Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship

Abstract

:1. Introduction

2. Analysis of Prefabricated Construction Quality and Its Influencing Factors

2.1. Characteristics of Quality Management of Prefabricated Construction

2.2. Factors Influencing Quality of Prefabricated Construction

3. Methods

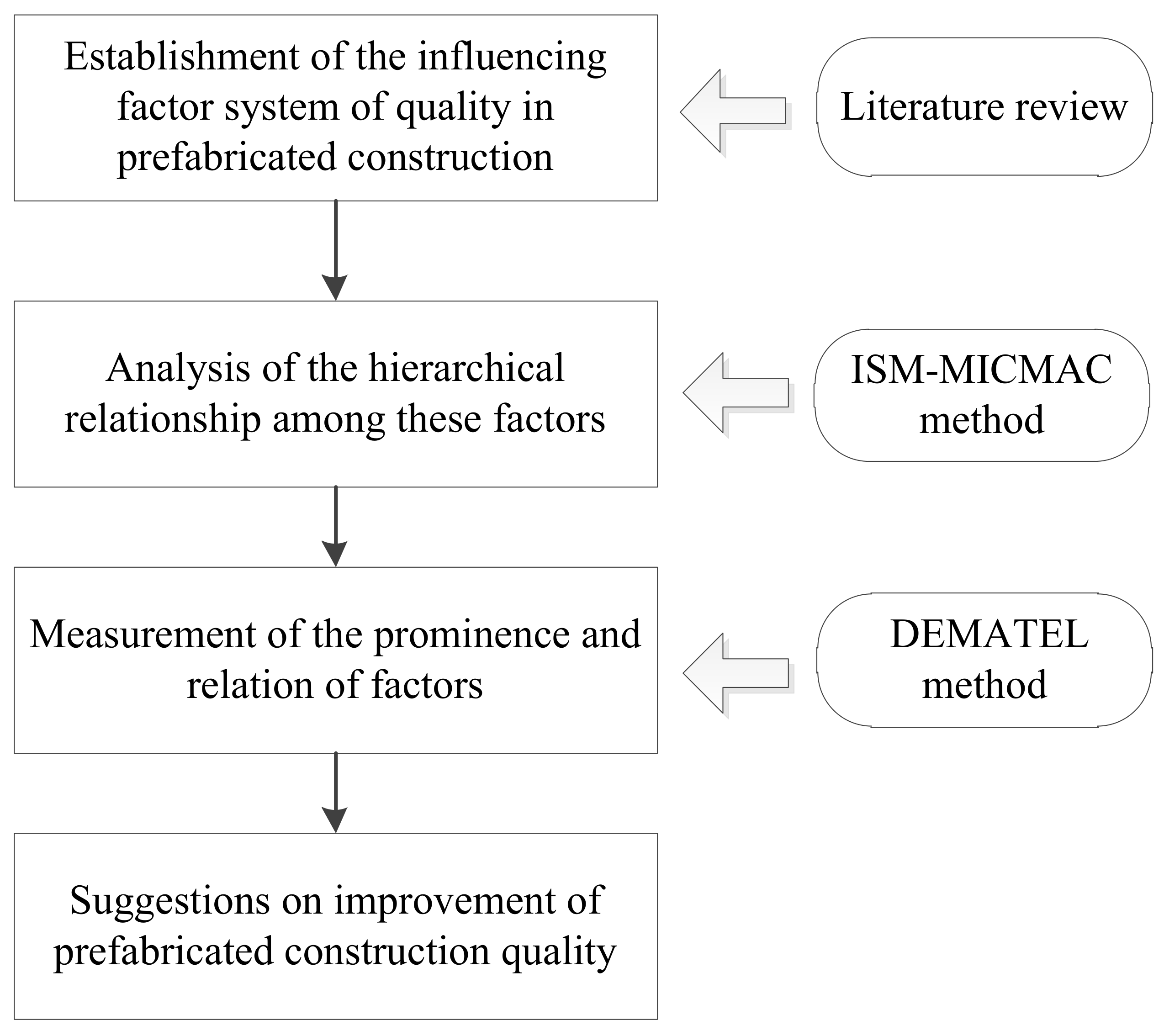

3.1. Research Framework

3.2. Influencing Factor System

3.3. ISM-MICMAC Method

3.4. DEMATEL Method

4. Results and Discussion

4.1. Data Collection

4.2. Relationship Analysis of Influencing Factors

4.2.1. Development of SSIM

4.2.2. Development of the Reachability Matrix

4.2.3. Development of the Hierarchical Model

4.2.4. Classification of Influencing Factors

4.3. Analysis of the Influence Degree of Critical Factors

4.4. Policy Suggestions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, N. The role of the construction industry in China’s sustainable urban development. Habitat Int. 2014, 44, 442–450. [Google Scholar] [CrossRef]

- Sev, A. How can the construction industry contribute to sustainable development? A conceptual framework. Sustain. Dev. 2009, 17, 161–173. [Google Scholar] [CrossRef]

- National Bureau of Statistics of the People’s Republic China. Statistical Yearbook 2021; National Bureau of Statistics of the People’s Republic China: Beijing, China, 2021.

- Zhang, J.; Li, H.; Xia, B.; Skitmore, M. Impact of environment regulation on the efficiency of regional construction industry: A 3-stage Data Envelopment Analysis (DEA). J. Clean. Prod. 2018, 200, 770–780. [Google Scholar] [CrossRef]

- Liu, B.; Wang, X.; Chen, Y.; Shen, Y. The energy efficiency of China’s regional construction industry based on the three-stage DEA model and the DEA-DA model. Ksce J. Civ. Eng. 2016, 20, 34–47. [Google Scholar]

- Xu, G.; Wang, W. China’s energy consumption in construction and building sectors: An outlook to 2100. Energy 2020, 195, 117045. [Google Scholar] [CrossRef]

- Biswas, W. Carbon footprint and embodied energy consumption assessment of building construction works in Western Australia. Int. J. Sustain. Built Environ. 2014, 3, 179–186. [Google Scholar] [CrossRef] [Green Version]

- Daghouri, A.; Mansouri, K.; Qbadou, M. Information system performance evaluation and optimization using AHP and TOPSIS: Construction industry case. In Proceedings of the 4th International Conference on Optimization and Applications (ICOA), Mohammedia, Morocco, 26–27 April 2018; pp. 1–8. [Google Scholar]

- Quinn, C.; Shabestari, A.Z.; Misic, T.; Gilani, S.; Mcarthur, J.J. Building automation system—BIM integration using a linked data structure. Autom. Constr. 2020, 118, 103257. [Google Scholar] [CrossRef]

- Chen, T.; Cao, Z. Construction safety: An analysis of the cross-influence of economic, construction, and accident death factors. Environ. Sci. Pollut. Res. 2021, 6, 1–12. [Google Scholar]

- Han, Y.; Jin, R.; Wood, H.; Yang, T. Investigation of demographic factors in construction employees’ safety perceptions. Ksce J. Civ. Eng. 2019, 23, 2815–2828. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Factors affecting the capital cost of prefabrication-A case study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- El-Abidi, K.M.A.; Ghazali, F.E.M. Motivations and Limitations of Prefabricated Building: An Overview. Appl. Mech. Mater. 2015, 802, 668–675. [Google Scholar] [CrossRef]

- Liu, G.; Li, K.; Zhao, D.; Mao, C. Business model innovation and its drivers in the Chinese construction industry during the shift to modular prefabrication. J. Manag. Eng. 2017, 33, 04016051. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Identifying barriers to off-site construction using grey dematel approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Dineshkumar, N.; Kathirvel, P. Comparative study on prefabrication construction with cast in-situ construction of residential buildings. IJISET—Int. J. Innov. Sci. Eng. Technol. 2015, 2, 527–532. [Google Scholar]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Pheng, L.S.; Teo, J.A. Implementing total quality management in construction firms. J. Manag. Eng. 2004, 20, 8–15. [Google Scholar] [CrossRef]

- Ma, Z.; Cai, S.; Mao, N.; Yang, Q.; Feng, J.; Wang, P. Construction quality management based on a collaborative system using BIM and indoor positioning. Autom. Constr. 2018, 92, 35–45. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Aoieong, R.T.; Tang, S.L.; Zheng, D.X. A comparison of quality management systems in the construction industries of Hong Kong and the USA. Int. J. Qual. Reliab. Manag. 2005, 22, 149–161. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost-benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Li, X.-J. Research on investment risk influence factors of prefabricated building projects. J. Civ. Eng. Manag. 2020, 26, 599–613. [Google Scholar] [CrossRef]

- Arashpour, M.; Kamat, V.; Bai, Y.; Wakefield, R.; Abbasi, B. Optimization modeling of multi-skilled resources in prefabrication: Theorizing cost analysis of process integration in off-site construction. Autom. Constr. 2018, 95, 1–9. [Google Scholar] [CrossRef]

- Yihua, M.; Tuo, X. Research of 4M1E’s effect on engineering quality based on structural equation model. Syst. Eng. Procedia 2011, 1, 213–220. [Google Scholar] [CrossRef]

- Hoonakker, P.; Carayon, P.; Loushine, T. Barriers and benefits of quality management in the construction industry: An empirical study. Total Qual. Manag. Bus. Excell. 2010, 21, 953–969. [Google Scholar] [CrossRef]

- Chen, Y.; Okudan, G.E.; Riley, D.R. Decision support for construction method selection in concrete buildings: Prefabrication adoption and optimization. Autom. Constr. 2010, 19, 665–675. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Towards a decision support for modular integrated construction: An integrative review of the primary decision-making actors. Int. J. Constr. Manag. 2019, 1–20. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Knowledge-based decision support system for prefabricated prefinished volumetric construction. Autom. Constr. 2018, 94, 168–178. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef] [Green Version]

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Haron, N.A.; Abdul-Rahman, H.; Wang, C.; Wood, L.C. Quality function deployment modelling to enhance industrialised building system adoption in housing projects. Total Qual. Manag. Bus. Excell. 2015, 26, 703–718. [Google Scholar] [CrossRef]

- Ansari, W.S.; Thaheem, M.J.; Khalfan, M. Use of offsite construction techniques in Pakistan. Middle East J. Manag. 2016, 3, 218–229. [Google Scholar] [CrossRef]

- Haron, N.A.; Rahman, H.A.; Hanid, M. A literature review of the advances and barriers to the implementation of industrialised building system (IBS) in construction industry. Malays. Constr. Res. J. 2009, 4, 10–14. [Google Scholar]

- Pan, W.; Gibb, A.F.; Dainty, A.R.J. Perspective of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef] [Green Version]

- Koespiadi, K.; Mudjanarko, S.W.; Rasidi, N.; Utomo, W.M.; Alimudin, A.; Supriyatno, D.; Haksama, S.; Dimyati, L.M.F.; Madun, A.B.; Wiwoho, F.P.; et al. The concrete quality testing for trapezoidal model of the prefabricated foundation. Int. J. Eng. Technol. 2018, 7, 311–315. [Google Scholar]

- Lovell, H.; Smith, S.J. Agencement in housing markets: The case of the UK construction industry. Geoforum 2010, 41, 457–468. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Zhao, Y. Some economic facts of the prefabricated housing. In Industry Report; Rutgers Business School: Newark, NJ, USA, 2010. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Jaillon, L.C.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Nick, B.; Ron, W. Drives, constraint and the future of offsite manufacture in Australia. Constr. Innov. Spec. Ed. 2007, 9, 72–83. [Google Scholar]

- Azman, M.N.A.; Ahamad, M.S.S.; Husin, W.M.W. Comparative study on prefabrication construction process. Int. Surv. Res. J. 2012, 2, 45–58. [Google Scholar]

- Durdyev, S.; Ismail, S. Offsite manufacturing in the construction industry for productivity improvement. EMJ-Eng. Manag. J. 2019, 31, 35–46. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef] [Green Version]

- Khalfan, M.M.A.; Maqsood, T. Corrigendum to “Current state of off-site manufacturing in Australian and Chinese residential construction”. J. Constr. Eng. 2016, 2016, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance review of prefabricated building systems and future research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef] [Green Version]

- Yunus, R.; Yang, J. Critical sustainability factors in industrialised building systems. Constr. Innov. 2012, 12, 447–463. [Google Scholar] [CrossRef] [Green Version]

- Zhai, X.; Reed, R.; Mills, A. Factors impeding the offsite production of housing construction in China: An investigation of current practice. Constr. Manag. Econ. 2014, 32, 40–52. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X. Sustainability perceptions of off-site manufacturing stakeholders in Australia. J. Clean. Prod. 2019, 227, 346–354. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X.; London, K. Understanding stakeholders in off-site manufacturing: A literature review. J. Constr. Eng. Manag. 2019, 145, 03119003. [Google Scholar] [CrossRef]

- Jeong, J.G.; Hastak, M.; Syal, M. Framework of manufacturer-retailer relationship in the manufactured housing construction. Constr. Innov. 2009, 9, 22–41. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; SAR, H.K. Key success factors for implementing modular integrated construction projects: A literature mining approach. In Proceedings of the 8th International Conference on Construction Engineering and Project Management, Hong Kong, China, 7–8 December 2020; pp. 343–352. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef] [Green Version]

- Lessing, J.; Stehn, L.; Ekholm, A. Industrialised housing: Definition and categorization of the concept. In Proceedings of the 13th Conference of the International Group for Lean Construction, Sydney, NSW, Australia, 18–21 July 2005; pp. 471–480. [Google Scholar]

- Kamar, K.A.M.; Hamid, Z.A.; Alshawi, M. The critical success factors (CSFs) to the implementation of industrialised building system (IBS) in Malaysia. In Proceedings of the 18th CIB World Building Congress, TG57-Industrialization in Construction, Salford, UK, 10–13 May 2010; pp. 64–76. [Google Scholar]

- Rashidi, A.; Ibrahim, R. Industrialized construction chronology: The disputes and success factors for a resilient construction industry in Malaysia. Open Constr. Build. Technol. J. 2017, 11, 286–300. [Google Scholar] [CrossRef]

- Nawi, M.M.; Lee, A.; Nor, K.M. Barriers to implementation of the Industrialised Building System (IBS) in Malaysia. Built Hum. Environ. Rev. 2011, 4, 22–35. [Google Scholar]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major barriers to off-site construction: The developer’s perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Xie, L.; Chen, Y.; Xia, B.; Hua, C. Importance-performance analysis of prefabricated building sustainability: A case study of guangzhou. Adv. Civ. Eng. 2020, 2020, 8839118. [Google Scholar] [CrossRef]

- Sevkli, M.; Koh, S.C.L.; Zaim, S.; Demirbag, M.; Tatoglu, E. An application of data envelopment analytic hierarchy process for supplier selection: A case study of BEKO in Turkey. Int. J. Prod. Res. 2007, 45, 1973–2003. [Google Scholar] [CrossRef] [Green Version]

- Ng, S.T.; Wong, Y.M.W.; Wong, J.M.W. A structural equation model of feasibility evaluation and project success for public—Private partnerships in Hong Kong. IEEE Trans. Eng. Manag. 2010, 57, 310–322. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Zhao, Y.; Shen, Q.; Yang, L.; Cai, H. Risk assessment and management via multi-source information fusion for undersea tunnel construction. Autom. Constr. 2020, 111, 103050. [Google Scholar] [CrossRef]

- Lee, T.S.; Kim, D.H.; Lee, D.W. A competency model for project construction team and project control team. Ksce J. Civ. Eng. 2011, 15, 781–792. [Google Scholar] [CrossRef]

- Warfield, J.N. Binary matrices in system modeling. IEEE Trans. Syst. Man Cybern. 1973, 3, 441–449. [Google Scholar] [CrossRef] [Green Version]

- Attri, R.; Dev, N.; Sharma, V. Interpretive structural modelling (ISM) approach: An overview. Res. J. Manag. Sci. 2013, 2319, 1171. [Google Scholar]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to building information modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Feng, H.; Wang, Y.; Fan, S. ISM-based relationship among critical factors that affect the choice of prefabricated concrete buildings in China. Int. J. Constr. Manag. 2019, 1–16. [Google Scholar] [CrossRef]

- Duperrin, J.C.; Godet, M. Méthode de Hiérarchisation des Eléments d’un Système; Rapport Economique du CEA: Paris, France, 1973. [Google Scholar]

- Chander, M.; Jain, S.K.; Shankar, R. Modeling of information security management parameters in Indian organizations using ISM and MICMAC approach. J. Model. Manag. 2013, 8, 171–189. [Google Scholar] [CrossRef]

- Bux, H.; Zhang, Z.; Ahmad, N. Promoting sustainability through corporate social responsibility implementation in the manufacturing industry: An empirical analysis of barriers using the ISM-MICMAC approach. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1729–1748. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL Technique: A systematic review of the state-of-the-art literature on methodologies and applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef] [Green Version]

- Bataglin, F.S.; Viana, D.D.; Formoso, C.T.; Bulhões, I.R. Model for planning and controlling the delivery and assembly of engineer-to-order prefabricated building systems: Exploring synergies between Lean and BIM 1. Can. J. Civ. Eng. 2020, 47, 165–177. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Shen, L. A conceptual development framework for prefabricated construction supply chain management: An integrated overview. Sustainability 2020, 12, 1878. [Google Scholar] [CrossRef] [Green Version]

- Jing, S.; Zhang, Z.; Yan, J. Government supervision mode selection in the promotion period of prefabricated construction using evolutionary game. Math. Probl. Eng. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Cheng, B.; Wei, Y.; Zhang, W.; Zhou, X.; Chen, H.; Huang, L.; Huang, J.; Kang, X. Evolutionary game simulation on government incentive strategies of prefabricated construction: A system dynamics approach. Complexity 2020, 2020, 8861146. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Mbachu, J. Development of intelligent prefabs using iot technology to improve the performance of prefabricated construction projects. Sensors 2019, 19, 4131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Category | Factor |

|---|---|

| Man | Skilled management and supervising team (F1) |

| Availability of experienced workforce (F2) | |

| Enough professional designers (F3) | |

| Adequate competency of construction workers (F4) | |

| Material | Quality of raw production materials (F5) |

| Machine and equipment | Manufacturing equipment for producing assembled components (F6) |

| Prefabricated construction equipment (F7) | |

| Transport equipment (F8) | |

| Method | Experience in assembly design (F9) |

| Prefabricated construction technology (F10) | |

| Information technology (F11) | |

| Unreasonable assembly strategies (F12) | |

| Environment | Poor integration in the supply chain (F13) |

| Complete quality management process (F14) | |

| Codes and standards for prefabricated components (F15) | |

| Stakeholder collaboration and coordination (F16) | |

| Efficient communication among professional designers (F17) | |

| Government guidance for prefabricated construction (F18) | |

| Changes in component design (F19) | |

| Standards for construction and acceptance (F20) | |

| Complete engineering feasibility study (F21) | |

| Reasonable project contracts (F22) | |

| Laws and regulations regarding quality management (F23) |

| Expert | Number | Percentage |

|---|---|---|

| Gender | ||

| Male | 10 | 67% |

| Female | 5 | 33% |

| Age | ||

| Below 30 years old | 3 | 20% |

| 31–40 | 6 | 40% |

| 41 years old or above | 6 | 40% |

| Education | ||

| Bachelor | 8 | 53% |

| Master | 5 | 33% |

| Doctor | 2 | 14% |

| Affiliation | ||

| Design institute | 3 | 20% |

| Production factory | 3 | 20% |

| Government | 3 | 20% |

| Construction enterprise | 3 | 20% |

| University | 3 | 20% |

| F23 | F22 | F21 | F20 | F19 | F18 | F17 | F16 | F15 | F14 | F13 | F12 | F11 | F10 | F9 | F8 | F7 | F6 | F5 | F4 | F3 | F2 | F1 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | A | V | V | A | V | A | O | O | A | O | A | V | O | O | O | V | V | V | V | O | O | O | |

| F2 | A | V | V | A | V | A | O | O | A | O | A | V | O | O | O | V | V | V | V | O | O | ||

| F3 | A | V | V | A | V | A | O | O | A | O | A | V | O | O | V | V | V | V | V | O | |||

| F4 | A | V | V | A | V | A | O | O | A | O | A | V | O | O | O | V | V | V | V | ||||

| F5 | A | A | A | A | A | A | A | A | A | A | A | A | A | A | A | O | O | O | |||||

| F6 | A | A | A | A | A | A | A | A | A | A | A | A | A | A | A | V | V | ||||||

| F7 | A | A | A | A | A | A | A | A | A | O | O | A | A | A | A | V | |||||||

| F8 | A | A | A | A | A | A | A | A | A | A | A | A | A | A | A | ||||||||

| F9 | A | V | V | A | V | A | A | A | A | A | A | V | A | A | |||||||||

| F10 | A | V | V | A | V | A | O | O | A | O | A | V | O | ||||||||||

| F11 | A | V | V | A | V | A | V | V | A | O | A | V | |||||||||||

| F12 | A | A | A | A | V | A | A | A | A | A | A | ||||||||||||

| F13 | O | V | V | O | V | A | V | V | O | V | |||||||||||||

| F14 | O | O | O | O | V | A | V | V | O | ||||||||||||||

| F15 | X | V | V | X | V | A | O | O | |||||||||||||||

| F16 | O | O | O | O | V | A | X | ||||||||||||||||

| F17 | O | O | O | O | V | A | |||||||||||||||||

| F18 | V | V | V | V | V | ||||||||||||||||||

| F19 | A | A | A | A | |||||||||||||||||||

| F20 | X | V | V | ||||||||||||||||||||

| F21 | A | V | |||||||||||||||||||||

| F22 | A | ||||||||||||||||||||||

| F23 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | F16 | F17 | F18 | F19 | F20 | F21 | F22 | F23 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F2 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F3 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F4 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F6 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| F9 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F10 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F11 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| F12 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F13 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| F14 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| F15 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| F16 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| F17 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| F18 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| F19 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| F20 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| F21 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 |

| F22 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 |

| F23 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| Reachability Set | Antecedent Set | Intersection Set | Level | |

|---|---|---|---|---|

| F1 | F1, F5, F6, F7, F8, F12, F19, F21, F22 | F1, F13, F15, F18, F20, F23 | F1 | 4 |

| F2 | F2, F5, F6, F7, F8, F12, F19, F21, F22 | F2, F13, F15, F18, F20, F23 | F2 | 4 |

| F3 | F3, F5, F6, F7, F8, F9, F12, F19, F21, F22 | F3, F13, F15, F18, F20, F23 | F3 | 4 |

| F4 | F4, F5, F6, F8, F12, F19, F21, F22 | F4, F13, F15, F18, F20, F23 | F4 | 4 |

| F5 | F5 | F1, F2, F3, F4, F5, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F5 | 1 |

| F6 | F6, F7, F8 | F1, F2, F3, F4, F6, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F6 | 1 |

| F7 | F7, F8 | F1, F2, F3, F4, F6, F7, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F7 | 1 |

| F8 | F8 | F1, F2, F3, F4, F6, F7, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F8 | 1 |

| F9 | F5, F6, F7, F8, F9, F12, F19, F21, F22 | F3, F9, F10, F11, F13, F14, F15, F16, F17, F18, F20, F23 | F9 | 3 |

| F10 | F5, F6, F7, F8, F9, F10, F12, F19, F21, F22 | F10, F13, F15, F18, F20 | F10 | 4 |

| F11 | F5, F6, F7, F8, F9, F10, F11, F12, F16, F17, F19, F21, F22 | F11, F13, F15, F18, F20 | F11 | 4 |

| F12 | F5, F6, F7, F8, F12, F19 | F1, F2, F3, F4, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F20, F21, F22, F23 | F12 | 2 |

| F13 | F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F13, F14, F16, F17, F19, F21, F22 | F13, F18 | F13 | 5 |

| F14 | F5, F6, F7, F8, F9, F12, F14, F16, F17, F19, F21, F22 | F13, F14, F18 | F14 | 4 |

| F15 | F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F15, F16, F17, F19, F20, F21, F22, F23 | F15, F18, F20, F23 | F15 | 5 |

| F16 | F5, F6, F7, F8, F9, F12, F16, F17, F19, F21, F22 | F11, F13, F14, F15, F16, F17, F18, F21, F23 | F16, F17 | 3 |

| F17 | F5, F6, F7, F8, F9, F12, F16, F17, F19, F21, F22 | F11, F13, F14, F15, F16, F17, F18, F21, F23 | F16, F17 | 3 |

| F18 | F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F18 | F18 | 6 |

| F19 | F5, F6, F7, F8, F19 | F1, F2, F3, F4, F9, F10, F11, F12, F13, F14, F15, F16, F17, F18, F19, F20, F21, F22, F23 | F19 | 2 |

| F20 | F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F15, F16, F17, F19, F20, F21, F22, F23 | F1, F2, F3, F4, F15, F18, F20, F23 | F20, F23 | 5 |

| F21 | F5, F6, F7, F8, F12, F19, F21, F22 | F1, F2, F3, F4, F9, F10, F11, F13, F14, F15, F16, F17, F18, F20, F21, F23 | F21 | 3 |

| F22 | F5, F6, F7, F8, F12, F19, F22 | F1, F2, F3, F4, F9, F10, F11, F13, F14, F15, F16, F17, F18, F20, F21, F22, F23 | F22 | 3 |

| F23 | F1, F2, F3, F4, F5, F6, F7, F8, F9, F10, F11, F12, F15, F16, F17, F19, F20, F21, F22, F23 | F15, F18, F20, F23 | F20, F23 | 5 |

| r | c | r + c | r − c | |

|---|---|---|---|---|

| F1 | 0.405 | 0.143 | 0.549 | 0.262 |

| F2 | 0.405 | 0.143 | 0.549 | 0.262 |

| F3 | 0.503 | 0.143 | 0.646 | 0.360 |

| F4 | 0.405 | 0.143 | 0.549 | 0.262 |

| F5 | 0.000 | 0.935 | 0.935 | −0.935 |

| F6 | 0.031 | 0.921 | 0.952 | −0.891 |

| F7 | 0.015 | 1.001 | 1.016 | −0.986 |

| F8 | 0.000 | 1.070 | 1.070 | −1.070 |

| F9 | 0.317 | 0.488 | 0.805 | −0.171 |

| F10 | 0.412 | 0.224 | 0.636 | 0.188 |

| F11 | 0.521 | 0.209 | 0.730 | 0.312 |

| F12 | 0.171 | 0.956 | 1.126 | −0.785 |

| F13 | 0.992 | 0.061 | 1.053 | 0.932 |

| F14 | 0.428 | 0.110 | 0.537 | 0.318 |

| F15 | 0.730 | 0.079 | 0.809 | 0.652 |

| F16 | 0.329 | 0.355 | 0.684 | −0.026 |

| F17 | 0.312 | 0.355 | 0.667 | −0.043 |

| F18 | 1.407 | 0.000 | 1.407 | 1.407 |

| F19 | 0.153 | 0.921 | 1.074 | −0.768 |

| F20 | 0.644 | 0.094 | 0.737 | 0.550 |

| F21 | 0.292 | 0.522 | 0.815 | −0.230 |

| F22 | 0.259 | 0.569 | 0.828 | −0.310 |

| F23 | 0.802 | 0.094 | 0.896 | 0.709 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Tsai, J.-S. Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship. Sustainability 2021, 13, 11081. https://doi.org/10.3390/su131911081

Zhang K, Tsai J-S. Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship. Sustainability. 2021; 13(19):11081. https://doi.org/10.3390/su131911081

Chicago/Turabian StyleZhang, Ke, and Jiin-Song Tsai. 2021. "Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship" Sustainability 13, no. 19: 11081. https://doi.org/10.3390/su131911081

APA StyleZhang, K., & Tsai, J.-S. (2021). Identification of Critical Factors Influencing Prefabricated Construction Quality and Their Mutual Relationship. Sustainability, 13(19), 11081. https://doi.org/10.3390/su131911081