Review of Research on Digital Supply Chain Management Using Network Text Analysis

Abstract

:1. Introduction

2. Digital Supply Chain

2.1. Definition of a Digital Supply Chain

2.2. Development Trends and Application of Digital Supply Chains

3. Methods

3.1. Network Text Analysis

3.2. Procedures of Network Text Analysis

4. Results

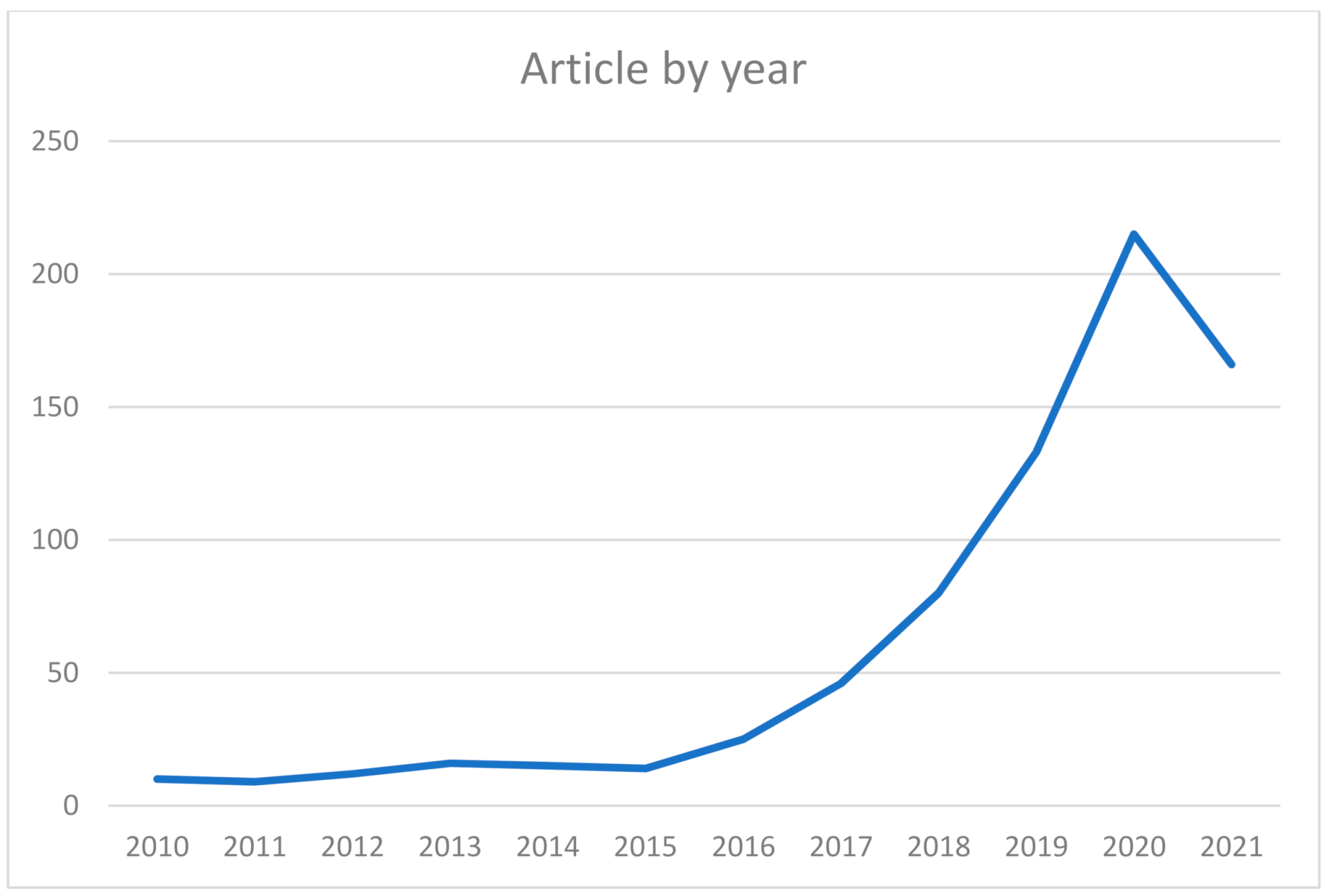

4.1. Subject Analysis

4.2. Network Text Analysis on Articles Published until 2019

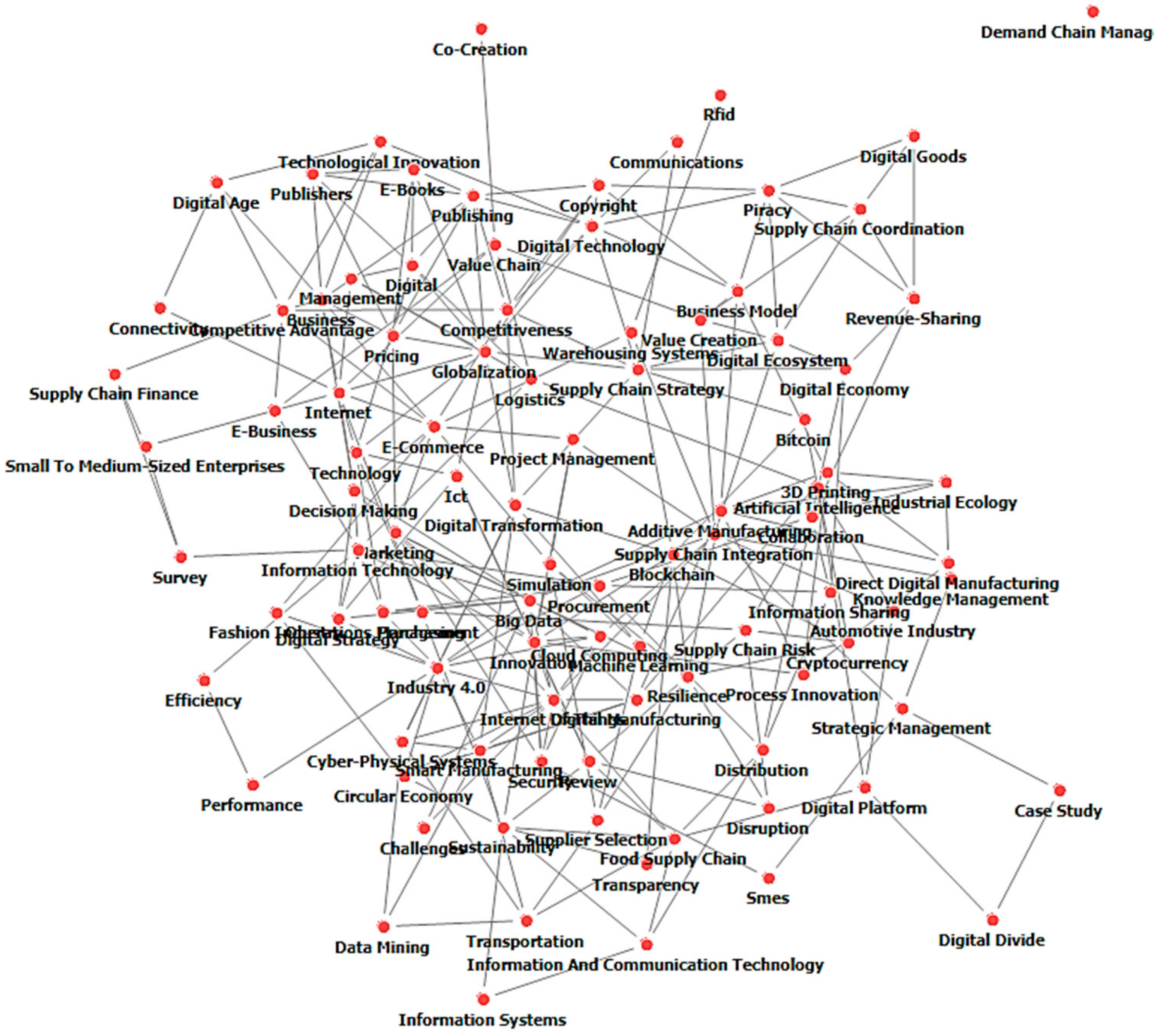

4.2.1. Building the Keyword Network

4.2.2. Centrality Analysis

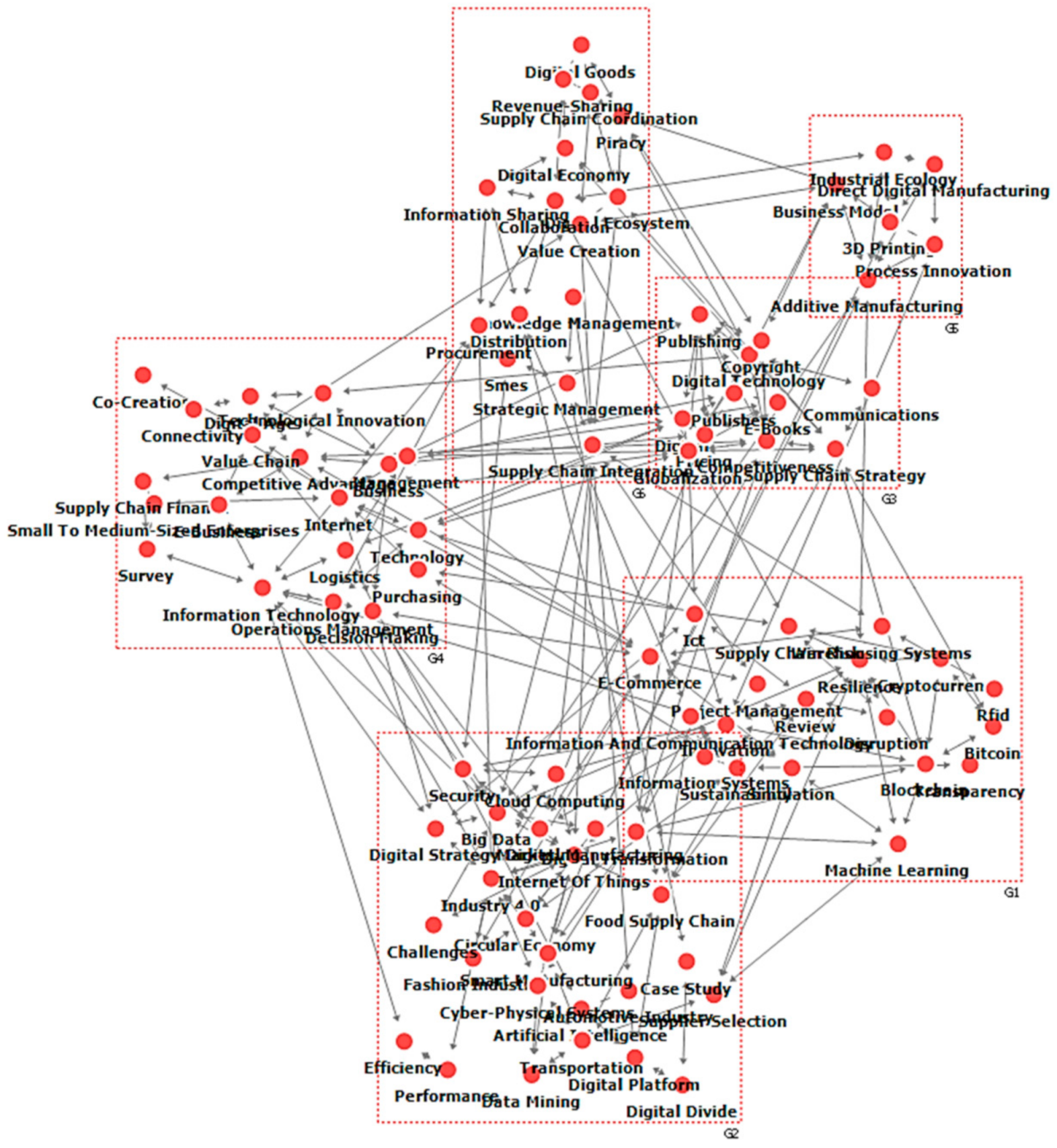

4.2.3. Cluster Analysis

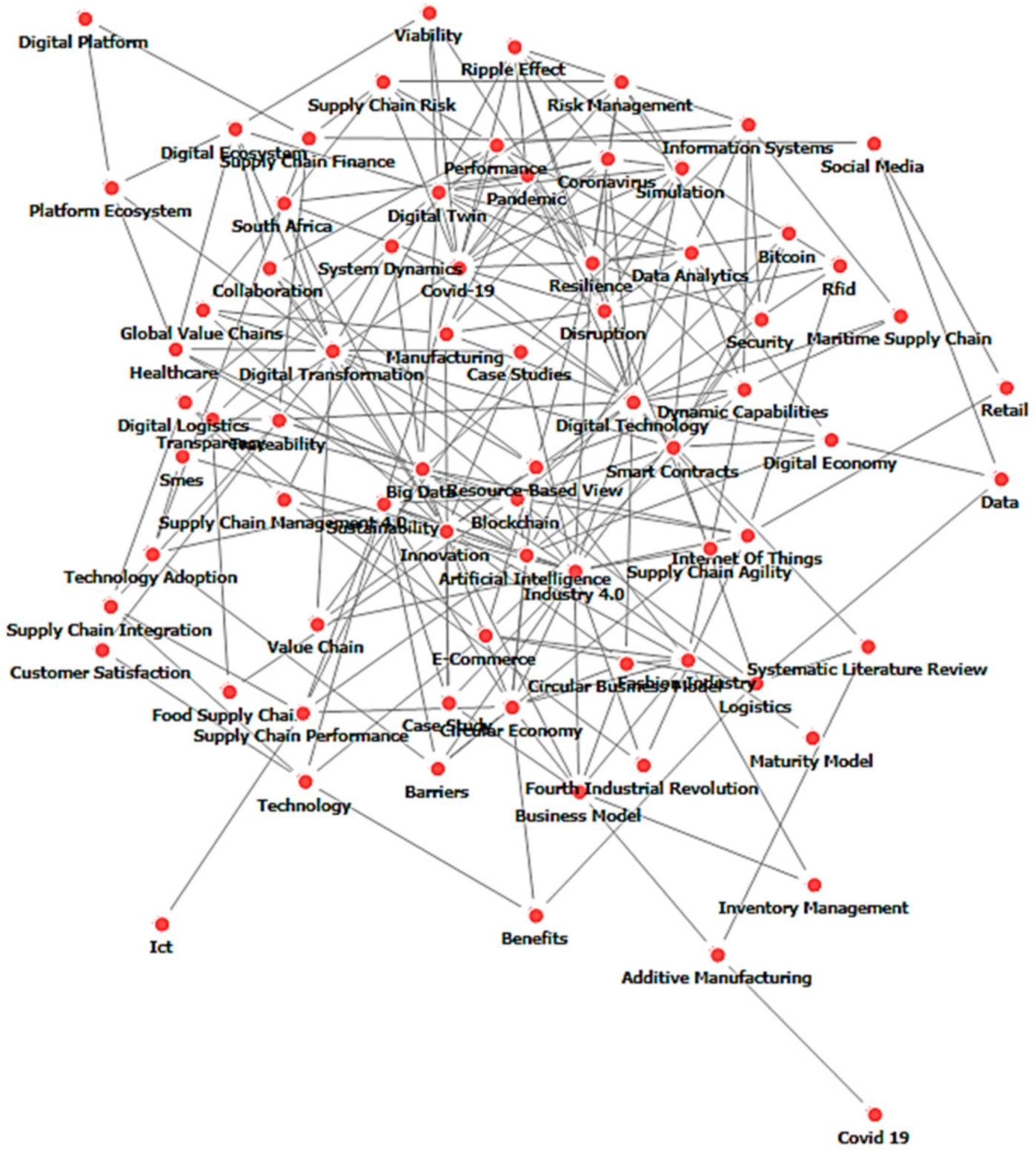

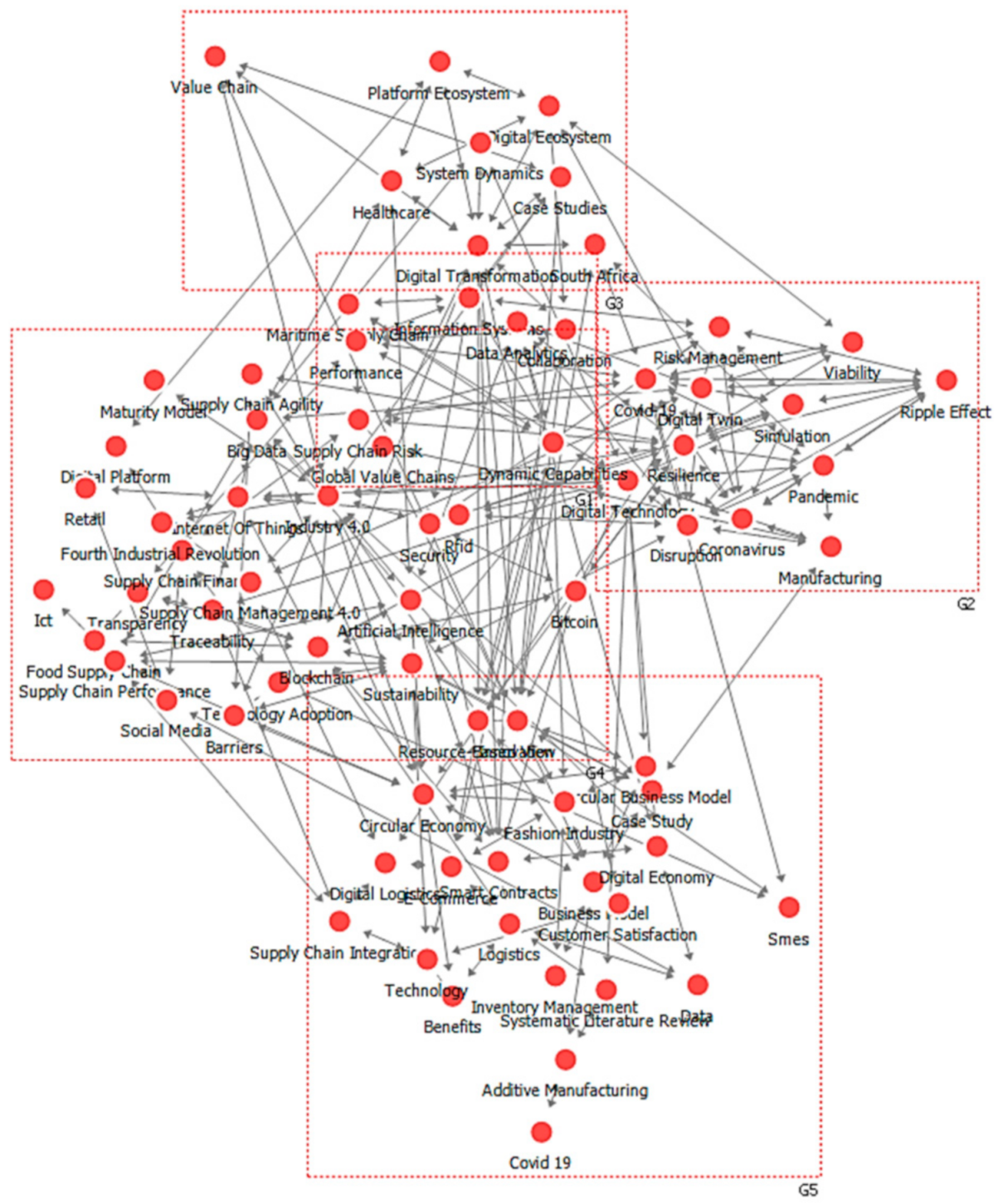

4.3. Network Text Analysis on Articles Published from 2020

4.3.1. Building the Keyword Network

4.3.2. Centrality Analysis

4.3.3. Cluster Analysis

5. Conclusions

6. Future Research and Limitations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Morales, S.O.C.; Aldrette-Malacara, A.J. Digital supply chain model in Industry 4.0. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Daniel, D. Digital Supply Chain. SearchERP.com. Available online: https://searcherp.techtarget.com/definition/digital-supply-chain?vgnextfmt=print (accessed on 22 March 2021).

- Kinnet, J. Creating a Digital Supply Chain: Monsanto’s Journey, SlideShare, 1–16. Volume 21. Available online: https://www.slideshare.net/BCTIM/creating-a-digital-supply-chain-monsantos-journey (accessed on 21 June 2015).

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- PwC. Industry 4.0 & How Digitization Makes the Supply Chain More Efficient, Agile, and Customer-Focused. 2016. Available online: https://www.strategyand.pwc.com/gx/en/insights/2016/digitization-more-efficient.html (accessed on 22 March 2021).

- Agile Elephant. What Is Digital Transformation. Available online: www.theagileelephant.com/what-is-digital-transformation (accessed on 22 March 2021).

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Bhargava, B.; Ranchal, R.; Ben Othmane, L. Secure information sharing in digital supply chains. In Proceedings of the 2013 3rd IEEE International Advance Computing Conference (IACC), Ghaziabad, India, 22–23 February 2013; pp. 1636–1640. [Google Scholar]

- Raab, M.; Griffin-Cryan, B. Digital Transformation of Supply Chains: Creating Value—When Digital Meets Physical. 2011. Available online: https://www.capgemini.com/wpcontent/uploads/2017/07/Digital_Transformation_of_Supply_Chains.pdf (accessed on 22 March 2021).

- The Centre for Global Enterprise. Digital Supply Chains: A Frontside Flip. 2016. Available online: https://www.dscinstitute.org/assets/documents/a-frontside-flip_white-paper_english-version.pdf (accessed on 28 April 2021).

- Wijoyo, S.; Abrianto, B.O.; Aris, M.S.; Nugraha, X.; Frisa, K.A.M. Digital Supply Chain Mechanism in Indonesian Society and Industrialization. Int. J. Supply Chain Manag. 2020, 9, 509–518. [Google Scholar]

- Digital Supply Chain Institute. Digital Supply Chain Transformation Guide: Essential Metrics; The Centre for Global Enterprise: New York, NY, USA, 2017. [Google Scholar]

- Kodolova, I.A.; MirgaziyanovnaYusupova, L.; Viktorovna Nikonova, T.; Kalimullina, R.R. Development of Innovative Activity and Supply Chain Strategy of Enterprises in the Age of Digital Economy. Int. J. Supply Chain Manag. 2019, 8, 525–531. [Google Scholar]

- Accenture. Supply Chain Transformation on the Cloud. Available online: https://www.accenture.com/us-en/insights/supply-chain-operations/supply-chain-transformation-cloud (accessed on 13 July 2021).

- Klötzer, C.; Pflaum, A. Toward the Development of a Maturity Model for Digitalization within the Manufacturing Industrys Supply Chain. In Proceedings of the 50th Hawaii International Conference on System Sciences, Waikoloa Village, HI, USA, 4–7 January 2017; pp. 4210–4219. [Google Scholar]

- Kartskhiya, A.A.; Tyrtychnyy, S.A.; Smirnov, M.G.; Dolgikh, M.G.; Khmelnitskiy, L.A. Digital Technologies in Supply Chain Management for Production and Digital Economy Development. Int. J. Supply Chain Manag. 2020, 9, 912–918. [Google Scholar]

- Simchenko, N.A.; Tsohla, S.Y.; Chyvatkin, P.P. IoT & Digital Twins Concept Integration Effects on Supply Chain Strategy: Challenges and Effect. Int. J. Supply Chain Manag. 2019, 8, 803–808. [Google Scholar]

- Cecere, L. Embracing the Digital Supply Chain. 2016. Available online: https://www.supplychainshaman.com/demand/demanddriven/embracing-the-digital-supply-chain (accessed on 22 March 2021).

- Di Nardo, M. Developing a Conceptual Framework Model of Industry 4.0 for Industrial Management. Ind. Eng. Manag. Syst. 2020, 19, 551–560. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Calatayud, A.; Mangan, J.; Christopher, M. The self-thinking supply chain. Supply Chain Manag. Int. J. 2019, 24, 22–38. [Google Scholar] [CrossRef]

- Kearney, A.T. Digital Supply Chains: Increasingly Critical for Competitive Edge; The Centre for Global Enterprise: New York, NY, USA, 2015. [Google Scholar]

- OECD. Available online: https://www.oecd.org/economic-outlook/june-2020 (accessed on 13 July 2021).

- Simchi-Levi, D.; Simchi-Levi, E. We Need a Stress Test for Critical Supply Chains. Harv. Bus. Rev. 2020. Available online: https://hbr-org.cdn.ampproject.org/c/s/hbr.org/amp/2020/04/we-need-a-stress-testfor-critical-supply-chains (accessed on 22 July 2020).

- Digital Supply Chain Institute. Bamboo Supply Chain: Resiliency in the Time of COVID-19; The Centre for Global Enterprise: New York, NY, USA, 2020. [Google Scholar]

- Iddris, F. Digital Supply Chain: Survey of the Literature. Int. J. Bus. Res. Manag. 2018, 9, 47–61. [Google Scholar]

- Robotics & Automation News. 2020. Available online: https://roboticsandautomationnews.com (accessed on 21 January 2021).

- USA Today. Available online: https://www.usatoday.com/story/tech/2020/07/22/amazon-taking-its-scout-delivery-robots-south/5485106002 (accessed on 22 July 2020).

- Amazon. Now-Has-200,000-Robots-Working-in-Its-Warehouses. Available online: https://roboticsandautomationnews.com/2020/01/21/amazon-now-has-200000-robots-working-in-its-warehouses (accessed on 22 March 2021).

- LCLO. Available online: https://clomag.co.kr/article/3393 (accessed on 13 July 2021).

- Samsung SDS. Available online: https://www.samsungsds.com/kr/scm/scm.html (accessed on 13 July 2021).

- Alonso-Muñoz, S.; González-Sánchez, R.; Siligardi, C.; García-Muiña, F. New Circular Networks in Resilient Supply Chains: An External Capital Perspective. Sustainability 2021, 13, 6130. [Google Scholar] [CrossRef]

- UKRI. Available online: https://www.ukri.org/opportunity/manufacturing-made-smarter-innovation-hub-digital-supply-chain (accessed on 13 July 2021).

- Cabinet Office, Government of Japan. Available online: https://www8.cao.go.jp/cstp/english/society5_0/manufacturing_e.html (accessed on 13 July 2021).

- White House. Available online: https://www.whitehouse.gov/briefing-room/presidential-actions/2021/02/24/executive-order-on-americas-supply-chains (accessed on 13 July 2021).

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Fahimnia, B.; Tang, C.S.; Davarzani, H.; Sarkis, J. Quantitative models for managing supply chain risks: A review. Eur. J. Oper. Res. 2015, 247, 1–15. [Google Scholar] [CrossRef]

- Feng, Y.; Zhu, Q.; Lai, K.-H. Corporate social responsibility for supply chain management: A literature review and bibliometric analysis. J. Clean. Prod. 2017, 158, 296–307. [Google Scholar] [CrossRef]

- Rha, J.S. Trends of Research on Supply Chain Resilience: A Systematic Review Using Network Analysis. Sustainability 2020, 12, 4343. [Google Scholar] [CrossRef]

- Blondel, V.D.; Guillaume, J.L.; Lambiotte, R.; Lefebvre, E. Fast Unfolding of Communities in Large Networks. J. Stat. Mech. Theor. Exp. 2008, 10, 10008. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain man-agement. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Ranganathan, C.; Teo, T.S.; Dhaliwal, J. Web-enabled supply chain management: Key antecedents and performance impacts. Int. J. Inf. Manag. 2011, 31, 533–545. [Google Scholar] [CrossRef]

- Bienhaus, F.; Haddud, A. Procurement 4.0: Factors influencing the digitisation of procurement and supply chains. Bus. Process. Manag. J. 2018, 24, 965–984. [Google Scholar] [CrossRef]

- Foster, C.; Graham, M.; Mann, L.; Waema, T.; Friederici, N. Digital Control in Value Chains: Challenges of Connectivity for East African Firms. Econ. Geogr. 2018, 94, 68–86. [Google Scholar] [CrossRef] [Green Version]

- Rai, A.; Patnayakuni, R.; Seth, N. Seth Firm Performance Impacts of Digitally Enabled Supply Chain Integration Capabilities. MIS Q. 2006, 30, 225. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.; Wallace, W.A. An industrial network flow information integration model for supply chain management and intelligent transportation. Enterp. Inf. Syst. 2007, 1, 327–351. [Google Scholar] [CrossRef]

- Bharadwaj, S.; Bharadwaj, A.; Bendoly, E. The Performance Effects of Complementarities between Information Systems, Marketing, Manufacturing, and Supply Chain Processes. Inf. Syst. Res. 2007, 18, 437–453. [Google Scholar] [CrossRef]

- Rajesh, R. Forecasting supply chain resilience performance using grey prediction. Electron. Commer. Res. Appl. 2016, 20, 42–58. [Google Scholar] [CrossRef]

- Graça, P.; Camarinha-Matos, L. Performance indicators for collaborative business ecosystems—Literature review and trends. Technol. Forecast. Soc. Chang. 2017, 116, 237–255. [Google Scholar] [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast. Soc. Chang. 2016, 102, 225–239. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Prod. Plan. Control. 2021, 32, 63–81. [Google Scholar] [CrossRef]

- Zeng, F.; Chan, H.K.; Pawar, K. The effects of inter- and intraorganizational factors on the adoption of electronic booking systems in the maritime supply chain. Int. J. Prod. Econ. 2021, 236, 108119. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Belhadi, A.; Kamble, S.; Jabbour, C.J.C.; Gunasekaran, A.; Ndubisi, N.O.; Venkatesh, M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. Chang. 2021, 163, 120447. [Google Scholar] [CrossRef]

- Ivanov, D. Lean resilience: AURA (Active Usage of Resilience Assets) framework for post-COVID-19 supply chain management. Int. J. Logist. Manag. 2021. [Google Scholar] [CrossRef]

- Zouari, D.; Ruel, S.; Viale, L. Does digitalising the supply chain contribute to its resilience? Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 149–180. [Google Scholar] [CrossRef]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning Supply Chains using Blockchain-Enabled Circular Economy and COVID-19 Experiences. Sustain. Prod. Consum. 2021, 27, 10–22. [Google Scholar] [CrossRef]

- Qian, X.A.; Papadonikolaki, E. Shifting trust in construction supply chains through blockchain technology. Eng. Constr. Arch. Manag. 2020, 28, 584–602. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z. A blockchain-based framework of cross-border e-commerce supply chain. Int. J. Inf. Manag. 2020, 52, 102059. [Google Scholar] [CrossRef]

- D’Adamo, I.; González-Sánchez, R.; Medina-Salgado, M.; Settembre-Blundo, D. E-Commerce Calls for Cyber-Security and Sustainability: How European Citizens Look for a Trusted Online Environment. Sustainability 2021, 13, 6752. [Google Scholar] [CrossRef]

- Arora, A.; Arora, A.S.; Sivakumar, K.; Burke, G. Strategic sustainable purchasing, environmental collaboration, and organizational sustainability performance: The moderating role of supply base size. Supply Chain Manag. Int. J. 2020, 25, 709–728. [Google Scholar] [CrossRef]

- Seyedghorban, Z.; Tahernejad, H.; Meriton, R.; Graham, G. Supply chain digitalization: Past, present and future. Prod. Plan. Control 2020, 31, 96–114. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Gunasekaran, A.; Bag, S. Dynamic capabilities and institutional theories for Industry 4.0 and digital supply chain. Supply Chain Forum Int. J. 2020, 21, 139–157. [Google Scholar] [CrossRef]

- Ganesan, S. Determinants of Long-Term Orientation in Buyer-Seller Relationships. J. Mark. 1994, 58, 1–19. [Google Scholar] [CrossRef]

- Di Nardo, M.; Clericuzio, M.; Murino, T.; Sepe, C. An Economic Order Quantity Stochastic Dynamic Optimization Model in a Logistic 4.0 Environment. Sustainability 2020, 12, 4075. [Google Scholar] [CrossRef]

- Di Nardo, M.; Yu, H. Special Issue “Industry 5.0: The Prelude to the Sixth Industrial Revolution”. Appl. Syst. Innov. 2021, 4, 45. [Google Scholar] [CrossRef]

- Nasiri, M.; Ukko, J.; Saunila, M.; Rantala, T. Managing the digital supply chain: The role of smart technologies. Technovation 2020, 96, 102121. [Google Scholar] [CrossRef]

- Williamson, O.E. Markets and Hierarchies: Analysis and Antitrust Implications; The Free Press: New York, NY, USA, 1975. [Google Scholar]

- Wathne, K.H.; Heide, J.B. Opportunism in Interfirm Relationships: Forms, Outcomes, and Solutions. J. Mark. 2000, 64, 36–51. [Google Scholar] [CrossRef]

- Villena, V.H.; Revilla, E.; Choi, T.Y. The dark side of buyer-supplier relationships: A social capital perspective. J. Oper. Manag. 2010, 29, 561–576. [Google Scholar] [CrossRef]

- Dyer, J.H. Effective Interfirm Collaboration: How Firms Minimize Transaction Costs and Maximize Transaction Value. Strateg. Manag. J. 1997, 18, 535–556. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F.; Tan, K.H. Effects of managerial ties and trust on supply chain information sharing and supplier opportunism. Int. J. Prod. Res. 2014, 52, 7046–7061. [Google Scholar] [CrossRef]

- Heide, J.B.; Wathne, K.H.; Rokkan, A.I. Interfirm Monitoring, Social Contracts, and Relationship Outcomes. J. Mark. Res. 2007, 44, 425–433. [Google Scholar] [CrossRef]

- Halaby, C.N. Worker Attachment and Workplace Authority. Am. Sociol. Rev. 1986, 51, 634. [Google Scholar] [CrossRef]

- Iansiti, M.; Levien, R. Strategy as Ecology. Harv. Bus. Rev. 2004, 82, 68–78. [Google Scholar] [PubMed]

| Procedures | Descriptions |

|---|---|

| Selecting the academic database and searching articles | Using the world-renowned academic database Scopus Searching articles using search words related to “digital supply chain” |

| Extracting keyword | Using keywords presented by the author Cleansing keywords to increase accuracy of analysis |

| Building keyword network | Building a two-mode network of article-keyword Building a one-mode network based on co-occurrence Using cosine similarity as an algorithm for transformation |

| Conducting network analysis | Analyzing keyword one-mode network Calculating degree centrality and betweenness centrality Identifying network clusters through community analysis Identifying research trends by analyzing the keyword group |

| Source Title | Number of Articles |

|---|---|

| International Journal of Supply Chain Management | 60 |

| Sustainability | 40 |

| International Journal of Production Economics | 31 |

| Journal of Cleaner Production | 30 |

| International Journal of Production Research | 29 |

| Production Planning and Control | 26 |

| Supply Chain Management | 17 |

| International Journal of Logistics Management | 11 |

| Supply Chain Forum | 11 |

| Technological Forecasting and Social Change | 11 |

| IEEE Transactions on Engineering Management | 10 |

| Industrial Management and Data Systems | 10 |

| Benchmarking | 9 |

| International Journal of Information Management | 9 |

| Journal of Manufacturing Technology Management | 9 |

| Annals of Operations Research | 8 |

| European Journal of Operational Research | 8 |

| International Journal of Physical Distribution and Logistics Management | 8 |

| Keywords | Degree Centrality |

|---|---|

| Big Data | 0.145833 |

| Internet of Things | 0.135417 |

| Globalization | 0.135417 |

| Industry 4.0 | 0.125 |

| Innovation | 0.125 |

| Resilience | 0.104167 |

| E-Commerce | 0.104167 |

| Supply Chain Integration | 0.104167 |

| Information Technology | 0.104167 |

| Internet | 0.104167 |

| Digital Technology | 0.09375 |

| Supply Chain Strategy | 0.09375 |

| Business | 0.09375 |

| Publishing | 0.09375 |

| Blockchain | 0.083333 |

| Digital | 0.083333 |

| Digital Transformation | 0.083333 |

| Sustainability | 0.083333 |

| Additive Manufacturing | 0.083333 |

| Marketing | 0.083333 |

| Smart Manufacturing | 0.083333 |

| Competitiveness | 0.083333 |

| Keywords | Node Betweenness Centrality |

|---|---|

| Supply Chain Integration | 0.130157 |

| Big Data | 0.106023 |

| Information Technology | 0.089664 |

| Innovation | 0.080355 |

| Internet | 0.078466 |

| Globalization | 0.076832 |

| Internet of Things | 0.067257 |

| E-Commerce | 0.067026 |

| Supply Chain Strategy | 0.062592 |

| Industry 4.0 | 0.053164 |

| Resilience | 0.052187 |

| Digital Transformation | 0.052162 |

| Food Supply Chain | 0.050802 |

| Sustainability | 0.048462 |

| Additive Manufacturing | 0.043211 |

| Digital Ecosystem | 0.038675 |

| Blockchain | 0.037176 |

| Collaboration | 0.037022 |

| Digital Technology | 0.035983 |

| Value Chain | 0.035457 |

| Logistics | 0.033814 |

| Marketing | 0.033204 |

| Cluster | Main Keywords | Related Topics |

|---|---|---|

| 1 | Blockchain, Sustainability, Innovation, Disruption Resilience, Transparency | Studies on the need to build a digital supply chain to promote resilience due to increased supply chain disruption Studies to build a sustainable supply chain by applying blockchain technology with high security |

| 2 | Industry 4.0, Digital Transformation, Circular Economy, Artificial Intelligence, Internet of Things | Studies on the background and triggers of supply chain digitalization such as Industry 4.0 and digital transformation |

| 3 | Globalization, Communication, Competitiveness, Supply Chain Strategy | Studies on communication among firms based on digital technology to enhance supply chain competitiveness due to globalization |

| 4 | Supply Chain Integration, Supply Coordination, Collaboration | Studies on promoting collaboration by building a digital supply chain for supply chain integration |

| 5 | Value Chain, Competitive Advantage, Supply Chain Performance | Studies on the performances of digital supply chains |

| 6 | Business Model, Additive Manufacturing, 3D Printing, Process Innovation | Studies on new business models and process innovations through digital manufacturing |

| Keywords | Degree Centrality |

|---|---|

| Digital Technology | 0.256757 |

| Industry 4.0 | 0.243243 |

| Resilience | 0.22973 |

| Innovation | 0.202703 |

| COVID-19 | 0.202703 |

| Digital Transformation | 0.189189 |

| Digital Twin | 0.175676 |

| Sustainability | 0.162162 |

| Blockchain | 0.162162 |

| Disruption | 0.162162 |

| Circular Economy | 0.148649 |

| Coronavirus | 0.135135 |

| Simulation | 0.121622 |

| Artificial Intelligence | 0.121622 |

| Big Data | 0.121622 |

| Risk Management | 0.121622 |

| Data Analytics | 0.121622 |

| Business Model | 0.108108 |

| Pandemic | 0.108108 |

| Resource-Based View | 0.108108 |

| Dynamic Capabilities | 0.108108 |

| Fashion Industry | 0.108108 |

| Smart Contracts | 0.108108 |

| Ripple Effect | 0.108108 |

| Internet of Things | 0.094595 |

| Information Systems | 0.094595 |

| Performance | 0.094595 |

| E-Commerce | 0.081081 |

| Keywords | Node Betweenness Centrality |

|---|---|

| Digital Technology | 0.157578 |

| Industry 4.0 | 0.145707 |

| Digital Transformation | 0.086762 |

| Blockchain | 0.08134 |

| Innovation | 0.079363 |

| Sustainability | 0.076611 |

| Resilience | 0.070143 |

| COVID-19 | 0.052188 |

| Digital Twin | 0.047308 |

| Business Model | 0.046842 |

| Circular Economy | 0.046083 |

| Internet of Things | 0.038434 |

| Big Data | 0.037876 |

| Traceability | 0.034921 |

| Supply Chain Finance | 0.03312 |

| Supply Chain Performance | 0.032956 |

| Logistics | 0.028666 |

| Additive Manufacturing | 0.027834 |

| Artificial Intelligence | 0.026272 |

| Resource-Based View | 0.025894 |

| Systematic Literature Review | 0.02343 |

| Data Analytics | 0.022839 |

| Supply Chain Risk | 0.022554 |

| Dynamic Capabilities | 0.022045 |

| Fashion Industry | 0.021602 |

| Smart Contracts | 0.020747 |

| Disruption | 0.020117 |

| Cluster | Main Keywords | Related Topics |

|---|---|---|

| 1 | Business Model, Supply Chain Integration, Digital Economy | Studies on supply chain integration and new business models using digital technology with the emergence of the era of digital economy |

| 2 | COVID-19, Disruption, Risk Management, Resilience, Viability | Studies on digital supply chain as a strategy to promote supply chain resilience as COVID-19 has increased the supply chain risks |

| 3 | Sustainability, Blockchain, Internet of Things, Artificial intelligence, Big Data | Studies on various digital technologies necessary for building a sustainable digital supply chain |

| 4 | Digital Transformation, Digital Ecosystem, Value Chain | Studies on building a new ecosystem and value change due to digital transformation of supply chains |

| 5 | Collaboration, Dynamic Capability, Performance | Studies on collaboration and dynamic capabilities among firms, which are necessary for building and operating a digital supply chain |

| Main Clusters of Keywords | Related Studies |

|---|---|

| Industry 4.0, Digital Transformation | The mega trends such as that of Industry 4.0 and digital transformation demand digital transformation of supply chains. It is necessary to establish general business strategies for the digital transformation of supply chains and reconsider existing business models and value chains. |

| Supply Chain Integration | Digital supply chains reinforce supply chain integration into a complicated global network beyond simple and linear supply chains. There must be viability as an organic ecosystem beyond simply connecting trade networks among firms with digital technology. |

| Resilience | A digital supply chain ultimately enables real-time end-to-end visibility and improves resilience. Supply chain risk management must be done with a focus on digitalization, especially in view of COVID-19. |

| Digital Technologies | A digital supply chain is not built at once in a short time but must be built by applying, step by step, various digital technologies. Due to the nature of supply chains, performance cannot be easily improved when only focal firms are digitalized. The supply chain must be digitalized overall by digitalizing small and medium-sized firms in the supply chain as well. |

| Author | Number of Articles |

|---|---|

| Ivanov, D. | 10 |

| Kumar, S. | 7 |

| Gunasekaran, A. | 6 |

| Dolgui, A. | 6 |

| Sarkis, J. | 6 |

| Graham, G. | 5 |

| Tsolakis, N. | 5 |

| Queiroz, M.M. | 5 |

| Kolesnikov, A.V. | 4 |

| Ukolov, V.F. | 4 |

| Barykin, S.Y. | 4 |

| Luthra, S. | 4 |

| Srai, J.S. | 4 |

| Holmström, J. | 4 |

| Rai, A. | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyun, J.; Rha, J.S. Review of Research on Digital Supply Chain Management Using Network Text Analysis. Sustainability 2021, 13, 9929. https://doi.org/10.3390/su13179929

Pyun J, Rha JS. Review of Research on Digital Supply Chain Management Using Network Text Analysis. Sustainability. 2021; 13(17):9929. https://doi.org/10.3390/su13179929

Chicago/Turabian StylePyun, Jebum, and Jin Sung Rha. 2021. "Review of Research on Digital Supply Chain Management Using Network Text Analysis" Sustainability 13, no. 17: 9929. https://doi.org/10.3390/su13179929

APA StylePyun, J., & Rha, J. S. (2021). Review of Research on Digital Supply Chain Management Using Network Text Analysis. Sustainability, 13(17), 9929. https://doi.org/10.3390/su13179929