case of the Greek dairy sector. Rev. Ind. Mark. Manag. 2014, 43, 56–66. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Moll, H.C.; Schoot Uiterkamp, A.J.M. Design and development of a measuring method for environmental sustainability in food production systems. Rev. Ecol. Econ. 2003, 46, 231–248. [Google Scholar] [CrossRef]

- Maloni, M.J.; Brown, M.E. Corporate social responsibility in the supply chain: An application in the food industry. Rev. J. Bus. Ethics 2006, 68, 35–52. [Google Scholar] [CrossRef]

- Kiil, K.; Hvolby, H.H.; Fraser, K.; Dreyer, H.; Strandhagen, J.O. Automatic replenishment of perishables in grocery retailing: The value of utilizing remaining shelf-life information. Br. Food J. 2018, 120, 2033–2046. [Google Scholar] [CrossRef]

- Kiil, K.; Dreyer, H.C.; Hvolby, H.H.; Chabada, L. Sustainable food supply chains: The impact of automatic replenishment in grocery stores. Prod. Plan. Control 2018, 29, 106–116. [Google Scholar] [CrossRef]

- Ivanov, P. Improving Availability and Waste via Order Timing in Quickly Perishable Goods Retail. Master’s Thesis, Aalto University, Espoo, Finland, 2019. Available online: https://aaltodoc.aalto.fi/handle/123456789/39844 (accessed on 26 October 2020).

- Gruen, T.W.; Corsten, D.S. A Comprehensive Guide to Retail Out-of-Stock Reduction in the Fast-Moving Consumer Goods Industry; Grocery Manufacturers of America: Washington, DC, USA, 2007. [Google Scholar]

- Long, J.S. Regression Models for Categorical and Limited Dependent Variables; Sage Publications: Thousand Oaks, CA, USA, 1997. [Google Scholar]

- León-Bravo, V.; Caniato, F.; Caridi, M.; Johnsen, T. Collaboration for Sustainability in the Food Supply Chain: A Multi-Stage Study in Italy. Sustainability 2017, 9, 1253. [Google Scholar] [CrossRef]

- Ganesh, M.; Raghunathan, S.; Rajendran, C. The value of information sharing in a multi-product, multi-level supply chain: Impact of product substitution, demand correlation, and partial information sharing. Rev. Decis. Support Syst. 2014, 58, 79–94. [Google Scholar] [CrossRef]

| Complexity | Manual Replenishment Systems | IT-Supported Replenishment Systems | Sales-Based Replenishment Systems | Demand-Based Replenishment Systems | |

|---|---|---|---|---|---|

| Modules | |||||

| Inventory visibility | Manual records | Electronic inventory records (Accuracy of inventory records increases) | |||

| Replenishment logic | Manual decision: quantity and time | Simple heuristics (T, Q), (T, S), (s, Q), (s, S) | (s, Q’) or (s, S) | ||

| Order restrictions | Manual consideration of restrictions | Basic restrictions visible in IT systems | Medium restrictions implemented in IT systems | Complex restrictions implemented in IT systems | |

| Forecasts | None or some kind of qualitative method | N/A | Time series/causal based forecasts | ||

| References | Stock-Keeping Unit (SKU) Drivers of Stock-Outs | Store Drivers of Stock-Outs | Efficency of Automated Replenishment Systems (ARS)/Automated Replenishment Programs ARP Examined | Agorithmic Stock-Out Identification, Large Sample |

|---|---|---|---|---|

| Angerer (2006) | ✓ | ✓ | ✓ | |

| Gruen and Corsten (2007) | ✓ | ✓ | ✓ | |

| Usman (2008) | ✓ | ✓ | ||

| Ettouzani et al. (2012) | ✓ | ✓ | ||

| Ehrenthal and Stölzle (2013) | ✓ | ✓ | ✓ | |

| Avlijas et al. (2015) | ✓ | ✓ | ✓ | |

| Grubor and Milicevic (2015) | ✓ | ✓ | ✓ | |

| Milicevic et al. (2018) | ✓ | ✓ | ✓ | |

| Avlijas et al. (2018) | ✓ | ✓ | ||

| Kiil et al. (2018) | ✓ | ✓ | ||

| Ivanov (2019) | ✓ | ✓ | ||

| This paper | ✓ | ✓ | ✓ | ✓ |

| System | Manual Replenishment | Automatic Replenishment | |

|---|---|---|---|

| Modules | |||

| Inventory visibility | Electronic inventory record system | ||

| Replenishment logic | Manual decision: Quantity and time | Automatic decision: Variable quantity and frequency (s, S) | |

| Order restrictions | Basic restrictions given in IT systems | Complex restrictions implemented into ERP system | |

| Forecasts | Qualitative, based on last week’s sales and experience | Quantitative, 105 weeks’ time series-based forecasts | |

| # | Variable | Obs | Mean | Std. Dev. | Min | Max |

|---|---|---|---|---|---|---|

| v1 | avg_sales_sku | 2,318,693 | 0.37904 | 0.67157 | 0.000 | 14.891 |

| v2 | sales_var | 2,318,693 | 0.56388 | 0.59389 | 0.000 | 12.147 |

| v3 | promotion | 2,318,693 | 0.13940 | 0.34637 | 0 | 1 |

| v4 | avg_sales_str | 2,318,693 | 1828.15 | 781.519 | 605.12 | 4228.46 |

| v5 | sku_dens | 2,318,693 | 0.02118 | 0.0066 | 0.007 | 0.045 |

| v6 | str_area | 2,318,693 | 177.390 | 43.3903 | 67 | 280 |

| v7 | total_sku_nmr | 2,318,693 | 8557.12 | 994.3883 | 4.202 | 10.107 |

| v8 | auto_ordr | 2,318,693 | 0.50841 | 0.49993 | 0 | 1 |

| stock_out | 2,318,693 | 0.0252733 | 0.156954 | 0 | 1 |

| System/Availability | Available | Stock-Out |

|---|---|---|

| Manual system | 96.28% | 3.72% |

| Automatic system | 98.62% | 1.38% |

| Total | 97.47% | 2.53% |

| v1 | v2 | v3 | v4 | v5 | v6 | v7 | v8 | |

|---|---|---|---|---|---|---|---|---|

| v1 | 1 | |||||||

| v2 | 0.8844 | 1 | ||||||

| v3 | 0.0333 | 0.0358 | 1 | |||||

| v4 | 0.2447 | 0.2297 | −0.0005 | 1 | ||||

| v5 | 0.0461 | 0.0393 | −0.0001 | 0.0853 | 1 | |||

| v6 | 0.0658 | 0.052 | −0.0007 | 0.147 | 0.835 | 1 | ||

| v7 | −0.011 | −0.0175 | −0.0011 | 0.026 | −0.5888 | −0.092 | 1 | |

| v8 | −0.1363 | −0.1731 | 0.0003 | −0.0086 | −0.007 | −0.0098 | −0.0026 | 1 |

| Stock_Out | Coef. | Std. Err. | z | P > z | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| avg_sales_sku | 0.091605 | 0.00202 | 45.3 | 0.000 | 0.08764 | 0.09557 |

| 1.promotion | 0.195557 | 0.00465 | 42.1 | 0.000 | 0.18645 | 0.20466 |

| avg_sales_str | 0.000019 | 0.00000 | 8.04 | 0.000 | 0.00001 | 0.00002 |

| sku_dens | 10.398930 | 0.25858 | 40.2 | 0.000 | 9.89213 | 10.90573 |

| 1.auto_ordr | −0.404573 | 0.00381 | −106.14 | 0.000 | −0.41204 | −0.39710 |

| _cons | −2.124528 | 0.00732 | −290.18 | 0.000 | −2.13888 | −2.11018 |

| LR chi2(5) = | 19.047.05 | Prob > chi2 = 0.000 | Pseudo R2 = 0.0348 | |||

| promo#auto_ordr | Margin | Std. Err. | z | P > z | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| 0#0 | 0.03455 | 0.00018 | 188.42 | 0.000 | 0.03419 | 0.03491 |

| 0#1 | 0.01241 | 0.00011 | 111.24 | 0.000 | 0.01219 | 0.01263 |

| 1#0 | 0.04741 | 0.00053 | 89.75 | 0.000 | 0.04637 | 0.04844 |

| 1#1 | 0.02448 | 0.00038 | 64.15 | 0.000 | 0.02374 | 0.02523 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avlijas, G.; Vukanovic Dumanovic, V.; Radunovic, M. Measuring the Effects of Automatic Replenishment on Product Availability in Retail Stores. Sustainability 2021, 13, 1391. https://doi.org/10.3390/su13031391

Avlijas G, Vukanovic Dumanovic V, Radunovic M. Measuring the Effects of Automatic Replenishment on Product Availability in Retail Stores. Sustainability. 2021; 13(3):1391. https://doi.org/10.3390/su13031391

Chicago/Turabian StyleAvlijas, Goran, Vesna Vukanovic Dumanovic, and Miljan Radunovic. 2021. "Measuring the Effects of Automatic Replenishment on Product Availability in Retail Stores" Sustainability 13, no. 3: 1391. https://doi.org/10.3390/su13031391

APA StyleAvlijas, G., Vukanovic Dumanovic, V., & Radunovic, M. (2021). Measuring the Effects of Automatic Replenishment on Product Availability in Retail Stores. Sustainability, 13(3), 1391. https://doi.org/10.3390/su13031391