Evaluation of Petroleum Resin in Rubberized Asphalt Binder

Abstract

:1. Introduction

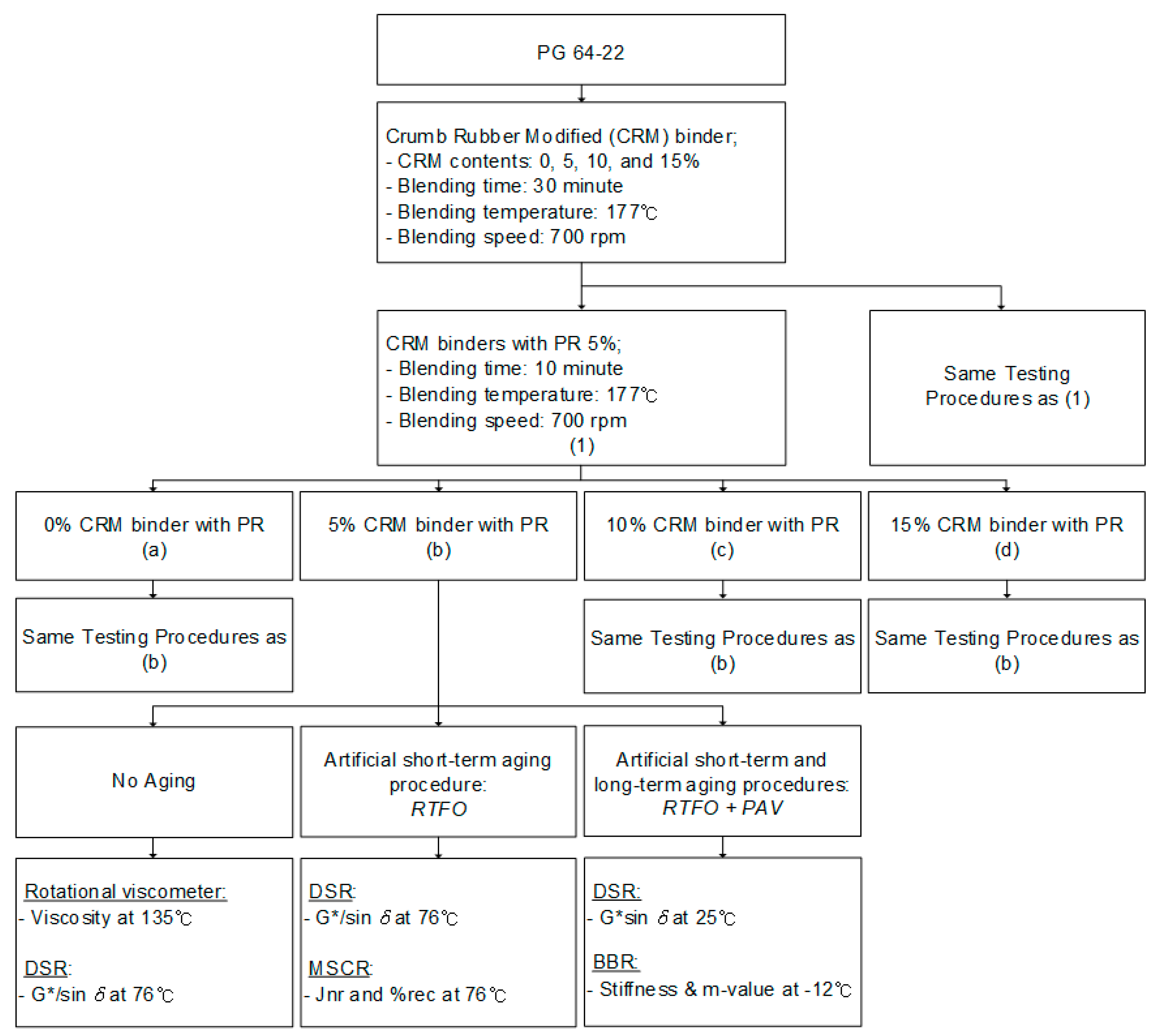

2. Experimental Design

2.1. Materials

2.2. Superpave Binder Tests

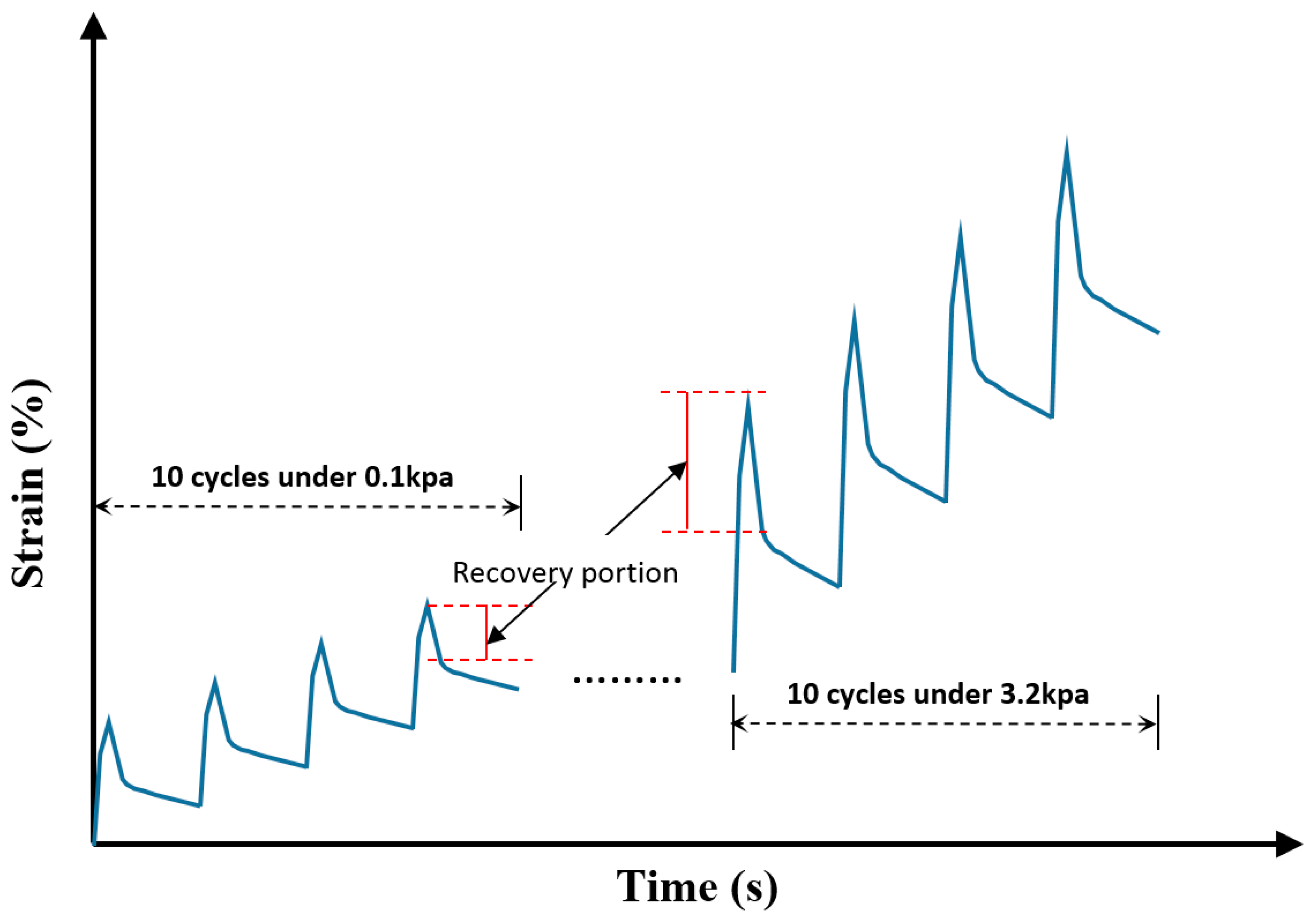

2.3. Multiple Stress Creep Recovery (MSCR) Tests

2.4. Statistical Analysis Method

3. Results and Discussions

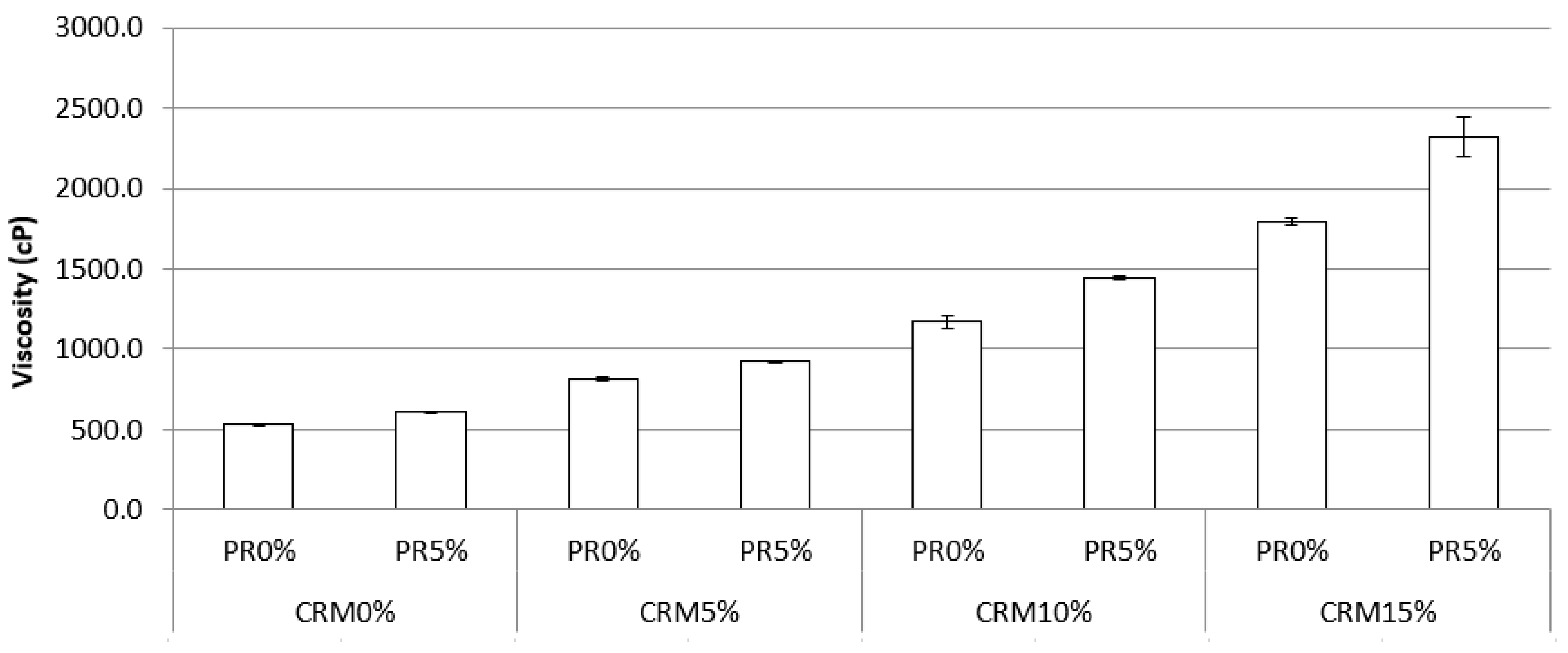

3.1. Rotational Viscosity

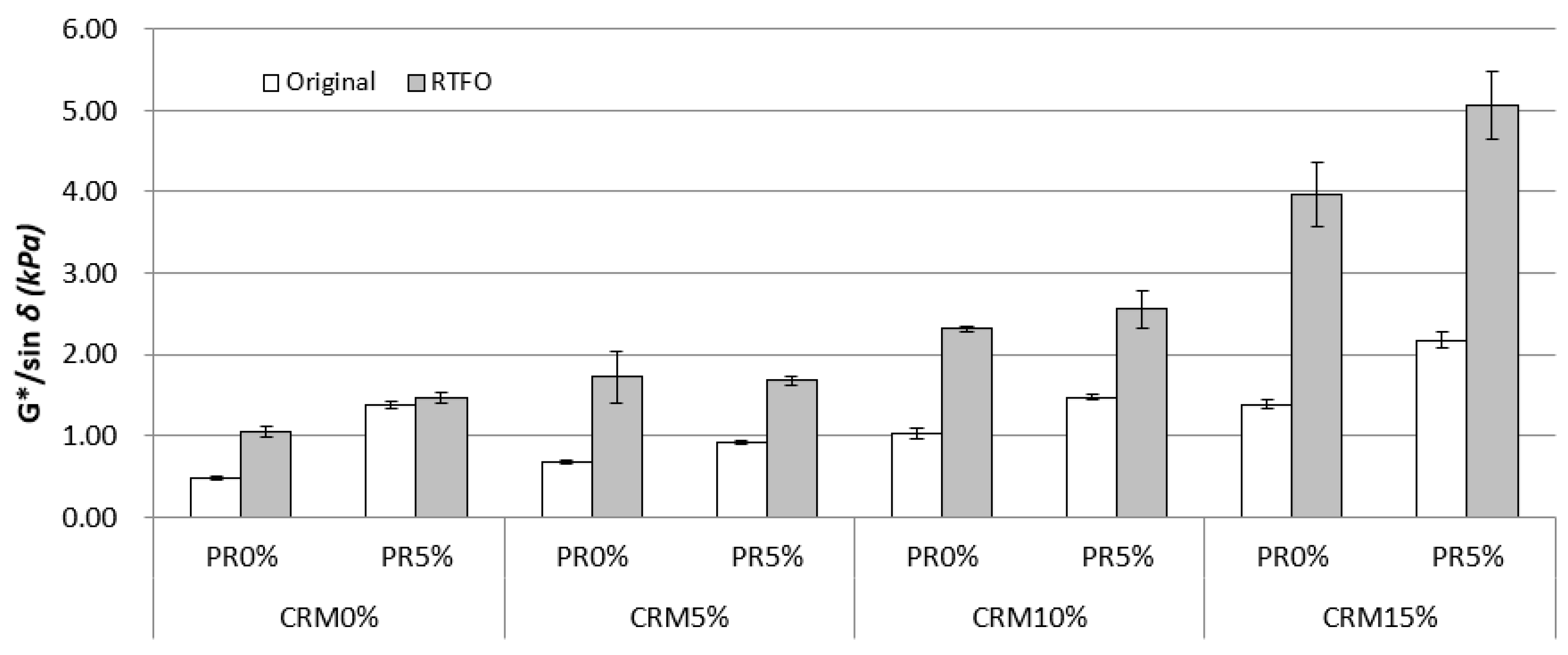

3.2. Rutting Property

3.2.1. Dynamic Shear Rheometer (DSR) Test

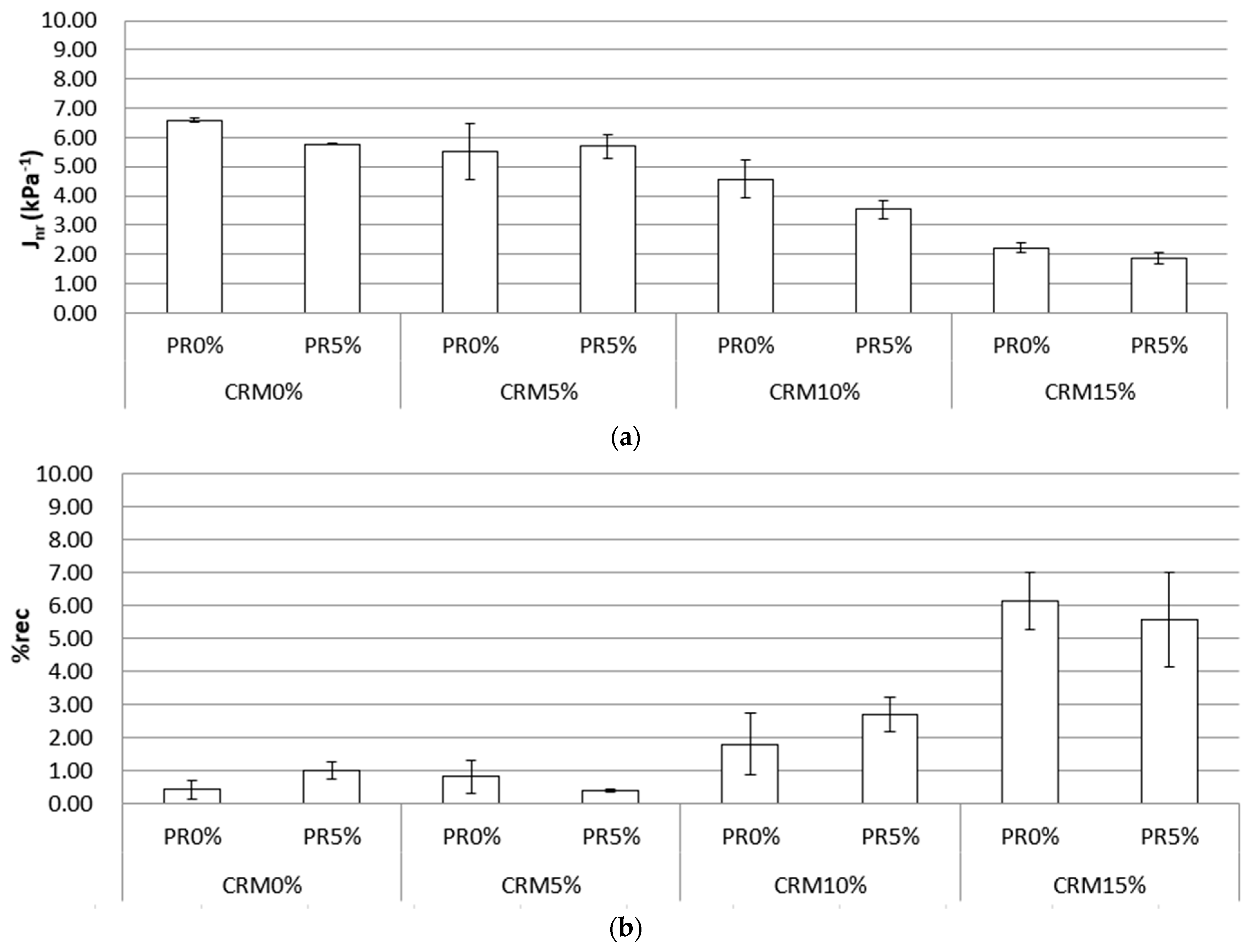

3.2.2. Multiple Stress Creep Recovery (MSCR) Test

3.3. Cracking Property

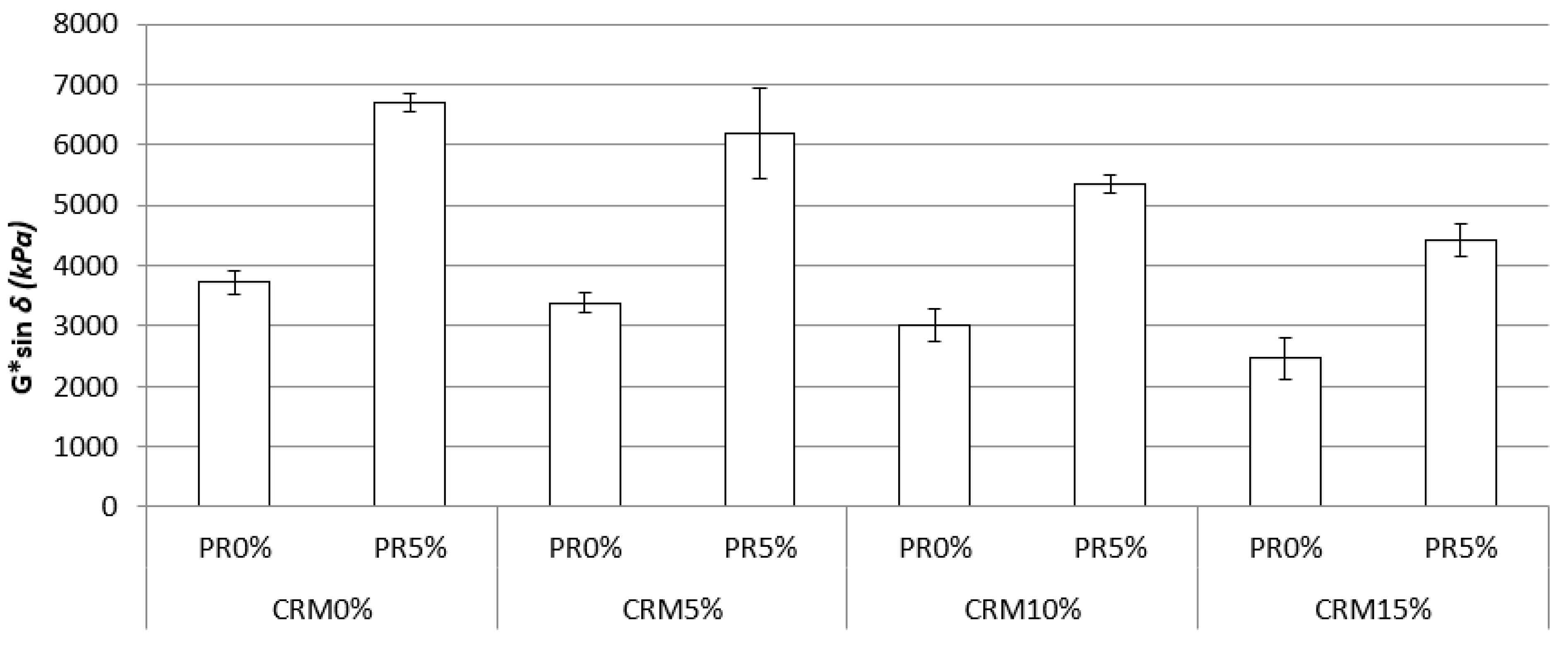

3.3.1. Fatigue Cracking at Intermediate Temperature

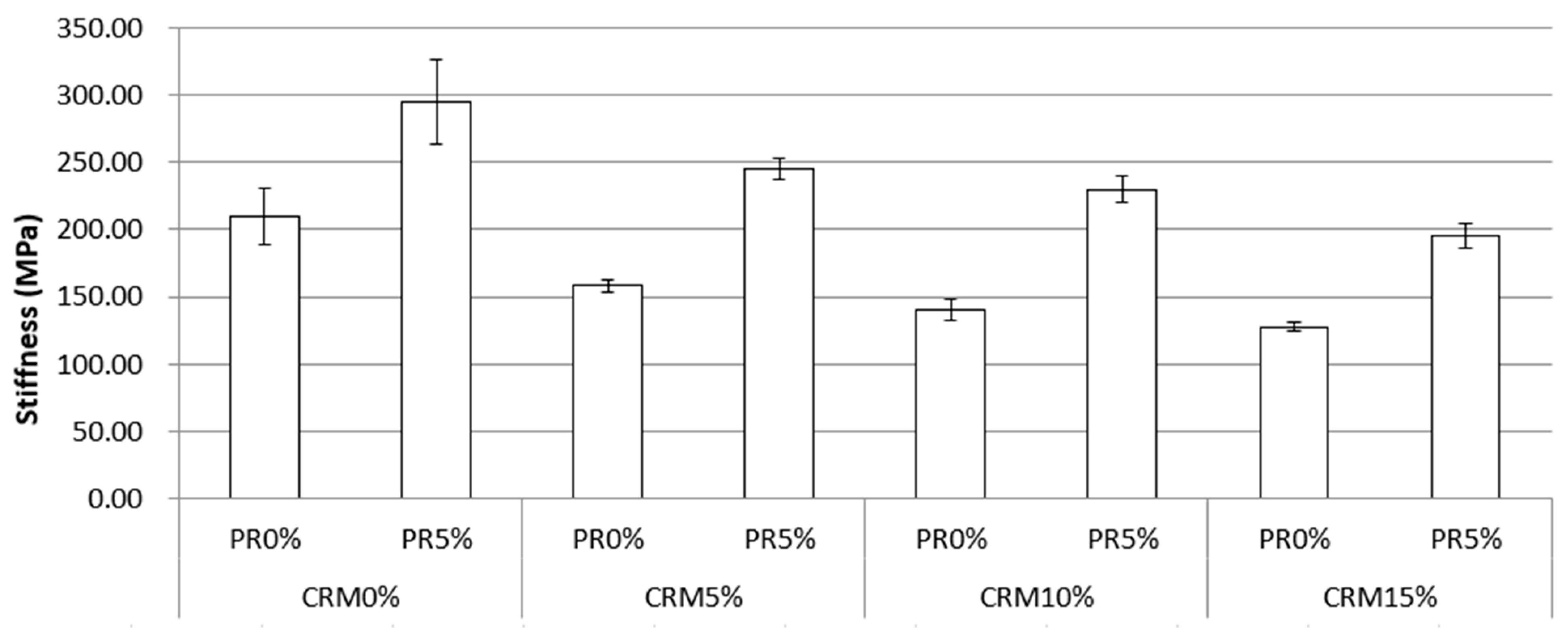

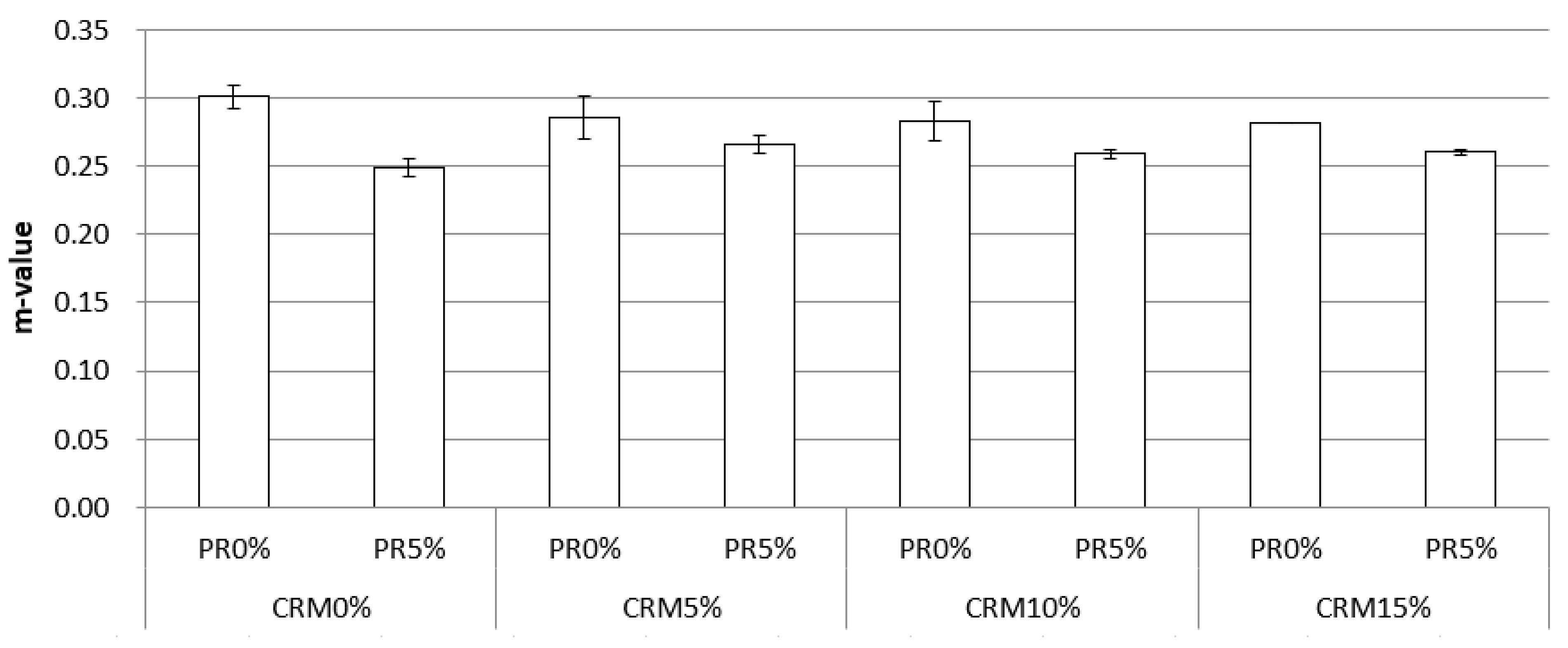

3.3.2. Thermal Cracking Properties at Low Temperature

4. Summary and Conclusions

- The higher CRM content led to an increase in the viscosity at 135 °C. The use of PR also increased binder viscosity. This indicates that it is required to have high production temperature to manufacture the asphalt mixture including CRM and PR.

- As the CRM percentage increased and PR was added, the rutting characteristics of the CRM binder improved. The application of both additives is more effective in producing a sustainable binder that is less susceptible to rutting at high pavement temperatures.

- The higher CRM content is considered to have better rutting resistance regarding elastic property according to the MSCR test results. Addition of PR also significantly decreases the Jnr value. Although it does not clearly have a positive effect on recoverable portion of binder by PR, it is considered that PR is effective in improving the elastic property considering some potential experimental errors.

- From the fatigue cracking test results, it was shown that higher CRM content has better fatigue crack resistance. However, the addition of PR is critical for declining the cracking property.

- The higher the CRM content, the lower the stiffness; however, the CRM binder including PR had a lower resistance to low-temperature cracking than without PR.

- It is recommended to conduct a future study to evaluate the effect of PR using different PMA binder or different types of PR which minimize the negative effect of PR on the cracking property. In addition, further study with many other experimental factors, such as different producing methods and testing temperatures, is needed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bukowski, J.; Youtcheff, J.; Harman, T. The Multiple Stress Creep Recovery (MSCR) Procedure; Office of Pavement Technol: Washington, DC, USA, 2011; pp. 1–9. [Google Scholar]

- Chen, T.; Ma, T.; Huang, X.; Guan, Y.; Zhang, Z.; Tang, F. The performance of hot-recycling asphalt binder containing crumb rubber modified asphalt based on physiochemical and rheological measurements. Constr. Build. Mater. 2019, 226, 83–93. [Google Scholar] [CrossRef]

- Class, J.B.; Chu, S.G. The viscoelastic properties of rubber–resin blends. I. The effect of resin structure. J. Appl. Polym. Sci. 1985, 30, 805–814. [Google Scholar] [CrossRef]

- Hicks, R.G.; Cheng, D.; Duffy, T.; Teesdale, T. Evaluation of rubberized asphalt terminal blends and a preliminary study on warm mix. Report 2010, CP2C-2010-104. Available online: https://journals.sagepub.com/doi/10.3141/2524-01 (accessed on 2 June 2021).

- Huang, S.C.; Pauli, A.T. Particle size effect of crumb rubber on rheology and morphology of asphalt binders with long-term aging. Road Mater. Pavement Des. 2008, 9, 73–95. [Google Scholar] [CrossRef]

- Kim, H.H.; Lee, S.J. Evaluation of rubber influence on cracking resistance of crumb rubber modified binders with wax additives. Can. J. Civ. Eng. 2016, 43, 326–333. [Google Scholar] [CrossRef]

- Kim, H. Characterization of Rubberized Binders with Wax Additives; Texas State University: San Marcos, TX, USA, 2016. [Google Scholar]

- Kim, H.H.; Mazumder, M.; Lee, M.S.; Lee, S.J. Effect of blending time on viscosity of rubberized binders with wax additives. Int. J. Pavement Res. Technol. 2018, 11, 655–665. [Google Scholar] [CrossRef]

- Kim, H.H.; Lee, M.S.; Lee, S.J. Performance evaluation of polymer modified asphalt (PMA) binders containing ground tire rubber (GTR). Int. J. Pavement Res. Technol. 2019, 12, 215–222. [Google Scholar] [CrossRef]

- Lee, S.J. Characterization of Recycled Aged CRM Binders. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2007. [Google Scholar]

- Ott, R.L.; Longnecker, M.T. An Introduction to Statistical Methods and Data Analysis; Cengage Learning: Boston, MA, USA, 2008. [Google Scholar]

- Tang, J.; Zhu, C.; Zhang, H.; Xu, G.; Xiao, F.; Amirkhanian, S. Effect of liquid ASAs on the rheological properties of crumb rubber modified asphalt. Constr. Build. Mater. 2019, 194, 238–246. [Google Scholar] [CrossRef]

- U.S. Tire Manufacturers Association. Scrap Tire Management Summary; U.S. Tire Manufacturers Association: Washington, DC, USA, 2018. [Google Scholar]

- Xiao, F.; Zhao, P.W.; Amirkhanian, S.N. Fatigue behavior of rubberized asphalt concrete mixtures containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 3144–3151. [Google Scholar] [CrossRef]

- Xiang, L.; Cheng, J.; Que, G. Microstructure and performance of crumb rubber modified asphalt. Constr. Build. Mater. 2009, 23, 3586–3590. [Google Scholar] [CrossRef]

- Yan, K.; Sun, H.; You, L.; Wu, S. Characteristics of waste tire rubber (WTR) and amorphous poly alpha olefin (APAO) compound modified porous asphalt mixtures. Constr. Build. Mater. 2020, 253, 119071. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Physical, rheological and chemical characterization of aging behaviors of thermochromic asphalt binder. Fuel 2018, 211, 850–858. [Google Scholar] [CrossRef]

- Zhuang, R.H.; Yu, J.Y.; Chang, H.; Zeng, Y.; Lan, X.Y. Effect of warm mix agent on physical and aging properties of crumb rubber modified bitumen. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2019; Volume 944, pp. 1226–1233. [Google Scholar]

- Zohuriaan-Mehr, M.J.; Omidian, H. Petroleum resins: An overview. J. Macromol. Sci. Part C Polym. Rev. 2000, 40, 23–49. [Google Scholar] [CrossRef]

| Aging States | Test Properties | Test Result |

|---|---|---|

| Unaged Binder | Viscosity @ 135 °C (Pa-S) | 0.531 |

| G*/sin δ @ 64 °C (Kpa) | 1.415 | |

| RTFO Aged Residual | G*/sin δ @ 64 °C (Kpa) | 2.531 |

| Rtfo + Pav Aged Residual | G*sin δ @ 25 °C (Kpa) | 2558 |

| Stiffness @ −12 °C (Mpa) | 287 | |

| M-Value @ −12 °C | 0.307 |

| Sieve No. (μm) | Ambient CRM | |

|---|---|---|

| % Cumulative Retained | % Cumulative Retained | |

| 30 (600) | 0 | 0 |

| 40 (425) | 91.0 | 9.0 |

| 50 (300) | 59.1 | 40.9 |

| 80 (180) | 26.2 | 73.8 |

| 100 (150) | 18.6 | 81.4 |

| 200 (75) | 0 | 100.0 |

| Viscosity | CRM Content | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Content | 0% | PR0% | - | 0 | 1 | 1 | 1 | 1 | 1 | 1 |

| PR5% | - | 1 | 1 | 1 | 1 | 1 | 1 | |||

| 5% | PR0% | - | 1 | 1 | 1 | 1 | 1 | |||

| PR5% | - | 1 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 1 | 1 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

| (a) | ||||||||||

| G*/sin δ Original | CRM Content | |||||||||

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Content | 0% | PR0% | - | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| PR5% | - | 1 | 1 | 1 | 0 | 0 | 1 | |||

| 5% | PR0% | - | 1 | 1 | 1 | 1 | 1 | |||

| PR5% | - | 0 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 1 | 1 | 1 | |||||

| PR5% | - | 0 | 1 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

| (b) | ||||||||||

| G*/sin δ Short-Term Aged | CRM Content | |||||||||

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM content | 0% | PR0% | - | 0 | 1 | 1 | 1 | 1 | 1 | 1 |

| PR5% | - | 0 | 0 | 1 | 1 | 1 | 1 | |||

| 5% | PR0% | - | 0 | 1 | 1 | 1 | 1 | |||

| PR5% | - | 1 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 0 | 1 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

| Jnr | CRM Content | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Content | 0% | PR0% | - | 0 | 1 | 0 | 1 | 1 | 1 | 1 |

| PR5% | - | 0 | 0 | 1 | 1 | 1 | 1 | |||

| 5% | PR0% | - | 0 | 0 | 1 | 1 | 1 | |||

| PR5% | - | 1 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 0 | 1 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 0 | |||||||

| PR5% | - | |||||||||

| %rec | CRM Content | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Content | 0% | PR0% | - | 0 | 0 | 0 | 0 | 1 | 1 | 1 |

| PR5% | - | 0 | 0 | 0 | 0 | 1 | 1 | |||

| 5% | PR0% | - | 0 | 1 | 1 | 1 | 1 | |||

| PR5% | - | 0 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 0 | 1 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 0 | |||||||

| PR5% | - | |||||||||

| PAV | CRM Content | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Content | 0% | PR0% | - | 1 | 0 | 1 | 0 | 1 | 1 | 0 |

| PR5% | - | 1 | 0 | 1 | 1 | 1 | 1 | |||

| 5% | PR0% | - | 1 | 0 | 1 | 0 | 1 | |||

| PR5% | - | 1 | 1 | 1 | 1 | |||||

| 10% | PR0% | - | 1 | 0 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

| Stiffness | CRM Contents | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM Contents | 0% | PR0% | - | 1 | 1 | 1 | 1 | 0 | 1 | 0 |

| PR5% | - | 1 | 1 | 1 | 1 | 1 | 1 | |||

| 5% | PR0% | - | 1 | 0 | 1 | 0 | 1 | |||

| PR5% | - | 1 | 0 | 1 | 1 | |||||

| 10% | PR0% | - | 1 | 0 | 1 | |||||

| PR5% | - | 1 | 1 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

| m-Value | CRM Contents | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 5% | 10% | 15% | |||||||

| PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | PR0% | PR5% | |||

| CRM contents | 0% | PR0% | - | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| PR5% | - | 1 | 0 | 1 | 0 | 1 | 0 | |||

| 5% | PR0% | - | 0 | 0 | 1 | 0 | 1 | |||

| PR5% | - | 0 | 0 | 0 | 0 | |||||

| 10% | PR0% | - | 1 | 0 | 0 | |||||

| PR5% | - | 1 | 0 | |||||||

| 15% | PR0% | - | 1 | |||||||

| PR5% | - | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.H.; Mazumder, M.; Lee, M.-S.; Lee, S.-J. Evaluation of Petroleum Resin in Rubberized Asphalt Binder. Sustainability 2021, 13, 9319. https://doi.org/10.3390/su13169319

Kim HH, Mazumder M, Lee M-S, Lee S-J. Evaluation of Petroleum Resin in Rubberized Asphalt Binder. Sustainability. 2021; 13(16):9319. https://doi.org/10.3390/su13169319

Chicago/Turabian StyleKim, Hyun Hwan, Mithil Mazumder, Moon-Sup Lee, and Soon-Jae Lee. 2021. "Evaluation of Petroleum Resin in Rubberized Asphalt Binder" Sustainability 13, no. 16: 9319. https://doi.org/10.3390/su13169319

APA StyleKim, H. H., Mazumder, M., Lee, M.-S., & Lee, S.-J. (2021). Evaluation of Petroleum Resin in Rubberized Asphalt Binder. Sustainability, 13(16), 9319. https://doi.org/10.3390/su13169319