Sustainable Supply Chains: Evidence from Small and Medium-Sized Manufacturers

Abstract

:1. Introduction

2. Literature Review

2.1. High-Value Manufacturing

2.2. Enterprise Commitment and Sustainability

2.3. SSCs and Performance

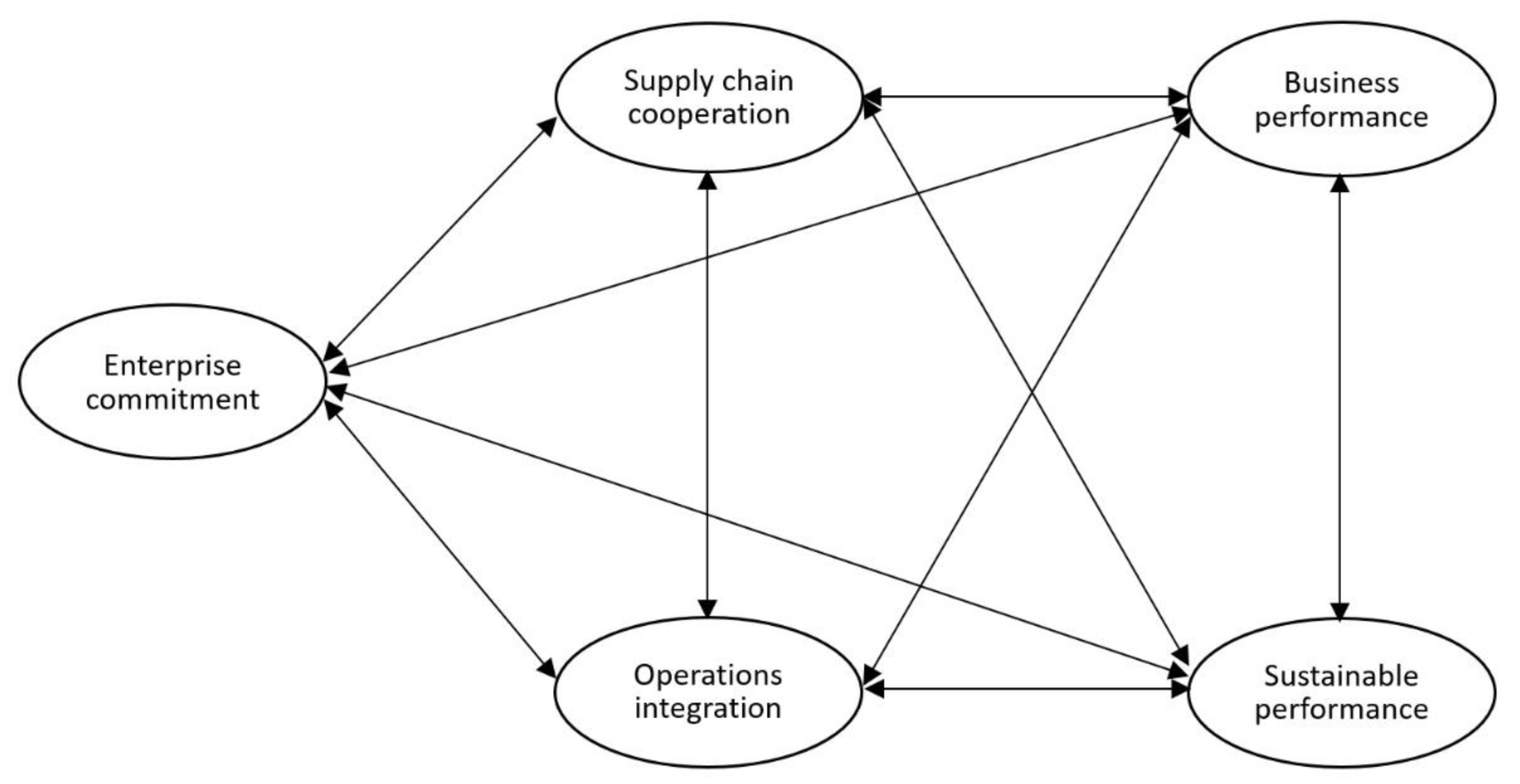

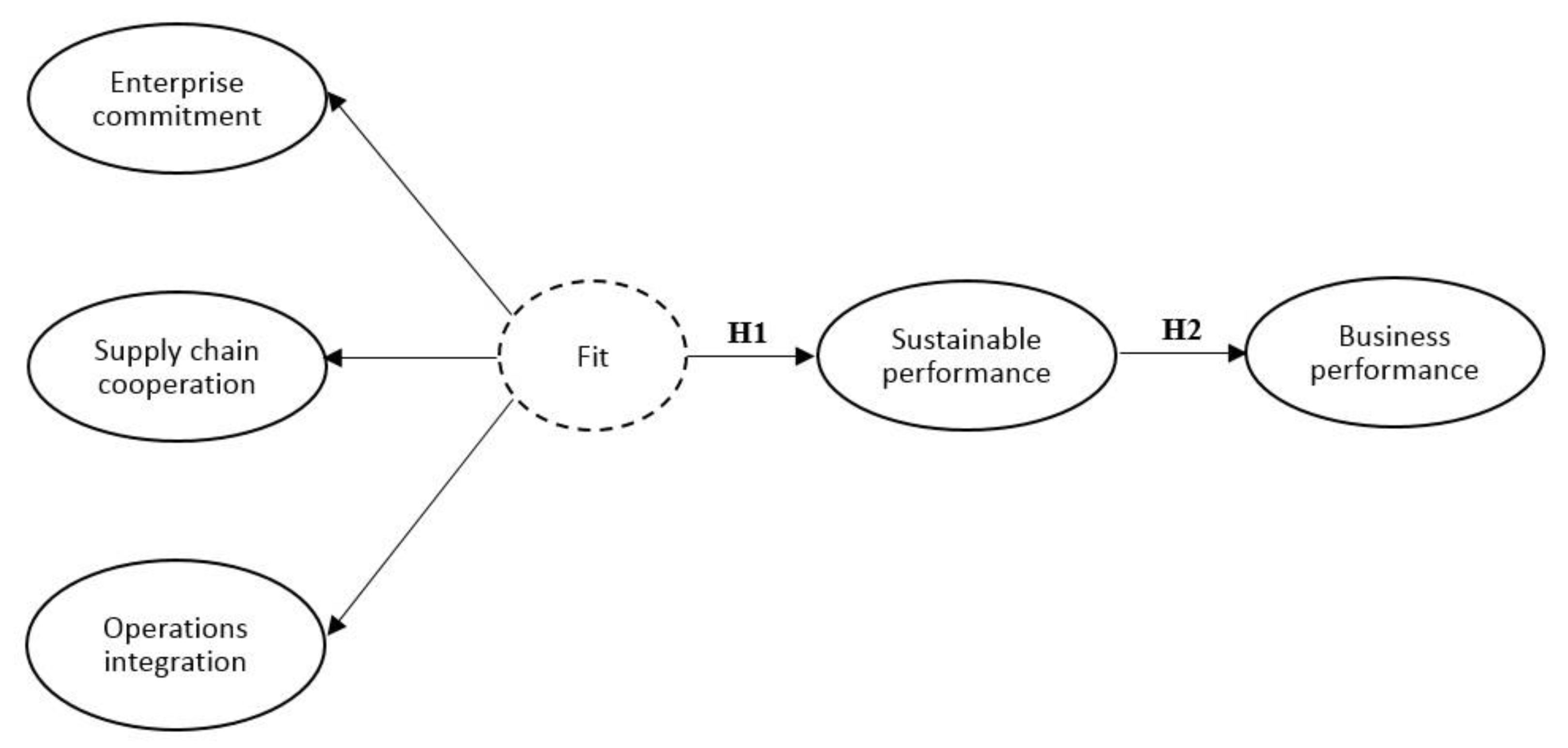

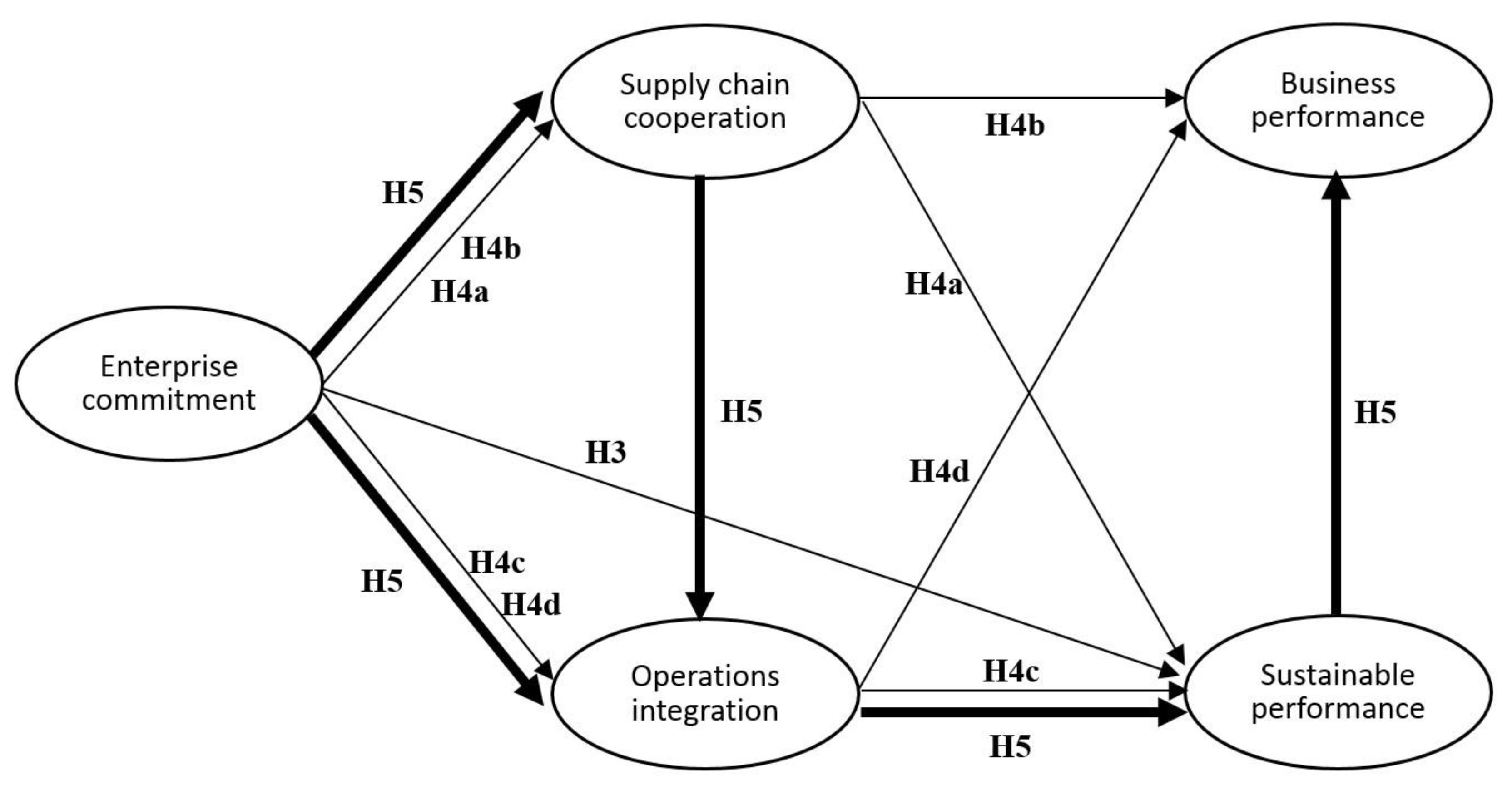

3. Research Model

3.1. Enterprise Commitment

3.2. Supply Chain Cooperation

3.3. Operation Integration

3.4. Sustainable Performance

3.5. Business Performance

3.6. Covariation Fit Model and Hypotheses

3.7. Mediation Fit Model and Hypothesis

4. Results and Discussion

4.1. Pearson Correlation Analysis

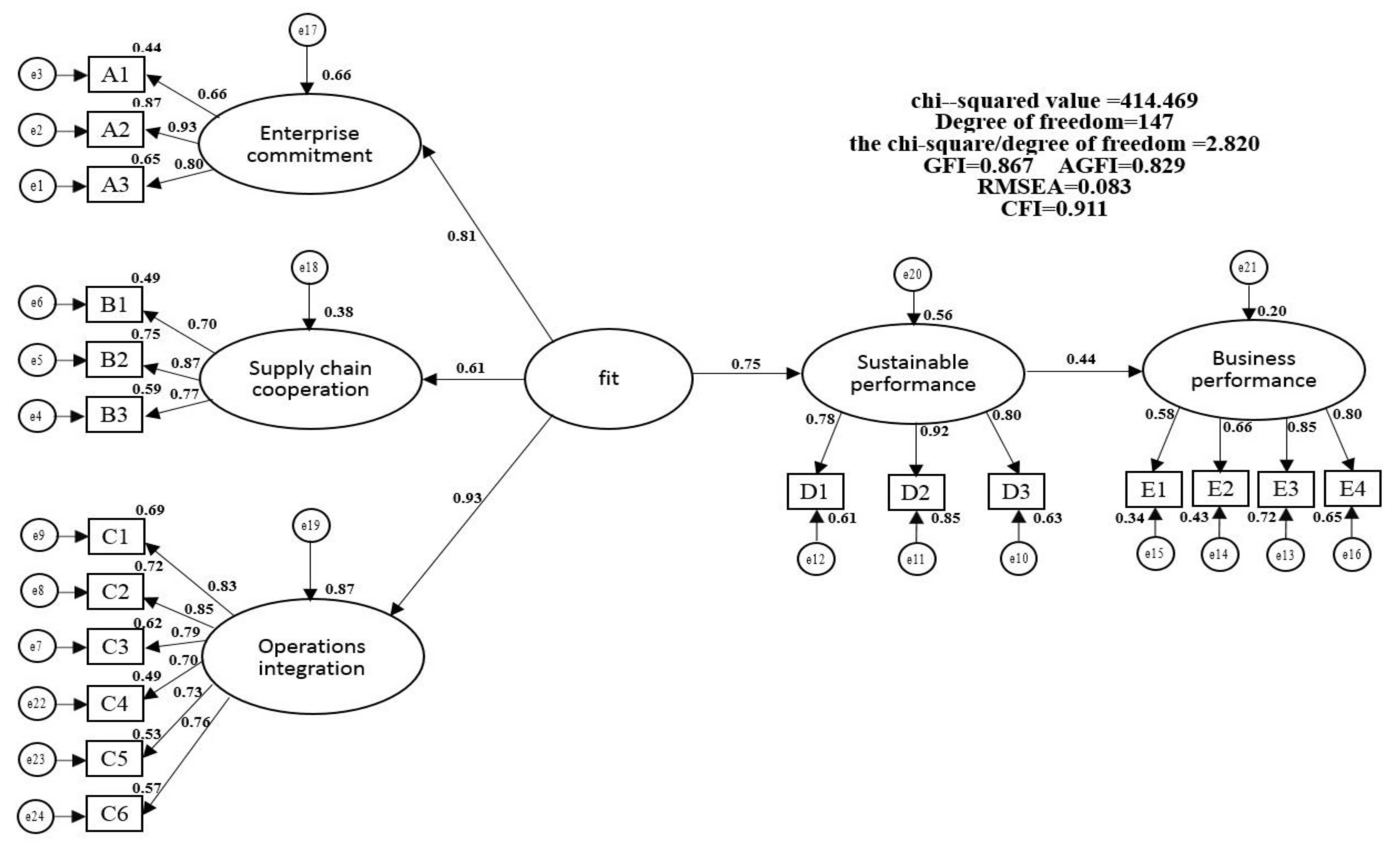

4.2. CFA

- Factor loads must be higher than 0.7; however, 0.6–0.7 is acceptable under validation analysis. Values lower than 0.6 are deleted;

- Composite reliability (CR) must be higher than 0.7 but not exceed 0.95;

- Average variance extracted (AVE) must be higher than 0.5;

- Square multiple correlations (SMCs) must be higher than 0.5.

4.3. Discriminant Validity Analysis

4.4. SEM Analysis of SSCs

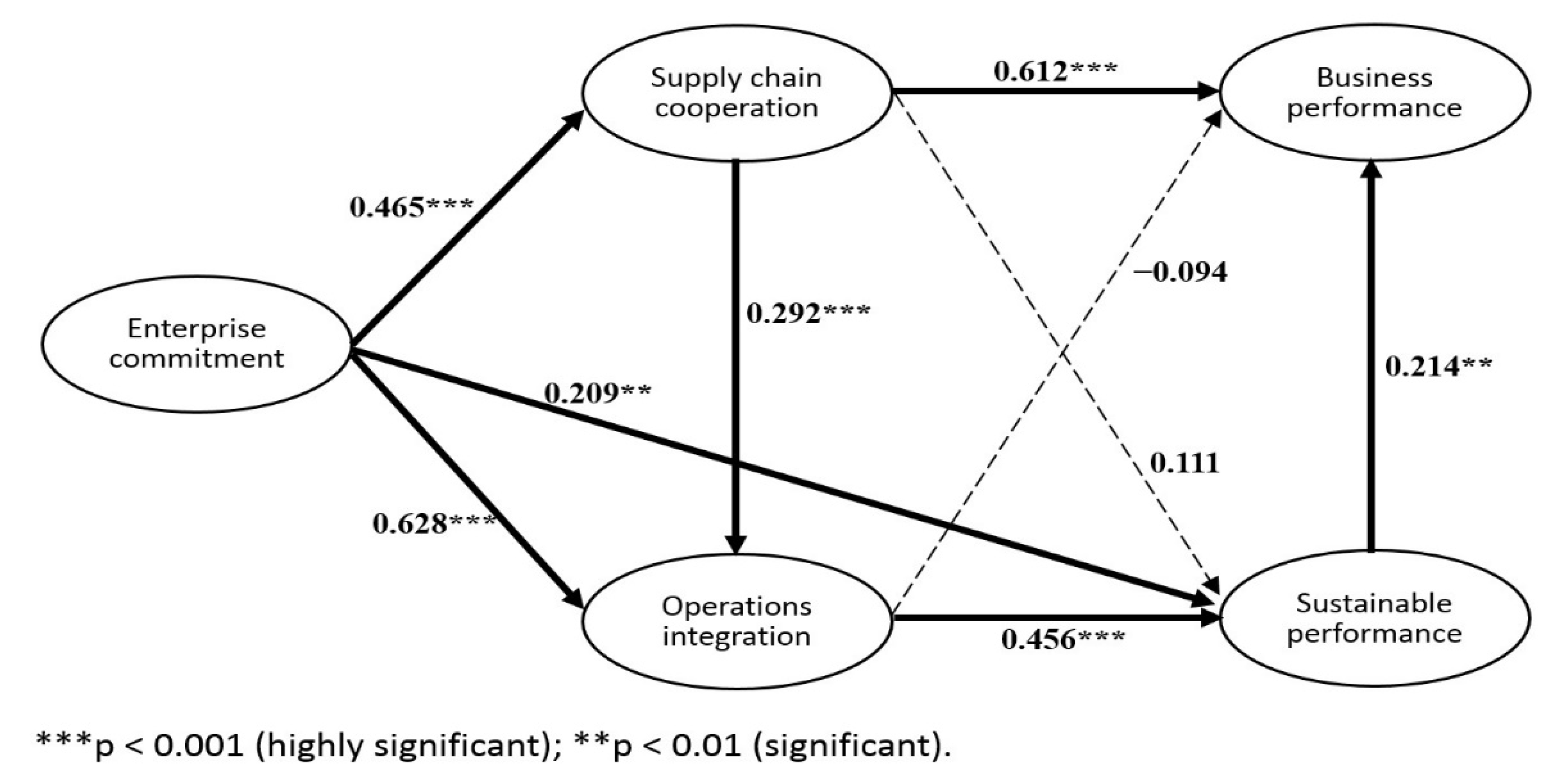

4.5. SSC Path Analysis

4.5.1. Manufacturer Mediation Fit Model: Process Fit

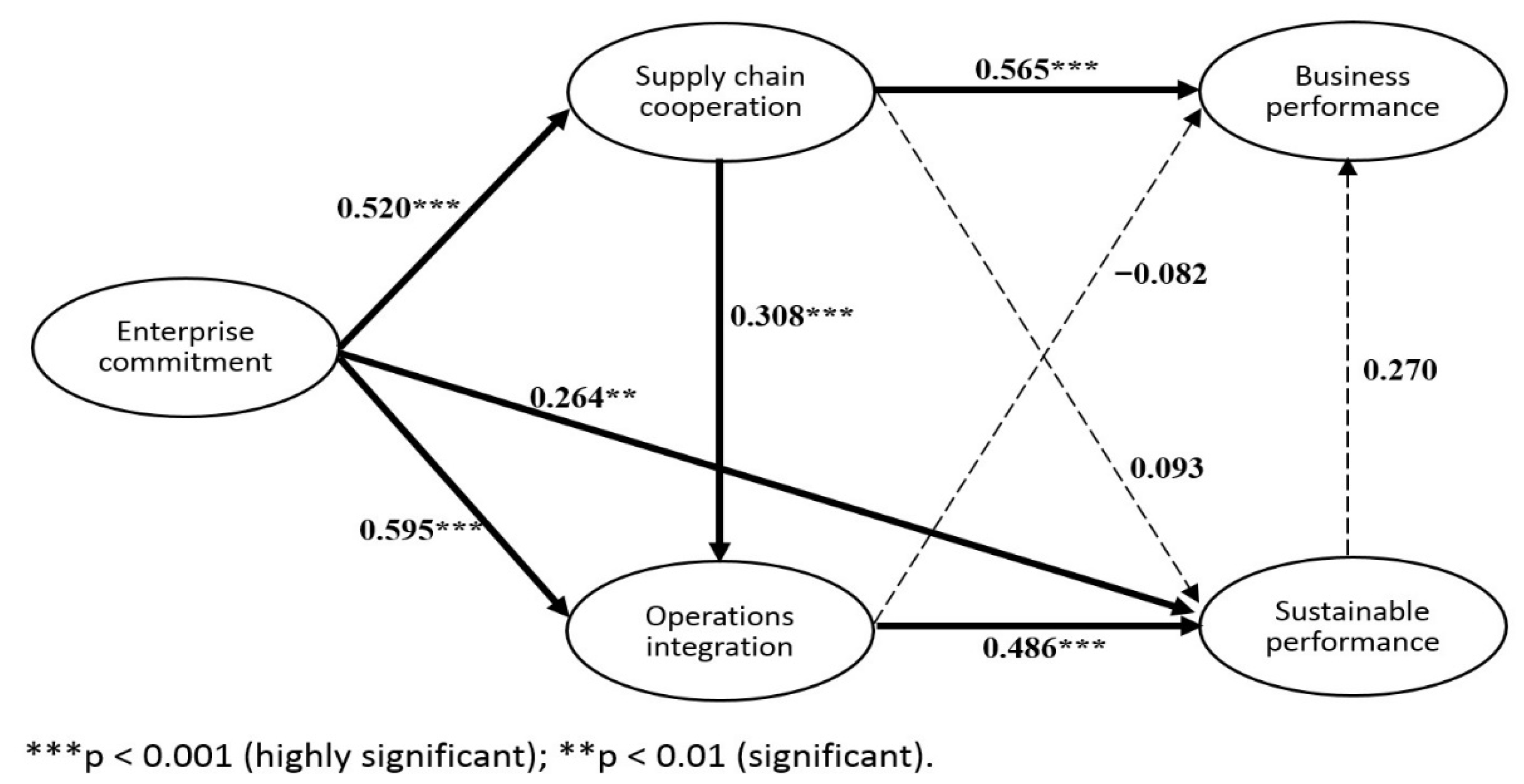

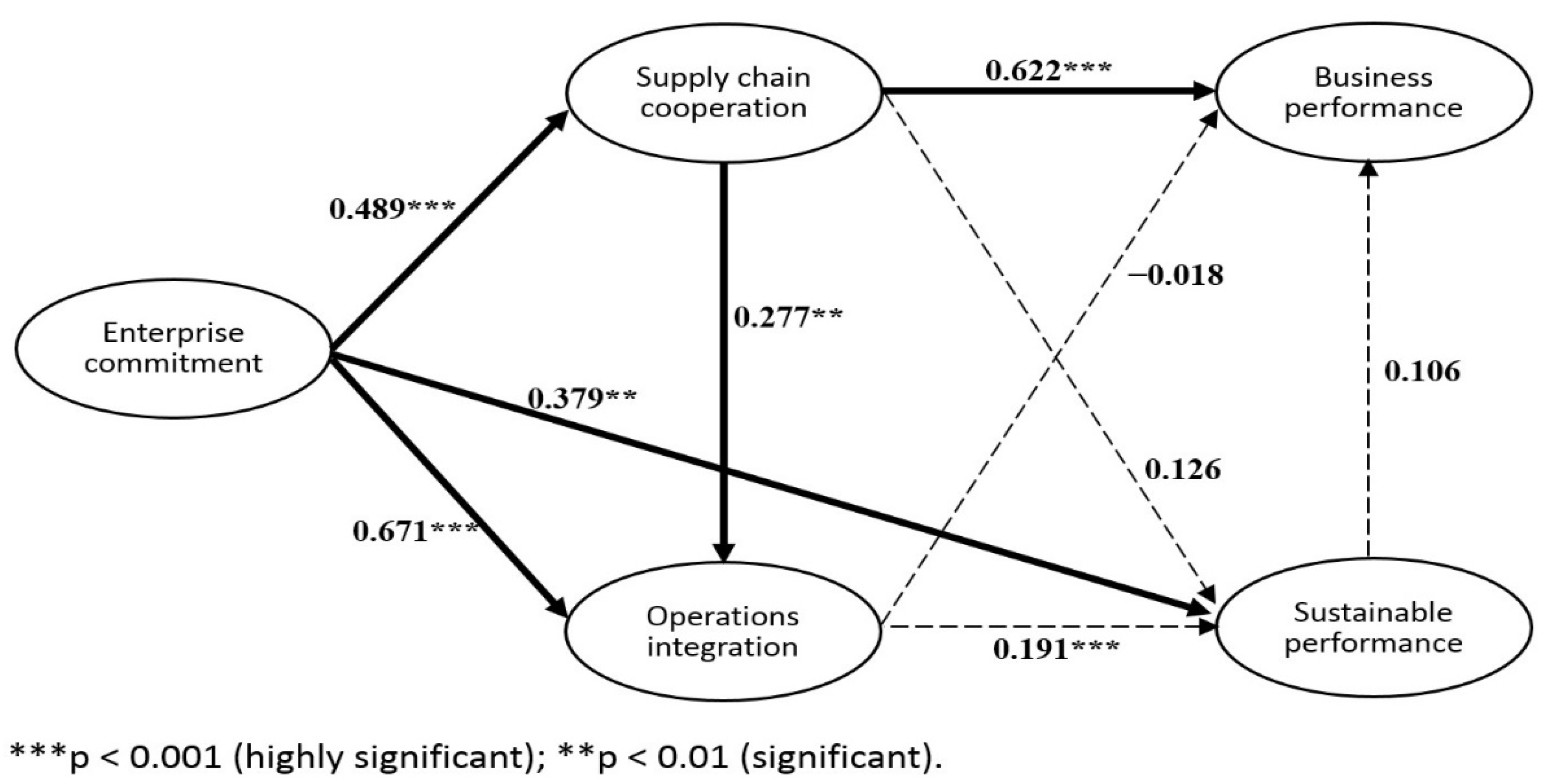

4.5.2. Manufacturer Mediation Fit Model: Industry Value Point

4.6. Results

5. Conclusions and Future Research

5.1. Academic Implications

5.2. Practical Implications

5.3. Limitation and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. Transforming our world: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Chow, W.S.; Madu, C.N.; Kuei, C.H.; Lu, M.H.; Lin, C.; Tseng, H. Supply chain management in the US and Taiwan: An empirical study. Omega 2008, 36, 665–679. [Google Scholar] [CrossRef]

- Koh, S.C.L.; Gunasekaran, A.; Tseng, C.S. Cross-tier ripple and indirect effects of directives WEEE and RoHS on greening a supply chain. Int. J. Prod. Econ. 2012, 140, 305–317. [Google Scholar] [CrossRef]

- Kot, S. Sustainable supply chain management in small and medium enterprises. Sustainability 2018, 10, 1143. [Google Scholar] [CrossRef] [Green Version]

- Martineau, P. Developing the Corporate Image; Charles Scribners Sons: New York, NY, USA, 1960; pp. 3–15. [Google Scholar]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; Van Der Laan, E.; Van Nunen, J.A.E.E.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply Chain Management: More Than a New Name for Logistics. Int. J. Logist. Manag. 1997, 8, 1–14. [Google Scholar] [CrossRef]

- Paulraj, A.; de Jong, P. The effect of ISO 14001 certification announcements on stock performance. Int. J. Oper. Prod. Manag. 2011, 31, 765–788. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Chen, C.W.; Wu, C.H.; Hung, H.C.; Lin, C.T. How do partners benefit from IT use in supply-chain management: An empirical study of Taiwan’s bicycle industry. Sustainability 2020, 12, 2883. [Google Scholar] [CrossRef] [Green Version]

- Imperatives, S. Report of the World Commission on Environment and Development: Our common future. Accessed Feb. 1987, 10, 1–300. [Google Scholar]

- Van Marrewijk, M. Concepts and Definitions of CSR and Corporate Sustainability: Between Agency and Communion. J. Bus. Ethics 2003, 44, 95–105. [Google Scholar] [CrossRef]

- Jayaram, J.; Avittathur, B. Green supply chains: A perspective from an emerging economy. Int. J. Prod. Econ. 2015, 164, 234–244. [Google Scholar] [CrossRef]

- Paliwal, V.; Chandra, S.; Sharma, S. Blockchain technology for sustainable supply chain management: A systematic literature review and a classification framework. Sustainability 2020, 12, 7638. [Google Scholar] [CrossRef]

- Bui, T.D.; Tsai, F.M.; Tseng, M.L.; Tan, R.R.; Yu, K.D.S.; Lim, M.K. Sustainable supply chain management towards disruption and organizational ambidexterity: A data driven analysis. Sustain. Prod. Consum. 2021, 26, 373–410. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M.I. Risk management in Halal supply chain: An integrated fuzzy Delphi and DEMATEL approach. J. Model. Manag. 2021, 16, 172–214. [Google Scholar] [CrossRef]

- Signori, P.; Flint, D.J.; Golicic, S. Toward sustainable supply chain orientation (SSCO): Mapping managerial perspectives. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 536–564. [Google Scholar] [CrossRef]

- Martinez, V.; Neely, A.; Ren, G.; Smart, A. High Value Manufacturing: Delivering on the Promise; Advanced Institute of Management Research (AIM): London, UK, 2008. [Google Scholar]

- Zhang, Y.; Gregory, M. Managing global network operations along the engineering value chain. Int. J. Oper. Prod. Manag. 2011, 31, 736–764. [Google Scholar] [CrossRef]

- MacBryde, J.; Paton, S.; Clegg, B. Understanding high-value manufacturing in Scottish SMEs. Int. J. Oper. Prod. Manag. 2013, 33, 1579–1598. [Google Scholar] [CrossRef]

- Mathieu, V. Service strategies within the manufacturing sector: Benefits, costs and partnership. Int. J. Serv. Ind. Manag. 2001, 12, 451–475. [Google Scholar] [CrossRef]

- Willard, B. The next sustainability wave. Ubiquity 2005, 2005, 1. [Google Scholar] [CrossRef]

- Keijzers, G. The transition to the sustainable enterprise. J. Clean. Prod. 2002, 10, 349–359. [Google Scholar] [CrossRef]

- Powell, W.W.; DiMaggio, P.J. The New Institutionalism in Organizational Analysis; University of Chicago Press: Chicago, IL, USA, 1991. [Google Scholar]

- Scott, W.R. Institutions and Organizations: Ideas and Interests; Sage publications: Los Angeles, FL, USA, 2008. [Google Scholar]

- Prajogo, D.; Huo, B.; Han, Z. The effects of different aspects of ISO 9000 implementation on key supply chain management practices and operational performance. Supply Chain Manag. 2012, 17, 306–322. [Google Scholar] [CrossRef]

- Borregan-Alvarado, J.; Alvarez-Meaza, I.; Cilleruelo-Carrasco, E.; Garechana-Anacabe, G. A Bibliometric Analysis in Industry 4.0 and Advanced Manufacturing: What about the Sustainable Supply Chain? Sustainability 2020, 12, 7840. [Google Scholar] [CrossRef]

- Carter, C.R. Ethical issues in international buyer-supplier relationships: A dyadic examination. J. Oper. Manag. 2000, 18, 191–208. [Google Scholar] [CrossRef]

- Krause, D.R.; Ragatz, G.L.; Hughley, S. Supplier development from the minority supplier’s perspective. J. Supply Chain Manag. 1999, 35, 33–41. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Wernerfelt, B. A resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Hart, S.L. A Natural-Resource-Based View of the Firm. In Corporate Environmental Responsibility; Routledge: London, UK, 2017; pp. 17–45. [Google Scholar]

- Vachon, S.; Klassen, R.D.; Johnson, P.F. Customers as Green Suppliers: Managing the complexity of the reverse supply chain. In Greener Manufacturing and Operations: From Design to Delivery and Back; Greenleaf Publishing: Austin, TX, USA, 2017; pp. 136–149. [Google Scholar]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef] [Green Version]

- Saeed, K.A.; Malhotra, M.K.; Grover, V. Examining the impact of interorganizational systems on process efficiency and sourcing leverage in buyer-supplier dyads. Decis. Sci. 2005, 36, 365–396. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Large, R.O.; Gimenez Thomsen, C. Drivers of green supply management performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Fabbe-Costes, N.; Roussat, C.; Taylor, M.; Taylor, A. Sustainable supply chains: A framework for environmental scanning practices. Int. J. Oper. Prod. Manag. 2014, 34, 664–694. [Google Scholar] [CrossRef] [Green Version]

- Blome, C.; Paulraj, A.; Schuetz, K. Supply chain collaboration and sustainability: A profile deviation analysis. Int. J. Oper. Prod. Manag. 2014, 34, 639–663. [Google Scholar] [CrossRef]

- Piercy, N.; Rich, N. The relationship between lean operations and sustainable operations. Int. J. Oper. Prod. Manag. 2015, 35, 282–315. [Google Scholar] [CrossRef]

- Ebner, D.; Baumgartner, R.J. The relationship between sustainable development and corporate social responsibility. In Proceedings of the Corporate Responsibility Research Conference, Dublin, Ireland, 4–5 September 2006; p. 2006. [Google Scholar]

- Carroll, A.B. A three-dimensional conceptual model of corporate performance. Acad. Manag. Rev. 1979, 4, 497–505. [Google Scholar] [CrossRef] [Green Version]

- Carroll, A.B. The pyramid of corporate social responsibility: Toward the moral management of organizational stakeholders. Bus. Horiz. 1991, 34, 39–48. [Google Scholar] [CrossRef]

- Carter, C.R.; Jennings, M.M. Social responsibility and supply chain relationships. Transp. Res. Part E Logist. Transp. Rev. 2002, 38, 37–52. [Google Scholar] [CrossRef]

- Carter, C.R.; Jennings, M.M. The role of purchasing in corporate social responsibility: A structural equation analysis. J. Bus. Logist. 2004, 25, 145–186. [Google Scholar] [CrossRef]

- Corsi, K.; Arru, B. Role and implementation of sustainability management control tools: Critical aspects in the Italian context. Account. Audit. Account. J. 2020, 34, 29–56. [Google Scholar] [CrossRef]

- Fisher, M.L. What is the right supply chain for your product? Harv. Bus. Rev. 1997, 75, 105–117. [Google Scholar]

- Pagell, M. Understanding the factors that enable and inhibit the integration of operations, purchasing and logistics. J. Oper. Manag. 2004, 22, 459–487. [Google Scholar] [CrossRef]

- Power, D. Supply chain management integration and implementation: A literature review. Supply Chain Manag. 2005, 10, 252–263. [Google Scholar] [CrossRef] [Green Version]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: An international study of supply chain strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Helper, S. How much has really changed between US automakers and their suppliers? MIT Sloan Manag. Rev. 1991, 32, 15. [Google Scholar]

- Botezat, E.A.; Dodescu, A.O.; Vaduva, S.; Fotea, S.L. An exploration of circular economy practices and performance among Romanian producers. Sustainability 2018, 10, 3191. [Google Scholar] [CrossRef] [Green Version]

- Porter, M.E. Technology and Competitive Advantage. J. Bus. Strategy 1985, 5, 60. [Google Scholar] [CrossRef]

- Denstadli, J.M.; Julsrud, T.E. Moving Towards Electrification of Workers’ Transportation: Identifying Key Motives for the Adoption of Electric Vans. Sustainability 2019, 11, 3878. [Google Scholar] [CrossRef] [Green Version]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Chardine-Baumann, E.; Botta-Genoulaz, V. A framework for sustainable performance assessment of supply chain management practices. Comput. Ind. Eng. 2014, 76, 138–147. [Google Scholar] [CrossRef]

- Ong, T.S.; Teh, B.H.; Lee, A.S. Contingent Factors and Sustainable Performance Measurement (SPM) Practices of Malaysian Electronics and Electrical Companies. Sustainability 2019, 11, 1058. [Google Scholar] [CrossRef] [Green Version]

- Theyel, G. Customer and supplier relations for environmental performance. Greener Manag. Int. 2001, 61–69. [Google Scholar] [CrossRef]

- Van Ewijk, S.; Stegemann, J.A.; Ekins, P. Limited climate benefits of global recycling of pulp and paper. Nat. Sustain. 2021, 4, 180–187. [Google Scholar] [CrossRef]

- Frosch, R.A. Industrial Ecology: Minimizing the Impact of Industrial Waste. Phys. Today 1994, 47, 63–68. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational determinants of environmental purchasing: Initial evidence from the consumer products industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Tiantian, G.; Yezhuang, T. Fit of strategies based on product-process matrix. Appl. Mech. Mater. 2012, 197, 266–270. [Google Scholar] [CrossRef]

- Smith, R.E.; Wright, W.F. Determinants of customer loyalty and financial performance. J. Manag. Account. Res. 2004, 16, 183–205. [Google Scholar] [CrossRef]

- Van Hoek, R.I. “Measuring the unmeasurable” measuring and improving performance in the supply chain. Supply Chain. Manag. An. Int. J. 1998, 3, 187–192. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Brady, K.; Henson, P.; Fava, J.A. Sustainability, eco-efficiency, life-cycle management, and business strategy. Environ. Qual. Manag. 1999, 8, 33–41. [Google Scholar] [CrossRef]

- Burnett, R.D.; Hansen, D.R.; Quintana, O. Eco-efficiency: Achieving productivity improvements through environmental cost management. Account. Public Interest 2007, 7, 66–92. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service (Second Edition). Int. J. Logist. Res. Appl. 1999, 2, 103–104. [Google Scholar] [CrossRef]

- Venkatraman, N. The concept of fit in strategy research: Toward verbal and statistical correspondence. Acad. Manag. Rev. 1989, 14, 423–444. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Al-Zabidi, A.; Rehman, A.U.; Alkahtani, M. An Approach to Assess Sustainable Supply Chain Agility for a Manufacturing Organization. Sustainability 2021, 13, 1752. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Faruk, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Ketchen, D.J., Jr.; Slater, S.F. Information processing, knowledge development, and strategic supply chain performance. Acad. Manag. J. 2004, 47, 241–253. [Google Scholar] [CrossRef]

- Ailawadi, K.; Farris, P.; Shames, E. Trade promotion: Essential to selling through resellers. MIT Sloan Manag. Rev. 1999, 41, 83. [Google Scholar]

- Han, S.L.; Wilson, D.T.; Dant, S.P. Buyer-supplier relationships today. Ind. Mark. Manag. 1993, 22, 331–338. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Sridharan, R. The collaboration index: A measure for supply chain collaboration. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 44–62. [Google Scholar] [CrossRef]

- Brandenburg, M.; Gruchmann, T.; Oelze, N. Sustainable Supply Chain Management—A Conceptual Framework and Future Research Perspectives. Sustainability 2019, 11, 7239. [Google Scholar] [CrossRef] [Green Version]

- Wijethilake, C.; Ekanayake, A. Proactive strategic responses to corporate sustainability pressures: A sustainability control system framework. Adv. Manag. Account. 2018, 30, 129–173. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Strategy & society: The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 84, 78–92. [Google Scholar]

- Boiral, O. ISO 9000: Outside the Iron Cage. Organ. Sci. 2003, 14, 720–737. [Google Scholar] [CrossRef] [Green Version]

- Vachon, S. Green supply chain practices and the selection of environmental technologies. Int. J. Prod. Res. 2007, 45, 4357–4379. [Google Scholar] [CrossRef]

- Hildalgo, A.; Albors, J. Innovation management techniques and tools: A review from theory to practice. R&D Manag. 2000, 38, 113–127. [Google Scholar]

- Dyer, J.H.; Singh, H. The relational view: Cooperative strategy and sources of interorganizational competitive advantage. Acad. Manag. Rev. 1998, 23, 660–679. [Google Scholar] [CrossRef] [Green Version]

- García Martín, C.J.; Herrero, B. Do board characteristics affect environmental performance? A study of EU firms. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 74–94. [Google Scholar] [CrossRef]

- Florida, R. Lean and green: The move to environmentally conscious manufacturing. Calif. Manag. Rev. 1996, 80–105. [Google Scholar] [CrossRef]

- Hill, R.C.; Griffiths, W.E.; Judge, G.G. Undergraduate Econometrics, 2nd ed.; John Wiley: New York, NY, USA, 2001. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: Global Edition; Pearson Education Limited: London, UK, 2010. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Doll, W.J.; Xia, W.; Torkzadeh, G. A confirmatory factor analysis of the end-user computing satisfaction instrument. MIS Q. Manag. Inf. Syst. 1994, 18, 453–460. [Google Scholar] [CrossRef]

- MacCallum, R.C.; Hong, S. Power analysis in covariance structure modeling using GFI and AGFI. Multivar. Behav. Res. 1997, 32, 193–210. [Google Scholar] [CrossRef]

- Fan, X.; Thompson, B.; Wang, L. Effects of sample size, estimation methods, and model specification on structural equation modeling fit indexes. Struct. Equ. Modeling 1999, 6, 56–83. [Google Scholar] [CrossRef]

- Piercy, N.; Brammer, S. A Complete Definition of Corporate Social Responsibility and Sustainability; British Academy Report: London, UK, 2012. [Google Scholar]

- Mageto, J. Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability 2021, 13, 7101. [Google Scholar] [CrossRef]

| Author(s) | Sustainability | Enterprise | Manufacturing | Supply Chain | Methods |

|---|---|---|---|---|---|

| Desa [1] | Include | Include | Include | Include | NA |

| Chow et al. [2] | NA | Include | Include | Include | SEM |

| Koh et al. [3] | Part | Part | Part | Green | Case |

| Kot [4] | Include | Include | Include | Include | Survey analysis |

| Martineau [5] | NA | NA | NA | Reverse logistics | OR |

| Fleischmann et al. [6] | Recycle | NA | Part | Reverse logistics | Review |

| Cooper et al. [7] | NA | Part | NA | SCM | Review |

| Paulraj and de Jong [8] | ISO-14001 | Include | NA | NA | Event-study |

| Li et al. [9] | Include | Part | Part | SCM | SEM |

| WCED [10] | Include | Include | Include | Include | NA |

| van Marrewijk [11] | Include | Include | NA | NA | Review |

| Jayaram and Avittathur [12] | Include | Include | Include | Include | Review |

| Paliwal et al. [13] | Include | Include | NA | Block chain | Review |

| Bui et al. [14] | Include | Include | NA | SSC | Data-driven literature review |

| Khan et al. [15] | Sustainability-related risks | Planning-related risks | NA | Logistic and outsourcing related risks | Fuzzy Delphi and fuzzy DEMATEL |

| Signori [16] | Include | Include | NA | SSC | Theory-building grounded |

| This study | Include | Include | Include | Include | SEM Mediation fit model |

| Facet | Questionnaire Item |

|---|---|

| A. Enterprise commitment | A1. The importance of “organizational development and growth” |

| A2. The importance of “green industry” | |

| A3. The importance of “social responsibility” | |

| B. Supply chain cooperation | B1. The maturity of the “production and sales synergy” mechanism |

| B2. The maturity of “customer relationship management” | |

| B3. The maturity of the “customer rating mechanism” | |

| C. Operations integration | C1. The degree to which market planning is conducted in the context of green products |

| C2. The extent to which production planning is conducted in the context of low-carbon production | |

| C3. The extent to which it is conducted in the context of green transport | |

| C4. The ability to reduce the “carbon footprint” of a product | |

| C5. The extent to which purchases are made in the context of “green suppliers” | |

| C6. The extent to which green storage is conducted | |

| D. Sustainable performance | D1. The capability to manage” environmentally hazardous substances” (e.g., lead, mercury, and cadmium) |

| D2. The capability to “use chemical substances” | |

| D3. The capability to “recycle waste” | |

| E. Business performance | E1. The capability to “order delivery” |

| E2. The capability to continually “reduce inventory” | |

| E3. The capability to continually “improve product yield” | |

| E4. The capability to continually “increase capacity utilization” |

| Classification | Questionnaire Item |

|---|---|

| Current state of business operations | 1.1. Age of the company |

| 1.2. Company patterns | |

| 1.3. Number of worldwide employees in the company | |

| 1.4. The global business scale of the company | |

| Range of the enterprise’s business services | 2.1. The company is in a primary industry |

| 2.2. The company’s primary business operations are conducted in various countries and regions | |

| Respondents’ information | 3.1. Respondent’s seniority |

| 3.2. Respondent’s position in the company |

| Enterprise Commitment | Supply Chain Cooperation | Operations Integration | Sustainable Performance | Business Performance | |

|---|---|---|---|---|---|

| Enterprise commitment | 1 | ||||

| Supply chain cooperation | 0.458 | 1 | |||

| Operations integration | 0.766 | 0.586 | 1 | ||

| Sustainable performance | 0.609 | 0.475 | 0.680 | 1 | |

| Business performance | 0.383 | 0.654 | 0.374 | 0.419 | 1 |

| Model Parameter Estimation | Convergence | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Facial Surface | Item | Non-Standard Factor Load | S.E. | C.R. | p | Standardization Factor Load | SMC | C.R | AVE |

| Enterprise commitment | A. 1 | 1.000 | 0.834 | 0.461 | 0.748 | 0.654 | |||

| A. 2 | 1.126 | 0.084 | 13.426 | *** | 0.897 | 0.805 | |||

| A. 3 | 0.710 | 0.062 | 11.540 | *** | 0.679 | 0.695 | |||

| Supply chain cooperation | B. 1 | 1.000 | 0.683 | 0.530 | 0.747 | 0.611 | |||

| B. 2 | 1.304 | 0.127 | 10.247 | *** | 0.914 | 0.836 | |||

| B. 3 | 1.043 | 0.100 | 10.457 | *** | 0.728 | 0.466 | |||

| Operations integration | C. 1 | 1.000 | 0.856 | 0.520 | 0.857 | 0.606 | |||

| C. 2 | 0.817 | 0.062 | 13.191 | *** | 0.713 | 0.547 | |||

| C. 3 | 0.890 | 0.055 | 16.168 | *** | 0.819 | 0.656 | |||

| C. 4 | 0.913 | 0.057 | 15.900 | *** | 0.810 | 0.670 | |||

| C. 5 | 0.874 | 0.063 | 13.889 | *** | 0.739 | 0.508 | |||

| C. 6 | 0.827 | 0.062 | 13.410 | *** | 0.721 | 0.734 | |||

| Sustainable performance | D. 1 | 1.000 | 0.757 | 0.593 | 0.747 | 0.700 | |||

| D. 2 | 1.270 | 0.091 | 13.912 | *** | 0.966 | 0.933 | |||

| D. 3 | 1.042 | 0.079 | 13.177 | *** | 0.770 | 0.574 | |||

| Business performance | E. 1 | 1.000 | 0.658 | 0.370 | 0.797 | 0.543 | |||

| E. 2 | 1.043 | 0.097 | 10.724 | *** | 0.860 | 0.630 | |||

| E. 3 | 0.998 | 0.095 | 10.459 | *** | 0.794 | 0.740 | |||

| E. 4 | 0.830 | 0.097 | 8.509 | *** | 0.608 | 0.433 | |||

| Enterprise Commitment | Supply Chain Cooperation | Operations Integration | Sustainable Performance | Business Performance | |

|---|---|---|---|---|---|

| Enterprise commitment | 0.654 | ||||

| Supply chain cooperation | 0.210 | 0.611 | |||

| Operations integration | 0.587 | 0.343 | 0.606 | ||

| Sustainable performance | 0.371 | 0.226 | 0.462 | 0.700 | |

| Business performance | 0.147 | 0.428 | 0.140 | 0.176 | 1 |

| Facial Surface | Direction | Facial Surface | Non-Standard Coefficient | Standardization Coefficient | S.E. | C.R. | p-Value |

|---|---|---|---|---|---|---|---|

| Sustainable performance | ← | Goodness of fit | 1.053 | 0.749 | 0.116 | 9.071 | *** |

| Enterprise commitment | ← | Goodness of fit | 1.000 | 0.814 | - | - | - |

| Supply chain cooperation | ← | Goodness of fit | 0.630 | 0.614 | 0.084 | 7.463 | *** |

| Operations integration | ← | Goodness of fit | 1.357 | 0.935 | 0.141 | 9.646 | *** |

| Business performance | ← | Sustainable performance | 0.299 | 0.442 | 0.048 | 6.279 | *** |

| Path | Path Coefficient | C.R. | p | ||

|---|---|---|---|---|---|

| Enterprise commitment | → | Supply chain cooperation | 0.465 | 5.965 | *** |

| Enterprise commitment | → | Operations integration | 0.628 | 8.110 | *** |

| Supply chain cooperation | → | Operations integration | 0.292 | 4.798 | *** |

| Supply chain cooperation | → | Sustainable performance | 0.111 | 1.569 | 0.117 |

| Operations integration | → | Sustainable performance | 0.456 | 4.325 | *** |

| Enterprise commitment | → | Sustainable performance | 0.209 | 2.293 | 0.022 * |

| Supply chain cooperation | → | Business performance | 0.612 | 6.227 | *** |

| Operations integration | → | Business performance | −0.094 | −0.993 | 0.321 |

| Sustainable performance | → | Business performance | 0.214 | 2.465 | 0.014 * |

| Path | High-Value Manufacturing | General Manufacturing | ||||

|---|---|---|---|---|---|---|

| Path Coefficient | C.R. | Path Coefficient | C.R. | |||

| Enterprise commitment | → | Supply chain cooperation | 0.520 | 4.415 *** | 0.489 | 3.861 *** |

| Enterprise commitment | → | Operations integration | 0.595 | 5.248 *** | 0.671 | 5.238 *** |

| Supply chain cooperation) | → | Operations integration | 0.308 | 3.269 ** | 0.277 | 2.951 ** |

| Supply chain cooperation | → | Sustainable performance | 0.093 | 0.943 | 0.126 | 1.029 |

| Operations integration | → | Sustainable performance | 0.486 | 3.373 *** | 0.191 | 1.015 |

| Enterprise commitment | → | Sustainable performance | 0.264 | 2.079 ** | 0.379 | 2.127 ** |

| Supply chain cooperation | → | Business performance | 0.565 | 3.972 *** | 0.622 | 3.856 *** |

| Operations integration | → | Business performance | −0.082 | −0.538 | −0.018 | −0.131 |

| Sustainable performance | → | Business performance | 0.270 | 1.899 | 0.106 | 0.937 |

| Hypothesis | p-Value | Support or Not | |

|---|---|---|---|

| Covariation Fit Model | H1: In a sustainable manufacturing supply chain, supply chain cooperation, enterprise commitment, and operation integration have a positive impact on sustainable performance. | *** | Support |

| H2: Sustainable performance has a positive impact on an enterprise’s business performance. | *** | Support | |

| Mediation Fit Model | H3: Enterprise commitment has a direct positive impact on sustainable performance. | ** | Support |

| H4a: Enterprise commitment has a direct positive impact on sustainable performance through supply chain cooperation. | 0.117 | Not support | |

| H4b: Enterprise commitment has a direct positive impact on business performance through supply chain cooperation. | *** | Support | |

| H4c: Enterprise commitment has a positive impact on sustainable performance through operation integration. | *** | Support | |

| H4d: Enterprise commitment has a positive impact on operating performance through operation integration. | 0.321 | Not support | |

| H5: Enterprise commitment forms an intermediary mediation fit with supply chain cooperation and operation integration, which has a positive impact on sustainable performance and a subsequent effect on business performance. | ** | Support | |

| Mediation Fit Model—industry perspective | H6: The supply chain structure adaptation model differs for diverse value-added industries. | - | Support |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leu, J.-D.; Lee, L.J.-H.; Huang, Y.-W.; Huang, C.-C. Sustainable Supply Chains: Evidence from Small and Medium-Sized Manufacturers. Sustainability 2021, 13, 9059. https://doi.org/10.3390/su13169059

Leu J-D, Lee LJ-H, Huang Y-W, Huang C-C. Sustainable Supply Chains: Evidence from Small and Medium-Sized Manufacturers. Sustainability. 2021; 13(16):9059. https://doi.org/10.3390/su13169059

Chicago/Turabian StyleLeu, Jun-Der, Larry Jung-Hsing Lee, Yi-Wei Huang, and Chia-Chi Huang. 2021. "Sustainable Supply Chains: Evidence from Small and Medium-Sized Manufacturers" Sustainability 13, no. 16: 9059. https://doi.org/10.3390/su13169059

APA StyleLeu, J.-D., Lee, L. J.-H., Huang, Y.-W., & Huang, C.-C. (2021). Sustainable Supply Chains: Evidence from Small and Medium-Sized Manufacturers. Sustainability, 13(16), 9059. https://doi.org/10.3390/su13169059