Inspection and Assessment of Masonry Arch Bridges: Ivanjica Case Study

Abstract

:1. Introduction

2. Research Objectives

- Active investigation of the site to determine the condition of the bridge and to ensure that adequate measures can be taken for the protection and safeguarding of this historic structure as well as the unique spirit and landmark quality of the entire Spatial Cultural-Historical Units of Great Importance in the Republic of Serbia.

- Conducting all necessary research to provide the protection measurements, the maintenance of stability and preservation of the integrity:

- -

- Geological testing for determination of soil quality and foundation stability;

- -

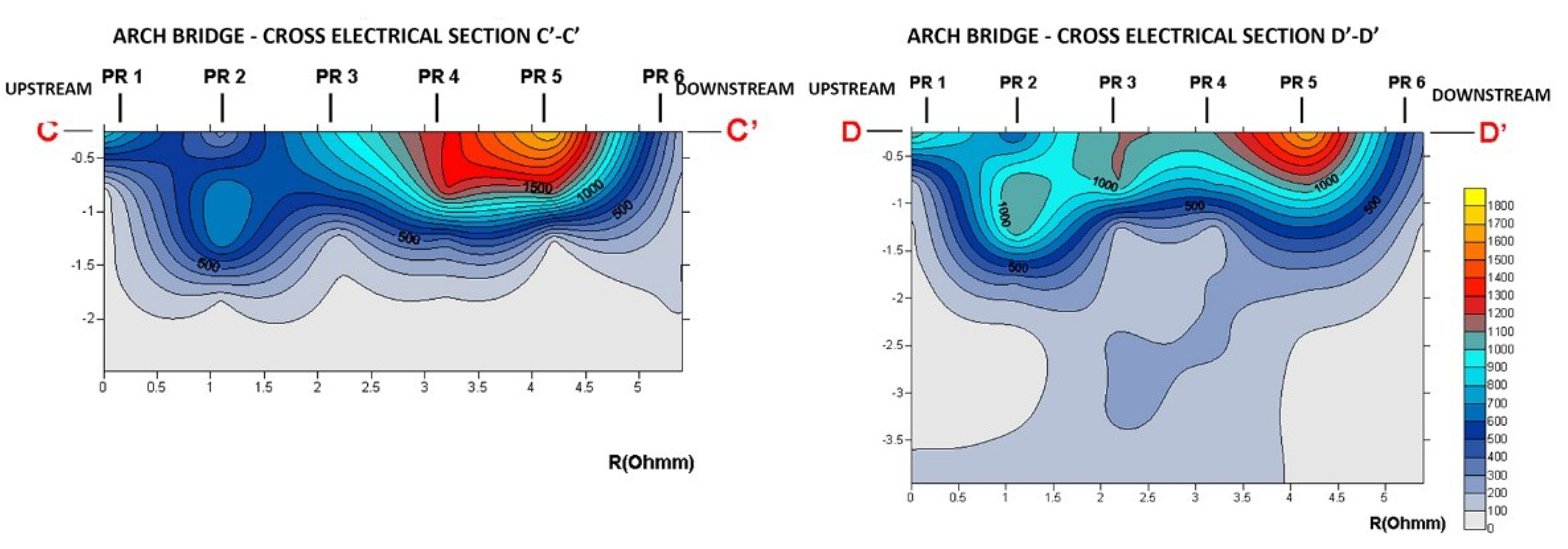

- Geophysical testing using geoelectrical tomography to determine the physical characteristics of the internal bridge structure;

- -

- Laboratory physical–mechanical testing of stone structure samples to determine physical and mechanical characteristics;

- -

- Biological analysis of damaged stones to determine degradation level;

- -

- Structural analysis through the numerical model for determining the causes of longitudinal cracks on the arch barrel.

- Perceiving the results of conducted research to determine the causes of deformations and cracks of the stone arch bridge.

- Systemise the obtained facts about the causes of deformations of the bridge and analyse its structural behaviour, assessing the stability of the structure, and suggest necessary measures to preserve this historic structure and prevent further deterioration.

- Enhancing knowledge about the possibility of protecting stone bridges to prevent further degradation, particularly the development of new cracks.

- Enhancing consciousness concerning the values and methods of historical monuments preservation.

Literature Review

3. Case Study Methodology

- Data analysis using literature review, analysis of previous studies and the systematisation of knowledge about the problem of cracks on arch stone bridges.

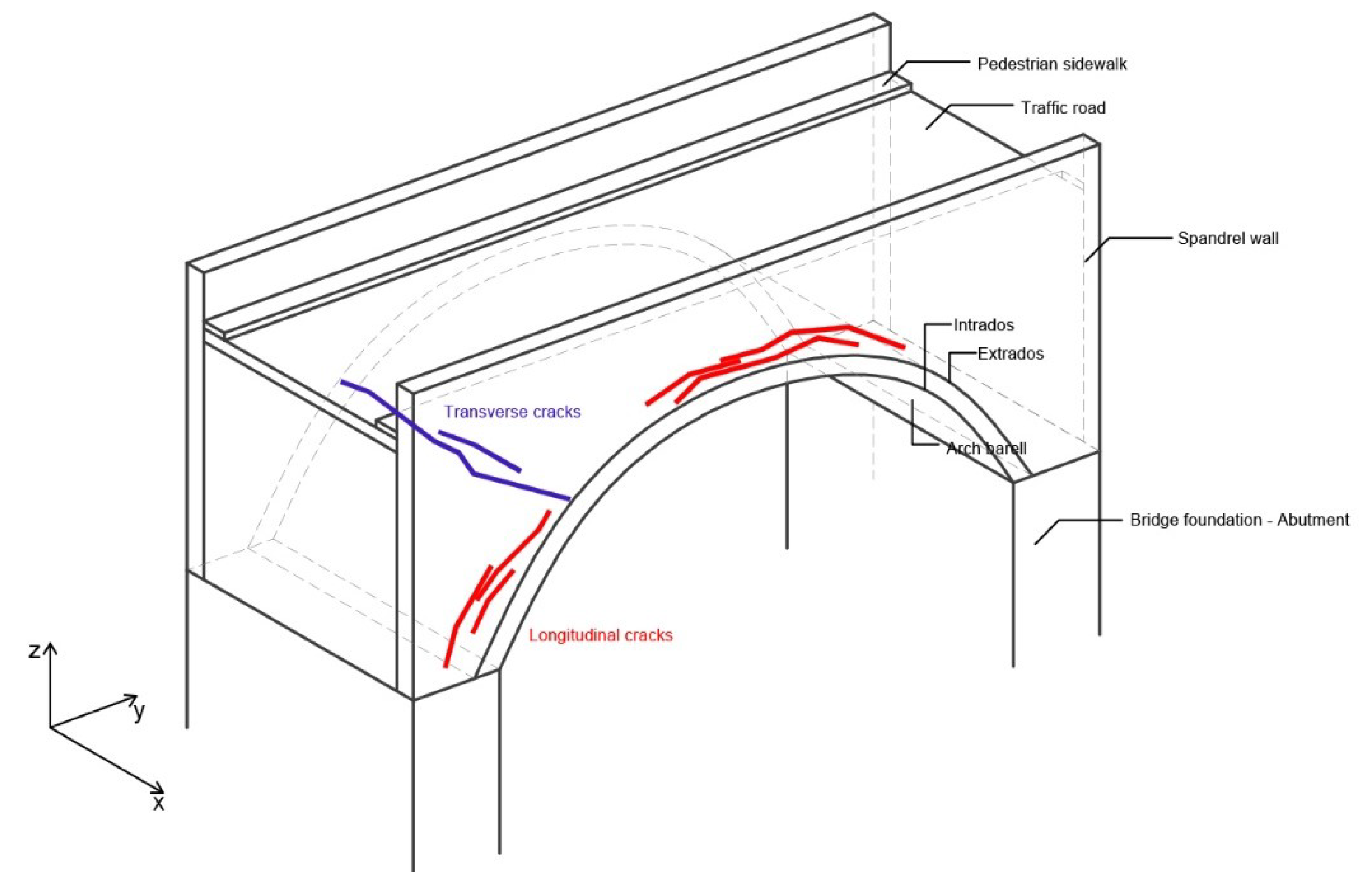

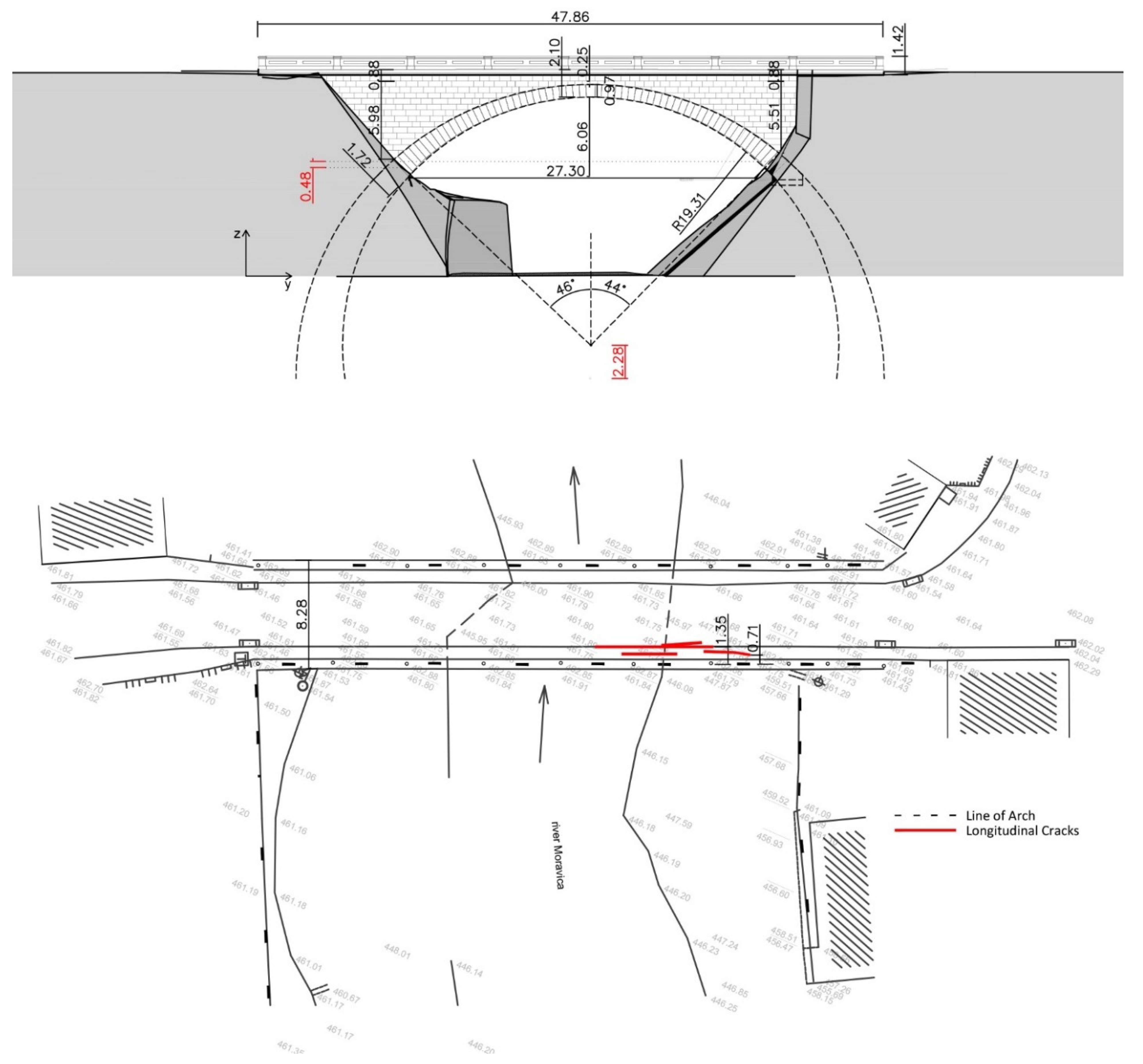

- Observation on the site focused on the built-in materials state, monitoring of supporting elements and the soil beneath the foundation, detection of cracks on the bridge’s arch barrel and detection of other damages related to the degradation of the stone structure on the bridge’s parapet.

- Geological research of the characteristics of the soil beneath the foundation of the stone bridge in Ivanjica and research of the geological and engineering properties of the geological substrate and its influence on the structural stability of the construction.

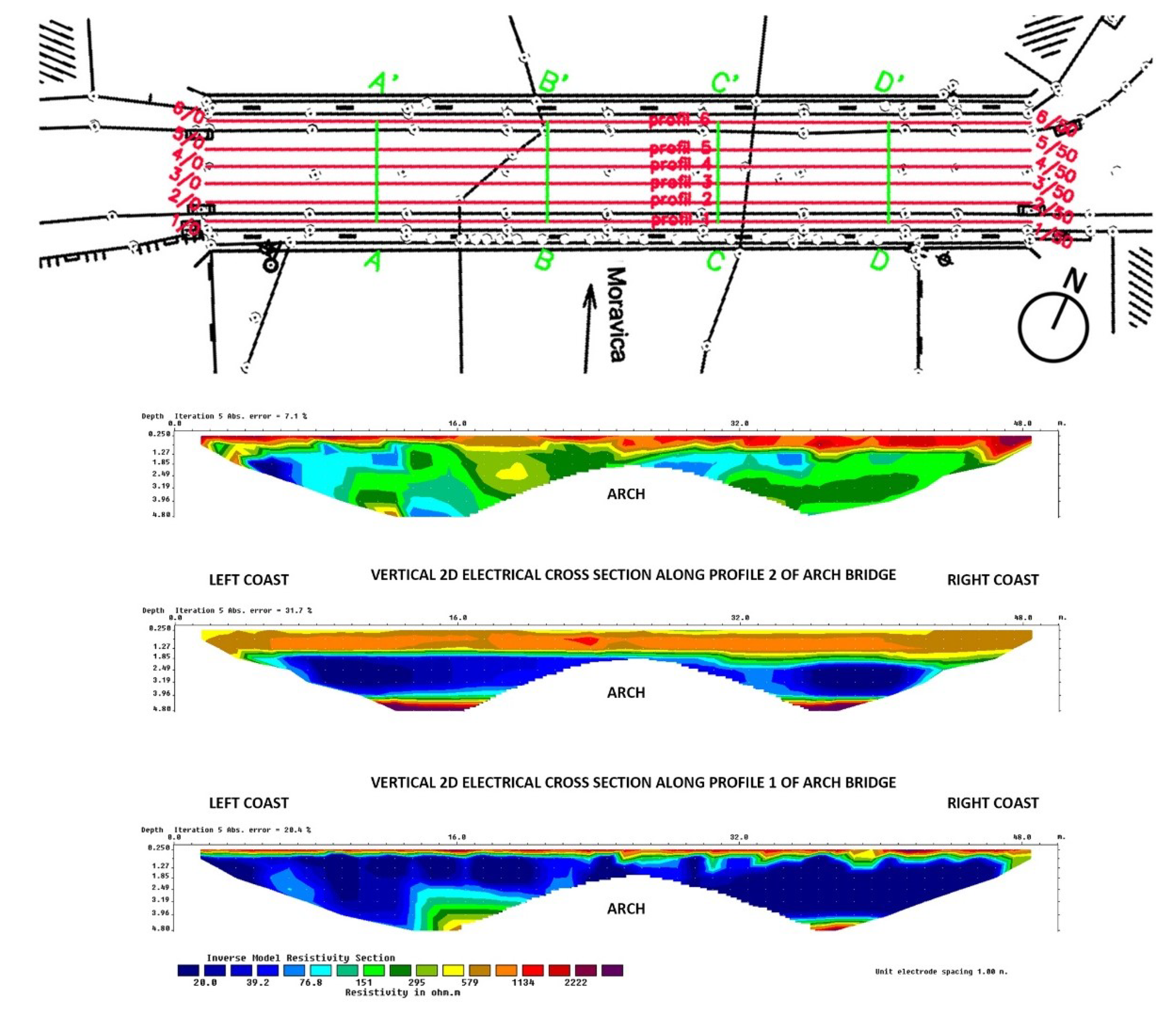

- Geophysical testing using a non-destructive method of electrical-scanning tomography and the analysis of the results.

- Physical–mechanical testing of stone characteristics used for the bridge structure based on stone samples gained using the mechanical sample destructive-extraction method for analysis. Laboratory testing also included the testing of mineral petrographic properties of stone, axial stress strength, volumetric of stone with and without the pores, stone porosity and its hygroscopic characteristics.

- Biological (mycological) analysis of the substrate samples from the stone bridge using macroscopic and microscopic examination.

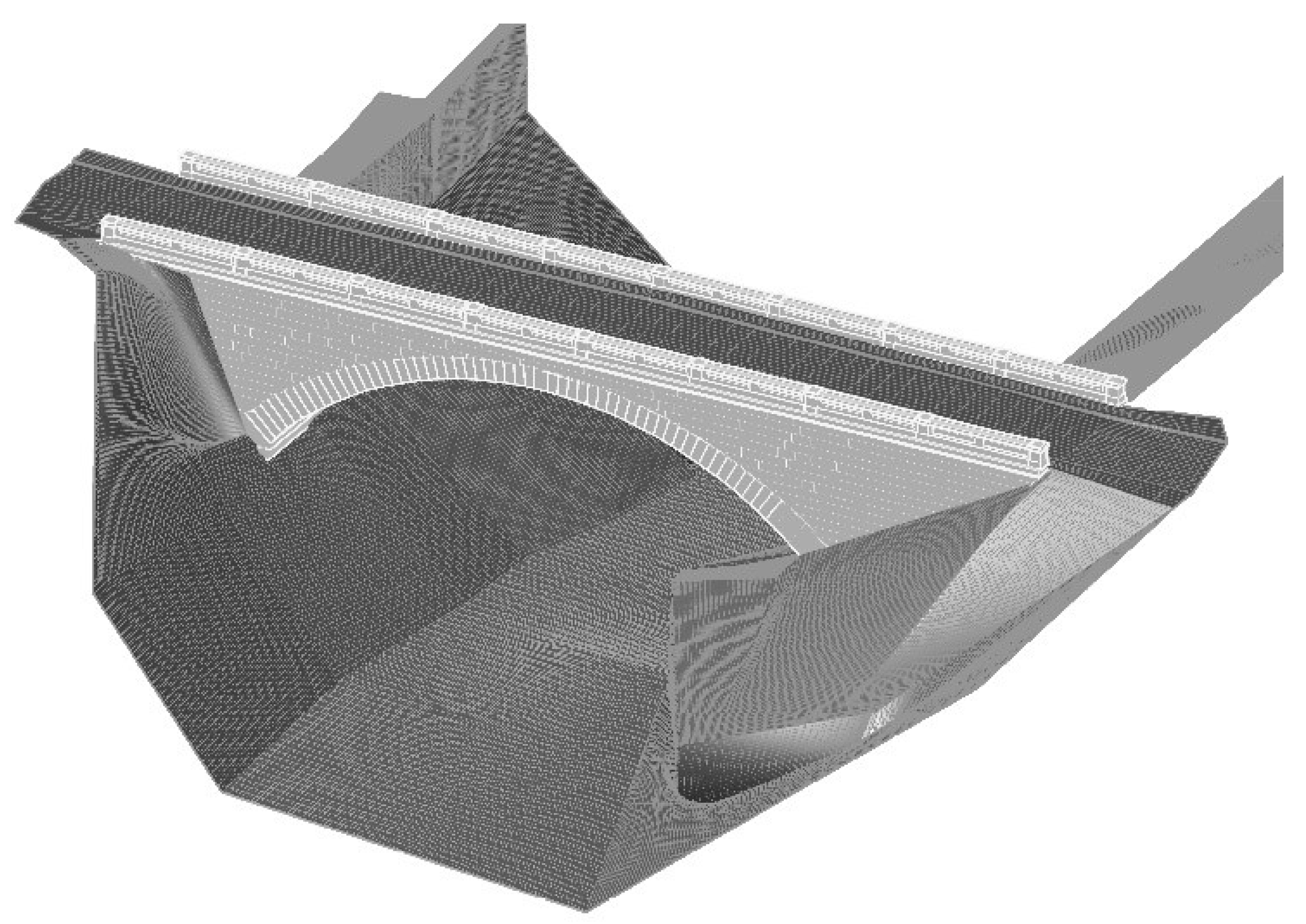

- Three-dimensional model simulation based on finite element method and bridge analysis under loads (Radimpex Software: Tower7).

- Discussion regarding previous analysis and developing conclusions about causes of bridge damages and the appearance of cracks.

- Proposition for the restoration of the arch stone bridge in Ivanjica based on the data given through previous analysis.

3.1. Ivanjica Stone Arch Bridge Background

3.2. Bridge Construction

- Spandrel and wing wall were formed in a regular pattern, in thirteen horizontal lines, with the height of the blocks 44 cm, while the length is varying and goes up to 140 cm. The third dimension could not be measured by visual inspection.

- Spandrel of the arch barrel’s cross section varies and the height of the stone at the keystone is 97 cm, up to 172 cm in the abutments. Stone is 51 cm wide, and its depth varies from 55 to 77 cm, which can be seen from the inner side of the arch barrel (Figure 5 and Figure 6). So, the dimensions of stone blocks are 97–172 cm × 51 cm × 77 cm and 97–172 cm × 51 cm × 55 cm. Joints between stone blocks are radially oriented towards the centre of the arch barrel’s radius.

- Arch barrel is built in a regular pattern. The dimensions of the blocks are 84 cm × 50 cm and the third dimension (the height) is 97–172 cm.

3.3. Geological Testing

3.4. Geophysical Testing

3.5. Physical–Mechanical Testing of Stone Structure

3.6. Biological Analysis of Damage on the Stone Bridge

3.7. Structural Analysis

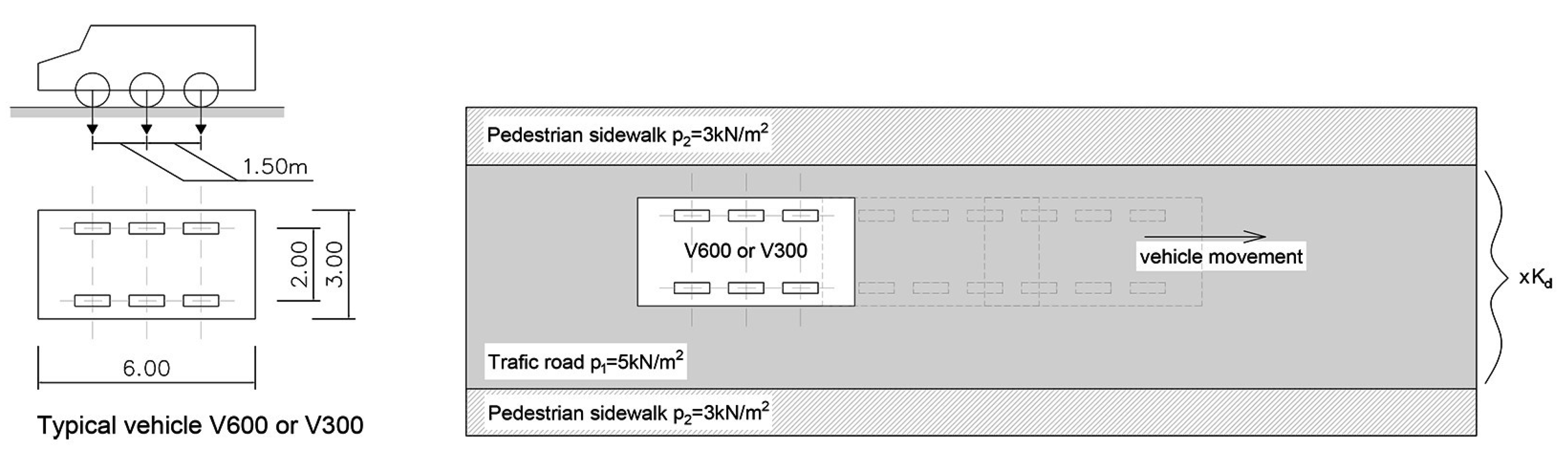

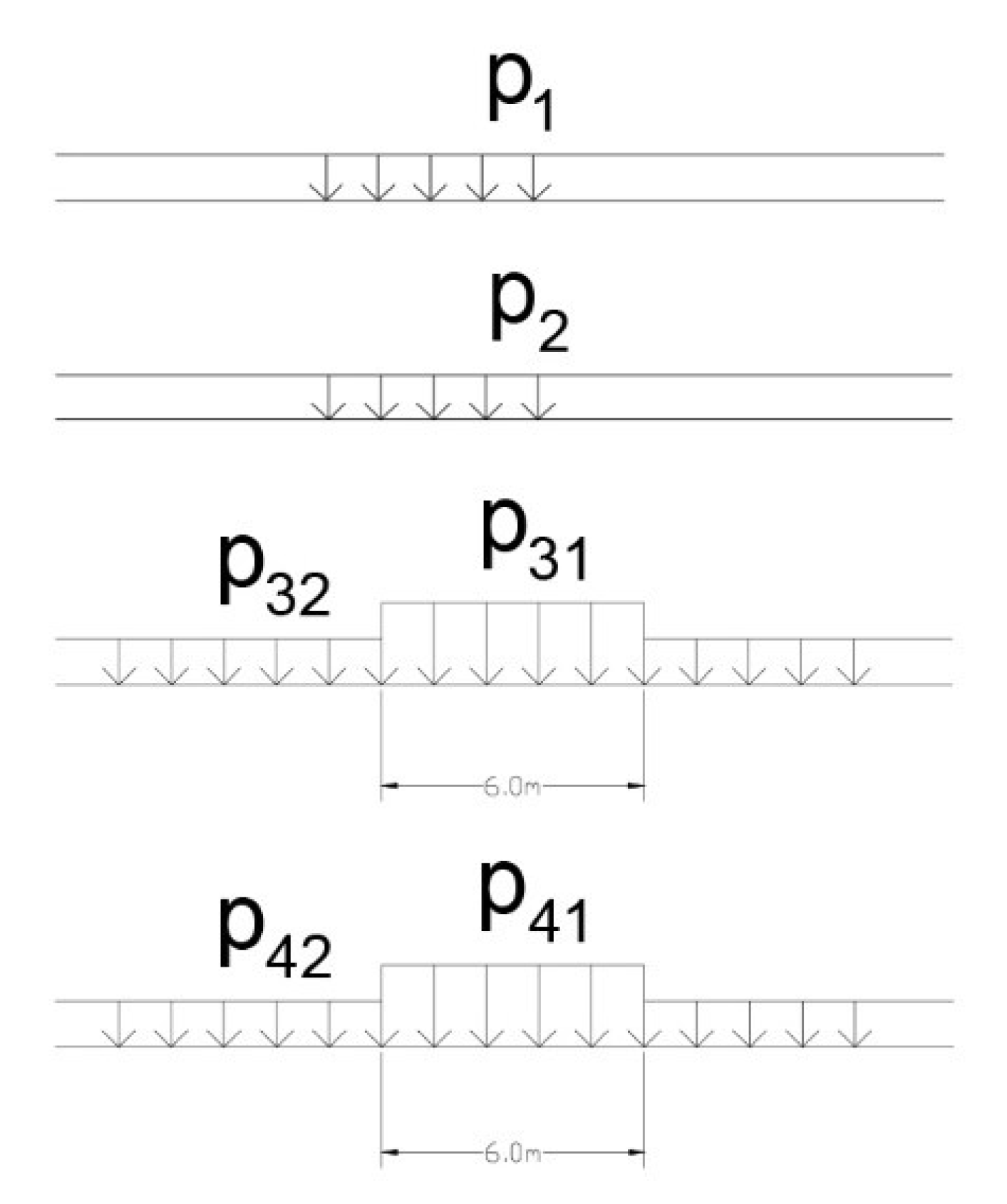

3.7.1. Load Analysis

- Uniform distributed load p1 = 3 kN/m2

- Uniform distributed load p2 = 5 kN/m2

- Scheme V600p31 = 33.33 × 1.2 = 40 kN/m2 p32 = 5 × 1.2 = 6 kN/m2

- Scheme V300p41 = 16.66 × 1.2 = 20 kN/m2 p42 = 5 × 1.2 = 6 kN/m2

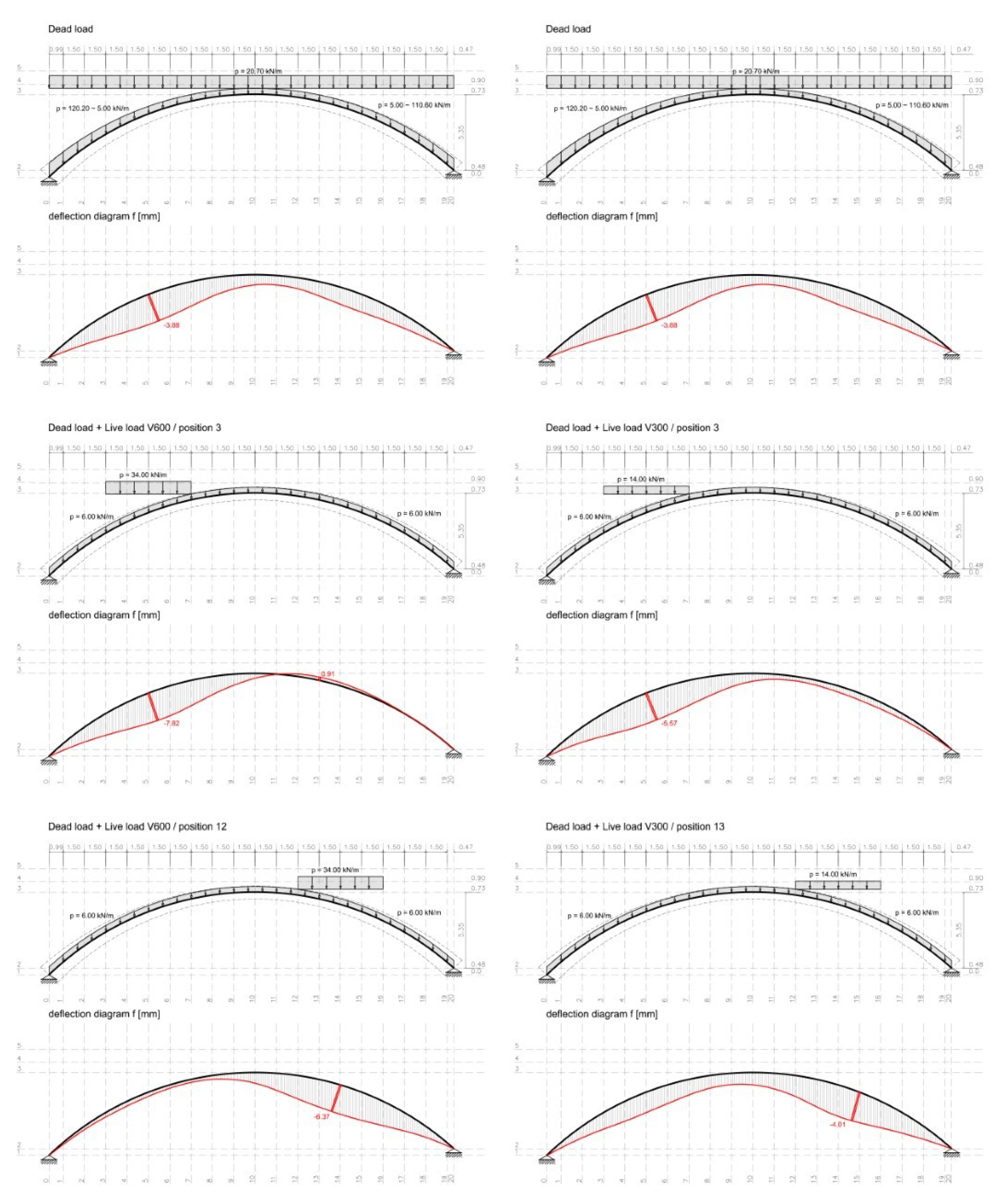

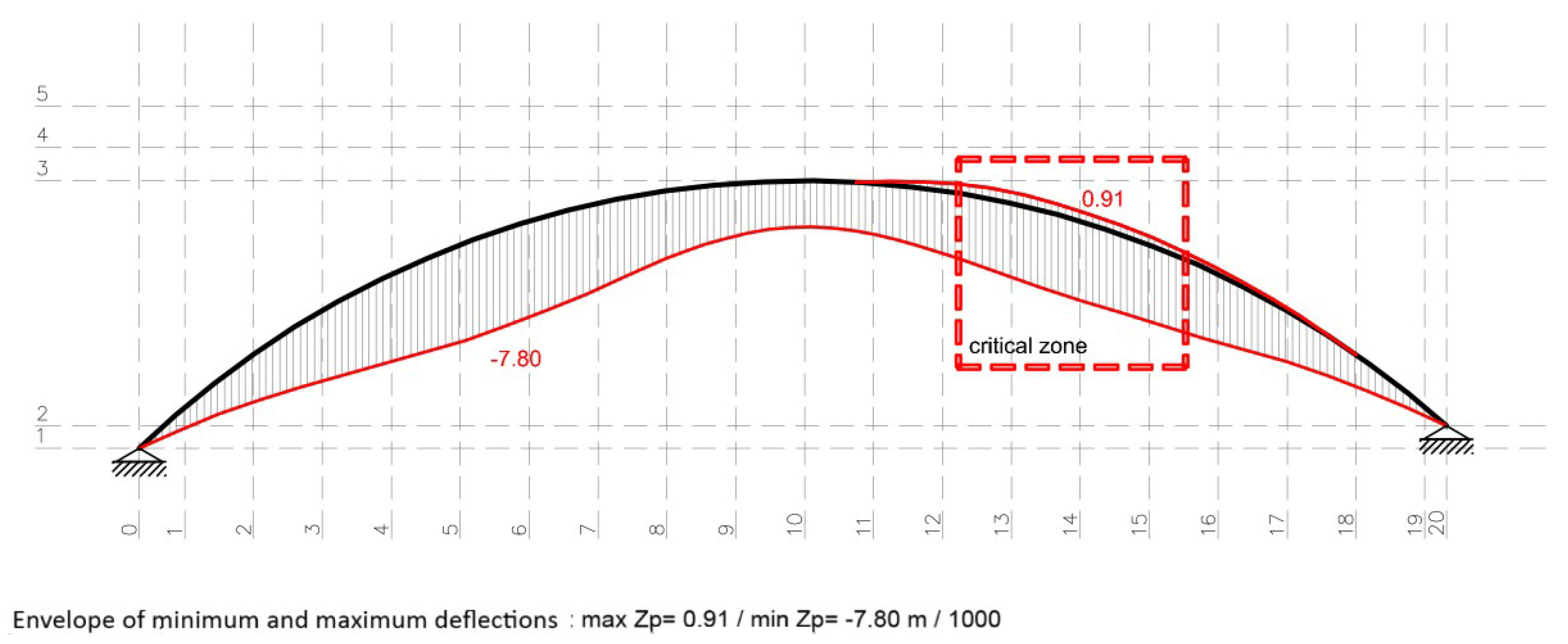

3.7.2. Deformation Analysis of the Structure

4. Discussion

5. Conclusions

- -

- Clean the structure from biological colonisation to stop potential further degradation.

- -

- Prevent moisture ingress by repointing the crack with a flexible grout that would not compromise the new-defined behaviour of the structure but close the path for moisture entrance.

- -

- Follow the propagation of cracks and their activity when the live load is applied.

- -

- Investigate possible failure mechanisms, evaluate them in order to predict future behaviour of the structure and set possible restrictions on its use.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Milani, G.; Lourenço, P.B. 3D non-linear behavior of masonry structures. Comput. Struct. 2012, 110–111, 133–150. [Google Scholar] [CrossRef] [Green Version]

- Lacanna, G.; Lancellotta, R.; Ripepe, M. Integrating Modal Analysis and Seismic Interferometry for Structural Analysis and Seismic Interferometry for Structural Dy-namic Response: The Case Study of Giotto’s Bell Tower in Florence (Italy). In Proceedings of the COMPDYN 2019 7th ECCOMAS Thematic Conference on Computational methods in structural Dynamics and Earthquake Engineering, Crete, Greece, 24–26 June 2019; pp. 9–15. [Google Scholar]

- Zampieri, P.; Zanini, M.A.; Faleschini, F.; Hofer, L.; Pellegrino, C. Failure analysis of masonry arch bridges subject to local pier scour. Eng. Fail. Anal. 2017, 79, 371–384. [Google Scholar] [CrossRef]

- Bergamo, O.; Campione, G.; Cucchiara, C.; Russo, G. Structural behavior of the old masonry bridge in the Gulf of Castellammare. Eng. Fail. Anal. 2016, 62, 188–198. [Google Scholar] [CrossRef]

- Choo, B.S.; Coutie, M.G.; Gong, N.G. The Effect of Cracks on the Behaviour of Masonry Arches. In Proceedings of the 9th International Brick/Block Masonry Conference, Berlin, Germany, 13–16 October 1991; Volume 2, pp. 948–955. [Google Scholar]

- Garrity, S.W. The Complex Engineering Design Challenges of Masonry arch Bridge Rehabilitation. In Proceedings of the 2nd International Conference on Preservation, Maintenance and Rehabilitation of Historical Buildings and Structures., Porto, Portugal, 22–24 July 2015; Amoêda, R.L., Piheiro, C., Eds.; 2015; pp. 139–150. [Google Scholar]

- Gibbons, N.; Fanning, P. Progressive cracking in masonry arch bridges. Bridge Eng. 2016, 169, 93–112. [Google Scholar] [CrossRef]

- Municipality of Ivanjica. Results of the competition: “Old Bazaar” and the Immediate Surroundings—The Conceptual Design of the New Bridge in Ivanjica. Available online: https://ivanjica.gov.rs/rezultati-konkursa-stara-carsija-i-neposredno-okruzenje-idejno-resenje-novog-mosta-u-ivanjici/?_rstr_nocache=rstr841618b9beb99b78 (accessed on 11 November 2021).

- Miri, M.; Hughes, T.G. The Effect of Spandrel Wall Strengthening on the Load Capacity of Masonry Arch Bridges. In Proceedings of the 10th Canadian Masonry Symposium, Baniff, Alberta, 8–12 June 2005; University of Calgary, Department of Civil Engineering: Calgary, AB, Canada, 2005. [Google Scholar]

- Ashurst, D. An Assessment of Repair and Strengthening Techniques for Brick and Stone Masonry Arch Bridges; Contractor Report 284; Transport Research Laboratory: Crowthorne, UK, 1992. [Google Scholar]

- Page, J. State of the Art Review. Masonry Arch Bridges; Transport research Laboratory: London, UK, 1993. [Google Scholar]

- Page, J. A Guide to Repair and Strengthening of Masonry Arch Highway Bridges; TRL Report 204; Transport research Laboratory: Crowthorne, UK, 1996. [Google Scholar]

- McKibbins, L.D.; Melbourne, C.; Sawar, N.; Sicilia Gaillard, C. Masonry Arch Bridges: Condition Appraisal and Remedial Treatment; CIRIA C656; Construction Insudtry Research and Information Association: London, UK, 2006. [Google Scholar]

- Wilmers, W. Restoration of masonry arch bridges. Bridge Eng. 2012, 165, 135–146. [Google Scholar] [CrossRef]

- Page, J. Repair and Strengthening of Arch Bridges; IABSE Reports; IABSE—International Association for Bridge and Structural Engineering: Zürich, Switzerland, 1993; pp. 565–572. [Google Scholar]

- Heyman, J. The Stone Skeleton. Int. J. Solids Struct. 1966, 2, 249–279. [Google Scholar] [CrossRef]

- Lourenço, P.B.; Oliveira, D.V. Strengthening of Masonry Arch Bridges: Research and Applications. In Proceedings of the First International Conference on Advances in Bridge Engineering: Bridges-Past, Present and Future, 26–28 June 2006, Brunel; Brunel University: London, UK, 2006; pp. 107–116. [Google Scholar]

- Giuriani, E.; Gubana, A.; Arenghi, A. Backfill and spandrels to limit the vault bending. WIT Trans. Built Environ. 1999, 42, 739–748. [Google Scholar]

- Giuriani, E.; Gubana, A.; Arenghi, A. Structural Rehabilitation of Masonry Vaults. In Proceedings of the UNESCO-ICOMOS Millennium Congress, Paris, France, 10–12 December 2001. [Google Scholar]

- Tomor, A.K.; Melbourne, C. Monitoring Masonry Arch Bridge Response to Traffic Loading Using Acoustic Emission Techniques. In Proceedings of the Arch’07—5th International Conference on Arch Bridges, Madeira, Portugal, 12–14 September 2007; pp. 281–288. [Google Scholar]

- Apreutesei, V. Strengthening of Stone Masonry Arch Bridges; Oliveira, D.V., Ed.; Technical University “Gh. Asachi” Romania and Universidade do Minho, Escola de engenharia: Gumaraes, Portugal, 2005. [Google Scholar]

- Boothby, T.E.; Hulet, M.K.; Stanton, T.R. Inspection, assessment and monitoring of Railroad arch bridges in Southwest Ern Pennsylvania. In Arch Bridges IV—Advances in Assessment, Structural Design and Construction; Roca, P., Oñate, E., Eds.; CIMNE: Barcelona, Spain, 2004; pp. 144–151. [Google Scholar]

- Proske, D.; Gelder, V.P. Safety of Historical Stone Arch Bridges; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Fanning, P.J.; Boothby, T.E.; Roberts, B.J. Longitudinal and transverse effects in masonry arch assessment. Constr. Build. Mater. 2001, 15, 51–60. [Google Scholar] [CrossRef]

- Page, J.; Ives, D.A.; Ashurst, D. Deterioration and Repair of Masonry Arch Bridges. In Proceedings of the 9th International Brick/Block Masonry Conference, Berlin, Germany, 13–16 October 1991; pp. 1591–1598. [Google Scholar]

- De Arteaga, I.; Morer, P. The effect of geometry on the structural capacity of masonry arch bridges. Constr. Build. Mater. 2012, 34, 97–106. [Google Scholar] [CrossRef]

- Conde, B.; Díaz-Vilariño, L.; Lagüela, S.; Arias, P. Structural analysis of Monforte de Lemos masonry arch bridge con-sidering the influence of the geometry of the arches and fill material on the collapse load estimation. Constr. Build. Mater. 2016, 120, 630–642. [Google Scholar] [CrossRef]

- Frunzio, G.; Monaco, M.; Gesualdo, A. 3D F.E.M. analysis of a Roman arch bridge. In Historical Constructions: Possibilities of Numerical and Experimental Techniques; Lourenço, P.B., Roca, P., Eds.; University of Minho: Guimarães, Portugal, 2001; pp. 591–598. [Google Scholar]

- Oliveira, D.V.; Lourenço, P.B.; Lemos, C. Geometric issues and ultimate load capacity of masonry arch bridges from the northwest Iberian Peninsula. Eng. Struct. 2010, 32, 3955–3965. [Google Scholar] [CrossRef] [Green Version]

- IMS Institute for testing of materials-IMS Institute. Study on the Examination of the Condition of the Stone on the Stone Bridge in IVANJICA—Stone Testing Report; Central Materials Testing Laboratory, Stone and Aggregate Laboratory of Institute for testing of materials-IMS Institute: Belgrade, Serbia, 2015. [Google Scholar]

- Ivanović, N. (Unpublished work); Geological Characteristics of the Terrain, Location Stone Bridge—Ivanjica; Geological Survey Report: Belgrade, Serbia, 2014. [Google Scholar]

- Vukadinović, M. (Unpublished work); Report of Geophysical Tests by the Method of Electric Scanning on the Stone Bridge in Ivanjica; Belgrade, Serbia, 2014. [Google Scholar]

- Bilbija, N.; Matović, V. Primenjena Petrografija: Svojstva i Primene Kamena; Građevinska knjiga: Beograd, Serbia, 2009. [Google Scholar]

- Službeni List SFRJ. Pravilnik o Tehničkim Normativima za Određivanje Veličina Opterećenja Mostova; Službeni list SFRJ: Beograd, Serbia, 1991; p. br. 1/91. [Google Scholar]

- Šekularac, N.; Čikić-Tovarović, J.; Ivanović-Šekularac, J. Investigating structural stability of historic buildings: A case study of a rampart wall of Hilandar Monastery. Struct. Eng. Int. 2017, 27, 353–361. [Google Scholar] [CrossRef]

| Sample Number | Location | Laboratory Mark of the Samples | Mineralogical–Petrological Composition | Physical–Mechanical Properties | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type of Rock | Structure | Texture | Bulk Density with Pores and Cavities (g/cm3) | Bulk Density without Pores and Cavities (g/cm3) | Porosity (%) | Coefficient of Bulk Density | Water Absorption (%) | Overburden Pressure in Dry Condition (MPa) | |||||||

| 1 | Arch barrel, right coast | KIA 0068/14 AGK | Sandstone | Arenaceous | massive | 2.231 | 2.594 | 14 | 0.860 | max. 4.07 | min. 3.97 | 4.01 | max. 80 | min. 40 | 64 |

| 2 | Wing wall, right coast | KIA 0069/14AGK | Sandstone | Arenaceous | massive | 2.222 | 2.584 | 14.1 | 0.859 | max. 4.50 | min. 4.00 | 4.18 | max. 62 | min. 44 | 51 |

| 3 | Belt course, right coast | KIA 0070/14 AGK | Sandstone | Arenaceous | massive | 2.224 | 2.609 | 14.8 | 0.852 | max. 4.38 | min. 4.18 | 4.28 | max. 64 | min. 42 | 52 |

| Dead Loads | d1 (m) | d2 (m) | γ (kN/m3) | g1 (kN/m) | g2 (kN/m) |

|---|---|---|---|---|---|

| Self-load of the arch barrel | 0.97 | 1.72 | 23.00 | 22.31 | 39.56 |

| Weight of the filling (from the top of the arch barrel to the right support) | 0.25 | 5.53 | 20.00 | 5.00 | 110.60 |

| Weight of the filling (from the top of the arch barrel to the left support) | 0.25 | 6.01 | 20.00 | 5.00 | 120.2 |

| Weight of the roadway and roadway structure with all its layers (d = const) | 0.90 | 23.00 | 20.70 |

| Classification of Bridge | Calculation Schemes | |

|---|---|---|

| I—motorway bridges | V600 + V300 | |

| II—trunk road, regional road and arterial road bridges | V600 | |

| III—bridges on all other roads | Lane widths ≥ 6.0 m | V300 + V300 |

| Lane widths < 6.0 m | V300 | |

| Calculation schemes | Distance from the Reference Axis 0.00 (m) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.99 | 7.22 | 8.39 | 19.36 | 19.60 | 20.00 | 20.40 | 20.88 | 21.69 | 22.55 | ||||

| 0 | Dead load | Deflections of arch-ƒ(mm) | −3.88 | −3.87 | −3.68 | −1.94 | −1.99 | −2.08 | −2.14 | −2.21 | −2.27 | −2.26 | |

| 1 | Dead load + Uniform Distributed Load 3 kN/m2 | −3.93 | −3.92 | −3.74 | −2.06 | −2.11 | −2.18 | −2.24 | −2.31 | −2.35 | −2.32 | ||

| 2 | Dead load + Uniform Distributed Load 5 kN/m2 | −3.96 | −3.95 | −3.80 | −2.14 | −2.19 | −2.26 | −2.32 | −2.37 | −2.41 | −2.36 | ||

| 3 | Dead load + V600 | position 3 (p31 = 40 kN/m2) | −7.78 | −7.80 | −7.56 | 0.90 | 0.91 | 0.89 | 0.85 | 0.79 | 0.67 | 0.54 | |

| position 12 (p31 = 40 kN/m2) | −0.78 | −0.76 | −0.67 | −6.03 | −6.13 | −6.26 | −6.34 | −6.37 | −6.26 | −5.96 | |||

| 4 | Dead load + V300 | position 3 (p41 = 20 kN/m2) | −5.57 | −5.57 | −5.37 | −0.91 | −0.94 | −0.98 | −1.03 | −1.09 | −1.16 | −1.19 | |

| position 13 (p41 = 20 kN/m2) | −2.73 | −2.71 | −2.57 | −3.62 | −3.71 | −3.83 | −3.91 | −3.99 | −4.01 | −3.89 | |||

| ∆ƒmax= ƒ(V600/position3)-ƒ (dead load) | I∆ƒmaxI | 3.91 | 3.93 | 3.88 | |||||||||

| ∆ƒmax= ƒ(V600/position12)-ƒ (dead load) | 4.08 | 4.14 | 4.18 | 4.20 | 4.16 | 3.99 | 3.70 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sokolović, N.M.; Petrović, M.; Kontić, A.; Koprivica, S.; Šekularac, N. Inspection and Assessment of Masonry Arch Bridges: Ivanjica Case Study. Sustainability 2021, 13, 13363. https://doi.org/10.3390/su132313363

Sokolović NM, Petrović M, Kontić A, Koprivica S, Šekularac N. Inspection and Assessment of Masonry Arch Bridges: Ivanjica Case Study. Sustainability. 2021; 13(23):13363. https://doi.org/10.3390/su132313363

Chicago/Turabian StyleSokolović, Neda M., Milica Petrović, Ana Kontić, Suzana Koprivica, and Nenad Šekularac. 2021. "Inspection and Assessment of Masonry Arch Bridges: Ivanjica Case Study" Sustainability 13, no. 23: 13363. https://doi.org/10.3390/su132313363

APA StyleSokolović, N. M., Petrović, M., Kontić, A., Koprivica, S., & Šekularac, N. (2021). Inspection and Assessment of Masonry Arch Bridges: Ivanjica Case Study. Sustainability, 13(23), 13363. https://doi.org/10.3390/su132313363