Prospective Environmental and Economic Assessment of a Sensor Network

Abstract

:1. Introduction

- Reduce the environmental impacts by reducing the energy consumption, the use of raw materials, pollutant emissions, etc.;

- Identify possible improvements in the system (hotspots);

- Improve the brand image through Corporate Social Responsibility strategies.

- The reduction of the greenhouse gas (GHG) emissions of the Spanish economy by at least 23% referred to 1990;

- Reaching a penetration of renewable energies of at least 42% in the final energy consumption;

- Achievement of an electrical system with at least 74% generation from renewable energy sources;

- Improvement in energy efficiency by reducing primary energy consumption by at least 39.5% with respect to the baseline, in accordance with community regulations.

1.1. Quality of Databases

1.2. Product Environmental Footprint

2. Materials and Methods

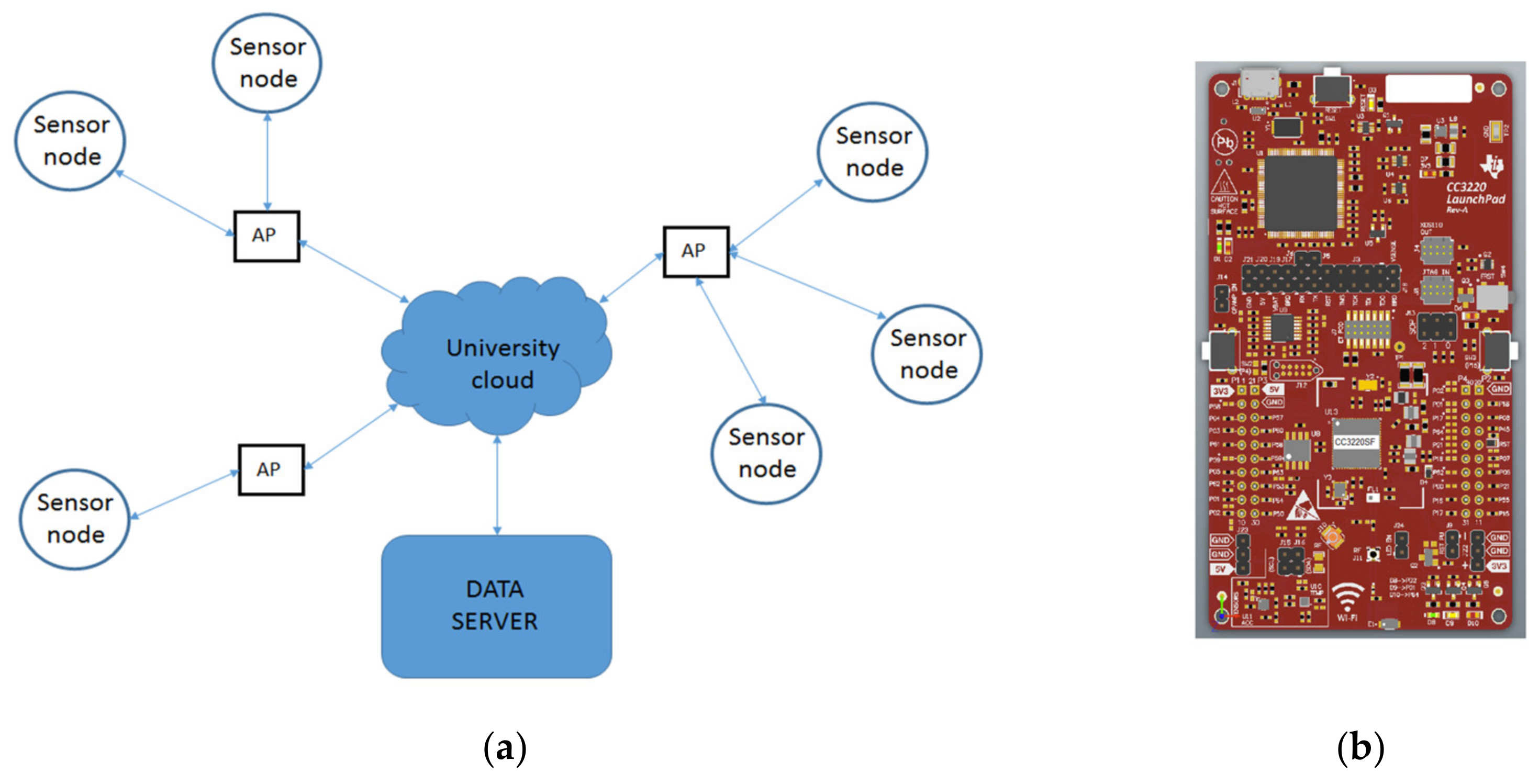

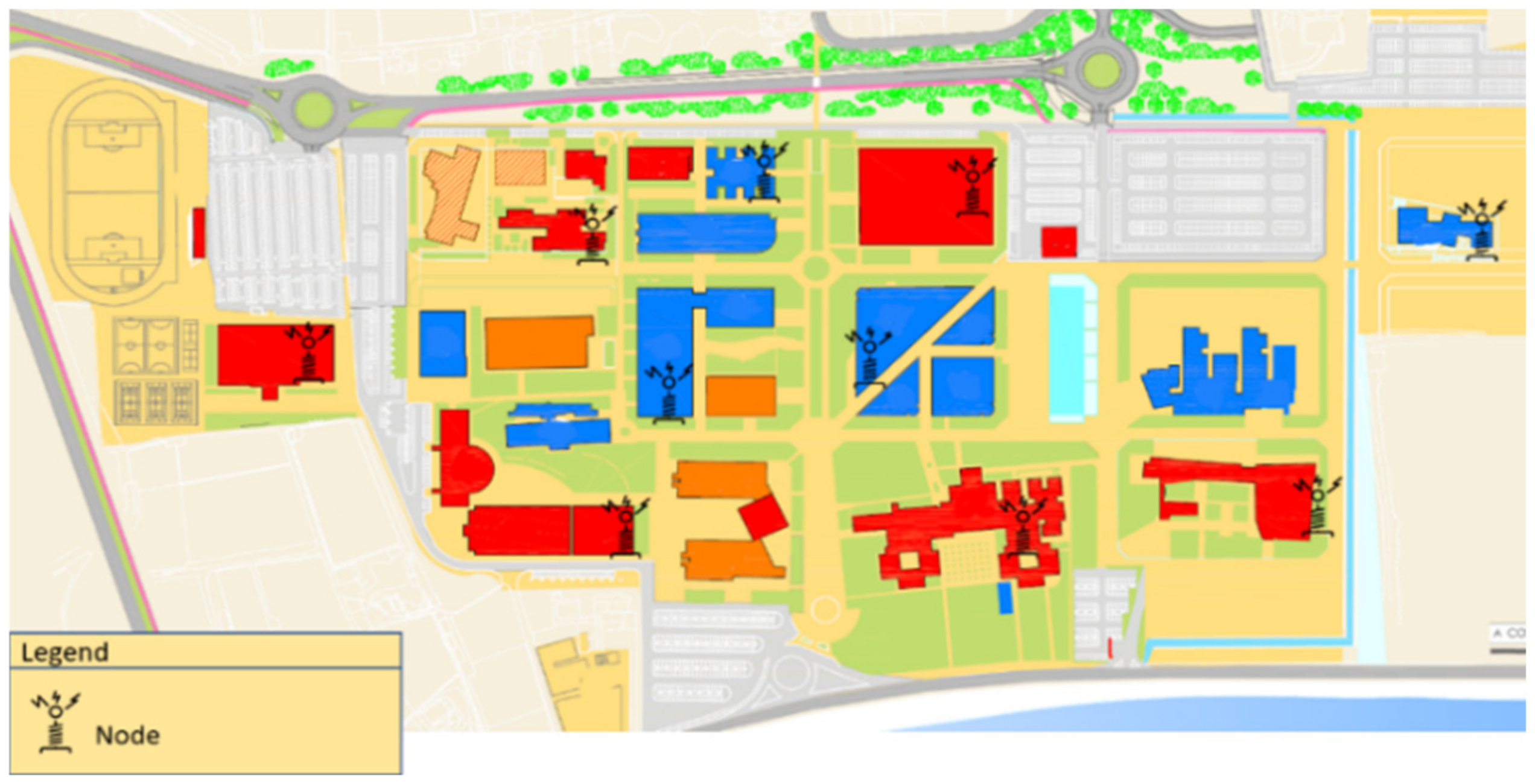

2.1. Project Description

- Electromagnetic sensor;

- Signal conditioning (SC);

- Analog–digital converter (ADC);

- Microcontroller (MC);

- Wi-Fi communication module (CM).

- There is only one electromagnetic sensor per node, so only one acquisition channel is required;

- The main supply voltage is 7.2 V. The SC supply voltage is 6 V, and the AMCM supply voltage is 3.3 V;

- The SC is permanently powered;

- The ADC acquires data (12 bits) continuously with a sample rate of 62.5 ksps;

- Data are processed in the MC, and the sample rate is decimated to 7.8125 kHz;

- Once the decimation process has been carried out, the data is grouped into 6” packages (750,000 data bits) to be sent by the CM to the data server via Wi-Fi;

- The transmission rate depends on the Wi-Fi link, and it ranges from 1 to 54 Mbps;

- The transmission energy consumption is difficult to evaluate because it depends on the proximity of the sensor to the AP, link conditions, etc. In an initial approach, the worst situation has been considered, and an energy consumption corresponding to maximum power is assumed;

- PV panel (off-grid option): 7.2 V, 240 mA (1.73 Wp);

- System autonomy (off-grid option): 10 days.

- The minimum consumption of the AMCM is 25.2 mA [54]. The ADC operates continuously, and because of this, it is not possible to bring the MC to any of its possible low-power states.

- The remaining consumption of the AMCM depends on the CM transmission rate. Two scenarios are assumed: in the most conservative one, the transmission speed is 6 Mbps (9.6 mA average current). In the most favorable one, the transmission rate is 54 Mbps (1 mA average current).

2.2. Methods, Goal, and Scenarios Assessed

- Selection of life cycle impact categories;

- Default transport distances;

- Allocation regarding input and output of secondary materials.

2.3. Functional Unit and Reference Flow

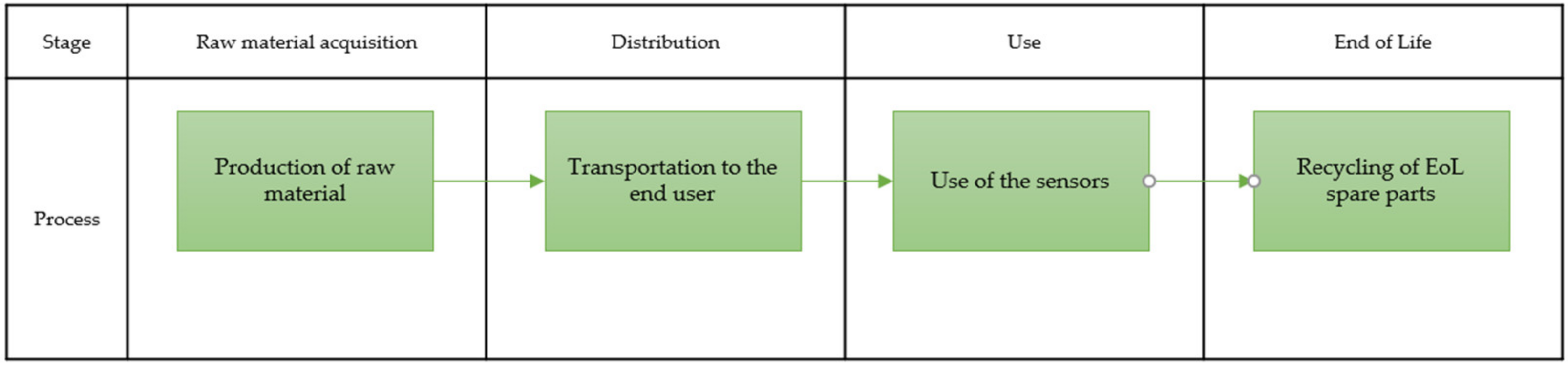

2.4. System Boundary

2.5. Data Collection for LCA

- 20 m of three-conductor cable, section 1.5 mm2, 60 g/m;

- 12 cylindrical connectors, section 1.5 mm2;

- Two-pole circuit breaker;

- 230 VAC/7.2 VDC power supply unit (PSU).

- PV panel from PowerFilm, model MP7.2-150F, 0.037 m2;

- 2 rechargeable Lithium-Ion batteries, 6.7 Ah 7.2 V.

- 20 years for the PV module and electrics components (cable, circuit breaker, and connectors);

- 10 years for electronics components (PSU);

- 8 years for batteries. According to Beltrán et al. [64], expectancy lifetime of a lithium-ion battery under real operation conditions is between 8 and 12 years. We choose 8 years, the lower value, since in this design phase we do not know the real conditions of the batteries (temperature, depth of discharge, etc.).

2.6. Data Collection for the TCO Analysis

- Investment;

- Operation during service life.

2.7. Impact Assessment Method

3. Results and Discussion

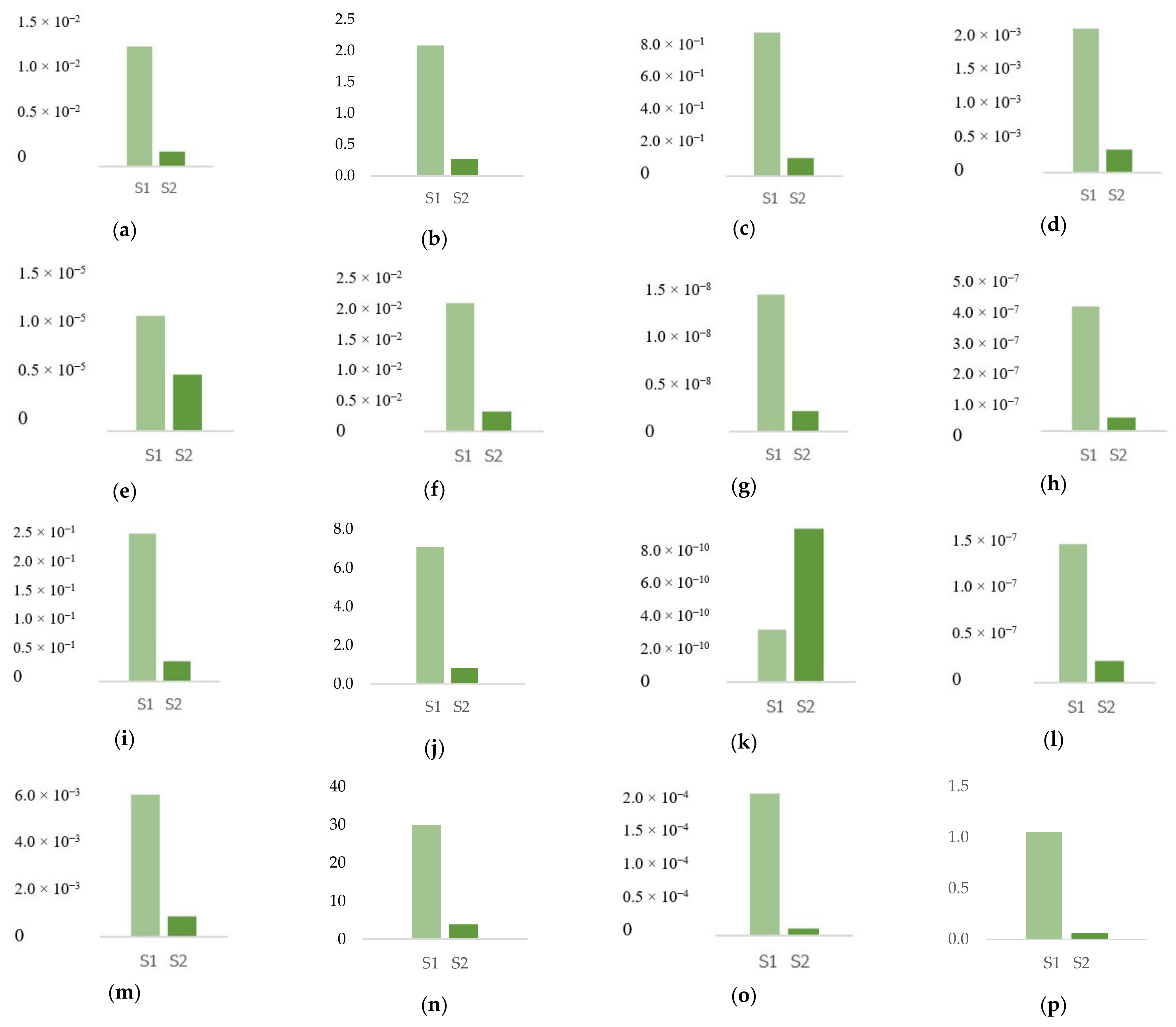

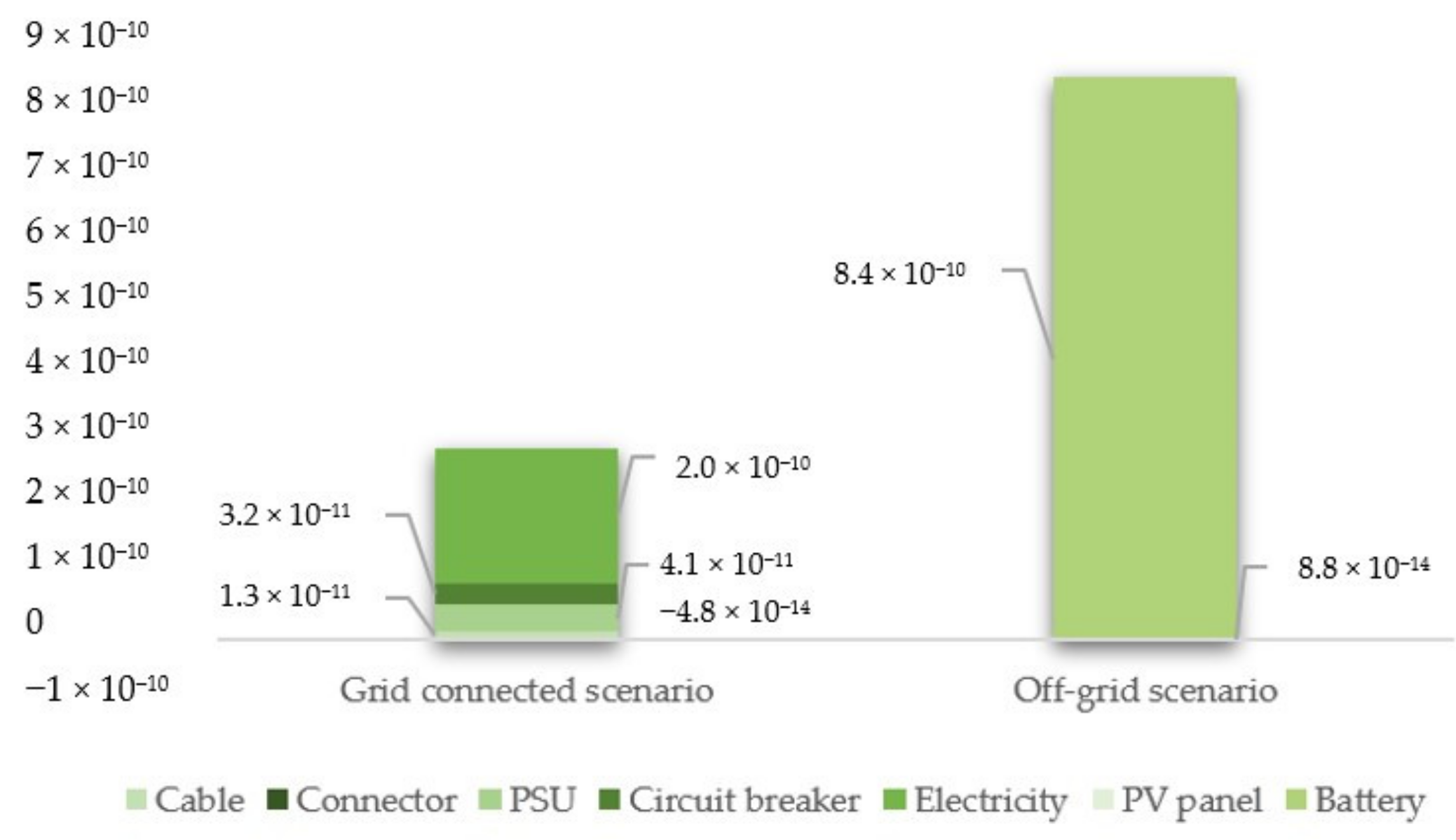

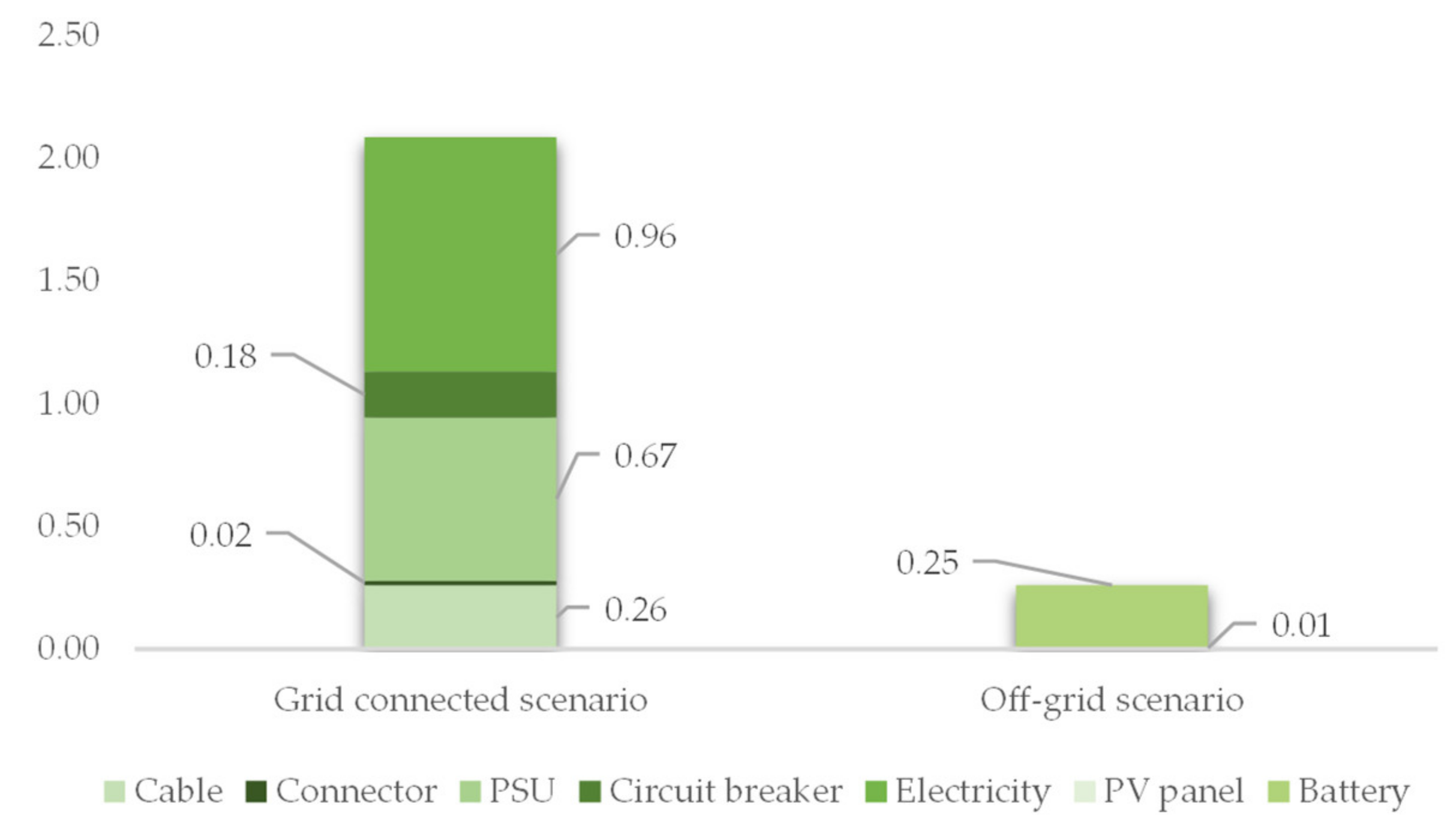

3.1. Lyfe Cycle Impact Assessment

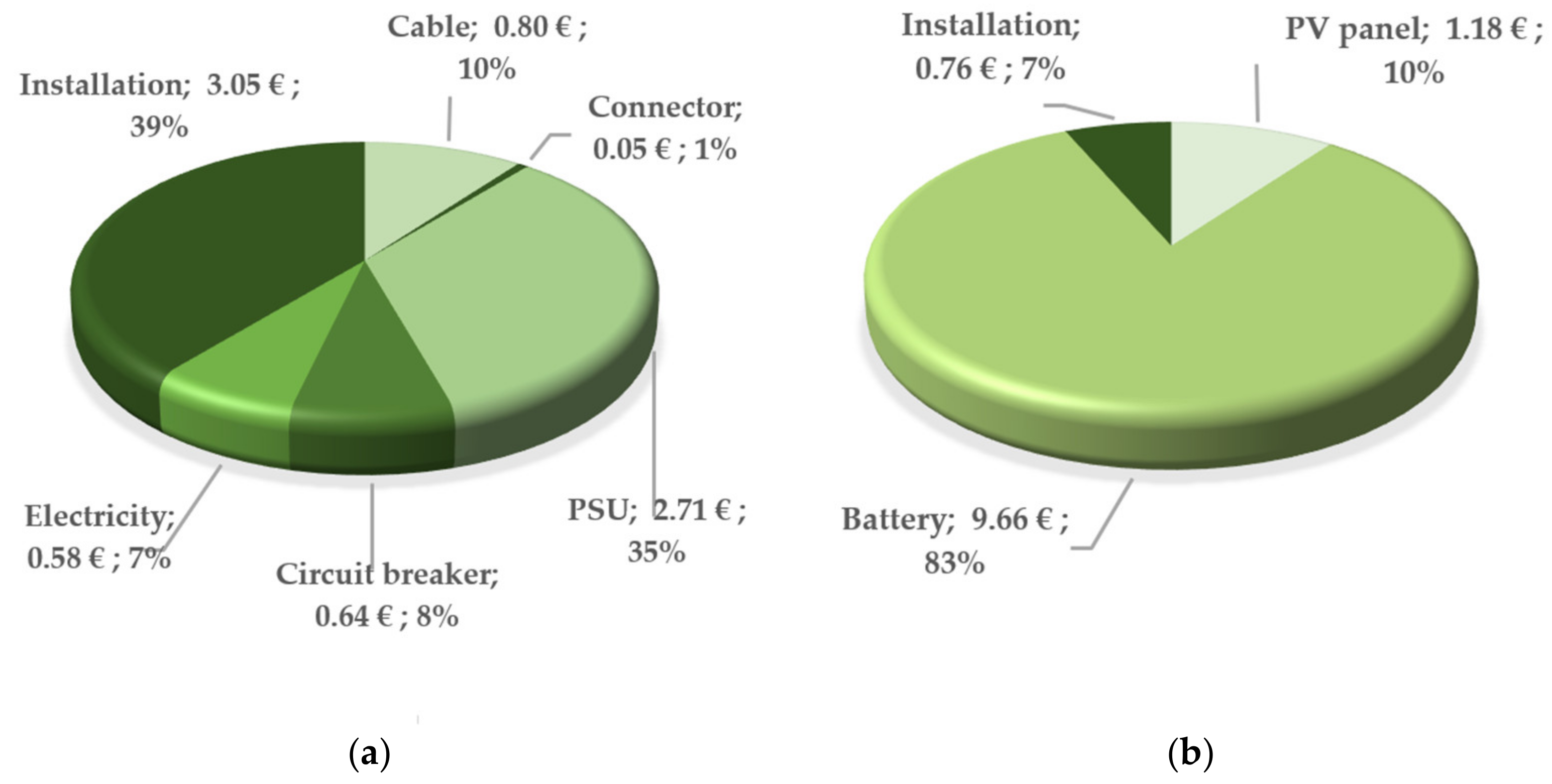

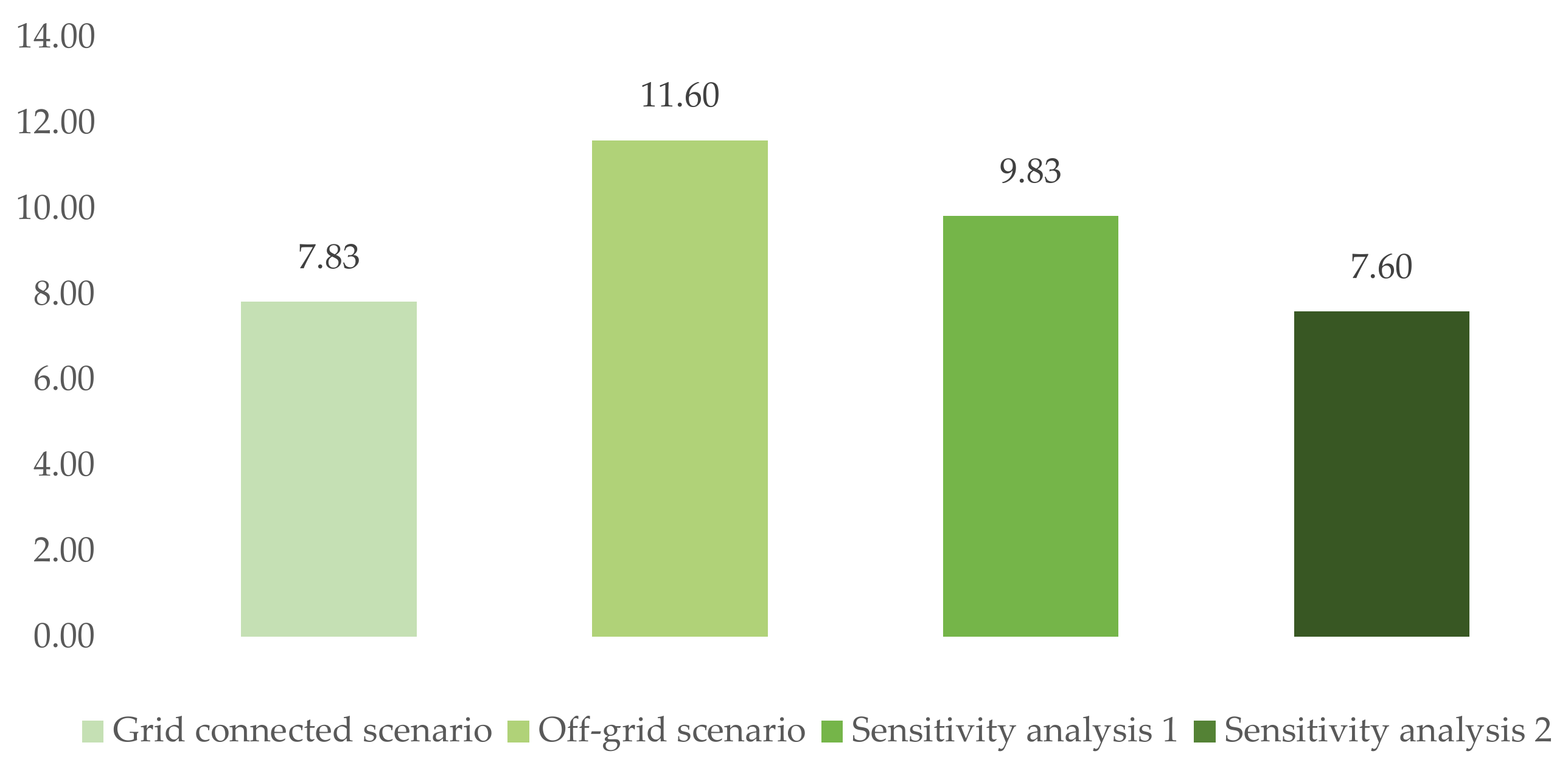

3.2. Total Cost of Ownership

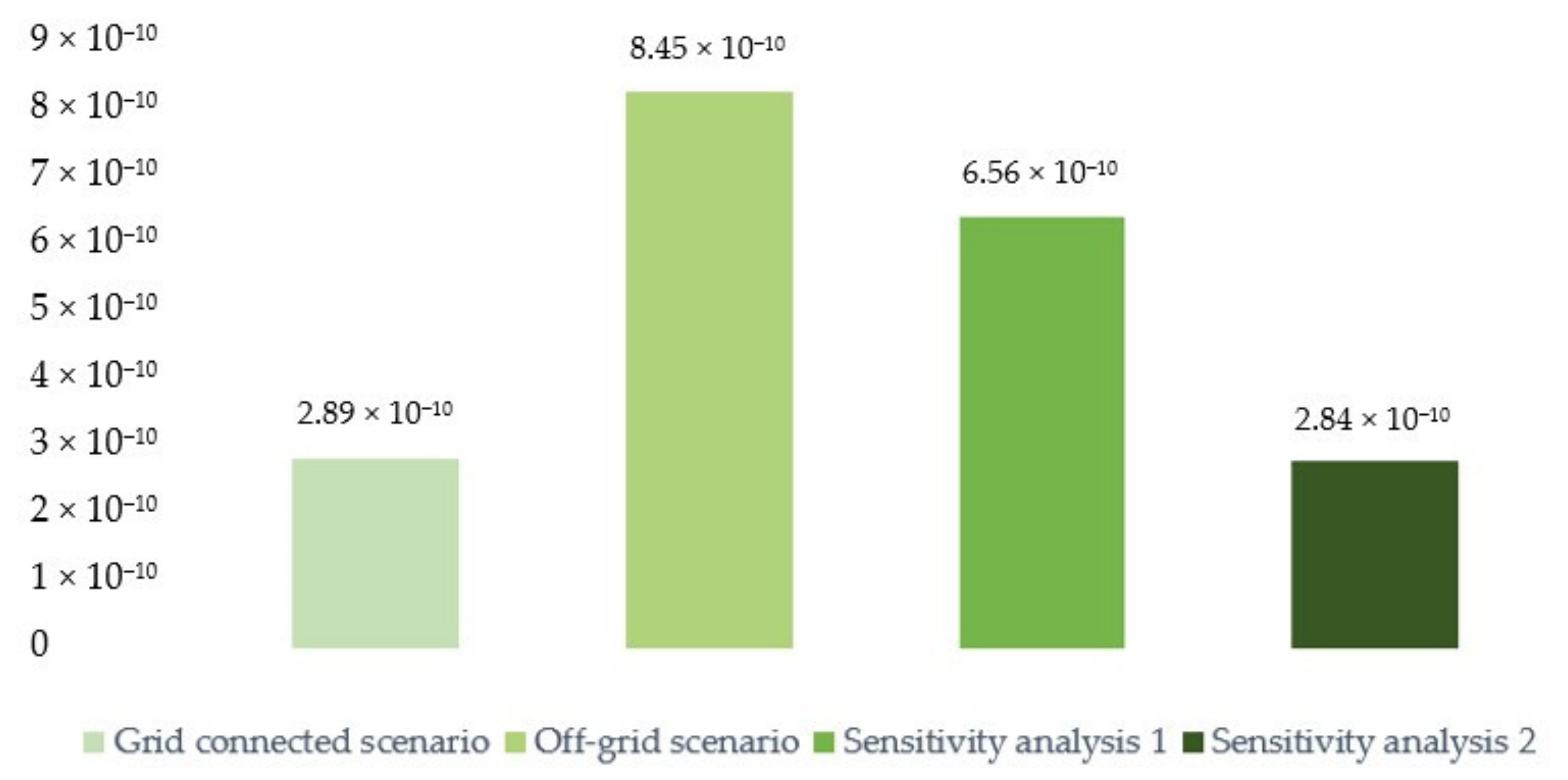

3.3. Sensitivity Analysis

- Sensitivity analysis 1: We considered a transmission rate of 54 Mbps due to the high density of AP in the UAL campus. The result was a consumption of 8508 mAh, and the selected batteries for this analysis were two 5200 mAh commercially rechargeable batteries.

- Sensitivity analysis 2: According to [69], the average hours of sun per year between 2011–2015 was 3201 h, and thus we proposed changing the parameter of the system autonomy from 10 days to 4 days of low solar irradiation. The result was a consumption of 4437 mAh in the most conservative scenario (6 Mbps transmission rate), and the selected batteries for this purpose were two 2250 mAh commercially rechargeable batteries.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Novas, N.; Garcia, R.M.; Camacho, J.M.; Alcayde, A. Advances in solar energy towards efficient and sustainable energy. Sustainability 2021, 13, 6295. [Google Scholar] [CrossRef]

- Walker, S.; Coleman, N.; Hodgson, P.; Collins, N.; Brimacombe, L. Evaluating the environmental dimension of material efficiency strategies relating to the circular economy. Sustainability 2018, 10, 666. [Google Scholar] [CrossRef] [Green Version]

- Katarzyna, P.; Izabela, P.; Patrycja, B.W.; Weronika, K.; Andrzej, T. Lca as a tool for the environmental management of car tire manufacturing. Appl. Sci. 2020, 10, 7015. [Google Scholar] [CrossRef]

- Hellweg, S.; Canals, L.M.I. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Heijungs, R.; Settanni, E.; Guinée, J. Toward a computational structure for life cycle sustainability analysis: Unifying LCA and LCC. Int. J. Life Cycle Assess. 2013, 18, 1722–1733. [Google Scholar] [CrossRef] [Green Version]

- Barbušová, M.; Medvecká, I.; Gašo, M. Use of TCO Analysis in Industry 4.0. In Proceedings of the Průmyslové Inženýrství 2019 Mezinárodní Studentská Vědecká Konference, Pilsen, Czech Republic, 3–4 September 2019. [Google Scholar]

- Spellerberg, I.; Fogel, D.S.; Fredericks, S.E.; Harrington, L.M.B. Berkshire Encyclopedia of Sustainability: Measurements, Indicators, and Research Methods for Sustainability; Berkshire Publishing Group: Great Barrington, MA, USA, 2012. [Google Scholar] [CrossRef]

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef]

- Piekarski, C.M.; da Luz, L.M.; Zocche, L.; de Francisco, A.C. Life cycle assessment as entrepreneurial tool for business management and green innovations. J. Technol. Manag. Innov. 2013, 8, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, I.; Peças, P.; Silva, A.; Henriques, E. Life cycle engineering methodology applied to material selection, a fender case study. J. Clean. Prod. 2008, 16, 887–1899. [Google Scholar] [CrossRef]

- Peças, P.; Ribeiro, I.; Folgado, R.; Henriques, E. A Life Cycle Engineering model for technology selection: A case study on plastic injection moulds for low production volumes. J. Clean. Prod. 2009, 17, 846–856. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Freitas, M.; Silva, A.J.; Luz, S.M.; Alves, D.E. Sustainable design procedure: The role of composite materials to combine mechanical and environmental features for agricultural machines. Mater. Des. 2009, 30, 4060–4068. [Google Scholar] [CrossRef]

- Simões, C.L.; Xará, S.M.; Bernardo, C.A. Life cycle assessment of a road safety product made with virgin and recycled HDPE. Waste Manag. Res. 2011, 29, 414–422. [Google Scholar] [CrossRef]

- Simões, C.L.; Pinto, L.M.C.; Bernardo, C.A. Modelling the environmental performance of composite products: Benchmark with traditional materials. Mater. Des. 2012, 39, 121–130. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Tacker, M. The influence of database selection on environmental impact results. Life cycle assessment of packaging using gabi, ecoinvent 3.6, and the environmental footprint database. Sustainability 2020, 12, 9948. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef] [Green Version]

- Wiedemann, S.; McGahan, E.; Murphy, C.; Yan, M.J.; Henry, B.; Thoma, G.; Ledgard, S. Environmental impacts and resource use of Australian beef and lamb exported to the USA determined using life cycle assessment. J. Clean. Prod. 2015, 94, 67–75. [Google Scholar] [CrossRef]

- Oğuz, E.; Şentürk, A.E. Selection of the most sustainable renewable energy system for Bozcaada Island: Wind vs. Photovoltaic. Sustainability 2019, 11, 4098. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, I.; Portillo, F.; Rosiek, S.; Batlles, F.J.; Martínez-Del-Río, J.; Acasuso, I.; Piergrossi, V.; De Sanctis, M.; Chimienti, S.; Di Iaconi, C. Prospective environmental and economic assessment of solar-assisted thermal energy recovery from wastewater through a sequencing batch biofilter granular reactor. J. Clean. Prod. 2019, 212, 1300–1309. [Google Scholar] [CrossRef]

- Salmerón-Manzano, E.; Rahmani-Andebili, M.; Alcayde, A.; Manzano-Agugliaro, F. Worldwide Research Trends on Smart Homes. In Operation of Smart Homes; Rahmani-Andebili, M., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–31. ISBN 978-3-030-64915-9. [Google Scholar]

- Aboubakar, M.; Kellil, M.; Roux, P. A Review of IoT Network Management: Current Status and Perspectives. Available online: https://www.sciencedirect.com/science/article/pii/S1319157821000707 (accessed on 10 July 2021).

- Kandaswamy, R.; Furlonger, D. Blockchain-Based Transformation: A Gartner Trend Insight Report. Available online: https://www.slideshare.net/SantiagoRiveraGonzle/blockchainbased-transformation-a-gartner-trend-insight-report (accessed on 10 July 2021).

- Millet, D.; Bistagnino, L.; Lanzavecchia, C.; Camous, R.; Poldma, T. Does the potential of the use of LCA match the design team needs? J. Clean. Prod. 2007, 15, 335–346. [Google Scholar] [CrossRef]

- Nakano, K.; Hirao, M. Collaborative activity with business partners for improvement of product environmental performance using LCA. J. Clean. Prod. 2011, 19, 1189–1197. [Google Scholar] [CrossRef]

- Miah, J.H.; Koh, S.C.L.; Stone, D. A hybridised framework combining integrated methods for environmental Life Cycle Assessment and Life Cycle Costing. J. Clean. Prod. 2017, 168, 846–866. [Google Scholar] [CrossRef]

- Laurent, A.; Weidema, B.P.; Bare, J.; Liao, X.; Maia de Souza, D.; Pizzol, M.; Sala, S.; Schreiber, H.; Thonemann, N.; Verones, F. Methodological review and detailed guidance for the life cycle interpretation phase. J. Ind. Ecol. 2020, 24, 986–1003. [Google Scholar] [CrossRef] [PubMed]

- Weidema, B.P. Consistency check for life cycle assessments. Int. J. Life Cycle Assess. 2019, 24, 926–934. [Google Scholar] [CrossRef]

- Shahabian, A.; Fadai, A.; Peruzzi, T. Future of Life-Cycle Assessment in a Smart and/or Sustainable World. In Interdisciplinary Approaches to Public Policy and Sustainability; Das, R., Mandal, N., Eds.; IGI Global: Harrisburg, PA, USA, 2020; pp. 177–207. [Google Scholar]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability 2017, 9, 706. [Google Scholar] [CrossRef] [Green Version]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Int. J. Life Cycle Assess. 2008, 13, 374–388. [Google Scholar] [CrossRef]

- Saadah, Y.; Abuhijleh, B. Decreasing CO2 emissions and embodied energy during the construction phase using sustainable building materials. Int. J. Sustain. Build. Technol. Urban Dev. 2010, 1, 115–120. [Google Scholar] [CrossRef]

- European Commission. Commission Recommendation of 9 April 2013 on the Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- European Commission. PEFCR Guidance Document; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Lehmann, A.; Bach, V.; Finkbeiner, M. EU product environmental footprint-mid-term review of the pilot phase. Sustainability 2016, 8, 92. [Google Scholar] [CrossRef] [Green Version]

- Bach, V.; Lehmann, A.; Görmer, M.; Finkbeiner, M. Product environmental footprint (PEF) pilot phase-comparability over flexibility? Sustainability 2018, 10, 2898. [Google Scholar] [CrossRef] [Green Version]

- Page, G.; Ridoutt, B.; Bellotti, B. Carbon and water footprint tradeoffs in fresh tomato production. J. Clean. Prod. 2012, 32, 219–226. [Google Scholar] [CrossRef]

- ISO 14040/14044. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Schau, E.; Chomkhamsri, K.; Pant, R.; Pennington, D. Comparing the European Commission product environmental footprint method with other environmental accounting methods. Int. J. Life Cycle Assess. 2015, 20, 389–404. [Google Scholar] [CrossRef]

- Wu, Y.; Su, D. LCA of an industrial luminaire using product environmental footprint method. J. Clean. Prod. 2021, 305, 127159. [Google Scholar] [CrossRef]

- Russo, C.; Cappelletti, G.M.; Nicoletti, G.M.; Michalopoulos, G.; Pattara, C.; Palomino, J.A.P.; Tuomisto, H.L. Product environmental footprint in the olive oil sector: State of the art. Environ. Eng. Manag. J. 2016, 15, 2019–2027. [Google Scholar] [CrossRef]

- Six, L.; De Wilde, B.; Vermeiren, F.; Van Hemelryck, S.; Vercaeren, M.; Zamagni, A.; Masoni, P.; Dewulf, J.; De Meester, S. Using the product environmental footprint for supply chain management: Lessons learned from a case study on pork. Int. J. Life Cycle Assess. 2017, 22, 1354–1372. [Google Scholar] [CrossRef] [Green Version]

- Soode-Schimonsky, E.; Richter, K.; Weber-Blaschke, G. Product environmental footprint of strawberries: Case studies in Estonia and Germany. J. Environ. Manag. 2017, 203, 564–577. [Google Scholar] [CrossRef] [PubMed]

- Famiglietti, J.; Guerci, M.; Proserpio, C.; Ravaglia, P.; Motta, M. Development and testing of the Product Environmental Footprint Milk Tool: A comprehensive LCA tool for dairy products. Sci. Total Environ. 2019, 648, 1614–1626. [Google Scholar] [CrossRef]

- Pyay, S.; Thanungkano, W.; Mungkalasiri, J.; Musikavong, C. A life cycle assessment of intermediate rubber products in Thailand from the product environmental footprint perspective. J. Clean. Prod. 2019, 237, 117632. [Google Scholar] [CrossRef]

- Corradini, G.; Pierobon, F.; Zanetti, M. Product environmental footprint of a cross-laminated timber system: A case study in Italy. Int. J. Life Cycle Assess. 2019, 24, 975–988. [Google Scholar] [CrossRef]

- Fuengwarodsakul, N.H. Battery management system with active inrush current control for Li-ion battery in light electric vehicles. Electr. Eng. 2016, 98, 17–27. [Google Scholar] [CrossRef]

- Kuo, T.C.; Lee, Y. Using Pareto optimization to support supply chain network design within environmental footprint impact assessment. Sustainability 2019, 11, 452. [Google Scholar] [CrossRef] [Green Version]

- Egas, D.; Ponsá, S.; Colon, J. CalcPEFDairy: A Product Environmental Footprint compliant tool for a tailored assessment of raw milk and dairy products. J. Environ. Manag. 2020, 260, 110049. [Google Scholar] [CrossRef]

- GreenDelta. OpenLCA Software. Available online: http://openlca.org (accessed on 31 May 2021).

- University of Almeria Campus Map. Available online: https://w3.ual.es/conocenos/en/img/UAL2007.pdf (accessed on 10 July 2021).

- Texas Instruments. INA 188 Datasheet. Available online: https://https://www.ti.com/product/INA188?keyMatch=INA%20188&tisearch=search-everything (accessed on 24 November 2020).

- Linear Technology. LT1490 Datasheet. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/14901fb.pdf (accessed on 24 June 2021).

- Texas Instruments. CC3220SF Datasheet. Available online: https://www.ti.com/lit/ds/symlink/cc3220sf.pdf?ts=1624459354119&ref_url=https%253A%252F%252Fwww.ti.com%252Fproduct%252FCC3220SF%253FkeyMatch%253DCC3220SF%2526tisearch%253Dsearch-everything (accessed on 24 June 2021).

- Texas Instruments. Microcontroller LaunchPad. Available online: https://www.ti.com/tool/CC3220SF-LAUNCHXL (accessed on 10 July 2021).

- European Commission. Photovoltaic Geographical Information System. Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 24 June 2021).

- Spani, R.C. The New Circular Economy Action Plan (1 July 2020). FEEM Policy Brief No. 09-2020. Available online: https://ssrn.com/abstract=3711331 (accessed on 31 May 2021).

- Simões, C.L.; Costa Pinto, L.M.; Simoes, R.; Bernardo, C.A. Integrating environmental and economic life cycle analysis in product development: A material selection case study. Int. J. Life Cycle Assess. 2013, 18, 1734–1746. [Google Scholar] [CrossRef]

- SimaPro. SimaPro Software. Available online: http://simapro.com (accessed on 31 May 2021).

- Sphere Solutions. GaBi Software. Available online: http://gabi-software.com (accessed on 31 May 2021).

- NIST. BEES Software. Available online: https://www.nist.gov/services-resources/software/bees (accessed on 31 May 2021).

- Weidema, B.; Wenzel, H.; Petersen, C.; Hansen, K. The Product, Functional Unit and Reference Flows in LCA. Available online: https://www2.mst.dk/udgiv/publications/2004/87-7614-233-7/pdf/87-7614-234-5.pdf (accessed on 10 July 2021).

- Ciroth, A.; Di Noi, C.; Burhan, S.; Srocka, M. LCA database creation. Indones. J. Life Cycle Assess. Sustain. 2019. [Google Scholar] [CrossRef]

- Beltran, H.; Ayuso, P.; Pérez, E. Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage. Energies 2020, 13, 568. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency Spain 2021 Energy Policy Review. Available online: https://iea.blob.core.windows.net/assets/2f405ae0-4617-4e16-884c-7956d1945f64/Spain2021.pdf (accessed on 9 February 2021).

- European Central Bank. Economic Bulletin. Available online: https://www.ecb.europa.eu/pub/pdf/ecbu/eb202104.en.pdf (accessed on 10 July 2021).

- EUROSTAT. Electricity Prices Components for Industrial Consumers-Annual Data (from 2007 Onwards) [nrg_pc_205_c]. Available online: http://appsso.eurostat.ec.europa.eu/nui/submitViewTableAction.do (accessed on 7 June 2021).

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley Blackwell: Hoboken, NJ, USA, 2014. [Google Scholar]

- Instituto Nacional de Estadística (INE). 2011–2015 Climatology. Available online: https://www.ine.es/daco/daco42/bme/c19.pdf (accessed on 24 June 2021).

| Component | Amount | Unit Weight (g) | Total Weight (g) | Service Life (Years) | Annual Consumption (g/Year) |

|---|---|---|---|---|---|

| Cable | 20 m | 60 | 1200 | 20 | 60 |

| Connector | 12 items | 0.52 | 6.24 | 20 | 0.312 |

| PSU | 1 item | 270 | 270 | 10 | 27 |

| Circuit breaker | 1 item | 231.86 | 231.86 | 20 | 11.593 |

| Component | Amount | Unit Weight (g) | Total Weight (g) | Service Life (Years) | Annual Consumption (g/Year) |

|---|---|---|---|---|---|

| PV solar panel | 1 item | 25.51 | 25.51 | 20 | 1.276 |

| Battery | 2 items | 196 | 392 | 8 | 49 |

| Electricity Mixture | Proportion |

|---|---|

| Natural gas | 30.8% |

| Nuclear | 21.3% |

| Wind | 20.3% |

| Hydro | 9.8% |

| Coal | 5.2% |

| Oil | 4.6% |

| Solar | 5.5% |

| Biofuels | 1.8% |

| Waste | 0.7% |

| Materials and Installation | Amount | Service Life (Years) | Annualized Cost (EUR/Year) |

|---|---|---|---|

| Cable | 20 m | 20 | 0.80 |

| Connector | 12 items | 20 | 0.05 |

| PSU | 1 item | 10 | 2.71 |

| Circuit breaker | 1 item | 20 | 0.64 |

| Installation | 1 item | 20 | 3.05 |

| Materials and Installation | Amount | Service Life (Years) | Annualized Cost (EUR/Year) |

|---|---|---|---|

| PV solar panel | 1 item | 20 | 1.18 |

| Battery | 2 items | 8 | 9.66 |

| Installation | 1 item | 20 | 0.76 |

| Activity | Grid Connected | Off-Grid | Difference |

|---|---|---|---|

| Materials investment | 4.20 | 10.84 | 6.64 |

| Installation | 3.05 | 0.76 | −2.29 |

| Electricity | 0.58 | 0 | −0.58 |

| Total | 7.83 | 11.60 | 3.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Portillo, F.; García, R.M.; Alcayde, A.; Gázquez, J.A.; Fernández-Ros, M.; Novas, N. Prospective Environmental and Economic Assessment of a Sensor Network. Sustainability 2021, 13, 10306. https://doi.org/10.3390/su131810306

Portillo F, García RM, Alcayde A, Gázquez JA, Fernández-Ros M, Novas N. Prospective Environmental and Economic Assessment of a Sensor Network. Sustainability. 2021; 13(18):10306. https://doi.org/10.3390/su131810306

Chicago/Turabian StylePortillo, Francisco, Rosa María García, Alfredo Alcayde, José Antonio Gázquez, Manuel Fernández-Ros, and Nuria Novas. 2021. "Prospective Environmental and Economic Assessment of a Sensor Network" Sustainability 13, no. 18: 10306. https://doi.org/10.3390/su131810306

APA StylePortillo, F., García, R. M., Alcayde, A., Gázquez, J. A., Fernández-Ros, M., & Novas, N. (2021). Prospective Environmental and Economic Assessment of a Sensor Network. Sustainability, 13(18), 10306. https://doi.org/10.3390/su131810306