Changes in Chemical Properties of Banana Pseudostem, Mushroom Media Waste, and Chicken Manure through the Co-Composting Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Collection, Preparation, and Pile Management

2.2. Research Design

2.3. Collection and Preparation of Compost Samples for Physicochemical Analysis

2.4. Monitoring of Temperature Profile (°C) and Moisture in the Composting Process

2.5. Chemical Analysis of the Compost Samples

2.6. Compost Toxicity Test

2.7. Statistical Analysis

3. Results

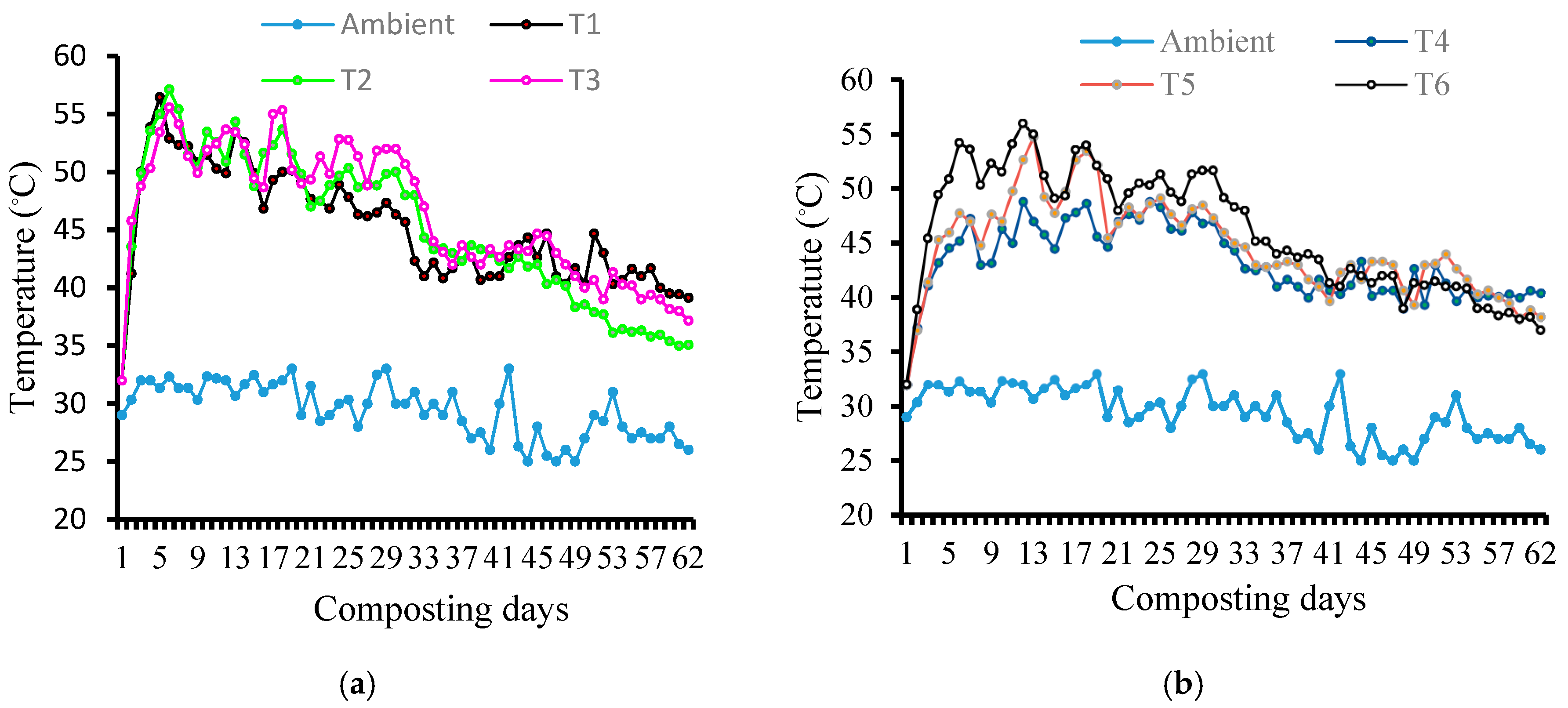

3.1. Monitoring Temperature Profile during the Composting Period

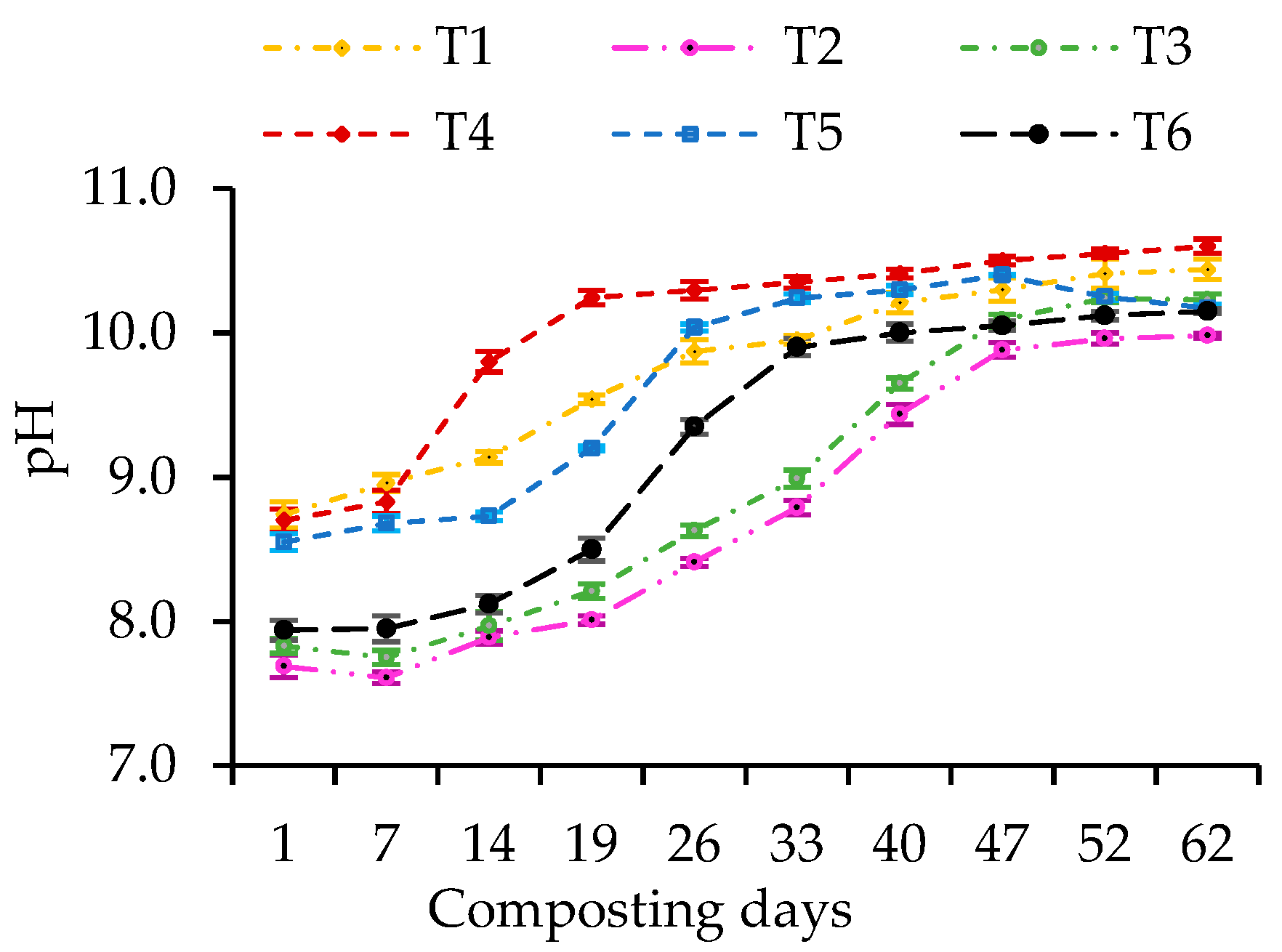

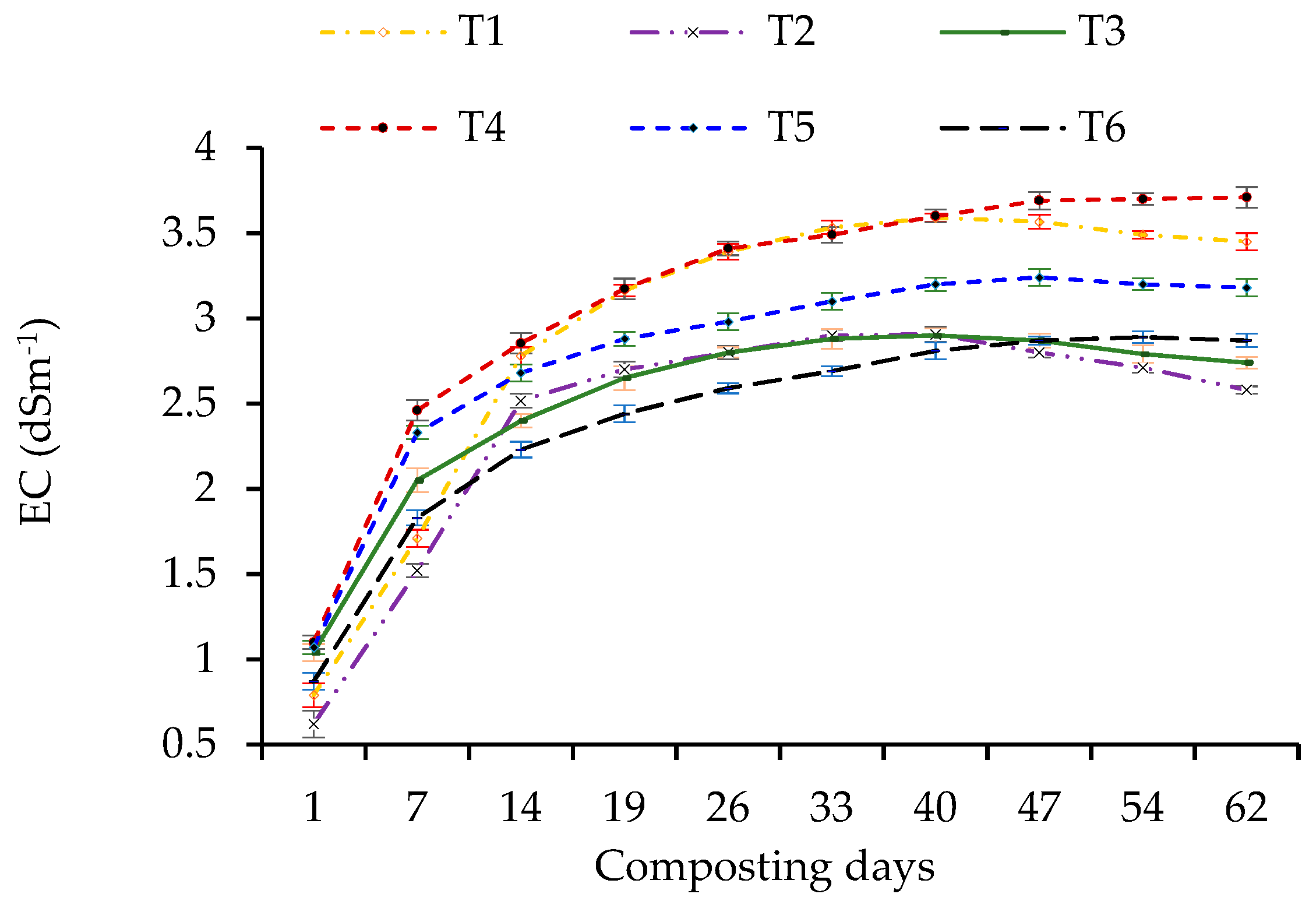

3.2. Changes in pH and EC during the Co-Composting

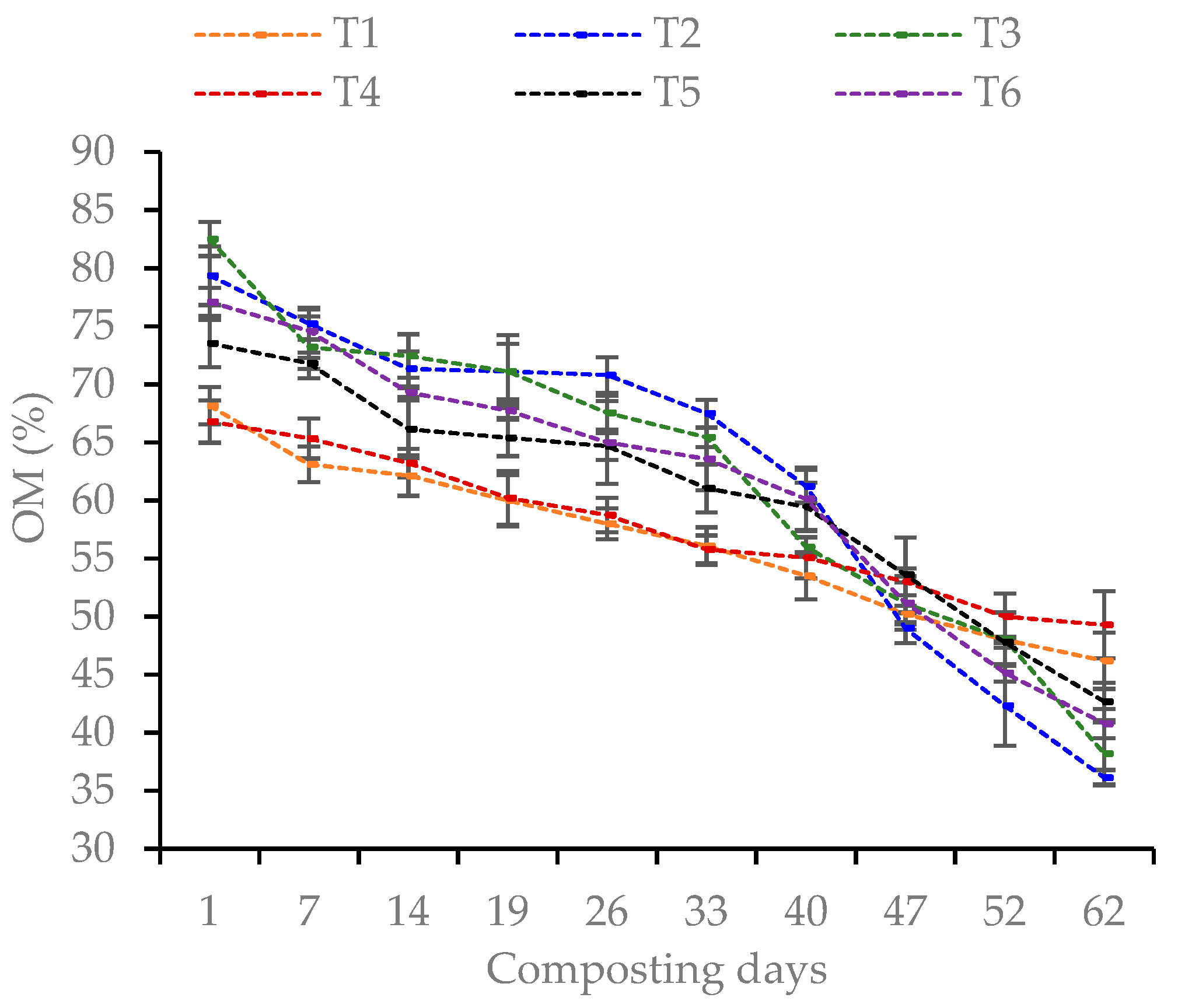

3.3. Organic Matter Degradation

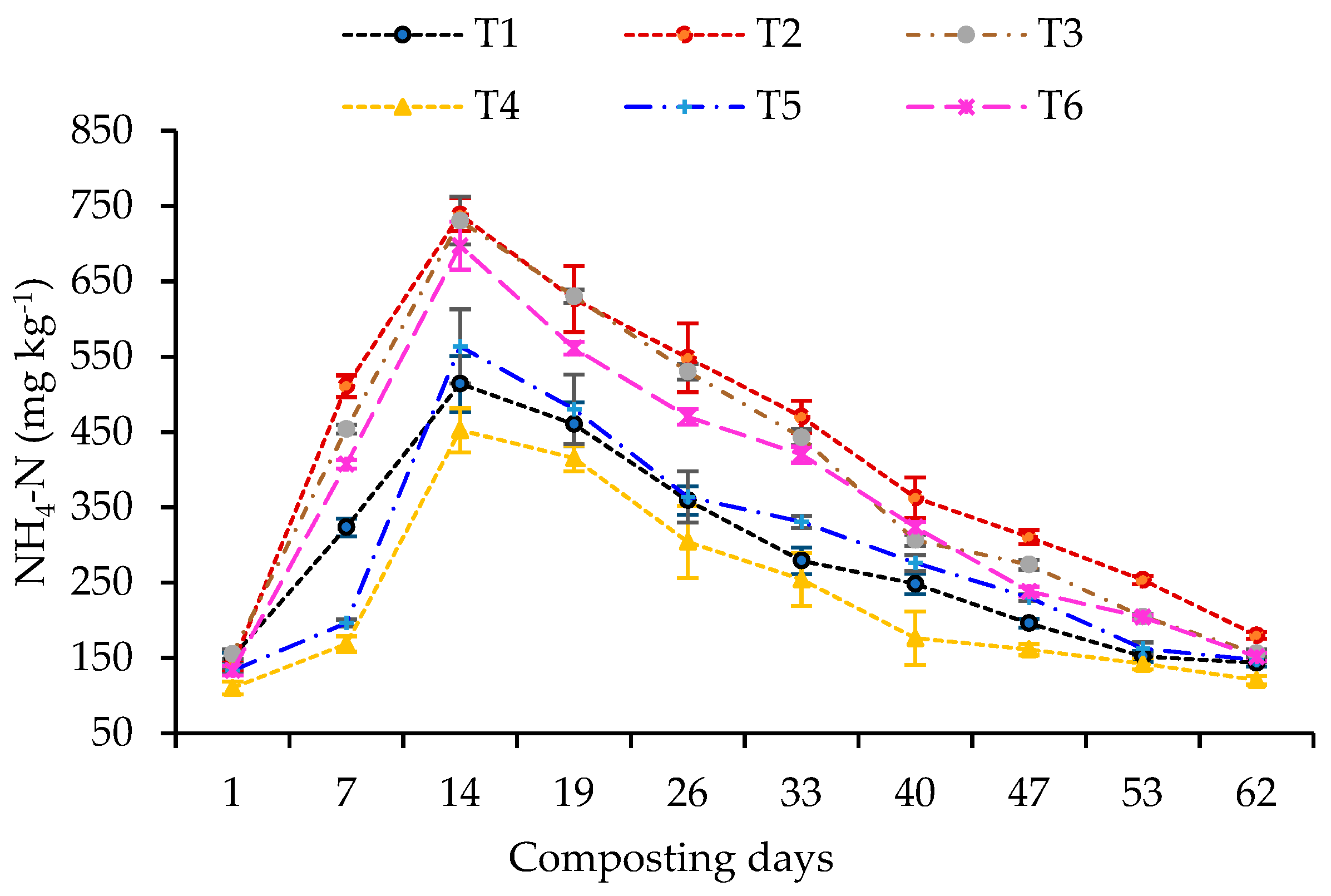

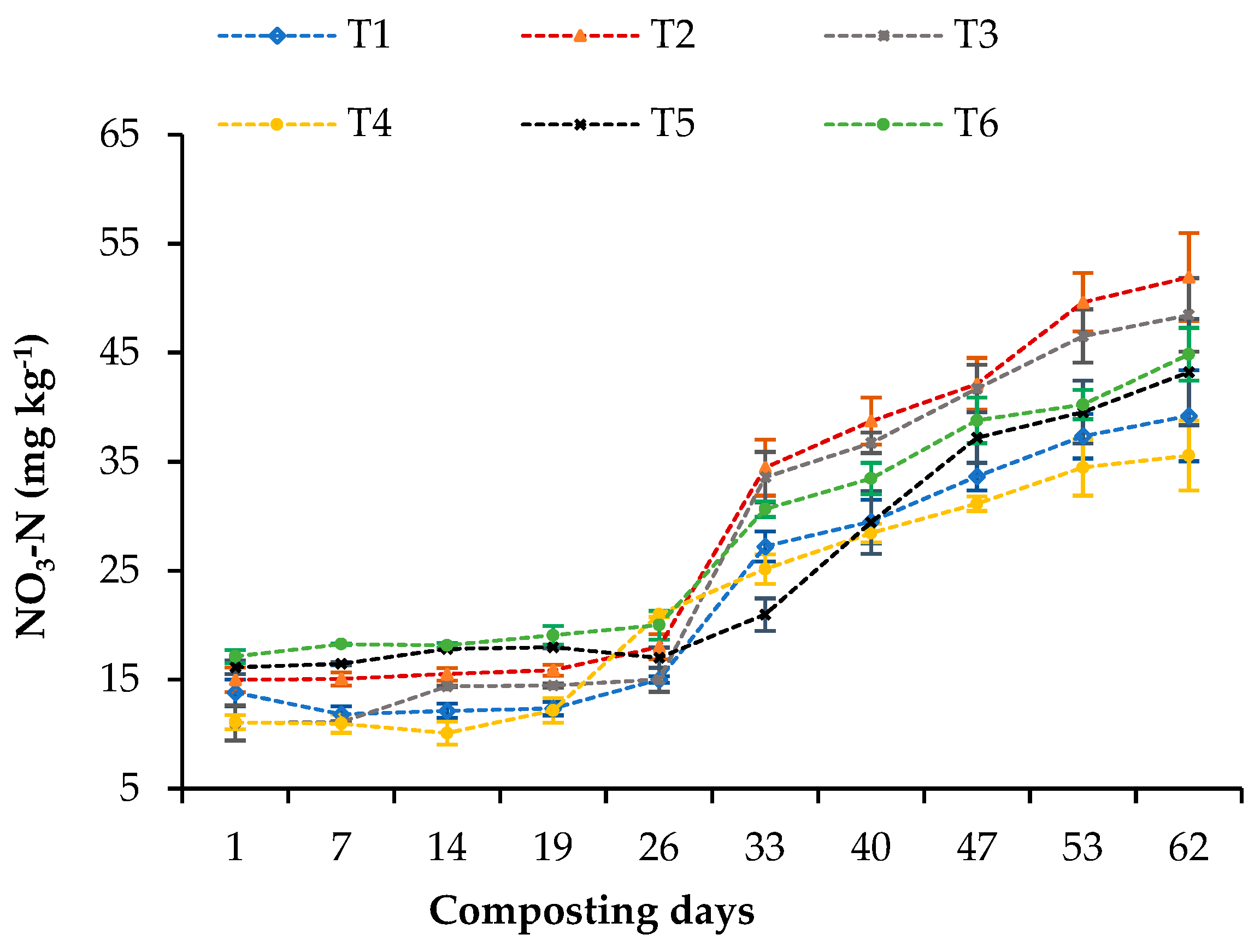

3.4. Changes of Total N, NH4-N, and NO3-N

3.5. Changes in Moisture

3.6. Changes in Total C

3.7. Changes in C:N Ratio

3.8. Changes in CEC

3.9. Changes in Macro- and Micro-Nutrients

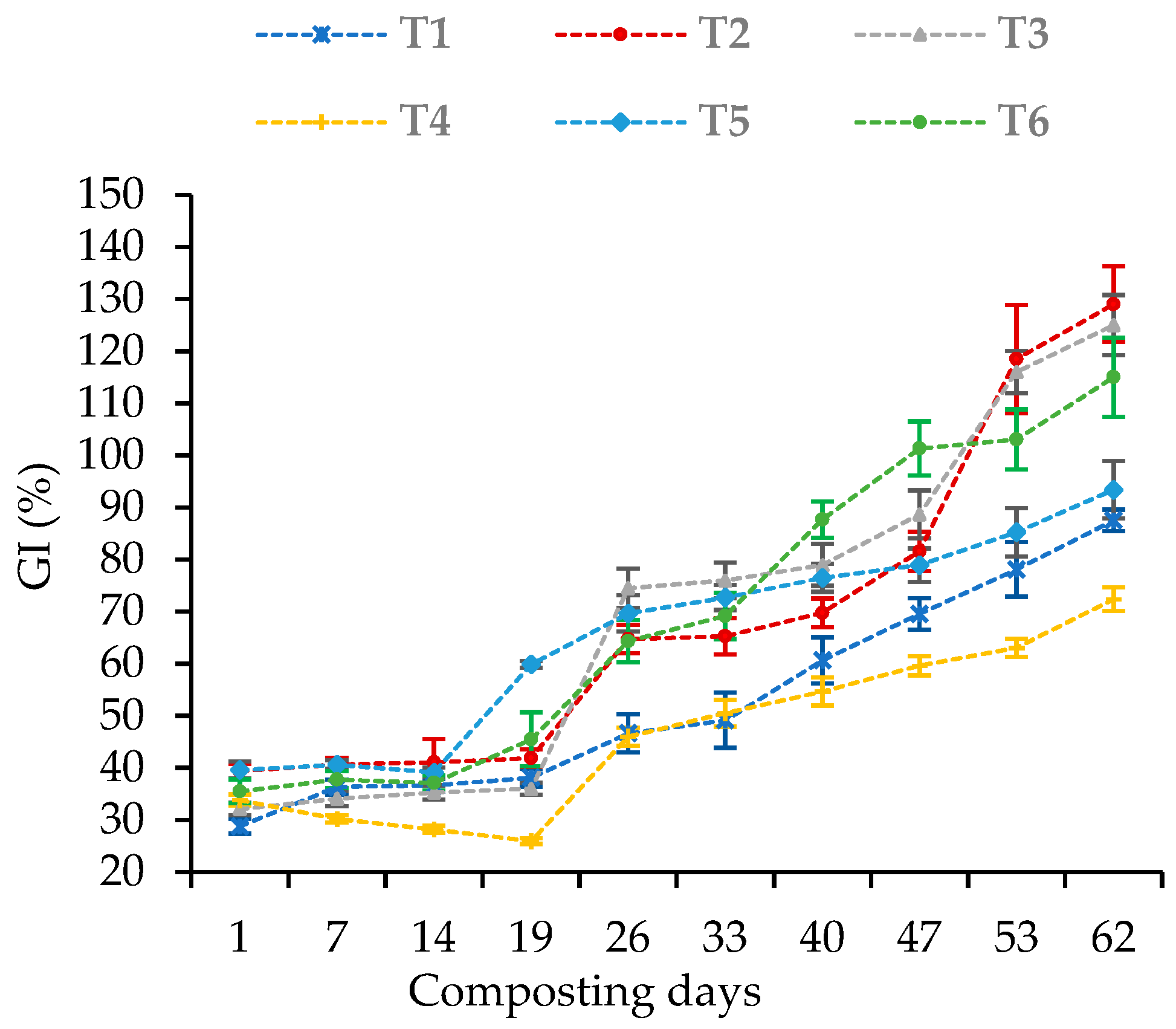

3.10. Germination Index (%) under the Compost

4. Discussion

4.1. Monitoring Temperature during the Composting

4.2. Changes in pH and EC during the Co-Composting

4.3. Changes in OM, TOC, C:N, and CEC during the Co-Composting

4.4. Changes in TN and Inorganic N during the Co-Composting

4.5. Changes in Nutrients Density during the Co-Composting

4.6. Changes in Germination Index during the Co-Composting

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bonoli, A.; Zanni, S.; Awere, E. Organic waste composting and sustainability in low-income communities in Palestine: Lessons from a pilot project in the village of Al Jalameh, Jenin. Int. J. Recycl. Org. Waste Agric. 2019, 8, 253–262. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chen, L.; Xia, S.; Zhao, J. Changes of Cu, Zn, and Ni chemical speciation in sewage sludge co-composted with sodium sulfide and lime. J. Environ. Sci. 2008, 20, 156–160. [Google Scholar] [CrossRef]

- Petric, I.; Helić, A.; Avdić, E.A. Evolution of process parameters and determination of kinetics for co-composting of organic fraction of municipal solid waste with poultry manure. Bioresour. Technol. 2012, 117, 107–116. [Google Scholar] [CrossRef]

- Yu, H.; Xie, B.; Khan, R.; Shen, G. The changes in carbon, nitrogen components and humic substances during organic-inorganic aerobic co-composting. Bioresour. Technol. 2019, 271, 228–235. [Google Scholar] [CrossRef]

- Sharma, M.; Patel, S.N.; Sangwan, R.S.; Singh, S.P. Biotransformation of banana pseudostem extract into a functional juice containing value added biomolecules of potential health benefits. Indian J. Exp. Biol. 2017, 55, 453–462. [Google Scholar]

- FAO. FAOSTAT [WWW Document]. 2017. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 31 January 2017).

- Bahtiar, S.A.; Muayyad, A.; Ulfaningtias, L.; Anggara, J.; Priscilla, C.; Miswar, M. Compost use banana weevil (Musa Acuminata) to boost growth and content of sugar sweet corn (Zea mays L. Saccharata). J. Agric. Sci. 2017, 14, 18–22. [Google Scholar]

- Medina, E.; Paredes, C.; Pérez-Murcia, M.D.; Bustamante, M.A.; Moral, R. Spent mushroom substrates as component of growing media for germination and growth of horticultural plants. Bioresour. Technol. 2009, 100, 4227–4232. [Google Scholar] [CrossRef]

- Fang, W.; Zhang, P.; Gou, X.; Zhang, H.; Wu, Y.; Ye, J.; Zeng, G. Volatile fatty acid production from spent mushroom compost: Effect of total solid content. Int. Biodeterior. Biodegrad. 2016, 113, 217–221. [Google Scholar] [CrossRef]

- Blazy, V.; De Guardia, A.; Benoist, J.C.; Daumoin, M.; Lemasle, M.; Wolbert, D.; Barrington, S. Odorous gaseous emissions as influence by process condition for the forced aeration composting of pig slaughterhouse sludge. Waste Manag. 2014, 34, 1125–1138. [Google Scholar] [CrossRef]

- Preusch, P.L.; Adler, P.R.; Sikora, L.J.; Tworkoski, T.J. Nitrogen and Phosphorus Availability in Composted and Uncomposted Poultry Litter. J. Environ. Qual. 2002, 31, 2051–2057. [Google Scholar] [CrossRef]

- Hepperly, P.; Lotter, D.; Ulsh, C.Z.; Seidel, R.; Reider, C. Compost, Manure and Synthetic Fertilizer Influences Crop Yields, Soil Properties, Nitrate Leaching and Crop Nutrient Content Paul. Compost Sci. Util. 2009, 17, 117–126. [Google Scholar] [CrossRef]

- Silva, M.E.; Brás, I. Co-Composting of Poultry Manure with Different Organic Amendments. Int. J. Environ. Ecol. Eng. 2016, 10, 848–852. [Google Scholar]

- Bilba, K.; Arsene, M.A.; Ouensanga, A. Study of banana and coconut fibers. Botanical composition, thermal degradation and textural observations. Bioresour. Technol. 2007, 98, 58–68. [Google Scholar] [CrossRef] [PubMed]

- Kalemelawa, F.; Nishihara, E.; Endo, T.; Ahmad, Z.; Yeasmin, R.; Tenywa, M.M.; Yamamoto, S. An evaluation of aerobic and anaerobic composting of banana peels treated with different inoculums for soil nutrient replenishment. Bioresour. Technol. 2012, 126, 375–382. [Google Scholar] [CrossRef] [PubMed]

- Soto-Paz, J.; Oviedo-Ocaña, E.R.; Manyoma, P.C.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P.; Barrena, R.; Sánchez, A.; Komilis, D. Influence of mixing ratio and turning frequency on the co-composting of biowaste with sugarcane filter cake: A mixture experimental design. Waste Biomass Valorization 2020, 11, 2475–2489. [Google Scholar] [CrossRef]

- Meunchang, S.; Panichsakpatana, S.; Weaver, R.W. Co-composting of filter cake and bagasse; by-products from a sugar mill. Bioresour. Technol. 2005, 96, 437–442. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 2016, 48, 115–126. [Google Scholar] [CrossRef]

- Nakasaki, K.; Nagasaki, K.; Ariga, O. Degradation of fats during thermophilic composting of organic waste. Waste Manag. Res. 2004, 22, 276–282. [Google Scholar] [CrossRef]

- Francou, C.; Linères, M.; Derenne, S.; Le Villio-Poitrenaud, M.; Houot, S. Influence of green waste, biowaste and paper-cardboard initial ratios on organic matter transformations during composting. Bioresour. Technol. 2008, 99, 8926–8934. [Google Scholar] [CrossRef]

- Vandecasteele, B.; Reubens, B.; Willekens, K.; De Neve, S. Composting for increasing the fertilizer value of chicken manure: Effects of feedstock on P availability. Waste Biomass Valorization 2014, 5, 491–503. [Google Scholar] [CrossRef]

- Petric, I.; Selimbašić, V. Composting of poultry manure and wheat straw in a closed reactor: Optimum mixture ratio and evolution of parameters. Biodegradation 2008, 19, 53–63. [Google Scholar] [CrossRef]

- Wang, P.; Changa, C.M.; Watson, M.E.; Dick, W.A.; Chen, Y.; Hoitink, H.A.J. Maturity indices for composted dairy and pig manures. Soil Biol. Biochem. 2004, 36, 767–776. [Google Scholar] [CrossRef]

- Paredes, C.; Roig, A.; Bernal, M.P.; Sánchez-Monedero, M.A.; Cegarra, J. Evolution of organic matter and nitrogen during co-composting of olive mill wastewater with solid organic wastes. Biol. Fertil. Soils 2000, 32, 222–227. [Google Scholar] [CrossRef]

- Ahn, H.K.; Richard, T.L.; Glanville, T.D. Laboratory determination of compost physical parameters for modeling of airflow characteristics. Waste Manag. 2008, 28, 660–670. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.F.; Wong, J.W.C.; Wu, Q.T.; Nagar, B.B. Effect of C/N on composting of pig manure with sawdust. Waste Manag. 2004, 24, 805–813. [Google Scholar] [CrossRef]

- Khan, S.; Chao, C.; Waqas, M.; Arp, H.P.H.; Zhu, Y.G. Sewage sludge biochar influence upon rice (Oryza sativa L) yield, metal bioaccumulation and greenhouse gas emissions from acidic paddy soil. Environ. Sci. Technol. 2013, 47, 8624–8632. [Google Scholar] [CrossRef] [PubMed]

- Petric, I.; Mustafić, N. Dynamic modeling the composting process of the mixture of poultry manure and wheat straw. J. Environ. Manage. 2015, 161, 392–401. [Google Scholar] [CrossRef]

- He, X.; Yin, H.; Han, L.; Cui, R.; Fang, C.; Huang, G. Effects of biochar size and type on gaseous emissions during pig manure/wheat straw aerobic composting: Insights into multivariate-microscale characterization and microbial mechanism. Bioresour. Technol. 2019, 271, 375–382. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, D.; Singh, B.L.; Kumar, U.; Shweta. Composting of sugar-cane waste by-products through treatment with microorganisms and subsequent vermicomposting. Bioresour. Technol. 2010, 101, 6707–6711. [Google Scholar] [CrossRef]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-composting of poultry manure mixtures amended with biochar—The effect of biochar on temperature and C-CO2 emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef]

- Oliveira, L.; Cordeiro, N.; Evtuguin, D.V.; Torres, I.C.; Silvestre, A.J.D. Chemical composition of different morphological parts from “Dwarf Cavendish” banana plant and their potential as a non-wood renewable source of natural products. Ind. Crops Prod. 2007, 26, 163–172. [Google Scholar] [CrossRef]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manage. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Krishnan, Y.; Bong, C.P.C.; Azman, N.F.; Zakaria, Z.; Othman, N.; Abdullah, N.; Ho, C.S.; Lee, C.T.; Hansen, S.B.; Hara, H. Co-composting of palm empty fruit bunch and palm oil mill effluent: Microbial diversity and potential mitigation of greenhouse gas emission. J. Clean. Prod. 2017, 146, 94–100. [Google Scholar] [CrossRef]

- Gaind, S. Effect of fungal consortium and animal manure amendments on phosphorus fractions of paddy-straw compost. Int. Biodeterior. Biodegrad. 2014, 94, 90–97. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Richard, T.L.; Honeyman, M.S. Effect of windrow turning and seasonal temperatures on composting of hog manure from hoop structures. Environ. Technol. 2000, 21, 1037–1046. [Google Scholar] [CrossRef]

- Cottenie, A. Soil testing and plant testing as a basis of fertilizer recommendation. FAO Soils Bull. 1980, 38, 70–73. [Google Scholar]

- Keeney, D.R.; Nelson, D.W. Nitrogen inorganic forms. In Methods of Soil Analysis Part 2; Page, A.L., Keeney, D.R., Baker, D.E., Miller, R.H., Ellis, R.J., Eds.; Agron. Monogr 9. ASA and SSSA: Madison, WI, USA, 1982; pp. 159–165. [Google Scholar]

- Guo, R.; Li, G.; Jiang, T.; Schuchardt, F.; Chen, T.; Zhao, Y.; Shen, Y. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost. Bioresour. Technol. 2012, 112, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Mirmostafaee, S.; Azizi, M.; Fujii, Y. Study of allelopathic interaction of essential oils from medicinal and aromatic plants on seed germination and seedling growth of lettuce. Agronomy 2020, 10, 163. [Google Scholar] [CrossRef] [Green Version]

- SAS. SAS Statistical Software; Release 9.4; SAS Institute: Cary, NC, USA, 2008. [Google Scholar]

- Zhang, L.; Sun, X. Changes in physical, chemical, and microbiological properties during the two-stage co-composting of green waste with spent mushroom compost and biochar. Bioresour. Technol. 2014, 171, 274–284. [Google Scholar] [CrossRef]

- Li, R.; Wang, J.J.; Zhang, Z.; Shen, F.; Zhang, G.; Qin, R.; Li, X.; Xiao, R. Nutrient transformations during composting of pig manure with bentonite. Bioresour. Technol. 2012, 121, 362–368. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Pandey, A.K.; Bundela, P.S.; Wong, J.W.C.; Li, R.; Zhang, Z. Co-composting of gelatin industry sludge combined with organic fraction of municipal solid waste and poultry waste employing zeolite mixed with enriched nitrifying bacterial consortium. Bioresour. Technol. 2016, 213, 181–189. [Google Scholar] [CrossRef]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.; Li, W.; Zhang, S.; Wu, C.; Lv, L. Feasibility of co-composting of sewage sludge, spent mushroom substrate and wheat straw. Bioresour. Technol. 2017, 226, 39–45. [Google Scholar] [CrossRef]

- Jolanun, B.; Towprayoon, S. Novel bulking agent from clay residue for food waste composting. Bioresour. Technol. 2010, 101, 4484–4490. [Google Scholar] [CrossRef]

- Mohee, R.; Boojhawon, A.; Sewhoo, B.; Rungasamy, S.; Somaroo, G.D.; Mudhoo, A. Assessing the potential of coal ash and bagasse ash as inorganic amendments during composting of municipal solid wastes. J. Environ. Manage. 2015, 159, 209–217. [Google Scholar] [CrossRef]

- Kulcu, R.; Sönmez, I.; Yaldiz, O.; Kaplan, M. Composting of spent mushroom compost, carnation wastes, chicken and cattle manures. Bioresour. Technol. 2008, 99, 8259–8264. [Google Scholar] [CrossRef] [PubMed]

- Steiner, C.; Das, K.C.; Melear, N.; Lakly, D. Reducing Nitrogen Loss during Poultry Litter Composting Using Biochar. J. Environ. Qual. 2010, 39, 1236–1242. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sullivan, D.M.; Bary, A.I.; Miller, R.O.; Brewer, L.J. Interpreting Compost Analyses; Oregon State University Extension Service: Corvallis, OR, USA, 2018; pp. 1–10. [Google Scholar]

- Tiquia, S.M.; Tam, N.F.Y. Fate of nitrogen during composting of chicken litter. Environ. Pollut. 2000, 110, 535–541. [Google Scholar] [CrossRef]

- Hu, W.; Zheng, G.; Fang, D.; Cui, C.; Liang, J.; Zhou, L. Bioleached sludge composting drastically reducing ammonia volatilization as well as decreasing bulking agent dosage and improving compost quality: A case study. Waste Manag. 2015, 44, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S.M. Evolution of extracellular enzyme activities during manure composting. J. Appl. Microbiol. 2002, 92, 764–775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, R.; Wang, Q.; Zhang, Z.; Zhang, G.; Li, Z.; Wang, L.; Zheng, J. Nutrient transformation during aerobic composting of pig manure with biochar prepared at different temperatures. Environ. Technol. 2015, 36, 815–826. [Google Scholar] [CrossRef]

- Ultra, V.U.; Mendoza, D.M.; Briones, A.M. Chemical changes under aerobic composting and nutrient supplying potential of banana residue compost. Renew. Agric. Food Syst. 2005, 20, 113–125. [Google Scholar] [CrossRef]

- Chimuka, L.; Manungufala, T.E. Sources, Bioavailability and Fate of Heavy Metals and Organic Contaminants in Compost Manure. Dyn. Soil Dyn. Plant 2009, 3, 32–38. [Google Scholar]

- Hsu, J.H.; Lo, S.L. Effect of composting on characterization and leaching of copper, manganese, and zinc from swine manure. Environ. Pollut. 2001, 114, 119–127. [Google Scholar] [CrossRef]

- Ho, L.H.; Noor Aziah, A.A.; Bhat, R. Mineral composition and pasting properties of banana pseudo-stem flour from Musa acuminata x balbisiana cv. Awak grown locally in Perak, Malaysia. Int. Food Res. J. 2012, 19, 1479–1485. [Google Scholar] [CrossRef]

- Luo, Y.; Liang, J.; Zeng, G.; Chen, M.; Mo, D.; Li, G.; Zhang, D. Seed germination test for toxicity evaluation of compost: Its roles, problems and prospects. Waste Manag. 2018, 71, 109–114. [Google Scholar] [CrossRef]

- Yang, F.; Li, G.X.; Yang, Q.Y.; Luo, W.H. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting. Chemosphere 2013, 93, 1393–1399. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Loizidou, M. Sawdust and natural zeolite as a bulking agent for improving quality of a composting product from anaerobically stabilized sewage sludge. Bioresour. Technol. 2008, 99, 7545–7552. [Google Scholar] [CrossRef]

| Properties | Banana Pseudostem (BPS) | Chicken Manure (CK) | Mushroom Media Waste (MMW) |

|---|---|---|---|

| Moisture (%) | 59.23 ± 4.74 | 14.52 ± 0.59 | 28.50 ± 0.35 |

| pH | 10.41 ± 0.18 | 9.53 ± 0.33 | 6.19 ± 0.13 |

| EC (dSm−1) | 4.74 ± 0.14 | 4.66 ± 0.13 | 0.70 ± 0.02 |

| Total C (%) | 35.14 ± 1.23 | 23.57 ± 1.08 | 40.12 ± 1.42 |

| OM (%) | 77.78 ± 2.10 | 50.0 ± 1.95 | 94.94 ± 3.03 |

| C:N ratio | 73.20 ± 1.56 | 8.93 ± 0.26 | 16.05 ± 0.51 |

| Total N (%) | 0.48 ± 0.07 | 2.64 ± 0.06 | 2.50 ± 0.06 |

| CEC (cmol (+)/kg−1) | 30.00 ± 1.25 | 24.85 ± 1.14 | 24.35 ± 0.88 |

| Potassium (K, g kg−1) | 14.06 ± 0.57 | 12.59 ± 0.47 | 3.24 ± 0.16 |

| Calcium (Ca, g kg−1) | 9.60 ± 0.35 | 12.36 ± 0.43 | 12.27 ± 0.55 |

| Magnesium (Mg, g kg−1) | 2.52 ± 0.09 | 3.60 ± 0.14 | 2.41 ± 0.08 |

| Sodium (Na, g kg−1) | 0.87 ± 0.04 | 2.48 ± 0.09 | 0.55 ± 0.04 |

| Total P (g kg−1) | 7.40 ± 0.31 | 6.20 ± 0.24 | 8.02 ± 0.37 |

| Copper (mg kg−1) | 35.40 ± 1.70 | 41.60 ± 1.66 | 14.10 ± 0.59 |

| Manganese (Mn, mg kg−1) | 160.3 ± 6.25 | 360.2 ± 13.69 | 101.2 ± 5.06 |

| Zinc (Zn, mg kg−1) | 60.2 ± 2.40 | 32.72 ± 0.98 | 163.8 ± 7.17 |

| Parameters | Time | T1 | T2 | T3 | T4 | T5 | T6 |

|---|---|---|---|---|---|---|---|

| Moisture content (%) | Initial Final | 72.12 ± 2.35 ab 45.24 ± 1.10 b | 68.52 ± 1.96 b 38.55 ± 0.94 d | 70.6 ± 1.73 ab 36.25 ± 0.74 d | 79.32 ± 2.91 a 50.10 ± 1.43 a | 75.1 ± 1.53 ab 43.41 ± 0.71 bc | 73.39 ± 1.19 ab 40.21 ± 0.70 cd |

| Total Organic C (%) | Initial Final | 35.25 ± 1.00 ab 24.08 ± 0.59 ab | 40.96 ± 1.01 a 18.90 ± 0.55 d | 42.56 ± 0.97 a 20.09 ± 0.57 cd | 34.55 ± 1.13 c 25.61 ± 0.52 a | 37.98 ± 0.93 abc 22.25 ± 0.40 bc | 39.80 ± 1.13 ab 21.28 ± 0.69 cd |

| Total N (%) | Initial Final | 1.91 ± 0.04 a 1.46 ± 0.03 a | 1.70 ± 0.03 b 1.53 ± 0.04 a | 1.68 ± 0.04 b 1.45 ± 0.04 a | 1.42 ± 0.03 c 1.10 ± 0.02 b | 1.76 ± 0.04 ab 1.48 ± 0.03 a | 1.70 ± 0.03 b 1.42 ± 0.02 a |

| C:N | Initial Final | 18.44 ± 0.60 c 16.49 ± 0.40 b | 24.09 ± 0.58 ab 12.35 ± 0.25 d | 25.33 ± 0.82 a 13.76 ± 0.22 cd | 24.33 ± 0.39 ab 23.28 ± 0.52 a | 21.57 ± 0.70 b 15.03 ± 0.42 bc | 23.14 ± 0.42 ab 14.98 ± 0.30 bc |

| CEC (cmol kg−1) | Initial Final | 24.85 ± 0.81 ab 38.00 ± 0.50 bc | 27.48 ± 0.63 ab 41.28 ± 0.98 a | 27.77 ± 0.56 a 40.14 ± 0.90 a | 24.00 ± 0.81 b 32.14 ± 0.55 c | 25.42 ± 0.71 ab 38.50 ± 0.68 abc | 25.21 ± 0.90 ab 40.07 ± 0.88 ab |

| Treatments | P (g kg−1) | K (g kg−1) | Ca (g kg−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | % Increase | Initial | Final | % Increase | Initial | Final | % Increase | |

| T1 | 4.14 ± 0.13 bc | 6.76 ± 0.27 b | 63.29 | 7.47 ± 0.18 b | 12.1 ± 0.47 a | 61.98 | 6.64 ± 0.26 b | 8.97 ± 0.19 c | 35.09 |

| T2 | 5.49 ± 0.20 a | 9.84 ± 0.35 a | 79.23 | 5.28 ± 0.11 c | 9.15 ± 0.46 b | 73.30 | 10.23 ± 0.23 a | 14.8 ± 0.17 a | 44.67 |

| T3 | 6.20 ± 0.15 a | 10.4 ± 0.16 a | 67.74 | 4.84 ± 0.22 c | 8.04 ± 0.42 b | 66.12 | 9.88 ± 0.09 a | 14.2 ± 0.26 ab | 43.72 |

| T4 | 3.45 ± 0.10 c | 4.39 ± 0.12 c | 27.25 | 10.6 ± 0.12 a | 9.85 ± 0.35 ab | −7.08 | 5.97 ± 0.14 c | 5.08 ± 0.17 d | −14.90 |

| T5 | 3.69 ± 0.13 bc | 6.64 ± 0.26 b | 79.95 | 6.04 ± 0.14 c | 9.26 ± 0.25 b | 53.31 | 6.43 ± 0.17 b | 8.46 ± 0.20 c | 31.57 |

| T6 | 4.39 ± 0.17 b | 7.50 ± 0.20 b | 70.84 | 5.81 ± 0.17 c | 7.55 ± 0.22 b | 29.95 | 9.18 ± 0.19 a | 12.8 ± 0.26 b | 39.43 |

| LSD (0.05) | 0.84 | 1.19 | - | 1.32 | 2.41 | - | 1.28 | 1.65 | - |

| Treatments | Mg (g kg−1) | Na (g kg−1) | S (mg kg−1) | ||||||

| Initial | Final | % Increase | Initial | Final | % Increase | Initial | Final | % Increase | |

| T1 | 3.77 ± 0.11 bc | 5.94 ± 0.03 a | 57.56 | 2.05 ± 0.02 b | 2.70 ± 0.04 a | 31.71 | 270 ± 8.15 a | 300 ± 6.12 a | 11.11 |

| T2 | 3.45 ± 0.02 c | 4.81 ± 0.04 b | 39.42 | 1.70 ± 0.02 d | 2.40 ± 0.02 b | 41.18 | 200 ± 4.89 d | 250 ± 4.08 c | 25.00 |

| T3 | 3.38 ± 0.07 c | 4.62 ± 0.03 c | 36.69 | 1.81 ± 0.01 c | 2.31 ± 0.03 c | 27.62 | 190 ± 3.67 d | 270 ± 8.16 bc | 42.11 |

| T4 | 4.51 ± 0.16 a | 4.12 ± 0.04 d | −8.65 | 2.14 ± 0.02 a | 2.10 ± 0.02 d | −1.87 | 230 ± 5.30 bc | 290 ± 3.26 ab | 26.09 |

| T5 | 3.91 ± 0.04 b | 4.86 ± 0.03 b | 24.30 | 1.81 ± 0.03 c | 2.30 ± 0.03 c | 27.07 | 250 ± 4.89 ab | 260 ± 4.48 c | 4.00 |

| T6 | 3.40 ± 0.08 c | 4.59 ± 0.03 c | 35.00 | 1.59 ± 0.02 e | 2.14 ± 0.05 d | 34.59 | 210 ± 4.08 cd | 250 ± 2.85 c | 19.05 |

| LSD (0.05) | 0.44 | 0.13 | - | 0.04 | 0.08 | - | 23.73 | 21.19 | - |

| Treatments | Zn (mg kg−1) | Cu (mg kg−1) | Mn (mg kg−1) | ||||||

| Initial | Final | % Increase | Initial | Final | % Increase | Initial | Final | % Increase | |

| T1 | 170 ± 3.26 d | 230 ± 6.12 d | 35.3 | 31.3 ± 1.02 ab | 49.0 ± 1.33 b | 56.5 | 270 ± 11.02 cd | 470 ± 8.16 d | 74.1 |

| T2 | 245 ± 4.08 a | 456 ± 6.53 a | 86.1 | 28.7 ± 0.81 b | 60.7 ± 1.17 a | 111 | 319 ± 11.71 ab | 784 ± 13.88 a | 145.8 |

| T3 | 241 ± 4.10 ab | 426 ± 6.53 ab | 76.8 | 21.4 ± 0.57 c | 59.6 ± 1.06 a | 178 | 255 ± 6.12 d | 670 ± 12.24 b | 162.7 |

| T4 | 150 ± 4.08 e | 170 ± 2.04 e | 13.3 | 33.4 ± 0.73 a | 34.0 ± 0.74 c | 1.8 | 342 ± 8.97 a | 370 ± 6.12 e | 8.2 |

| T5 | 193 ± 2.86 c | 310 ± 8.16 c | 60.6 | 29.3 ± 0.53 b | 51.3 ± 0.69 b | 75.1 | 292 ± 4.89 bc | 583 ± 8.87 c | 99.7 |

| T6 | 224 ± 4.49 b | 419 ± 7.75 b | 87.1 | 22.3 ± 0.93 c | 47.7 ± 0.37 b | 113.9 | 244 ± 5.71 d | 602 ± 12.23 c | 146.7 |

| LSD (0.05) | 18.82 | 31.11 | - | 3.53 | 6.61 | - | 35.50 | 50.09 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.S.; Kasim, S.; Alam, K.M.; Amin, A.M.; Geok Hun, T.; Haque, M.A. Changes in Chemical Properties of Banana Pseudostem, Mushroom Media Waste, and Chicken Manure through the Co-Composting Process. Sustainability 2021, 13, 8458. https://doi.org/10.3390/su13158458

Islam MS, Kasim S, Alam KM, Amin AM, Geok Hun T, Haque MA. Changes in Chemical Properties of Banana Pseudostem, Mushroom Media Waste, and Chicken Manure through the Co-Composting Process. Sustainability. 2021; 13(15):8458. https://doi.org/10.3390/su13158458

Chicago/Turabian StyleIslam, Mahammad Shariful, Susilawati Kasim, Khairul Md. Alam, Adibah Mohd Amin, Tan Geok Hun, and Mohammad Amdadul Haque. 2021. "Changes in Chemical Properties of Banana Pseudostem, Mushroom Media Waste, and Chicken Manure through the Co-Composting Process" Sustainability 13, no. 15: 8458. https://doi.org/10.3390/su13158458

APA StyleIslam, M. S., Kasim, S., Alam, K. M., Amin, A. M., Geok Hun, T., & Haque, M. A. (2021). Changes in Chemical Properties of Banana Pseudostem, Mushroom Media Waste, and Chicken Manure through the Co-Composting Process. Sustainability, 13(15), 8458. https://doi.org/10.3390/su13158458