Abstract

Due to the need for resource utilization and environmental protection, remanufacturing is used as an effective means to achieve a circular economy. To focus on the production and sales of new products, manufacturers outsource the remanufacturing of used products to remanufacturers. Aiming at helping manufacturers to choose between self-remanufacturing and outsourcing remanufacturing policies, a closed-loop supply chain network equilibrium model considering the remanufacturing policy options is established. The equilibrium decision-making is obtained by using the variational inequality method. Furthermore, the criteria for manufacturers to choose between the two remanufacturing policies based on different factors such as recovery rates of the used products, remanufacturing costs, and environmental impact parameters, are given. Numerical examples show the following results: (1) When compared with self-remanufacturing policy, outsourcing remanufacturing policy can save resources, increase the sales of products, and have a smaller environmental impact. (2) When the recycling rate of used products is low, choosing an outsourcing remanufacturing policy can increase the sales of products. When the recycling rate is high, choosing a self-remanufacturing policy can get more profits. (3) When the costs of a self-remanufacturing policy and an outsource-remanufacturing policy are quite different, choosing the outsourcing remanufacturing policy can save resources and protect the environment.

1. Introduction

Due to the rapid development of industrialization and rapid product updates, the problems of global environmental pollution and resource shortages are becoming more and more serious. A large number of used products are accumulating throughout the whole world. To achieve sustainable development, enterprises in various countries (such as Dell, Kodak, IBM, Xerox, Fuji, Bosch [1]) are actively seeking various effective methods for recycling and reusing the used products; remanufacturing is one of the effective methods. It was found in [2] that the application of used engine remanufacturing can save up to 50% of costs, 60% of energy, and reduce environmental impact by 80%. Moreover, in the extended producer responsibility (EPR) system stipulated by the country, manufacturing companies are responsible for the disposal and utilization of used products. However, due to insufficient remanufacturing technologies and equipment [3], original manufacturing companies (see, e.g., Ford, BMW, HP) also need to entrust their remanufacturing business to other manufacturing companies to form outsourced remanufacturing [4,5]. For example, Apple has authorized Foxconn to remanufacture its iPhone and other products in China [6].

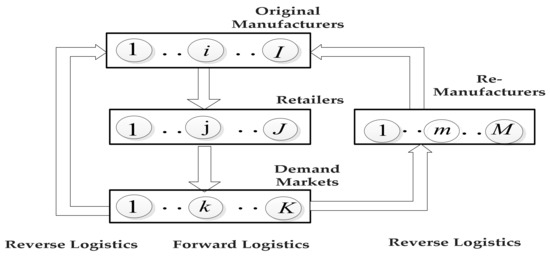

Existing studies [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21] have analyzed the importance of outsourcing remanufacturing business in a closed-loop supply chain (CLSC) which consists of a single manufacturer and a single remanufacturer. After the manufacturing companies have outsourced their remanufacturing businesses, they can change their disadvantaged positions in the competition by recycling more used products, increasing their resource utilization rate, and reducing environmental impact. When multiple competing manufacturing enterprises produce new products and remanufacture used products to meet market demands, their strategies are called CLSC network (shown in Figure 1) equilibrium decision-making [22,23]. The forward flows of the CLSC involve new products, which are produced by the original manufacturers and sold to customers in the demand market through retailers. The reverse flows of CLSC involve used products, which are returned from the demand markets to the original manufacturers or the remanufacturers for recycling.

Figure 1.

Closed-loop supply chain network.

However, existing research on the CLSC network equilibrium problem [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37] have not considered the manufacturers’ options of remanufacturing their products or outsourcing their products to other manufacturers for remanufacturing. Moreover, the actual production and operation of manufacturing companies may also need to consider third-party remanufacturing. For example, Apple has outsourced its mobile phone remanufacturing business to remanufacturing enterprises in China [6]. When a manufacturing company chooses its remanufacturing policy, it needs to consider the following issues: (1) How can an equilibrium model of the CLSC network that considers self-remanufacturing and outsourcing remanufacturing policy options be established? (2) What is the criterion for choosing different remanufacturing policies? (3) What are the impacts of different remanufacturing policies on raw material utilization, used product utilization, and environmental protection?

To study these issues deeply, this article focuses on the CLSC network equilibrium that considers the original manufacturers’ self-remanufacturing and outsourcing remanufacturing options. Based on the factors such as used product recovery rates, remanufacturing costs, and environmental protection parameters, the original manufacturer should decide whether he should remanufacture the used products himself or entrust other enterprises for remanufacturing (i.e., outsourcing remanufacturing). The main contributions of this paper are:

- (1)

- A CLSC network equilibrium model considering self-remanufacturing and outsourcing remanufacturing options is constructed and analyzed for the first time in the literature.

- (2)

- The equilibrium decision-makings of the original manufacturers, the remanufacturers, and the entire network using different remanufacturing policies are obtained.

- (3)

- The importance of the outsourcing remanufacturing policy is discussed; the criteria for the original manufacturers to choose between the self-remanufacturing policy and the outsourcing remanufacturing policy are obtained.

2. Literature Review

2.1. Outsourcing Remanufacturing

Due to the rapid development of science and technology in recent years and the acceleration of product updates, original equipment manufacturers (OEMs) continue to develop and sell new products. The creation of new products has led to the emergence of a large number of used products, which can be recycled by the remanufacturing business. However, due to the shortages of equipment and financial supports, OEMs need to outsource their remanufacturing businesses to remanufacturers. Alumur et al. [7] constructed several recycling models for remanufacturing used products and gave the boundary conditions for outsourcing their used products to other remanufacturers for recycling. Abdulrahman et al. [8] studied the remanufacturing of Chinese auto-part companies and provided the strategic decision to OEMs to decide on whether to remanufacture their used products or to outsource their remanufacturing business to remanufacturers. Zou et al. [9] provided the OEMs with outsourcing and authorization methods to remanufacture their products. Ameknassi et al. [10] studied how the green supply chain design can affect the outsourcing policies of the remanufacturers. Wang et al. [11] assessed whether OEMs should remanufacture themselves or outsource the remanufacturing business to remanufacturers from both the economic and environmental viewpoint. Esenduran et al. [12] studied how government regulations can affect the OEM’s choice between different remanufacturing policies. Yan et al. [13] analyzed the remanufacturing policy from the economic, social, and environmental perspectives. Sun et al. [14] studied the impact of product upgrades on remanufacturing operation management. Zou et al. [15] studied the impact of consumers’ environmental awareness on the outsourcing remanufacturing business; they discovered that outsourcing remanufacturing business does not reduce the number of new products produced by the OEMs. Zheng et al. [16] and Wang et al. [17] studied the competition of new and remanufactured products in the CLSC. He et al. [18] and Zhang et al. [19] studied the economic, environmental, and remarketing channels’ impacts on outsourcing and remanufacturing issues. Feng et al. [20] studied the impact of green consumption behaviors on the choice between using an outsourcing remanufacturing policy or licensing remanufacturing policy. Alegoz et al. [21] analyzed the optimal policy of self-manufacturing and outsourcing remanufacturing under the carbon tax policy. Although all the above papers have studied the economic and environmental benefits of a CLSC considering outsourcing remanufacturing, the research work so far is limited to the case that the CLSC consists of an OEM and a third-party remanufacturer (3PR) only. In this present paper, we fill in the gap of the existing literature by considering a remanufacturing problem involving a competitive CLSC network, in which there are multiple OEMs and 3PRs. For every OEM, he can use in-house remanufacturing or outsource the remanufacturing business to 3PRs according to profits, sales volumes, costs, resources, and environmental impacts.

2.2. Equilibrium in a Competitive CLSC Network

Nagurney and Toyasaki [22] first used the variational inequality (VI) to establish the reverse supply chain network equilibrium model for electronic waste products. Hammond and Beullen [23] further extended the reverse supply chain network considered by Nagurney and Toyasaki [22] to a CLSC network equilibrium model. Yang et al. [24] established a CLSC network equilibrium model which includes raw material suppliers and recovery centers. Qiang et al. [25] studied the influence of random demand on the CLSC network equilibrium decision-making. Qiang [26] further analyzed the equilibrium decision-making of differential pricing between new products and remanufactured products. Chan et al. [27] studied the dynamic equilibrium of a CLSC network considering the production planning periods. Zhen et al. [28] and Nayeri et al. [29] studied the multi-objective problem of minimizing the total cost and reducing and controlling the total amount of carbon emission in a CLSC network. Wang et al. [30] provided the CLSC network equilibrium decision-making for retailers who need to recycle used products themselves. Yang et al. [31] studied the CLSC network dynamics considering pollution permits. Wu et al. [32] analyzed how the government subsidy and the asymmetry of enterprise costs can affect the equilibrium decision-making of the CLSC network. Duan et al. [33] considered the impact of consumers’ preference and AI-Push on the CLSC network equilibrium. Biçe and Batun [34] studied the CLSC network equilibrium considering the qualities of the returned products. Pourmehdi et al. [35] studied the equilibrium decision-making of a steel CLSC network involving production technology. Diabat and Jebali [36] studied a CLSC network problem for durable products under the take-back legislation. Fu et al. [37] proposed a CLSC network model dealing with heterogeneous products facing different market demands. Existing research work [23,24,25,26,27,28,29,30,31,32,33,34,35,36,37] not only obtained CLSC network equilibrium decision-making but also analyzed how external factors, such as random demand, manufacturing level, production period, carbon emission, etc., can affect the equilibrium decision-making. However, all these research works only considered the OEMs’ self-remanufacturing policy but did not consider their outsourcing remanufacturing policy. On the other hand, Zhang et al. [38] recently proposed a 3PR option, in which the OEM can choose the best way to do outsourcing remanufacturing business. Thus, since there is no research work in the current literature considering both OEMs’ self-remanufacturing and outsourcing remanufacturing business, we extend the existing literature of the CLSC network by considering OEMs’ remanufacturing policy choices between a self-remanufacturing policy and outsourcing remanufacturing policy. That is, our study considers a competitive CLSC network, in which every OEM, such as Kodak, IBM, Bosch, Xerox, Fuji, and Dell [1], can choose self-remanufacturing or outsource the remanufacturing business to 3PRs according to profits, sales volumes, costs, resources, and environmental impacts.

Based on the research work of the above researchers, this paper focuses on the competitive CLSC network of the OEMs’ remanufacturing policy options, in which the OEM can decide whether to remanufacture himself or outsource the remanufacturing business to remanufacturers. Moreover, this paper not only establishes an equilibrium model of the CLSC network that considers remanufacturing policy options and calculates the optimal decisions for each decision maker but also analyzes how the OEM should choose a remanufacturing policy based on external factors such as the recovery rates of the used products, remanufacturing costs, and environmental impact parameters. Thus, this paper contributes a lot to the operation management of the remanufacturing business.

3. Model

3.1. Model Description and Assumption

Consider a CLSC network that consists of original manufacturers, retailers, demand markets, and outsourced remanufacturers (referred to as remanufacturers). The situation is depicted in Figure 1. In Figure 1, multiple nodes in the top-level (respectively, the second level) of the forward logistic represent non-cooperation competitions between different original manufacturers (respectively, different retailers), whereas multiple nodes in the reverse logistic represent non-cooperation competitions between different remanufacturers. These mutual competitions constitute non-cooperative games. The links between different layers in the forward logistics (respectively, the reverse logistics) represent product transactions between original manufacturers and retailers and between retailers and demand markets (respectively, between original manufacturers and remanufacturers and between remanufacturers and demand markets). New products produced by the original manufacturers are sold to customers in the demand market through retailers, and these products become used products after they have been used by customers.

Due to the EPR system stipulated by the country, original manufacturers need to recycle and remanufacture used products to save resources and reduce environmental pollution. The original manufacturer can choose to remanufacture himself [23], or because of the lack of remanufacturing knowledge and equipment [3], he can entrust a third party (i.e., remanufacturers) to remanufacture his products, forming an outsourcing remanufacturing strategy [38]. The decision variables and the parameters in our model are defined in Table 1. We assume that the following conditions hold throughout this paper:

Assumption 1.

A single production period without considering storage decisions is used.

Assumption 2.

The quality of remanufactured products is the same as that of new products [23].

Assumption 3.

The cost functions are convex and continuous, and the demand function is a decreasing function of price.

Assumption 4.

All decision variables are non-negative, and all the decision vectors are column vectors.

Table 1.

Definition of the decision variables and the parameters in the model.

Table 1.

Definition of the decision variables and the parameters in the model.

| Symbol | Definition |

|---|---|

| The number of new products produced by the original manufacturer . | |

| The vector consisting of the numbers of new products produced by all the original manufacturers. | |

| The number of transaction products between the original manufacturer and retailer . | |

| The vector consisting of the numbers of transaction products between all original manufacturers and all retailers. | |

| The number of products sold by retailers to demand market . | |

| The vector consisting of the numbers of products sold by all the retailers to all the demand markets. | |

| The number of used products returned to the original manufacturer from demand market . | |

| The vector consisting of the numbers of used products returned to all the original manufacturers from all the demand markets. | |

| The number of used products returned to the remanufacturer from demand market . | |

| The vector consisting of the numbers of used products returned to all the remanufacturers from all the demand markets. | |

| The number of remanufactured products sold by remanufacturer to the original manufacturer . | |

| The vector consisting of the numbers of remanufactured products sold by all the remanufacturers to all the original manufacturers. | |

| The price per item at demand market (unit: yuan/item). | |

| The vector consisting of the prices per item at all the demand markets. | |

| The fraction of the used products that can be used for remanufacturing after they have been recovered from the demand markets. | |

| Percentage of the used products recovered from the demand markets. | |

| The cost of sending 1 item of the waste product to the landfill for disposal. | |

| The pollution coefficient of the new product (unit: kg/item). | |

| The pollution coefficient of the remanufactured product (unit: kg/item). |

3.2. The Equilibrium Decisions of the Original Manufacturers

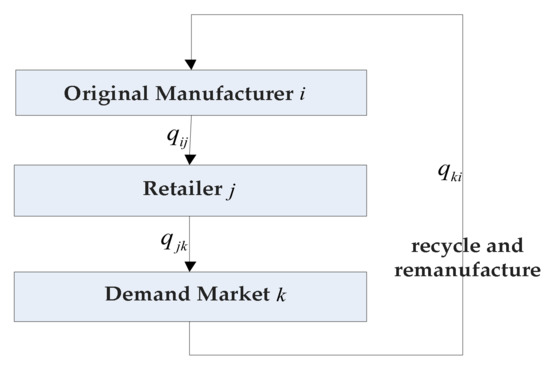

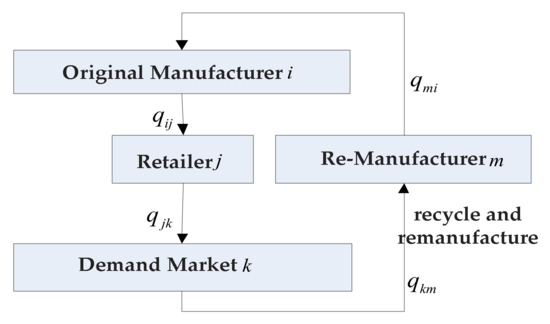

In the CLSC network, original manufacturers compete non-cooperatively with each other for profits. A competing original manufacturer uses raw materials to produce new products and sells them to retailers to obtain revenue. For used products returned from a demand market, he can choose to remanufacture himself (the transaction diagram is shown in Figure 2) or outsource to a remanufacturer for remanufacturing (the transaction diagram is shown in Figure 3).

Figure 2.

The transaction diagram of the self-remanufacturing policy.

Figure 3.

The transaction diagram of the outsourcing remanufacturing policy.

Case 1. Self-remanufacturing policy.

In Case 1, original manufacturer chooses to remanufacture the used products himself. As shown in Figure 2, in the forward logistics, original manufacturer produces items of new products with production cost . He sells items of these products to the retailer with cost. In the reverse logistics, he collects items of used products from demand market with cost ; the total number of used products that he collects from all the demand markets is . Since only a fraction of the used products can be remanufactured and the remaining used products (i.e., the waste product) will be sent to landfill for disposal, his costs involved in the reverse logistics are for remanufacturing used products, for cleaning used products, and for disposing of waste products. Thus, the optimization problem of the original manufacturer who chooses to remanufacture the used products himself is as follows:

where is the net profit of manufacturer in Case 1.

In Equation (1), and are endogenous prices. Constraint (2) indicates that the total number of transaction products of manufacturer with all the retailers should not exceed the total number of his new products and his self-remanufactured products. Constraint (3) indicates that the used product has a minimum recovery quantity.

Case 2. Outsourcing remanufacturing policy.

In Case 2, original manufacturer chooses to outsource the remanufacturing business to remanufacturer . As shown in Figure 3, the forward logistics involving the original manufacturer is the same as that in Case 1. In the reverse logistics, he does not need to pay multiple costs related to recycling and remanufacturing of used products, but only pays remanufacturer the outsourcing cost and the transaction cost , where is the endogenous outsourcing price per unit item of the remanufactured products. Thus, the optimization problem of the original manufacturer who chooses to outsource his remanufacturing business is as follows:

where is the net profit of manufacturer in Case 2.

Constraint (6) indicates that the total number of transaction products of manufacturer should not exceed the total number of his new products and his remanufactured products outsourced to all the remanufacturers. Constraint (7) indicates that the used product has a minimum recovery quantity. (Since only a fraction of the used products can be recovered from the demand market for remanufacturing and is the total number of remanufactured products of manufacturer obtained from all remanufacturers, is the total number of used products of manufacturer received from all the demand markets).

For each let be a new decision variable that determines whether the original manufacturer chooses the self-remanufacturing policy or outsourcing remanufacturing policy. More precisely, means that original manufacturer chooses to remanufacture the used products himself and means that original manufacturer chooses to outsource the used products to remanufacturers. When the original manufacturer chooses to remanufacture the used products himself, he needs to pay the recycling costs (such as the costs related to the cleaning of the used products, and the disposal of waste products) together with the remanufacturing costs. On the other hand, when original manufacturer chooses to outsource the used products to remanufacturers for remanufacturing, he does not bear the costs of recycling and remanufacturing, but only pays the outsourcing costs and the transaction costs. Thus, the optimization problem of manufacturer who considers both the self-remanufacturing policy and the outsourcing remanufacturing policy is as follows:

where is the net profit of manufacturer

Proposition 1.

The profit function of the original manufacturer given by the optimization problem (9)–(12), i.e., the optimization problem when manufacturer considers both the self-remanufacturing policy and the outsourcing remanufacturing policy, is convex.

Proof.

See Appendix A.1. □

Theorem 1.

Suppose that all the original manufacturers are competing non-cooperatively for their profits. Suppose that the conditions imposed by Assumption 3 hold. Then the equilibrium decisions of all the original manufacturing are obtained by solving the following VI: Findwhich satisfies

In VI (13),andare the Lagrange multiplier of (10) and (11), respectively.

Proof.

See Appendix A.2. □

3.3. The Equilibrium Decisions of the Retailers

In the CLSC network, retailers compete non-cooperatively with each other for products manufactured by original manufacturers to satisfy the demands at demand markets. Thus, each retailer needs to decide on the number of his transaction products with the original manufacturer and the number of products sold to demand markets to maximize his profit. Since the only cost paid by retailer is his handling cost , the optimization problem of the retailer can be stated as follows [39]:

where is the net profit of retailer .

In Equation (14), is the endogenous price. Constraint (15) indicates that the total number of products sold by retailer to all the demand markets should not exceed the total number of products purchased from all the original manufacturers.

Theorem 2.

Suppose all the retailers are competing non-cooperatively for their profits. Suppose that the conditions imposed by Assumption 3 hold. Then the equilibrium decisions of all the retailers are obtained by solving the following VI [39]: Find which satisfies

In VI (17),is the Lagrange multiplier of (15).

Proof.

The proof of this theorem is similar to that of Theorem 1. □

3.4. The Equilibrium Decisions of the Demand Markets

At demand market , the number of products received from retailer and the price satisfy, respectively, the complementary conditions (18) and (19) given below:

(See [23] for details.)

Condition (18) provides a necessary condition for the required price at the demand market to attract customers to buy its commodities, whereas condition (19) provides a necessary condition for the total required number of products to be stored at the demand market to satisfy the demand of the customers.

The used products at demand market can either be returned to the original remanufacturers or returned to the remanufacturers for remanufacturing. Let (respectively, ) be the number of used products returned from demand market to manufacturer (respectively, returned to remanufacturer ) for remanufacturing.

Suppose that the used products at demand market are returned to the original manufacturer , the number of returned products needs to satisfy the complementary condition (20) together with the constraint condition (21) given below:

(See [23] for details.)

Suppose that the used products at demand market are returned to the remanufacturer , the number of the returned products needs to satisfy the complementary condition (22) together with the constraint condition (23) given below:

Complementary conditions (20) and (22) provide a necessary condition for the price of the returned products offered by the original manufacturer or remanufacturer to obtain the used products from the demand markets, whereas constraints (21) and (23) state that the total number of used products returned to all the manufacturers or remanufacturers should not exceed the total number of new products obtained from all the retailers.

For each , let be a new decision variable that determines whether the used products from demand market are returned to original manufacturer or not. More precisely, means that the used products from demand market are returned to the original manufacturer and means that the used products from the demand market are not returned to the original manufacturer . Similarly, for each , let be a new decision variable that determines whether the used products from demand market are returned to the remanufacturer or not. More precisely, means that the used products from demand market are returned to remanufacturer and means that the used products from demand market are not returned to remanufacturer

Theorem 3.

Then the equilibrium decisions of all the demand markets are obtained by solving the following VI: Find which satisfies

In VI (24),is the Lagrange multiplier of (21) and (23).

Proof.

The conditions (18)–(23) are complementary conditions for the decision variables of the demand markets at equilibrium. Thus, VI (24) can be obtained from the equivalence of complementary condition and VI. (See [40] for details.) □

3.5. The Equilibrium Decisions of the Remanufacturers

In the CLSC network, remanufacturers compete non-cooperatively with each other for contracts from the original manufacturers for remanufacturing. After the original manufacturer has chosen to outsource his remanufacturing business to remanufacturers, remanufacturer receives the used products from demand markets for remanufacturing. After the used products have been thoroughly cleaned and inspected, of these used products will be used for remanufacturing and the remaining used products, i.e., the waste products, will be sent to the landfill for disposal. Thus, remanufacturer needs to decide on his remanufacturing quantity with the original manufacturer and the quantity of used products received from the demand market (the total quantity of used products received from all the demand markets is ) to maximize his profit. Since the costs paid by remanufacturer are his transaction costs with the original manufacturer and with the demand market , his remanufacturing costs , the external cost , together with the cost involved in the disposal of waste products. The optimization problem of remanufacturer can be stated as follows:

where is the net profit of remanufacturer .

In Equation (25), is the endogenous price for the remanufactured product transaction with the original manufacturer and is the endogenous price for the used product transaction with demand market . Constraint (26) indicates that for remanufacturer , the total number of remanufactured products for all the original manufacturers should not exceed (the total number of his used products received from all the demand markets).

For each , let be a new decision variable which determines whether the original manufacturer chooses to purchase the remanufactured products from remanufacturer or not. More precisely, means that the original manufacturer chooses to purchase the remanufactured products from remanufacturer and means that the original manufacturer chooses not to purchase the remanufactured products from remanufacturer .

Theorem 4.

Suppose that all the remanufacturers are competing non-cooperatively for their profits. Suppose that the conditions imposed by Assumption 3 hold. Then the equilibrium decisions of all the remanufacturers are obtained by solving the following VI: Find which satisfies

whereare the decision variables of the demand marketwhich assume the integer values 0 or 1 as described in Section 3.4. In VI (28),is the Lagrange multiplier of (26).

Proof.

The proof is similar to that of Theorem 1. □

3.6. The Equilibrium Decisions of the CLSC Network

Suppose the decisions of all the decision-makers of the CLSC network (i.e., the original manufacturers, together with all the retailers, together with all the demand markets, together with the remanufacturers) are at equilibrium simultaneously, then VI (13), VI (17), VI (24), and VI (28) hold simultaneously. Thus, by adding VI (13), VI (17), VI (24), and VI (28) together and subtracting all the endogenous prices from the above sum, we obtain the equilibrium decisions of the CLSC network as follows:

Find which satisfies

where , and are, respectively, the decision variables of original manufacturer , demand market associated original manufacturer , demand market associated with remanufacturer , and remanufacturer associated with original manufacturer , which assume the integer values 0 or 1 as described in Section 3.2, Section 3.3, Section 3.4, and Section 3.5, respectively.

Case 1. Self-remanufacturing policy.

In Case 1, the original manufacturer chooses to remanufacturer himself, that is .

When the equilibrium decisions , , are positive, we have the following: From the equivalence of VI (13) and its complementary condition [40], the endogenous wholesale price is . From the equivalence of VI (17) and its complementary condition, the endogenous retail price is . From the equivalence of VI (24) and its complementary condition, the endogenous recovery price is .

Case 2. Outsourcing remanufacturing policy.

In Case 2, the original manufacturer chooses to outsource his remanufacturing business to remanufacturers, that is .

When the equilibrium decisions , , and are positive, we have the following: From the equivalence of VI (13) and its complementary condition [40], the endogenous wholesale price is , . From the equivalence of VI (17) and its complementary condition, the endogenous retail price is . From the equivalence of VI (24) and its complementary condition, the endogenous recovery price is .

Theorem 5.

Suppose that the conditions imposed by Assumption 3 hold. Suppose that the costs are strictly convex and have bounded second-order derivatives and the demand function is strictly monotone decreasing and has bounded first-order derivatives. Then, the monotone and Lipschitz continuity of VI (29) hold, which ensures that the equilibrium decisions of the CLSC exist and are unique.

Proof.

The proof is similar to those given in Theorem 3.4 of [41]. □

To analyze the environmental impact generated by the decisions of original manufacturers and the remanufacturers, we define the environmental impact generated by the original manufacturer ’s new products as , the original manufacturer ’s remanufactured products as , and the products outsourced by the original manufacturer to the remanufacturer for remanufacturing as , which are consistent with life cycle assessment (LCA) [42,43]. Thus, when the original manufacturer chooses to remanufacture himself, the total environmental impact generated is When the original manufacturer chooses to outsource the remanufacturing business to remanufacturers, the total environmental impact generated is .

4. Numerical Examples

In Section 3, the CLSC network equilibrium decisions and the optimal profits of all the decision-makers considering remanufacturing options are obtained. In this section, numerical examples are solved to test the performance of our models. The importance of the outsourcing remanufacturing business is analyzed, and the impacts of the various factors, such as waste product recovery rate, remanufacturing cost, and environmental impact on the original manufacturers’ remanufacturing policies are also studied. The following example is taken from [24]. In this example, there are two original manufacturers , two retailers , two demand markets , and two remanufacturers in the CLSC network. In this example, the original manufacturers produce electronic products, such as computers. The cost functions and the demand functions of all the decision-makers are as follows:

Cost functions of the original manufacturers:

Cost function of the retailers:

Cost functions of the demand markets:

Cost function of the remanufacturers:

The remanufacturers do not need to pay the transaction cost to the original manufacturers when they receive the used products from the demand markets.

The above cost functions and demand functions satisfy the conditions imposed by Theorem 5. Similar to References [23,24,25], we use the modified projection algorithm [44] (see [44] for details) implemented by MATLAB to solve VI (29) to obtain the optimal decisions of all the decision-makers, their respective profits, and their respective environmental impact at equilibrium.

4.1. The Importance of the Outsourcing Remanufacturing Policy

This section focuses on analyzing the importance of the outsourcing remanufacturing policy of the original remanufacturers. By comparing the equilibrium results obtained when the original manufacturers choose to remanufacture the used products on their own and when they choose to outsource their remanufacturing businesses to remanufacturers, we can easily understand the importance of the outsourcing remanufacturing policy.

The parameters are defined as follows: (these parameters are taken from one example from [24]) and (these parameters are taken from one example from [43]). We first solve VI (29) by using (i.e., both remanufacturers choose to remanufacture on their own). We next solve VI (29) by using (i.e., both remanufacturers choose to outsource their remanufacturing businesses to remanufacturers) Comparison of the results at equilibrium obtained when the original remanufacturers choose the self-remanufacturing policy and when they choose the outsourcing remanufacturing policy is given in Table 2. In Table 2, is the number of new products produced by original manufacturer from raw materials, is the number of transaction products between original manufacturer and retailer , is the number of products sold by retailer to demand market , (respectively, ) is the number of used products returned from demand market to original manufacturer (respectively, remanufacturer ) for recycling, is the number of remanufactured products sold by remanufacturer to original manufacturer , is the price per item of the new products in demand market , the quantity of the environmental impact is described in the last paragraph of Section 3, is the net profit of manufacturer as defined in (9), and the total profit is the sum of the profits of all the manufacturers and all retailers when the original manufacturers choose the self-remanufacturing policy, and it is the sum of the profits of all the manufacturers, all the retailers, and all the remanufacturers when the original manufacturers choose the outsourcing remanufacturing policy.

Table 2.

Comparison of the results at equilibrium between the self-remanufacturing policy and the outsourcing remanufacturing policy.

From Table 2, it can be seen that if the original remanufacturers choose the outsourcing remanufacturing policy, we have the following results:

- (1)

- The numbers of new products produced from raw materials are reduced, thus natural resources from raw materials are saved.

- (2)

- The sales quantities of the original manufacturers and the retailers are increased.

- (3)

- The number of recycled products is increased, and the recycling rates of the used products are also increased.

- (4)

- Due to the increase in trade quantities of the new products, the prices of the new products in the demand markets are decreased.

- (5)

- The profits of the original manufacturers are decreased, but the profit of the entire supply chain is significantly increased.

- (6)

- The environmental impacts of both the new products and the remanufactured products are reduced, hence the problem of air pollution in the environment created by the CLSC network becomes less severe.

From the analysis of this section, it can be seen that the choice of the outsourcing remanufacturing policy of the original manufacturers will reduce the use of raw materials, increase the utilization rate of used products, and reduce the environmental impact. Although the original manufacturers sacrifice part of their profits, it achieves the purpose of saving resources and protecting the environment, and further promotes the recycling of resources for reuse.

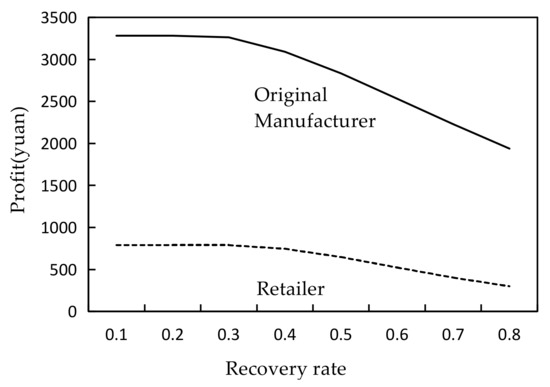

4.2. The Impact of the Recovery Rates

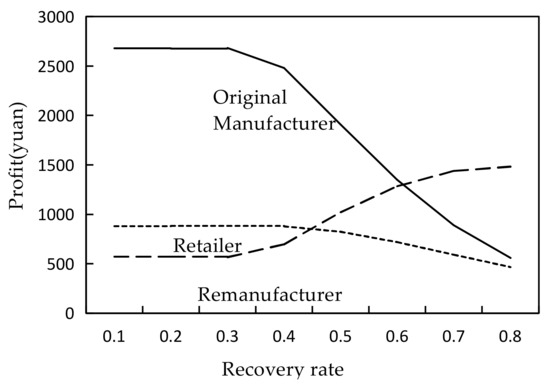

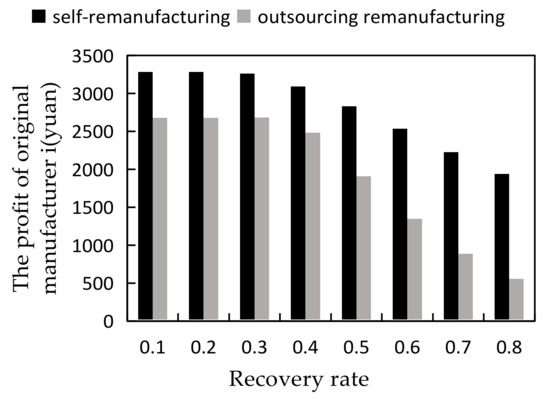

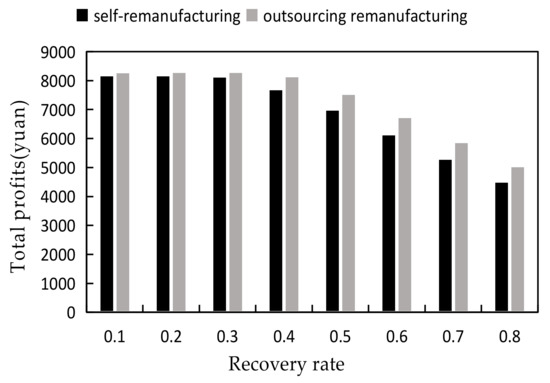

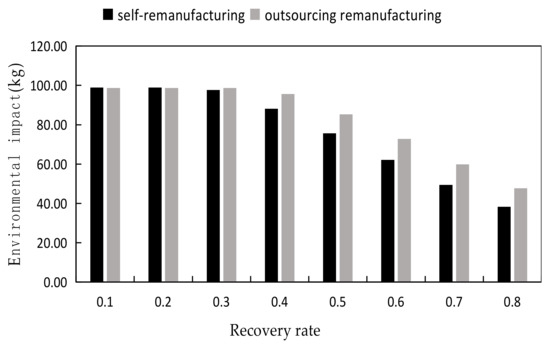

This section focuses on analyzing how the original manufacturers’ remanufacturing policy options depend on different recovery rates of the used products. In this example, we use the same parameters as those used in Section 4.1 and we use the recovery rate = 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, and 0.8, respectively. The equilibrium decisions of self-remanufacturing and outsourcing remanufacturing policies corresponding to different recovery rates are obtained, which are given in Table 3 and Table 4, respectively. The criteria for the original manufacturer to choose between different remanufacturing policies are obtained by calculating their profits and those of the entire supply chain corresponding to each of the available recovery rates, which are shown in Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8.

Table 3.

The equilibrium decisions of self-remanufacturing policy under different recovery rates (β), given α = 0.8.

Table 4.

The equilibrium decisions of outsourcing remanufacturing policy under different recovery rates (β), given α = 0.8.

Figure 4.

Profit of each decision maker when the self-remanufacturing policy is used.

Figure 5.

Profit of each decision maker when the outsourcing remanufacturing policy is used.

Figure 6.

Comparison of the profits of the original manufacturer.

Figure 7.

Comparison of the total profits of the CLSC network.

Figure 8.

Comparison of the environmental impact.

From the above results, we observe that:

- (1)

- When the recovery rate is low, the original manufacturers’ decision to outsource their remanufacturing businesses can save raw materials to meet the production demand, but when the recovery rate is high, the above result is reversed.

- (2)

- The original manufacturers’ decision to outsource their remanufacturing businesses can increase sales of new products and recycling of used products and reduce product prices in the demand markets.

- (3)

- When the recovery rate is low, the original manufacturers’ decision to outsource their remanufacturing businesses can reduce the environmental impact, but when the recovery rate is high, the above result is reversed.

- (4)

- When the recovery rate is high, the original manufacturers’ decision to outsource their remanufacturing businesses can increase the profits of the remanufacturers but will decrease the profits of the original manufacturers; thus, the profits of the original manufacturers will be lower than those of the remanufacturers. Thus, when the recovery rate is high, the original manufacturers should abandon the outsourcing remanufacturing policy and choose to remanufacture on their own.

Thus, from the point of view of obtaining more profits, saving natural resources, and reducing environmental impact, the original manufacturers should choose the outsourcing remanufacturing policy only when the recovery rate is low. When the recovery rate is high, the original manufacturers should remanufacture on their own to obtain better results.

4.3. The Impact of the Remanufacturing Cost

This section focuses on analyzing how the original manufacturers’ remanufacturing policy options depend on different remanufacturing costs. The equilibrium decisions of self-remanufacturing corresponding to different remanufacturing costs are obtained. The criteria for the original manufacturer to choose between a self-remanufacturing policy and an outsourcing remanufacturing policy are obtained by calculating their profits and those of the entire CLSC corresponding to each of the available remanufacturing costs.

In this example, we use the same parameters as those used in Section 4.1. The cost of resourcing remanufacturing is fixed as where is the cost coefficient, which assumes the values 2, 1.5, 1, 0.5, and 0.1, respectively. The equilibrium results corresponding to each of the remanufacturing costs are given in Table 5. In Table 5, is the profit of retailer as defined in (14), and is the profit of remanufacturer as defined in (25).

Table 5.

The equilibrium results under different costs.

From Table 5, it can be seen that when the cost of outsourcing remanufacturing decreases, the difference in costs between self-remanufacturing and outsourcing remanufacturing increases. Thus, when the original remanufacturers choose the outsourcing remanufacturing policy, we have the following results:

- (1)

- The numbers of the new products are decreased, the recovery rates of the sale products and used products are increased. Thus, the prices of the commodities are decreased.

- (2)

- The profits of the original manufacturers are decreased, but the profits of the other decision-makers in the CLSC network are increased; hence the total profit of the entire CLSC is increased.

- (3)

- The numbers of the new products are decreased, but the numbers of the remanufactured products are increased. Due to the increase in numbers between the remanufactured products and manufactured products, the environmental impact of the CLSC network is also decreased.

Thus, from the discussion of this section, when the outsourcing remanufacturing cost decreases, natural resources can be saved, and the problem of environmental pollution can be improved. Thus, the remanufacturers should develop new techniques to decrease the remanufacturing costs. On the other hand, when the outsourcing remanufacturer cost is low, the original manufacturers should outsource their remanufacturing businesses to remanufacturers so that more resources can be saved, and the problem of environmental pollution can be improved further.

4.4. The Impact of the Environmental Impact Parameters

This section focuses on analyzing the environmental impact parameters of the new and the remanufactured products on the remanufacturing policy of the original manufacturers. The environmental impacts of the new products, the self-remanufactured and the outsourcing remanufactured products corresponding to each available environmental impact parameter are obtained. Hence the impacts of the environmental impact parameters on the remanufacturing policy of the original manufacturers are obtained.

In this example, we use the same parameters as those used in Section 4.1. We first fix the environmental impact parameter of the new products and increase the environmental impact parameter of the remanufactured product gradually from 0.3 to 2.1 (see [43] for details). The results concerning the total environmental impacts of the self-remanufacturing policy and the outsourcing remanufacturing policy corresponding to different environmental impact parameters are given in Table 6. We next fix the environmental impact parameter of the remanufactured products and increase the environmental impact parameter of the new products gradually from 3 to 5 (see [43] for details). The results of the total environmental impact concerning the self-remanufacturing policy or outsourcing remanufacturing policy corresponding to different environmental impact parameters are given in Table 7.

Table 6.

The total environmental impact due to the environmental impact parameter of the remanufactured product.

Table 7.

The total environmental impact due to the environmental impact parameter of the new product.

From Table 6, it can be seen that when the environmental impact parameter of the remanufactured products increases, the environmental impacts of both the self-manufactured policy and the outsourcing remanufactured policy increase. On the other hand, when the environmental impact parameter of the remanufactured products decreases, the environmental impacts of the above two remanufactured policies also decrease; however, the environmental impact of the outsourcing remanufactured policy is smaller than that of the self-remanufactured policy.

From Table 7, it can be seen that when the environmental impact parameter of the new products increases, the environmental impacts of both the self-manufactured policy and the outsourcing remanufactured policy also increase; however, the environmental impact of the outsourcing remanufactured policy is smaller than that of the self-remanufactured policy.

From the discussions of this section, we have the following results: From the perspective of environmental protection, when the remanufactured products have a small impact on the environment, the original manufacturers should outsource their remanufacturing businesses to remanufacturers, and when the remanufactured products have a large impact on the environment, the original manufacturers should choose to remanufacture on their own. As far as the impact of the new products on environmental protection is concerned, the original manufacturers should always choose to outsource their remanufacturing businesses to remanufacturers.

4.5. Comparison of the Equilibrium Decisions of the Supply Chain Obtained When the Original Manufacturers Choose Different Remanufacturing Policies

In Section 4.1, Section 4.2, Section 4.3 and Section 4.4, we mainly analyzed the equilibrium decisions of the CLSC network when two competing original manufacturers both choose to remanufacture on their own or both choose to outsource their remanufacturing businesses to remanufacturers. This section focuses on the analysis of the comparison results when two competing original manufacturers choose different remanufacturing policies.

Without loss of generality, we assume that original manufacturer 1 chooses the self-remanufacturing policy, and original manufacturer 2 chooses the outsourcing remanufacturing policy. Then we have . Moreover, since the used products must be remanufactured by remanufacturers, we have

In this example, we use the same parameters as those used in Section 4.1. We solve VI (29) to obtain the equilibrium results, which are given in Table 8.

Table 8.

Equilibrium results under different remanufacturing options.

From Table 8, it can be seen that when manufacturer 1 chooses the self-remanufacturing policy and manufacturer 2 chooses the outsourcing remanufacturing policy, then:

- (1)

- The sale of new products of manufacturer 2 increases, which leads to the improvement of their competitiveness in the demand markets;

- (2)

- The return rate of the used products of manufacturer 2 increases, which leads to the increase in the recycling of raw material in the CLSC network;

- (3)

- The demand for the new product of manufacturer 2 decreases, which leads to the reduction in the consumption of raw materials;

- (4)

- The profit of manufacturer 2 who chooses the outsourcing remanufacturing policy decreases when compared with the profit of manufacturer 1 who chooses the self-remanufacturing policy.

From the above analysis, it is found that the original manufacturers’ choice of using different remanufacturing policies will affect their equilibrium decisions and their competitive relations in the CLSC network; the original manufacturer who chooses to outsource his remanufacturing business will increase the sales of his new products, and increase his utilization of used products, which leads to the reduction in the consumption of raw material in the CLSC network; however, his profit will be decreased due to the outsourcing cost.

5. Conclusions

This paper analyzes how the original manufacturers should choose their remanufacturing options between self-remanufacturing policy and outsourcing remanufacturing policy based on factors such as recovery rate of used products, remanufacturing costs, and environmental impact parameters. The main results are as follows:

- (1)

- When compared with the self-remanufacturing policy, the outsourcing remanufacturing policy can save resources, increase sales volume, lower the prices at the demand markets and have a smaller environmental impact.

- (2)

- When the recovery rate of used products is low, the original manufacturers who choose the outsourcing remanufacturing policy can increase sales of new products and recycling of used products. When the recovery rate is high, the original manufacturers who choose the self-remanufacturing policy can gain more profits.

- (3)

- When the costs of self-remanufacturing and outsourcing remanufacturing are quite different, choosing the outsourcing remanufacturing policy can save resources and protect the environment. Thus, by promoting the recycling of resources, the network as a whole will also obtain more profits.

- (4)

- When the environmental impact parameter of remanufactured products is small, choosing the outsourcing remanufacturing policy can reduce the environmental impact.

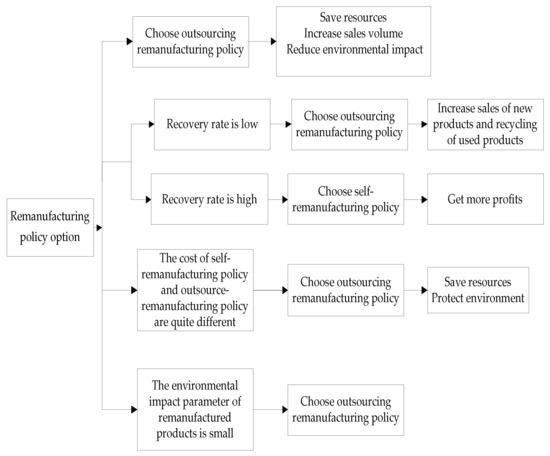

A decision-making flow chart for choosing the remanufacturing policies is shown in Figure 9.

Figure 9.

The decision-making for choosing the remanufacturing policy.

The following managerial insights can be gained from the research of this paper:

- (1)

- From the perspective of saving resources, reducing environmental impact, and generating more profits, the original manufacturers should choose the outsourcing remanufacturing policy when the recovery rates of used products are low; when the recovery rates of used products are high, they should choose the self-remanufacturing policy to gain more profits.

- (2)

- When the outsourcing remanufacturing cost decreases further, its effect on saving natural resources and reducing environmental impact becomes more acute. Thus, the remanufacturers should develop new techniques to decrease the remanufacturing costs. On the other hand, when the remanufacturers’ costs are low, the original manufacturers should choose to outsource their remanufacturing businesses to remanufacturers to achieve the purpose of saving resources, and protecting the environment, which further promotes the recycling of used products.

- (3)

- When the environmental impact parameters of remanufactured products are small, the original manufacturers should choose to outsource their remanufacturing businesses to remanufacturers.

The research in this paper not only helps the original manufacturers to choose their remanufacturing policies between self-remanufacturing and outsourcing remanufacturing according to scientific methods but also helps to achieve the purpose of saving resources, recycling used products, and reducing the air pollution in the environment for the CLSC network by using the outsourcing remanufacturing policy, i.e., third-party remanufacturing, which is also supported by [45].

There are still some limitations in this paper, which can be overcome in our future research as follows:

- (1)

- In this paper, we only consider the static price and the static demand in the demand markets. In other words, we do not consider how inflation can influence the demands and the prices at the demand markets. In the future, we can modify our paper by considering the equilibrium decision-making of the network in a dynamic environment (see [27] for details), which involves time-dependent demands.

- (2)

- In this paper, we consider that each manufacturer and remanufacturer is operating independently in his manufacturing and remanufacturing business. In the future, we can improve the management of the supply chain by considering the cooperation between original manufacturers and remanufacturers to achieve a win-win situation for both the original manufacturers and the remanufacturers (see [46] for details).

Author Contributions

These authors contributed equally to this work. Y.Z. and X.-Q.L. contributed to model development and writing; K.-H.W. contributed to writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 71901129.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the editors and reviewers for their valuable comments and suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Proofs

Appendix A.1. Proof of Proposition 1

- (1)

- When manufacturer chooses self-remanufacturing policy, we have Hence, by differentiating the profit function with respect to , we obtain from (1) thatLet the Hessian matrix represent the second partial derivative of with respect to . Then we haveDue to Assumption 3 that all the cost functions are convex, it is clear that is negative definite. Thus, when the original manufacturer chooses the self-remanufacturing policy, the profit function of is a concave function of the decision variables

- (2)

- When manufacturer chooses the outsourcing remanufacturing policy, we have . Hence, by differentiating the profit function with respect to , we obtain from (5) thatLet the Hessian matrix represent the second partial derivative of with respect to . Then we haveDue to Assumption 3 that all the cost functions are convex, it is clear that is negative definite. Thus, when the original manufacturer chooses the outsourcing remanufacturing policy, the profit function is a concave function of . Hence, the proof of this proposition is complete. □

Appendix A.2. Proof of Theorem 1

Let and be the Lagrange multipliers of (10) and (11), respectively. Then the Lagrange function of the optimization problem defined by (9)–(11) is

By differentiating the function with respect to we get

Thus, we obtain (13) from the above formulas. Hence, the proof of this theorem is complete. □

References

- Mitra, S. Models to explore remanufacturing as a competitive strategy under duopoly. Omega 2016, 59, 215–277. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Li, H.L.; Zhou, S.L.; Lun, V. Redesign of service modes for remanufactured products and its financial benefits. Int. J. Prod. Econ. 2016, 171, 231–240. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, Y. Does the entry of third-party remanufacturers always hurt original equipment manufacturers? Decis. Sci. 2016, 47, 762–780. [Google Scholar] [CrossRef]

- Atasu, A.; Guide, V.D.R.; Van Wassenhove, L.N. So, what if remanufacturing cannibalizes my new product sales? Calif. Manag. Rev. 2010, 52, 56–76. [Google Scholar] [CrossRef]

- Ferrer, G.; Whybark, D.C. Material planning for a remanufacturing facility. Prod. Oper. Manag. 2001, 10, 112–124. [Google Scholar] [CrossRef]

- WMXA.cn. Price of Official Refurbished IPHONE and Purchasing Way. 2018. Available online: http://www.wmxa.cn/a/201504/228289.html (accessed on 23 April 2015). (In Chinese).

- Alumur, S.A.; Nickel, S.; Saldanha-Da-Gama, F.; Verter, V. Multi-period reverse logistics network design. Eur. J. Oper. Res. 2012, 220, 67–78. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.; Subramanian, N.; Liu, C.; Shu, C.Q. Viability of remanufacturing practice: A strategic decision makingframework for Chinese auto-parts companies. J. Clean. Prod. 2015, 105, 311–323. [Google Scholar] [CrossRef]

- Zou, Z.B.; Wang, J.J.; Deng, G.S.; Chen, H.Z. Third-party remanufacturing mode selection: Outsourcing or authorization? Transp. Res. Logist. Trans. Rev. 2016, 87, 1–19. [Google Scholar] [CrossRef]

- Ameknassi, L.; Ait-Kadi, D.; Rezg, N. Integration of logistics outsourcing decisions in a green supply chain design: A stochastic multi-objective multi-period multi-product programming model. Int. J. Prod. Econ. 2016, 182, 165–184. [Google Scholar] [CrossRef]

- Wang, L.; Cai, G.S.; Tsay, A.A.; Vakharia, A.J. Design of the reverse channel for remanufacturing: Must profit-maximization harm the environment? Prod. Oper. Manag. 2017, 26, 1585–1603. [Google Scholar] [CrossRef]

- Esenduran, G.; Kemahlloglu-Ziya, E.; Swaminathan, J.M. Impact of take-back regulation on the remanufacturing industry. Prod. Oper. Manag. 2017, 26, 924–944. [Google Scholar] [CrossRef]

- Yan, W.; Chai, J.W.; Qian, Z.F.; Tsai, S.B.; Chen, H.; Xiong, Y. Operational decisions on remanufacturing outsourcing involved with corporate environmental and social responsibility a sustainable perspective. Sustainability 2018, 10, 1132. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, L.J.; Li, Y.W. Sustainable decisions on product upgrade confrontations with remanufacturing operations. Sustainability 2018, 10, 4090. [Google Scholar] [CrossRef]

- Zou, Z.B.; Wang, F.; Lai, X.F.; Hong, J.X. How does licensing remanufacturing affect the supply chain considering customer environmental awareness? Sustainability 2019, 11, 1898. [Google Scholar] [CrossRef]

- Zheng, X.X.; Li, D.F.; Liu, Z.; Jia, F.; Sheu, J.B. Coordinating a closed-loop supply chain with fairness concerns through variable-weighted Shapley values. Transp. Res. Logist. Trans. Rev. 2019, 126, 227–253. [Google Scholar] [CrossRef]

- Wang, N.M.; He, Q.D.; Jiang, B. Hybrid closed-loop supply chains with competition in recycling and product markets. Int. J. Prod. Econ. 2019, 217, 246–258. [Google Scholar] [CrossRef]

- He, W.; Liang, L.; Wang, K. Economic and environmental implications of quality choice under remanufacturing outsourcing. Sustainability 2020, 12, 874. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, H.; Xiong, Y.; Yan, W.; Liu, M.L. Managing collecting or remarketing channels: Different choice for cannibalisation in remanufacturing outsourcing. Int. J. Prod. Res. 2020, 1–16. [Google Scholar] [CrossRef]

- Feng, Z.W.; Xiao, T.J.; Robb, D.J. Environmentally responsible closed-loop supply chain models with outsourcing and authorization options. J. Clean. Prod. 2021, 278, 123791. [Google Scholar] [CrossRef]

- Alegoz, M.; Kaya, O.; Bayindir, Z.P. A comparison of pure manufacturing and hybrid manufacturing-remanufacturing systems under carbon tax policy. Eur. J. Oper. Res. 2021, 294, 161–173. [Google Scholar] [CrossRef]

- Nagurney, A.; Toyasaki, F. Reverse supply chain management and electronic waste recycling: A multitiered network equilibrium framework for e-cycling. Transp. Res. Logist. Trans. Rev. 2005, 41, 1–28. [Google Scholar] [CrossRef]

- Hammond, D.; Beullens, P. Closed-loop supply chain network equilibrium under legislation. Eur. J. Oper. Res. 2007, 183, 895–908. [Google Scholar] [CrossRef]

- Yang, G.F.; Wang, Z.P.; Li, X.Q. The optimization of the closed-loop supply chain network. Transp. Res. Logist. Trans. Rev. 2009, 45, 16–28. [Google Scholar] [CrossRef]

- Qiang, Q.; Ke, K.; Anderson, T.; Dong, J. The closed-loop supply chain with competition distribution channel investment and uncertainties. Omega 2013, 41, 186–194. [Google Scholar] [CrossRef]

- Qiang, Q. The closed-loop supply chain network with competition and design for remanufactureability. J. Clean. Prod. 2015, 105, 348–356. [Google Scholar] [CrossRef]

- Chan, C.K.; Zhou, Y.; Wong, K.H. A dynamic equilibrium model of the oligopolistic closed-loop supply chain network under uncertain and time-dependent demands. Transp. Res. Logist. Trans. Rev. 2018, 118, 325–354. [Google Scholar] [CrossRef]

- Zhen, L.; Huang, L.F.; Wang, W.C. Green and sustainable closed-loop supply chain network design under uncertainty. J. Clean. Prod. 2019, 227, 1195–1209. [Google Scholar] [CrossRef]

- Nayeri, S.; Paydar, M.M.; Asadi-Gangraj, E.; Emami, S. Multi-objective fuzzy robust optimization approach to sustainable closed-loop supply chain network design. Comput. Ind. Eng. 2020, 148, 106716. [Google Scholar] [CrossRef]

- Wang, W.B.; Zhang, P.; Ding, J.F.; Li, J.; Sun, H.; He, L.Y. Closed-loop supply chain network equilibrium model with retailer-collection under legislation. J. Ind. Manag. Optim. 2019, 15, 199–219. [Google Scholar] [CrossRef]

- Yang, Y.X.; Huang, Z.Q.; Zhang, B.Y.; Meng, L.J. Closed-loop supply chain network static equilibrium and dynamics under pollution permits system. Environ. Prog. Sustain. 2019, 38, e13021. [Google Scholar] [CrossRef]

- Wu, H.X.; Xu, B.; Zhang, D. Closed-loop supply chain network equilibrium model with subsidy on green supply chain technology investment. Sustainability 2019, 11, 4403. [Google Scholar] [CrossRef]

- Duan, C.Q.; Xiu, G.Y.; Yao, F.M. Multi-period e-closed-loop supply chain network considering consumers’ preference for products and ai-push. Sustainability 2019, 11, 4571. [Google Scholar] [CrossRef]

- Biçe, K.; Batun, S. Closed-loop supply chain network design under demand, return and quality uncertainty. Comput. Ind. Eng. 2021, 155, 107081. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Asadi-Gangraj, E. Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J. Clean. Prod. 2020, 277, 123298. [Google Scholar] [CrossRef]

- Diabat, A.; Jebali, A. Multi-product and multi-period closed loop supply chain network design under take-back legislation. Int. J. Prod. Econ. 2021, 231, 107879. [Google Scholar] [CrossRef]

- Fu, R.; Qiang, Q.; Ke, K.; Huang, Z. Closed-loop supply chain network with interaction of forward and reverse logistics. Sustain. Prod. Consump. 2021, 27, 737–752. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, W.; Mi, Y. Third-party remanufacturing mode selection for competitive closed-loop supply chain based on evolutionary game theory. J. Clean. Prod. 2020, 263, 1–12. [Google Scholar] [CrossRef]

- Nagurney, A.; Dong, J.; Zhang, D. A supply chain network equilibrium model. Transp. Res. Logist. Trans. Rev. 2002, 38, 281–303. [Google Scholar] [CrossRef]

- Kinderlehrer, D.; Stampacchia, G. An Introduction to Variational Inequalities and Their Applications; Academic Press: Cambridge, MA, USA, 1980. [Google Scholar]

- Zhou, Y.; Chan, C.; Wong, K. A multi-period supply chain network equilibrium model considering retailers’ uncertain demands and dynamic loss-averse behaviors. Transp. Res. Logist. Trans. Rev. 2018, 118, 51–76. [Google Scholar] [CrossRef]

- Atasu, A.; Souza, G.C. How does product recovery affect quality choice? Prod. Oper. Manag. 2013, 22, 991–1010. [Google Scholar] [CrossRef]

- Orsdemir, A.; Ziya, E.K.; Parlakturk, A.K. Competitive quality choice and remanufacturing. Prod. Oper. Manag. 2014, 23, 48–64. [Google Scholar] [CrossRef]

- Korpelevich, G.M. The extra gradient method for finding saddle points and other problems. Matekon 1976, 12, 747–756. [Google Scholar]

- Zhou, Y.; Xiong, Y.; Jin, M. The entry of third-party remanufacturers and its impact on original equipment manufacturers in a two-period game-theoretic model. J. Clean. Prod. 2021, 279, 123656. [Google Scholar] [CrossRef]

- Jin, M.; Li, G.; Reimann, M. Team of rivals: How should original equipment manufacturers cooperate with independent remanufacturers via authorisation? Eur. J. Oper. Res 2021. In press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).