Abstract

Sustainability in construction can be perceived across several areas. Sustainable supply chain and cost management are two of them. If this issue is addressed in the management of sustainable building materials and waste management in the implementation of construction projects, in the context of sustainability, cost management and supply chain management affect the overall success of construction projects. The aspect of sustainability is based on reducing costs and, thus, also material items. At the same time, there is a focus on the use of waste or its economic and ecological disposal. Finally, sustainability means the setting up of logistics processes. Information and communication technologies can significantly help supply chain and cost management and construction waste management. This means, on the one hand, minimizing the consumption of materials and, thus, also costs, and on the other hand, by optimally setting up the supply chain and logistics, using materials and funds efficiently and optimizing waste management. The research discusses the impact of information and communication technology on a sustainable chain and cost management on various construction projects in Slovakia. The research aims to analyze information and communication technology’s influence on a sustainable chain and cost savings of waste in construction projects. The main research hypothesis is based on the assumption that information and communication technology positively affect sustainable chain and cost management of waste in the Slovak construction industry. Data collection was performed through an online questionnaire. It contained three primary areas of data collection: The first part contained questions about the characteristics of the research sample. The second concerned the use of information and communication technologies and the third pertained to their impact on sustainability and reducing the costs of the waste management process in construction. The research samples consisted primarily of foreign companies operating in Slovakia. From the point of view of the participants in the construction project, these were developers, contractors, sub-contractors and designers. The Kruskal–Wallis test was used to confirm this hypothesis. The research provides an overview of information and communication technologies and their impact on supply chain and cost management of waste in construction.

1. Introduction

The sustainable waste management in construction and key performance indicators (KPIs) in the manufacturing and construction industry is discussed by other studies that agree on the importance of this issue [1,2]. Furthermore, the competitiveness increasing in construction companies is an essential task in the country and national economics [3,4]. Moreover, the increase in efficiency results in an increase in the amount of waste. From this point of view, it is, therefore, important to address waste management to improve key performance indicators and special costs. Therefore, it is necessary to look at the issue of costs from the perspective of the entire life cycle of the construction. A study of Slovakian authors addressed the issue of lost profits in the construction industry [5]. Other researchers discussed the issue of construction worker productivity from KPIs [6]. In many cases, KPIs are discussed as costs in the manufacturing and construction industry [7]. Costs associated with construction projects’ sustainable management and the construction project’s total cost are discussed many studies [8,9].

The other authors solved the life cycle cost (LCC) estimate system in construction projects focusing on train transport infrastructure projects’ waste cost. The LCC Estimation Model was the subject of a study by Biolek and Hanák [10]. Researchers [11] addressed prices and costs and the development of material costs throughout the construction project and waste management. Energy upgrading of a residential building in the context of LCC analysis was discussed in a case study in Italy. LCC assessment approaches are described in detail in some sources [12]. Nevertheless, sustainable cost, waste, and supply chain management still represent a significant research gap.

Information and communication technology (ICT) in the supply chain and cost and waste management in the construction industry also have several advantages, according to studies and surveys [13]. BIM technology is used to control the cost of the whole process of the construction project [14], waste cost included. It based on realizing effective management and avoiding out-of-control investments [15]. Progress in using advanced materials in the industrial area has also occurred using information technology [16]. Many studies point to the positive economic and sustainable impact of information technology utilization [17]. The use of information and communication technologies also has other benefits. Economic benefits include improved competitiveness and productivity in the industry [18]. It has an equally positive influence on safety in the manufacturing and construction industry. According to researchers [19], these factors have been improved using mainly building information modeling technology and the Internet of Things (IoT). Researchers at New York University Abu Dhabi (NYUAD) [20] have pointed to the positive impact on digitization productivity in the construction industry. However, construction projects delaying completion and lack of coordination within departments due to unavailability of real-time information hampers daily operations’ effectiveness [21].

Another study [22] pointed to the positive impact of digital technologies in manufacturing and construction industry performance improvement. Implementing information and communication technology in AEC also brings progressive construction projects and waste management [23]. A study by Khayyat [24] pointed to the positive impact of technology on sustainable cost management. The development of the digital economy and the impact of sustainable technologies are gradually increasing to many demands for devices that can process large amounts of data, improving these businesses’ performance in the industry [25]. Information and communication technologies based on large amounts of data are prerequisites for making the right decisions [26]. Construction and industry logistics are essential parts of the process of management. They have become new sources of profit for the construction industry [27]. The supply chain management (SCM) study argues that the biggest challenges in implementing supply chain management technologies are the two most important challenges: IT adoption in material flow management and lowered training and worker motivation [28]. Supply chain management can be considered sustainable if short delivery times and minimum costs are ensured. Mainly from an economic point of view and in increasing competitiveness, sustainability in the supply chain is focused on cost optimization [29]. Effective supply chain management also leads to waste minimization: the material is ordered and delivered on time without leftovers and surpluses.

Based on the above literature and a summary of this information, it can be assumed that information and communication technology in sustainable supply chain and cost management in the construction industry positively impacts waste management. Therefore, the research’s main hypothesis is the positive impact of using information and communication technology on sustainable supply chain, cost and waste management in each construction project stage. This assumption is confirmed based on studies already performed, which do not quantify the degree of impact [1,7,11]. In other words, the use of information and communication technology leads to cost savings in the construction project supply chain and waste management.

This raises another scientific question of how these technologies affect costs throughout a construction project’s life cycle. However, these scientific studies do not quantify the extent of the impact on these cost processes. This is why this research works with the already confirmed assumption and tries to expand the claim that, based on comprehensive research, it is possible to quantify the impact of information and communication technologies on sustainable supply chain, cost and waste management.

Therefore, it is logical to determine how to measure this impact and what methods should be used. Simultaneously, the research aims to identify the information and communication technologies that positively impact the sustainable supply chain, cost and waste management during the entire life of the construction project. The research areas of sustainable supply chain, cost and waste management and information and communication technology are relatively often discussed topics between researchers and experts. For example, another study confirmed the positive impact of building information modeling technology in sustainable cost and waste management of projects implemented in Western Europe [30]. Further research sought to demonstrate the validity of machine learning technology in sustainable cost management [31]. However, this research did not quantify the impact of technologies on the sustainable chain and cost management in individual life stages.

Similar impacts in construction have been examined in several major studies, such as “Determinants of the Turnover Intention of Construction Professionals: A Mediation Analysis”, and analysis of supply chain management in small- and medium-sized enterprises [32,33]. The cross-sectional comparative investigation of the mediating effect of strategic supply chain management in the SMEs operating in distinctive economies of Canada, Iran and Turkey on the social and environmental sustainability was subject of another quality study in this field. The data was collected from 613 small- and medium-sized enterprises. The aim of the research was confirming that strategic supply chain management has a statistically significant positive mediating role in improving the social and environmentally sustainable performances [34].

A detailed analysis of the impact of information and communication technology on sustainable supply chain, cost and waste management in various stages of a construction project is still not described. This research seeks to answer these questions. Statistical tests must confirm that these technologies positively affect reducing costs and waste at each stage of the construction project. Main hypotheses (more described in Materials and Methods) have to be tested by a statistical test. However, this cannot be demonstrated based on statistical tests, alone.

Based on a theoretical analysis, the research deals with examining the impact of information and communication technologies on the sustainability and costs of waste management in construction projects. This research works with the introductory statement that information and communication technology impact the rate of sustainable supply chain and that cost reduction of waste management in construction projects will be greater than 3.5, (on scale from 1 to 5) representing a high impact. A questionnaire survey carried out data collection for research purposes. It is structured into three parts: The first collects information on respondents, the second on the use of information and communication technologies and the third on their impact on sustainability, which is perceived by reducing waste disposal costs in construction. The research sample consisted of companies operating on the Slovak construction market. These are participants in construction projects consisting of: developers, contractors, sub-contractors and designers. Several statistical methods were used for the processing of research data. Cronbach’s alpha was chosen to verify the suitability of the research questions in the questionnaire. Subsequently, a scale of significance and value was used, which is renovated to look for the impact of technologies on sustainability and quality. Following the established research hypothesis, the data were processed through statistical programs. The result is a list of technologies and the impact on sustainability perceived by reducing costs and optimizing waste management processes in construction. The significance of these results was verified through the Kruskal–Wallis test.

2. Materials and Methods

The impact of information and communication technology on sustainable supply chain, cost and waste management of construction projects is a topic that requires the constant attention of participants in the construction project at all times. Overall, the study of the impact of information and communication technology on KPIs is a comprehensive topic discussed in many studies published in the most valuable databases. However, the need to discuss this issue is not just about a scientific problem but also about the practice and use of this industry knowledge. The sustainable costs of construction projects or their savings and optimization belong to one of the basic KPIs, monitored mainly in practice. Trying to analyze this information and find the optimal solution for setting up technologies is challenging in every industry.

2.1. Research Aim and Steps

The research aims to analyze the impact of information and communication technology on sustainable supply chain, waste management and cost reduction in individual stages of a construction project in Slovakia.

This goal was created after a thorough analysis of theoretical background and research in the field. The primary research statement was, “using information and communication technology in construction projects’ cost and waste management positively impacts the projects”. This impact can be quantified by conducting a study and using appropriate statistical methods. A positive impact means the impact of information and communication technology on sustainable cost reduction. Several studies have confirmed that cost reductions can also be included in the benefits and positive effects [32,33,34].

Based on interviews with practitioners, a stimulus arose to solve this problem scientifically. The output of this research is an impact value of technology that can be applied and verified in the industry. To achieve the research aim, it is necessary to perform several research steps:

- Establish a research hypothesis based on a research problem;

- Evaluate the questionnaire and questions (by Cronbach’s alpha);

- Verify this hypothesis (via statistical tests, in this case, Kruskal–Wallis).

The first step in establishing this scientific problem was an in-depth analysis of in-formation and communication technology resources while managing the cost of construction projects. This was also supported by interviews with experts in practice, including all participants in construction projects.

After determining the research problem and identifying the practice’s needs, a research goal was subsequently formulated. After formulating the research goal and main research hypothesis, the available scientific and statistical methods used to achieve the set goal were evaluated (more detailed research methods are described in Section 2.5 Data Processing).

2.2. Research Hypotheses

The hypotheses were based on the research statement that using information and communication technology in the sustainable cost and waste management of construction projects positively impacts those projects. Studies based on which rate results in values higher than 3.5 can define the positive impact of ICT.

Hypothesis 1 (H1).

Information and communication technology impact rate on sustainable supply chain and cost reduction of waste management in construction projects is ≤3.5.

Hypothesis 2 (H2).

Information and communication technology impact rate sustainable supply chain and cost reduction of waste management in construction projects is >3.5.

This means that if it exceeds a given value of 3.5, this result can be considered important and that ICTs impact sustainable cost and waste management. Conversely, if that value is equal to or lower, this hypothesis will not be rejected, and from this point of view, the assumption will be rejected. This value is considered critical in similar surveys. Therefore, all values above 3.5 can be considered positive and significant. On the contrary, smaller values are unsatisfactory. Section 2.5 describes in more detail the range of values as well as the references to studies that use the same metric.

Due to the research problem, data collection was provided by a questionnaire on industry practices. The questionnaire was divided into several specific sections. The questionnaire was disseminated online to contractors, sub-constructors, designers and developers. It included questions focused on research issues. However, this was preceded by the selection of appropriate statistical methods. The choice of specific statistical methods was influenced primarily by the research sample and the identified research problem. It mainly distributed the research sample concerning the number of respondents and the data’s nature. In addition, the scientific aim narrowed the use of appropriate methods.

2.3. Data Collection and Research Sample

An online questionnaire provided data collection. This form appeared to be the most efficient way to collect data due to its speed and simplicity. The questionnaire contained several thematic sections. The first part concerned general information about the research sample, with which it was possible to make dependencies between the investigated phenomena. Although this information characterized the research sample, anonymity was ensured. The next part dealt with using information and communication technology in various stages of the construction project. The next part was based on determining individual technologies’ impacts on sustainable supply chain and cost optimization in construction projects. The selection of the research sample was random. It was based on a database of construction companies. Construction companies of various sizes were involved in the survey. Likewise, the construction project’s selection reflected all the interest groups in the construction project. Their relative distribution copied the distribution on the market so that there was no disparity between the real distribution of construction companies and the respondents in industry. However, it should be emphasized that large multinational construction companies, which also operate on the Slovak construction industry, took part in the survey. As many as 12.73% of respondents were large multinational companies operating in this market, as well. Of the total number of operating companies in Slovakia, approximately 65% of companies were involved in the research. These companies operate and apply their knowledge in other countries, as well. Therefore, their opinion can be respected worldwide. Some companies also operate outside the region of Slovakia. Therefore, the blending of knowledge as an experience of interest, even in participating in research results, cannot be clearly perceived as the Slovak construction market. The close cooperation and work of some respondents abroad (especially in neighboring countries) needs to be taken into account, which may reflect a situation wider than the borders of Slovakia.

A total of 1276 respondents (participants in construction projects in Slovakia) were asked to answer basic research questions. A total of 55 companies filled in a complete questionnaire, usable in our research, representing a return of 4.31%. Given the scope of the examined areas in the questionnaire survey, the return at the level of 4.31% can be considered good. Due to the implementation of professional research, the return in several studies was achieved only at the level of 2 to 4 percent. For this reason, the perceived value of the issues of research and technology is perceived as positive.

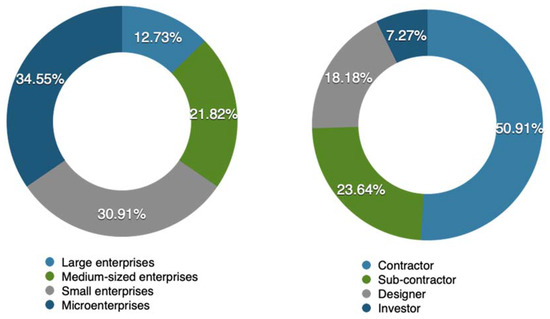

A total of 12.73% of the respondents were large enterprises. This is not a breakdown by the total number of construction companies, but it is an interesting sample for the survey. SMEs respondents accounted for 52.73%. According to a participant’s status in a construction project, the breakdown of respondents can be characterized as follows: 50.91% were contractors, 23.64% sub-contractors, 18.18% designers, and 7.27% developers.

Respondents provided their information with implemented projects of various kinds, from residential buildings, to infrastructure projects, engineering and transport construction. Reconstructions, historic buildings, etc. were also mentioned, which is suitable in terms of diversity (Figure 1).

Figure 1.

Research sample by company’s size and participants of construction project.

2.4. Structure of Questionnaire

This research understood the impact of information and communication technology on sustainable supply chain, cost and waste management. Therefore, research questions aimed at identifying and collecting data to analyze the impact of information and communication technology on sustainable supply chain, cost and waste management had to be asked for each construction project’s monitored stage. These stages, pre-design, design and construction, were monitored based on information from completed construction projects, which are already in use at this time. The use stage could not yet be processed in the research, as data collection is ongoing, and the processing of this stage takes a long time. See Section 3.2 Research Limitations for more details.

The first part of the data presents the basic characteristics of the research sample, with which it was possible to make dependencies and categorize research groups and results. This was information on the size of the construction company, the participant in the construction project, foreign capital and knowledge, the region of operation, project managers’ experience, information on the construction project and other industry information.

The second part deals with issues related to the use of information and communication technology for each stage, separately. Information technologies aimed at reducing costs were mainly monitored. The third part was the most important from the point of view of the research topic. The instructions for completing the questionnaire also contained additional texts, which described how the respondents should proceed. For example, to remove the subjective perception of use, individual values within the intensity of use were explained on the scale (this means specific numerical and measurable values for quantification of use and impact, how many times the technology was used, etc.). Project managers and other respondents were tasked with identifying on a scale from 1 to 5 (where 1 is the minimum impact of IT on sustainable supply chain and cost reduction, and 5 is the maximum impact) to determine the level of impact of selected IT on cost reduction for the relevant construction cycle. This level should also be determined as a percentage (verification of construction project costs and possible savings) to verify the results’ objectivity and a correct understanding of quantification perception. It should be emphasized here that the respondents had a clear reminder in the questionnaire that they should draw data from official accounting records, not just feelings.

Cronbach’s alpha analyzed the reliability of the questionnaire. The questionnaire consisted of 42 questions focused on 14 technologies requiring impact in three stages: pre-design phase, design phase and the narrowing stage.

2.5. Data Processing

The data were evaluated based on several statistical methods using MS Excel and STATISTICA and MatLab software. Mostly descriptive and inductive statistics were used in processing the results of the research. The reliability of the investigated questions was analyzed based on the application of Cronbach’s alpha (as already mentioned). All respondents were marked as valid, answering all questions (14 questions on technology in each stage examined). See Table 1 for more detailed information.

Table 1.

Case processing summary.

Cronbach’s alpha reached a value of 0.86, representing the validity of the questionnaire questions and a relatively high value of reliability (Table 2).

Table 2.

Reliability statistics.

Table 3 shows the effects of individual items (questions) on the overall result if the question were deleted. The modified item correlation and Cronbach’s alpha for the whole file are listed here if we deleted a specific question. These results only confirmed the high value of reliability and that every question examined the idea that technology at every stage of the project is important.

Table 3.

Item–Total statistics.

We evaluated data from research areas of the use of information and communication technologies and their influx to optimize the costs of construction projects to find the so-called utilization rate (or the degree of impact or importance rate) they used in research to identify and quantify the benefits of using ICT in construction [20,35], including the importance of the 3.5 thresholds. A value below 3.5 is not considered important. Conversely, values that exceed 3.5 can be considered important. Using this methodology, it is based on the average value at the level of 3.5, which already represents an important value of the technology’s impact or the researched factor. This means that the interval from 1 to 3.49 cannot be considered important impact rates. Values greater than 3.5 inclusive are considered important. The measure of arithmetic averages came from selected areas. A scale in the range 1 to 5 was used to determine the response. Based on the determined values, an arithmetic average of the selected research area values was made. The result was the mentioned rate of utilization or degree of impact. Subsequently, the results were interpreted in verbal and graphic form.

The PAGES and NUMBERS tools and Excel were used for graphical processing and presentation of results. When comparing these values, however, arithmetic means with a reference value only indicate a trend. It is necessary to perform statistical tests of significance to determine whether, in fact, these obtained and recalculated data have a high informative value. This means that appropriate tests must test all technologies. Given the number of respondents, the statistical sample distribution and the possibility of statistical tests, the Kruskal–Wallis test appeared to be the best choice. This was to confirm the potential impact of selected technologies on sustainable supply chain and cost management. Therefore, all data representing selected information and communication technologies had to be tested. These tests made it possible to reject or accept the main research hypothesis, which is the first step toward fulfilling the research goal. If the influence of cost optimization in the life cycle of a construction project is confirmed in selected technologies, it is possible to analyze further and quantify the degree of this impact based on other research methods. Only technologies with a tame impact result were significantly positive, i.e., reached a value higher than 3.5, and, at the same time, this result was confirmed in a group of respondents who use the technology and could be further included in the final list of technology that the impact rate was significant in individual stages of the construction project.

The quantities RIJ, the relative significances of the criteria, are arranged in a square matrix of relative significances R [35]:

The intensity coefficients of the relation of the i-th variant to the j-th variant are determined in the same way as Saaty states:

where m is the calculation of variants and n is the number of criteria. The final rating is determined as the weighted sum of the intensity coefficients [36,37]:

3. Results

3.1. Results and Discussion

Being efficient in the construction industry means optimizing costs and waste management. If various factors limit production, the only way to achieve a state of efficiency is to optimize costs and waste. The same applies to the implementation of construction projects. One of the conditions for implementing a successful construction project is to optimize, i.e., minimize costs and maintain high quality and optimize and eliminate waste. In addition to the efforts of participants in construction projects to achieve cost and waste reduction through the new technologies used in construction processes, there is room to reduce the construction project management process cost. Sustainable information and communication technologies are a tool for reducing the waste and costs of managing construction projects and the overall costs of construction projects.

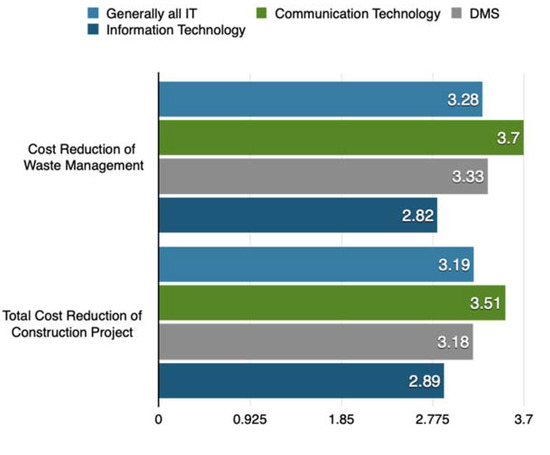

The impact of using ICTs in the pre-design stage of a construction project on the sustainable supply chain and cost reduction of construction project reaches a value of 3.19, which represents a relatively significant impact. When assessing the impact of these selected technologies on the costs associated with the waste management of construction projects, it is an even higher value, 3.28. Figure 2 describes ICT impact on cost reduction in the pre-design stage. However, compared to communication systems or DMS (Document Management Systems), they have reached a lower impact level.

Figure 2.

The impact level of the use of information and communication technology on cost reduction in the pre-design stage.

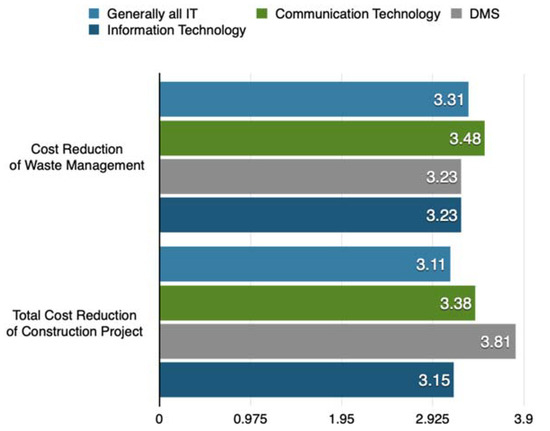

The design stage confirmed the assumption of a large impact of technologies associated with the development of project documentation and other requirements associated with preparing for the implementation of construction projects. Their frequent and necessary use also led to cost savings for selected sustainable processes and waste management within the construction project.

In construction projects where BIM technology was used, a reduction in costs was recorded. For contractors and sub-contractors, software for creating construction budgets and calculations and tools for creating time plans and schedules represented a relatively large impact on saving the construction project’s total costs. Large companies reported a relatively large impact on reducing the overall cost of managing construction projects in complex ERP systems. Overall, IS reduces construction project costs in the design stage. See Figure 3 for more detailed information.

Figure 3.

The impact level of the use of information technology on cost reduction in the design stage.

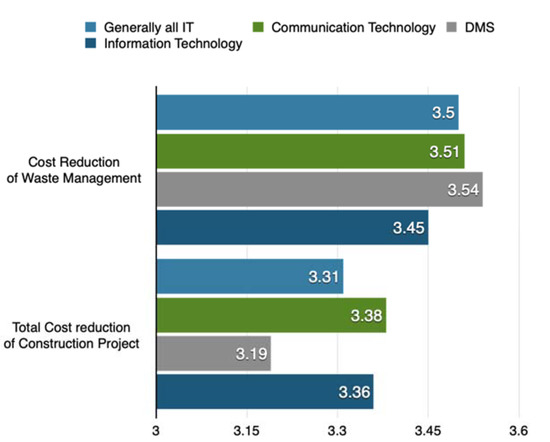

The impact level of the use of information technology on cost management is described in Figure 4. These results point to the impact of information technology on cost reduction of waste management at 3.45 and of total costs of CP to 3.19 impact level. These results show that the use of information technology reduces costs in the waste management of construction projects. These are mainly BD and SCM tools that are used to control costs for construction managers. BIM technology also proved its worth in this stage, as checking the actual stage with project documentation was simpler and more efficient. These technologies have directly indicated a high degree of efficiency, as long as their use is common and the processes are well set up.

Figure 4.

The impact level of the use of information technology on cost reducing in the construction stage.

These results were averaged for each technology group. However, Table 1, Table 2 and Table 3 provide specific K–W ANOVA values for technologies in construction life cycles. The research also assumed that some companies use these information technologies to a greater extent. This also results in a greater impact. One criterion was the company’s size, which could, thus, also have a higher impact level. However, the reality is not so clear-cut. The research showed that, even small companies, where the rate of use of selected technologies was lower, could achieve good results in cost reduction in individual stages due to their use.

According to the participants in the construction project, another view was also the division of the research group. The assumption was that this should have a different effect. With some technologies, this has been strongly confirmed. It was also interesting to compare the results in individual stages, especially when dividing the research sample based on construction project participants. The results were especially different when comparing the design stage and the construction stage. Since the Kruskal–Wallis test was performed at 95% significance levels, p values less than 0.05 can be considered highly relevant (these are indicated in Table 4, Table 5 and Table 6 by bold font).

Table 4.

K–W ANOVA for information technology in the pre-design stage of construction project.

Table 5.

K–W ANOVA for information technology in the design stage of construction project.

Table 6.

K–W ANOVA for information technology in the construction stage of construction project.

Likewise, according to sources listed in the literature and methodologies, specific impact level values can be considered significant if they reach an impact level value 3.50 or more. These technologies and their value are also bolded in Table 4, Table 5 and Table 6.

Table 4 contains the results processed for the pre-design stage of the construction project. The research pointed to a significant impact of cost management software among several participants in a construction project. These results are also supported by the BIM technologies used in this stage of the construction project.

Table 5 contains the results processed for the construction stage of the construction project. BD and SCM systems were the biggest benefit here. These systems clearly bring benefits in the form of cost savings in this stage of the construction project. This was confirmed by almost all respondents.

Therefore, at a significance level of α 0.05, we could reject the null hypothesis that the information and communication technology impact rate on sustainable supply chain and cost reduction of waste management in construction projects is ≤3.5. That means the information and communication technology impact rate on sustainable and cost reduction of waste management in construction projects is >3.5 and ICTs have impact on sustainable supply chain and cost management in waste management (Table 7).

Table 7.

Hypothesis results.

The effects of the use of information and communication technologies, according to research, suggest that these technologies are an essential tool to ensure sustainability, reduce costs and effectively manage construction waste. Here, we discuss our results and make comparisons with other studies. Several studies of a similar nature have focused on other key performance indicators in construction. The issue of waste management is a current topic. This research has quantified the impacts of information and communication technologies on the sustainable optimization of costs and wastes in construction. By shortening supply chain management and effective management through information and communication technologies, this survey is an important finding applicable to waste management in construction. The list of described technologies and their quantification of the impact can significantly achieve this issue as sustainable.

What is important to mention is that these technologies had a more significant impact in the management of larger projects and the case of the involvement of larger companies. Tests statistically confirmed this. This is a significant finding. Based on these results, it can be assumed that this impact is more significant for companies that are larger and make greater use of these information and communication technologies.

Future research should focus on the following inquiry: What impact does the size of the company play? In addition, more research needs to be conducted in the future. The phase of collecting data from other countries has just started. Thus, in addition to foreign companies operating in the domestic market, it will be possible to compare these data with other European countries. It is this shift in research that should achieve a more comprehensive mapping and verification of research results.

3.2. Research Limitations

Research activities in this area have brought several limitations that could reduce the value of the results or change the research conclusions. The research focused on the influence of information and communication technologies on sustainable supply chain, cost and waste management of construction projects in individual stages of those projects. These factors may lead to the question of the subjective evaluation of each respondent. However, this was prevented by a detailed description with percentages for each research area and question. Based on accurate accounting data, the respondents clearly defined the answer within the scale from 1 to 5.

Another issue from the point of view of the correct interpretation of the results and comparison was the size of the companies participating in the research and establishing a condition to compare these results. For this purpose, the answers were determined on a scale with a description of the values (relative indicator in percent). Therefore, in cost perception in projects of different sizes, comparing absolute values was not possible, and a relative indicator appears to be the most relevant type of research data acquisition.

The research also considered the number of information systems and the technologies used, but only at intervals. Information systems and technologies were considered all construction projects that pointed to three or more IS and IT. However, the results may be skewed according to the number of information systems and technologies used for comparison.

Another possible limit of research may be the unstoppable development of technologies and their efficiency of use. As research was conducted across the span of the construction projects, advances in technology may have adjusted perceptions and outcomes. However, we think that this impact is negligible due to the short period of the study.

We studied the importance of the impact of information and communication technology on sustainable supply chain and cost reduction of the overall cost of construction projects. This modification of the method’s main purpose excludes subjective evaluation and ensures independence in evaluating individual criteria based on data. Entropy measures the information content of a particular data set. It is a criterion for the degree of uncertainty represented by a discrete probability distribution. The selected method works by determining weights based on the “amount” of data it contains.

The research is also at the stage of evaluating the maintenance and use stage of the construction project. As only a short time has passed for some construction projects, it is not easy to evaluate this stage. Therefore, the final model does not include these results from this stage, but the conclusions contain a clearing trend. This stage’s results will be possible to evaluate in the coming years, where it will be possible to determine the solution strictly based on appropriate methods.

The location of the research should also be mentioned. Since the research was carried out in Slovakia (on behalf of large companies from abroad), and some companies operate abroad (especially the V4 countries and neighboring countries), this research’s results consider these markets. From this point of view, the final model may reflect the situation and conditions of the V4 countries, which is not guaranteed by its clear global contribution.

4. Conclusions

According to the latest studies, the management of construction projects is a demanding process that requires the implementation of information technologies. As this research has arrived at, information and communication technology is beneficial for construction projects’ sustainable cost and waste management. The research worked with data obtained from the practice, based on the testimonies of experts, project managers and other participants in the construction project. Data collection was carried out by a questionnaire survey and took into account the current situation in the construction market.

The implementation and use of information and communication technology positively impacts the sustainable supply chain, cost and waste management in each construction project stage. Their levels for individual stages are specified in more detail by the final model. However, it can be stated unequivocally that it is appropriate to use these technologies from the initial stage of a construction project. The results in the individual stages vary. In each stage, these positive impact results were precisely confirmed. This recommended nature applies to all examined stages of the life cycle of the project under construction.

The results also varied between technologies. In the initial stage, the positive impact of planning software (cost management software, BIM, CAD, etc.) prevailed, i.e., applications primarily intended for planning, not control. In the construction stage, control systems predominated, and this phenomenon was significant. In the construction stage, the control systems were significantly suitable for GPS and RFID systems. ERP systems showed a constant impact of use and a positive impact on sustainable supply chain and cost management.

The information and communication technology impact list brings a situation and technology that points to the impact of individual technologies on cost and waste reduction in individual stages of a construction project’s life cycle. Here, it is crucial to state several facts arising from the research. This ICT list is a situation where other fundamental factors do not change, meaning influences that the construction market and participants in construction projects cannot influence. This is, for example, the macroeconomic situation and the development of economies. The impact of the COVID-19 pandemic may also affect this area. Similar economic cycles and turbulence can affect cost management outcomes, and this model cannot take them into account. Another indicator is the difference based on the project’s size, which, in many cases, confirmed this research. It is also essential to monitor the development of costs and information and communication technologies’ impact during the last stage of a construction project’s life cycle. The currently processed results point to a similar trend, but these still need to be confirmed by statistical methods.

This research and the resulting model are the results of demanding research and are applicable in practice. It is currently being verified, and the results appear to be successful. However, it should be noted that this process is long-term, and the results can only be evaluated later. The processing of results for individual research groups is currently underway. Other factors could be added (size of the company, size of the construction project and participant position in the construction project). This means that the resulting ICT list would consider other factors and would be more specific based on the specification of the construction project. It is also interesting to draw relationships between different types of construction projects. These are other options that are already being worked on intensively, and the results should be available in the future.

Author Contributions

Conceptualization, T.M. and M.S.; methodology, T.M. and P.M.; software, T.M. and P.M.; validation, T.M., P.M. and M.S.; formal analysis, T.M.; investigation, M.S.; resources, T.M.; data curation, T.M.; writing—original draft preparation, T.M. and M.S.; writing—review and editing, P.M.; visualization, T.M.; supervision, P.M.; project administration, T.M.; funding acquisition, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Research and Development Agency under the contract no. APVV-17-0549. This paper presents partial research results of project VEGA 1/0557/18 Research and development of process and product innovations of modern methods of construction in the context of the Industry 4.0 principles. The paper presents a partial research results of project KEGA 059TUKE-4/2019 “M-learning tool for intelligent modeling of building site parameters in a mixed reality environment”.

Data Availability Statement

All research activities have been carried out in accordance with the MDPI Ethics, and there is no obstacle on our part.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rahman, I.A.; Abdul Azis, A.A. Time and cost performance of construction projects in Southern and central regions of Penisular Malaysia. In Proceedings of the IEEE Colloquium on Humanities, Science & Engineering Research (CHUSER 2012), Kota Kinabalu, Malaysia, 3–4 December 2012; pp. 52–57. [Google Scholar]

- Mellado, F.; Lou, E.C.W. Building information modelling, lean and sustainability: An integration framework to promote performance improvements in the construction industry. Sustain. Cities Soc. 2020, 61, 102355. [Google Scholar] [CrossRef]

- Naugolnova, I. The process approach to cost management in project-oriented enterprises of engine building. Lect. Notes Netw. Syst. 2021, 139, 85–91. [Google Scholar]

- Koľveková, G.; Liptáková, E.; Štrba, Ľ.; Kršák, B.; Sidor, C.; Cehlár, M.; Khouri, S.; Behún, M. Regional Tourism Clustering Based on the Three Ps of the Sustainability Services Marketing Matrix: An Example of Central and Eastern European Countries. Sustainability 2019, 11, 400. [Google Scholar] [CrossRef] [Green Version]

- Majer, R.; Ellimgerová, H.; Gašparík, J. Methods for the calculation of the lost profit in construction contracts. Buildings 2020, 10, 74. [Google Scholar] [CrossRef]

- Malara, J.; Plebankiewicz, E.; Juszczyk, M. Formula for determining the construction workers productivity including environmental factors. Buildings 2019, 9, 240. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Tang, L. BIM-based integrated management workflow design for schedule and cost planning of building fabric maintenance. Autom. Constr. 2019, 107, 102944. [Google Scholar] [CrossRef]

- de Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Kambanou, M.L. Life Cycle Costing: Understanding How It Is Practised and Its Relationship to Life Cycle Management—A Case Study. Sustainability 2020, 12, 3252. [Google Scholar] [CrossRef] [Green Version]

- Kim, G.T.; Kim, K.T.; Lee, D.H.; Han, C.H.; Kim, H.B.; Jun, J.T. Development of a life cycle cost estimate system for structures of light rail transit infrastructure. Autom. Constr. 2010, 19, 308–325. [Google Scholar] [CrossRef]

- Biolek, V.; Hanák, T. LCC estimation model: A construction material perspective. Buildings 2019, 9, 182. [Google Scholar] [CrossRef] [Green Version]

- Ali Musarat, M.; Salah Alaloul, W.; Liew, M.S.; Maqsoom, A.; Hannan Qureshi, A. Investigating the impact of inflation on building materials prices in construction industry. J. Build. Eng. 2020, 32, 101485. [Google Scholar] [CrossRef]

- Fantozzi, F.; Gargari, C.; Rovai, M.; Salvadori, G. Energy Upgrading of Residential Building Stock: Use of Life Cycle Cost Analysis to Assess Interventions on Social Housing in Italy. Sustainability 2019, 11, 1452. [Google Scholar] [CrossRef] [Green Version]

- Zima, K.; Plebankiewicz, E.; Wieczorek, D. A SWOT analysis of the use of BIM technology in the Polish construction industry. Buildings 2020, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Yu, L. Effective control method of the whole process project cost based on BIM. Adv. Intell. Syst. Comput. 2021, 1283, 327–332. [Google Scholar]

- Gasparik, J.; Funtik, T.; Gasparik, M.; Alamro, B. Continuing increasing of quality management level in construction company using excellence model with software support. In Proceedings of the ISARC 2018—35th International Symposium on Automation and Robotics in Construction and International AEC/FM Hackathon: The Future of Building Things, Berlin, Germany, 20–25 July 2018; pp. 207–213. [Google Scholar]

- Knapčíková, L.; Funtik, T.; Gasparik, M.; Alamro, B. Material recycling of some automobile plastics waste. Przem. Chem. 2018, 95, 1716–1720. [Google Scholar]

- Behun, M.; Kascak, P.; Hrabcak, M.; Behunova, A.; Knapcikova, L.; Sofranko, M. Investigation of Sustainable Geopolymer Composite Using Automatic Identification Technology. Sustainability 2020, 12, 6377. [Google Scholar] [CrossRef]

- Behún, M.; Gavurova, B.; Tkacova, A.; Kotaskova, A. The impact of the manufacturing industry on the economic cycle of European Union countries. J. Compet. 2018, 10, 23–39. [Google Scholar] [CrossRef] [Green Version]

- Love, P.D.E.; Matthews, J. The ‘how’ of benefits management for digital technology: From engineering T to asset management. Autom. Constr. 2019, 107, 102930. [Google Scholar] [CrossRef]

- Augustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Misra, S.C. Identifying Challenges in the adoption of industry 4.0 in the Indian construction industry. In Advances in Intelligent Systems and Computing; Springer: Singapore, 2021; pp. 380–398. [Google Scholar]

- Tetik, M.; Peltokorpi, A.; Seppänen, O.; Holmstrom, J. Direct digital construction: Technology-based operations management T practice for continuous improvement of construction industry performance. Autom. Constr. 2019, 107, 102910. [Google Scholar] [CrossRef]

- Heigermoser, D.; Garcia de Soto, B.; Sidney Abbott, E.L.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Chen, D.Q.; Preston, D.S.; Swink, M. How the use of big data analytics affects value creation in supply chain management. J. Manag. Inf. Syst. 2015, 32, 4–39. [Google Scholar] [CrossRef]

- Nolz, P.C. Optimizing construction schedules and material deliveries in city logistics: A case study from the building industry. Flex. Serv. Manuf. J. 2020, 1–33. [Google Scholar] [CrossRef]

- Okafor, C.C.; Ani, U.S.; Ugwu, O. Evalution of supply chain management lapses in Nigeria’s construction industry. Int. J. Constr. Res. 2021. [Google Scholar] [CrossRef]

- Wan, L.; Bai, Y. Application Research on the BIM and Internet of Things Technology in Construction Logistics Management in the Period of Big Data. Adv. Intell. Syst. Comput. 2021, 1191, 704–716. [Google Scholar]

- Knapčíková, L.; Behúnová, A.; Behún, M. Using a discrete event simulation as an effective method applied in the production of recycled material. Adv. Prod. Eng. Manag. 2020, 15, 431–440. [Google Scholar]

- Khayyat, N.T. Effects of information technology on cost, quality and efficiency in provision of public services. In Information and Communication Technologies; Nova Science Publishers, Inc.: New York, NY, USA, 2010. [Google Scholar]

- Santos, R.; Aguiar Costa, A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Uğural, M.N.; Giritli, H.; Urbański, M. Determinants of the Turnover Intention of Construction Professionals: A Mediation Analysis. Sustainability 2020, 12, 954. [Google Scholar] [CrossRef] [Green Version]

- Kot, S.; Haque, A.U.; Baloch, A. Supply chain management in SMEs: Global perspective. Montenegrin J. Econ. 2020, 16, 87–104. [Google Scholar] [CrossRef]

- Kot, S.; Haque, A.U.; Kozlovski, E. Mediating effect of strategic supply chain management on social and environmental sustainability: Evidence from SMEs of Canada, Iran and Turkey. Int. J. Supply Chain Manag. 2019, 8, 105–117. [Google Scholar]

- Pérez-López, R.J.; Olguín-Tiznado, J.E.; García-Alcaraz, J.L.; Camargo-Wilson, C.; López-Barreras, J.A. The Role of Planning and Implementation of ICT in Operational Benefits. Sustainability 2018, 10, 2261. [Google Scholar] [CrossRef] [Green Version]

- Chi, C.; Liu, Y. Measurement of ICT impact. J. Adv. Commun. Syst. A Technol. 2011, 13, 1–11. [Google Scholar]

- Anindita, T.; Tirtana Siregar, M. Analytical hierarchy process (AHP) for selecting freight forwarder services to get minimum shipping cost for export goods. Int. J. Innov. Creat. Chang. 2019, 9, 270–283. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).