Abstract

The depletion of conventional energy resources has drawn the world’s attention towards the use of alternate energy resources, which are not only efficient but sustainable as well. For this purpose, hydrogen is considered the fuel of the future. Liquid organic hydrogen carriers (LOHCs) have proved themselves as a potential option for the release and storage of hydrogen. The present study is aimed to analyze the performance of the perhydro-dibenzyl-toluene (PDBT) dehydrogenation system, for the release of hydrogen, under various operational conditions, i.e., temperature range of 270–320 °C, pressure range of 1–3 bar, and various platinum/palladium-based catalysts. For the operational system, the optimum operating conditions selected are 320 °C and 2 bar, and 2 wt. % Pt/Al2O3 as a suitable catalyst. The configuration is analyzed based on exergy analysis i.e., % exergy efficiency, and exergy destruction rate (kW), and two optimization strategies are developed using principles of process integration. Based on exergy analysis, strategy # 2, where the product’s heat is utilized to preheat the feed, and utilities consumption is minimized, is selected as the most suitable option for the dehydrogenation system. The process is simulated and optimized using Aspen HYSYS® V10.

1. Introduction

With the increase in the world’s population with time, followed by the increased demand for better living standards, it can be forecasted that future energy demand will be increased tremendously, and meeting this extreme energy requirement is a challenging task for the world. In the existing state, most of the energy requirement of the world is linked with heating and transportation, and is met using fossil fuels, mainly natural gas, coal, and crude oil. However, these energy resources are non-sustainable and non-renewable, as their use is linked with the increased greenhouse gases emissions, and these resources are depleting rapidly with time, respectively [1,2,3]. Therefore, the world has diverted its attention towards two important aspects: (1) the investigation and use of such energy resources in the existing infrastructure, that are sustainable and renewable, (2) use of energy resources in a way that these resources are capable of meeting the energy demand and do not cause any harm to the environment [4].

For more than 120 years ago, hydrogen has been considered an ideal energy carrier. The heating value (HHV) of the fuel is linked with the hydrogen contents, i.e., the more the hydrogen contents in the fuel, the higher will be its HHV. Therefore, pure hydrogen has proved itself as an ideal energy source since it has the highest value of HHV amongst all energy fuels. Hydrogen has been termed as the “fuel of the future” because of various reasons: (1) the combustion of hydrogen is clean, as NOx, and SOx are not produced, (2) the combustion results in the generation of water with a net heat release of 242 kJ/mol, (3) in comparison to the petroleum products, the energy density of hydrogen is 3 times higher, i.e., 120 kJ/g [4,5]. Based on the energy contents (kJ/g), the comparison of hydrogen with other fuels is presented in Table 1 [6].

Table 1.

Energy contents of various fuels [6].

For hydrogen storage, various methods have been reported in the literature. A comparative analysis, based on energy demand and cost estimation, is presented in Table 2. For the cost estimation, the following important parameters are considered: (1) catalyst cost, (2) operational expenses, (3) electricity cost, (4) depreciation cost, and (5) substation of LOHC material [5,6]. The analysis shows that liquid organic hydrogen carriers (LOHC) are the most suitable option for the storage and release of hydrogen since the energy demand and cost required for the LOHC system is the lowest, followed by compressed hydrogen storage, and liquid hydrogen storage [7].

Table 2.

Comparative analysis of various hydrogen storage system [5,6].

Based on the reported literature, a good LOHC system must have the following characteristics, so these systems can be utilized for practical application (on a large scale):

- Non-toxic and safe during transportation and use, with an acceptable eco-toxicology profile.

- Low production cost and compatibility with current fuel infrastructure.

- To attain the stability of LOHC molecules, an enthalpy of 40–70 kJ/mol is required.

- Gravimetric storage capacities are greater than 6 wt. % and volumetric storage capacities greater than 56 kg/m3 are required.

- To simplify hydrogen purification and to require low dynamic viscosity for fast pumping, a high boiling point is required, i.e., greater than 300 °C.

- Lower melting point i.e., less than—30 °C is required for two reasons: (1) to eliminate the requirement for the addition of external solvents, and (2) to eliminate the requirements for solid-based fuel infrastructure [8,9,10].

The comparison between various LOHC systems, as reported in the literature, is presented in Table 3. MCH-Toluene system (MTH) remained a well-known system in the early stages of the LOHC system. However, there are certain drawbacks associated with the use of this system, i.e., (1) thermodynamically, MCH requires harsh conditions, owing to the high heat demand for the dehydrogenation process, (2) catalyst deactivation/coke-formation, and by-product formation at higher temperatures ≥350 °C, (3) lower values of flashpoints and boiling points are problematic towards selectivity, reversibility, etc. The major hurdle associated with the implementation of the benzene-toluene system is the carcinogenic property of the benzene. There are several problems associated with the naphthalene-decalin system, which makes this system unfavorable for the operation, (1) the solid nature of naphthalene which causes difficulties in transportation and storage, and (2) high energy requirement for the dehydrogenation.

Table 3.

Comparison of various LOHC system [7,10,11,12,13,14].

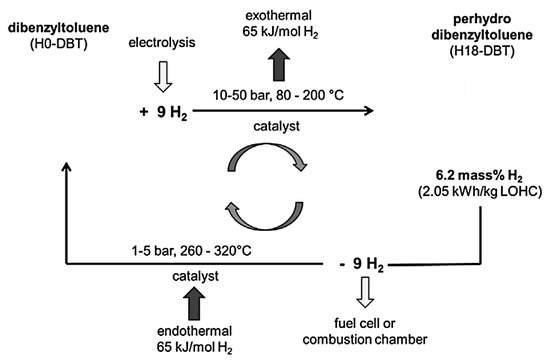

In comparison to these three systems, the perhydro-dibenzyl-toluene and dibenzyl-toluene (PDBT-DBT) system provides several advantages: (1) none of the components is carcinogenic, (2) liquid nature, therefore no handling, storage, and transportation issues, (3) lower vapor pressure of DBT allow easy release of hydrogen in the liquid phase, low vapor pressure is advantageous with respect to the safety and storage of PDBT-DBT, low vapor pressure means that these compounds can be stored at atmospheric conditions and when needed, these can be dehydrogenated via reaction, (4) lower volatility helps in obtaining comparatively higher purities of hydrogen, and (5) higher value of volumetric density [7,10,11,12,13,14]. Regarding the high energy requirements of dehydrogenation in this system, it has been reported that the process can be performed efficiently by using a micro-structured reactor [14,15]. Therefore, the PDBT-DBT system is taken as the LOHC system in this study. The overall working of the LOHC system is depicted in Figure 1 [16].

Figure 1.

LOHC system based on PDBT-DBT (Adapted from [16]).

In the overall LOHC system, there are various sub-systems. Among them, the dehydrogenation process plays a vital role towards overall system efficiency, as the % conversion is dependent on various parameters, i.e., temperature range, pressure range, a suitable catalyst, etc. Usually, the % conversion of the hydrogenation process is above 98%. Therefore, dehydrogenation of the DBT-PDBT system is considered for this study.

In recent years, research has focused on the PDBT (H18-DBT)—DBT (H0-DBT) system [17]. H0-DBT is a heat transfer oil that is widely used in industry and is available as high purity/quality oil on a large scale [18]. H0-DBT is a wide liquid range, as it exists in the liquid phase, both under process conditions and room temperature. It has low vapor pressure and high thermal stability, allowing it to be used in a reversible phase for a long time. It also meets the Department of Energy’s storage requirement, with a storage capacity of 6.2%. It also meets all the previously stated safety criteria, such as non-toxicity and low flammability [9,19,20,21].

The dehydrogenation of perhydro-dibenzyl-toluene for hydrogen production was first reported by Bruckner et al. in 2014 [22]. Since then, the DBT/PDBT pair has become the center of attention for many researchers [19,21,23,24]. Various researchers have conducted investigations for the identification of the characteristics of the dehydrogenation reaction conditions. They have reported the following operational conditions for the dehydrogenation system: (1) temperature range of 290–320 °C, (2) pressure below 5 bar [25]. For cycloaliphatic hydrogen carrier molecules, platinum (Pt) is a well-known dehydrogenation catalyst. Several authors have investigated the dehydrogenation system using Pt-based catalysts for dehydrogenation and have reported these catalysts as most suitable for the system [26,27].

Shi et al. [28] integrated both dehydrogenation and hydrogenation systems based on DBT and investigated the effect of temperature on the degree of dehydrogenation (DoD) for a time interval of 300 min using a catalyst of 5 wt. % Pt/Al2O3. With the increase in temperature from 270 to 320 °C, the value of DoD was increased from 50.8 to 81.3%. Modisha et al. [29,30] studied the impact of various parameters on hydrogen production through catalytic dehydrogenation of PDBT. When using a 1 wt. % Pt/Al2O3 catalyst, the DoD was increased from 40 to 90%, by increasing reaction temperature from 290 to 320 °C. With the increase in temperature, the rate of hydrogen production increased while the purity of hydrogen decreased due to the creation of by-products. However, when 2 wt. % Pt/Al2O3 was used at 320 °C, a DoD of 96% was obtained. Pd, Pt, and Pt-Pd catalysts had shown DoD values of 11, 82, and 6%, respectively. As a result, both in monometallic and bimetallic systems, Pd was reported to be not suitable for PDBT dehydrogenation.

For the catalytic dehydrogenation of PDBT, the kinetic model was presented by Peter et al. [16]. To determine the kinetic parameters, the catalyst selected was Pt/Al2O3, with a temperature range of 260–310 °C, for hydrogen release. To verify the complete sequence of LOHC-bound hydrogen-to-electric power conversion, the hydrogen release from PDBT was coupled with a solid oxide fuel cell device model. The maximum efficiency of LOHC-bound hydrogen-to-electricity was calculated as 45% (at full load). Fikrt et al. [26] evaluated a PDBT-based LOHC for dynamic power supply using a fixed-bed reactor loaded with 0.5 wt. % Pt/Al2O3. The dehydrogenation reaction was carried out at 1.2–1.5 bar hydrogen pressure with a temperature range of 563–593 K. As the pressure level of the release unit improved from 0.9 to 2.1 wt. % per cycle, while light byproducts remained below 0.3 wt. %, the hydrogen supply response time from a LOHC system was observed to be the highest. Thermal cracking of the molecule created heavy byproducts, which were measured and increased on a cycle-by-cycle basis. The increase in the number of heavy byproducts resulted in a decrease in catalyst activity.

Jorshick et al. [31] demonstrated the complex realization of the LOHC principle. The dehydrogenation reaction was carried out with platinum on an alumina catalyst in a tube reactor at 300 °C. In addition, the so-called one-reactor model was developed. The authors reported that hydrogenation and dehydrogenation can be done in the same pressure swing reactor with this concept. Ali et al. [32] performed dehydrogenation of PDBT (4.26 wt. % and 2 wt. %) using 1 wt. % Pt/C at 290 °C, for the analysis of the amount of evolved hydrogen. The research proved the amount of hydrogen evolved was almost twice in the case of 4.26 wt. % of PDBT as compared to 2 wt. %. In comparison to pure DBT equivalents, Jorshick et al. [33] suggested combining H12-BT (perhydro-benzyl-toluene) with H18-DBT (PDBT) to reduce viscosity and increase hydrogen release/productivity. At 10 °C, the viscosity was reduced by 79%, with the addition of 20% H12-BT to H18-DBT. The hydrogen release rate was comparatively increased by 12–16%, when dehydrogenation of H12/H18 mixture was carried out, instead of H18 dehydrogenation, using Pt/Al2O3 catalyst at 260 °C.

For the PDBT dehydrogenation, the effect of Zn and Mg dopants on the catalytic efficiency of Pt/Al2O3 was investigated by Garidzirai et al. [34]. Zn-Al2O3 and Mg-Al2O3 with a target loading of 3.8 wt. % for dopants were generated by modifying Al2O3 supports with Mg and Zn. The catalysts Pt/Al2O3, Pt/Mg-Al2O3, and Pt/Zn-Al2O3 with 0.5 wt. % Pt loading was made by impregnating the modified supports with the chloroplatinic acid solution. For Pt/Al2O3, Pt/Zn-Al2O3, and Pt/Mg-Al2O3, the conversion of H18-DBT ranges from 90–96%, 90–97%, and 92–99%, respectively, with the selectivity ranges from 57–78%, 51–75%, and 45–71%, respectively. As a result, the catalytic efficiency of Pt/Mg-Al2O3 in the dehydrogenation of H18-DBT was significantly improved.

The literature survey shows that experimental studies for dehydrogenation of PDBT are reported extensively. However, these studies are not conducted yet using any simulation approach, i.e., Aspen HYSYS, Aspen Plus, etc. Further, the temperature, and pressure ranges, and various catalysts are reported in the literature using experimental studies, however, the selection of suitable parameters and catalyst is not reported in the literature yet. This novel study aims to address this research gap by examining the dehydrogenation system (for the release of hydrogen) based on various operational parameters, i.e., temperature, pressure, use of various catalysts, and then the examination of the suitable configuration (providing the highest value of the degree of dehydrogenation, corresponding to the suitable temperature, pressure, and catalyst) based on a key performance indicator, i.e., exergy analysis, followed by the development of optimization strategies of the system based on exergy analysis and concepts of the pinch. Aspen HYSYS® V10 has been used to conduct the simulation study, exergy analysis, and optimization. The thermodynamic property package used for the system is Peng-Robinson.

2. Model Development

Following assumptions are fixed for the simulation study:

- Steady-state

- Pressure drop (ΔP) in the heat exchangers = 10 kPa or 0.1 bar

- No pressure drop in the reactor

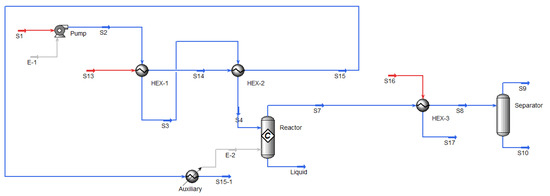

The process flowsheet of the overall dehydrogenation system is presented in Figure 2. The components (PDBT and DBT) are not present initially in the library of Aspen HYSYS. So, these are added as a hypothetical component by drawing their molecular structure, and then Peng-Robinson as thermodynamic property package is selected. The feed, perhydro-dibenzyl-toluene (PDBT), is pumped using the centrifugal pump to the dehydrogenation reactor. The feed is pre-heated using two heat exchangers (HEX-1 and HEX-2), with heating media being the saturated steam coming from the steam generation section. The feed is then introduced into the reactor, where the dehydrogenation reaction takes place. For the simulation study, the conversion reactor model is assumed, and the values provided in the literature are taken as the reference point. The products of the reactor are first cooled down in the 3rd heat exchanger (HEX-3), with cooling media as cooling water. The stream is then passed through the flash separator, with the top product obtained as hydrogen while the bottom product as dibenzyl-toluene (DBT).

Figure 2.

Process flowsheet developed and simulated in Aspen HYSYS.

Various types of catalysts for the PDBT dehydrogenation have been reported in the literature, i.e., Pd/Al2O3, Pt-Pd/Al2O3, and Pt/Al2O3. However, since palladium (Pd), and platinum-palladium (Pt-Pd) based catalyst have exhibited a maximum of 6 and 11% DoD, respectively, therefore, these catalysts were not chosen for the study. Pt/Al2O3 catalysts have shown comparatively better results, i.e., 40–96% for various weight fractions of platinum on alumina, therefore, this catalyst has been chosen for this study. Since variations in weight fractions of platinum on alumina exhibit a significant impact on the value of DoD, therefore, following weight fraction of Pt/Al2O3 catalysts were chosen for the study, and optimized based on DoD:

- 0.5 wt.% Pt/Al2O3 catalyst

- 1 wt.% Pt/Al2O3 catalyst

- 2 wt.% Pt/Al2O3 catalyst

- 5 wt.% Pt/Al2O3 catalyst [28,29,30].

Followed by the selection of catalyst and further optimization of the catalyst based on wt.% of platinum, the exergy analysis of the system was conducted. To analyze the performance of chemical processes, the exergy methods have been widely used in recent years [35]. The exergy methods help in evaluating various parameters i.e., the process irreversibility, utilization of energy resources, and optimal process design [36]. Exergy analysis is useful to determine the effects of key operational parameters on process efficiency [37,38,39]. For the exergy analysis, two key terms i.e., % exergy efficiency, and exergy destruction rate (kW) were used. % exergy efficiency is defined as the cumulative exergy value of the outlet streams divided by the cumulative exergy value of the inlet streams. The difference between the cumulative exergy value of inlet and outlet streams is called exergy destruction. The exergy of a stream is calculated by summing physical and chemical exergy values, which are calculated as presented in Equations (1) and (2) [40]:

Table 4.

Formulae used for exergy analysis in the study [39,40].

Optimization of a chemical process has always remained a hot topic to find the most suitable parameters to obtain the highest possible efficiency of the system. During the optimization of the PDBT dehydrogenation system, the concept of process integration, and hierarchy of energy reduction, as proposed by Kemp and Lim [41,42], were considered.

The hierarchy of energy reduction specific to this study is: (1) avoid or reduce the energy requirement, (2) recover the heat from the process. The overall process is using external utilities, i.e., cooling water and steam. On analyzing the system based on exergy analysis, it was revealed that there is a potential to minimize the utilities consumption in the process and that can be done by enhancing the process-to-process heat recoveries. Further, it was observed (based on exergy analysis) that the hydrogen stream (S9) has the potential to produce power, thereby meeting the energy requirement of the pump, and helpful in reducing the steam consumption for feed preheating. Accordingly, the two strategies are proposed for the system:

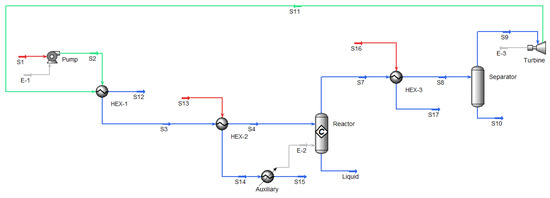

- Strategy #1: It is observed during the simulation, that stream S9 (consists of hydrogen) has a considerably high temperature, which can be extracted, i.e., power can be produced, and the hydrogen stream can exchange heat with the reactor feed (in HEX-1) to reduce the steam consumption in the system. The scheme is presented in Figure 3.

Figure 3. Optimization strategy #1 of the dehydrogenation system.

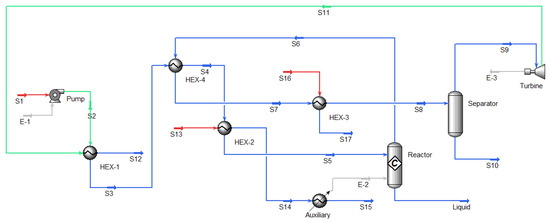

Figure 3. Optimization strategy #1 of the dehydrogenation system. - Strategy #2: In addition to the scheme developed in strategy # 1, the product of the reactor is at the highest temperature in the system, so its heat can also be used to pre-heat the reactor feed (in HEX-1). The scheme is presented in Figure 4.

Figure 4. Optimization strategy #2 of the dehydrogenation system.

Figure 4. Optimization strategy #2 of the dehydrogenation system.

3. Results

The first part of this study is focused on the optimization of the weight fraction of platinum on an alumina catalyst for the dehydrogenation system under suitable conditions. The analysis shows that for 0.5 wt.% Pt/Al2O3 catalyst, a maximum of 40% degree of dehydrogenation is obtained at a temperature of 270 °C, while for 5 wt.% Pt/Al2O3 catalyst, 51.3% degree of dehydrogenation is obtained, which makes 0.5 wt.% Pt/Al2O3 catalyst unfavorable for the system. At the highest temperature of 320 °C, the degree of dehydrogenation obtained for 5 wt. %, 1 wt. %, and 2 wt.% Pt/Al2O3 catalysts are 81.3, 90, and 96%, respectively, which shows that 2 wt.% Pt/Al2O3 catalyst is the most suitable catalyst for the dehydrogenation of perhydro-dibenzyl-toluene. The analysis shows an increase in metal loading (platinum) from 0.5 to 2 wt.% has led to an increase in the value of DoD, however, the further increase has led to a decrease in the degree of dehydrogenation, as shown for 5 wt.% catalyst. This is in agreement with the study by Palma et al. [43], i.e., for the metal loading of 2 wt. %, there is a fine dispersion on the base surface with the least agglomeration, while the increase in metal loading from 2 to 5 wt.% has led to a comparative increase in the agglomeration, reduced dispersion, reduced metallic surface area, and reduced number of reducible species, thereby leading to reduced catalytic activity. For the study presented so far, the pressure is taken as 1 bar. Since the dehydrogenation process is endothermic, so the value of DoD is found to be decreasing with the increase in pressure up to 3 bar. However, for the real-time operation of the system, 1 bar pressure is not sufficient. Since pressure drops are considered in the heat exchangers (in accordance with the real-time operation), therefore, for the real-time operation of the system, the followings conditions are selected:

- Catalyst: 2 wt.% Pt/Al2O3 catalyst

- Temperature: 320 °C

- Pressure: 2 bar

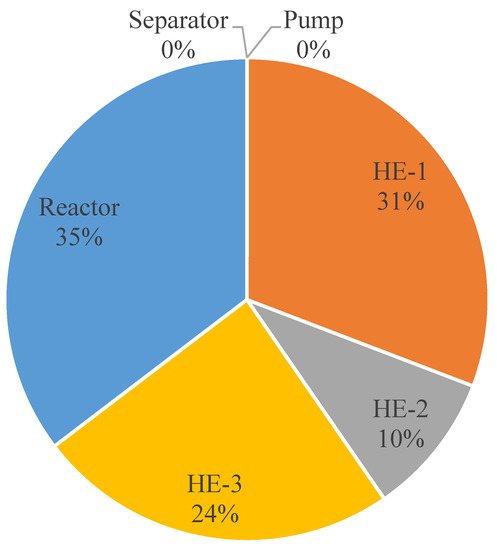

The second part of the study is focused on the exergy analysis of the overall system. The exergy analysis of the system is presented in Figure 5. The analysis shows that the reactor and heat exchangers #1 and 3 are responsible for major exergy destruction in the process. Further improvement in the reactor conditions or further decrease in exergy destruction rate is not possible since reaction conditions cannot be changed. However, for heat exchangers #1 and 3, the improvement is still possible, which has been considered during the optimization study, using the concepts of process integration.

Figure 5.

Contribution of different equipment in total exergy destruction rate—base case (%).

The third part of this study is focused on optimization of the system, based on results obtained from exergy analysis. Two strategies are developed for improving the overall efficiency of the system (presented in the methodology). The overall results of the strategies are presented as follows:

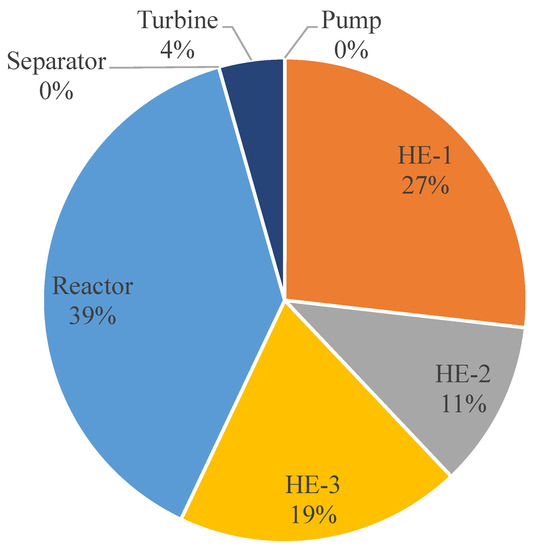

- Strategy #1: hot utility consumption is reduced by 47.06%, while cold utility consumption is reduced by 30%, with an overall reduction in utility consumption rate by 37.84%. The electricity is produced in the system, i.e., the turbine is producing a power of 485 kW, an important aspect missing in the base case, and therefore an improvement in the overall system. The % exergy destruction rate of strategy #1 is presented in Figure 6. The % exergy destruction in heat exchanger #1 is reduced from 31 (base-case) to 27%, while in heat exchanger #3, it is reduced from 24 (base-case) to 19%. The overall exergy destruction rate is reduced by 9.01% in comparison to the base case.

Figure 6. Contribution of different equipment in total exergy destruction rate—strategy #1 (%).

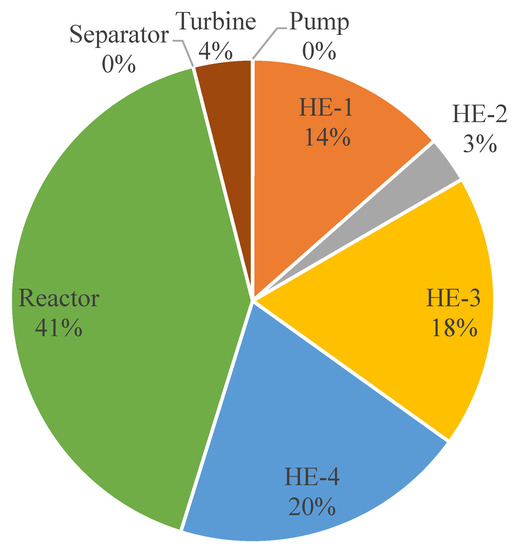

Figure 6. Contribution of different equipment in total exergy destruction rate—strategy #1 (%). - Strategy #2: hot utility consumption is reduced by 70.59%, while cold utility consumption is reduced by 30%, with an overall reduction in utility consumption by 48.65%, at an expense of installation of one extra heat exchanger. In this case, the turbine is comparatively producing lesser power, i.e., 359 kW in the system, because the product of the reactor (S7) is exchanging heat with feed stream (S3); therefore, comparatively lesser heat is available for electricity generation. However, in this strategy, the % exergy destruction rate is reduced by 14.28% in comparison to the base case. The % exergy destruction rate in heat exchanger #1 is reduced from 31 (base-case) to 14%, in heat exchanger #2, it is reduced from 10 (base-case) to 3%, and in exchanger #3, it is reduced from 24 (base-case) to 18%, as presented in Figure 7.

Figure 7. Contribution of different equipment in total exergy destruction rate—strategy #2 (%).

Figure 7. Contribution of different equipment in total exergy destruction rate—strategy #2 (%).

The performance analysis of the strategies developed for the dehydrogenation system is summarized in Table 5.

Table 5.

Performance analysis of strategies developed for the dehydrogenation system.

The analyses reveal that strategy #2 is the most suitable option for the dehydrogenation system, because for various reasons:

- Although an extra heat exchanger is required which contributes to the higher fixed cost of the system in strategy #2, however, the benefit associated with this strategy is the reduction in the utility consumption rate by 48.65%, thereby, reducing the operational cost of the system. In comparison, the utility consumption rate is reduced by 37.84% in strategy #1, which can lead to the higher operational cost of the system. Therefore, considering the trade-off between operational and capital cost, strategy #2 appears to be the most suitable for the dehydrogenation system.

- In comparison to the base case, the exergy destruction rate is reduced by 14.28% in strategy #2, while in strategy #1 is reduced by 9.01%. The overall exergy efficiency of the base case is 84.61%. In comparison, the overall exergy efficiency in the case of strategy #1 and strategy #2 is 91.06 and 94.86%, respectively, thus favoring strategy #2 for the system.

4. Conclusions

The performance of the PDBT dehydrogenation system was analyzed based on various parameters, i.e., selection of optimum operational conditions, exergy analysis of the process, and development of optimization strategies for the system to identify the most suitable configuration. The analysis showed that the most suitable catalyst for the system was 2 wt.% Pt/Al2O3 with optimum temperature and pressure condition as 320 °C, and 2 bar, respectively. The exergy analysis of the base-case showed that reactor and heat exchanger-2 had caused a comparatively higher exergy destruction rate. The exergy analysis and process integration helped in the optimization of the system, i.e., two design strategies were developed for the system. The optimization increased the overall exergy efficiency of the overall system up to 7.08 and 10.81% with the exergy destruction rate reduced by 9.01 and 14.28% for strategy #1 and strategy #2, respectively. Therefore, strategy 2 is the most suitable option for the dehydrogenation system.

Author Contributions

Conceptualization, M.H. and Y.-K.P.; methodology, M.H. and I.M.M.; software, F.A., M.H.H., and A.H.; validation, F.A., and A.H.; formal analysis, F.A., and M.H.H.; investigation, A.H., and M.H.H.; resources, I.M.M.; data curation, I.M.M.; writing—original draft preparation, F.A., M.H.H., and A.H.; writing—review and editing, M.H., I.M.M., and Y.-K.P.; visualization, M.H.; supervision, M.H., and Y.-K.P.; project administration, M.H., and Y.-K.P.; funding acquisition, M.H., and Y.-K.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by NRF of Korea (2019R1A4A1027795).

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding authors upon request.

Acknowledgments

The authors are thankful to COMSATS University Islamabad, Lahore Campus for providing access to the registered version of Aspen HYSYS® V10.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Exergy destruction (kW) | |

| Exergy supplied through heat flow (kW) = Q (1 − To/T) [44] | |

| Exergy of inlet stream (kW) | |

| Exergy of outlet stream (kW) | |

| Physical exergy (kW) | |

| Chemical exergy (kW) | |

| Po | Reference pressure (bar) |

| R | Ideal gas constant |

| To | Reference temperature (°C) |

| W | Work required by pump/Work generated by the turbine (kW) |

| xi | Mole fraction of component, i |

| ΔP | Pressure drop (bar) |

| Greek Letters | |

| εk | Exergy efficiency (%) |

| εche, i | Standard chemical exergy of component, i (kJ/mol) |

| Abbreviations | |

| DoD | Degree of dehydrogenation |

| DBT | Dibenzyl toluene |

| HHV | Higher heating value |

| HEX | Heat exchanger |

| PDBT | Perhydro-dibenzyl-toluene |

References

- Perwez, U.; Sohail, A.; Hassan, S.F.; Zia, U. The long-term forecast of Pakistan’s electricity supply and demand: An application of long range energy alternatives planning. Energy 2015, 93, 2423–2435. [Google Scholar] [CrossRef]

- Hussain, M.; Deorsola, F.A.; Russo, N.; Fino, D.; Pirone, R. Abatement of CH4 emitted by CNG vehicles using Pd-SBA-15 and Pd-KIT-6 catalysts. Fuel 2015, 149, 2–7. [Google Scholar] [CrossRef]

- Rashid, R.; Shafiq, I.; Iqbal, M.J.; Shabir, M.; Akhter, P.; Hamayun, M.H.; Ahmed, A.; Hussain, M. Synergistic effect of NS co-doped TiO2 adsorbent for removal of cationic dyes. J. Environ. Chem. Eng. 2021, 9, 105480. [Google Scholar] [CrossRef]

- Zhu, Q.L.; Xu, Q. Liquid organic and inorganic chemical hydrides for high-capacity hydrogen storage. Energy Environ. Sci. 2015, 8, 478–512. [Google Scholar] [CrossRef]

- Teichmann, D.; Arlt, W.; Wasserscheid, P. Liquid Organic Hydrogen Carriers as an efficient vector for the transport and storage of renewable energy. Int. J. Hydrogen Energy 2012, 37, 18118–18132. [Google Scholar] [CrossRef]

- Haris Hamayun, M.; Hussain, M.; Maafa, I.M.; Aslam, R. Integration of hydrogenation and dehydrogenation system for hydrogen storage and electricity generation—Simulation study. Int. J. Hydrogen Energy 2019, 44, 20213–20222. [Google Scholar] [CrossRef]

- Haris Hamayun, M.; Maafa, I.M.; Hussain, M.; Aslam, R. Simulation Study to Investigate the Effects of Operational Conditions on Methylcyclohexane Dehydrogenation for Hydrogen Production. Energies 2020, 13, 206. [Google Scholar] [CrossRef]

- Markiewicz, M.; Zhang, Y.Q.; Bösmann, A.; Brückner, N.; Thöming, J.; Wasserscheid, P.; Stolte, S. Environmental and health impact assessment of Liquid Organic Hydrogen Carrier (LOHC) systems-challenges and preliminary results. Energy Environ. Sci. 2015, 8, 1035–1045. [Google Scholar] [CrossRef]

- Preuster, P.; Papp, C.; Wasserscheid, P. Liquid Organic Hydrogen Carriers (LOHCs): Toward a Hydrogen-free Hydrogen Economy. Acc. Chem. Res. 2017, 50, 74–85. [Google Scholar] [CrossRef]

- Rao, P.C.; Yoon, M. Potential Liquid-Organic Hydrogen Carrier (LOHC) Systems: A Review on Recent Progress. Energies 2020, 13, 6040. [Google Scholar] [CrossRef]

- Preuster, P.; Fang, Q.; Peters, R.; Deja, R.; Nguyen, V.N.; Blum, L.; Stolten, D.; Wasserscheid, P. Solid oxide fuel cell operating on liquid organic hydrogen carrier-based hydrogen—Making full use of heat integration potentials. Int. J. Hydrogen Energy 2018, 43, 1758–1768. [Google Scholar] [CrossRef]

- Michalska, K.; Kowalik, P.; Konkol, M.; Próchniak, W.; Stołecki, K.; Słowik, G.; Borowiecki, T. The effect of copper on benzene hydrogenation to cyclohexane over Ni/Al2O3 catalyst. Appl. Catal. A Gen. 2016, 523, 54–60. [Google Scholar] [CrossRef]

- Wijayanta, A.T.; Oda, T.; Purnomo, C.W.; Kashiwagi, T.; Aziz, M. Liquid hydrogen, methylcyclohexane, and ammonia as potential hydrogen storage: Comparison review. Int. J. Hydrogen Energy 2019, 44, 15026–15044. [Google Scholar] [CrossRef]

- Müller, K.; Aslam, R.; Fischer, A.; Stark, K.; Wasserscheid, P.; Arlt, W. Experimental assessment of the degree of hydrogen loading for the dibenzyl toluene based LOHC system. Int. J. Hydrogen Energy 2016, 41, 22097–22103. [Google Scholar] [CrossRef]

- Cholewa, M.; Pfeifer, P. Characterization of Microstructured Reactors for Dehydrogenation of Liquid Organic Hydrogen Carriers. In Proceedings of the 24th International Symposium on Chemical Reaction Engineering, Minneapolis, MN, USA, 12–15 June 2016. [Google Scholar]

- Peters, R.; Deja, R.; Fang, Q.; Nguyen, V.N.; Preuster, P.; Blum, L.; Wasserscheid, P.; Stolten, D. A solid oxide fuel cell operating on liquid organic hydrogen carrier-based hydrogen—A kinetic model of the hydrogen release unit and system performance. Int. J. Hydrogen Energy 2019, 44, 13794–13806. [Google Scholar] [CrossRef]

- Inhetveen, P.; Alt, N.S.A.; Schluecker, E. Measurement of the hydrogenation level of dibenzyltoluene in an innovative energy storage system. Vib. Spectrosc. 2016, 83, 85–93. [Google Scholar] [CrossRef]

- Aslam, R.; Minceva, M.; Müller, K.; Arlt, W. Development of a liquid chromatographic method for the separation of a liquid organic hydrogen carrier mixture. Sep. Purif. Technol. 2016, 163, 140–144. [Google Scholar] [CrossRef]

- Aslam, R.; Khan, M.H.; Ishaq, M.; Müller, K. Thermophysical Studies of Dibenzyltoluene and Its Partially and Fully Hydrogenated Derivatives. J. Chem. Eng. Data 2018, 63, 4580–4587. [Google Scholar] [CrossRef]

- Müller, K.; Stark, K.; Emelyanenko, V.N.; Varfolomeev, M.A.; Zaitsau, D.H.; Shoifet, E.; Schick, C.; Verevkin, S.P.; Arlt, W. Liquid Organic Hydrogen Carriers: Thermophysical and Thermochemical Studies of Benzyl- and Dibenzyl-toluene Derivatives. Ind. Eng. Chem. Res. 2015, 54, 7967–7976. [Google Scholar] [CrossRef]

- Heller, A.; Rausch, M.H.; Schulz, P.S.; Wasserscheid, P.; Fröba, A.P. Binary Diffusion Coefficients of the Liquid Organic Hydrogen Carrier System Dibenzyltoluene/Perhydrodibenzyltoluene. J. Chem. Eng. Data 2016, 61, 504–511. [Google Scholar] [CrossRef]

- Brückner, N.; Obesser, K.; Bösmann, A.; Teichmann, D.; Arlt, W.; Dungs, J.; Wasserscheid, P. Evaluation of industrially applied heat-transfer fluids as liquid organic hydrogen carrier systems. ChemSusChem 2014, 7, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Leinweber, A.; Müller, K. Hydrogenation of the Liquid Organic Hydrogen Carrier Compound Monobenzyl Toluene: Reaction Pathway and Kinetic Effects. Energy Technol. 2018, 6, 513–520. [Google Scholar] [CrossRef]

- Modisha, P.M.; Jordaan, J.H.L.; Bösmann, A.; Wasserscheid, P.; Bessarabov, D. Analysis of reaction mixtures of perhydro-dibenzyltoluene using two-dimensional gas chromatography and single quadrupole gas chromatography. Int. J. Hydrogen Energy 2018, 43, 5620–5636. [Google Scholar] [CrossRef]

- Wunsch, A.; Berg, T.; Pfeifer, P. Hydrogen production from the LOHC perhydrodibenzyl-toluene and purification using a 5 μm PdAg-membrane in a coupled microstructured system. Materials 2020, 13, 277. [Google Scholar] [CrossRef] [PubMed]

- Fikrt, A.; Brehmer, R.; Milella, V.O.; Müller, K.; Bösmann, A.; Preuster, P.; Alt, N.; Schlücker, E.; Wasserscheid, P.; Arlt, W. Dynamic power supply by hydrogen bound to a liquid organic hydrogen carrier. Appl. Energy 2017, 194, 1–8. [Google Scholar] [CrossRef]

- Auer, F.; Blaumeiser, D.; Bauer, T.; Bösmann, A.; Szesni, N.; Libuda, J.; Wasserscheid, P. Boosting the activity of hydrogen release from liquid organic hydrogen carrier systems by sulfur-additives to Pt on alumina catalysts. Catal. Sci. Technol. 2019, 9, 3537–3547. [Google Scholar] [CrossRef]

- Shi, L.; Qi, S.; Qu, J.; Che, T.; Yi, C.; Yang, B. Integration of hydrogenation and dehydrogenation based on dibenzyltoluene as liquid organic hydrogen energy carrier. Int. J. Hydrogen Energy 2019, 5345–5354. [Google Scholar] [CrossRef]

- Modisha, P.M.; Ouma, C.N.M.; Garidzirai, R.; Wasserscheid, P.; Bessarabov, D. The Prospect of Hydrogen Storage Using Liquid Organic Hydrogen Carriers. Energy Fuels 2019, 33, 2778–2796. [Google Scholar] [CrossRef]

- Modisha, P.; Gqogqa, P.; Garidzirai, R.; Ouma, C.N.M.; Bessarabov, D. Evaluation of catalyst activity for release of hydrogen from liquid organic hydrogen carriers. Int. J. Hydrogen Energy 2019, 44, 21926–21935. [Google Scholar] [CrossRef]

- Jorschick, H.; Preuster, P.; Dürr, S.; Seidel, A.; Müller, K.; Bösmann, A.; Wasserscheid, P. Hydrogen storage using a hot pressure swing reactor. Energy Environ. Sci. 2017, 10, 1652–1659. [Google Scholar] [CrossRef]

- Ali, A.; Udaya Kumar, G.; Lee, H.J. Parametric study of the hydrogenation of dibenzyltoluene and its dehydrogenation performance as a liquid organic hydrogen carrier. J. Mech. Sci. Technol. 2020, 34, 3069–3077. [Google Scholar] [CrossRef]

- Jorschick, H.; Geißelbrecht, M.; Eßl, M.; Preuster, P.; Bösmann, A.; Wasserscheid, P. Benzyltoluene/dibenzyltoluene-based mixtures as suitable liquid organic hydrogen carrier systems for low temperature applications. Int. J. Hydrogen Energy 2020, 45, 14897–14906. [Google Scholar] [CrossRef]

- Garidzirai, R.; Modisha, P.; Shuro, I.; Visagie, J.; van Helden, P.; Bessarabov, D. The effect of Mg and Zn dopants on Pt/Al2O3 for the dehydrogenation of perhydrodibenzyltoluene. Catalysts 2021, 11, 490. [Google Scholar] [CrossRef]

- Kaushik, S.C.; Reddy, V.S.; Tyagi, S.K. Energy and exergy analyses of thermal power plants: A review. Renew. Sustain. Energy Rev. 2011, 15, 1857–1872. [Google Scholar] [CrossRef]

- Mohammadi, A.; Mehrpooya, M. Energy and exergy analyses of a combined desalination and CCHP system driven by geothermal energy. Appl. Therm. Eng. 2017, 116, 685–694. [Google Scholar] [CrossRef]

- Haris Hamayun, M.; Ramzan, N.; Hussain, M.; Faheem, M. A Comparison of Cryogenic Air Separation Processes Based on Exergy Analysis. In Proceedings of the 2020 Virtual AIChE Annual Meeting, 16–20 November 2020. [Google Scholar]

- Mehrpooya, M.; Dehghani, H.; Ali Moosavian, S.M. Optimal design of solid oxide fuel cell, ammonia-water single effect absorption cycle and Rankine steam cycle hybrid system. J. Power Sources 2016, 306, 107–123. [Google Scholar] [CrossRef]

- Haris Hamayun, M.; Hussain, M.; Shafiq, I.; Ahmed, A.; Park, Y.-K. Investigation of the thermodynamic performance of an existing steam power plant via energy and exergy analyses to restrain the environmental repercussions: A simulation study. Environ. Eng. Res. 2022, 27, 200683. [Google Scholar] [CrossRef]

- Haris Hamayun, M.; Ramzan, N.; Hussain, M.; Faheem, M. Evaluation of Two-Column Air Separation Processes Based on Exergy Analysis. Energies 2020, 13, 6361. [Google Scholar] [CrossRef]

- Kemp, I.C.; Lim, J.S. Introduction. In Pinch Analysis for Energy and Carbon Footprint Reduction, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–17. ISBN 978-0-08-102536-9. [Google Scholar]

- Kemp, I.C.; Lim, J.S. Key concepts of pinch analysis. In Pinch Analysis for Energy and Carbon Footprint Reduction, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–17. ISBN 978-0-08-102536-9. [Google Scholar]

- Palma, V.; Ruocco, C.; Cortese, M.; Renda, S.; Meloni, E.; Festa, G.; Martino, M. Platinum based catalysts in the water gas shift reaction: Recent advances. Metals 2020, 10, 866. [Google Scholar] [CrossRef]

- Marques, J.G.O.; Costa, A.L.; Pereira, C.; Fortini, Â. Energy and Exergy Analyses of Angra 2 Nuclear Power Plant. Braz. J. Radiat. Sci. 2019, 7, 1–15. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).