Abstract

The first and most important target of the industrial world is to offer products that appeal to customers’ demands (affordable prices), while at the same time, respect the global effort of CO2 emissions reductions, which is required under strict emissions rules. There is, however, an apparent contradiction between the two concepts; productivity and sustainability, leading to two strategies—innovation economy and circular economy, respectively. To this end, this work aims, through modeling the long-term environmental impact of producing new goods in short terms (innovation economy) and impact of rebuying, repairing and reusing products for extended use (circular economy), to study the relationship between the two economies. For this purpose, the terms of innovation and circular economy are introduced and described, in order to define the environmental impact during the lifecycle of a product. Two products are assessed for this study—a well-known, medium price vehicle, as well as an expensive mobile phone with several generations. The cost of purchase and the recurring costs are used as indicators of environmental impact, instead of calculating the impact directly for the production phase, due to the enormous size of the production data that are desired. The results, despite being indicative of the modelling complexity, can still be used to pave the way towards a modelling framework, proving, at the same time, that innovation and circular economy are not contradictive concepts.

1. Introduction

The performance, efficiency and flexibility of manufacturing systems are vital parameters for each economy; either circular or innovation, directly affecting the cost and the environmental footprint of each product [1]. A circular economy (often referred to simply as “circularity” [2]) is an economic system aimed at minimizing waste and making the most of resources. In a circular system resource, input and waste, emission, and energy leakage are minimized by slowing, closing, and narrowing energy and material loops; this can be achieved through long-lasting design, maintenance, repair, reuse, remanufacturing, refurbishing, and recycling [3,4]. This regenerative approach is in contrast to the traditional linear economy, which has a ‘take, make, dispose’ model of production [5]. Circular economy has the tendency for products with longer product lifecycles. Today’s world manufacturing is mainly based on the linear model. The “take-make-waste” approach is used for describing that model, showing that the materials used currently in production are wasted after the product’s life cycle ends, and so is their remaining value [6]. While consumption becomes more and more intense over the years, and production needs to follow this increase rate in order to sustain and enhance the industry’s revenue, several economic, environmental, and social problems have arisen [7]. In addition, global competition requires the launch of new products with a shortened commercial life cycle, and with a high degree of innovation and product-added value. Furthermore, with the time passing, the understanding of processes and the utilization of modern tools/machinery steer the industrial world to a more sustainable era [1,8]. However, environmental sustainability is pushing for an extension of the life cycle of products.

A circular approach to economy (hereafter C.E) refers to using fewer materials and fewer resources and utilizing those resources at their maximum. This is possible through several strategies, such as long-lasting design, maintenance and repair, reuse, remanufacturing, refurbishing, recycling, etc. C.E principles are linked with products of a rather longer lifecycle [2]. However, the industrial world tries to minimize the environmental impact that is connected to the production phase, following a different approach that aims to reduce the wasted resources. The effects of additive manufacturing and dematerialization to this effort are explained in detail in [9,10]. In [5,6], the concepts of C.E are thoroughly explained. As a result of the constant research on the topic, a wide range of articles has been published over the years [11,12]. Actions towards the implementation of C.E are presented and promoted through organizations [13]. The European Union is promoting strategies based on the principles of circular economy on an attempt to reduce the total environmental footprint of the European industrial sector [14]. A circular business model, providing a conceptual framework for implementing C.E, has been proposed in [15]. Similarly, in [16], a framework for circular design, providing some key strategies to be considered, has been suggested. Additionally, interesting work on C.E strategies, suggesting that dematerialization could play an important role in the development of C.E, has been presented in [17], where it is claimed that C.E has the tendency to have products with relatively longer life cycles.

An economy based on innovation, on the contrary, is the attempt to continuously come up with new products that spur economic growth [18] and adopt the new way of living of customers [19]. As described in [20], “innovation describes the development and application of ideas and technologies that improve goods and services or make their production more efficient”. Bearing these in mind, one can assume that the innovation approach to economy (hereafter I.E) leads to a short life cycle of products, as implied also by the literature [21], coming up continuously with new products. That seems to lead to a conflict between circular and innovation approach to economy. This work is an attempt to study the way that the following conflict can be addressed. By developing and creating a product, a certain amount of environmental impact is stored for the following X years. During that time period and for a certain product, there can be no intervention from human beings to affect the environmental footprint. Consequently, it can be said that, from the one side, a product with a long-lasting lifetime stores a Y amount of environmental footprint, simultaneously makes impossible an improvement due to technological development, while from the other side, a product with short lasting lifetime stores significantly less impact. For these reasons, the innovation approach to economy can contribute to a shift to a more sustainable production in the recent future, by adopting advanced technologies (e.g., bioeconomy [22]) and advanced manufacturing methods (e.g., laser-based processes and additive manufacturing [23]), as well as by maximizing the production rate in an efficient way (produce more with less [10,24]), which can be done with improved process modelling and monitoring [25], machine monitoring and control [26]. It is noted that a very interesting comparison between the two different economies has also been presented in the literature in terms of golden-ration economy, where the question that drives this research is generated. The main research question is around the dilemma of which of the two economies, circular and innovation, can be more sustainable in terms of footprint, and where is the section point; the year when a condition can change in favor of innovation, or circular [27]. This is also the main target of the present study, considering the existence of the section point.

With ISO 14040 defining life cycle assessment (LCA) as “a standardized technique for assessing the potential environmental burdens associated with product or service, by: compiling an inventory of relevant inputs and outputs, evaluating the potential environmental impacts associated with those inputs and outputs, interpreting the results of the inventory and impact phases in relation to the objectives of the study” [28], it can be regarded that this would be an appropriate way of proceeding, despite the various drawbacks, such as temporal issues (i.e., assessment time horizon) [29], uncertainty [30], and optimization challenges [2].

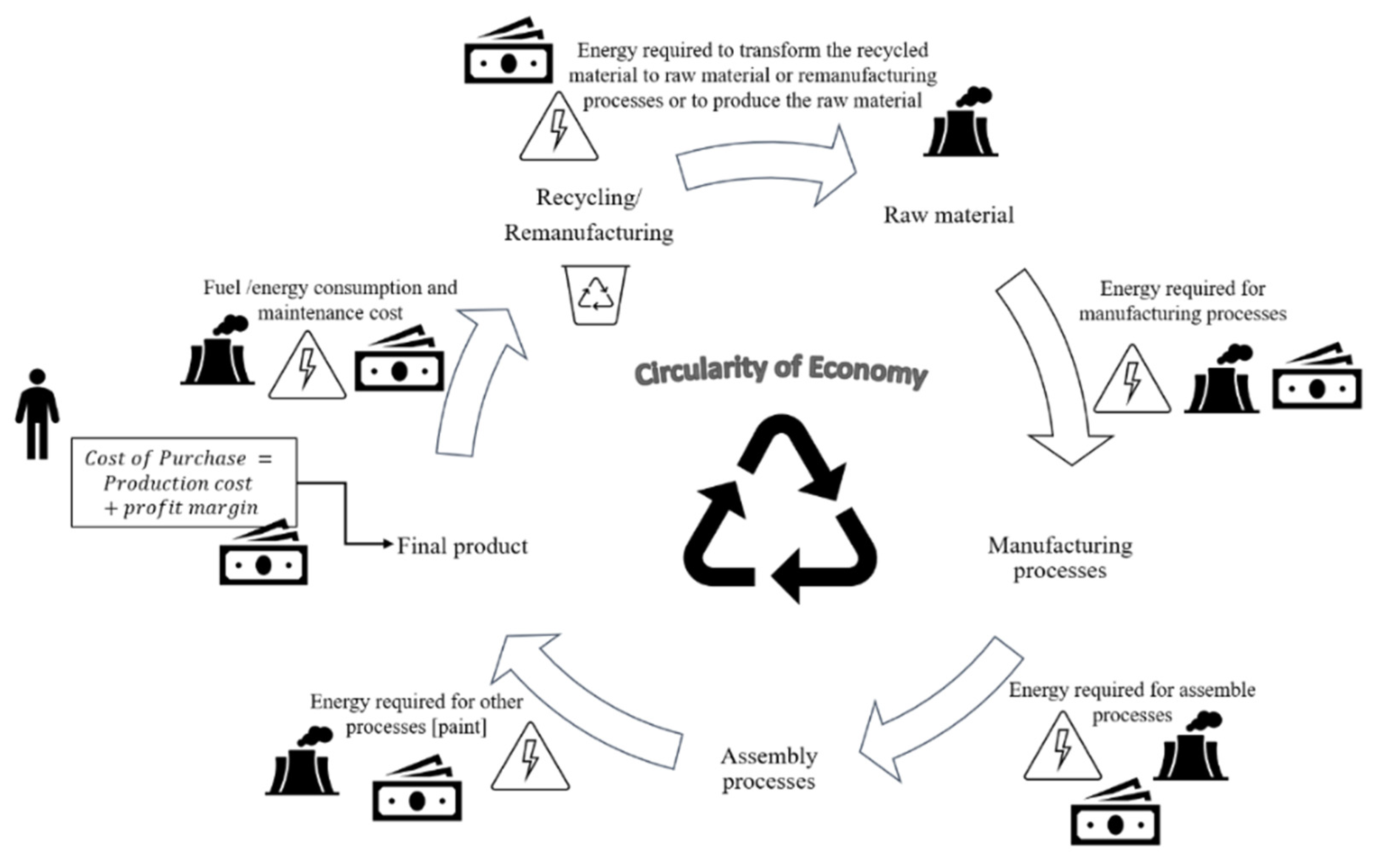

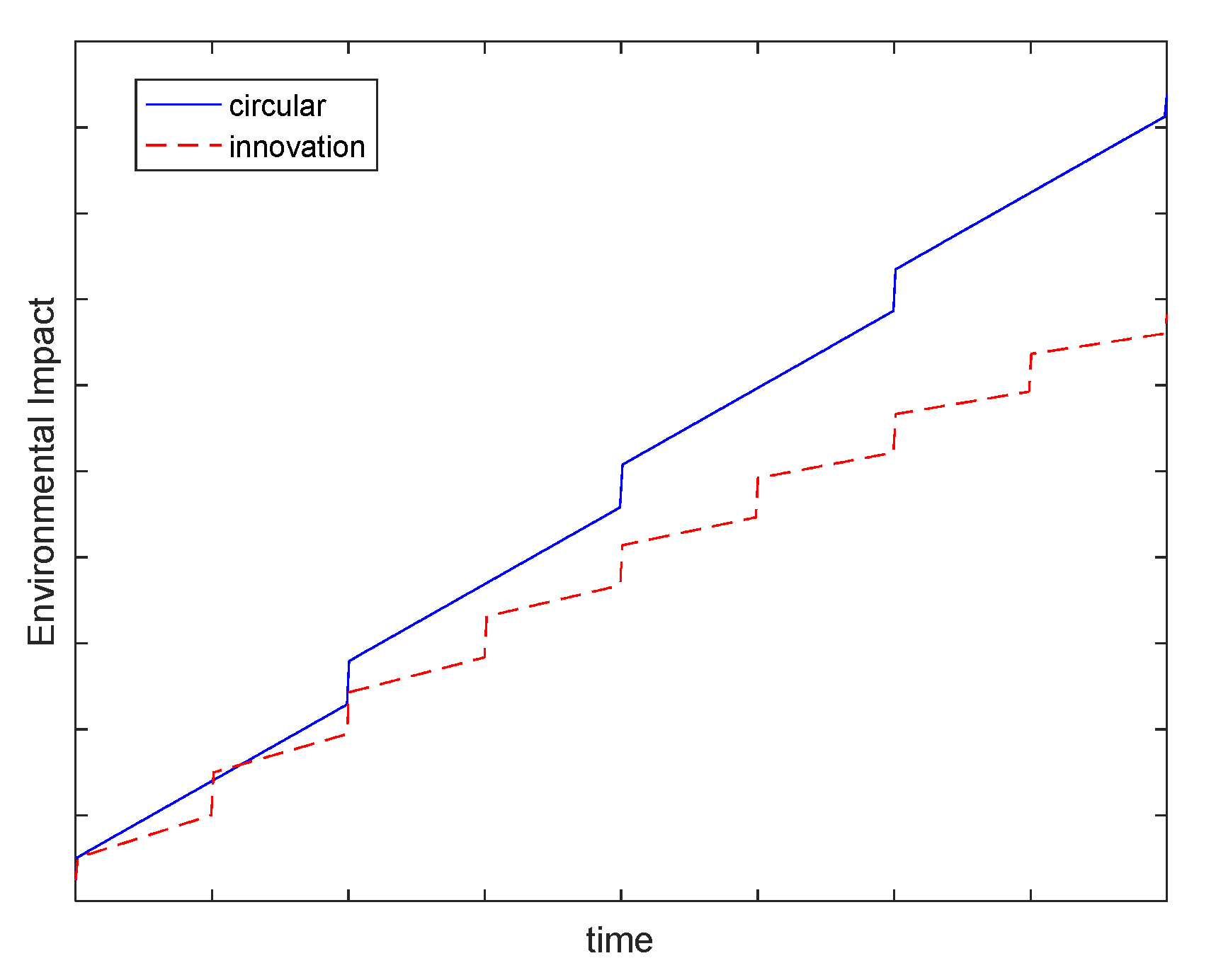

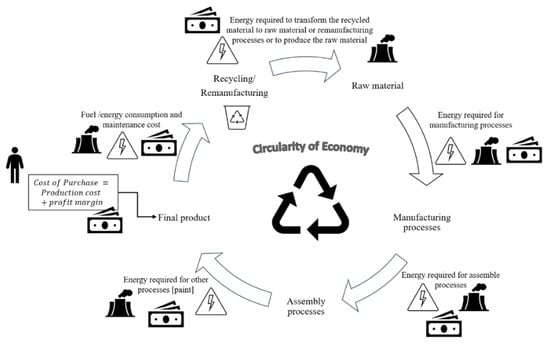

According to [31], the data which determine the impact of a circular and innovation economy are considered as inputs of a (LCA) model [32]. In addition, the energy requirements of several manufacturing/assembly processes are proportional to the production cost, while the energy requirements can be expressed also as environmental impacts of the production phase [33], while impact is also produced from the R&D stages, as mentioned in [34]. Thus, it can be said that there is a direct and reverse relationship for the production cost and the environmental impact. The LCA model structure strengthens this theory [35], including various types of costs [36,37], throughout the various phases [38]. Thus, the interactions can be seen in Figure 1. The limitations of the impact assessment are pointed out through this analysis, as it is important to obtain data from different manufacturing stages, from the initial to the final stages, and calculate the impact in terms of emissions. These data are not available, creating a gap for further research, since it is not possible for an industry to have two parallel running productions for the same product in order to create data for evaluation and compare the two different approaches to economy; circular vs. innovation.

Figure 1.

Circularity of economy, as per the costs [36] and the phases [38] defined in literature.

2. Current Status

A report from Montalvo et al. [39] refers to the Directorate General for Internal Policies of the EU, providing an evaluation of the potential impact of a longer lifetime for products in Europe on the economy, on society, and on the environment. This document also offers a comprehensive review of the issues surrounding a longer lifetime for products in relation to consumer protection and the economic performance of enterprises, while discussing the current policy framework in the EU, regarding promoting the extended life of products. It was suggested that sectors providing services for specific product R&D, repair, maintenance, leasing and renting are those most likely to benefit from longer product lifetimes, while the manufacturing sectors have the potential to suffer from an increase in product lifetimes. The document also discusses the effect of standards such as the Eco-design and Ecolabelling Directives, in an attempt to control the environmental performance of products. Moreover, the role of extended durability of products in reducing the lifetime environmental impacts of products is discussed on the later chapters of the document. Issues related to practical limits on products lifetimes, cost implication in changing materials and manufacturing processes, consumers habit etc. are also discussed. The purpose of the study was to identify two (priority) products and develop a methodology for measuring their durability. The benefits and costs of more durable products were also discussed.

Ardente et al. [40] discuss whether the extension of the lifetime of energy using products is desirable. The article presents a method for environmental assessment of the durability of energy-using products. They based their method on the comparison of scenarios for products of different lifetimes and their substitution with more energy-efficient products. The article concludes that some life-cycle environmental benefits can be gained by extending the lifetime of the products, though it greatly depends on the multiple variables. Moreover, Tasaki et al. [41] used an assessment approach based on LCA for evaluating whether replacing an existing product with a more energy efficient product is environmentally preferable. The method was then used for the evaluation of selected products. In addition, Bobba et al. [31] used a quantitative assessment of the benefits/burdens of extending the lifetime of products. The authors present a set of indicators developed for the assessment of products durability. The authors argue that the extension of product lifetime ultimately leads to the reduction of environmental impacts (for the studied products). In addition, according to Sangprasert et al. [33], an evaluation of environmental impacts of mobile phones throughout their life cycle, is provided, using an LCA method. The assessment considered four main components of a mobile phone. The authors concluded that the charger has the highest impact compared with other parts of the phone, while they presented that the development of efficient waste collection and recycling systems may lead to the further reduction and minimization of the environmental impacts of a mobile phone.

Finally, the way in which the energy consumption (production cost) and the environmental impact are affected during the machining of different materials, as well as by producing the desired quantities of materials, is elaborated with the aid of the following sources. According to [42], the machining process of a steel workpiece seems to be more energy-intensive in comparison with aluminum and polycarbonate, while the measurements that were taken during the experimental work of [43], represent how the environmental impact is affected by the raw material selection; aluminum vs. steel case study. Within the same references, it has been shown that, by producing a certain mass of aluminum that is oriented as an alternative solution in the development of a new part, it is more energy-intensive, with higher environmental impact compared to the production of the steel mass that is suitable for the same use. Moreover, the energy that is spent during the machining of an aluminum workpiece is significantly higher than the wasted energy for the machining of steel. In conclusion, the examined factors are capable of affecting the environmental impact via increased energy consumption that is considered to be obtained from the same source. Finally, the increased energy needs lead to increased production cost. It is extracted that the required energy for the impact that arise from the production phase is measured in terms of cost, while the reverse is also true [44]. This conclusion is an important understanding for the innovation economy, due to the fact that for different product requirements (design, specifications, material), the related process is selected, affecting the production footprint, either positively or negatively. In the same manner, the energy/power and footprint correlation can also be extracted.

Detailed Comparison of the Two Economies and Literature Gap

As such, it can be verified that the two economies appear to be quite contradictive with respect to the products’ lifetimes. However, regarding a more detailed comparison between the two of them, it seems that there may be some connections between the two. Firstly, the type of technology (and consequently innovation) that can be introduced in a system towards eco-efficiency, can be used to categorize among reformist, techno-centric, transformational and fortress circular economy [45]. In addition, the term “Circular innovation” often comes up in relevant discussions, with the corresponding technologies being characterized as “difficult to scale up”, while some of the best practices have been proven not to be efficient [46]. Furthermore, it can be claimed that the short life cycles of products under innovation economy, may be only a by-product of the innovation’s “dynamism”, as its goal is the contribution to competitive advantages and economic growth [47]. An additional common factor for both economies, after all, would be the digitalization under Industry 4.0 movement; this can act as an enabler for achieving eco-design and R-operations of circular economy, such as remanufacturing and re-engineering [48,49]. Moreover, the more generic term is “extension of lifecycle” [50], however, in any case, one could claim also that “Long-life products (value proposition) that are serviced during its lifetime can create a long-term customer relationship (value creation & delivery)” [51]. In any case, the enterprises are called to apply innovation in either case of prevailing economy [2,18,51,52]. Thus, given the issue of comparison stated above, an open question is how such a comparison would be made in terms of ecological footprint, at least from a theoretical point of view.

3. Approach

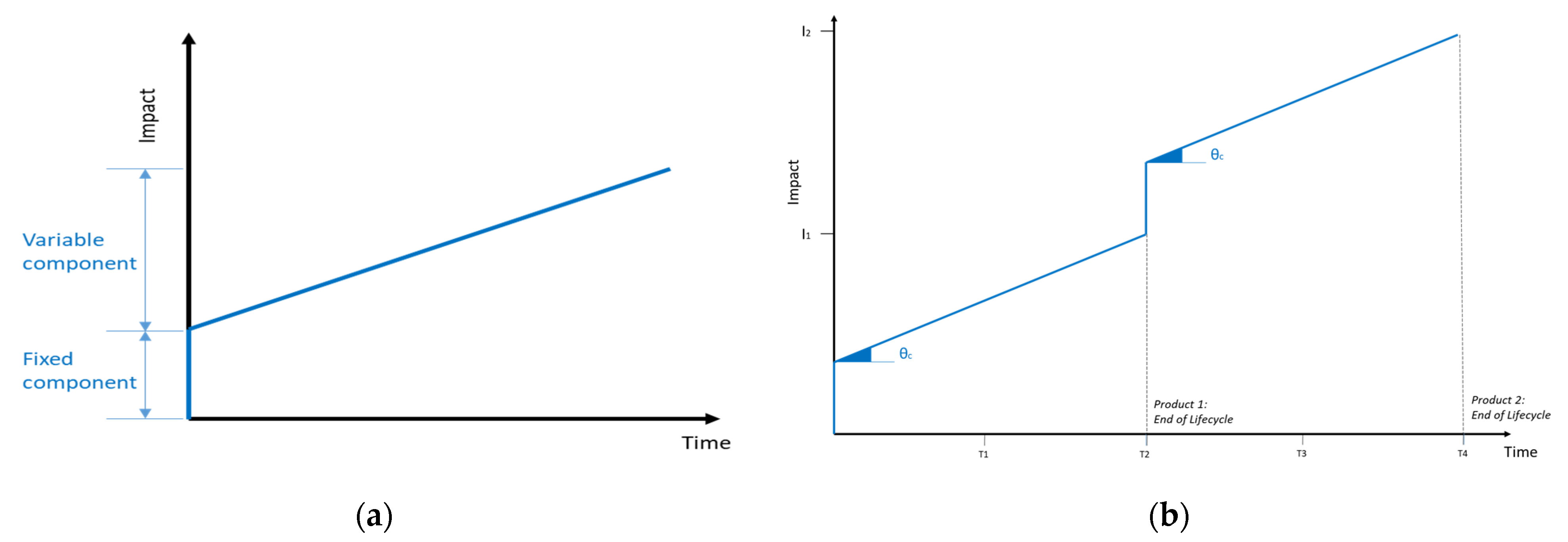

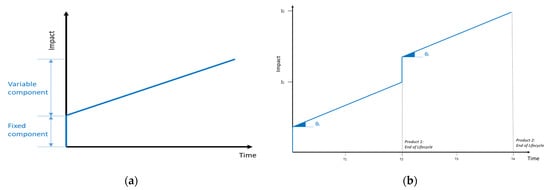

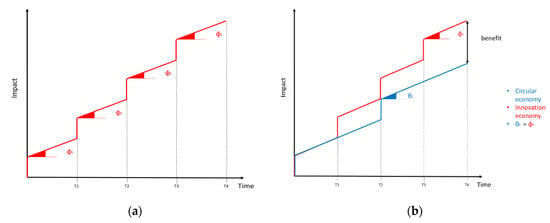

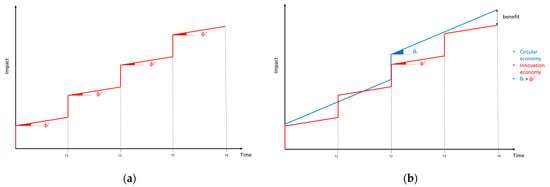

The environmental impact of a product is simplified with two components; namely, a fixed component and a variable one that grows with time. The fixed component represents the impacts associated with material production and manufacturing. The variable component is related to the product’s use phase and maintenance (Figure 2a). When a product’s lifecycle ends (manufacturing and use), it is replaced with a new one, reflecting the total environmental impact (Figure 2b). As a matter of fact, this abstract model has been a subject matter of communication between Prof. G. Chryssolouris and Prof. T. Gutowski [53], and has been utilized in terms of reuse quantification [54].

Figure 2.

(a) Environmental impact of a product across its lifecycle; (b) Environmental impact of a product across its lifecycle—C.E-based product.

In case of new innovative products with (for example) half-life (Figure 3a) compared to a “regular” product, the environmental impact over the same time span may increase dramatically (Figure 3b).

Figure 3.

(a) Environmental impact of a product across its lifecycle—I.E-based product; (b) Short life cycle product as opposed to that of C.E.

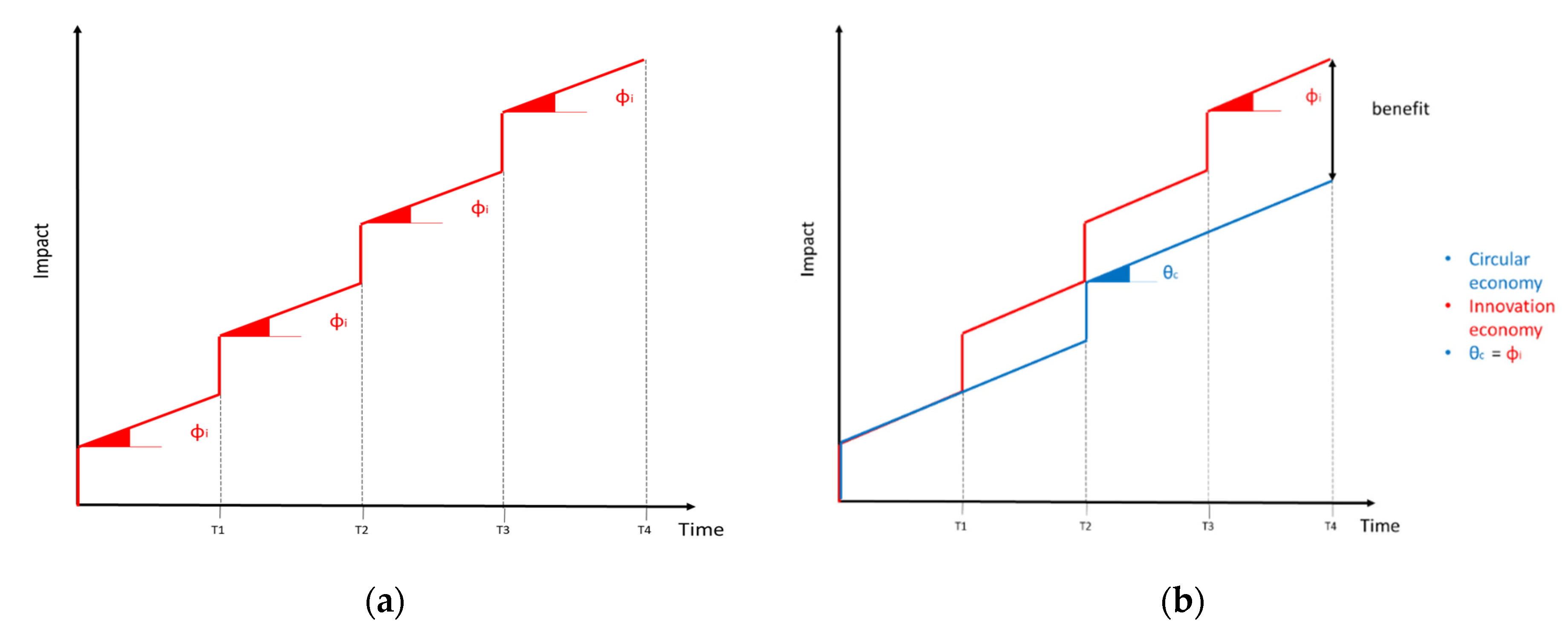

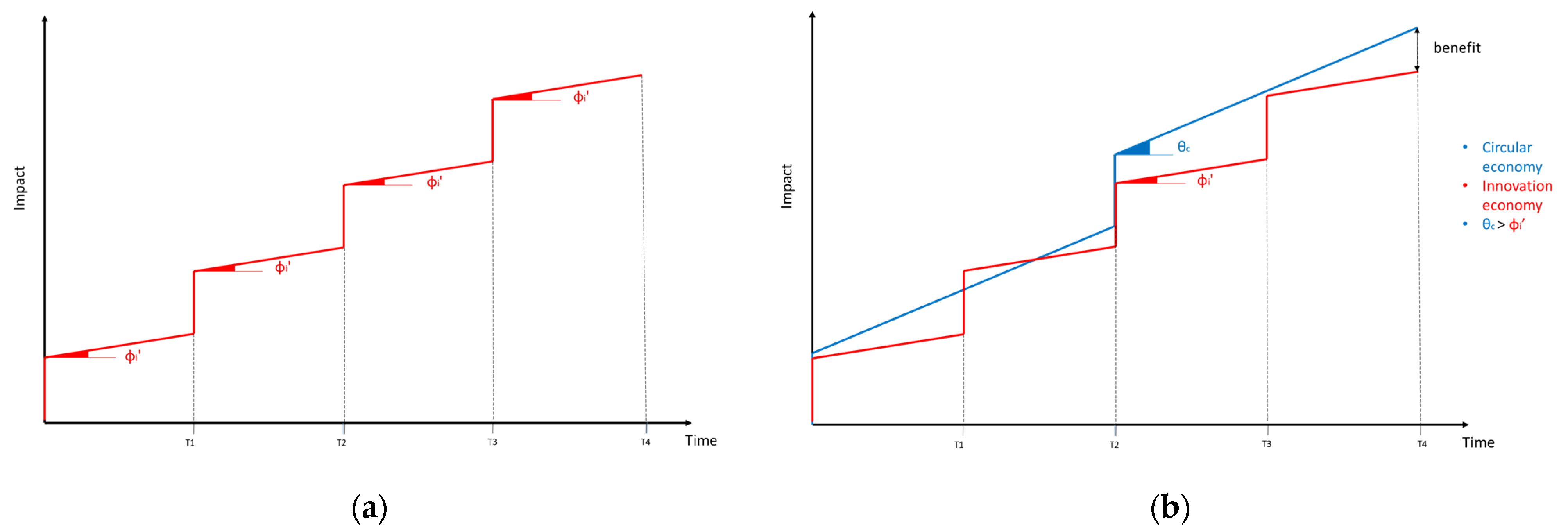

3.1. Innovation Economy (I.E)-Reduced Components

However, one can strive for innovative products with a lower variable component (Figure 4a), and thus, with a lower environmental impact (Figure 4b).

Figure 4.

(a) Environmental impact of a product across its lifecycle—I.E-based product (reduced components values); (b) I.E impact (reduced component values), as opposed to that of C.E.

An example of what might be a combination of the circular approach to the economy with the innovation approach to economy is presented in Figure 5. This presents a reduction of both the fixed and the variable component (red dotted line).

Figure 5.

Combining circular and innovation approaches to economy.

From the aforementioned, it can be extracted that there has to be a section point between these two approaches to the economy, and this point depends mostly on the innovation potential of the sector that undertakes the production of the studied product. The capabilities of the modern tools and equipment can contribute to a significant reduced energy consumption at the production phase, while the existence of high-durable and high-performance materials can also elongate the lifecycle with efficient way, reducing both the short-term and long-term impact, improving the sustainability of innovation and circular economy at the same time. To this end, the appropriate data have to be found in order to make a conclusion in each study.

3.2. A Modified Version of the Method

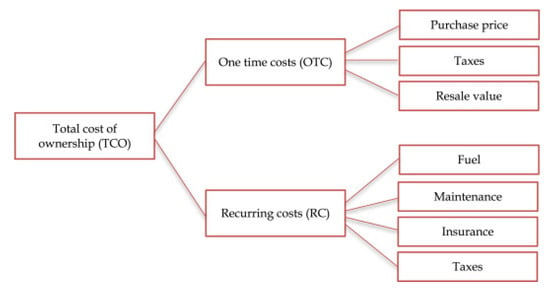

Whilst the raw material, manufacturing processes and energy demands during production are often unknown, this paper aims to characterize the cost of purchase and the cost of use as a possible indicator of the environmental footprint of several generations of product of everyday life.

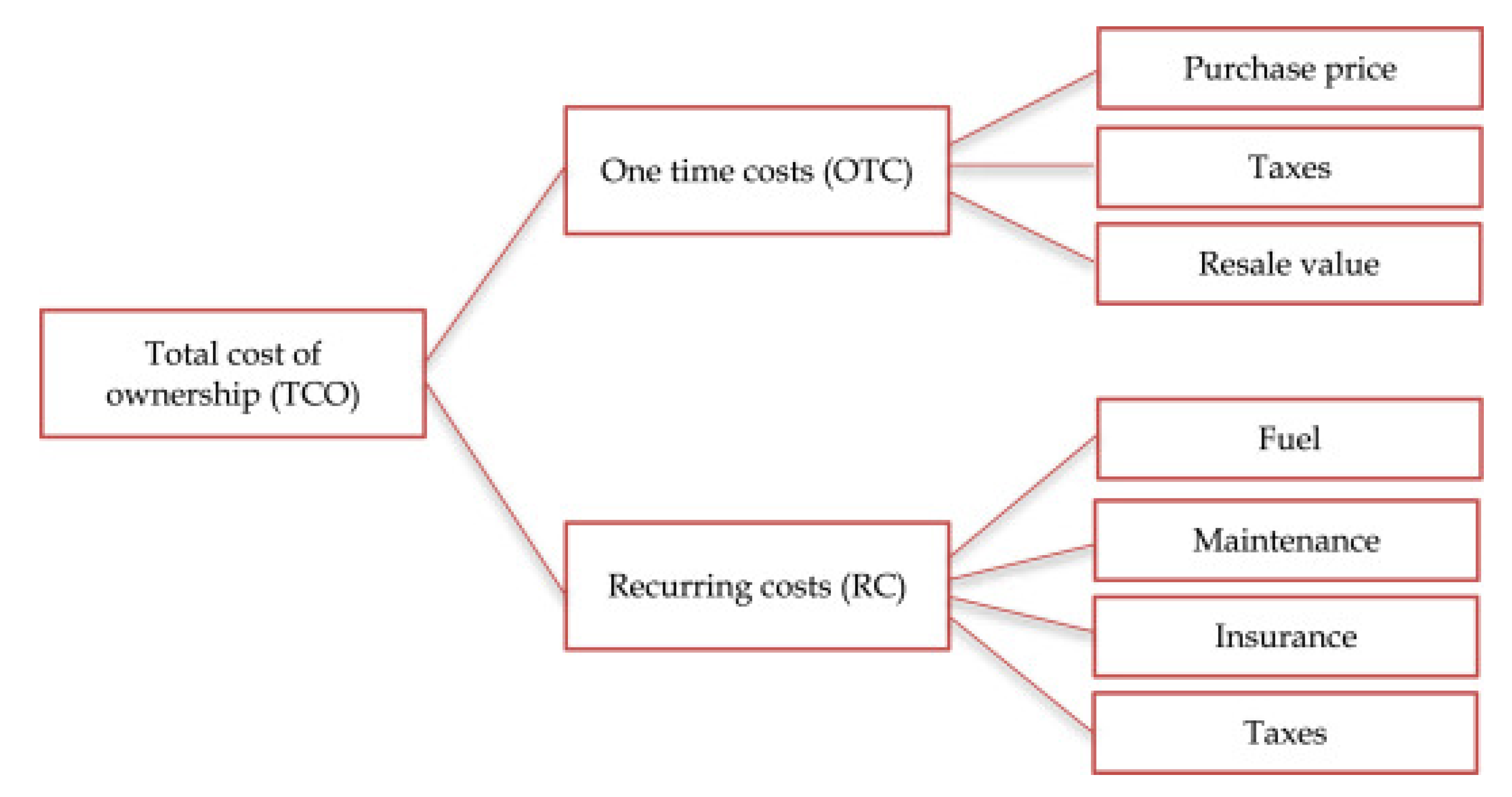

The lack of production data in terms of size and inputs, suitable for the calculation of production footprint, leads to a qualitative assessment for the relationship between the environmental impact and purchase cost. The profit margin and the inflation of prices for the studied time period are not examined at this point, as they are considered as parameters that cannot directly affect the impact, but only qualitatively some of the following diagrams. Moreover, the profit margin depends on the financial policy that an industry follows. In any case, the income from product sales can be re-invested or spend in a way to support the development of the next generations of products, to create new ones or to be invested for equipment, supporting the manufacturing of a wide range of products [55]. To this end, profit margin can be said that it cannot be expressed as a parameter that affects the environmental impact, because of the complexity of the decision making for the re-investment process. More specifically, the vehicle development based on innovative solutions could directly affects the price of the latest vehicle generation, the research on the integration of automation (robotics arms, moving robots, etc.) in the production line, as well as the research on the optimization of the manufacturing methods aiming to limit the production expenses. The fixed cost represents the one-time expenses, such as the purchase price and the taxes, while the variable cost depicts the recurring cost for the following years (Figure 6). The visit of the authorized service for maintenance at defined time intervals or after a pre-defined number of kilometers, the fuel expenses as well as the insurance’s cost and taxes can be considered as the annual expenses of a car owner. On the one hand, neither insurance nor taxes expenses can be considered as direct operational expenses [56], due to their dependence on the national economic policy, while on the other hand, the fuel expenses indicate the engine’s efficiency, and therefore it is considered as a critical parameter for the comparison of a circular and an innovation approach to economy.

Figure 6.

Total cost of ownership framework [56].

4. Case Studies

The assessment of the abovementioned approach is presented in the following paragraphs, while the limitations are identified on the amount and the kind of data that will be used during the implementation of this approach, as well as the interpretation of the result that is related only to a specific product and manufacturer, due to the fact that incorporates the used technology within the production and the impact from the use. The iPhone, a high-tech and expensive mobile phone, as well as a well-known, middle-class car, were identified as products of everyday life with several generations during the last two decades. Both of them were examined for their impact, and they were studied under the principles of circular and innovation economy. According to a survey [57], in a circular economy approach, the first generation of iPhone is considered to be replaced with a same generation brand new device every time when a new generation is released, while the first generation of the automotive case study is replaced with a new, first generation vehicle (MK1), when the third generation (MK3) is released. For the innovation economy approach, the consumers replace their old products with new ones, when the new generations are being released. For the mobile phone case study, each time that a new generation is released, it is assumed that there is also an upgrade on the operating system and several applications.

As a means of communication, the mobile phone was introduced in the 1990s [58], and it became very quickly a familiar and necessary device for everyone. From the 1990s until today, the research and development of the mobile phone’s operating system, as well as the many functionalities that serve, led to the characterization of “Smart Phones”. Meanwhile, in 2021, smartphones with touchscreens have dominated the market share compared to mobile phones with buttons and sliding keyboards. Today, iPhone is a market leader on smartphones with advanced and optimized technologies, including IoT and Cloud services, as well as 4G and 5G network speeds, which improve customer satisfaction and facilitate the interaction between human beings and mobile phone devices [59]. According to [60], 60% of the cost for a new generation of iPhone suggests the profit margin, while the remaining 40% of the purchase expense depicts, on the one hand, the amount of money required for the development of new features (Airpods) and the improvement of common features such as camera resolution and touchscreen sensitivity. These upgrades lead to a satisfied customer, since their needs are served in a more efficient (energy consumption), reliable and safe (image recognition, fingerprint to unlock the device) way. On the other hand, the cost of purchase suggests that the expenses needed for innovative solutions and adjustments in production phase aim to raise the productivity rates and reduce the production cost, by integrating automation and green energy sources in the factory. According to [60], it is suggested that there is a direct correlation among the production, the purchase, and the recurring costs, as well as the produced environmental impact. In a circular economy aspect, the recurring cost for a smartphone owner, is defined as the cost of buying the same generation of mobile phone every time a new version is released, due to the fact that the energy consumption during charging is negligible. In the following table (Table 1), the fixed and variable costs are found.

Table 1.

Mobile phone case study [61].

Furthermore, the automotive case with more than 5 million sales has been assessed under circular and innovation approach, as a product of the automotive industry. According to [62], the evolution of transportation means, especially of automotive industry, is guided through more efficient solutions in terms of engine efficiency and CO2 emissions, as well as in terms of passenger comfort, safety, and entertainment. The research on material science for the development of new, lighter, durable and high-strength materials, results in stiff structures with high power-to-weight ratio and improved vehicle handling, satisfying the drivers.

For this study, the following assumptions have been made: (1) in the innovation economy, an automotive industry usually replaces an old generation with a new one after 5–6 years [63], (2) European customers tend to replace their vehicles after 5 years [64]. When a new vehicle generation is released, consumers will replace their old ones. In circular economy approach customers tend to replace their vehicle after 10–12 years, which coincides with the release of a new vehicle generation. The table below describes the relationship between fixed and variable costs, as well as the engine efficiency improvement over the years for the four generations of the product [14]. Assuming the same number of km per year and different price of the gasoline per year [65], the following table (Table 2) can be seen. Also, the estimation of the price evolution is not straightforward, since there are a lot of factors to take into account, such as the variability of the car variants [66], the time evolution [67], the differentiation among countries [68] and the inflation [69]. Thus, the mean fuel consumption for several everyday cars, as well as the mean cost for the purchase of an everyday car, are included in the following table (Table 2).

Table 2.

Automotive case study.

5. Results

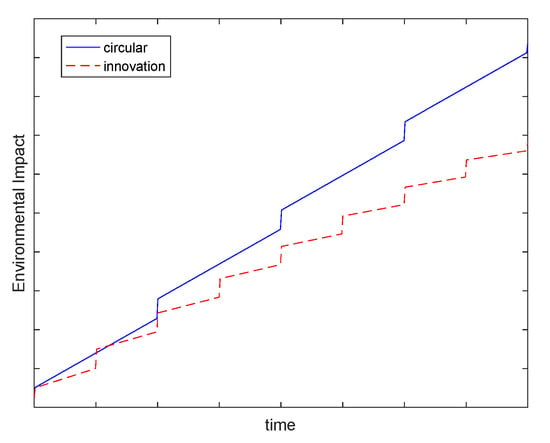

The relationship between cost of use and cost of purchase among the different product generations can be considered proportional to the environmental footprint during production. Therefore, the analysis of Table 1 and Table 2 led us to create the following plots. At this stage, it has to be mentioned that the time intervals between the production of two consecutive product generations, defines the impact/environmental impact. On the one hand by releasing new products with advanced and environmentally friendly specifications, limits the long-term footprint, but on the other hand, the regular/continuous development of new products includes the manufacturing phase, where production line adjustments and new equipment are required, leading to a significant short-term impact, which counteracts the benefit of long-term impact reduction. Thus, it is suggested that a compromise point has to be found, where the environmental impact of an old product matches the impact of the development of a new generation. Meanwhile, the industrial R&D works in a direction where products have increased lifecycle, while the need for repair is reduced, insisting that new generations of products can endure for many years, with less impact during their lifecycle.

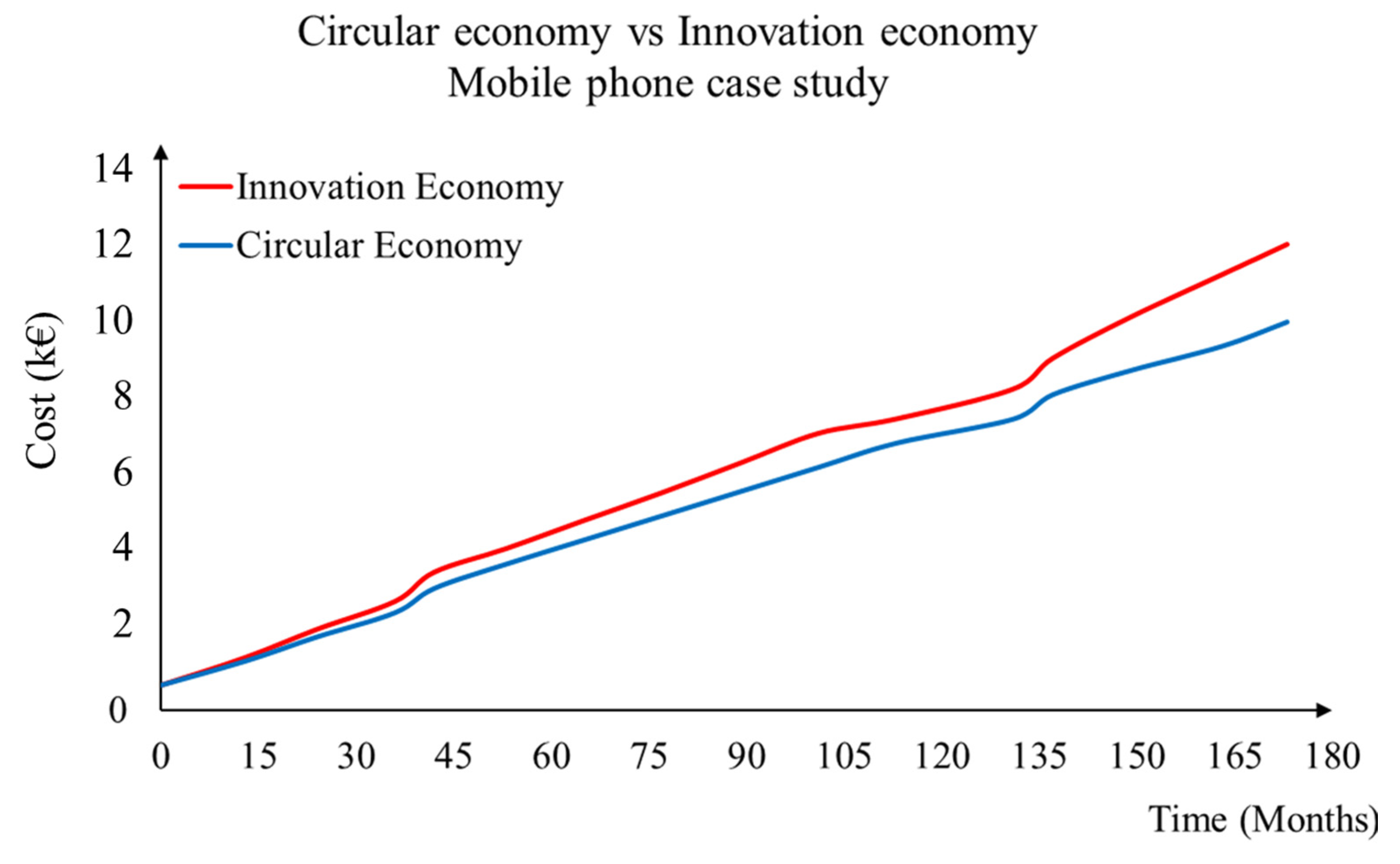

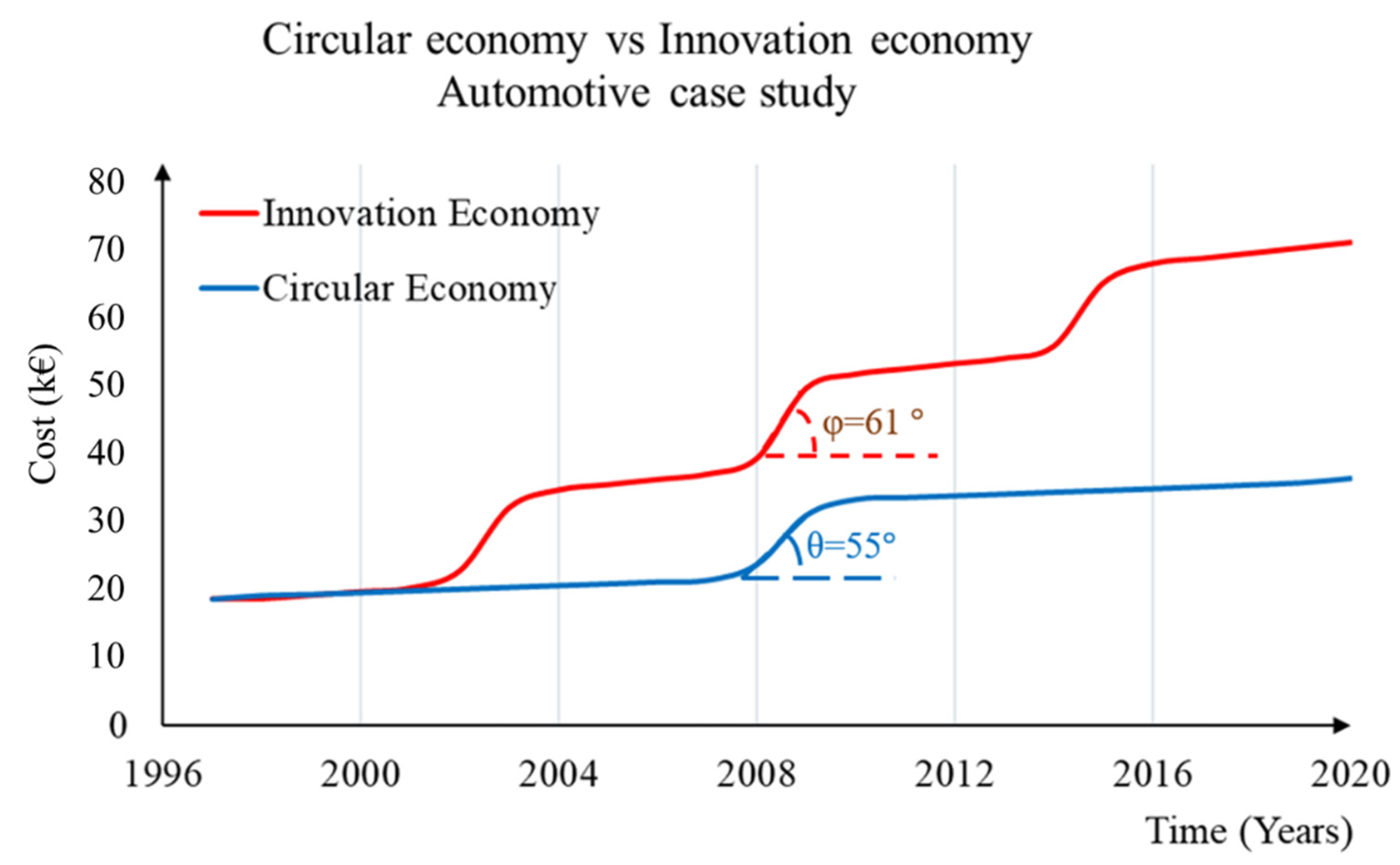

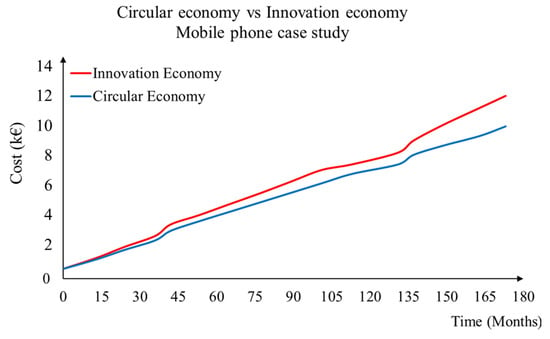

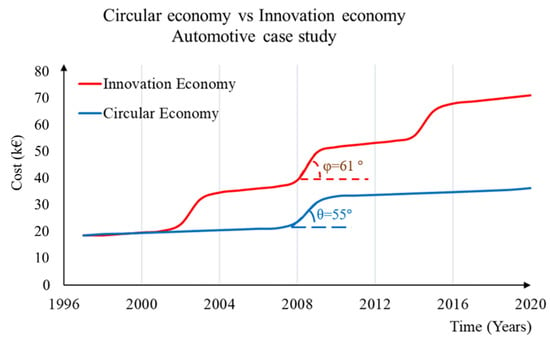

Finally, for the mobile phone case study, considering that it is a mean of communication without recurring costs, the plot suggests that the circular economy approach leads to less impact, compared to the innovational economy. This result can be explained by considering that until today, the industry has not managed to absorb the innovation cost for the development of each new generation. The following plot denotes that the latest generations tend to deviate with a high rate comparing to the first generations (Figure 7). Due to the simplicity of this case without recurring costs, we are not interested in calculating the impact angles. However, the plot seems to follow the presented approach. The next figure (Figure 8) points out that circular economy approach gives the opportunity to reduce the impact which comes from the innovation and manufacturing of new vehicles. The deviation seems to be higher year by year due to the fact that the modern cars are equipped with a number of technologies, leading to higher fixed costs. Latest technology vehicles are equipped with eco-friendly engines with less CO2 emissions and fuel consumption than before, but it is not enough to counteract the fixed cost which is necessary for the development of a new generation. These results can be validated by calculating the mean impact angles considering zero profit margin, are , for the innovation and the circular economy, accordingly. The rising plots depict the recurring costs that deviate by years.

Figure 7.

Mobile Phone case study.

Figure 8.

Automotive case study.

6. Discussion

As mentioned, the cost can be quite indicative of the environmental impact of a production. However, this may contradict partial results, as in the case of disruptive innovation, where the environmental impact is taken into consideration. The electric cars production may be such a case. To this end, the aforementioned results are discussed with respect to elaborating their interpretation.

6.1. Critique of the Monetary Approach

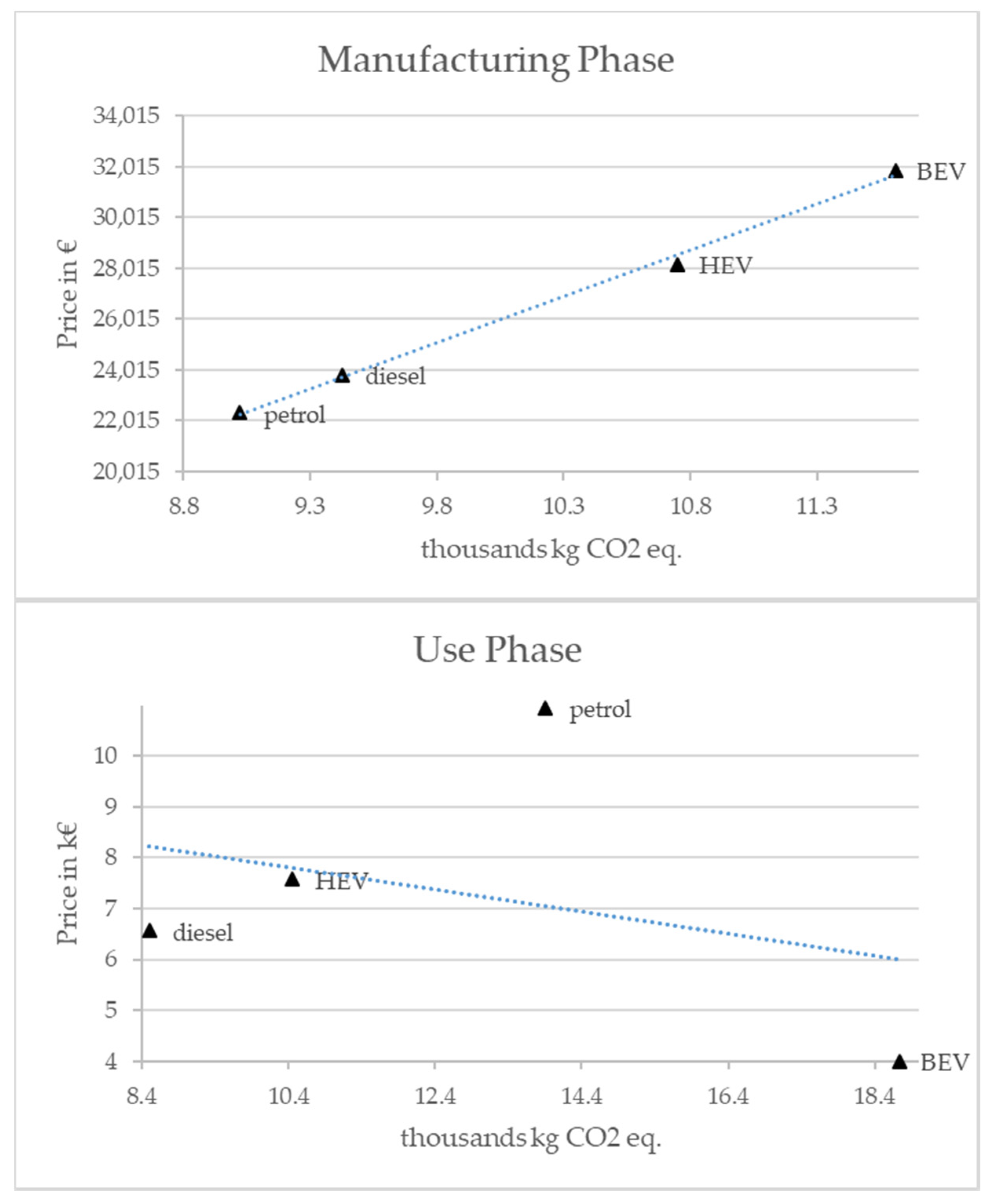

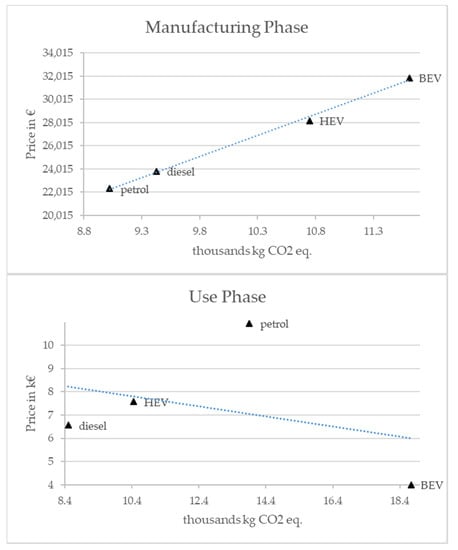

In this section, the approach is evaluated with respect to its validity. An approach to this is the direct comparison to LCA data. However, there are no lines referring to the same product running in parallel following a different economy strategy. To this end, the monetary and LCA data for different technologies are compared, and various outcomes occur. To begin with, data from [70] are adopted, referring to petrol, diesel, hybrid electric vehicles (HEVs), and battery electric vehicles (BEVs), denoting also a kind of disruption in technologies. As such, the following plots (Figure 9) have been retrieved, correlating the monetary data with environmental impact data, during both the manufacturing and use phases.

Figure 9.

Correlation between environmental impact (kg CO2) and monetary cost in the case of vehicles: Manufacturing phase (top) and Use phase (bottom) have both been considered [70].

In each diagram, the points indicate a different type of vehicle. The first diagram has been created assigning in the horizontal axis the production related CO2 emissions and the vertical axis the price of the vehicle. Similarly, in the second diagram, the axes x and y denote similar metrics for the use phase.

The results are quite interesting; in the case of manufacturing, the monetary cost is correlated to a high extent with the environmental impact; thus, monetary data can be adopted, with relative caution. However, during the use phase, the price of fuel (per 150,000 km) may not be indicative of the environmental impact. As a matter of fact, it is the case of BEVs that ruins the correlation. The rebound effects are the most prominent candidates as reasons. However, it is worth noting that the other three points form an almost linear relationship, like in the case of manufacturing. Thus, the combination between profit margin and disruptive innovation may appear as limitations to the present methodology. In any case, a variable profit margin analysis would be highly interesting in case an agnostic methodology needs to be founded.

6.2. Variable Profit Margin Analysis

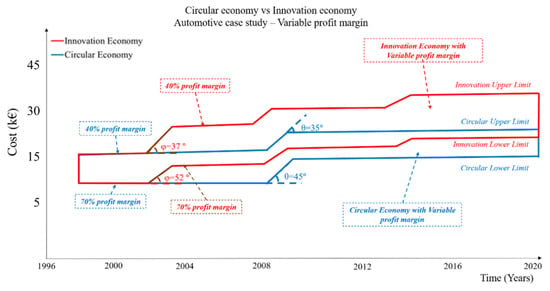

The proposed approach can also be assessed for different profit margins in order to identify whether this parameter is capable of affecting the results. The profit margin represents the relationship between the production cost and the purchase cost, as has been described before. The analysis of the comparison between circular and innovation economy states that the profit margin in a non-known value, for simplicity, is equal to zero. In the case that profit margin varies, the production cost can be found easily.

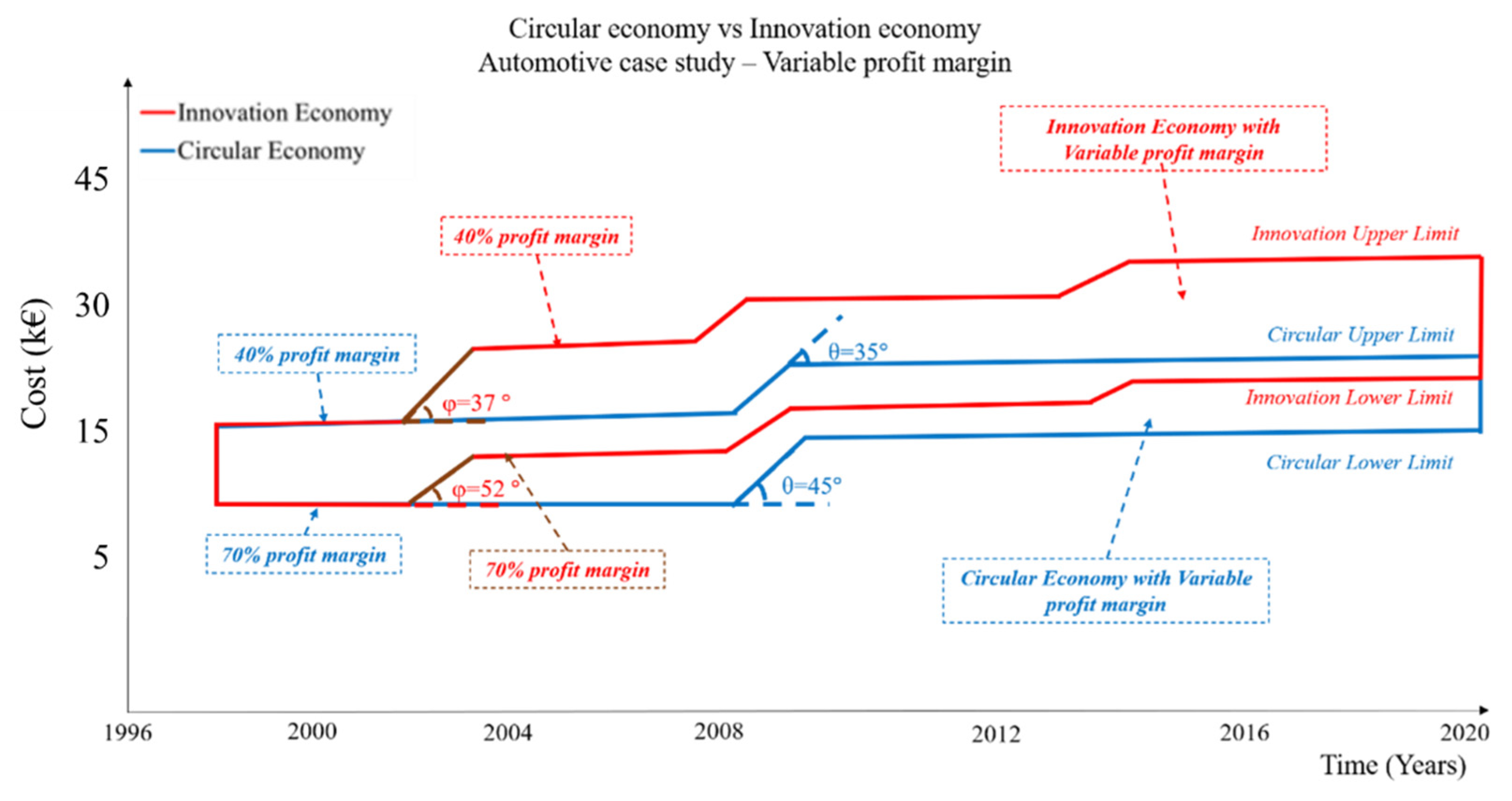

When the profit margin increases, the production cost decreases. By considering the theoretical background, the reduced production cost indicates lower energy costs due to reduced energy consumption, leading to reduced impact. With a high profit margin, the costs of owing a vehicle in terms of circular and innovation economy proof that these values are closer than with a low profit margin. When the production cost is high, there is a great deviation between these two approaches, which can be explained by taking into consideration that this cost is added in every new generation of products. The higher production cost leads to increased environmental impact. To this end, it can be said that a higher profit margin which is accompanied by low production cost equals the two approaches. Figure 10 depicts this relationship for profit margin between 40–70% and for all the generation of the studied vehicle. By calculating the impact angles , for the variable profit margin analysis, it is depicted that, for specific values of profit margin, the innovation approach to economy can provide less impact than the circular for the automotive case study. This can be done for medium values of profit margin 50%, where , , while varies from to and varies from to . In addition, for the variable profit margin analysis, the impact angles are significantly lower, considering that the purchase expenses do not refer only to production costs. So, by increasing the profit margin, production costs drop.

Figure 10.

Variable profit margin—Automotive case study.

7. Conclusions

Considering the lack of data from production phase for this study in order to execute a lifecycle analysis and the fact that recurring, and purchase costs proved to be indicators of the production phase impact, this study is an effort to correlate the impact of following the innovation economy theory compared to circular economy on widely spread and commercial vehicles and mobile phones. For the studied product, with a total lifecycle of 15–25 years and several generations, it can be observed that the innovation approach to economy with products with significant low lifecycle estimations and many revised versions results in a greater impact compared to the circular economy approach. In the case that profit margin is taken into consideration, the innovation economy approach seems to create reduced environmental impact for high profit margin values. Additionally, this work presents a methodology for a qualitative analysis of the environmental impact by considering the fixed cost directly connected to the production cost and the production impact, without executing life cycle analysis models for several generations of products.

Theoretically, it seems that breaking down the cost properly could compare two different strategies. However, practically, the implications of each economy are multifold, and the justification behind such a comparison cannot be retrieved without some thorough analysis. Furthermore, regarding the repercussions of the two economies, it is the way of their simultaneous integration that will be the main factor on the eventual product lifecycle efficiency. With respect to their co-existence, it seems that they can be adopted simultaneously, however it is probably up to the technology integration and the adopted metrics to regulate the overall lifecycle environmental impact. As a matter of fact, it has already become obvious through literature that the integration of Industry 4.0 tools and techniques will be a major milestone towards achieving sustainable production. Hopefully, circularity, and eventually sustainability, will be an additional criterion of absorbing knowledge and technology towards innovation in products.

As a future step, the processing of production data could proof how close is this approach to the reality. It would be really interesting to be able to understand the sustainability of the production, either on the circular or the innovation economy, calculating the presented indicators with a very small but specific amount of data. In addition, a future outlook of the stochastic breakdown of cost could help towards including social impact in the context of Industry 5.0.

Author Contributions

Conceptualization, G.C.; Methodology, A.P.; Formal Analysis, D.P. and P.S.; Investigation, K.T.; writing—original draft preparation, K.T.; writing—review and editing, P.S. and G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work is under the framework of AVANGARD. This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 869986. The dissemination of results herein reflects only the authors’ view, and the Commission is not responsible for any use that may be made of the information it contains.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chryssolouris, G. Manufacturing Systems: Theory and Practice, 2nd ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Stavropoulos, P.; Giannoulis, C.; Papacharalampopoulos, A.; Foteinopoulos, P.; Chryssolouris, G. Life Cycle Analysis: Comparison between Different Methods and Optimization Challenges. In Proceedings of the 48th CIRP Conference on Manufacturing Systems (CIRP CMS 2015), Procedia CIRP, Naples, Italy, 24–26 June 2016; Volume 41, pp. 626–631. [Google Scholar]

- Bocken, N.M.P.; Pauw, I.; Bakker, C.; Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Stavropoulos, P.; Spetsieris, A.; Papacharalampopoulos, A. A Circular Economy based Decision Support System for the Assembly/Disassembly of Multi-Material Components. In Proceedings of the 2nd CIRP Conference on Composite Material Parts Manufacturing (CIRP-CCMPM 2019), Elsevier Procedia CIRP, Catcliffe, UK, 10–11 October 2019; Volume 85, pp. 49–54. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Lacy, P.; Rutqvist, J. Waste and Wealth: The Circular Economy Advantage; Palgrave, Macmillan: London, UK, 2015. [Google Scholar]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in Circular Economy. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Fysikopoulos, A.; Pastras, G.; Alexopoulos, T.; Chryssolouris, G. On a generalized approach to manufacturing energy efficiency. Int. J. Adv. Manuf. Technol. 2014, 73, 1437–1452. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, I.; Alonso-Madrid, J.; Menéndez-Muñiz, M.; Uhart, M.; Canou, J.; Martin, C.; Fabritius, M.; Calvo, L.; Poudelet, L.; Cardona, R.; et al. Life cycle assessment of integrated additive–subtractive concrete 3D printing. Int. J. Adv. Manuf. Technol. 2021, 112, 2149–2159. [Google Scholar] [CrossRef]

- Petrides, D.; Papacharalampopoulos, A.; Stavropoulos, P.; Chryssolouris, G. Dematerialization and Environmental Sustainability: Challenges and Rebound Effects. Procedia CIRP 2018, 72, 845–849. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 15, 36–51. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, M.P.N.; Hultink, E.J. The Circular Economy—A new sustainability paradigm. J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Beaulieu, L.; Durme, G.; Arpin, M.L. Circular Economy: A Critical Review of Concepts. In International Reference Centre for the Lifecycle of Products, Processes and Services; CIRAIG: Montréal, QC, Canada, 2015. [Google Scholar] [CrossRef]

- Durand, P. On a Longer Lifetime for Products: Benefits for Consumers and Companies (2016/2272(INI)); European Parliament—Committee on the Internal Market and Consumer Protection: Brussels, Belgium, 2017. [Google Scholar]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Mariale, M.; Rios, C.D.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar]

- Wang, L.; Li, H. Decomposition Analysis on Dematerialization for the Further Development of Circular Economy. In Proceedings of the 4th International Conference on Bioinformatics and Biomedical Engineering, Granada, Spain, 10–12 June 2010; pp. 1–4. [Google Scholar] [CrossRef] [Green Version]

- Mamasioulas, A.; Mourtzis, D.; Chryssolouris, G. A manufacturing innovation overview: Concepts, models and metrics. Int. J. Comput. Integr. Manuf. 2020, 33, 769–791. [Google Scholar] [CrossRef]

- Meglio, O.; Di Paola, N. Innovation and Entrepreneurship for Well-Being and Sustainability. Sustainability 2021, 13, 9154. [Google Scholar] [CrossRef]

- Pece, A.M.; Simona, O.E.O.; Salisteanu, F. Innovation and Economic Growth: An Empirical Analysis for CEE Countries. Procedia Econ. Financ. 2015, 26, 461–467. [Google Scholar] [CrossRef] [Green Version]

- Duesenberry, J. Papers and Proceedings of the Sixty-eighth Annual Meeting of the American Economic Association. In Innovation and Growth, The American Economic Review; American Economic Association: Evanston, IL, USA, 1956; Volume 46, pp. 134–141. [Google Scholar]

- Reim, W.; Parida, V.; Sjödin, D.R. Circular Business Models for the Bioeconomy: A Review and New Directions for Future Research. Sustainability 2019, 11, 2558. [Google Scholar] [CrossRef] [Green Version]

- Papacharalampopoulos, A.; Stavropoulos, P.; Stavridis, J. Adaptive control of thermal processes: Laser welding and additive manufacturing paradigms. In Proceedings of the CIRP Conference on Intelligent Computation in Manufacturing Engineering, (ICME 2017), Gulf of Naples, Italy, 19–21 July 2017; Volume 67, pp. 233–237. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Papakostas, N.; Mavrikios, D. A perspective on manufacturing strategy: Produce more with less. CIRP J. Manuf. Sci. Technol. 2008, 1, 45–52. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Bikas, H.; Michail, C.; Stavropoulos, P. On the generation of validated manufacturing process optimization and control schemes. In Proceedings of the 8th CIRP Conference of Assembly Technology and Systems (CIRPe 2020), Procedia CIRP, Athens, Greece, 29 September–1 October 2020; Volume 96, pp. 57–62. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Petridis, D. A vision-based system for real-time defect detection: A rubber compound part case study. In Proceedings of the 53rd CIRP Conference on Manufacturing Systems (CIRP 2020), Procedia CIRP, Chicago, IL, USA, 1–3 July 2020; Volume 93, pp. 1230–1235. [Google Scholar] [CrossRef]

- Allwood, J.M.; Gutowski, T.G.; Serrenho, A.C.; Skelton, A.C.; Worrell, E. Industry 1.61803: The transition to an industry with reduced material demand fit for a low carbon future, Philosophical transactions. Ser. A Math. Phys. Eng. Sci. 2017, 375, 2095. [Google Scholar]

- Fridrihsone, A.; Romagnoli, F.; Kirsanovs, V.; Cabulis, U. Life Cycle Assessment of vegetable oil based polyols for polyurethane production. J. Clean. Prod. 2020, 266, 121403. [Google Scholar] [CrossRef]

- Lueddeckens, S.; Saling, P.; Guenther, E. Temporal issues in life cycle assessment—A systematic review. Int. J. Life Cycle Assess. 2020, 25, 1–17. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to conduct prospective life cycle assessment for emerging technologies? A systematic review and methodological guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- Bobba, S.; Ardent, F.; Fabrice, M. Environmental and economic assessment of durability of energy-using products: Method and application to a case-study vacuum cleaner. J. Clean. Prod. 2016, 137, 762–776. [Google Scholar] [CrossRef]

- Bakshi, B.R.; Gutowski, T.G.; Sekulic, D.P. Claiming sustainability: Requirements and challenges. ACS Sustain. Chem. Eng. 2018, 6, 3632–3639. [Google Scholar] [CrossRef]

- Sangprasert, W.; Pharino, C. Environmental Impact Evaluation of Mobile Phone via Life Cycle Assessment, In Proceedings of the 3rd International Conference on Chemical, Biological and Environment Sciences (ICCEBS’2013), Kuala Lumpur, Malaysia, 8–9 January 2013.

- Loyarte-López, E.; Barral, M.; Morla, J.C. Methodology for Carbon Footprint Calculation towards Sustainable Innovation in Intangible Assets. Sustainability 2020, 12, 1629. [Google Scholar] [CrossRef] [Green Version]

- Chrysostomou, C.; Kylili, A.; Nicolaides, D.; Fokaides, P. Life Cycle Assessment of concrete manufacturing in small, isolated states: The case of Cyprus. Int. J. Sustain. Energy 2015, 36, 825–839. [Google Scholar] [CrossRef]

- Braakman, L.; Bhochhibhoya, S.; de Graaf, R. Exploring the relationship between the level of circularity and the life cycle costs of a one-family house. Resour. Conserv. Recycl. 2021, 164, 105149. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Michail, C.; Vassilopoulos, V.; Alexopoulos, K.; Perlo, P. A two-stage decision support system for manufacturing processes integration in microfactories for electric vehicles. Procedia Manuf. 2021, 54, 106–111. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Montalvo, C.; Peck, D.; Rietveld, E. A longer lifetime for products: Benefits for consumers and companies. In Directorate General for Internal Policies, Policy Department A: Economic and Scientific Policy; European Parliament: Brussels, Belgium, 2016. [Google Scholar]

- Ardente, F.; Fabrice, M. Environmental assessment of the durability of energy-using products: Method and application. J. Clean. Prod. 2014, 74, 62–73. [Google Scholar] [CrossRef]

- Tasaki, T.; Masaharu, M.; Hiroyuki, U.; Yasufumi, S. Assessing the Replacement of Electrical Home Appliances for the Environment an Aid to Consumer Decision Making. J. Ind. Ecol. 2013, 17, 290–298. [Google Scholar] [CrossRef]

- Mattila, T. Use of Input-Output Analysis in LCA; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Han, N. The environmental impact of steel and aluminum body-in-whites. JOM 1996, 48, 33–38. [Google Scholar] [CrossRef]

- ISO 13.020.60. Product Life-Cycles. Available online: https://www.iso.org/ics/13.020.60/x/ (accessed on 2 September 2021).

- Friant, M.C.; Vermeulen, W.J.; Salomone, R. A typology of circular economy discourses: Navigating the diverse visions of a contested paradigm. Resour. Conserv. Recycl. 2020, 161, 104917. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2021, 1–12. [Google Scholar] [CrossRef]

- Singh, S.; Aggarwal, Y. In search of a consensus definition of innovation: A qualitative synthesis of 208 definitions using grounded theory approach. Innov. Eur. J. Soc. Sci. Res. 2021, 1–19. [Google Scholar] [CrossRef]

- Vacchi, M.; Siligardi, C.; Ferrari, A.M.; Settembre-Blundo, D. Industry 4.0 and Smart Data as Enablers of the Circular Economy in Manufacturing: Product Re-Engineering with Circular Eco-Design. Sustainability 2021, 13, 10366. [Google Scholar] [CrossRef]

- Ciliberto, C.; Szopik-Depczyńska, K.; Tarczyńska-Łuniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy transition: A sustainable lean manufacturing recipe for Industry 4.0. Bus. Strategy Environ. 2021, 1–18. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Fiorini, P.D.C.; Wong, C.W.; Jugend, D.; Jabbour, A.B.L.D.S.; Seles, B.M.R.P.; Pinheiro, M.A.P.; da Silva, H.M.R. First-mover firms in the transition towards the sharing economy in metallic natural resource-intensive industries: Implications for the circular economy and emerging industry 4.0 technologies. Resour. Policy 2020, 66, 101596. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 123741. [Google Scholar] [CrossRef]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability transition in industry 4.0 and smart manufacturing with the triple-layered business model canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef] [Green Version]

- Gutowski, T.; Chryssolouris, G. Personal Communication, 2017.

- Cooper, D.R.; Gutowski, T.G. The environmental impacts of reuse: A review. J. Ind. Ecol. 2017, 21, 38–56. [Google Scholar] [CrossRef]

- Clifford, M. 17-Motorcycles—Design and project costing. In Case Studies in Engineering Design; Matthews, C., Ed.; Butterworth-Heinemann: Oxford, UK, 1998; pp. 192–216. ISBN 9780340691359. [Google Scholar] [CrossRef]

- Arjan, V.; Annema, A.J.; Geerten, K.; Bert, W. Proposing a more comprehensive future total cost of ownership estimation framework for electric vehicles. Energy Policy 2019, 129, 1034–1046. [Google Scholar] [CrossRef]

- Pantano, E.; Priporas, C.V. The effect of mobile retailing on consumers’ purchasing experiences: A dynamic perspective. Comput. Hum. Behav. 2016, 61, 548–555. [Google Scholar] [CrossRef] [Green Version]

- Dunnewijk, T.; Hultén, S. A brief history of mobile communication in Europe. Telemat. Inform. 2007, 24, 164–179. [Google Scholar] [CrossRef]

- Holl, K.; Elberzhager, F. Chapter One-Mobile Application Quality Assurance. In Advances in Computers; Memon, A.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 112, pp. 1–77. ISSN 0065-2458. ISBN 9780128151211. [Google Scholar] [CrossRef]

- Giachetti, C. Smartphone Start-Ups: Navigating the IPhone Revolution. 2018. Available online: https://link.springer.com/book/10.1007%2F978-3-319-67973-0 (accessed on 12 March 2021).

- Braden, T. Beginning of the New Smartphone Era. Marriott Stud. Rev. 2019, 3. Available online: https://scholarsarchive.byu.edu/marriottstudentreview/vol3/iss1/10 (accessed on 20 September 2021).

- Kobayashi, S.; Plotkin, S.; Ribeiro, S. Energy efficiency technologies for road vehicles. Energy Effic. 2009, 2, 125–137. [Google Scholar] [CrossRef]

- Haugh, D.; Mourougane, A.; Chatal, O. The Automobile Industry in and beyond the Crisis. In OECD, Economics Department, OECD Economics Department Working Papers; OECD: Paris, France, 2010. [Google Scholar] [CrossRef]

- Krupa, J.S.; Rizzo, M.D.; Eppstein, M.J.; Lanute, D.B.; Gaalema, D.E.; Lakkaraju, K.; Warrender, C.E. Analysis of a consumer survey on plug-in hybrid electric vehicles. Transp. Res. Part A Policy Pract. 2014, 64, 14–31. [Google Scholar] [CrossRef]

- Fuel Consumption of Cars and Vans. Available online: https://www.iea.org/reports/fuel-consumption-of-cars-and-vans (accessed on 12 March 2021).

- Ford. The Ford Focus case. Available online: https://www.ford.gr/content/dam/guxeu/gr/documents/pricelists/PL-Cars.pdf (accessed on 20 September 2021).

- European Commission. Car prices within the European Union. Available online: https://ec.europa.eu/competition/sectors/motor_vehicles/prices/2010_07_full.pdf (accessed on 20 September 2021).

- Statista. Average Price of Passenger Cars in the EU in 2015 and 2019. Available online: https://www.statista.com/statistics/425095/eu-car-sales-average-prices-in-by-country/ (accessed on 20 September 2021).

- European Commission. Convergence of Car Prices Improves within EU. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_05_1027 (accessed on 20 September 2021).

- Petrauskienė, K.; Galinis, A.; Kliaugaitė, D.; Dvarionienė, J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability 2021, 13, 957. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).