Abstract

Circular economy (CE) is increasingly seen as a promising paradigm for transitioning agri-food systems towards more sustainable models of production and consumption, enabling virtuous and regenerative biological metabolisms based on strategies of eco-efficiency and eco-effectiveness. This contribution seeks to provide a theoretical and empirical framework for operationalizing the CE principles into the olive oil supply chain, that plays a central role in the agroecological systems of the Mediterranean region. A scoping literature review has been conducted in order to identify the available pathways so far explored by scholars for reshaping the olive oil supply chain from a circular perspective. The analyzed literature has been charted on the base of the circular pathway examined, and according to the supply chain subsystem(s) to which it refers. Results are discussed highlighting the main issues, the technology readiness level of the available pathways, the prevailing approaches and knowledge gaps. A synthetic evidence map is provided, framing visually the scrutinized pathways into the Ellen MacArthur Foundation’s CE ‘butterfly’ graph. The work is intended to be a valuable baseline for inquiring how circularity can be advanced in the specific supply chain of olive oil, and which are the strategic opportunities, as well as the barriers to overcome, in order to foster the transition.

1. Introduction

In the context of end-of-life processes for organic waste management, a crucial and impelling challenge is to reshape the agri-food systems, currently operating mainly with a dissipative and wasteful open-ended conception [1], so as to enable virtuous practices of biovalorization grounded on zero-discharge principles, and cyclical and regenerative thinking. While creating new promising value chains, radically new ways of handling organic streams can result in drastic decreases of loss and waste production, inputs requirements, virgin, and non-renewable resources usage, and environmental footprint, according to the principles of circular economy (CE).

On the wave of the growing scholarly attention for this emergent key paradigm, over recent years a number of scientific works based on literature review has arisen in order to examine the adoption of CE models and tools within the agri-food sector [2,3], also on account of the well-established understanding of the latter’s pivotal role for transitioning towards more sustainable futures. Different from previous studies, which examined literature systematically to outline a general framework for the agri-food sector, the present study adopts a scoping review approach to provide specific insights on how CE can be operationalized into a particular agri-food system, i.e., the olive oil supply chain. To the best of our knowledge, this is the first study expressly aimed at framing the viable options for valorizing the organic waste streams related to the olive oil production and consumption system, from a CE perspective.

Olive oil represents a very relevant agri-food system in the Mediterranean region, accounting for 87% of the 11.5 million hectares dedicated to olive trees (Olea europea L.) worldwide, 86.6% of whom is devoted to olive oil supply [4]. The European Union is the world’s biggest producer, consumer, and exporter of olive oil, with Spain, Italy, and Greece accounting together for roughly 66% of the global production [5]. A still geographically localized production has tripled over the last three decades, reaching over 3 million tons of final product delivered yearly, to afford an increasing and globally spread demand, mainly driven by changes in dietary patterns (i.e., the rising attention to health-related issues, and the success of the Mediterranean diet) and pushed by new, non-traditional consumer countries. In the face of novel quantitative and qualitative challenges posed by a growing and evolving market, structural changes have occurred along the whole supply chain towards higher rationalization, product innovations, and greater attention to quality and traceability [6]. Nevertheless, serious environmental challenges remain open and in need of innovative approaches for improving the sustainability of the sector [7]. In fact, it involves resource-intensive activities (in terms of chemical, energy, and water requirements) and generates several by-products and residues, which usually end up as wastes. The waste streams deriving from the milling stage are particularly troubling to manage, being produced in huge amounts on a seasonal base and in a short period of time (typically from October to January) [8], presenting high phytotoxic and polluting properties, and causing severe environmental impacts if inappropriately disposed [9,10].

1.1. The Current State of the Olive Oil Supply Chain’s Organic Waste Streams

Within the three main subsystems in which the olive oil supply chain is structured, from production to post-consumption [11], different types and volumes of organic waste and by-products are generated. Considering the European countries alone, a total amount of about 11.8 million tons of agricultural residue and 9.6 million tons of milling waste are estimated per year [12].

The agro-ecological subsystem, constituted by olive groves cultivation, is responsible for producing tree-pruning residues, namely olive wood, branches, and leaves. Approximately 25 kg of biomass per tree is expected to be collected yearly [13]. Having a low commercial value, those residues are often burned on site in open-air firewalls [10,14], causing not only a loss of valuable low-content moisture biomass, but also direct CO2 releases in the atmosphere. To a lesser extent, they are alternatively used for energy production, for animal feeding, or just landfilled [13].

The by-products of olive oil extraction process generated by the agro-industrial subsystem are solid and liquid olive mill wastes (OMWs), in varying amounts and physiochemical compositions depending on fruit-related factors (e.g., variety or ripening stage of the processed olives) or production year and microbial treatments [8], as well as on the extraction method employed (i.e., traditional discontinuous pressure system and three-phase, two-phase or multi-phase decanter continuous centrifugation cycle). Apart from olive leaves and olive stones, that can be minor agro-industrial by-products (the former resulting from the initial washing phase, the latter obtainable by separation from pulp before or after oil extraction), the main OMWs are the following:

- Olive mill solid or semi-solid waste (OMSW), which is lignocellulosic biomass also including phenolic compounds, uronic acids, and residual oil, consisting in a mixture of crushed olive pulp, skin, stones, and water remaining after oil extraction. While a solid olive pomace is obtained from the pressure and the three-phase extraction methods (respectively, in amounts of 400 and 550 kg ca. per tons of processed olives), a slurry wet pomace, with about 60% of water content, results from the two-phase extraction method (averagely 800 kg/tons of olives). Currently, if not sent to pomace oil extraction facilities, which are not equipped to accept wet pomace by the way, exhausted pomace is commonly destinated to incineration, with consequent loss of organic matter [15]. By mechanically separating the pulp from kernels during the extraction process, the recently introduced multi-phase decanter technology produces two novel by-products: a wet destoned fraction, called patè olive cake, and a dry kernel-enriched fraction [8].

- Olive mill wastewater (OMWW), which is a dark-brown liquid composed by 83–92% of water (vegetative and process water) and for the remaining part by an heterogeneous complex of organic matter constituted by olive oil residues and olive pulp [8,13]. This by-product is generated at the highest rates by the pressure system and above all by the three-phase extraction method (respectively, 600 and 800–950 kg per ton of processed olives), and in drastically reduced quantities (250 kg) by the two-phase extraction method. While containing valuable substances such as mineral nutrients and bioactive molecules, OMWW is also characterized by an high degree of phytotoxicity, important polluting charge, and low biodegradability [16], for which it is known as one of the most harmful effluents in agriculture, and it has been considered and treated for a long time only as an environmental problem and an economic burden, due to its high disposal costs [8,17]. The direct use of this by-product as a water source is limited: in order to be safely utilized in other production cycles, it requires a detoxifying treatment [8].

Downstream of the consumption subsystem, crude or non-edible cooking olive oil are the main organic by-products generated by households, catering businesses, and food processing facilities. Waste cooking oil (WCO), deriving from vegetable oils used at high temperatures for preparing or frying food, represents a low- or negative-value hydrophobic material that contains undesired substances, harmful for both the environment and human health [18]. Often discharged through public sewerage system, this oily waste also increases the operating costs of wastewater treatment [19].

On account of current domestic and industrial practices, waste cooking oils (WCO) are generated in high and increasing volumes: about 1 million tons of WCO has been estimated to be produced by European countries per year [18]. An important fraction of such waste is represented by used olive oil, since European Union accounts alone for around 53% of word olive oil consumption, with Italy and Spain being the biggest consumer countries [5].

On the consumption side, another kind of non-organic waste is constitute by olive oil packaging, that can be represented by glass or plastic bottles, metal cans made of steel, or metal spray mainly made of aluminum [20].

1.2. An Alternative Approach for a Sustainable and Efficient Management of Olive Oil Supply Chain’s Waste and By-Products

There is rising awareness of the biological and economic value of olive oil waste and by-products as resources to be recovered in a circular and regenerative perspective. Circular economy is increasingly seen as a winning model to properly approach and address olive oil waste management [21], beyond the business-as-usual “take-make-dump” scheme. As noticed by some authors [22], the paradigm of CE, being a resource-oriented model of economic production and consumption that puts forward the environmental sustainability, usually unaccompanied by social issues, is epistemologically narrower than the one of sustainable development, which is based on multi-dimensional notions of sustainability and on inter-generational equity (whose implementation, by contrast, has been often framed within a linear thinking). However, the CE perspective offers valid operative visions and solutions for reaching tangible objectives of long-term sustainability, notably in a context of shrinking resources even more undermined by the effects of climate change and, becomes a promising tool of sustainable development especially for overcoming the drawbacks of the conventional linear model. Besides, being mainly defined at the micro-level and focused on the design of innovative business models, CE appears to be more capable: (i) to outline feasible ways for internalizing environmental and health-related external costs, while creating value added; (ii) to “operationalize the concept of sustainable development for business activities” [23]; and (iii) to enable the development of contracts “that can better align incentives and lead to more eco-efficient uses of resources” [22].

However, innovative valorization patterns, entrepreneurial initiatives, and policy efforts in this regard within the olive oil sector have been so far quite limited, and the great potential of making the most of the overall available biomass, generating environmental benefits and creating new economic opportunities at the same time, is still under-exploited [16].

The purpose of this study is to inquire how CE has been so far approached and declined specifically into the olive oil supply chain in order to establish both an analytical and operative background useful for designing transition trajectories, as well as to identify little-explored issues and knowledge gaps. In particular, the study aims to: (i) identify and featuring a descriptive overview; (ii) map available evidence on the possible conversion and valorization pathways (theoretical or applied solutions) that are acknowledged for implementing circularity in the olive oil supply chain (i.e., closing/narrowing/slowing loops, or transforming second raw materials into new resources of greater value for other production cycles in a bioeconomic perspective). The identified circular pathways are meant as virtuous ways of handling bioresources that lead to: (i) minimize the production of disposable waste; (ii) optimize the use of the available internal resources, also for lowering the resorting to external, non-renewable inputs; (iii) enhance the efficiency of the whole agri-food system, (iv) create new value chains by converting under-valorized by-products into valuable resources; (v) enable regenerative and restorative metabolic ecologies.

2. Materials and Methods

To identify the existing circular pathways, a scoping literature review has been conducted. Scoping review is a method of knowledge synthesis valid for addressing a broad, exploratory research question in an emerging or not yet comprehensively reviewed field of inquiry, and thus determining the available range of evidence, with the purpose of “informing practice, programs, and policy and providing direction to future research priorities” [24]. Scoping studies adopt a systematic approach to map rapidly the literature coverage, main concepts and issues, evidence types and gaps on a given topic, especially from a large and heterogeneous body of knowledge [25]. Since the purpose of the method is the reconnaissance of the boundaries and key elements underpinning a research area—rather than a critical summary of “the best available research on a specific question” as for systematic reviews [26]—a formal assessment of methodological quality and risk of bias of the literature reviewed is not required.

Following the methodological framework firstly outlined by [27] and integrated by others [25,28], the protocol adopted for carrying out the scoping review has been based on five key-steps: (1) defining the research question, (2) identifying relevant studies through a search strategy, (3) selecting studies basing on eligibility criteria, (4) charting the data, and (5) collating, summarizing, and reporting the results.

The main research question guiding the review was formulated as the following: ‘Which are the pathways for implementing circular economy into the olive oil supply chain already available and acknowledged by scholars?’.

According to the guidelines for scoping reviews, the reference query for selecting the literature was defined so as to be as inclusive and open as possible, consistently with the aim of inquiring how circular economy has been so far embodied specifically into the olive oil sector, from a research perspective. The search terms were identified in order to cover all the research fields and the supply chain stages potentially involved in the implementation of circular principles. The simple combination of keywords ((oliv*) AND (circular* AND econom* OR CE)) was applied to the titles, abstracts and keywords present on Scopus and Web of Science (last accessed on 21 April 2021). The two databases chosen for locating relevant studies are the main accredited sources of scholarly literature.

The studies selection process was performed according to PRISMA protocol (Figure 1). The initial search returned 114 results from Scopus, and 97 from Web of Science, and no filters, such as date range or document type, were used to narrow down the outcomes. After having removed the duplicates, over all 132 studies left.

Figure 1.

PRISMA flowchart of the studies selection process for scoping review.

The relevance and pertinence to our domain of interest of the gained documents were checked by screening all the titles, keywords, and abstracts, based on the guiding question if each study address, or is related to, the application of circular economy principles or the development of circular economy models into the olive oil supply chain. When not clear from abstract, the full text has been retrieved and rapidly read. During the abstract screening, an initial list of the emerging circular pathways (theoretical or applied) was compiled.

After the exclusion of 21 non-applicable items, 111 reportable documents were assessed for eligibility. Then, full texts were retrieved and read in order to verify their specificity to the research question. During the assessment process 10 more items were eliminated, because not directly addressing CE-based approach into the olive oil supply chain. At the end, 101 relevant studies were included for the review.

The data were charted by creating and classifying the database on a spreadsheet (including authors, titles, date of publication, abstracts, link to full-text) and classifying them according to: (i) the study approach, (ii) the type(s) of waste or by-product of the olive oil supply chain considered, (iii) the valorization output(s), (iv) the conversion technology, (v) the pertaining circular pathway recognizable, (vi) the extremes of the pathways (i.e., the departing and destination internal chain stage or external sector involved in the valorization process). The circular pathways were recognized and outlined by the authors of this study, and not explicitly declared within the reviewed studies. The initial list drafted during the screening phase was integrated and redefined, also by bringing together similar pathways. Minor disagreements among authors about the final definition of the pathways and the ascription of the relating literature were resolved through discussion.

3. Results

A descriptive analysis of the volume, origin, subject area, topics covered, scope, and types of evidence, and leading approaches of the literature has been undertaken, and presented in this section, followed by a brief description of each circular pathway found out. As suggested by the PRISMA extension for scoping review [25]—that recommend to present the mapped evidence in an agile communicative format, such as a visual, diagrammatic or logical representation—the charted circular pathways have been lastly framed within the well-known butterfly graph developed by the Ellen MacArthur Foundation [29].

3.1. Descriptive Analysis of the Selected Body of Literature

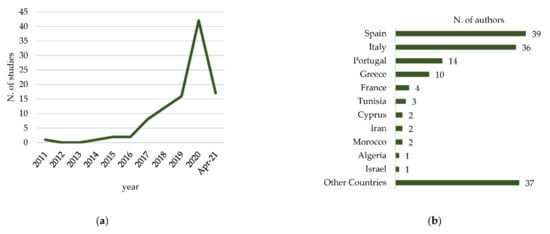

The publication timeline (Figure 2a) shows a recent but growing interest on the considered field of inquiry among scholars. Although the first study specifically focused on olive oil supply chain in the realm of CE came out in 2011, followed by a second one in 2014, and another two in 2015, the bulk of items were published during the last three years (70 works issued between 2018 and 2020), with the highest score reached in 2020 (42 items). The increasing tendency seems to be confirmed, since 17 studies came to light just in the first quarter of 2021. The prominence gained by the new conceptual model still under development into the public discourses and policy agendas, especially within the European Union—starting from the first Action Plan for Circular Economy released in 2015 [30]—undoubtedly contributed to make circular economy a trendy topic, even more explored by researchers.

Figure 2.

Distribution of studies included in the scoping review by year of publication (a) and of the related authors by country of origin (b). The group ‘Other Countries’ include the ones outside the Mediterranean region: Belgium, Ireland, United Kingdom, Canada, Denmark, Netherlands, Poland, Saudi Arabia, South Korea, Sweden, Brazil, Chile, China, Colombia, Czech Republic, India, Malaysia, Mexico, Oman, Pakistan, Serbia, Ukraine, United States, and Vietnam.

The main area of origin of the selected literature (Figure 2b) coincides with the Mediterranean countries in which olive oil production is most economically relevant, with authors from Spain and Italy covering alone half of the total (respectively, 39 and 36 out of 101), followed to a lesser extent by scholars from Portugal (14) and Greece (10).

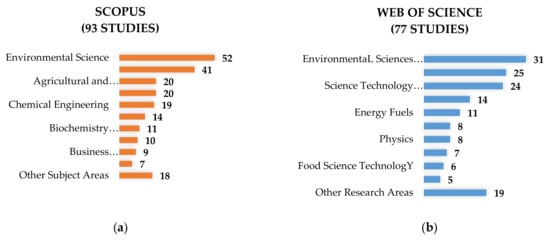

As for the most involved research fields, Environmental Science is reported as the leading subject area in the ranking systems of both questioned databases (Figure 3), followed by Energy, Agricultural and Biological sciences, Engineering, and Chemical Engineering with regard to Scopus’ classification; similarly, by Engineering, Science Technology, Chemistry and Energy Fuels with respect to Web of Science’s categorization. Such overview suggests that technical or technological solutions in addressing CE-based models prevails. In fact, only a few works cover organizational or economic-related research areas—such as Social Sciences or Business, Management and Accounting—reflecting the circumstance that innovation in business model design or sustainable chain management, which are crucial for driving systemic transition, are still under-explored issues.

Figure 3.

Distribution of studies included in the scoping review, by Subject Area of SCOPUS database (a), and by Research Areas of WEB OF SCIENCE database (b). Other Subject Areas (SCOPUS) include Physics and Astronomy; Computer Science; Earth and Planetary Sciences; Immunology and Microbiology; Mathematics; Nursing; Pharmacology Toxicology and Pharmaceutics; Economics Econometrics and Finance; Health Professions; Multidisciplinary. Other Research Areas (WEB OF SCIENCE) include Metallurgy Metallurgical Engineering; Nutrition Dietetics; Water Resources; Biotechnology Applied Microbiology; Pharmacology Pharmacy; Life Sciences Biomedicine Other Topics; Meteorology Atmospheric Sciences; Plant Sciences; Veterinary Sciences.

Much of the analyzed literature focus on the by-products generated from the agro-industrial subsystem: 38 studies deal with olive mill solid waste (olive pomace, olive cake, destoned olive pulp), 23 take into account olive mill wastewater, nine consider olive stones (retrieved after treating olive pomace), and eight olive leaves (resulting from the initial washing phase). Lesser works deal with the biomass produced within the agro-ecological subsystem: 16 of them address the valorization of olive tree pruning residues (two of which focusing specifically on olive leaves from olive farming). Only four studies consider waste cooking oil as second raw material to be converted into new resources. The sum of these numbers is higher than the total amount of the reviewed works, since some studies consider more than one by-product at a time.

As for the proposed solutions, most studies propose recycling solutions at the milling stage; only a few goes through agricultural practices, while consumption is quite neglected and marginally considered. Indeed, consumption subsystem is mainly explored in relation with consumers’ acceptance of nutraceutical/pharmaceutical application of OMW-derived bioactive compounds, reusing olive mill by-products for animal feeding, and consumers’ perception of packaging sustainability and eco-labels.

Many studies perform biochemical analysis of OMWs in order to characterize the composition and properties of the starting biomass or the derivable output(s)—which is a step of paramount importance for properly valorizing waste streams and introducing valuable inputs into the production cycle [8]—or even to assess the performance and suitability of a conversion technology.

3.2. Overview of the Identified Circular Pathways and Literature Coverage

The available circular pathways related to the olive oil supply chain that have been found out through the literature review are listed in Table 1. Consistently with the aim of the work, the table has been organized per pathways, even though each one can be operationalized recurring to different processes and technologies. A total of 11 circular pathways have been identified, while the last row of the table gathers a miscellanea of 12 works that do not address a specific way to recover and valorize organic waste streams from the olive oil supply chain, but rather inquire other important aspects for driving transition towards a circular model for the considered agri-food system.

The circular pathways (CPs) are reported in decreasing order of numerosity of the associated publications—which are instead ordered alphabetically basing on first author’s name. In doing so the most considered and explored pathways among scholars are ordered, which makes evidence of their degree of establishment within the emerging theoretical framework. Borrowing the two dimensions applied by [31] for keyword-based analysis, the dominance and persistence of the recognized pathways can be outlined. The former is measured in terms of frequency (namely, the number of articles that explored a given pathway), and the latter in terms of continuity over time (that is, the number of years covered by afferent publications).

The first two CPs reported in Table 1 are the most dominant within the considered literature, given that they are investigated by the largest number of studies (respectively, scoring 24 and 23 out of 101 works, while the third CP only counts eight). Although the body of literature is quite recent and a timeline-based assessment cannot be corroborated, almost all CPs also show a good persistence over time. Since the two most investigated CPs (N. 1 and N. 2) also cover an enduring publication timespan (from 2016 to 2021), we can consider them as the core research areas. Pathways number 4, 6, 8 and 10 are newly emerging, since the related studies arose mainly from 2019 (with one publication dating back to 2018 just in the case of CP N. 6, and all the ones dating from 2020 in the case of CP N. 4). The less dominant pathway (N. 11, to which just 2 works refer), appears intermittently but is not likely to be neglected, having the first been published in 2017, and the last in 2020.

Table 1.

Overview of the identified circular pathways and related literature.

Table 1.

Overview of the identified circular pathways and related literature.

| ID | Name of the Pathway | No. of Studies | List of the Studies Related to Each Pathway |

|---|---|---|---|

| #1 | High-added value bioactive compounds recovery from olive mill waste, olive leaves or waste cooking oil | 24 | Ben Harb et al. 2020 [32]; Blasi & Cossignani 2020 [33]; Castro-Munoz et al. 2018 [34]; Chebbi et al. 2021 [35]; Cifuentes-Cabezas et al. 2021 [36]; Cristóbal et al. 2018 [37]; del Pozo et al. 2018 [38]; Leite et al. 2020 [39]; Lopes et al. 2019 [18]; Luzi et al. 2021 [40]; Mallamaci et al. 2021 [41]; Mapelli et al. 2019 [15]; Markhali et al. 2020 [42]; Martínez-Beamonte et al. 2020 [43]; Mirabella et al. 2014 [44]; Nikkhah et al. 2021 [45]; Nunes et al. 2020 [46]; Ochando-Pulido & Martínez-Férez 2017 [17]; Ochando-Pulido et al. 2017 [47]; Ochando-Pulido et al. 2020 [48]; Romani et al. 2016 [49]; Romani et al. 2019 [50]; Romani et al. 2020 [51]; Serrano et al. 2017 [52] |

| #2 | Biofuel production from pruning residues and/or olive mill wastes, or waste cooking oil | 23 | Aguado et al. 2021 [53]; Cavalaglio et al. 2020 [54]; Costa et al. 2019 [55]; Costa et al. 2020 [56]; de la Torre Maroto et al. 2020 [57]; Fragoso et al. 2019 [58]; Hermoso-Orzáez et al. 2020 [59]; Hermoso-Orzáez et al. 2020 [60]; Lago et al. 2018 [61]; López-García et al. 2018 [62]; Meena et al. 2020 [63]; Molina-Moreno et al. 2016 [64]; Nunes et al. 2020 [65]; Nunes et al. 2020 [66]; Palchetti et al. 2019 [67]; Palmieri et al. 2020 [68]; Puig-Gamero et al. 2021 [69]; Sánchez-Sánchez et al. 2020 [70]; Spyridonidis et al. 2020 [71]; Tapia-Quirós et al. 2020 [72]; Torrisi et al. 2018 [73]; Tsoutsos et al. 2019 [19]; Valenti et al. 2020 [74] |

| #3 | Olive mill waste reused as component in the manufacture of sustainable building materials | 8 | Díaz-García et al. 2017 [75]; Font et al. 2020 [76]; López-garcía et al. 2021 [77]; Moreno-Maroto et al. 2019 [78]; Spiliotis et al. 2019 [79]; Spiliotis et al. 2020 [80]; Terrones-Saeta et al. 2021 [81]; Uceda-Rodríguez et al. 2020 [82] |

| #4 | Olive mill wastewater reused for soil conditioning/fertilization/irrigation | 6 | Almeida et al. 2021 [83]; Bargaoui et al. 2020 [84]; Domingues et al. 2020 [85]; Magdich et al. 2020 [86]; Ramires et al. 2020 [87]; Zerva et al. 2020 [88] |

| #5 | Pruning residues and/or olive mill waste valorized for regenerative agriculture | 6 | Aleandri et al. 2015 [89]; Bechara et al. 2018 [90]; Delgado-Moreno et al. 2017 [91]; Estrella-González et al. 2020 [92]; Michalopoulos et al. 2020 [10]; Romero et al. 2017 [93] |

| #6 | Biochar (bio-oil, syngas) production from olive mill waste and/or pruning residues | 6 | Casson Moreno et al. 2020 [14]; Esteves et al. 2020 [94]; Gomez-Martin et al. 2018 [95]; Kostas et al. 2020 [96]; Photiou et al. 2021 [97] |

| #7 | Olive leaves or olive cake reused for animal feed | 4 | Branciari et al. 2017 [98]; Garcia-Rodriguez et al. 2019 [99]; Proietti et al. 2018 [100]; Viti et al. 2021 [101] |

| #8 | Polymeric biomaterials production from pruning residues, olive mill by-products or waste cooking oil | 4 | Kuranska et al. 2019 [102]; Sánchez-Gutiérrez et al. 2020 [103]; Talan et al. 2020 [104]; Teigiserova et al. 2019 [105] |

| #9 | Olive mill waste recycled as bio-adsorbent material for treating aqueous effluents | 3 | Abu Tayeh et al. 2020 [21]; Angosto et al. 2020 [106]; Vilardi et al. 2018 [107] Zabaniotou et al. 2015 [108] |

| #10 | Biofertilizers or biostimulants and biopesticides production from olive mill waste | 3 | Diacono et al. 2019 [109]; Sciubba et al. 2020 [8]; Tallou et al. 2021 [110]; |

| #11 | Treated urban/industrial wastewater reused for agricultural purposes | 2 | Mininni et al. 2020 [111]; Pirrera & Pluchino 2017 [112] |

| n.a. | Miscellanea: collection of studies that are not focused on a specific pathway | 12 | Attard et al. 2020 [113]; Berbel & Posadillo 2018 [12]; Boesen et al. 2019 [20]; D’Adamo et al. 2019 [114]; Donner & Radić. 2021 [16]; Galati et al. 2018 [9]; Gómez et al. 2020 [115]; Hamelin et al. 2019 [116]; Khounani et al. 2021 [7]; Kosseva 2011 [117]; Pérez et al. 2021 [118]; Raimondo et al. 2021 [119] |

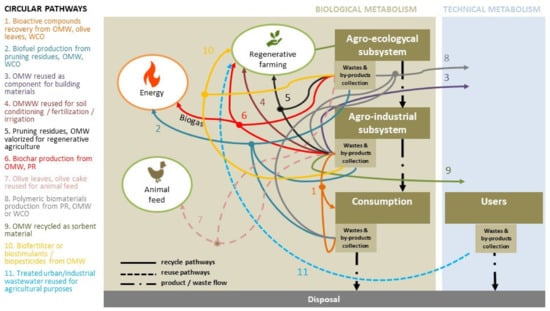

In order to provide a visual evidence synthesis, the scrutinized pathways have been graphically framed into the butterfly diagram of circular economy (Figure 4) adapted from [29]. The Ellen MacArthur Foundation distinguishes the ways circular economy works in practice into two main cycles: the biological one, related to bio-based biodegradable raw materials, and the technical one, concerning man-made materials that can be hazardous if improperly released into the biosphere. As may be expected, most of the CPs fall within the left side of the graph, which pertains to the biological metabolism. Questioning the rigid separation between biological and technical cycles claimed by [29], pathways number 3, 8 and 9 end up into the right side of the graph, being respectively the building industry, biopolymers production, and treatment of aqueous effluents the destinations of olive oil by-products recycling. Only one pathway (N. 11) involves the reuse of an output of technical cycles (treated wastewater) for agricultural purposes, thus tracking a route from the right to the left side of the diagram.

Figure 4.

Butterfly diagram of the available circular pathways for the olive oil supply chain (our own elaboration, adapted from [29]).

3.3. Available Circular Pathways

This section provides a descriptive overview of the possible conversion pathways identified through the scoping literature review.

3.3.1. High Value-Added Bioactive Compounds Recovery from OMW, Olive Leaves or Waste Cooking Oil

Most of the works (24 out of 101) deal with the recovery of the valuable biomolecules of which olive fruits are naturally endowed (for 1–2% of their weight) and that are lost in large part into OMWs during the oil extraction process, for enabling their conversion into high value-added substances. The derivable bioactive compounds are particularly relevant for human health [50] and they can find interesting applications in bioeconomic sectors such as functional food, nutraceutical, biomedical, pharmaceutical or cosmetic, also as safer substitutes of synthetic equivalents [42]. Less explored possible applications are in building industry, such in the case of dried olive leaves extract used as a corrosion inhibitor in reinforced concrete [32].

The largest part of the recoverable molecules from OMW is constituted by polyphenols, 98% of whose fruit content ends up in olive mill wastewaters or olive pomace [15], and other minor components such as phytosterols, tocopherols, and squalene [50].

The molecules extraction from OMWs occurs mainly by means of physicochemical procedures (with use of organic solvents such as methanol, dichloromethane, ethyl acetate and hexane) or of new, more sustainable physical techniques based on membrane technologies, such as microfiltration, ultrafiltration, nanofiltration [34] or reverse osmosis [8], eventually followed by quick centrifugation [47]. Membrane technologies are already implemented at industrial level, defined as Best Available Technology, and recognized by the Environmental Protection Agency [52]. Other novel green processes are currently under development and testing, such as: microwave or ultrasound assisted recovery of phenolic compounds from olive pomace, whose eventual upscaling should be assessed basing on extraction performance, investment and operational costs [72]; weak-base ion exchange resins applied to olive mill wastewater for concentrating and retrieving phenols, while optimizing the integral treatment of the effluent [48].

The very appreciable market price of the extractable substances makes the activation of such new promising value chains a potential leverage for enhancing the economic sustainability of the milling industry [15]. However, it should be taken into account that the molecules content in the extracts can change according to factors such as the processed olive variety and ripeness level, and the pedo-climatic conditions [72].

3.3.2. Biofuel Production from Pruning Residues and/or Olive Mill Wastes, or Waste Cooking Oil

The second most investigated route, addressed by 23 studies out of 101, focuses on the exploitation of olive tree pruning biomass, olive oil industry by-products, or olive oil post-consumption waste for energy production (heat, electricity, or biofuel), that currently represents the best-established valorization option.

A wide range of conversion technologies are available for energy valorization of the olive oil sector by-products, with different possible outputs. The existing literature explores the opportunities of producing: syngas, to obtain electrical and thermal energy, by feeding a heat and power biomass plant with olive pomace [55,56,57], olive stones [59,60,62], or olive tree pruning residues [54,61]; electric energy [68] through the combustion of pruning residues; methanol from olive pomace via gasification [69], or from OMW via anaerobic digestion [58,70]; biogas by means of anaerobic digestion of olive pomace [67,74] or OMWW [71]; biofuel—as a sustainable alternative of biofuels based on specialized grown crops [21]—obtained from pruning residues combustion [64], from solid part of olive pomace gasification [73], or from waste cooking oil through homogenously catalyzed esterification [19]; combustible products from olive pomace (torrefied biomass or charcoal obtained, respectively, through torrefaction or slow pyrolysis processes) as sustainable substitutes of fossil fuels, such as coal [46,65].

The most proposed and technologically ready technology is gasification. Gasification plants can be installed at the olive oil mills in self-consumption mode, in order to reduce the electricity costs. This solution require regular maintenance, then enabling “the creation of a permanent part-time technical job” [53]. Presenting a high content of carbon and hydrogen, and conversely a low level of ash and moisture, with a considerable heating value, exhausted olive pomace is considered to be the most appropriate olive oil by-product for feeding the gasifier plants [53], also thanks to its massive production rate and thus high-volume availability. However, due to the small size of olive pomace’s raw particles, pelletizing it in advance is preferable to a direct use (ibidem).

Thermochemical processes, such as torrefaction and pyrolysis, also can function as pre-processing treatments before applying other conversion technologies [65].

Biochemical conversion processes mainly operated recurring to anaerobic digestion.

3.3.3. Olive Mill Waste Reused as Component in the Manufacture of Sustainable Building Materials

An emerging route for valorizing the by-products of the milling industry, explored in 8 studies out of 101, is their employment for manufacturing greener structural materials for the construction industry.

The possible incorporation of olive pomace into clay bodies for developing eco-friendly ceramic materials has been positively assessed [75,80], although results from a Life Cycle Assessment (LCA) indicate that associated environmental benefits are very limited [77]. Biomass bottom ash deriving from the combustion of olive cake or olive pomace together with almond shell can act as alkaline activator to develop chamotte-based geopolymers as substitutes for ceramic bricks [81]. Olive mill wastewater can replace fresh water, conventionally mixed with ceramic clayey raw materials, for developing building bricks with improved thermal insulation capability and reliable mechanical behavior [79].

Other authors [78,82] investigate the utilization of olive pomace as component for producing artificial lightweight aggregates.

Lastly, the employment of olive stones biomass ash as alkali source for manufacturing a novel one-part eco-cellular concrete has been studied [76].

The reviewed literature points out the technical feasibility and economic viability of this kind of OMW application, although suggesting to add olive pomace in low proportions (a maximum of 2.5% in the case of lightweight aggregates [78] and of 3% in the case of clay bodies [75]) for preserving the materials’ density values. Moreover, the studies highlights that the high calorific value of olive pomace incorporated in alternative building materials can contribute to improve energy savings.

3.3.4. Olive Mill Wastewater Reused for Soil Conditioning/Fertilization/Irrigation

A less explored pathway, addressed by six studies out of 101, concerns the agronomic application of olive mill wastewater, that can play a crucial role in regenerative farming practices.

This aqueous effluent can be spread on olive orchards as a low-cost soil conditioner and fertilizer. In particular, an experimental study demonstrates its positive effects also on olive production and oil quality [86].

Furthermore, treated olive mill wastewater can be beneficially utilized for irrigation purposes. From an agronomic point of view, the reuse of treated OMWWs is a strategic opportunity considering that most olive oil producer countries suffer from water deficit [120]. Various treating techniques have been investigated. First, a combination of impregnation onto raw cypress sawdust followed by electrocoagulation with mild steel electrodes is an efficient solution to remove chemical oxygen demand (COD) while improving organic and mineral contents [84]. Second, a low-cost aerobic treatment for bio-detoxifying OMWW in situ on industrial scale, without pre-treatment or supplementation, by using selected degrading microorganisms (yeasts and bacteria) to reduce antimicrobial and phytotoxic properties [87]. Other tested techniques are the enzymatic pretreatment for removing phenolic compounds [88], and the heterogeneous Fenton process [85].

3.3.5. Pruning Residues and/or Olive Mill Waste Valorized for Regenerative Agriculture

Only a few studies (6 out of 101) go through the valorization of organic waste recovered from the production and processing phases for agricultural purposes, in an effort to enable regenerative metabolisms in which nutrients and organic matter are looped back into the biosphere, and the agro-environmental systems are sustainably managed (e.g., mulching with pruning residues). If properly performed, pruning itself is a practice that help to increase the efficiency of inputs such as water, fertilizers, or labor [10]. According [10] pruning residues bring to the soil the highest carbon content, while compost provides the greater supply of nitrogen, phosphorus and potassium. Field studies [10] have proven that recycling without supplementary inputs improves or stabilize olive yields and soil fertility, reducing the carbon-environmental footprint of production activities and “enhancing the agroecosystem resilience”. [89] explores the feasibility of a close-cycle olive trees nursery system, consisting in producing on farm renewable organic compost from the crop residues (mowing and pruning) of nursery activities, to partially substitute peat (15% to 30%) in the mixed substrates used for growing new olive pot plants, propagated from cuttings.

Composting is considered as one of the most important systems for sustainably managing biological waste streams [121], but it is essential to obtain a high quality, stable and mature compost in order to avoid the release of toxic substances, immobilize nitrogen in the soil and inhibit plant growth [92]. Solid olive mill by-products can be combined in various mixtures and proportions with other elements (i.e., with manure and olive leaves or straw, as suggested by [92]).

Finally, it is worth mentioning that industrial composting processes have a high degree of technological readiness and, are mainly based on open air turned windrows.

3.3.6. Biochar (Bio-Oil, Syngas) Production from Olive Mill Waste and/or Pruning Residues

The sixth pathway found out, explored by six works out of 101, focus on the production of biochar from agricultural residues and/or mill by-products. The biochar is a very interesting output of processes of pyrolysis, which offers a very important and yet unknown potential for farmers. Due to its macroscopic structure and composition, it acts as an amendment to the soil, returning the carbon captured by olive trees to the soil and providing numerous benefits in terms of plant growth, water and nutrients retention, soil erosion contrast, microbial life improvement [53]. Moreover, it constitutes a good “remediation co-product for very old plantations” [108]. However, the biochar properties are mainly dependent on the chemical and physical characteristics of the original feedstock from which it derives, and on the temperature reached in the conversion processes.

Other possible applications suggested are the utilization of the biochar as adsorbent for removing phosphate from wastewaters [97], or as catalyst for Fenton-like treatment of olive mill wastewater [94].

Besides pyrolysis-based systems, the biochar can be obtained from biomass gasification at high temperatures (>700 °C), by means of microwave heating [96], or from a novel technology that integrates pyrolysis with downstream post-catalytic reforming of its volatile products: thermocatalytic reforming (TCR) process [14].

The char has a very attractive market price and can be coupled with bio-energy production. Among crucial aspects to ensure the economic viability of biochar production, [108] suggest the closeness of the conversion facilities to the feedstock catchment (i.e., symbiosis of pyrolysis reactor with olive mill) to cut logistic costs, as well as and transport-related CO2 emissions.

3.3.7. Olive Leaves or Olive Cake Reused for Animal Feed

Olive leaves or solid mill wastes can be fruitfully used in animal feeding experimental studies [98,99,100,101] have shown the beneficial role of dietary administration of such by-products due to their antioxidative properties for poultry industry. In particular, ref. [100] studies the beneficial effect of using as sheep feeding the pruned olive leaves treated with inorganic selenium for reducing the stress caused by drought in trees, which acts also as organic source of selenium.

3.3.8. Polymeric Biomaterials Production from Pruning Residues, Olive Mill By-Products, or Waste Cooking Oil

This promising albeit underexplored pathway involves upcycling processes perfectly ascribable to a bio-economy scenario, referring to the production of high value-added cellulosic biopolymers. [103] focus on the possibility of deriving cellulose nanofibers (CNFs) from olive tree pruning biomass, as a sustainable alternative to virgin lignocellulosic sources. The innovative extraction process of nanofibrillation—consisting in defibrating cellulosic pulp to the nanometric level in a high-pressure homogenizer—following mechanical pretreatment and TEMPO-mediated oxidation, allows to obtain an advanced material that presents outstanding morphological, physical, and chemical properties as against those of conventional cellulose, with a wide range of applications in different sectors.

A second interesting avenue consists in synthetizing bio-components for the production of bioplastic from olive tree pruning residues and olive pomace [109] or from waste cooking oil [104], that can substitute petroleum-based polymers. Also, industrial application of used cooking oil collected from restaurants, as a valid alternative to virgin vegetable oil for developing bio-polyol has also been positively evaluated [102].

Another option proposed by [81] is combusting olive cake or olive pomace together with almond shell to obtain an alkaline activator from biomass bottom ash, to develop chamotte-based geopolymers, as substitutes of traditional ceramics for brick manufacture.

3.3.9. Olive Mill Waste Recycled as Bio-Adsorbent Material for Treating Aqueous Effluents

The olive mill waste could be recycled as bio-adsorbent. [21] proposes the utilization of the hydrolysate solids of the three-phase OMSW subjected to enzymatic saccharification—separated through vacuum filtration from the liquid fraction, that can be used for ethanol production—as a sorbent for diluting or removing heavy metals, also in low concentrations, from industrial wastewater. This technological solution could be applied where other treatments such as filtration, reverse osmosis, extraction, chemical precipitation, and others, result expensive or less effective. [106] suggests the utilization of olive mill residues, among other agri-food wastes, as sorbents of diclofenac present in aqueous effluents.

3.3.10. Biofertilizers or Biostimulants and Biopesticides Production from Olive Mill Waste

This pathway draws the opportunities for an agronomic exploitation of OMW. Natural OMW-derived bioactive molecules can be employed for producing plant biostimulants and biopesticides for sustainable integrated management of growth promotion and phytopathogens control. They can replace chemical counterparts, although their effectivity against severe plant diseases, and the opportunity of large-scale applications should be better characterized through more extensive field research [8].

3.3.11. Treated Urban/Industrial Wastewater Reused for Agricultural Purposes

The less explored pathway focuses on recovering for agricultural purposes water resources, whose lack represents a crucial issue especially in Mediterranean countries facing desertification processes. Among other sustainable management practices, drip irrigation of olive orchards with urban wastewater is proposed by [111] as a mean to address soil restoration, as well as to improve plant status and product quality. Natural depuration systems of polluted river, rain and industrial wastewater based on phytoremediation and bio-ponds can be integrated in agricultural landscape and used for fertigating olives and other fruit trees [112].

4. Discussion

The results reveal that technological solutions are broadly predominant in the considered body of literature, as the bulk of the works focus on possible technologies or technical practices for recovering and utilizing the waste streams produced within the olive oil supply chain. Only a few studies slightly consider some market aspects, while other key-dimensions of transition trajectories [11] are disregarded. Indeed, very marginal attention is paid to the design of innovative CE-based business models (micro-level, at the business stage) [9], to coordination challenges (meso-level, looking at the whole agri-food system) or to policy and/or regulatory issues. Besides, valorization pathways and related novelties are mostly explored at theoretical level, or within techno-economic feasibility studies, most of which aim at characterizing the physio-chemical composition of the claimed waste materials and/or of the new product(s) obtained, or at assessing the performance of a specific conversion process or technology. The shortage of real case-studies suggests that the application of circular solutions among the firms in the olive oil supply chain is still in its infancy. Incidentally, [9] pinpoint a limited diffusion of innovations related to environmental management among the businesses operating in this supply chain, thus determining higher operational and transitioning costs, and a low level of competitiveness, both in terms of “organizational efficiency” and of “external legitimacy”.

Among the available circular pathways, recycling systems are much more considered than solutions based on reusing resources, as a consequence downcycling is more explored than upcycling. The reviewed studies approaching CE seem to be still widely embedded in an efficiency-oriented approach, rather than being committed to an eco-efficacy perspective.

The only pathways seeking to transform waste materials into new products of greater quality and economic value are N. 1 (high value-added bioactive compounds recovery from OMW, olive leaves or WCO), N. 8 (polymeric biomaterials production from pruning residues, OMW or WCO), and N.10 (biofertilizers or biostimulants and biopesticides production from OMW).

It is worth mentioning that the two most explored pathways are those placed at the extremes (top and bottom) of the value pyramid conceptualized by [12]. The latter is a useful evaluation tool to assess which valorization option should be prioritized for the organic waste from olive oil supply chain, especially under conditions of competitiveness between different uses of the available second raw material. According to the authors, the value of the biomass is determined by its application and descends from high-value uses related to the utilization of bioactive components extracted in pharmaceutical or cosmetic industries, or as functional components to improve human food, to medium-value uses for animal feed, to low-value uses as sources of biofuel, compost or energy. In this perspective, energy recovery stands out as a valuable end-of-life option only when biomaterials cannot practically or economically meet alternative uses or disposals apart from landfilling. Besides, among other necessary conditions for considering the energetic valorization route as a tile of a circular strategy, [122] argue that energy recovery should be optimized, and that also the conversion of by-products (e.g., digestate) should be safe and biologically beneficial for the ecosystems in which they are received.

In order to maximize the life cycle, the reachable value and the economic viability of biomass circular recovery, some conversion solutions can be profitably combined in subsequent processes within an integrated valorization pathway (such as obtaining sorbents after ethanol production from OMSW), especially when the commercial value of the conversion output is low (as for biofuels) and its production is economically limited. Very promising is the biorefinery model, that enables the optimal use of all biomass components integrating different conversion processes [37], first isolating the most valuable parts that can be converted into higher quality products that are also economically more rewarding, and then using residual material for lower value applications. Economies of scope can be realized by cascading production, where integration of several products in one biorefinery can minimize waste generation by using the waste from one production as a secondary resource for another product. Such cascading system allows to make the most of the available biomass, as in the case of bioactive molecules extraction from olive pomace or waste cooking oil followed by bio-methanization [52]. Despite the great ecological desirability and profitability potential of biorefineries, techno-economic analyses show a low technology readiness level of such model [37].

Albeit a CE perspective applied to organic waste streams should take great care with restoring and closing biological cycles, such as returning to the soil nutrients or organic matter, only a few studies go through the agronomic valorization of second raw materials by means of regenerative agricultural practices. Despite being clearly the final target of many pathways, among the considered studies the agro-ecological subsystem is more regarded as a source of resources (e.g., green wastes and pruning residues), than as a receptor of other processes outputs (e.g., reuse of urban wastewater).

5. Conclusions

This study brought out that many circular pathways are already acknowledged and viable for triggering the transition of the olive oil supply chain towards a CE model, although most of them are defined only at the niche level. The pathways identified from literature analysis are predominantly focused on technological issues, while other very relevant factor such as organizational and coordination are very underscored.

Various conversion technologies with different degrees of readiness are currently available. In general terms, technologies as well as processes aimed at refining biomass components into high value-added products still present a low TRL, also due to the uncertainty of cost estimation [37]. In some cases, pretreatment procedures are needed or advisable for improving the efficiency of the conversion process. Although many feasibility studies of some of the conversion technologies have been carried out, none of the existing valorization solutions has yet been estimated economically viable [21] or applied at industrial scale—apart from experimental trials—as confirmed by the shortage of real case studies. This is evidence that technological aspects are crucial but not sufficient for triggering innovation and transitioning towards drastically novel operative models (as the paradigm of CE demands).

The circular pathways ascribable to the emerging frame of bio-economy offer the greatest opportunities for maximizing the value of the available resources through advanced recovery and upcycling processes. At the same time, the enactment of CE paradigm into agri-food chains—that are intrinsically embedded, deeply reliant and at the same time impactful on natural ecosystems—cannot prescind from the priority goal of modelling environmentally sound and restorative metabolic ecologies. To this end, it is paramount to expand the farmers’ agency for sustainably handling organic streams and enabling virtuous biological cycles through regenerative agriculture.

Finally, a systemic envisioning of overarching strategies for moving towards a CE model with a chain-based approach, with exchange of resources flowing from one stage of the chain, or from one sector to another in a symbiotic functioning, is fundamentally missing, and only a few segments or interrelations are considered jointly at a time.

The evidence mapped through this scoping literature review can represent a valuable starting point to advance research and strategies for implementing CE into the olive oil supply chain. However, we acknowledge that the study is not exempt from limitations. The main methodological limitation concerns the formulation of the reference query used for sampling the papers, that may have caused a selection bias and impacted the findings of the study. More search terms could have been identified, even by performing a snowballing process, in order to detect some valorization pathways that, even if not framed within the label of “circular economy”, could be circular de facto. Moreover, only two databases, Scopus and Web of Science, have been browsed. Although they are considered comprehensive of relevant scientific publications, further contributions can be gathered by exploring other databases, as well as grey literature, or by considering cross-references. In addition, more extensive analysis could have been performed, both at descriptive and content level. In particular, technical and economic feasibility of each pathway deserves further deepening.

According to the results of the scoping literature review, further research and envisioning efforts must be done to unlock the true potential of circular thinking for the olive oil sector, beyond the technological aspects, such as addressing economic, coordination and governance challenges. Besides, further qualitative and on-field research can be done to investigate which circular pathways are the most promptly available for adoption in particular contexts, according to the preferences of socio-economic actors, to milieu-specific features, as well as to the economic and environmental benefits that can be maximized at local level. Further research should also be extended to understand the main barriers hindering the transition to CE models, that can be related to costs, to the access to advanced technologies, to market aspects, or to regulative issues. In particular, the development of case studies can show how specific pathways work in practice, or how business models can be redesigned in order to operationalize CE and contribute to sustainability in the long term.

Author Contributions

Conceptualization, G.G.; methodology, S.S. and L.R.; validation, L.R., D.C. and B.C.d.G.; formal analysis, S.S., L.R. and G.G.; data curation, S.S.; writing—original draft preparation, S.S., L.R. and GG; writing—review and editing, S.S., L.R., D.C., G.G. and B.C.d.G.; visualization, S.S., L.R., G.G., D.C. and B.C.d.G.; project administration, G.G.; funding acquisition, G.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received grant from the Project PRIN DRASTIC “Driving the Italian Agri-Food System into A Circular Economy Model” (cod. 2017JYRZFF), PRIN-MIUR—Call 2017, funded by the Italian Ministry of Education, University and Research (MIUR), Italy.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Additional data available on request.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; de Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.; Sica, D.; Malandrino, O. Towards circular economy in the agri-food sector. A systematic literature review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular economy models in agro-food systems: A review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Hernández, J.V.; Pereira, J.E.; Urieta, D.; Menor, A.; Caño, S.; Barreal, J.; Gámez, M.D.M.V.; Poyatos, R.P. International Olive Growing: Worldwide Analysis and Summary; Fundación Caja Rural Jaén: Jaen, Spain, 2018. [Google Scholar]

- European Commission Factsheet. EU Olive Oil. 2021. Available online: https://ec.europa.eu/info/food-farming-fisheries/plants-and-plant-products/plant-products/olive-oil_it (accessed on 16 April 2021).

- International Oil Council Country Profiles. Overview of the Olive and Olive Oil Sector Itemised by Country and Based on the Official Replies to IOC Questionnaires—Italy; IOC: Madrid, Spain, 2012. [Google Scholar]

- Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Moustakas, K.; Talebi, A.F.; Goli, S.A.H.; Rajaeifar, M.A.; Khoshnevisan, B.; Jouzani, G.S.; Peng, W.; Kim, K.-H.; et al. Environmental life cycle assessment of different biorefinery platforms valorizing olive wastes to biofuel, phosphate salts, natural antioxidant, and an oxygenated fuel additive (triacetin). J. Clean. Prod. 2020, 278, 123916. [Google Scholar] [CrossRef]

- Sciubba, F.; Chronopoulou, L.; Pizzichini, D.; Lionetti, V.; Fontana, C.; Aromolo, R.; Socciarelli, S.; Gambelli, L.; Bartolacci, B.; Finotti, E.; et al. Olive mill wastes: A source of bioactive molecules for plant growth and protection against pathogens. Biology 2020, 9, 450. [Google Scholar] [CrossRef]

- Galati, A.; Schifani, G.; Crescimanno, M.; Vrontis, D.; Migliore, G. Innovation strategies geared toward the circular economy: A case study of the organic olive-oil industry. Riv. Studi Sulla Sostenibilita 2018, 1, 137–158. [Google Scholar] [CrossRef]

- Michalopoulos, G.; Kasapi, K.A.; Koubouris, G.; Psarras, G.; Arampatzis, G.; Hatzigiannakis, E.; Kavvadias, V.; Xiloyannis, C.; Montanaro, G.; Malliaraki, S.; et al. Adaptation of mediterranean olive groves to climate change through sustainable cultivation practices. Climate 2020, 8, 54. [Google Scholar] [CrossRef] [Green Version]

- Cembalo, L.; Borrello, M.; De Luca, A.I.; Giannoccaro, G.; D’Amico, M. Transitioning agri-food systems into circular economy trajectories. Aestimum 2021, 199–218. [Google Scholar] [CrossRef]

- Berbel, J.; Posadillo, A. Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 2018, 10, 237. [Google Scholar] [CrossRef] [Green Version]

- Kapellakis, I.E.; Tsagarakis, K.P.; Crowther, J.C. Olive oil history, production and by-product management. Rev. Environ. Sci. Bio/Technol. 2007, 7, 1–26. [Google Scholar] [CrossRef]

- Moreno, V.C.; Iervolino, G.; Tugnoli, A.; Cozzani, V. Techno-economic and environmental sustainability of biomass waste conversion based on thermocatalytic reforming. Waste Manag. 2019, 101, 106–115. [Google Scholar] [CrossRef]

- Mapelli, S.; Ventimiglia, G.; Sala, C.; Castelli, S. Biogas production from exhausted pomace after polyphenol recovery. In Proceedings of the 2019 7th International Renewable and Sustainable Energy Conference (IRSEC), Agadir, Morocco, 27–30 November 2019. [Google Scholar]

- Donner, M.; Radić, I. Innovative circular business models in the olive oil sector for sustainable mediterranean agrifood systems. Sustainability 2021, 13, 2588. [Google Scholar] [CrossRef]

- Ochando-Pulido, J.M.; Martínez-Férez, A. About the recovery of the phenolic fraction from olive mill wastewater by micro and ultracentrifugation membranes. Chem. Eng. Trans. 2017, 60, 271–276. [Google Scholar] [CrossRef]

- Lopes, M.; Miranda, S.; Alves, J.M.; Pereira, A.S.; Belo, I. Waste cooking oils as feedstock for lipase and lipid-rich biomass production. Eur. J. Lipid Sci. Technol. 2018, 121, 1800188. [Google Scholar] [CrossRef] [Green Version]

- Tsoutsos, T.; Tournaki, S.; Gkouskos, Z.; Paraíba, O.; Giglio, F.; García, P.Q.; Braga, J.; Adrianos, H.; Filice, M. Quality characteristics of biodiesel produced from used cooking oil in Southern Europe. ChemEngineering 2019, 3, 19. [Google Scholar] [CrossRef] [Green Version]

- Boesen, S.; Bey, N.; Niero, M. Environmental sustainability of liquid food packaging: Is there a gap between Danish consumers′ perception and learnings from life cycle assessment? J. Clean. Prod. 2018, 210, 1193–1206. [Google Scholar] [CrossRef]

- Abu Tayeh, H.N.; Azaizeh, H.; Gerchman, Y. Circular economy in olive oil production—Olive mill solid waste to ethanol and heavy metal sorbent using microwave pretreatment. Waste Manag. 2020, 113, 321–328. [Google Scholar] [CrossRef]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Rocchi, L.; Paolotti, L.; Cortina, C.; Fagioli, F.F.; Boggia, A. Measuring circularity: An application of modified material circularity indicator to agricultural systems. Agric. Food Econ. 2021, 9, 9. [Google Scholar] [CrossRef]

- Colquhoun, H.L.; Levac, D.; O’Brien, K.K.; Straus, S.; Tricco, A.C.; Perrier, L.; Kastner, M.; Moher, D. Scoping reviews: Time for clarity in definition, methods, and reporting. J. Clin. Epidemiol. 2014, 67, 1291–1294. [Google Scholar] [CrossRef] [PubMed]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for scoping Reviews (PRISMA-ScR): Checklist and explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef] [Green Version]

- Pham, M.T.; Rajić, A.; Greig, J.D.; Sargeant, J.M.; Papadopoulos, A.; McEwen, S.A. A scoping review of scoping reviews: Advancing the approach and enhancing the consistency. Res. Synth. Methods 2014, 5, 371–385. [Google Scholar] [CrossRef]

- Arksey, H.; O’Malley, L. Scoping studies: Towards a methodological framework. Int. J. Soc. Res. Methodol. 2005, 8, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Levac, D.; Colquhoun, H.; O’Brien, K.K.; Levac, D.; Colquhoun, H.; O′Brien, K.K. Scoping studies: Advancing the methodology. Implement. Sci. 2010, 5, 69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- MacArthur, E. Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Wilmington, UK, 2012; Volume 1. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Fadlalla, A.; Amani, F. A keyword-based organizing framework for ERP intellectual contributions. J. Enterp. Inf. Manag. 2015, 28, 637–657. [Google Scholar] [CrossRef]

- Ben Harb, M.; Abubshait, S.; Etteyeb, N.; Kamoun, M.; Dhouib, A. Olive leaf extract as a green corrosion inhibitor of reinforced concrete contaminated with seawater. Arab. J. Chem. 2020, 13, 4846–4856. [Google Scholar] [CrossRef]

- Blasi, F.; Cossignani, L. An Overview of natural extracts with antioxidant activity for the improvement of the oxidative stability and shelf life of edible oils. Processes 2020, 8, 956. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Barragán-Huerta, B.E.; Fíla, V.; Denis, P.C.; Ruby-Figueroa, R. Current role of membrane technology: From the treatment of agro-industrial by-products up to the valorization of valuable compounds. Waste Biomass-Valori. 2017, 9, 513–529. [Google Scholar] [CrossRef]

- Chebbi, A.; Franzetti, A.; Castro, F.D.; Tovar, F.H.G.; Tazzari, M.; Sbaffoni, S.; Vaccari, M. Potentials of winery and olive oil residues for the production of rhamnolipids and other biosurfactants: A step towards achieving a circular economy model. Waste Biomass-Valori. 2021, 12, 4733–4743. [Google Scholar] [CrossRef]

- Cifuentes-Cabezas, M.; Carbonell-Alcaina, C.; Vincent-Vela, M.C.; Mendoza-Roca, J.A.; Álvarez-Blanco, S. Comparison of different ultrafiltration membranes as first step for the recovery of phenolic compounds from olive-oil washing wastewater. Process. Saf. Environ. Prot. 2021, 149, 724–734. [Google Scholar] [CrossRef]

- Cristóbal, J.; Caldeira, C.; Corrado, S.; Sala, S. Techno-economic and profitability analysis of food waste biorefineries at European level. Bioresour. Technol. 2018, 259, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Del Pozo, C.; Bartrolí, J.; Puy, N.; Fàbregas, E. Separation of value-added chemical groups from bio-oil of olive mill waste. Ind. Crop. Prod. 2018, 125, 160–167. [Google Scholar] [CrossRef]

- Leite, P.; Salgado, J.M.; Belo, I. Improvement of antioxidant compounds extraction by ssf from agro-food wastes. In Wastes: Solutions, Treatments and Opportunities III, Proceedings of the 5th International Conference Wastes: Solutions, Treatments and Opportunities, Lisbon, Portugal, 4–6 September 2019; Vilarinho, C., Castro, F., Gonçalves, M., Fernando, A.L., Eds.; CRC Press Balkema: Amsterdam, The Netherlands, 2020; pp. 187–192. [Google Scholar]

- Luzi, F.; Pannucci, E.; Clemente, M.; Grande, E.; Urciuoli, S.; Romani, A.; Torre, L.; Puglia, D.; Bernini, R.; Santi, L. Hydroxytyrosol and oleuropein-enriched extracts obtained from olive oil wastes and by-products as active antioxidant ingredients for poly (vinyl alcohol)-based films. Molecules 2021, 26, 2104. [Google Scholar] [CrossRef] [PubMed]

- Mallamaci, R.; Budriesi, R.; Clodoveo, M.L.; Biotti, G.; Micucci, M.; Ragusa, A.; Curci, F.; Muraglia, M.; Corbo, F.; Franchini, C. Olive tree in circular economy as a source of secondary metabolites active for human and animal health beyond oxidative stress and inflammation. Molecules 2021, 26, 1072. [Google Scholar] [CrossRef]

- Markhali, F.S.; Teixeira, J.A.; Rocha, C.M.R. Olive tree leaves—A source of valuable active compounds. Processes 2020, 8, 1177. [Google Scholar] [CrossRef]

- Beamonte, R.M.; Sanclemente, T.; Surra, J.C.; Osada, J. Could squalene be an added value to use olive by-products? J. Sci. Food Agric. 2019, 100, 915–925. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- Nikkhah, A.; Firouzi, S.; Dadaei, K.; Van Haute, S. Measuring circularity in food supply chain using life cycle assessment; refining oil from olive kernel. Foods 2021, 10, 590. [Google Scholar] [CrossRef]

- Nunes, M.A.; Páscoa, R.; Alves, R.C.; da Costa, A.G.; Bessada, S.; Oliveira, M.B.P. Fourier transform near infrared spectroscopy as a tool to discriminate olive wastes: The case of monocultivar pomaces. Waste Manag. 2020, 103, 378–387. [Google Scholar] [CrossRef]

- Ochando-Pulido, J.M.; Fragoso, R.; Macedo, A.; Carvalho, A.R.; Duarte, E. Secondary Raw Materials from Agroindustrial by-Products and Waste Through Nanofiltration; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2017; ISBN 9781536119725. [Google Scholar]

- Ochando-Pulido, J.M.; Vellido-Pérez, J.A.; González-Hernández, R.; Martínez-Férez, A. Optimization and modeling of two-phase olive-oil washing wastewater integral treatment and phenolic compounds recovery by novel weak-base ion exchange resins. Sep. Purif. Technol. 2020, 249, 117084. [Google Scholar] [CrossRef]

- Romani, A.; Pinelli, P.; Ieri, F.; Bernini, R. Sustainability, Innovation, and green chemistry in the production and valorization of phenolic extracts from Olea europaea L. Sustainability 2016, 8, 1002. [Google Scholar] [CrossRef] [Green Version]

- Romani, A.; Ieri, F.; Urciuoli, S.; Noce, A.; Marrone, G.; Nediani, C.; Bernini, R. Health effects of phenolic compounds found in extra-virgin olive oil, by-products, and leaf of Olea europaea L. Nutrients 2019, 11, 1776. [Google Scholar] [CrossRef] [Green Version]

- Romani, A.; Campo, M.; Urciuoli, S.; Marrone, G.; Noce, A.; Bernini, R. An industrial and sustainable platform for the production of bioactive micronized powders and extracts enriched in polyphenols from Olea europaea L. and Vitis vinifera L. Wastes. Front. Nutr. 2020, 7, 120. [Google Scholar] [CrossRef] [PubMed]

- Serrano, A.; Fermoso, F.G.; Alonso-Fariñas, B.; Gutiérrez, G.R.; Fernandez-Bolaños, J.; Borja, R. Olive mill solid waste biorefinery: High-temperature thermal pre-treatment for phenol recovery and biomethanization. J. Clean. Prod. 2017, 148, 314–323. [Google Scholar] [CrossRef] [Green Version]

- Aguado, R.; Vera, D.; López-García, D.A.; Torreglosa, J.P.; Jurado, F. Techno-economic assessment of a gasification plant for distributed cogeneration in the agrifood sector. Appl. Sci. 2021, 11, 660. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Cotana, F.; Nicolini, A.; Coccia, V.; Petrozzi, A.; Formica, A.; Bertini, A. Characterization of various biomass feedstock suitable for small-scale energy plants as preliminary activity of biocheaper project. Sustainability 2020, 12, 6678. [Google Scholar] [CrossRef]

- Costa, M.; Massarotti, N.; Stasi, A.; Cirillo, D.; Villetta, M.L.; Di Blasio, G.; Prati, M.V.; Costagliola, M.A.; Mauro, A.; Vanoli, L.; et al. Innovative plants for distributed poly-generation by residual biomass. In Proceedings of the European Biomass Conference and Exhibition Proceedings, ETA-Florence Renewable Energies, Lisbon, Portugal, 27–30 May 2019; pp. 834–848. [Google Scholar]

- Costa, M.; Buono, A.; Caputo, C.; Carotenuto, A.; Cirillo, D.; Costagliola, M.A.; Di Blasio, G.; La Villetta, M.; Macaluso, A.; Martoriello, G.; et al. The “INNOVARE” project: Innovative plants for distributed poly-generation by residual biomass. Energies 2020, 13, 4020. [Google Scholar] [CrossRef]

- Maroto, M.D.L.T.; Herrera, J.A.L.C.; Vilar, M.M. Dry olive pomace gasification to obtain electrical energy in a downdraft gasifier. Environ. Eng. 2020, 247, 137–144. [Google Scholar] [CrossRef]

- Fragoso, R.; Henriques, A.C.; Gominho, J.; Ochando-Pulido, J.M.; Duarte, E. Integrated management of sewage sludge and olive oil production chain waste: Improving conversion process into biomethane. In Proceedings of the European Biomass Confer-ence and Exhibition Proceedings, ETA-Florence Renewable Energies, Lisbon, Portugal, 27–30 May 2019; pp. 983–986. [Google Scholar]

- Hermoso-Orzáez, M.J.; Mota-Panizio, R.; Carmo-Calado, L.; Brito, P. Gasification of biomass and plastic waste from the dis-assembly of public lighting luminaires for energy valorization. Case study of circular economy applied to the Alentejo region in Portugal. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Marselle, France, 6–9 July 2020; pp. 422–433. [Google Scholar]

- Hermoso-Orzáez, M.J.; Mota-Panizio, R.; Carmo-Calado, L.; Brito, P. Thermochemical and economic analysis for energy recovery by the gasification of WEEE plastic waste from the disassembly of large-scale outdoor obsolete luminaires by LEDs in the Alto Alentejo Region (Portugal). Appl. Sci. 2020, 10, 4601. [Google Scholar] [CrossRef]

- Lago, C.; Herrera, I.; Lechón, Y. Cover crop carbon sequestration potential and associated trade-offs: The olive tree debris as feedstock of a local bio-refinery case study. In Proceedings of the European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–17 May 2018; pp. 1425–1428. [Google Scholar]

- López-García, E.; Chacartegui, R.; Palomo-Guerrero, F.J.; Becerra, J.A.; Valverde, J.M. Simulation of biomass gasification in a downdraft fixed bed using Aspen: Optimal operation conditions and influence of biomass type. In Proceedings of the ECOS 2018—31st International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Braga, Portugal, 2 May 2018. [Google Scholar]

- Meena, R.A.A.; Banu, J.R.; Kannah, R.Y.; Yogalakshmi, K.; Kumar, G. Biohythane production from food processing wastes—Challenges and perspectives. Bioresour. Technol. 2019, 298, 122449. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Sánchez-Molina, J. Pellet as a technological nutrient within the circular economy model: Comparative analysis of combustion efficiency and CO and NOx emissions for pellets from olive and almond trees. Energies 2016, 9, 777. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.J.; Loureiro, L.M.; Sá, L.C.; Silva, H.F. Evaluation of the potential for energy recovery from olive oil industry waste: Thermochemical conversion technologies as fuel improvement methods. Fuel 2020, 279, 118536. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Loureiro, L.M.E.F.; Sá, L.C.R.; Silva, H.F. Thermochemical conversion of olive oil industry waste: Circular economy through energy recovery. Recycling 2020, 5, 12. [Google Scholar] [CrossRef]

- Palchetti, E.; Calamai, A.; Verdi, L.; Masoni, A.; Marini, L.; Chiaramonti, D. Preliminary screening of agricultural feedstocks for anaerobic digestion. Adv. Hortic. Sci. 2019, 33, 333–344. [Google Scholar] [CrossRef]

- Palmieri, N.; Suardi, A.; Alfano, V.; Pari, L. Circular economy model: Insights from a case study in South Italy. Sustainability 2020, 12, 3466. [Google Scholar] [CrossRef] [Green Version]

- Puig-Gamero, M.; Trapero, J.; Pedregal, D.; Sánchez, P.; Sanchez-Silva, L. Impact of the forecast price on economic results for methanol production from olive waste. Fuel 2021, 295, 120631. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, C.; González-González, A.; Cuadros-Salcedo, F.; Cuadros-Blázquez, F. Two-phase Olive mill waste: A circular economy solution to an imminent problem in Southern Europe. J. Clean. Prod. 2020, 274, 122789. [Google Scholar] [CrossRef]

- Spyridonidis, A.; Vasiliadou, I.; Akratos, C.; Stamatelatou, K. Performance of a full-scale biogas plant operation in Greece and its impact on the circular economy. Water 2020, 12, 3074. [Google Scholar] [CrossRef]

- Tapia-Quirós, P.; Montenegro-Landívar, M.; Reig, M.; Vecino, X.; Alvarino, T.; Cortina, J.; Saurina, J.; Granados, M. Olive mill and winery wastes as viable sources of bioactive compounds: A study on polyphenols recovery. Antioxidants 2020, 9, 1074. [Google Scholar] [CrossRef]

- Torrisi, S.; Anastasi, E.; Longhitano, S.; Longo, I.C.; Zerbo, A.; Borzì, G. Circular economy and the benefits of biomass as a renewable energy source. Procedia Environ. Sci. Eng. Manag. 2018, 5, 175–181. [Google Scholar]

- Valenti, F.; Liao, W.; Porto, S.M.C. Life cycle assessment of agro-industrial by-product reuse: A comparison between anaerobic digestion and conventional disposal treatments. Green Chem. 2020, 22, 7119–7139. [Google Scholar] [CrossRef]