Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia

Abstract

:1. Introduction

2. Material and Methods

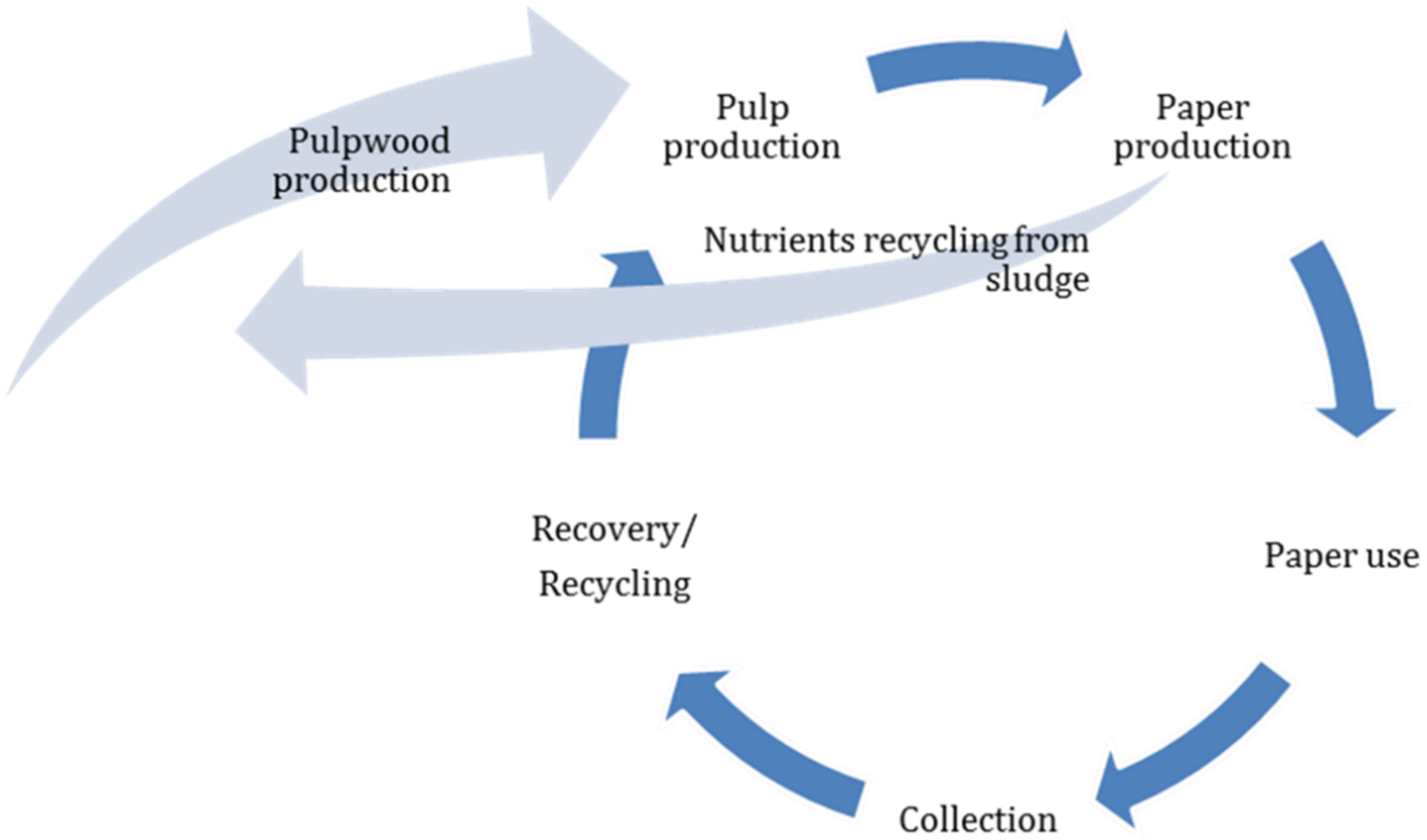

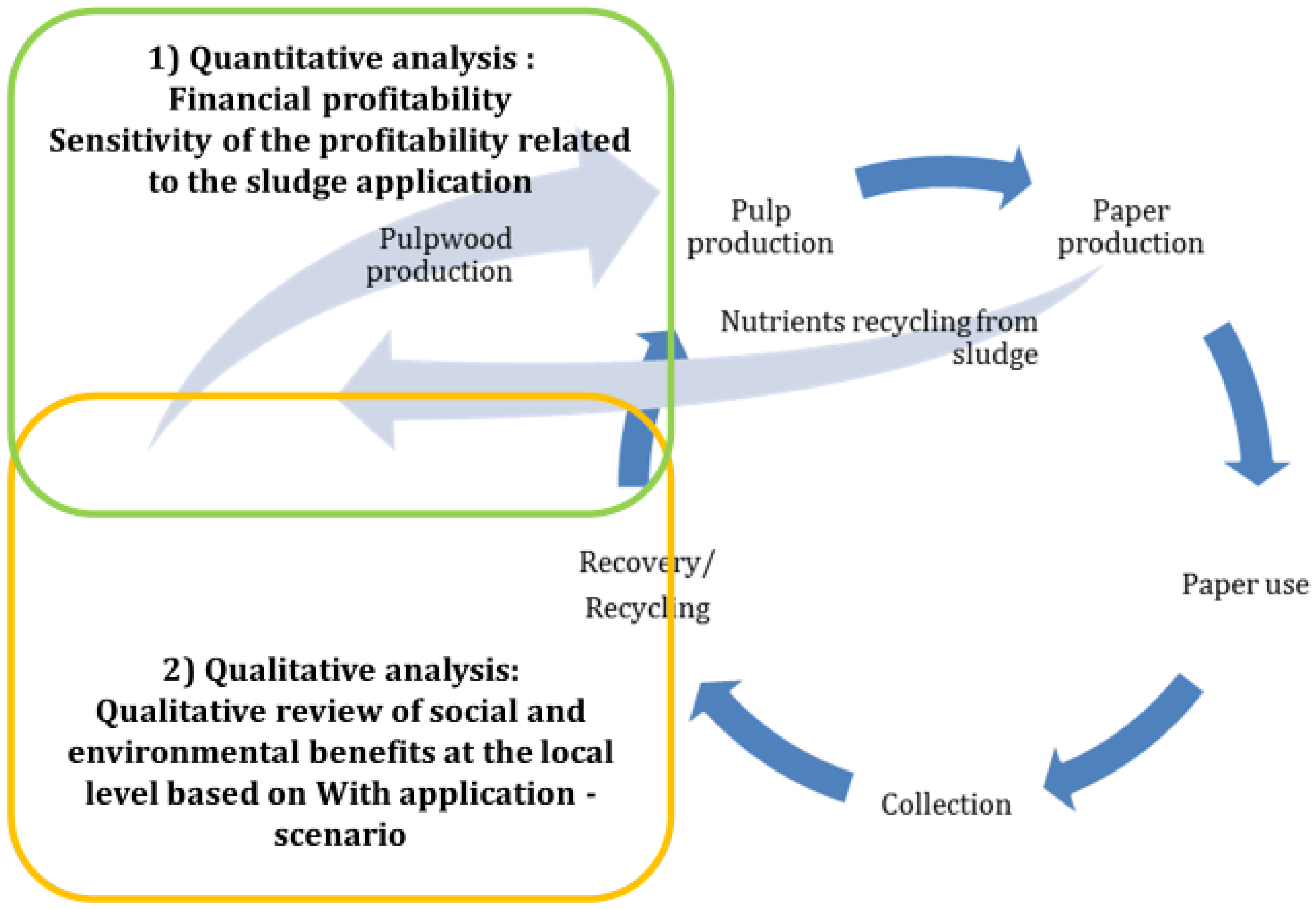

2.1. Research Design

2.2. Materials

2.2.1. Characteristics of the Sludge

2.2.2. Pulpwood Production

2.3. Evaluation of the Costs of the Use of Sludge

2.4. Financial Methodology

2.4.1. Discounted Cash Flow

2.4.2. Fixed Prices vs. Variable Prices

2.5. Qualitative Sustainability Analysis

3. Financial Analysis

3.1. Nutrient Contents

3.2. Application Rate and Cost Estimates

3.2.1. Application Cost

3.2.2. Transport Cost

3.2.3. Triple Phosphate Cost

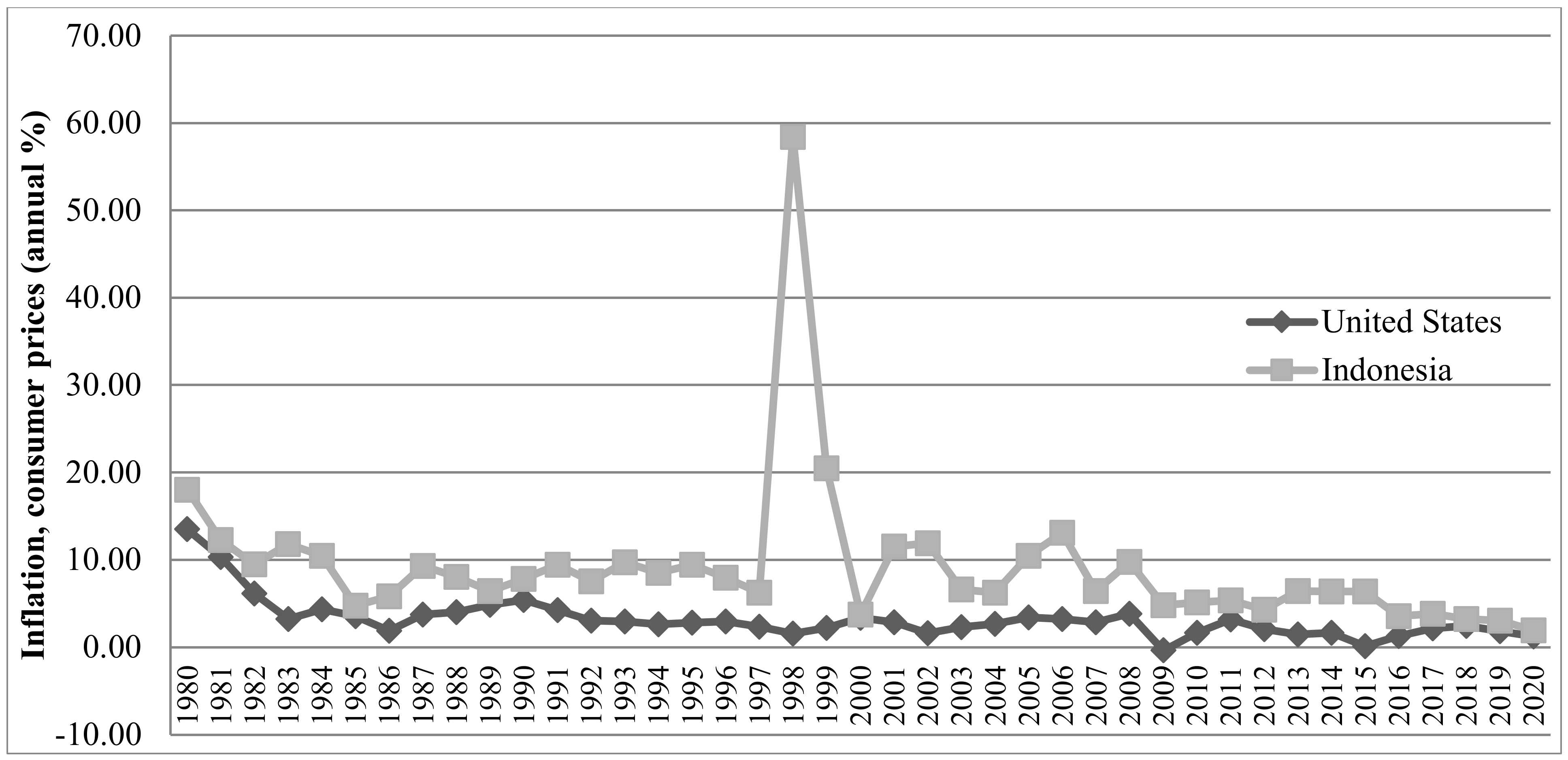

3.3. Inflation Correction

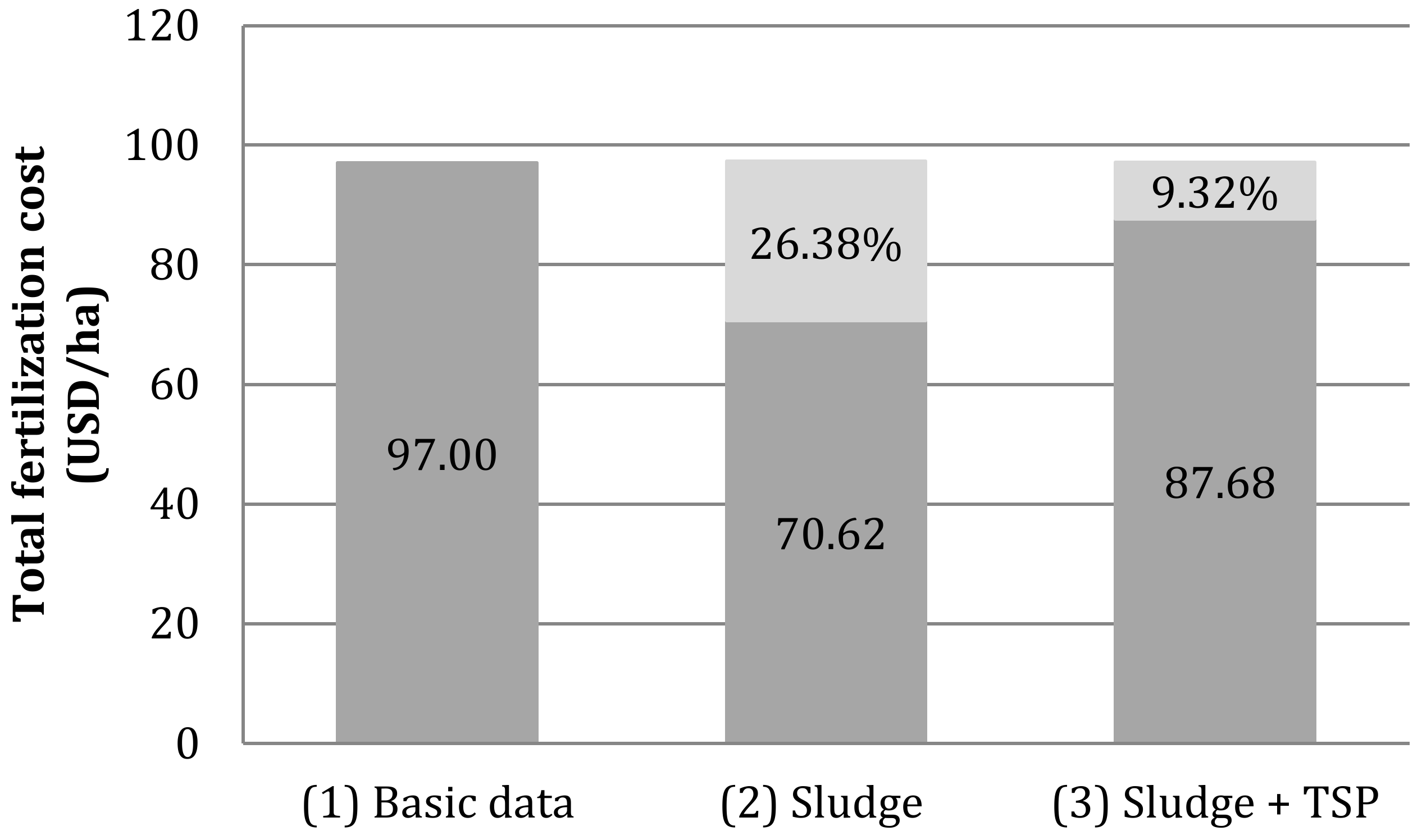

3.4. Estimated Fertilization Cost

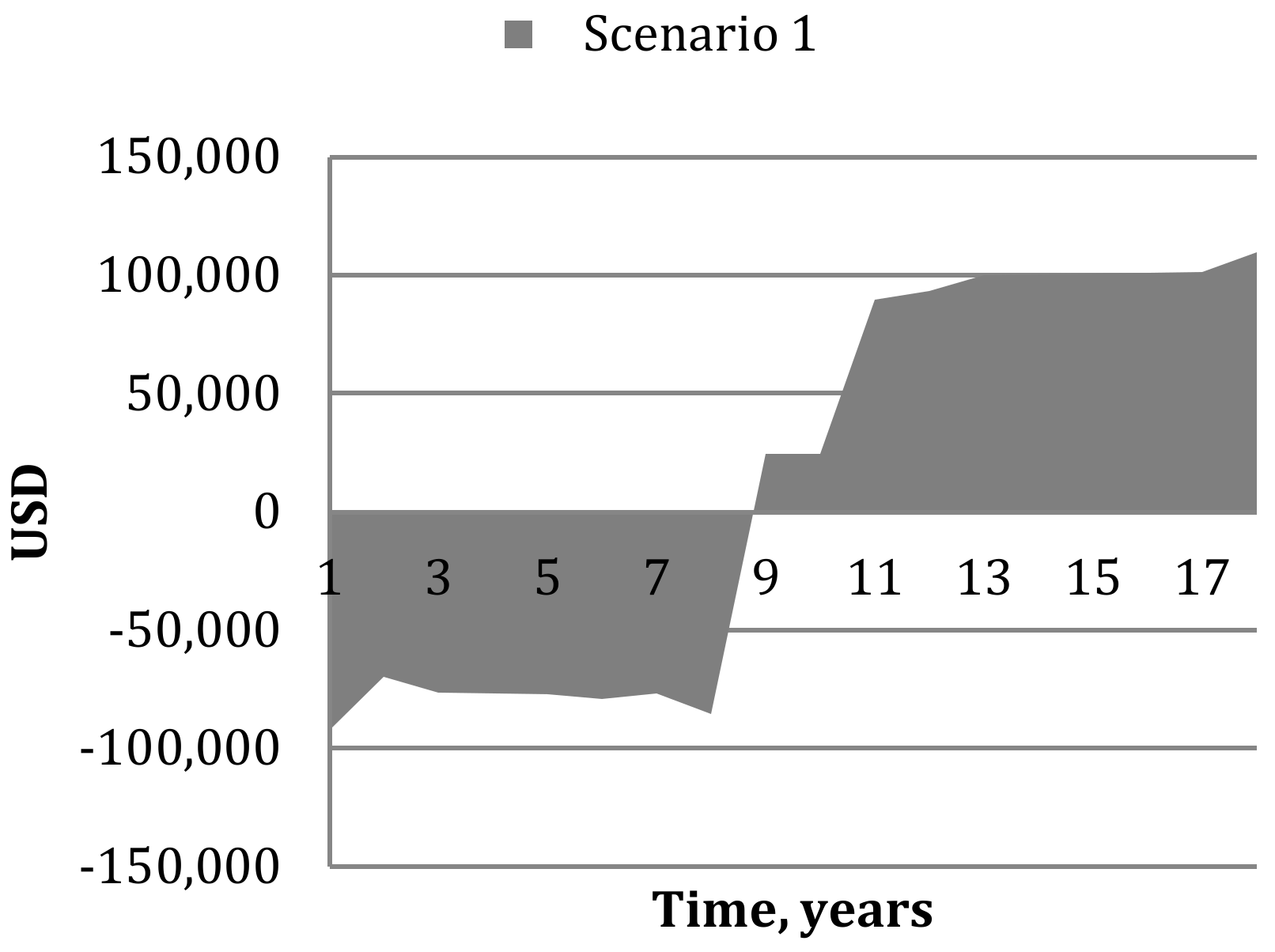

- Scenario (1)—Base case: the fertilization cost based on the reference study. The cost breakdown was not explained and considered;

- Scenario (2)—Use of sludge. The total costs include the transport and application;

- Scenario (3)—Use of sludge with TSP fertilizer. The total cost covers transport and application costs, the price of TSP, and TSP application costs.

3.5. Financial Profitability

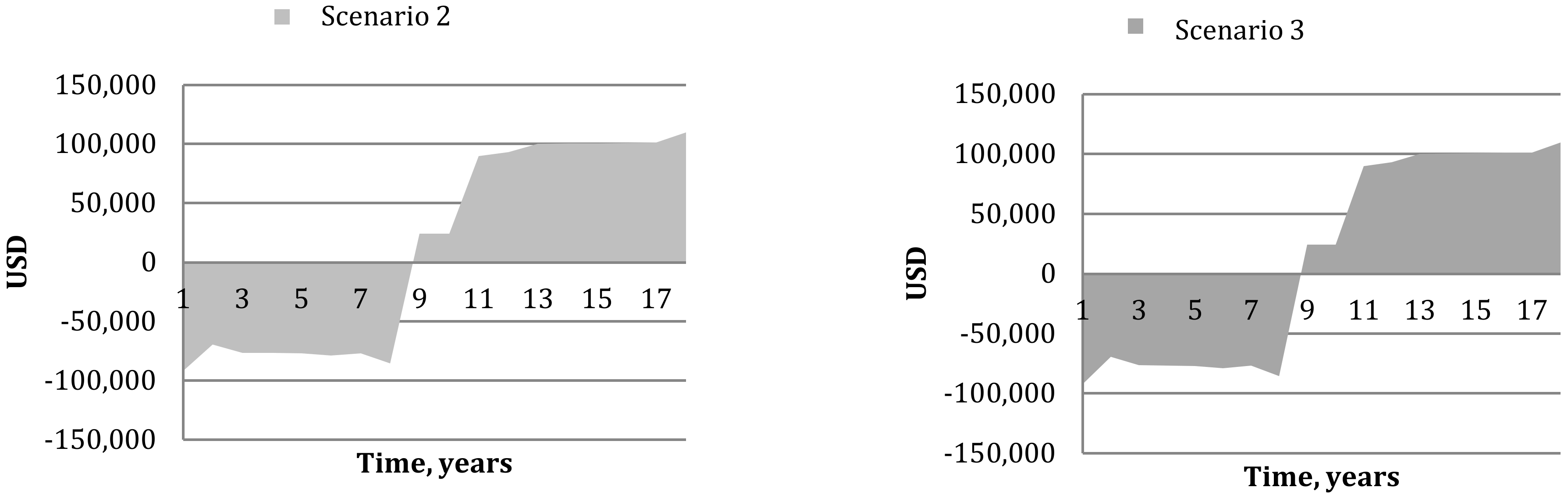

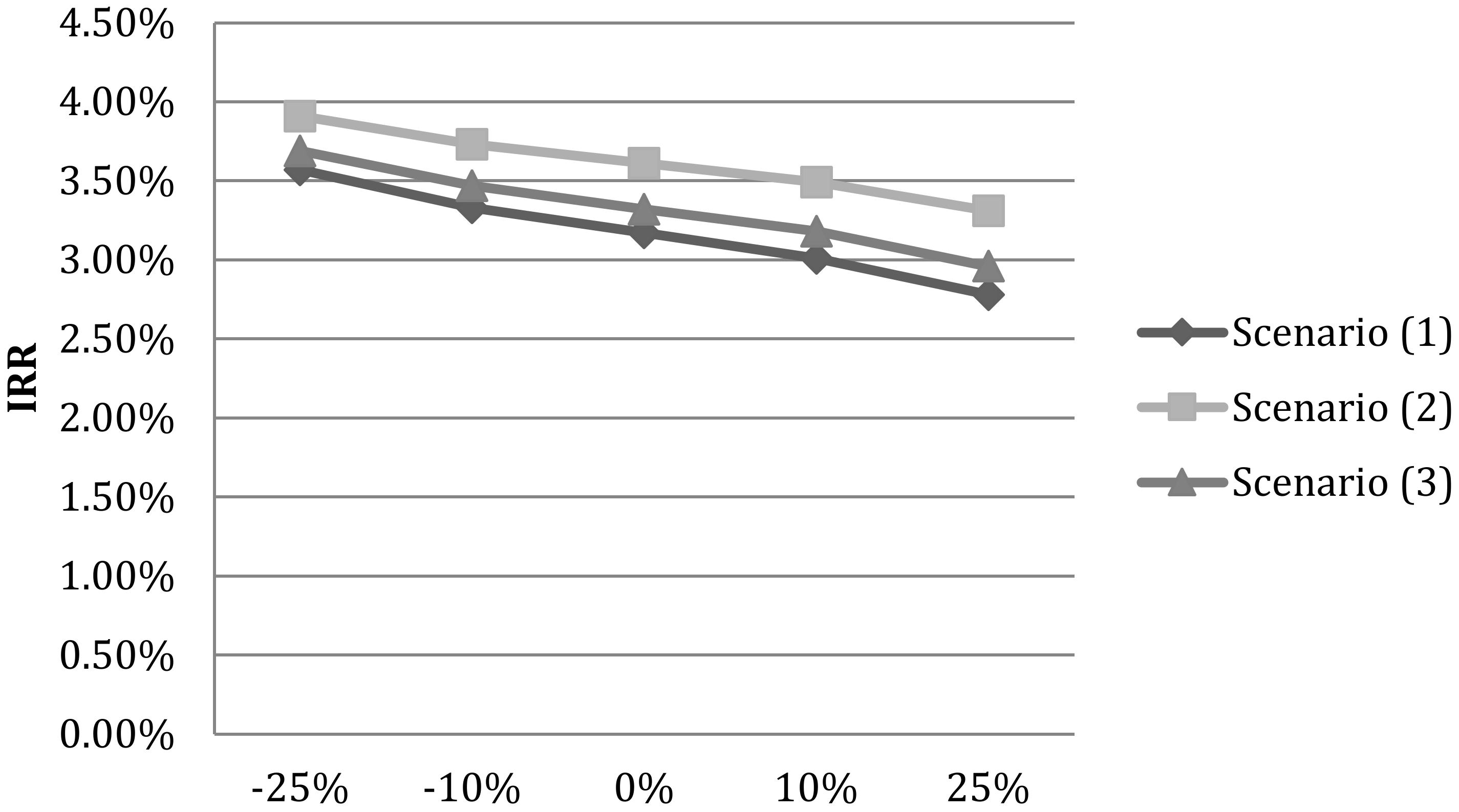

3.6. Sensitivity Analysis

4. Incorporation of the Circular Bioeconomy Model with Sustainability Analysis

5. Discussion

5.1. Financial Profitability and Generalizability of the Results

5.2. N Immobilization

5.3. Regulatory Concerns

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Unit | Cost | Source |

|---|---|---|---|

| Scenario 1: Basic data | USD/ha | 97.00 | [16] |

| Scenario 2: Sludge | USD/ha | 70.62 | Calculated. |

| Sludge application rate | Mg/ha (wet) | 6.56 | Estimated based on [21,23] |

| Sludge transport cost | USD/t | 5.00 | [35] |

| Sludge application cost | USD/ha | 37.82 | [33] |

| Scenario 3: Sludge + TSP | USD/ha | 87.68 | Calculated |

| Sludge application rate | Mg/ha (wet) | 6.56 | Estimated based on [21,23] |

| Sludge transport cost | USD/t | 5.00 | [35] |

| Sludge application cost | USD/ha | 37.82 | [33] |

| TSP application rate | kg/ha | 30.00 | Estimated based on [23] |

| TSP price | USD/ton | 156.40 | Estimated based on [37] |

| TSP spreading cost (original) | USD/acre | 5.00 | Adjusted based on [39] |

| TSP spreading cost (used) | USD/ha | 12.36 | Calculated |

References

- Lampert, A. Over-exploitation of natural resources is followed by inevitable declines in economic growth and discount rate. Nat. Commun. 2019, 10, 1419. [Google Scholar] [CrossRef]

- Kuokkanen, A.; Mikkilä, M.; Kahiluoto, H.; Kuisma, M.; Linnanen, L. The need for policy to address the food system lock-in: A case study of the Finnish context. J. Clean. Prod. 2017, 140, 933–944. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 6219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Foley, J.A.; Defries, R.; Asner, G.P.; Barford, C.; Bonan, G.; Carpenter, S.R.; Chapin, F.S.; Coe, M.T.; Daily, G.C.; Gibbs, H.K.; et al. Global consequences of land use. Science 2005, 309, 570. [Google Scholar] [CrossRef] [Green Version]

- Worrell, E.; Phylipsen, D.; Einstein, D.; Martin, N. Energy Use and Energy Intensity of the U.S. Chemical Industry; Lawrence Berkeley National Lab: Berkeley, CA, USA, 2000. [Google Scholar]

- Bennett, E.M.; Carpenter, S.R.; Caraco, N.F. Human impact on erodible phosphorus and eutrophication: A global perspective. Biosciences 2001, 51, 227–234. [Google Scholar] [CrossRef]

- Haes, H.A.U.; Voortman, R.L.; Bastein, T.; Bussink, D.W.; Rougoor, C.W.; Weijden, W.J. Scarcity of Micronutrients in Soil, Feed, Food, and Mineral Reserves: Urgency and Policy Options; The Dutch Platform for Agriculture, Innovation and Society: Culemborg, The Netherlands, 2012. [Google Scholar]

- Camberato, J.J.; Gagnon, B.; Angers, D.A.; Chantigny, M.H.; Pan, W.L. Pulp and paper mill by-products as soil amendments and plant nutrient sources. Can. J. Soil Sci. 2006, 86, 641–653. [Google Scholar] [CrossRef]

- Benedetti, V. Bio-Solids have potential-An alternative method for the disposal of industrial waste as fertilizer in eucalyptus plantations. Pulp Pap. Int. 2014, 56, 38–41. [Google Scholar]

- Bajpai, P. Management of Pulp and Paper Mill Waste; Springer International Publishing: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Joona, J.; Kuisma, M.; Alakukku, L.; Kahiluoto, H. Carbon flows of waste biomasses applicable to agricultural soils in Finland. In Global Assessment for Organic Resources and Waste Management, Proceedings of the 8th International Conference ORBIT2012, 12–14 June 2012, Rennes, France; Trémier, A., Dabert, P., Druilhe, C., Maudet, M.N., Barth, J., Siebert, S., Bidlingmaier, W., Eds.; Verlag ORBIT: Weimar, Germany, 2012; pp. 160–164. [Google Scholar]

- CEPI. Discovering the High Potential of Pulp and Paper Production Residues; CEPI: Brussels, Belgium, 2004. [Google Scholar]

- Zhang, L.; Xu, C.C.; Champagne, P. Energy recovery from secondary pulp/paper-mill sludge and sewage sludge with supercritical water treatment. Bioresour. Technol. 2010, 101, 2713–2721. [Google Scholar] [CrossRef]

- Usman, K.; Khan, S.; Ghulam, S.; Khan, M.U.; Khan, N. Sewage Sludge: An important biological resource for sustainable agriculture and its environmental implications. Am. J. Plant Sci. 2012, 3, 1708–1721. [Google Scholar] [CrossRef] [Green Version]

- Kosonen, M.; Otsamo, A.; Kuusipalo, J. Financial, economic and environmental profitability of reforestation of Imperata grassland in Indonesia. For. Ecol. Manag. 1997, 99, 249–259. [Google Scholar] [CrossRef]

- Kosonen, M.; Otsamo, A.; Kuusipalo, J. Financial, Social and Environmental Profitability of Rehabilitation of Logged-Over Dipterocarp Forests—A Case Study from South-Kalimantan, Indonesia; Technical Report No. 63; Reforestation and Tropical Forest Management Project, Phase VI, ATA-267; The Ministry of Forestry of Indonesia/Ministry for Foreign Affairs of Finland/Enso Forest Development Oy Ltd.: Imatra, France, June 1996.

- Kuusipalo, J.; Ådjers, G.; Jafarsidik, Y.; Otsamo, A.; Tuomela, K.; Vuokko, R. Restoration of natural vegetation in degraded Imperata cylindrica grassland: Understorey development in forest plantations. J. Veg. Sci. 1996, 6, 205–210. [Google Scholar] [CrossRef]

- Tuomela, K.; Otsamo, A.; Kuusipalo, J.; Vuokko, R.; Nikles, G. Effect of provenance variation and singling and pruning on early growth of Acacia mangium Willd. plantation on Imperata cylindrica (L.) Beauv. dominated grassland. For. Ecol. Manag. 1996, 84, 241–249. [Google Scholar] [CrossRef]

- Utanun, P. Feasibility of the Use of Recycled Nutrients in Fast Growing Pulpwood Production. Ph.D. Thesis, Lappeenranta-Lahti University of Technology, Lappeenranta, Finland, 2015. Available online: https://lutpub.lut.fi/handle/10024/104633 (accessed on 22 June 2021).

- Rashid, M.T.; Barry, D.; Goss, M. Paper mill biosolids application to agricultural lands: Benefits and environmental concerns with special reference to situation in Canada. Soil Environ. 2006, 25, 85–98. [Google Scholar]

- Bresters, A.R.; Coulomb, I.; Deak, B.; Matter, B.; Saabye, A.; Spinosa, L.; Utvik, Å.Ø.; Uhre, L.; Meozzi, P. Sludge Treatment and Disposal: Management Approaches and Experiences; Environmental Issues, 7; European Environment Agency (EEA); International Solid Waste Association (ISWA): Copenhagen, Denmark, 1998. [Google Scholar]

- Adjers, G.; Luukkanen, O. Fertilization Trial of Recently Plant Acacia Mangium Seedlings, 1988 ed.; Research Paper No. 3; Department of Silviculture, University of Helsinki: Helsinki, Finland, 1988; p. 77. [Google Scholar]

- Florio, M. The rate of return of development projects: An international comparison. In Proceedings of the XII Riunione Scientifica: Politica Fiscale, Flessibilità dei Mercati e. Crescita, Pavia, Italy, 6–7 October 2000. [Google Scholar]

- Liljeblom, E.; Vaihekoski, M. Investment evaluation methods and required rate of return in Finnish publicly listed companies. Liiketal. Aikakauskirja 2004, 1, 9–24. [Google Scholar]

- World Bank. World DataBank: Explore, Create Report. Databases: World Development Indicators > Country: Indonesia > Series: Inflation, Consumer Prices (Annual %) > Time: Year 1980–2020. Available online: https://data.worldbank.org/indicator/FP.CPI.TOTL.ZG?locations=ID (accessed on 1 August 2021).

- World Bank. World DataBank: Explore, Create Report. Databases: World Development Indicators > Country: United States > Series: Inflation, Consumer Prices (Annual %) > Time: Year 1980–2020. Available online: https://data.worldbank.org/indicator/FP.CPI.TOTL.ZG?locations=US (accessed on 1 August 2021).

- Kuckartz, U. Qualitative Text Analysis: A Guide to Methods, Practice & Using Software; Metzler, K., Ed.; Sage: London, UK, 2014. [Google Scholar]

- Fiksel, J.; Bruins, R.; Gatchett, A.; Gilliland, A.; Brink, M.T. The triple value model: A systems approach to sustainable solutions. Clean Technol. Environ. Policy 2013, 16, 691–702. [Google Scholar] [CrossRef]

- Trautmann, N.M.; Porter, K.S.; Wagenet, R.J. Modern Agriculture: Its Effects on the Environment. Available online: http://psep.cce.cornell.edu/facts-slides-self/facts/mod-ag-grw85.aspx (accessed on 1 August 2021).

- Anderson, R.K.; Weddle, B.R.; Hillmer, T.; Geswein, A. Cost of Landspreading and Hauling Sludge from Municipal Wastewater Treatment Plants: Case Studies; Solid Waste Management Series, SW-619; United States Environmental Protection Agency: Columbus, OH, USA, 1977; Volume 530.

- Ferrara, P.; Weber, B. Land Application of Sewage Sludge in the Willamette Valley: Farm Operator Attitudes and Municipal Costs; Special Report; Agriculture Experiment Station, Oregon State University: Corvallis, OR, USA, 1982; Volume 658. [Google Scholar]

- Gray, C.W.; Chen, L.; Haro-Martí, M.E.; Chahine, M.; Neibling, H. Costs of Liquid-Manure Application Systems; University of Idaho, BUL 888; The College of Agricultural and Life Sciences, University of Idaho: Moscow, ID, USA, 2014. [Google Scholar]

- Ministry of Environment. Towards a Recycling Society—The National Waste Plan for 2016. Available online: https://helda.helsinki.fi/handle/10138/38022 (accessed on 1 August 2021).

- UNEP. P.T. PINDO DELI: Company Case Study; Green Industry Platform: Geneva, Switzerland, 2006. [Google Scholar]

- US EPA. Handbook: Estimating Sludge Management Costs; National Service Center for Environmental Publications: Cincinnati, OH, USA, 1985.

- Rasi, S.; Lehtonen, E.; Aro-Heinilä, E. From Waste to Traffic Fuel–Projects: Final Report, Finnish Case Regions; MTT Agrifood Research Finland: Jokioinen, Finland, 2012. [Google Scholar]

- FAO. Fertilizer Use by Crop in Indonesia; FAO, Land and Water Development Division: Rome, Italy, 2005. [Google Scholar]

- Ferguson, K.W.; McKinley, T.L. Fertilizer Cost Calculator. Available online: http://economics.ag.utk.edu/fertilizer.html (accessed on 1 August 2021).

- World Bank. World DataBank: Explore, Create Report. Databases: Global Economic Monitor (GEM) Commodities > Series: Woodpulp, $/mt, Real 2010$ > Time: Annual, Year 1995–2013 Country: World. Available online: https://databank.worldbank.org/source/global-economic-monitor-(gem) (accessed on 1 August 2021).

- Kahiluoto, H.; Smith, P.; Moran, D.; Olesen, J.E. Enabling food security by verifying agricultural carbon. Nat. Clim. Change 2014, 4, 309–311. [Google Scholar] [CrossRef]

- Otsamo, A.; Adjers, G.; Hadi, T.S.; Kuusipalo, J.; Tuomela, K.; Vuokko, R. Effect of site preparation and initial fertilization on the establishment and growth of four plantation tree species used in reforestation of Imperata cylindrica (L.) Beauv. dominated grasslands. For. Ecol. Manag. 1995, 73, 271–277. [Google Scholar] [CrossRef]

- Culp, J.; Podemski, C.; Cash, K. Interactive effects of nutrients and contaminates from pulp mill effluents on riverine benthos. J. Aquat. Ecosyst. Stress Recovery 2000, 8, 67–75. [Google Scholar] [CrossRef]

- Millennium Ecosystem Assessment. Ecosystems and Human Well-Being: Synthesis; Island Press: Washington, DC, USA, 2005. [Google Scholar]

- Alexander, M. Introduction to Soil Microbiology, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1977. [Google Scholar]

- Simard, R.R.; Baziramakenga, R.; Yelle, S.; Coulombe, J. Effects of de-inking paper sludges on soil properties and crop yields. Can. J. Soil Sci. 1998, 78, 689–697. [Google Scholar] [CrossRef] [Green Version]

- Zibilske, L.M. Dynamics of nitrogen and carbon in soil during papermill sludge decomposition. Soil Sci. 1987, 143, 26–33. [Google Scholar] [CrossRef]

- Dolar, S.G.; Boyle, J.R.; Keeney, D.R. Paper mill sludge disposal on soils: Effects on the yield and mineral nutrition of oats (Avena sativa L.). J. Environ. Qual. 1972, 1, 405–409. [Google Scholar] [CrossRef]

- McClellan, T. Nitrogen, Immobization. Available online: http://www.ctahr.hawaii.edu/mauisoil/c_nutrients01.aspx (accessed on 1 August 2021).

- EFAR. Regulation in Europe. Available online: http://www.efar.be/biosolid-production/#REGULATION-IN-EUROPE (accessed on 1 August 2021).

- CPI. Code of Good Practice for Landspreading Paper Mill Sludges; CPI: Swindon, UK, 2014. [Google Scholar]

| Analysis | Goss et al., 2003 (n = 3) | Atiken et al., 1998 (n = 1) | Simard et al., 1998 (n = 3) |

|---|---|---|---|

| EC (mS cm−1) | 0.39–0.87 | 0.09–0.20 | |

| pH | 7.7–8.2 | 7.7 | 7.8–9.1 |

| Dry matter (% dry) | 39.7–49.0 | 31.5 | |

| Organic Carbon (% dry) | 29.7–33.4 | 31.8 | 42.3–44.2 |

| Total N (% dry) | 0.27–0.73 | 0.37 | 0.15 |

| C:N ratio | 42–124 | 86 | 284–292 |

| Total P (%) | 0.072–0.093 | 0.08 | 0.0096–0.0097 |

| Total K (%) | 0–0.09 | 0.20 | 0.0029–0.0034 |

| Total Ca (%) | 2.86–5.85 | 0.46–0.56 | |

| Total Mg (%) | 0–0.06 | 0.235 | 0.026–0.031 |

| Total Na (%) | 0.05–0.06 | 0.073–0.084 |

| Cost Item | Remark | Source | ||

|---|---|---|---|---|

| Variable Cost | Interviews, | |||

| Establishment cost | USD/ha | 1994 | ||

| Site preparation | 213 | 1st year | ||

| Seedlings and their transport | 120 | 1st year | ||

| Planting | 18 | 1st year | ||

| Fertilization | 97 | 1st year | ||

| Weeding | 30 | 1st and 2nd yr | (610 USD/ha on 3rd year) | |

| Monitoring | 3 | 3rd till last yr | ||

| Supervision | 75 | 1st year | (5 USD/ha from 2nd to last year) | |

| USD/m3 | Hakkila, 1994 | |||

| Harvesting and transport cost | 10.3 | Last year | (During harvesting) | Interviews, 1996 |

| Reforestation fee | 1.5 | Last year | (During harvesting) | World bank, 1993 |

| Fixed Cost | USD/year | Rissanen, 1995 | ||

| Fixed establishment costs | 15,525 | 1st year | (During planting) | |

| Fixed harvesting costs | 53,865 | Last year | (During harvesting) | |

| Depreciation of machinery | 800 | First 5 years | ||

| Investments | USD | Rissanen, 1995 | ||

| Buildings | 12,500 | 1st year | ||

| Buildings | 8300 | 1 year | Before harvesting | |

| Fire protection | 2450 | 1st and 6th yr | ||

| Machinery and equipment | 4100 | 1st year | ||

| Roundwood price | USD/m3 | Interviews, 1996 | ||

| Acacia mangium | 20.00 | Roadside price | ||

| Characteristic | Amount |

|---|---|

| Dry matter (% dry) | 30.48 |

| C:N ratio | 25.83:1 |

| Total N (g kg−1 dry) | 16.20 |

| Total P (g kg−1 dry) | 2.92 |

| Total K (g kg−1 dry) | 2.44 |

| Characteristic | Defined Annual Rate of Nutrients (kg/ha) | Required Amount of Sludge (kg Dry) | Calculated Amount from the Sludge Amount of 2000 kg (kg Dry) |

|---|---|---|---|

| Total N | 22 | 1358 | 32 |

| Total P | 20 | 6853 | 6 |

| Total K | 10 | 4107 | 5 |

| Factor | Unit | Cost | Source |

|---|---|---|---|

| Application rate | Mg/ha (wet) | 6.56 | Calculated |

| Application cost | USD/ha | 37.82 | [33] |

| Transport cost | USD/ton | 5 | [35] |

| TSP price | USD/ton | 156.4 | [38] |

| TSP spreading cost | USD/ha | 12.36 | [39] |

| Fertilization Scenario | NPV—0% Discount (’000 USD) | IRR (%) | ||

|---|---|---|---|---|

| 1 Basic data | 222.90 | 3.17 | ||

| 2 Sludge | 249.28 | 3.61 | ||

| 3 Sludge + TSP | 232.22 | 3.32 | ||

| Average | 248.18 | 3.63 | ||

| NPVs at 0, 5, 11, and 20 percent | ||||

| NPV (’000 USD) | ||||

| % Discount | 0% | 5% | 11% | 20% |

| 1 Basic data | 222.90 | −79.64 | −204.82 | −231.06 |

| 2 Sludge | 249.28 | −59.28 | −189.29 | −220.00 |

| 3 Sludge + TSP | 232.22 | −72.44 | −199.33 | −227.15 |

| IRR (%) | |||||

|---|---|---|---|---|---|

| Total Fertilization Cost, Change | −25% | −10% | 0% | 10% | 25% |

| (1) Basic data | 3.57 | 3.33 | 3.17 | 3.01 | 2.78 |

| (2) Sludge | 3.91 | 3.73 | 3.61 | 3.49 | 3.31 |

| (3) Sludge + TSP | 3.69 | 3.47 | 3.32 | 3.18 | 2.96 |

| Total Fertilization Cost (USD/ha) | |||||

|---|---|---|---|---|---|

| Application Rate Changed | −25% | −10% | 0 | 10% | 25% |

| 2 Sludge | 62.42 | 67.34 | 70.62 | 73.91 | 78.83 |

| 3 Sludge + TSP | 79.48 | 84.40 | 87.68 | 90.96 | 95.88 |

| Fertilization Scenario | IRR (%) | ||

|---|---|---|---|

| MAI = 25 m3/ha (Basic Analysis) | MAI = 30 m3/ha | MAI = 36 m3/ha | |

| 1 Basic data | 3.17 | 6.87 | 10.37 |

| 2 Sludge | 3.61 | 7.66 | 11.23 |

| 3 Sludge + TSP | 3.32 | 7.35 | 10.91 |

| Fertilization Scenario | MAI (m3/ha) | Roundwood Price (USD/m3) |

|---|---|---|

| Base case | 25.00 | 20.00 |

| (1) Basic data | 41.45 | 25.40 |

| (2) Sludge | 40.38 | 23.47 |

| (3) Sludge + TSP | 41.07 | 25.05 |

| Environment | Economy | Society | References | |

|---|---|---|---|---|

| Micro (local level) | ||||

| Improvement in soil properties | • Possible to improve soil organic matter and biological processes, soil bulk density and aggregation, soil water holding capacity, cation exchange capacity, and liming benefits |

| • Better soil quality

| [9,42] |

| Homogeneous and less contaminating sludge properties of sludge | • Less harmful to aquatic ecosystems and food networks due to leaching and erosion | • Simple processes with existing equipment, no need for additional investments in sludge preparation | • Fewer risks to people caused by contaminated water | [43] |

| Application in rapidly growing plantation |

|

|

| [10,16] |

| Macro (global level) | ||||

| Potential as a practice that provides ecosystem services |

| • Provisioning services—fiber and fuel (wood products can also serve as an energy source) | • Cultural services—cultural diversity and social relations among actors involved | [44] |

| Potential as a substitute for mineral fertilizers. |

| • A step towards a circular bioeconomy within pulp and paper industry |

| Chapter 1, Figure 1, Figure 7, [12,41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikkilä, M.; Utanun, P.; Luhas, J.; Horttanainen, M.; Linnanen, L. Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia. Sustainability 2021, 13, 10169. https://doi.org/10.3390/su131810169

Mikkilä M, Utanun P, Luhas J, Horttanainen M, Linnanen L. Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia. Sustainability. 2021; 13(18):10169. https://doi.org/10.3390/su131810169

Chicago/Turabian StyleMikkilä, Mirja, Papitchaya Utanun, Jukka Luhas, Mika Horttanainen, and Lassi Linnanen. 2021. "Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia" Sustainability 13, no. 18: 10169. https://doi.org/10.3390/su131810169

APA StyleMikkilä, M., Utanun, P., Luhas, J., Horttanainen, M., & Linnanen, L. (2021). Sustainable Circular Bioeconomy—Feasibility of Recycled Nutrients for Biomass Production within a Pulp and Paper Integration in Indonesia, Southeast Asia. Sustainability, 13(18), 10169. https://doi.org/10.3390/su131810169