1. Introduction

Aerogels in general represent a fourth state of matter. Molecules and atoms are arranged by covalent junctions in a loose structure with a very high porosity of 90% and higher. This structural arrangement is achieved by drying respective gels and preventing them from collapsing. The SiO

2-aerogel is an aerogel that is also used in the building industry. A concise and informative overview regarding the synthesis, properties and applications of SiO

2-aerogels can be found in [

1], with a special emphasis on building applications.

The application of aerogel-based renderings, i.e., aerogel granules embedded in a porous phase of binder mixture for energy-efficient retrofitting, is spreading fast throughout Europe for both multi-story concrete buildings [

2], as well as small and large historic buildings [

3] where available space is scarce and changes to the external appearance of buildings by must be avoided if possible.

The first communication addressing the hygrothermal properties of an aerogel-based rendering was published by Th. Stahl et al. [

4]. This new high-performance rendering was the result of a joint research and development project co-funded by the Swiss government and an industrial partner, and won the “Swiss Environment” Prize, 2014, in the “Innovation” category [

5]. In addition, the prestigious German BAKA Prize, 2015, was also awarded to this product [

6], which has been available on the market since 2013, and has been applied to hundreds of buildings, mainly in Switzerland. Different researchers have since published studies on the hygro-thermal performance of different mixtures of aerogel-based insulating renderings, and the topic is continuing to interest both academia and industry, especially with the prospect of obtaining a cheaper production procedure [

7]. Ibrahim et al. [

8] reported on a rendering with a density of 156 kg/m

3 and its application on a test building, including a parametric study with a simulation of the temperature and moisture distribution within different wall assemblies. The same authors reported on the beneficial contribution obtained by coupling low-e coating and interior aerogel plaster to enable energy savings of 21% and 30% for 0.5 cm and 1 cm of aerogel plaster, respectively [

9]. Furthermore, aerogel-containing plasters were developed at a laboratory scale by Buratti et al. [

10], who studied aerogel contents of approximately 96% and a thermal conductivity of around 0.015 W/(m·K). A study on the internal application of 5 mm of this material on the internal side of a building, including infrared thermography, has also been reported by these authors. Another group has investigated cementitious aerogel-based renders and reached a thermal conductivity of 0.084 W/(m·K), with a compressive strength of 0.92 MPa for the partial replacement of the aerogel aggregate by other lightweight aggregates, such as expanded clay and perlite, helping to improve its mechanical stability [

11]. A more recent publication deals with differences in water absorption and its impact on the thermal conductivity of light-weight mortars when cement-lime is replaced by hydrophobic aerogel granules [

12].

The rendering investigated here has been examined in research projects to get more information on its practical performance on-site. Application on a historical façade at the Vienna University of Technology has been reported by Ghazi Wakili et al. [

13]. Another application using this rendering as an infill/internal insulation for a half-timbered test wall has been discussed by Stahl et al. [

14]. The first professional application of this aerogel-based rendering to the external wall surfaces of a historical building was carried out by the FIXIT company in Switzerland. Following this application, a monitoring period of 5 years (2013–2018) was scheduled and executed to measure the temperature and moisture evolution between the original wall and the aerogel-based rendering. The results showed unambiguously that no moisture accumulation occurred at this critical site [

15]. As yet, no deteriorations, detachments or cracks in the final rendering have been detected during regular annual controlling.

Recently, the energetic retrofit of a 30-m high building by means of the external application of the same aerogel-based rendering carried out by CERABRAN, a private German company, has been investigated, and the results published by Ghazi Wakili et al. [

2]. The in-situ U-value was measured by two different methods before and after the execution of the energy-efficient retrofit procedure, and comparison was made to another but originally identical building, retrofitted by applying a conventional insulating rendering.

A revealing investigation into the aging of aerogel granules by moisture and solar radiation has been reported by Ihara et al. [

16], where measured thermal conductivity was chosen as a performance indicator for moisture-induced aging. The study showed that aerogel granules with a hydrophobic surface exposed to moisture-induced aging did not take up more than 1.5–2.0 wt.% of moisture, and this in turn does not significantly change its thermal performance. The authors stated that “a relatively long time (years to decades) may be needed to observe such a change”.

The influence of the hydrophobized granule surface is decisive in reaching a low thermal conductivity of the rendering, irrespective of the added binder. The hydrophobization prevents water from entering the granules, which is very positive for keeping the overall thermal conductivity of the rendering as low as possible. The hydrophobization process has been explained extensively in [

17]. On the other hand, it is necessary to create a hydrophilic coating around the hydrophobic core of the aerogel granule, to enable the formation of water-based slurries applicable to building surfaces. This is achieved with an appropriate surfactant (surface active agent), which creates a hydrophilic coating surrounding the granules. An investigation in this respect, on a composite insulation material based on hydrophobized aerogel granules and anhydrite binder, has been reported by Sanz-Pont et al. [

18], who detail the role of the surfactant with respect to the formation of water-based slurries, despite the hydrophobic surface of the aerogel granules. The negative impact of this hydrophilic coating is an increase in water uptake, and hence an increase in the overall thermal conductivity. The mentioned authors [

18] tried to keep a balance between the amount of surfactant and water entering the granules. An influential parameter in this respect is the size distribution of the granules. A large number of small granules will necessitate a larger total hydrophilic coating surface in comparison to cases with fewer but larger aerogel granules, resulting in a considerable reduction of the mentioned surface. That means to keep the overall thermal conductivity low using less hydrophilic coating, and at the same time to enable the formation of water-based slurries to be applied to the walls, larger aerogel granules are needed, and aerogel powder avoided. Experience showed that a diameter of 1.2 to 4 mm is ideal, and smaller granules, as well as thin powders, must be avoided.

A further interesting topic is the long-term performance of aerogel-containing materials such as plasters and blankets when subject to different loads. Recently, Nosrati et al. [

19] reported on the aging conditions (high temperature, freezing and moisture) and application of different test durations to represent 20 years aging. For aerogel-based plasters with different percentages of aerogel granules, they found an increasing aging with decreasing granular content. The authors did not supply any interpretation for this result. It seems that the binder material, which makes a secondary porous phase where the granules are embedded in, is apparently affected by the impact of aging more than the granules themselves. This would explain the rising aging effect with rising percentage of the binder material.

Soares et al. [

20] reported on the contact radius between water droplets and the hydrophobized aerogel granule surface and highlighted the relevance of understanding how each characteristic of the aggregate influences the behavior of the final rendering, focusing on requirements of the corresponding standards. The investigation concludes that an overall improvement of the rendering’s performance needs an adaptation of the composition, such as water to binder ratio and surfactant content. An extensive parametric analysis of the influence of different binders on the performance of aerogel-based renders is given in [

21]. The lowest thermal conductivity reported therein was around 0.057 W/(m·K), which is not competitive as there are conventional insulating plasters with a slightly higher value of around 70–80 W/(m·K) at a much lower price. The improvement of the mechanical properties of plasters incorporating aerogels by using fiber additives has also been investigated, but without reaching the expected low values of thermal conductivity for them [

22]. A recent review [

23] dealt with the prospects of applying aerogel-based plasters to historic buildings, including a guideline for test samples to access the thermal performance of such plasters.

The present investigation aims to contribute to clarification regarding water uptake of the aerogel granules as the main ingredient, after various preliminary treatments and the workability and durability of the rendering as a whole system (granules and binder) on a historic façade by omitting the usually installed reinforcement mesh.

2. Materials and Methods

For the following investigations, commercially available aerogel granules with bulk hydrophobization, a particle size range of 1.2–4.0 mm, an average bulk density of 75 kg/m3 and a porosity above 90% have been used. These granules are the main ingredients of the aerogel-based rendering as a whole system (granules and binders) which has been supplied by an industrial supplier (Fixit AG, Holderbank, Switzerland).

2.1. Immersion in Water

To find out how hydrophobized aerogel granules react to moisture and water, a preliminary simple test under extreme conditions was carried out. It must be stated that this was a straightforward procedure and did not follow any existing or projected standard.

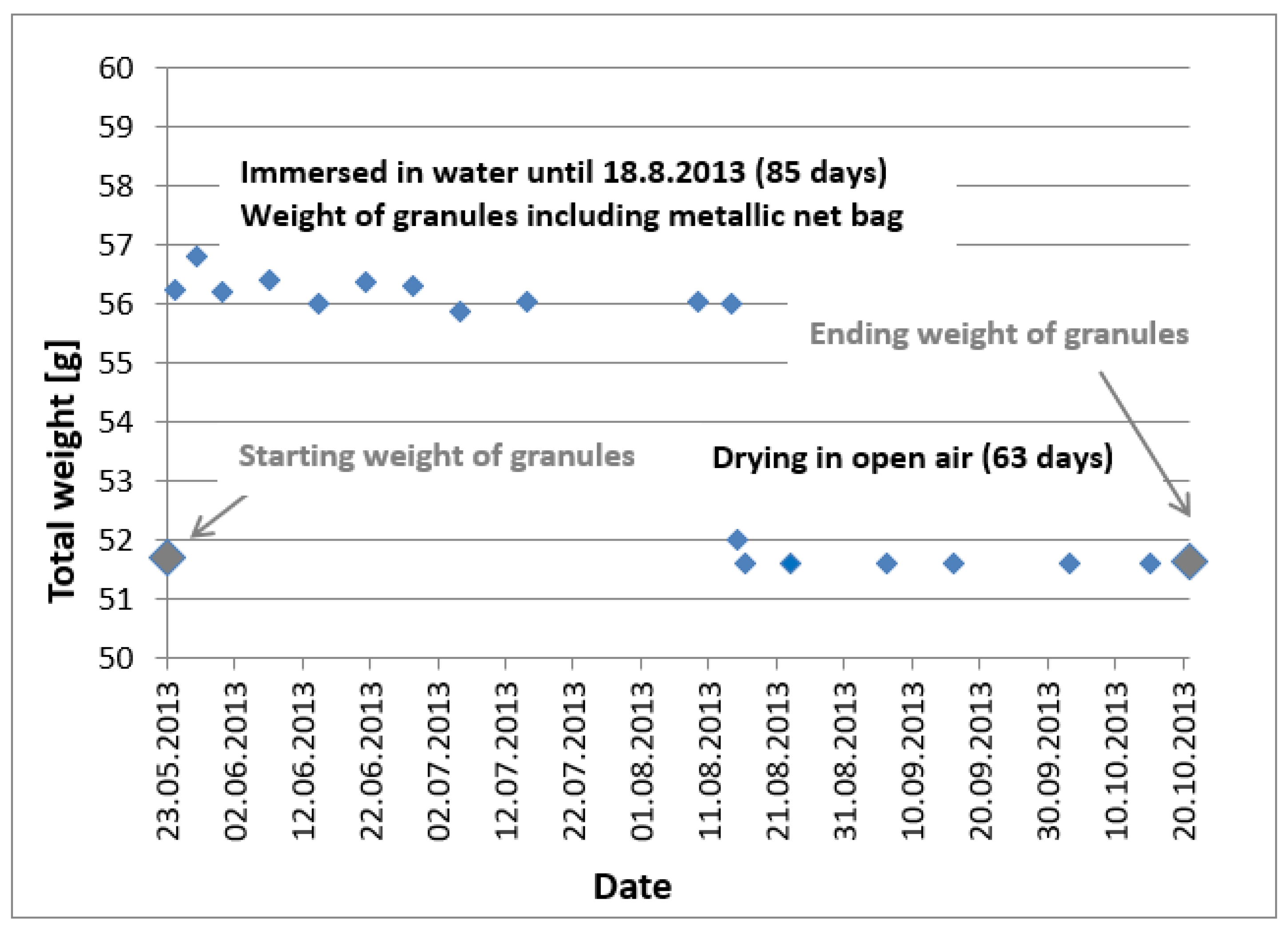

Approximately 50 g of hydrophobized aerogel granules were put in a small bag made of a metallic net (

Figure 1). The initial weight was determined first and then the bag was totally immersed in a cup of pure distilled water so that the granules were surrounded by water from all sides. The assembly remained in this condition for a duration of 85 days, and was then dried in the open air for a period of 63 days. During the drying period, only the water on the surface and between the granules evaporated, whereas the water captured inside the aerogel pores (50–100 nm) remained there as negative pressure would have been needed to extract it from these small pores [

24]. The weight of the assembly was registered during the total conditioning period once a week. This meant that if water was captured within the pores of the granules, it would result in an increase in weight at the end of the drying period with respect to the initial value. These long periods were chosen to be on the safe side. In reality, the building components with the rendering are never under such severe conditions for such a long time.

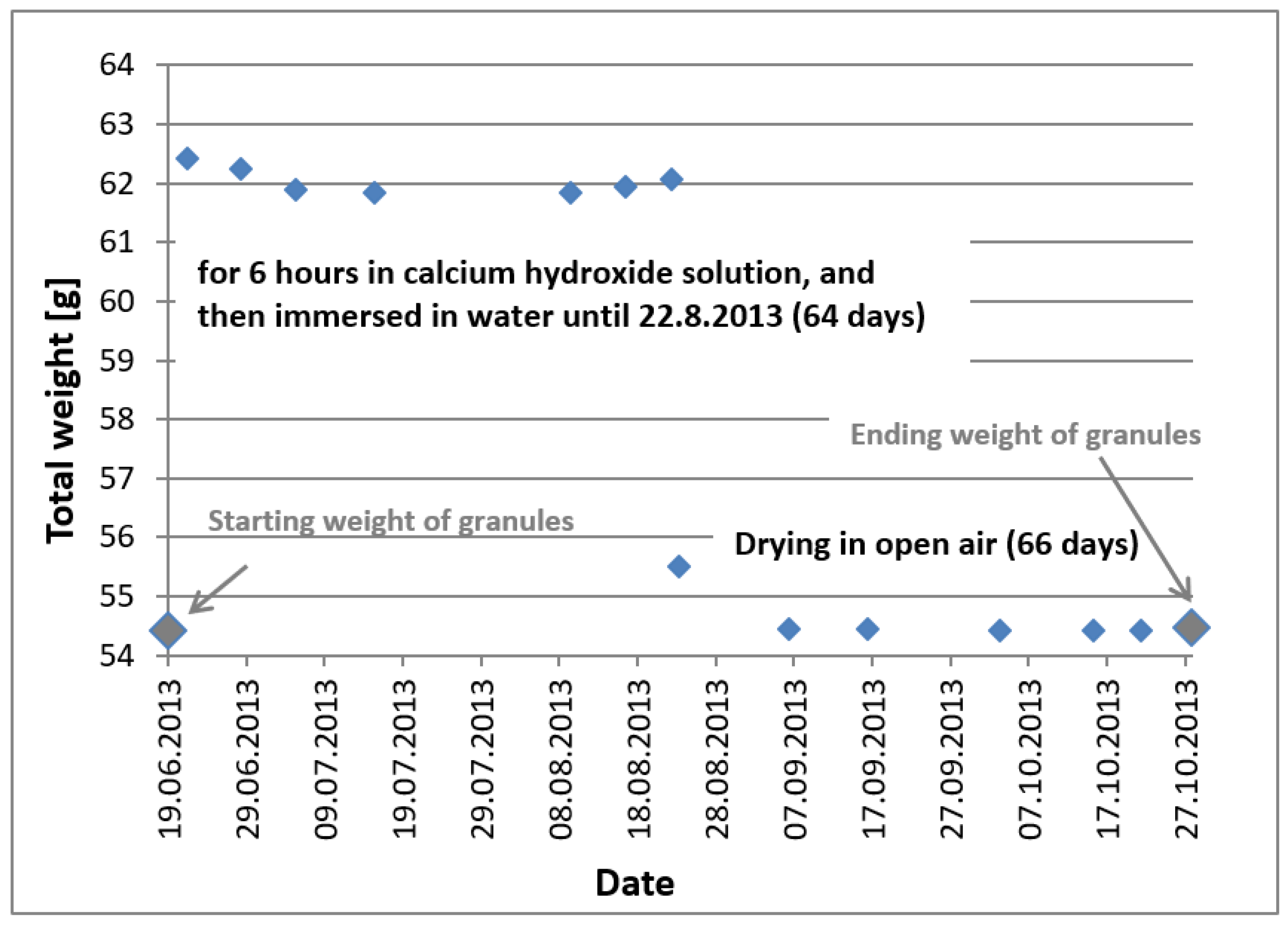

2.2. Immersion in Calcium Hydroxide Ca (OH)2 at Room Temperature

Besides water uptake, another property of the aerogel granules which is important to investigate is their reaction to alkali environments, especially at pH > 13 which is common in the vicinity of lime-based binders. In this respect, it is important to know if the hydrophobic quality of the granules is affected negatively by this environmental condition, or if it remains intact. For this reason, a second test was carried out by immersing the metallic net bag with aerogel granules inside (new samples) first into a solution of Calcium Hydroxide (pH > 13) for a period of 6 h, and then into pure distilled water for 64 days. Calcium hydroxide was chosen as it represents a major ingredient of mineral-based renderings and results in the presence of water in a highly alkali environment. A detection of water uptake by weighting the granules would indicate a destruction of the granules hydrophobization. This is clearly a rather harsh treatment representing a worst case scenario and an accelerated aging.

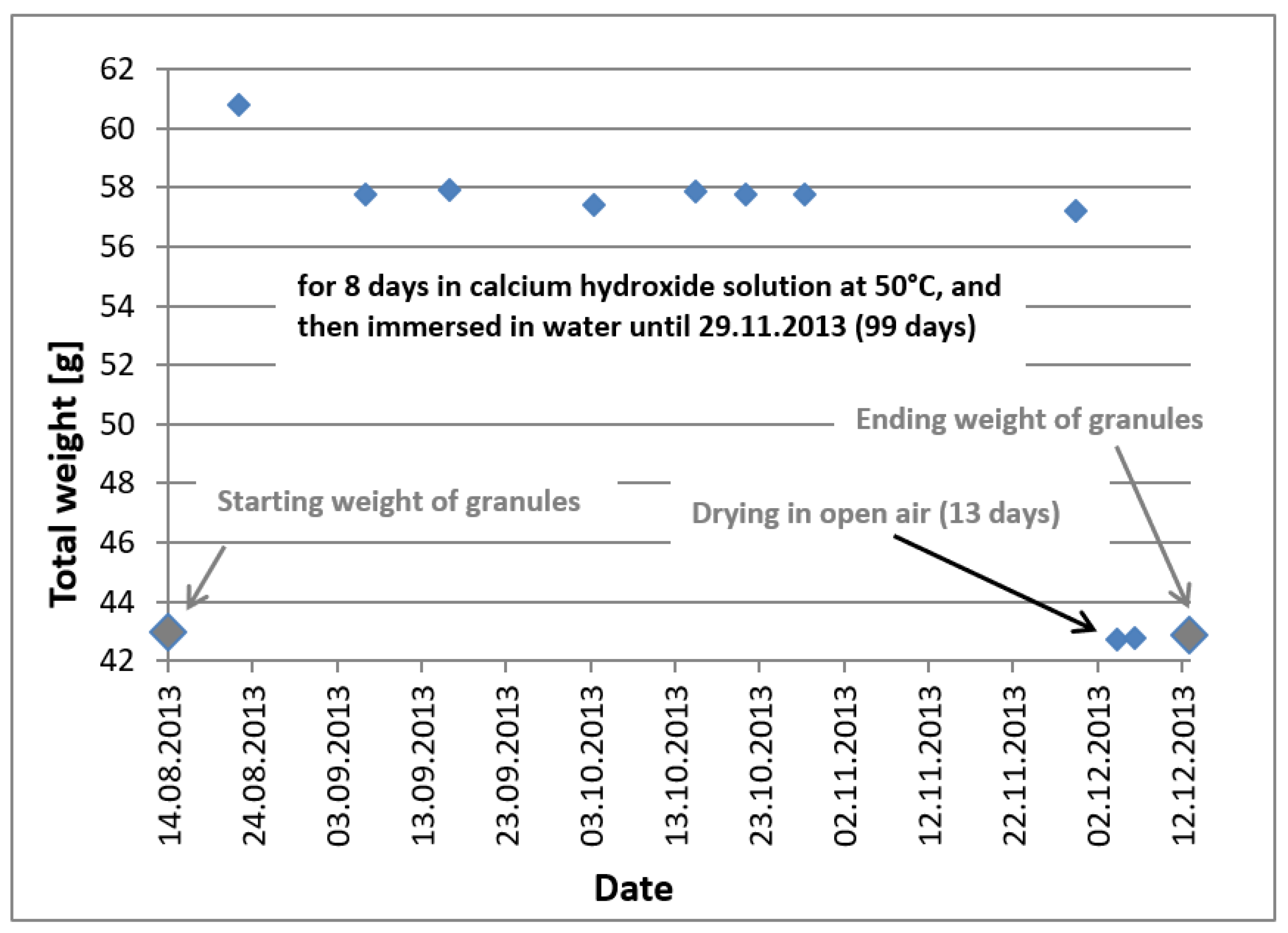

2.3. Immersion in Calcium Hydroxide Ca (OH)2 at 50 °C

In a third test, the aerogel granules (new samples) underwent a far more rigorous treatment. They were immersed for a period of 8 days in a calcium hydroxide solution, but at a temperature of 50 °C. This high temperature was chosen as a maximum so that the outcome would also apply to lower temperatures where the chemical reactions are less intense. After this harsh treatment the samples were again immersed in water for a period of 99 days and then dried in open air for only 3 days. Here, once again, measuring the water uptake would indicate if the hydrophobization had remained intact or not.

2.4. Weathering of the Aerogel-Based Rendering without Reinforcement Mesh

The rendering is in practice a multi-layered application. First, an adhesive primer is applied to the original wall surface. The aerogel-based rendering is then applied, followed by a thin base coat, a reinforcement mesh and finally a finishing coat.

When it comes to the application of newly-developed materials to old buildings under heritage protection, several hurdles are encountered which do not occur when dealing with newer buildings. One of them is the usage of the reinforcement mesh mentioned above, due to the aversion of conservationists versus plastic-based materials. Within a research project funded by the Austrian government, a series of weathering tests were carried out for the aerogel-based rendering omitting the disputed reinforcement mesh. It has been shown that the rendering remains stable and durable even without the reinforcement mesh [

13].

A next step in this respect was to investigate how the omission of the reinforcement mesh would influence the behavior of the rendering system when exposed to weathering.

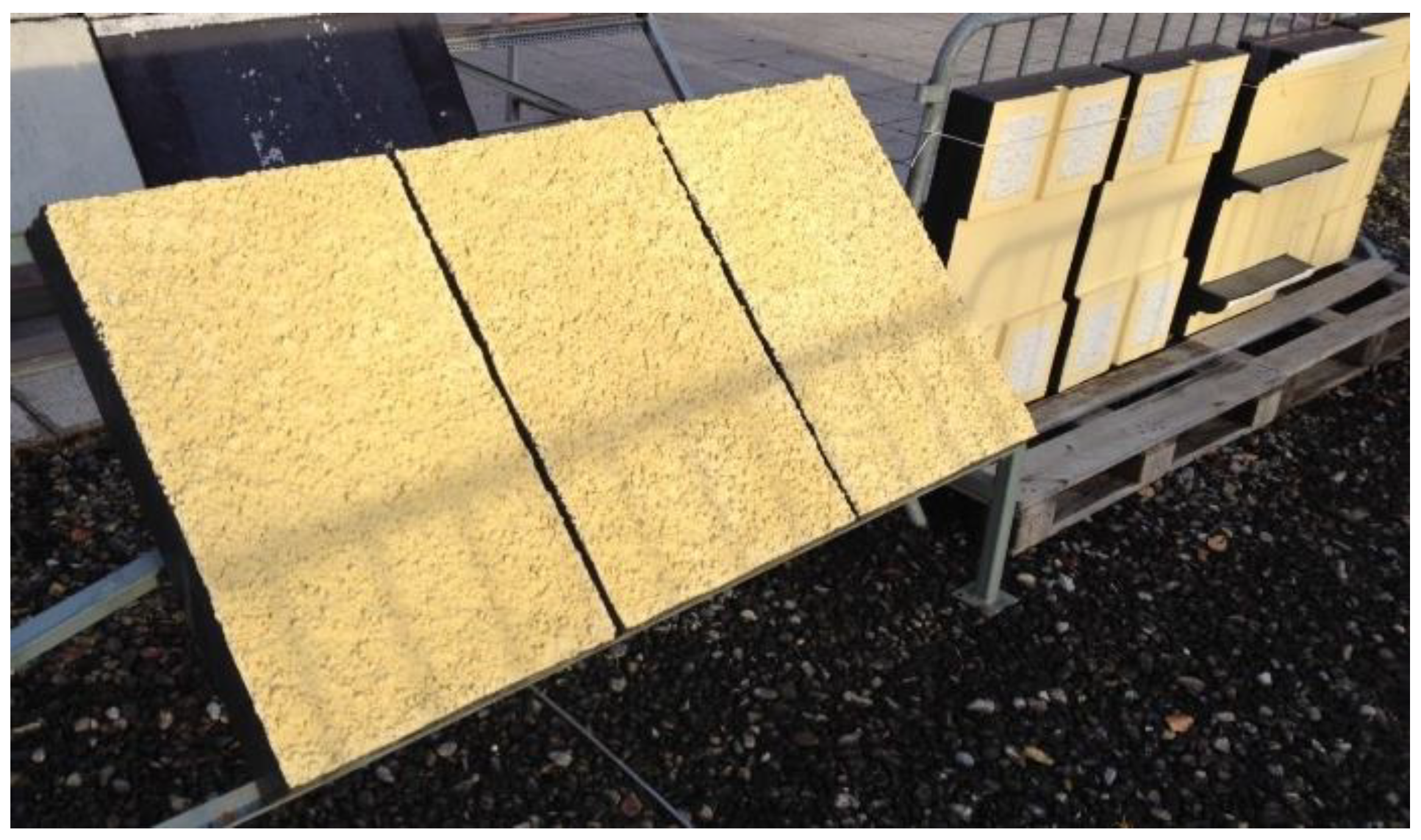

Figure 2 shows a series of samples exposed to free weathering on a roof at the R&D of Fixit Group in Röthis (Austria). All samples are made of bricks with a 6-cm thick layer of the aerogel-based rendering system on top of them. The lateral surfaces have been waterproof sealed by means of a bituminous layer so that water uptake can only take place by the exposed sample surface. The three samples on the left of

Figure 2 have a relatively rough finishing (final render with mineral paint) and are exposed without any protection at an angle of 135°, which is an extreme exposure compared to the common natural aging tests reported in [

25,

26,

27]. Then there are several other samples with a smooth finishing, with some structures on them as it will be the case for structured façades. No reinforcement mesh was used at all.

2.5. Aerogel-Based Rendering on a Historic Façade

During the mentioned research project, a historic building of the Wilhelminian era in the city of Vienna underwent an energy-efficient retrofit by applying the above-mentioned aerogel-based rendering without reinforcement mesh, and with the additional requirement to restructure the façade while keeping all decorative elements as similar to the original as possible. An overview of the sequence of work steps is shown in

Figure 3. It is evident that this kind of application needs special skills and extra time to be executed properly and simultaneously to fulfil the requirements of the conservation bodies.

3. Results and Discussion

Throughout the immersion of the granules in pure water over a period of 85 days, only small fluctuations were detected in the mass of the metallic net bag filled with granules as shown in

Figure 4.

The granules were then taken out of the bag and dried (

Figure 4 right), and this value remained practically unchanged for 63 days. The starting weight (left) and the ending weight (right) are at the same level, a clear indication that during this treatment no water uptake in the granules occurred. It should be kept in mind that water molecules which enter the nano-porous material cannot be driven out by drying in air, but only by applying a negative pressure.

The results of the second treatment can be seen in

Figure 5. Here too, the starting (left) and the ending (right) weight of the granules are practically identical, proving the absence of any water uptake in the aerogel granules.

The situation remained unchanged again for the third and most harsh treatment, as depicted in

Figure 6. No indication was found of water uptake into the aerogel granules. Hence, the hydrophobization of the granules easily survived all three treatments. This means that the portion of the aerogel-based rendering which can take up water is the porous region of the binder which surrounds the granules and can easily dry out when the amount of water or moisture is reduced. Even under these harsh conditions there is no quasi-irreversible water uptake detectable for the aerogel granules which would deteriorate their thermal insulation property.

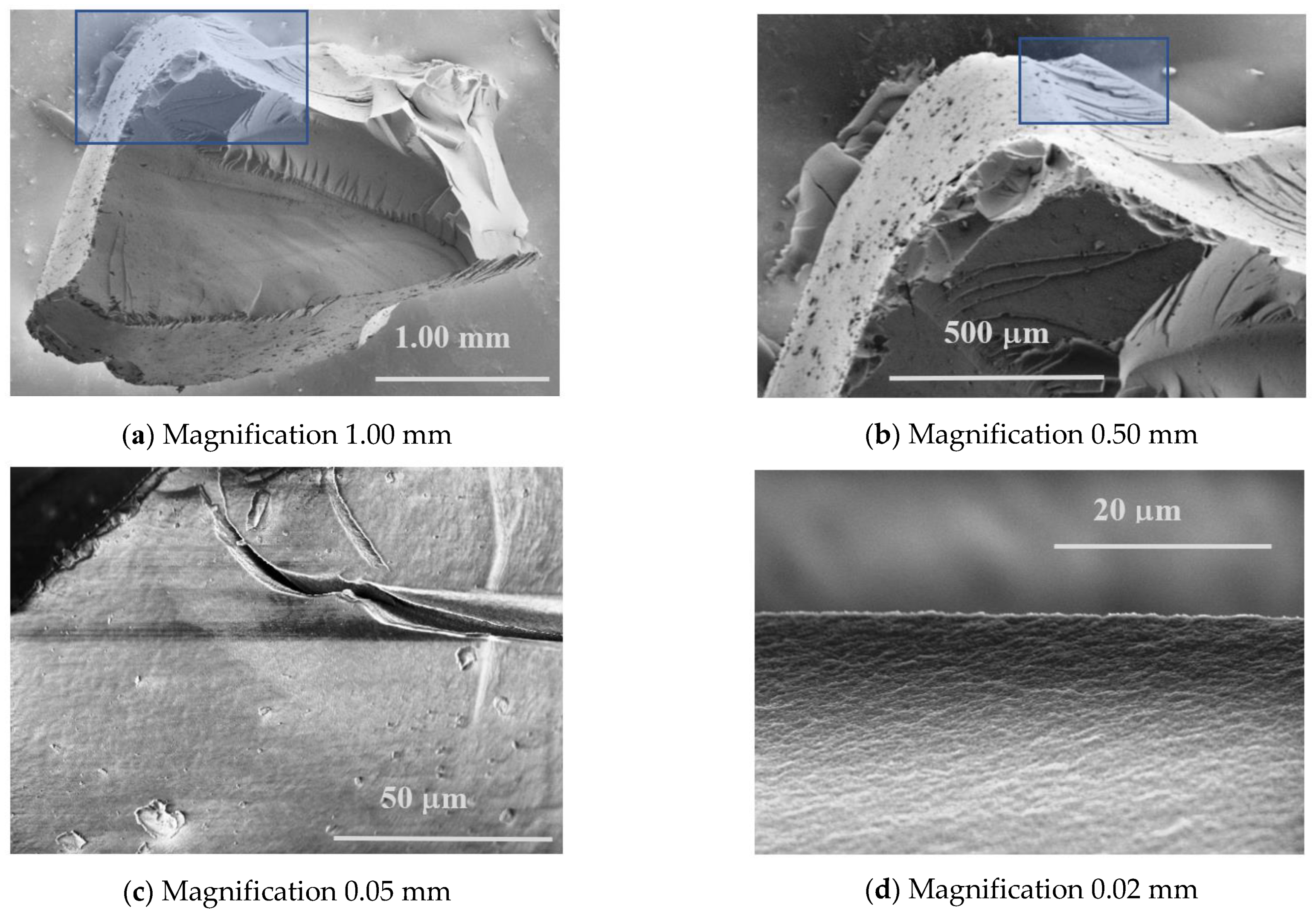

A further indication that the aerogel hydrophobized granules remained unchanged during all three treatments listed above is their surface structure seen by SEM. The untreated so called “as received samples” are shown at different scales in

Figure 7.

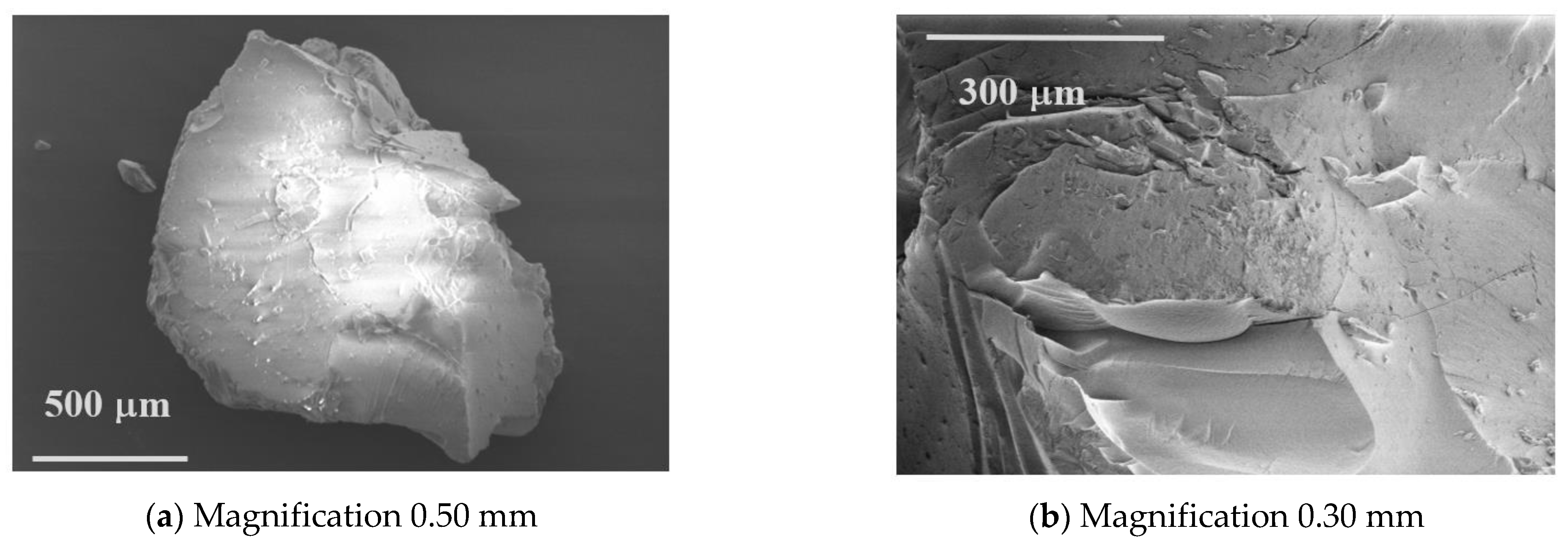

In comparison,

Figure 8 depicts the surface of an aerogel granule subjected to the harshest treatment explained above (immersion in Calcium Hydroxide at 50 °C). There are no significant differences recognizable on the four different scales.

The samples of the whole rendering system in

Figure 2, which have been weather exposed (including snow accumulation) at an angle of 135°, first showed small cracks in the finishing layer after the third consecutive winter. The layer with the aerogel-based rendering remained sane. The abovementioned represents an accelerated aging with respect to vertical façades exposed to the same weather. In cases of samples with structural elements, some parts showed colour changes and small frost-induced ablations. This occurred mainly where rainwater was not able to flow off. However, in summary, the whole rendering system without reinforcement mesh had a rather satisfying performance.

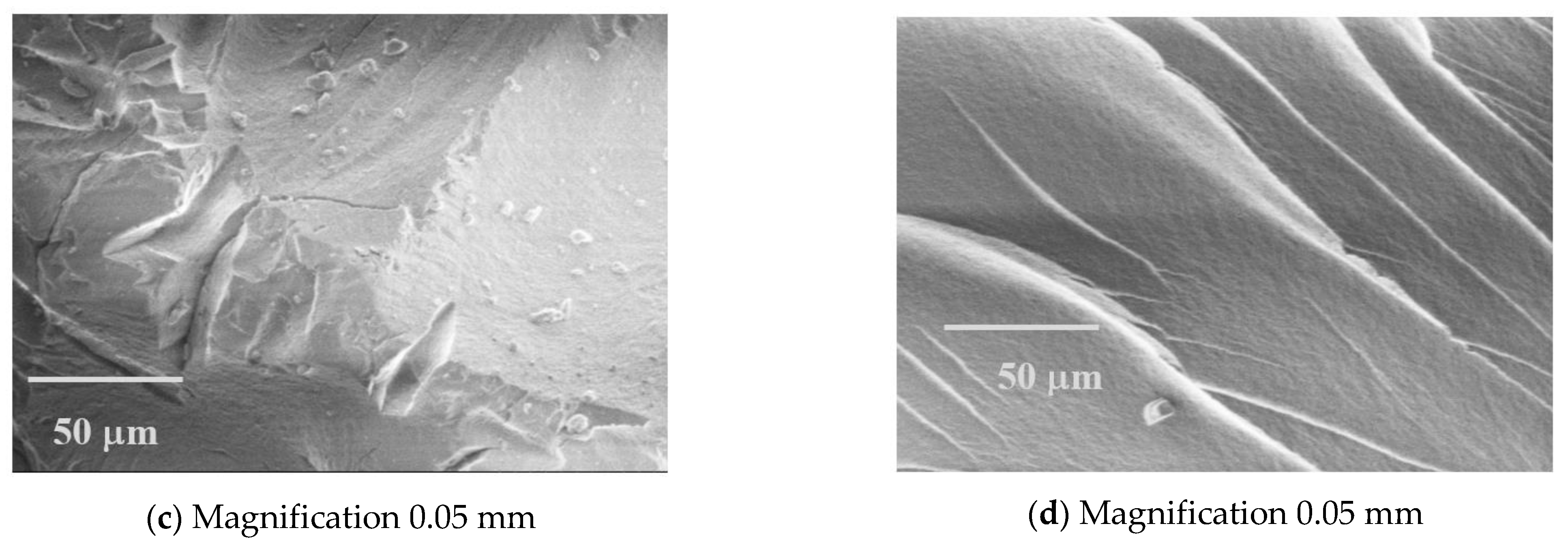

Finally,

Figure 9 shows the original and the retrofitted façade in comparison, both from a visual and infrared view. The tremendous similarity of the structured façades is obvious, as all details of the original façade were copied in the new one due to the excellent workability of the aerogel-based rendering.

Simultaneously, the infrared thermography inlay in

Figure 9 shows the thermal impact of the retrofitted façade whose external surface temperature has been measured on a winter day (15 February 2017) to be 2–2.5 K lower than the external temperature of the original façade. A clear affirmation for the perfect workability and insulating properties of the aerogel-based rendering, even without applying a reinforcement mesh.