Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution

Abstract

:1. Introduction

- Effective radial distance (ERD): the distance from a chemical droplet-stain on a target at which a pest is controlled by the chemical. The ERD of each crop and pest under different conditions should be defined by the chemical manufacturers on the labels.

- Spray coverage efficiency: percentage of area affected by the droplets on a target, relative to total target area; affected by spray rate, droplet-stain size distribution, droplet-stain spread, the effective radial distance (ERD) of the chemical on the pest, and target surface characteristics.

- Affected area by a chemical droplet-stain on a target: the area around the chemical droplet-stain on a target at which the pest is fully controlled. Its boundaries are at the effective radial distance (ERD) from the droplet-stains on the target.

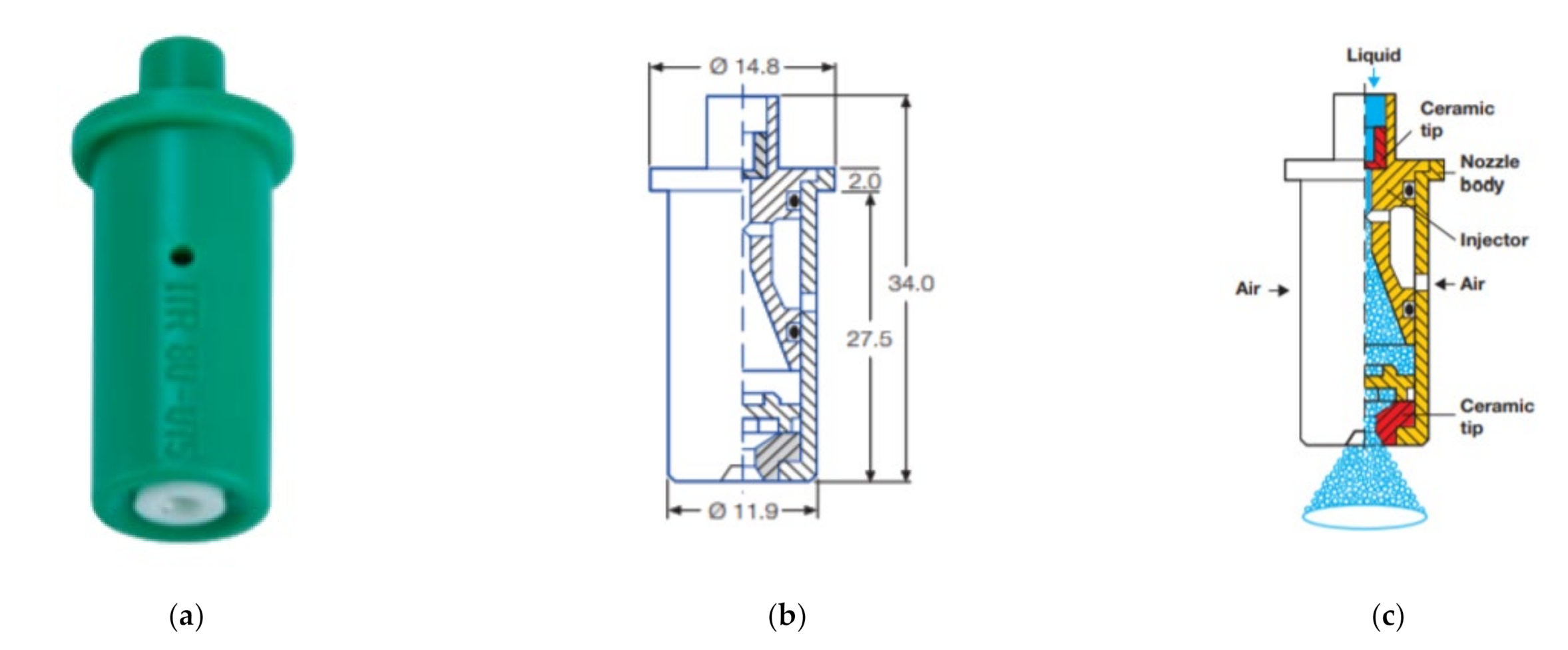

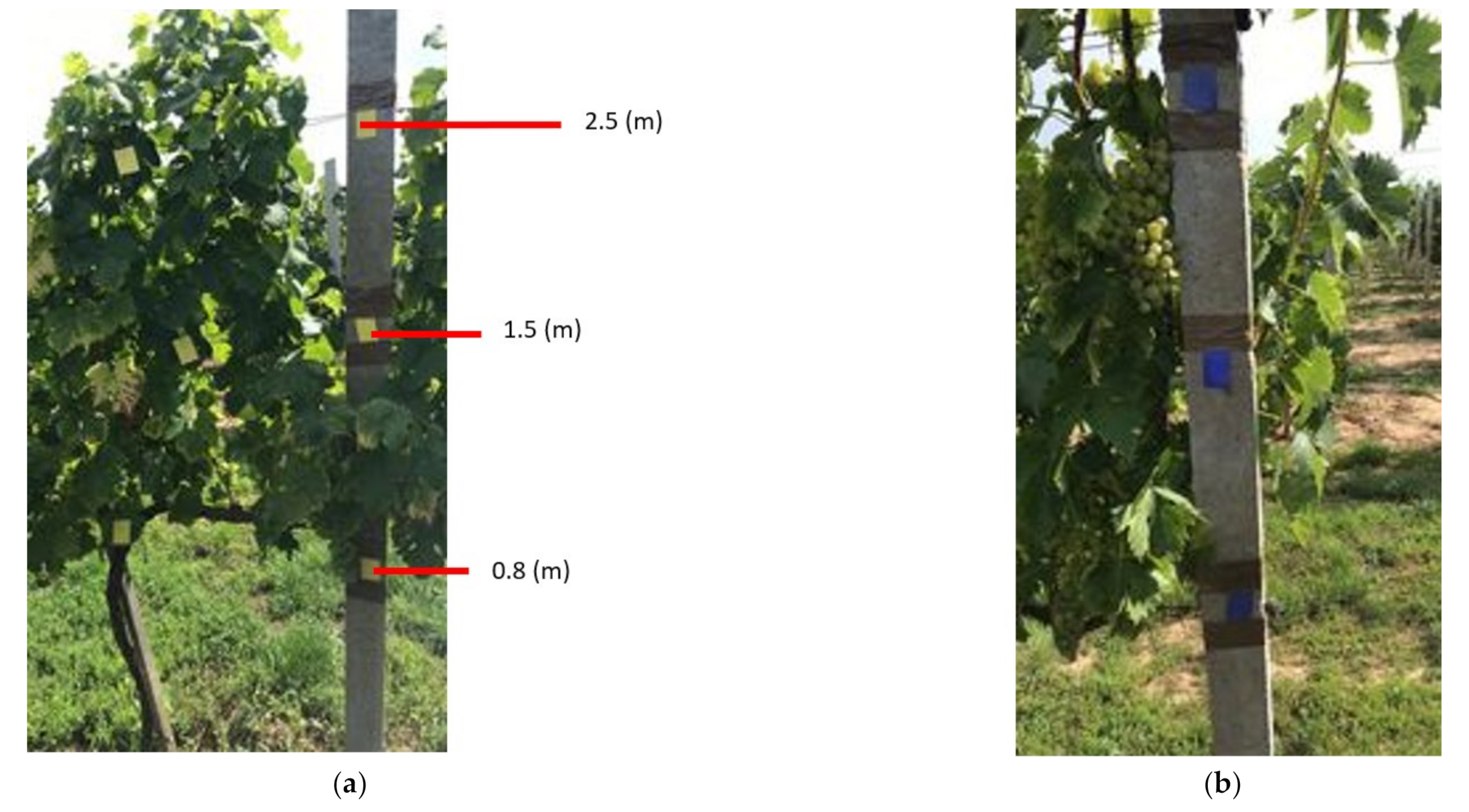

2. Materials and Methods

Experiment Design

3. Results

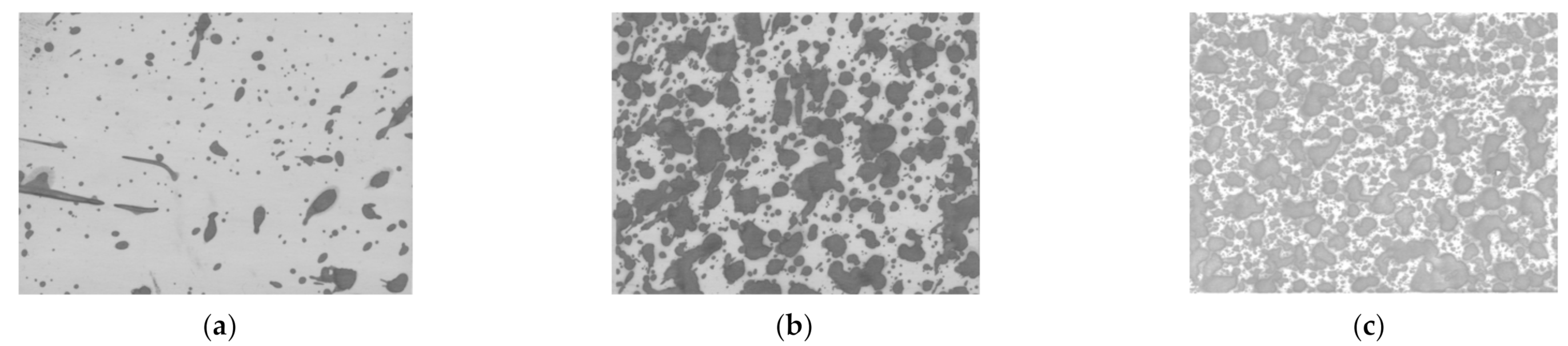

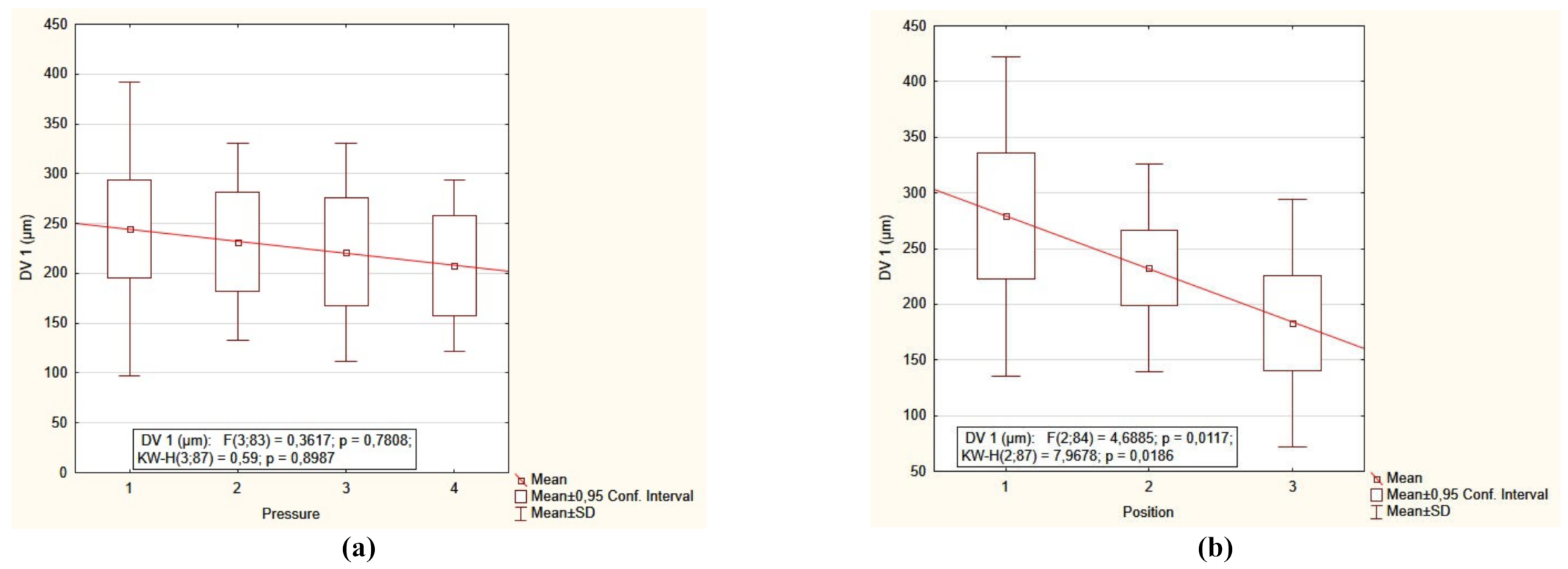

3.1. Influence of Pressure on Droplets Size Parameters and Spraying Coverage

3.2. Influence of Height from the Ground on Droplets Size Parameters and Spraying Coverage

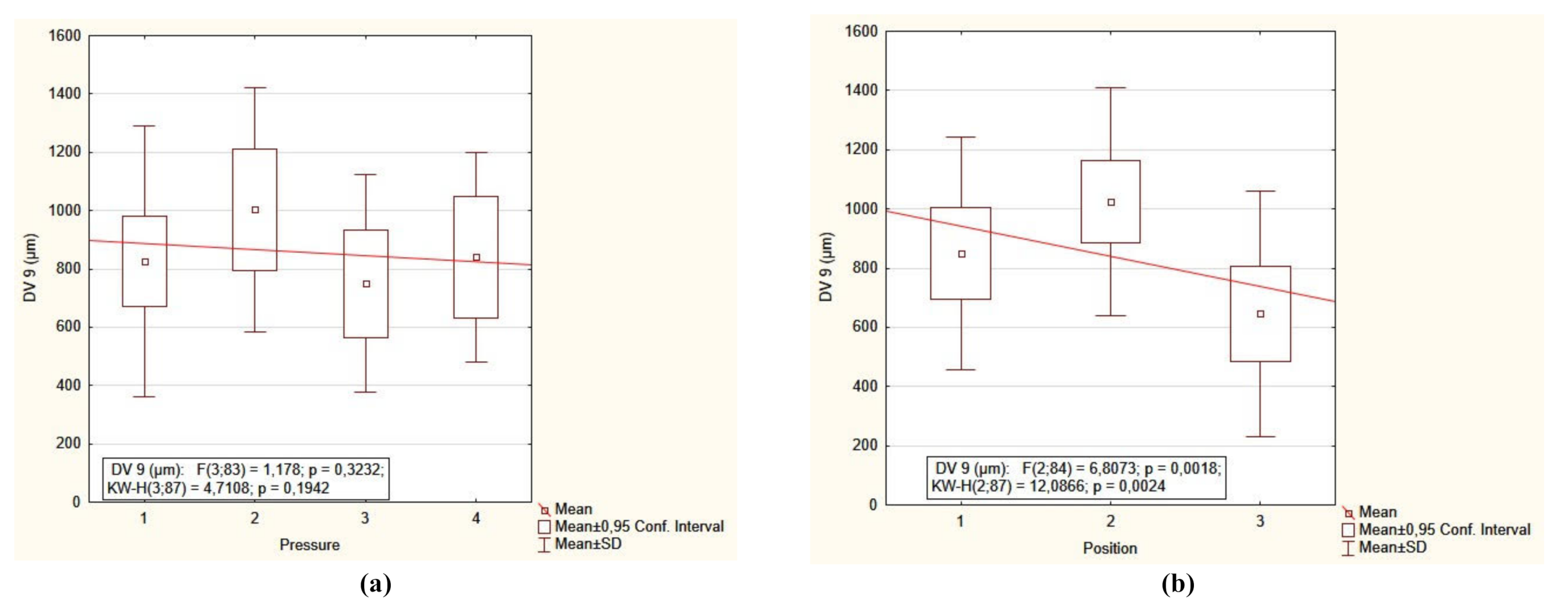

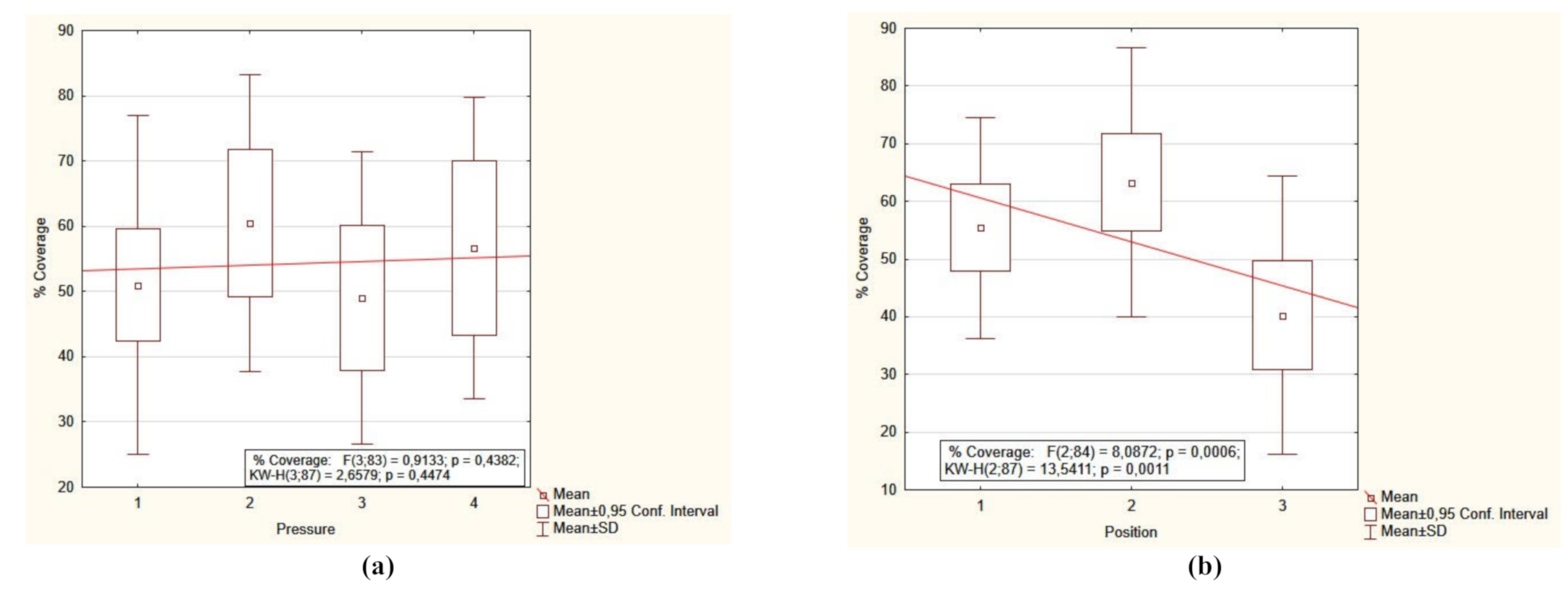

3.3. Dynamic of Volumetric Median Diameter of Droplets and of the Spraying Coverage under Pressure and Position Gradients

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kirk, I.W.; Bouse, L.F.; Carlton, J.B.; Franz, E.; Stermer, R.A. Aerial Spray Deposition in Cotton. Trans. ASAE 1992, 35, 1393–1399. [Google Scholar] [CrossRef]

- Salyani, M.; Cromwell, R.P. Spray Drift From Ground and Aerial Applications. Trans. ASAE 1992, 35, 1113–1120. [Google Scholar] [CrossRef]

- Yates, W.E.; Akesson, N.B.; Cowden, R.E. Criteria for Minimizing Drift Residues on Crops Downwind from Aerial Applications. Trans. ASAE 1974, 17, 0627–0632. [Google Scholar] [CrossRef]

- Grella, M.; Miranda-Fuentes, A.; Marucco, P.; Balsari, P.; Gioelli, F. Development of Drift-Reducing Spouts For Vineyard Pneumatic Sprayers: Measurement of Droplet Size Spectra Generated and Their Classification. Appl. Sci. 2020, 10, 7826. [Google Scholar] [CrossRef]

- Grella, M.; Gallart, M.; Marucco, P.; Balsari, P.; Gil, E. Ground Deposition and Airborne Spray Drift Assessment in Vineyard and Orchard: The Influence of Environmental Variables and Sprayer Settings. Sustainability 2017, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Arvidsson, T.; Bergström, L.; Kreuger, J. Spray Drift as Influenced by Meteorological and Technical Factors. Pest Manag. Sci. 2011, 67, 586–598. [Google Scholar] [CrossRef]

- Grella, M.; Marucco, P.; Balafoutis, A.T.; Balsari, P. Spray Drift Generated in Vineyard during Under-Row Weed Control and Suckering: Evaluation of Direct and Indirect Drift-Reducing Techniques. Sustainability 2020, 12, 5068. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Gallart, M. Use of a Terrestrial LIDAR Sensor for Drift Detection in Vineyard Spraying. Sensors 2013, 13, 516–534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gregorio, E.; Rosell-Polo, J.R.; Sanz, R.; Rocadenbosch, F.; Solanelles, F.; Garcerá, C.; Chueca, P.; Arnó, J.; del Moral, I.; Masip, J.; et al. LIDAR as an Alternative to Passive Collectors to Measure Pesticide Spray Drift. Atmos. Environ. 2014, 82, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Furness, G. Spraying for Pest and Diseases: An Overview of Equipment and Techniques. Aust. N. Zealand Wine Ind. J. 1993, 8, 250. [Google Scholar]

- van de Zande, J.; Holterman, H.; Wenneker, M. Nozzle Classification for Drift Reduction in Orchard Spraying: Identification of Drift Reduction Class Threshold Nozzles. Agric. Eng. Int. 2008, 10, 1–12. [Google Scholar]

- Nuyttens, D.; Schampheleire, M.D.; Steurbaut, W.; Baetens, K.; Nicolaï, B.; Ramon, H.; Sonck, B. Experimental Study of Factors Influencing the Risk of Drift from Field Sprayers, Part 2: Spray Application Technique. Asp. Appl. Biol. 2006, 77, 331–339. [Google Scholar]

- Derksen, R.; Zhu, H.; Fox, R.D.; Brazee, R.D.; Krause, C.R. Coverage and Drift Produced by Air Induction and Conventional Hydraulic Nozzles Used for Orchard Applications. Trans. ASABE 2000, 50. [Google Scholar] [CrossRef]

- ASAE. Standard S 327.2. Dec. 2001. Terminology & Definitions for Agricultural Chemical Application; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2001. [Google Scholar]

- Hoffmann, C.; Hewitt, A. Comparison of Three Imaging Systems for Water-Sensitive Papers. Appl. Eng. Agric. 2005, 21. [Google Scholar] [CrossRef]

- Fisher, R.W.; Menzies, D.R. Effect of Spray Droplet Density and Exposure Time on the Immobilization of Newly-Hatched Oriental Fruit Moth Larvae1. J. Econ. Entomol. 1976, 69, 438–440. [Google Scholar] [CrossRef]

- Sundaram, K.M.S.; de Groot, P.; Sundaram, A. Permethrin Deposits and Airborne Concentrations Downwind from a Single Swath Application Using a Back Pack Mist Blower. J. Environ. Sci. Health Part B 1987, 22, 171–193. [Google Scholar] [CrossRef]

- Thériault, R.; Salyani, M.; Panneton, B. Spray Distribution and Recovery in Citrus Application with a Recycling Sprayer. Trans. ASAE 2001, 44. [Google Scholar] [CrossRef]

- Fox, R.; Derksen, R.; Zhu, H.; Brazee, R.; Svensson, S. A History of Air-Blast Sprayer Development and Future Prospects. Trans. Am. Soc. Agric. Biol. Eng. 2008, 51. [Google Scholar] [CrossRef]

- Water-Sensitive Paper|Check Your Spray Coverage. Available online: https://www.syngenta.com.au/awri (accessed on 19 April 2021).

- Zhu, H.; Salyani, M.; Fox, R.D. A Portable Scanning System for Evaluation of Spray Deposit Distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- Wang, G.; Lan, Y.; Yuan, H.; Qi, H.; Chen, P.; Ouyang, F.; Han, Y. Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers. Appl. Sci. 2019, 9, 218. [Google Scholar] [CrossRef] [Green Version]

- Lechler Agrar. Available online: https://www.Lechler.Com/Fileadmin/Media/Datenblaetter/Agrar/EN/Lechler_agrar_datenblatt_itr80_en.Pdf (accessed on 6 March 2021).

- Griesang, F.; Decaro, R.A.; dos Santos, C.A.M.; Santos, E.S.; Roque, N.H. de L.; Ferreira, M. da C. How Much Do Adjuvant and Nozzles Models Reduce the Spraying Drift? Drift in Agricultural Spraying. Am. J. Plant Sci. 2017, 8, 2785–2794. [Google Scholar] [CrossRef] [Green Version]

- Ferguson, J.C.; O’Donnell, C.C.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; Wang, R.; Urach Ferreira, P.H.; Hewitt, A.J. Determining the Uniformity and Consistency of Droplet Size across Spray Drift Reducing Nozzles in a Wind Tunnel. Crop Prot. 2015, 76, 1–6. [Google Scholar] [CrossRef]

- Vallet, A.; Tinet, C. Characteristics of Droplets from Single and Twin Jet Air Induction Nozzles: A Preliminary Investigation. Crop Prot. 2013, 48, 63–68. [Google Scholar] [CrossRef]

- McArtney, S.J.; Obermiller, J.D. Comparative Performance of Air-Induction and Conventional Nozzles on an Axial Fan Sprayer in Medium Density Apple Orchards. HortTechnology 2008, 18, 365–371. [Google Scholar] [CrossRef] [Green Version]

- DepositScan: USDA ARS. Available online: https://www.ars.usda.gov/midwest-area/wooster-oh/application-technology-research/docs/depositscan/ (accessed on 19 April 2021).

- Understanding Droplet Size—Pesticide Environmental Stewardship. Available online: https://pesticidestewardship.org/pesticide-drift/understanding-droplet-size/ (accessed on 4 June 2021).

- ATOM 300 (400)—Tehnofavorit. Available online: http://tehnofavorit.ro/produse/atom-300-400/ (accessed on 2 June 2021).

- Herbst-Pflanzenschutztechnik. Available online: http://www.herbst-pflanzenschutztechnik.de/index-Dateien/ED20_900_A4Englisch.pdf (accessed on 6 April 2021).

- Nahm, F.S. What the P Values Really Tell Us. Korean J. Pain 2017, 30, 241–242. [Google Scholar] [CrossRef] [PubMed]

- Pourreza, A.; Moghimi, A.; Niederholzer, F.J.A.; Larbi, P.A.; Zuniga-Ramirez, G.; Cheung, K.H.; Khorsandi, F. Spray Backstop: A Method to Reduce Orchard Spray Drift Potential without Limiting the Spray and Air Delivery. Sustainability 2020, 12, 8862. [Google Scholar] [CrossRef]

- Tona, E.; Calcante, A.; Oberti, R. The Profitability of Precision Spraying on Specialty Crops: A Technical–Economic Analysis of Protection Equipment at Increasing Technological Levels. Precis. Agric. 2018, 19, 606–629. [Google Scholar] [CrossRef] [Green Version]

- Garcerá, C.; Moltó, E.; Chueca, P. Spray Pesticide Applications in Mediterranean Citrus Orchards: Canopy Deposition and off-Target Losses. Sci. Total Environ. 2017, 599–600, 1344–1362. [Google Scholar] [CrossRef]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of Nozzle Type, Size and Pressure on Spray Droplet Characteristics. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Nuyttens, D.; De Schampheleire, M.; Verboven, P.; Brusselman, E.; Dekeyser, D. Droplet Size and Velocity Characteristics of Agricultural Sprays. Trans. ASABE 2009, 52, 1471–1480. [Google Scholar] [CrossRef]

- Torrent, X.; Garcera, C.; Molto, E.; Chueca, P.; Abad Moyano, R.; Grafulla, C.; Román, C.; Planas de Martí, S. Comparison between Standard and Drift Reducing Nozzles for Pesticide Application in Citrus: Part I. Effects on Wind Tunnel and Field Spray Drift. Crop Prot. 2017, 96, 130–143. [Google Scholar] [CrossRef] [Green Version]

- Bayat, A.; Ulusoy, M.; Karaca, Ý.; Uygun, N. Spray Coverage and Citrus Pest Control Efficiency with Different Types of Orchard Sprayers. AMA Agric. Mech. Asia Afr. Lat. Am. 2000, 31, 45–51. [Google Scholar]

- Kasner, E.J.; Fenske, R.A.; Hoheisel, G.A.; Galvin, K.; Blanco, M.N.; Seto, E.Y.W.; Yost, M.G. Spray Drift from Three Airblast Sprayer Technologies in a Modern Orchard Work Environment. Ann. Work Expo. Health 2020, 64, 25–37. [Google Scholar] [CrossRef] [PubMed]

- Directive 2009/128/EC of the European Parliament and of the Council of 21 October 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32009L0128 (accessed on 19 April 2021).

- Best Management Practices to Reduce Spray Drift. Available online: http://www.topps-life.org/uploads/8/0/0/3/8003583/ansicht_drift_book_englisch.pdf (accessed on 3 June 2021).

- Decision No. 135/12.03.2019 for the Approval of National Action Plan Regarding Reduction of Risks Associated with the Use of Plant Protection Products. Available online: https://www.madr.ro/docs/fitosanitar/legislatie-nationala/hotarare-135-2019-plan-nat-diminuare-riscuri-prod-protectie-plate.pdf (accessed on 19 April 2021).

- Gil, E. Inspection of Sprayers in Use: A European Sustainable Strategy to Reduce Pesticide Use in Fruit Crops. Appl. Eng. Agric. 2007, 23, 49–56. [Google Scholar] [CrossRef]

| Variables | Pressure | 3 bar | 5 bar | 7 bar | 9 bar | Average |

|---|---|---|---|---|---|---|

| DV 1 | 3 bar | - | p = 0.714006 | p = 0.506333 | p = 0.338471 | 244.65 μm |

| 5 bar | p = 0.714006 | - | p = 0.796744 | p = 0.582995 | 231.72 μm | |

| 7 bar | p = 0.506333 | p = 0.796744 | - | p = 0.757739 | 221.17 μm | |

| 9 bar | p = 0.338471 | p = 0.582995 | p = 0.757739 | - | 207.67 μm | |

| DV 5 | 3 bar | - | p = 0.136953 | p = 0.621155 | p = 0.950223 | 533.18 μm |

| 5 bar | p = 0.136953 | - | p = 0.088728 | p = 0.20898 | 640.71 μm | |

| 7 bar | p = 0.621155 | p = 0.088728 | - | p = 0.731031 | 497.66 μm | |

| 9 bar | p = 0.950223 | p = 0.20898 | p = 0.731031 | - | 528.29 μm | |

| DV 9 | 3 bar | - | p = 0.145618 | p = 0.533702 | p = 0.909157 | 825.06 μm |

| 5 bar | p = 0.145618 | - | p = 0.074665 | p = 0.281566 | 1003.50 μm | |

| 7 bar | p = 0.533702 | p = 0.074665 | - | p = 0.546975 | 749.16 μm | |

| 9 bar | p = 0.909157 | p = 0.281566 | p = 0.546975 | - | 840.24 μm | |

| Coverage degree | 3 bar | - | p = 0.176285 | p = 0.780247 | p = 0.458605 | 50.982% |

| 5 bar | p = 0.176285 | - | p = 0.160181 | p = 0.658025 | 60.457% | |

| 7 bar | p = 0.780247 | p = 0.160181 | - | p = 0.380654 | 49.038% | |

| 9 bar | p = 0.458605 | p = 0.658025 | p = 0.380654 | - | 56.630% |

| Variables | Position | Lower Part | Middle Part | Upper Part | Average |

|---|---|---|---|---|---|

| DV 1 | Lower part | - | p = 0.133562 | p = 0.002969 ** | 278.94 μm |

| Middle part | p = 0.133562 | - | p = 0.100652 | 232.96 μm | |

| Upper part | p = 0.002969 ** | p = 0.100652 | - | 183.05 μm | |

| DV 5 | Lower part | - | p = 0.217061 | p = 0.041396 * | 561.56 μm |

| Middle part | p = 0.217061 | - | p = 0.000985 *** | 638.48 μm | |

| Upper part | p = 0.041396 * | p = 0.000985 *** | - | 429.33 μm | |

| DV 9 | Lower part | - | p = 0.095264 | p = 0.060166 | 849.99 μm |

| Middle part | p = 0.095264 | - | p = 0.000398 *** | 1025.40 μm | |

| Upper part | p = 0.060166 | p = 0.000398 *** | - | 645.51 μm | |

| Coverage degree | Lower part | - | p = 0.182296 | p = 0.013697 | 55.447% |

| Middle part | p = 0.182296 | - | p = 0.000144 | 63.306% | |

| Upper part | p = 0.013697 | p = 0.000144 | - | 40.257% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranta, O.; Marian, O.; Muntean, M.V.; Molnar, A.; Ghețe, A.B.; Crișan, V.; Stănilă, S.; Rittner, T. Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution. Sustainability 2021, 13, 7780. https://doi.org/10.3390/su13147780

Ranta O, Marian O, Muntean MV, Molnar A, Ghețe AB, Crișan V, Stănilă S, Rittner T. Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution. Sustainability. 2021; 13(14):7780. https://doi.org/10.3390/su13147780

Chicago/Turabian StyleRanta, Ovidiu, Ovidiu Marian, Mircea Valentin Muntean, Adrian Molnar, Alexandru Bogdan Ghețe, Valentin Crișan, Sorin Stănilă, and Tibor Rittner. 2021. "Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution" Sustainability 13, no. 14: 7780. https://doi.org/10.3390/su13147780

APA StyleRanta, O., Marian, O., Muntean, M. V., Molnar, A., Ghețe, A. B., Crișan, V., Stănilă, S., & Rittner, T. (2021). Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution. Sustainability, 13(14), 7780. https://doi.org/10.3390/su13147780