Characteristics of Volatile Organic Compound Leaks from Equipment Components: A Study of the Pharmaceutical Industry in China

Abstract

1. Introduction

2. Overview of VOC Emissions in the Pharmaceutical Industry

3. Requirements to Control VOC Leaks from Equipment

4. Characteristics of VOC Emissions Derived from Equipment Leaks

4.1. Basic Situation

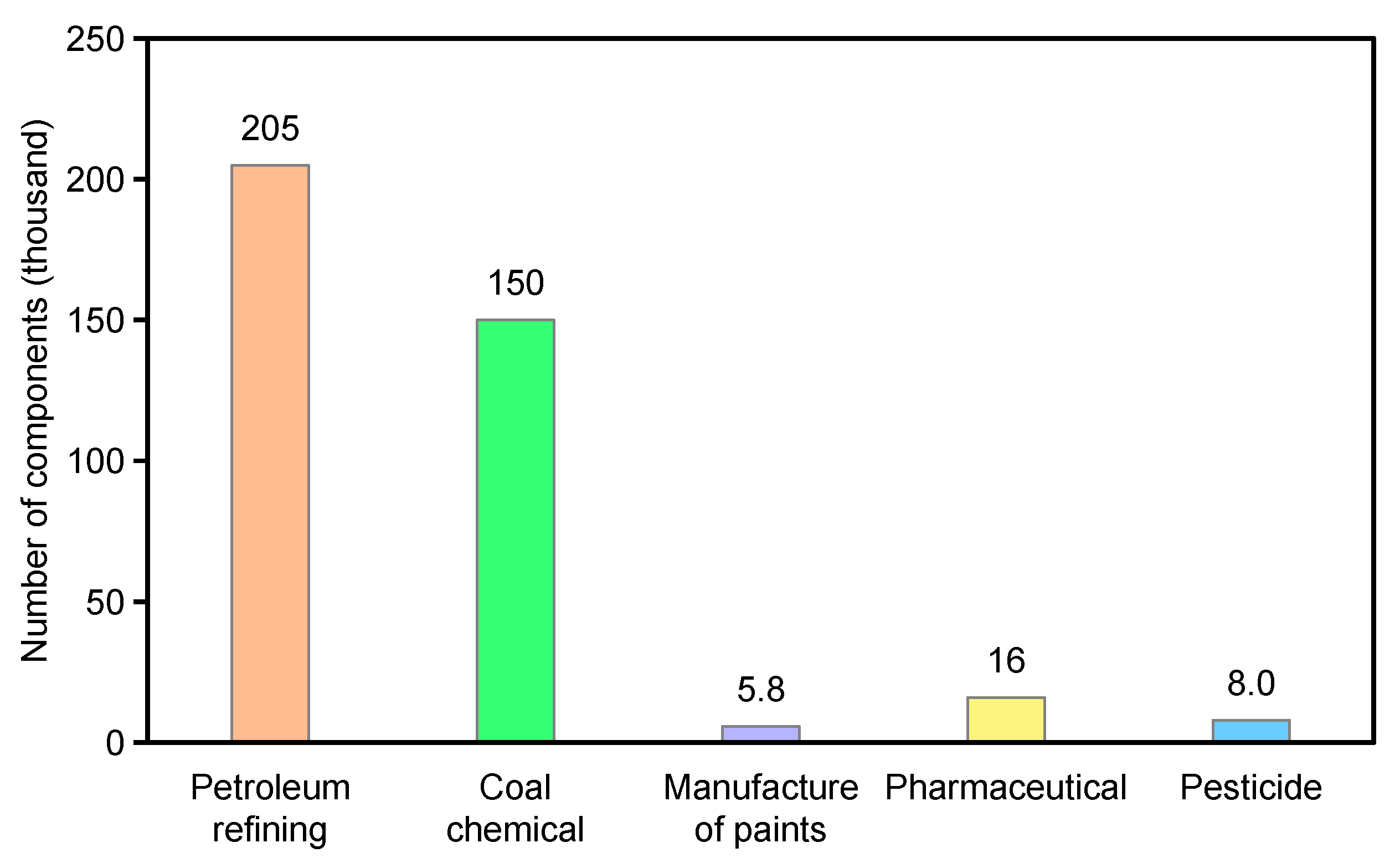

4.1.1. Number of Components

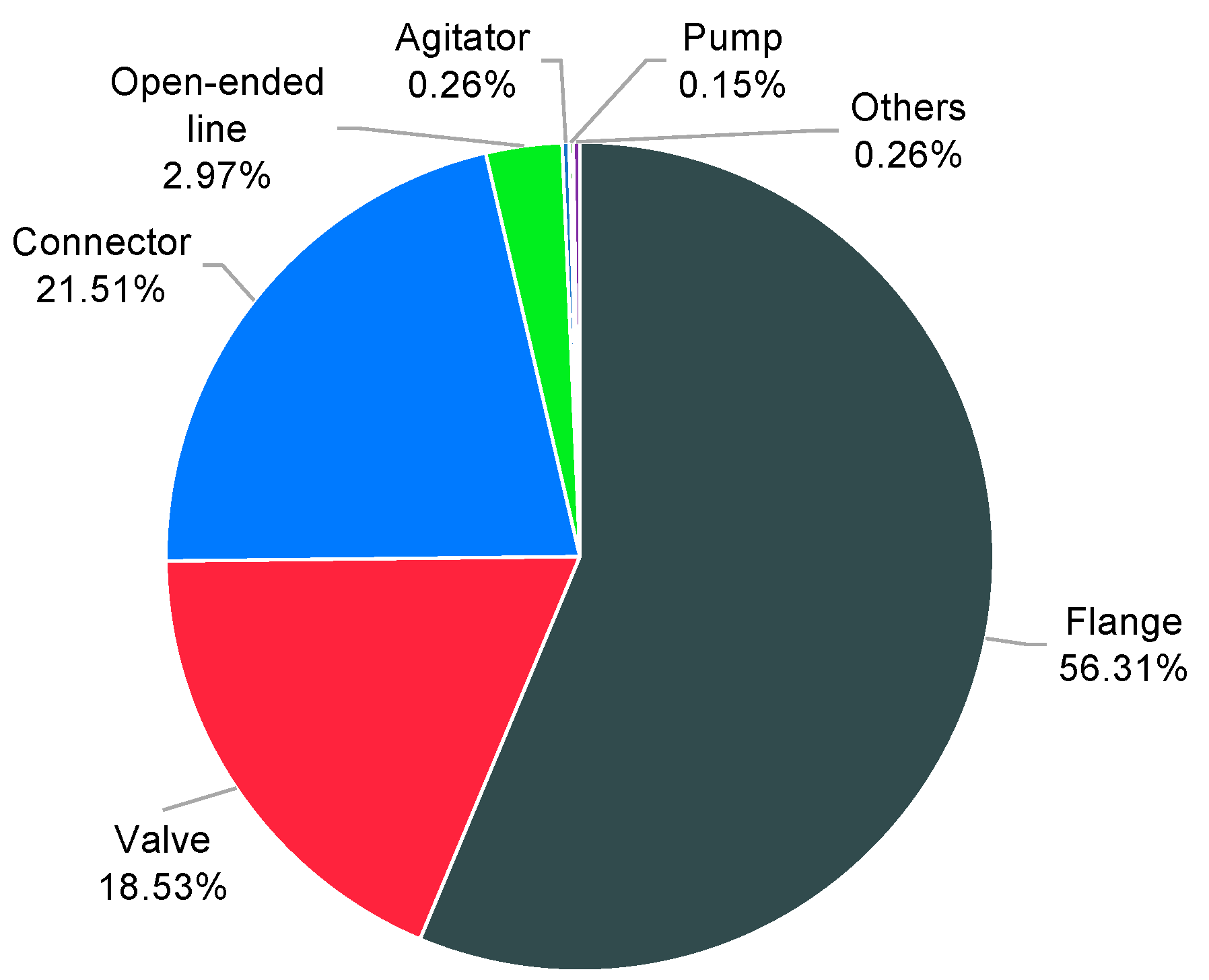

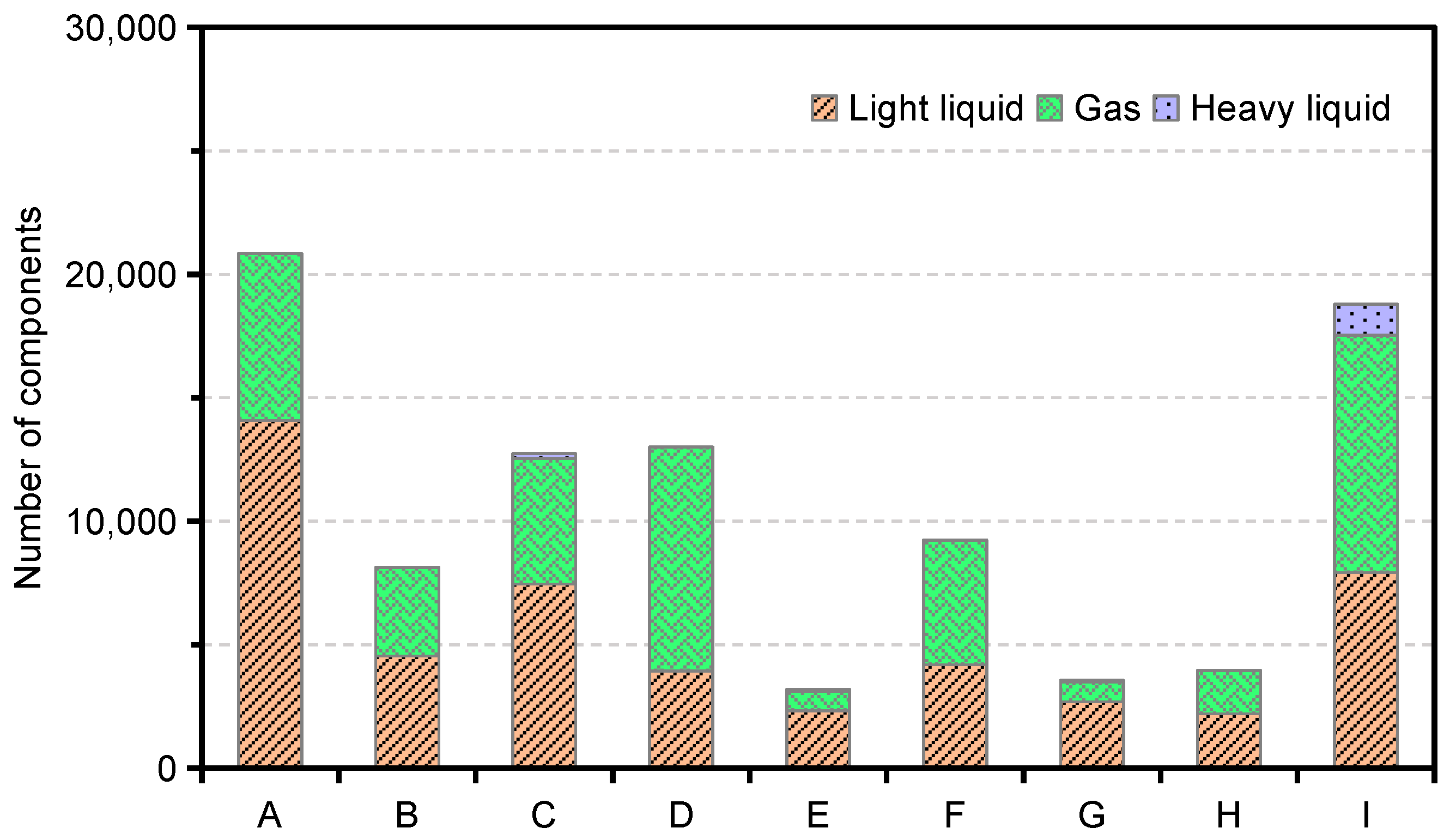

4.1.2. Distribution of Different Types of Components in Nine Pharmaceutical Enterprises

4.2. Leak Characteristics

4.2.1. Leak Ratio

Overall Leak Ratio

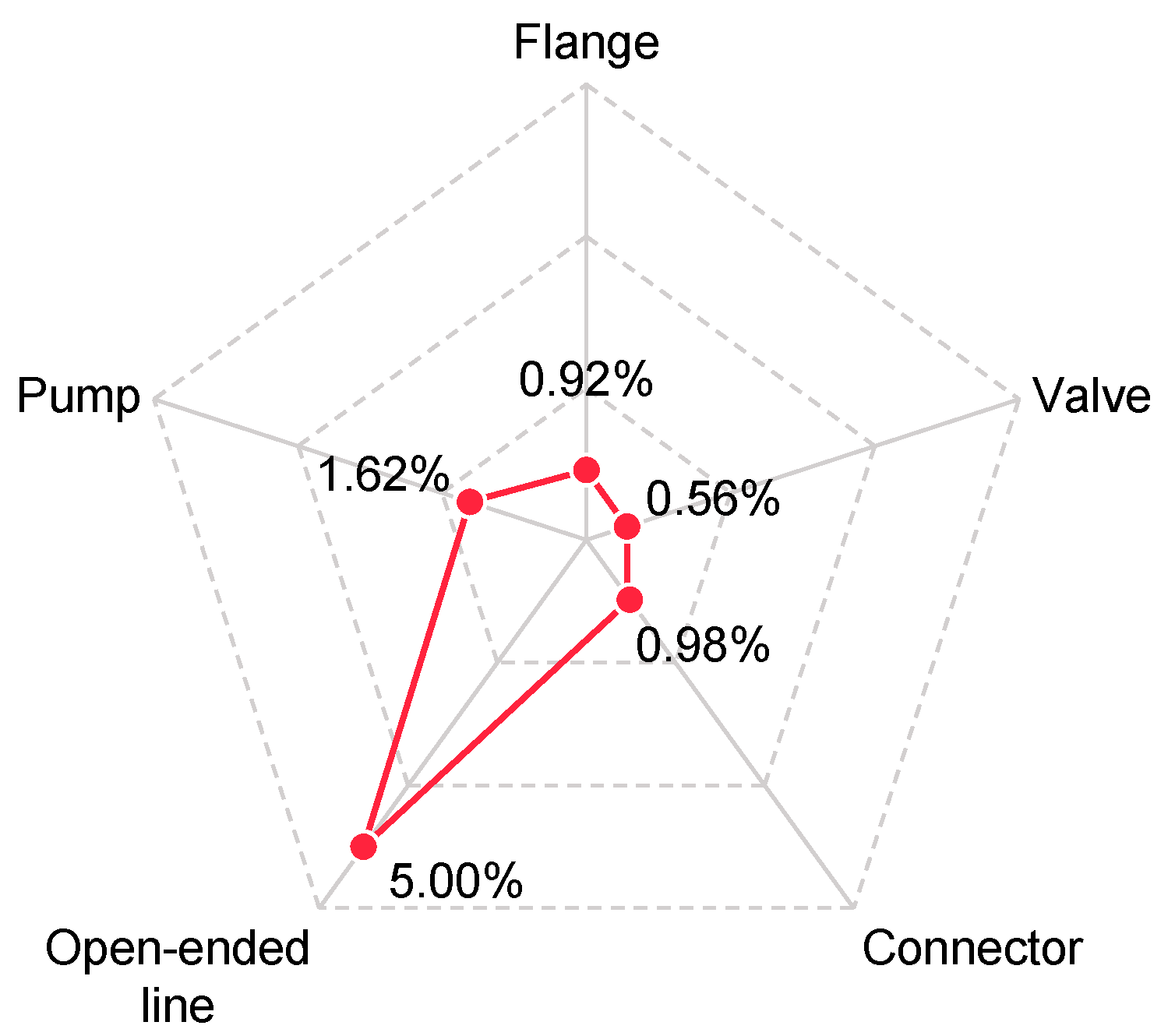

Leak Ratios of Different Types of Component

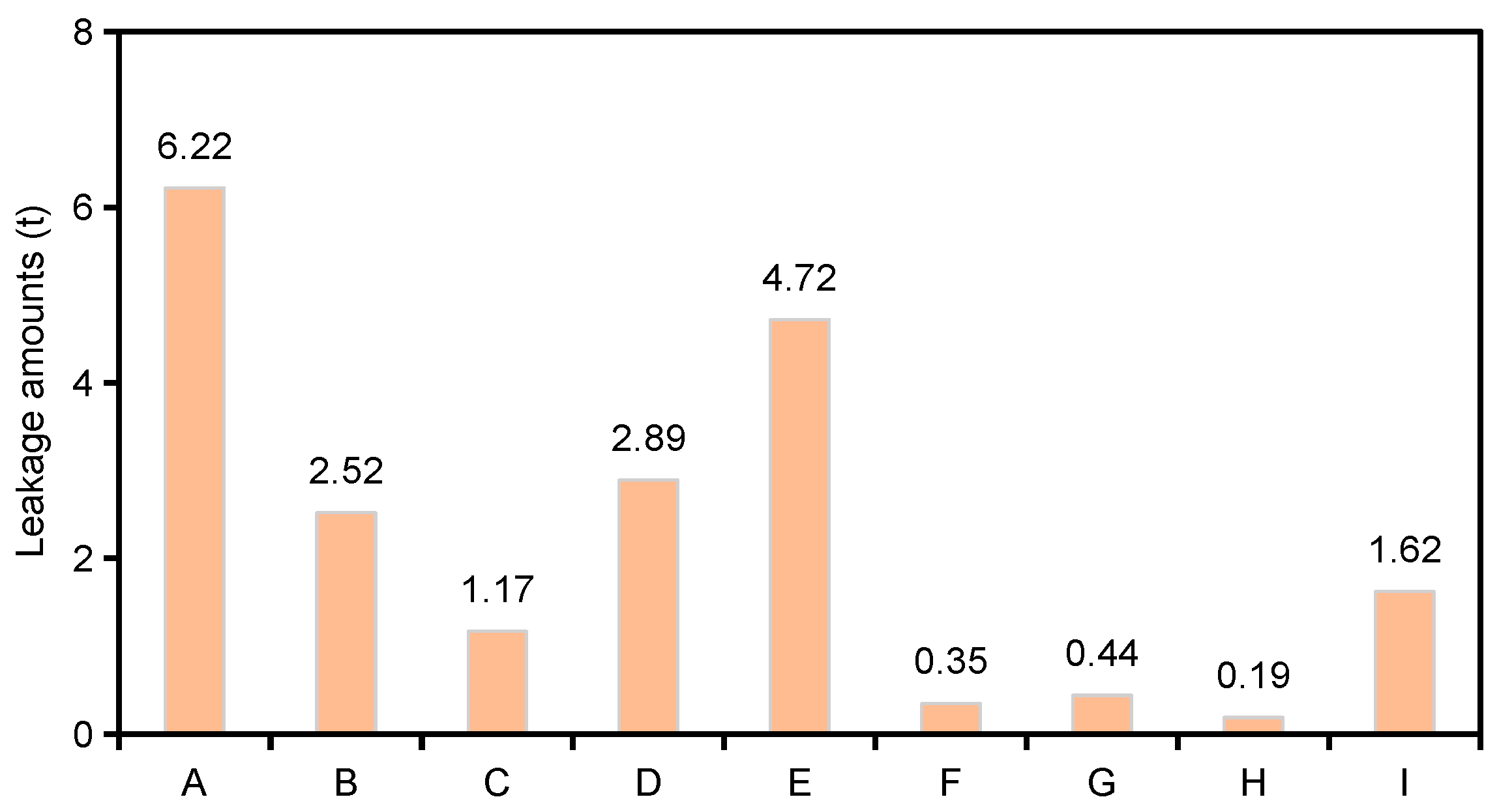

4.2.2. Leakage Levels

Overall Leak Levels

- e = Emission rate of VOC for a specific type of equipment (kg/h)

- SV = Concentration of leakage detected by the instruments (μmol/mol)

- e0,i = Default zero emission rate of equipment i (kg/h)

- ep,i = Pegged emission rates of equipment i (kg/h)

- ef,i = Correlation equation of equipment i (kg/h)

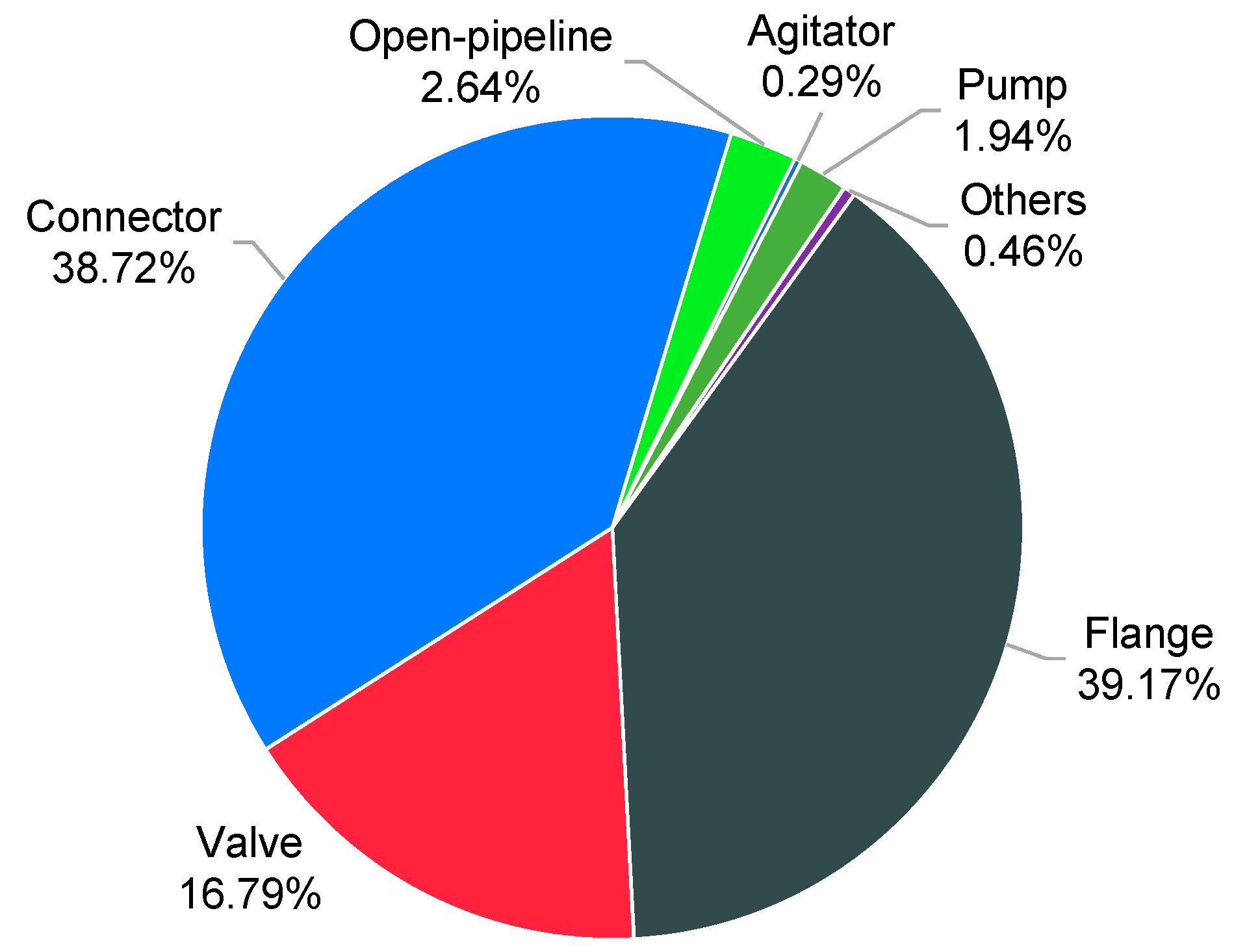

Levels of Leakage from Different Types of Equipment

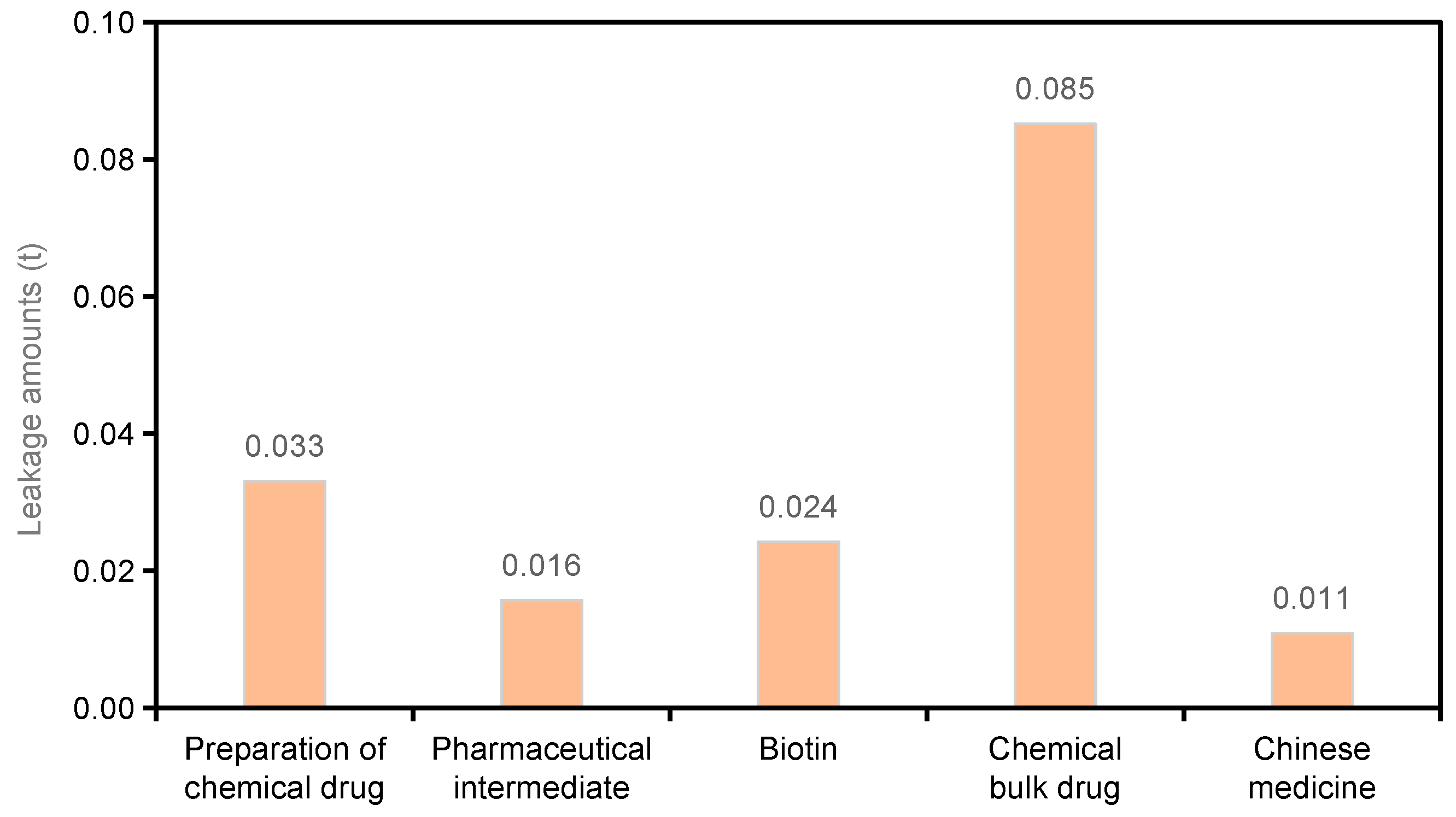

Levels of Leakage from Enterprises Manufacturing Different Types of Products

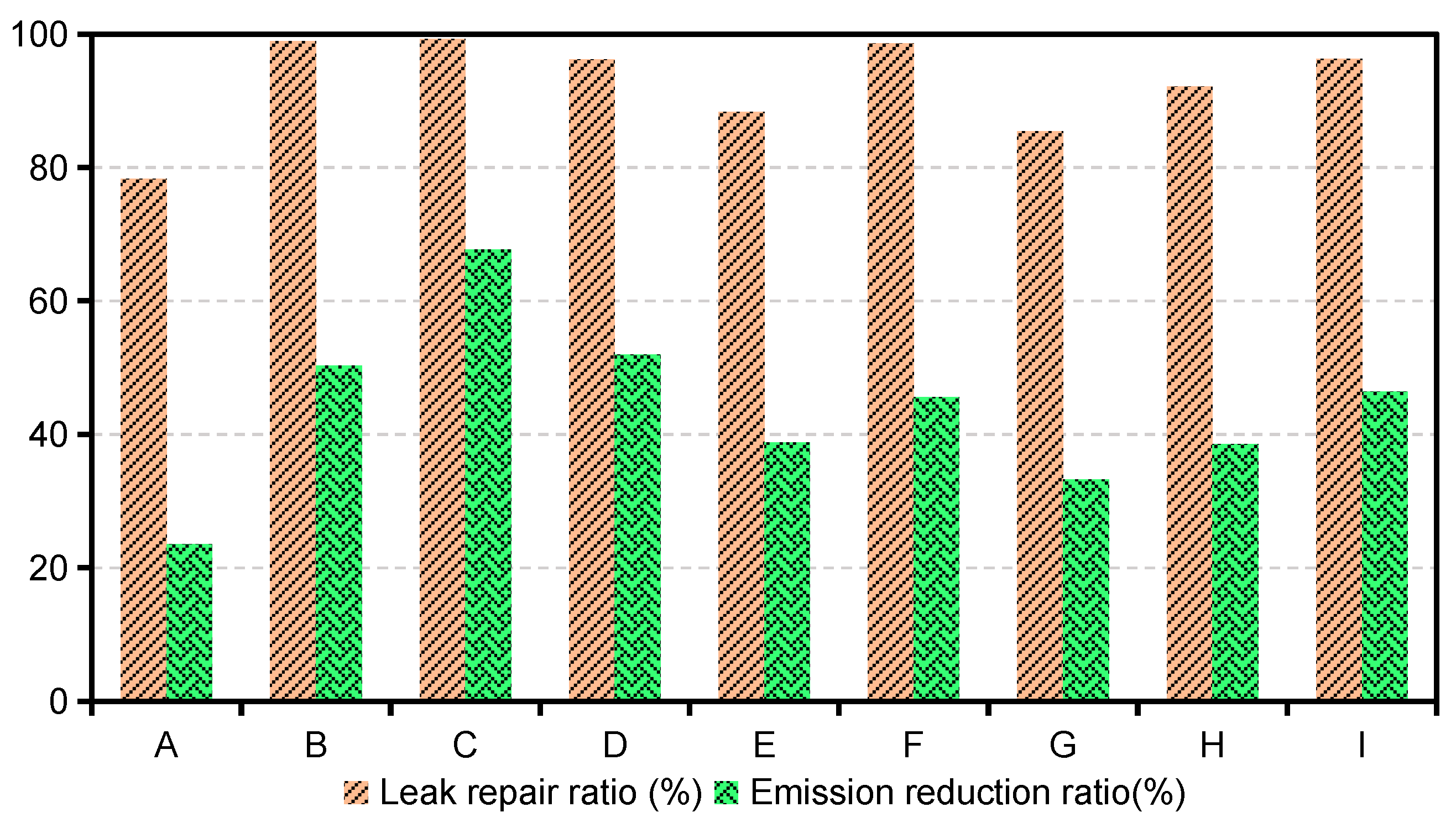

4.3. Repair and Emission Reduction

5. Control Suggestions

5.1. Promote the Implementation of Quality LDAR

5.2. Emphasize Controlling Sources of Leaks

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chan, C.K.; Yao, X. Air pollution in mega cities in China. Atmos. Environ. 2008, 42, 1–42. [Google Scholar] [CrossRef]

- Wang, T.; Wei, X.L.; Ding, A.J.; Poon, C.N.; Lam, K.S.; Li, Y.S.; Chan, L.Y.; Anson, M. Increasing surface ozone concentrations in the background atmosphere of Southern China, 1994–2007. Atmos. Chem. Phys. 2009, 9, 6217–6227. [Google Scholar] [CrossRef]

- Ma, Z.; Xu, J.; Quan, W.; Zhang, Z.; Lin, W.; Xu, X. Significant increase of surface ozone at a rural site, north of eastern China. Atmos. Chem. Phys. 2016, 16, 3969–3977. [Google Scholar] [CrossRef]

- Verstraeten, W.W.; Neu, J.L.; Williams, J.E.; Bowman, K.W.; Boersma, F.K. Rapid increases in tropospheric ozone production and export from China. Nat. Geosc. 2015, 8, 690–695. [Google Scholar] [CrossRef]

- Derwent, R.G.; Jenkin, M.E.; Saunders, S.M.; Pilling, M.J.; Simmonds, P.G.; Passant, N.R.; Dollard, G.J.; Dumitrean, P.; Kent, A. Photochemical ozone formation in north west Europe and its control. Atmos. Environ. 2003, 37, 983–1991. [Google Scholar] [CrossRef]

- Dechapanya, W.; Eusebi, A.; Kimura, Y.; Allen, D.T. Secondary organic aerosol formation from aromatic precursors.1.Mechanisms for individual hydrocarbons. Environ. Sci. Technol. 2003, 37, 3662–3670. [Google Scholar] [CrossRef]

- Giakoumi, A.; Maggos, T.; Michopoulos, J.; Helmis, C.; Vasilakos, C. Pm2.5 and volatile organic compounds (vocs) in ambient air: A focus on the effect of meteorology. Environ. Monit. Assess. 2009, 152, 83–95. [Google Scholar] [CrossRef] [PubMed]

- Cai, C.J.; Geng, F.H.; Tie, X.X.; Yu, Q.; An, J. Characteristics and source apportionment of VOCs measured in Shanghai, China. Atmos. Environ. 2010, 44, 5005–5014. [Google Scholar] [CrossRef]

- Yen, C.H.; Horng, J.J. Volatile organic compounds (VOCs) emission characteristics and control strategies for a petrochemical industrial area in middle Taiwan. J. Environ. Sci. Health A 2009, 44, 1424–1429. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.F. Application and development trend of leak detection and repair (LDAR). Chin. J. Environ. Eng. 2016, 10, 4621–4627. [Google Scholar]

- Hang, C.Y.; Zhao, X.; Shan, Y.H.; Zhang, X.Y.; Ying, T.B.; Zhang, C.L.; Lin, Y.S. A Review of Researches on Atmospheric VOCs Monitoring Technique and Pollution Characteristics in China. J. Ecol. Rural Environ. 2018, 34, 114–123. [Google Scholar]

- Chen, L. Summary of VOCs Waste Gas Treatment Technology in Chemical Industry. Henan Chem. Ind. 2018, 35, 3–6. [Google Scholar]

- Hu, X.Y.; Liu, H.; Wang, N.Y.; Wang, C.; Chuai, Y. Industrial VOCs Emission in Qinhuangdao. Environ. Sci. 2018, 39, 543–550. [Google Scholar]

- Lu, B.; Huang, C.; Lu, Q.; Yang, Q.; Jing, B.L.; Xia, Y.; Tang, W.; Gu, Z.P. Emission Inventory and Pollution Characteristics of Industrial VOCs in Hangzhou, China. Environ. Sci. 2018, 39, 533–542. [Google Scholar]

- Liu, J.; Wang, X.Y.; Yang, W.; Guo, F.Y.; Wu, L.D. Emission Characteristics and Environmental Impact of VOCs in Tianjin Lingang Petrochemical Enterpris. Res. Environ. Sci. 2018, 31, 215–220. [Google Scholar]

- Yuan, B.; Shao, M.; Lu, S.H.; Wang, B. Source profiles of volatile organic compounds associated with solvent use in Beijing, China. Atmos. Environ. 2010, 44, 1919–1926. [Google Scholar] [CrossRef]

- Piccot, S.D.; Watson, J.J.; Jones, J.W. A global inventory of volatile organic compound emissions from anthropogenic sources. J. Geophys. Res. Atmos. 1992, 97, 9897–9912. [Google Scholar] [CrossRef]

- Wei, W.; Wang, S.; Chatani, S.; Klimont, Z.; Cofala, J.; Hao, J. Emission and speciation of non-methane volatile organic compounds from anthropogenic sources in China. Atmos. Environ. 2008, 42, 4976–4988. [Google Scholar] [CrossRef]

- Duan, J.; Tan, J.; Liu, Y.; Shan, W.; Hao, J. Concentration, sources and ozone formation potential of volatile organic compounds (VOCs) during ozone episode in Beijing. Atmos. Res. 2008, 88, 25–35. [Google Scholar] [CrossRef]

- Berenjian, A.; Chan, N.; Malmiri, H.J. Volatile organic compounds removal methods: A review. Am. J. Biochem. Biotechnol. 2012, 4, 220–229. [Google Scholar]

- Ke, J.; Li, S.; Zhao, D.F. The application of leak detection and repair program in VOCs control in China’s petroleum refineries. J. Air Waste Manag. Assoc. 2020, 70, 862–875. [Google Scholar] [CrossRef]

- Stefan, S.; Matthew, H.; Terri, L.; Ken, B.; Stephen, C.; George, F.C.; Doug, J.; Jersey, G.R.; Zhang, C.; Mairs, H.L. Aerially guided leak detection and repair: A pilot field study for evaluating the potential of methane emission detection and cost-effectiveness. J. Air Waste Manag. Assoc. 2019, 69, 71–88. [Google Scholar]

- The Intergovernmental Panel on Climate Change. Working Group I: The Scientific Basis: 4.2.3.2 Volatile Organic Compounds (VOCs). 2000. Available online: https://archive.ipcc.ch/ipccreports/tar/wg1/140.htm (accessed on 10 April 2021).

- He, Z.; Wang, X.; Ling, Z.; Wang, Z. Contributions of different anthropogenic volatile organic compound sources to ozone formation at a receptor site in the Pearl River Delta region and its policy implications. Atmos. Chem. Phys. 2019, 19, 8801–8816. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, S.; Fu, X.; Watson, J.G.; Jiang, J.; Fu, Q.; Chen, C.; Xu, B.; Yu, J.; Chow, J.C.; et al. Impact of biomass burning on haze pollution in the Yangtze River delta, China: A case study in summer 2011. Atmos. Chem. Phys. 2014, 14, 4573–4585. [Google Scholar] [CrossRef]

- Karagulian, F.; Belis, C.A.; Dora, C.; Prüss-Ustün, A.M.; Bonjour, S.; Heather, A.; Amann, M. Contributions to cities’ ambient particulate matter (PM): A systematic review of local source contributions at global level. Atmos. Environ. 2015, 120, 475–483. [Google Scholar] [CrossRef]

- Chen, J.; Li, C.; Ristovski, Z.; Milic, A.; Gu, Y.; Islam, M.S.; Wang, S.; Hao, J.; Zhang, H.; He, C.; et al. A review of biomass burning: Emissions and impacts on air quality, health and climate in China. Sci. Total Environ. 2016, 579, 1000–1034. [Google Scholar] [CrossRef]

- Li, L.Y.; Xie, S.D.; Zeng, L.M.; Wu, R.; Jing, L. Characteristics of volatile organic compounds and their role in ground-level ozone formation in the Beijing-Tianjin-Hebei Region, China. Atmos. Environ. 2015, 113, 247–254. [Google Scholar] [CrossRef]

- Cheremisinoff, N.P. Pollution Control Handbook for Oil and Gas Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Curry, R. Approval and Promulgation of Implementation Plans; Texas; Revision to Control of Air Pollution from Volatile Organic Compounds. Alternative Leak Detection and Repair Work Practice. Available online: https://www.federalregister.gov/documents/2015/02/26/2015-03588/approval-and-promulgation-of-implementation-plans-texas-revision-to-control-of-air-pollution-from (accessed on 25 May 2021).

- Siegell, J.H. Exploring VOC Control Options. Chem. Eng. 1996, 103, 92–96. [Google Scholar]

- Du, J.J.; Qiang, N.; Zeng, P.; Long, H.Y.; Wang, J.C. The interpretation of “emission standard of air pollutants for pharmaceutical industry” (GB 37823—2019). Environ. Monit. Forewarn. 2020, 12, 1–8. [Google Scholar]

- Li, Y.W.; Zhang, G.F.; Chen, Y.H.; An, J.Y. Study on typical cases of equipment leak detection and repair project in chemical Industry. Shanghai Chem. Ind. 2017, 42, 22–25. [Google Scholar]

- Ding, D.W.; Jia, R.Z.; Zhu, S.J. Discussion on the application of relevant standards for leakage detection and repair (LDAR). Saf. Health Environ. 2018, 18, 86–89. [Google Scholar]

- Peng, Y.; Ji, S.; Zhao, Z.W.; Zheng, X.C.; Huang, H.Y. Research and evaluation recommendation on management system of leak detection and repair technology. Modern Chem. Ind. 2017, 37, 10–14. [Google Scholar]

- US Environmental Protection Agency. Leak Detection and Repair: A Best Practices Guide; US EPA: Washington, DC, USA, 2007.

- Wu, J.L.; Zou, C.; Wu, S.H. Calculation of VOCs source intensity and application of LDAR technology in petrochemical industry. Environ. Sci. Man. 2017, 42, 121–125. [Google Scholar]

- Chris, H.; Roger, M.; Julius, B. The experience in using LDAR for monitoring fugitive emissions of Volatile Organic Compounds with special reference to RasGas’ experience. Proc. Ann. Gas Process. Symp. 2010, 14, 51–58. [Google Scholar]

- Zhang, X.Y.; Gao, F.; Lv, J.W. Theoretical and empirical study on technologies of VOC LDAR. Environ. Sci. Man. 2017, 42, 138–142. [Google Scholar]

- Zhang, G.F.; Fei, B.; Xiu, G.L. Application research of leak detection and repair (LDAR) technology in paint manufacturing industry. Paint Coat. Ind. 2020, 50, 63–68. [Google Scholar]

- US EPA. Emissions Estimation Protocol for Petroleum Refineries Version 3. 2015. Available online: http://www.epa.gov/sites/production/files/2020-11/documents/protocol_report_2015.pdf (accessed on 10 April 2021).

- Epperson, D.; Lev-On, M.; Taback, H.; Siegell, J.; Ritter, K. Equivalent leak definitions for smart LDAR (leak detection and repair) when using optical imaging technology. Air Repair 2007, 57, 1050–1060. [Google Scholar] [CrossRef] [PubMed][Green Version]

| No. | Documents | Specific Requirements |

|---|---|---|

| 1 | National: The 13th Five Year Plan for Prevention and Control of Volatile Organic Compound Pollution | The implementation of LDAR should be promoted in industries such as pharmaceuticals (the first instance of such a requirement for LDAR implementation in this industry in a national document). |

| 2 | National: Comprehensive Treatment Scheme of Volatile Organic Compound in Key Industries | The control of volatile organic compound (VOC) in industries such as pharmaceuticals should be improved. LDAR should be implemented if there are 2000 or more components involved. |

| 3 | National: Emission Standard of Air Pollutants for Pharmaceutical Industry (GB 37823-2019) | If there are more than 2000 components in the equipment and pipeline components containing gaseous or liquid VOC in a pharmaceutical enterprise, LDAR technology should be used. Detection frequency: every 6 months for pumps, compressors, agitators, valves, open-valves or open-ended lines, pressure relief equipment, and sampling connection systems; every 12 months for flanges, other connectors, and other components. Threshold concentrations to identify leakage in key areas: ≥2000 μmol/mol for gaseous volatile organic compound (VOC) and volatile organic liquids; ≥500 μmol/mol for other liquid VOC. Threshold concentrations to identify leakage in common areas: ≥5000 μmol/mol for gaseous VOC and volatile organic liquids; ≥2000 μmol/mol for other liquid VOC. |

| 4 | Beijing: Emission Standards for Air Pollutants of Miscellaneous Organic Chemicals Manufacturing (DB 11/1385-2017) | For enterprises in industries such as those in the manufacturing of raw materials used to produce organic chemicals; pesticides; coatings/inks/pigments and similar products; special chemical products; and chemical bulk drug production, LDAR technologies including VOC detectors should be implemented with equipment or pipeline components that could possibly leak. Detection frequency: every 3 months for pumps and compressors; every 6 months for other equipment. Threshold concentration to identify leakage: ≥1000 μmol/mol for pumps and compressors with gas and volatile organic liquid flowing through them; ≥500 μmol/mol for other equipment. |

| 5 | Tianjin: Emission Control Standard for Industrial Enterprises Volatile Organic Compound (DB 12/524-2014) | Enterprises involved in refining petroleum or manufacturing petrochemicals and pharmaceuticals should enact pollution control measures, utilize LDAR technology, and record test data based on the requirements for controlling pollution from fugitive VOC. Detection frequency: every 3 months for gas/steam and light liquids. Threshold concentration to identify leakage: ≥2000 μmol/mol for pumps, compressors, and agitators; ≥500 μmol/mol for other equipment. |

| 6 | Jiangsu: Emission Standard of Volatile Organic Compound for Chemical Industry (DB 32/3151-2016) | Enterprises where VOC leakage is likely such as in industries involved in the manufacturing of raw materials to produce organic chemicals, organic and microbial fertilizer, pesticides, coatings/inks/pigments and similar products, special and daily chemical products, and biopharmaceuticals and chemical bulk drugs, in the preparation of chemical drugs, and in veterinary medicine production should implement LDAR technology according to the Guide for Leak Detection and Repair in Petrochemical Enterprises. |

| 7 | Zhengjiang: Emission Standard of Air Pollutants for Pharmaceutical Industry: Chemistry Synthesis Products Category (DB 33/2015-2016) | Enterprises in the chemically synthesized pharmaceutical industry should strengthen protocols to detect leaks in equipment and pipeline components containing VOC, such as reactors, tanks, valves, and flanges and other crevices to reduce fugitive exhaust gas emissions. |

| 8 | Hebei: Emission Control Standard of Volatile Organic CompoundsVolatile Organic Compound for Industrial Enterprises (DB 13/2322-2016) | LDAR should be implemented in the pharmaceuticals manufacturing, petroleum refining, petrochemicals, organic chemicals, and coking industries. Detection frequency: every 3 months for pumps, compressors, valves, open-valves or open-ended lines, gas/steam pressure relief equipment, and sampling connection systems; every 6 months for flanges, other connectors, and other components. Threshold concentration for identifying leakage: ≥2000 μmol/mol for equipment and pipeline components with organic gas and volatile organic liquid flowing through them; ≥500 μmol/mol for other equipment. |

| Enterprise | Location | Main Product Types | Output (unit: t/a) |

|---|---|---|---|

| A | Zhejiang | Chemical bulk drug | 190 |

| Pharmaceutical intermediates | 40 | ||

| B | Zhejiang | Preparation of chemical drug | 85 |

| C | Jiangsu | Pharmaceutical intermediates | 50 |

| D | Jiangsu | Biotin | 120 |

| E | Shanghai | Chemical bulk drug | 30 |

| F | Shanghai | Pharmaceutical intermediates | 34.5 |

| G | Shanghai | Chinese medicine | 40 |

| H | Guangdong | Pharmaceutical intermediates | 80 |

| I | Jiangxi | Chemical bulk drug | 135 |

| Enterprise | Total Number of Components | Number of Accessible Components | Number of Inaccessible Components and Proportion of the Total (%) |

|---|---|---|---|

| A | 22,436 | 20,842 | 1594 (7.10) |

| B | 8454 | 8128 | 326 (3.86) |

| C | 13,215 | 12,739 | 476 (3.60) |

| D | 13,551 | 13,005 | 546 (4.03) |

| E | 3521 | 3186 | 335 (9.51) |

| F | 9534 | 9232 | 302 (3.17) |

| G | 3632 | 3504 | 128 (3.52) |

| H | 4134 | 3956 | 178 (4.31) |

| I | 19,698 | 18,792 | 906 (4.60) |

| Sum | 98,175 | 93,384 | 4791 (4.88) |

| Enterprise | Flange | Valve | Connector | Open-Ended Line | Agitator | Pump | Others |

|---|---|---|---|---|---|---|---|

| A | 13,906 | 3459 | 2127 | 1119 | 0 | 1 | 230 |

| B | 4494 | 1430 | 1942 | 250 | 3 | 9 | 0 |

| C | 7049 | 2900 | 2411 | 326 | 23 | 22 | 8 |

| D | 3329 | 1877 | 7594 | 200 | 0 | 3 | 2 |

| E | 2360 | 541 | 192 | 77 | 0 | 16 | 0 |

| F | 4892 | 1914 | 2026 | 298 | 65 | 37 | 0 |

| G | 995 | 576 | 1784 | 143 | 4 | 2 | 0 |

| H | 2603 | 677 | 579 | 76 | 16 | 2 | 3 |

| I | 12,955 | 3932 | 1436 | 283 | 134 | 52 | 0 |

| Sum | 52,583 | 17,306 | 20,091 | 2772 | 245 | 144 | 243 |

| Enterprise | Total Number of Components | Number of Components with Leaks | Number of Components with Serious Leaks | Leak Ratio (%) |

|---|---|---|---|---|

| A | 20,842 | 175 | 9 | 0.96 |

| B | 8128 | 636 | 8 | 0.93 |

| C | 12,739 | 511 | 17 | 1.52 |

| D | 13,005 | 723 | 26 | 1.37 |

| E | 3186 | 77 | 7 | 2.43 |

| F | 9232 | 282 | 8 | 0.99 |

| G | 3504 | 19 | 0 | 0.27 |

| H | 3956 | 8 | 0 | 0.11 |

| I | 18,792 | 54 | 2 | 0.29 |

| Sum | 93,384 | 2485 | 77 | 0.99 (average) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Fei, B.; Xiu, G. Characteristics of Volatile Organic Compound Leaks from Equipment Components: A Study of the Pharmaceutical Industry in China. Sustainability 2021, 13, 6274. https://doi.org/10.3390/su13116274

Zhang G, Fei B, Xiu G. Characteristics of Volatile Organic Compound Leaks from Equipment Components: A Study of the Pharmaceutical Industry in China. Sustainability. 2021; 13(11):6274. https://doi.org/10.3390/su13116274

Chicago/Turabian StyleZhang, Gangfeng, Bo Fei, and Guangli Xiu. 2021. "Characteristics of Volatile Organic Compound Leaks from Equipment Components: A Study of the Pharmaceutical Industry in China" Sustainability 13, no. 11: 6274. https://doi.org/10.3390/su13116274

APA StyleZhang, G., Fei, B., & Xiu, G. (2021). Characteristics of Volatile Organic Compound Leaks from Equipment Components: A Study of the Pharmaceutical Industry in China. Sustainability, 13(11), 6274. https://doi.org/10.3390/su13116274