The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia

Abstract

:1. Introduction

2. Experimental Materials

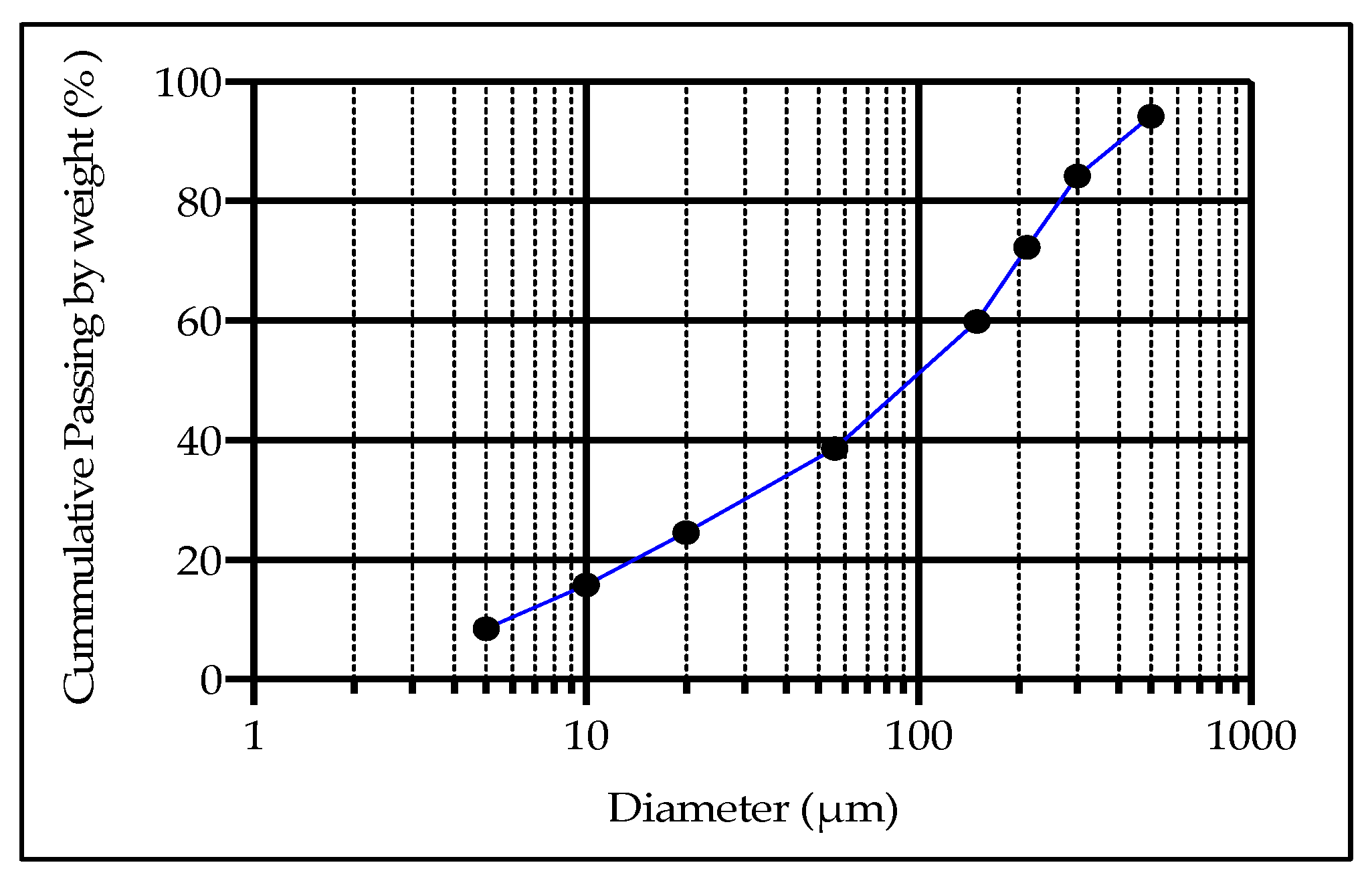

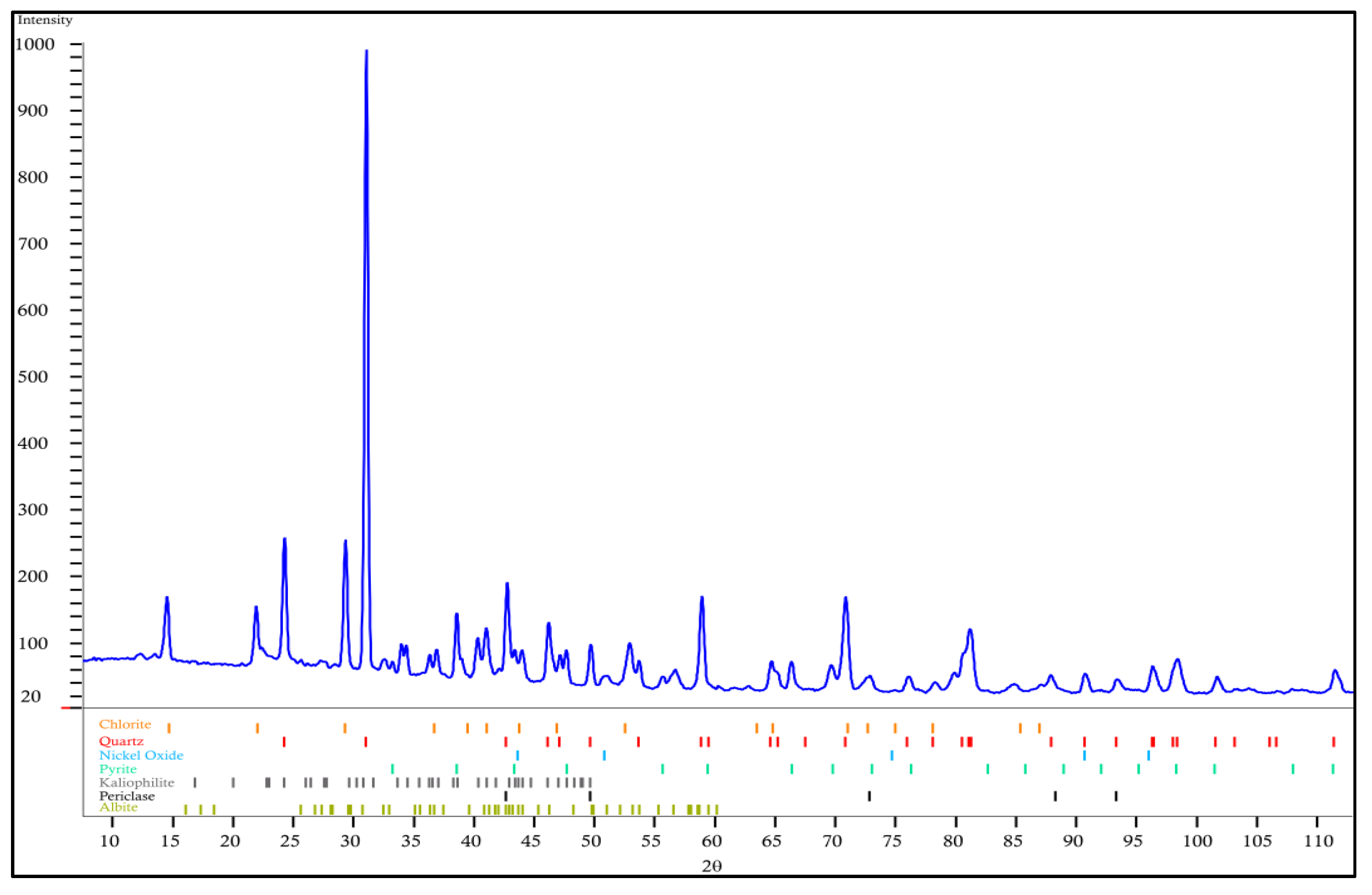

2.1. Tailings

2.2. Water

2.3. Binders

3. Experimental Design

3.1. Mixture Design

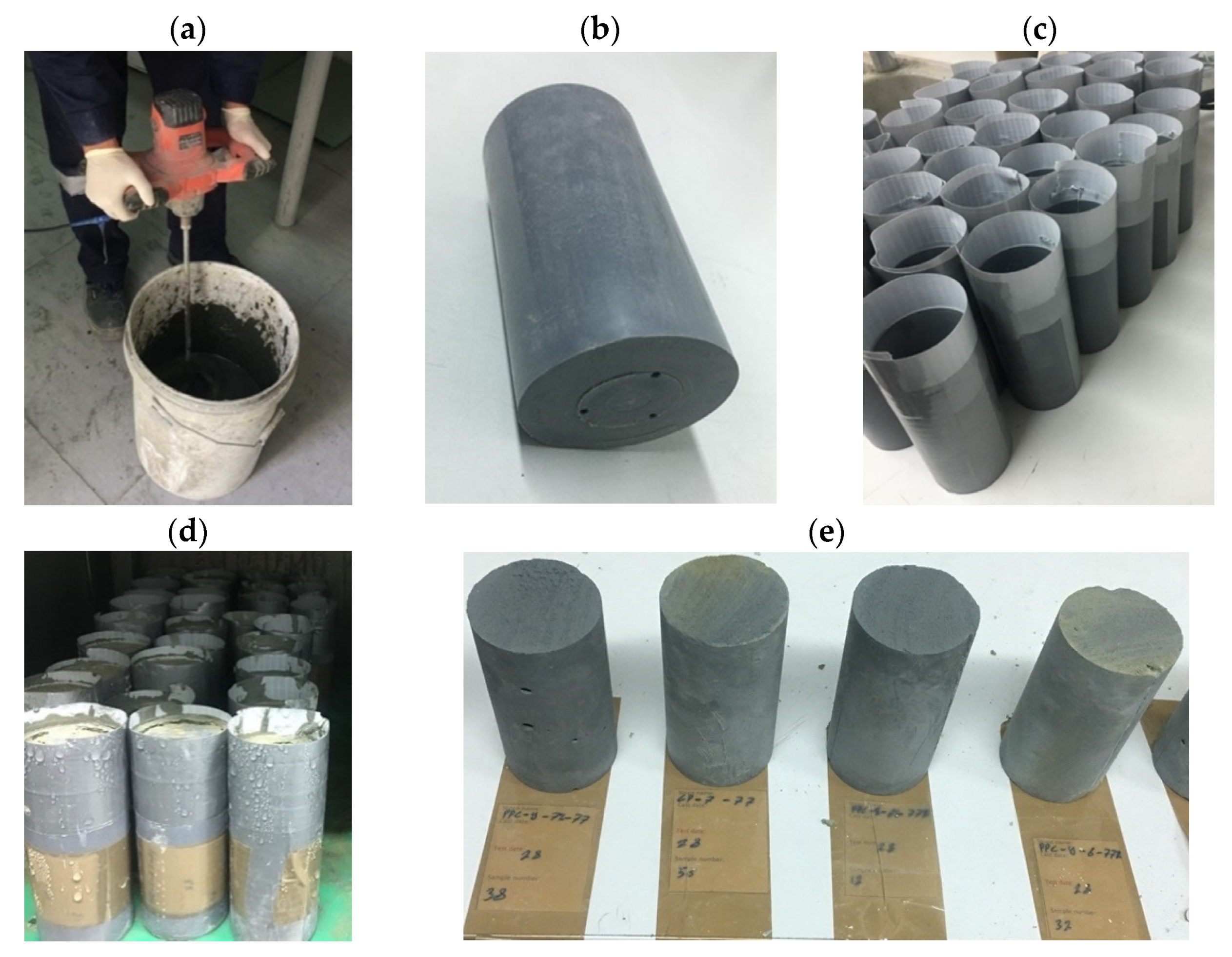

3.2. Preparation of Backfill Samples

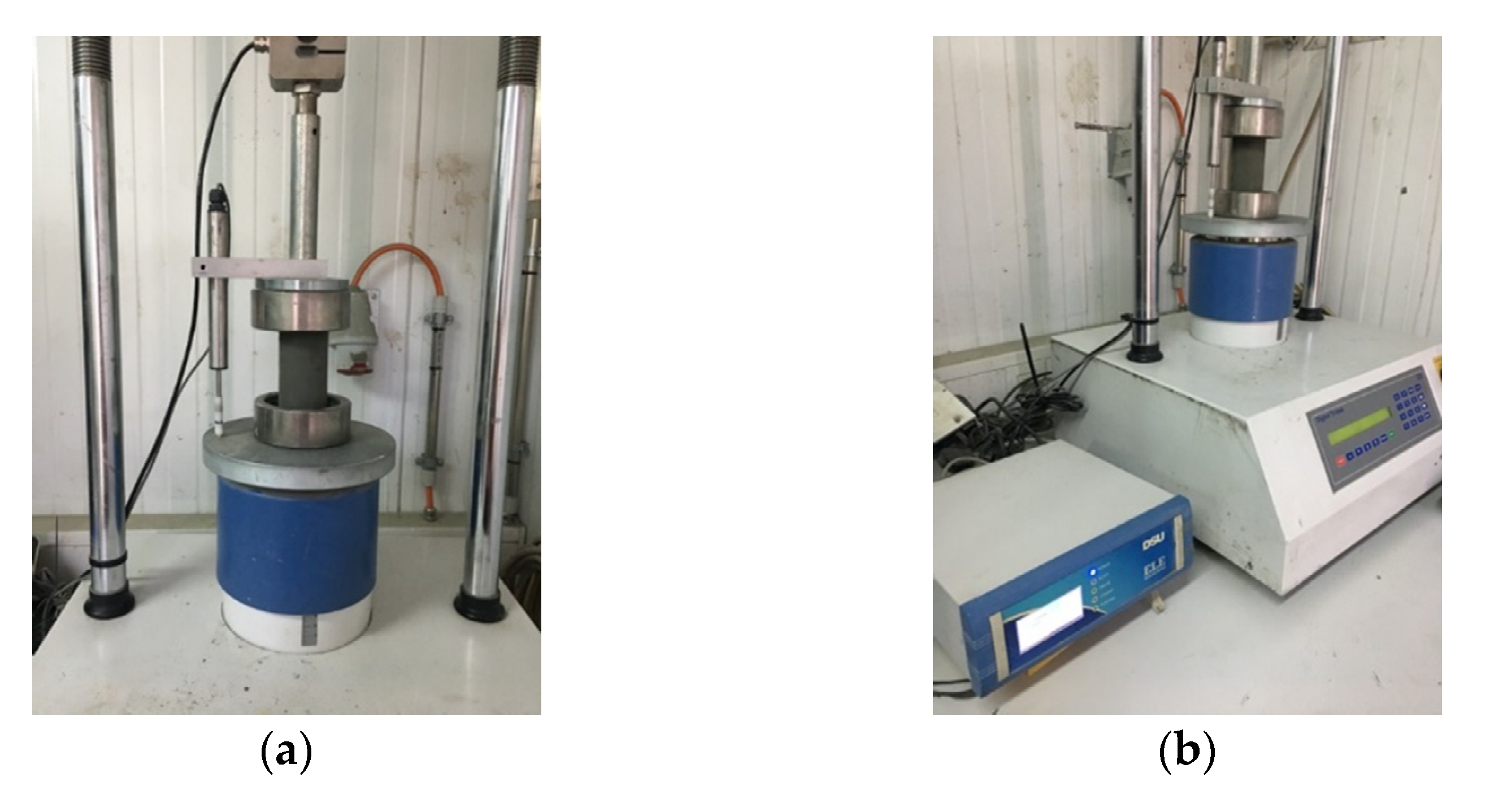

3.3. Unconfined Compressive Strength Testing

4. Results and Discussion

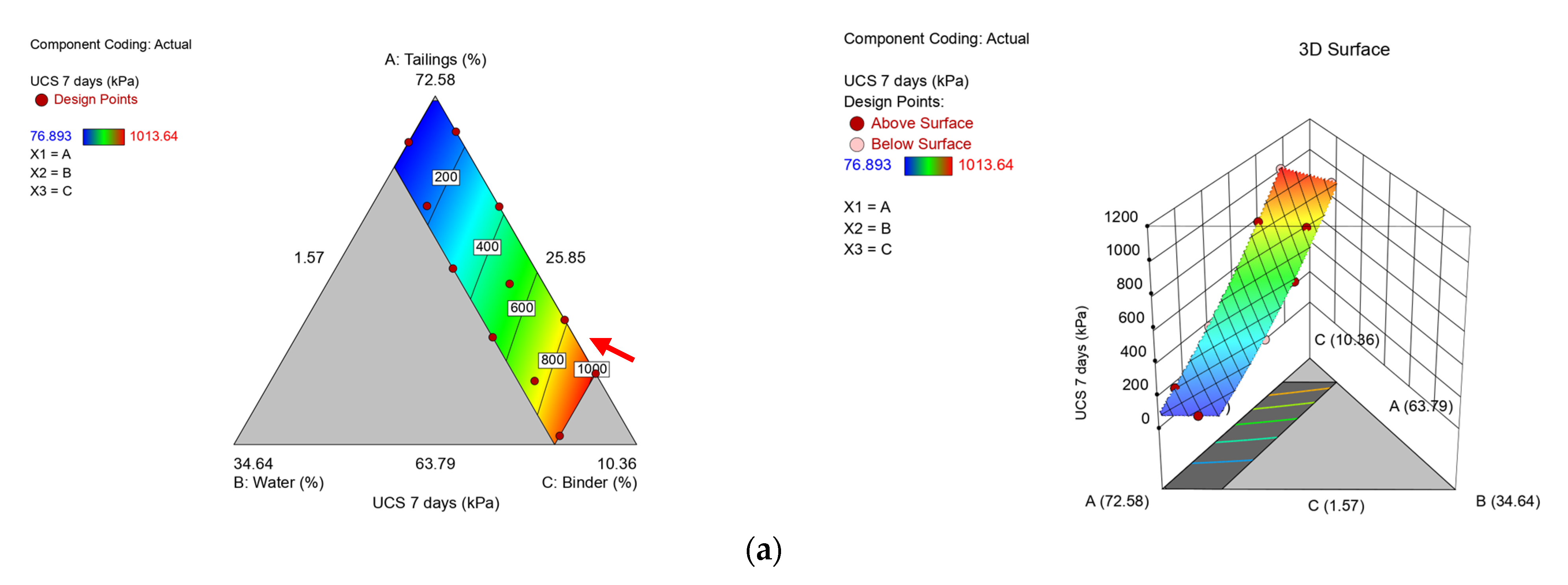

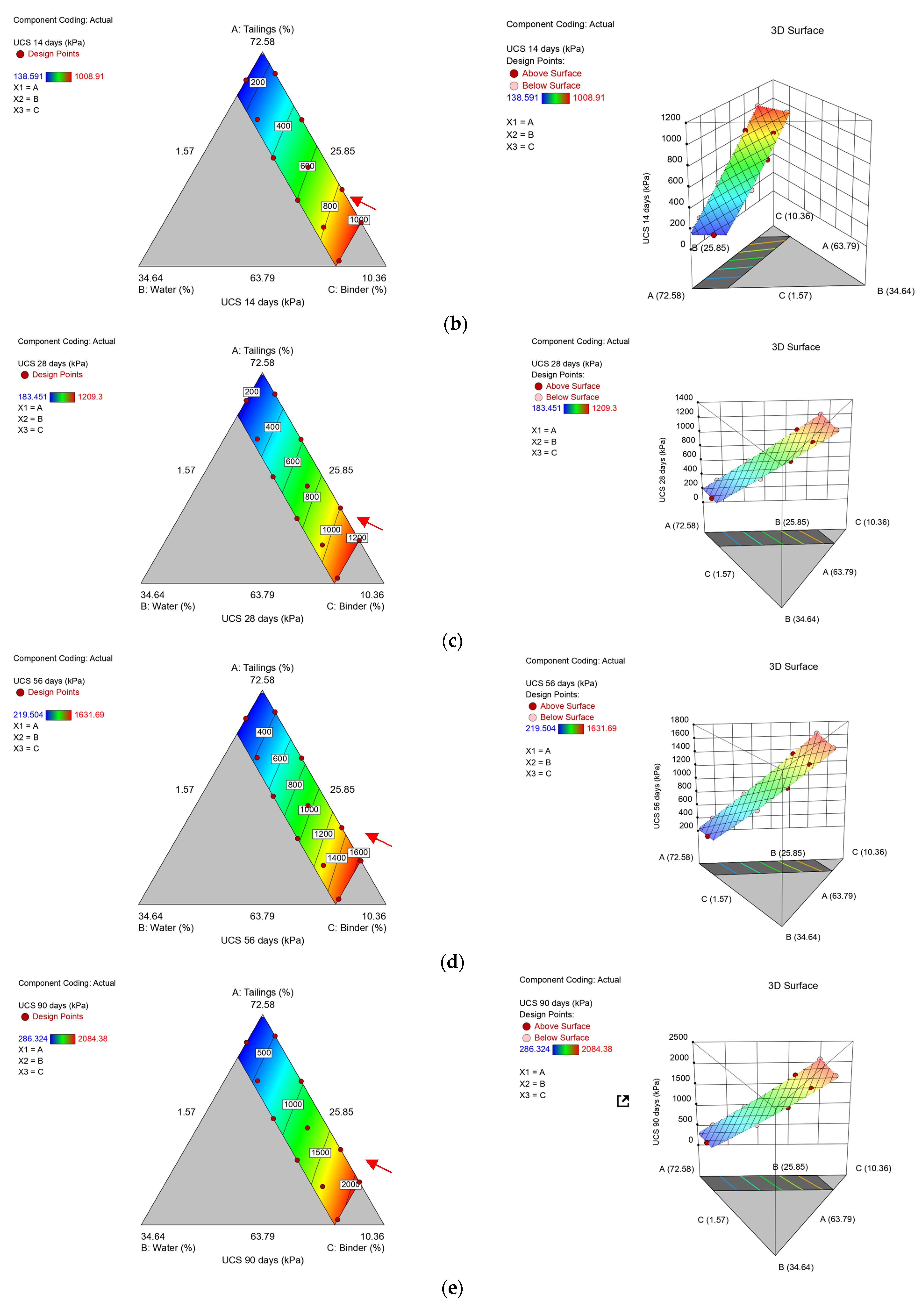

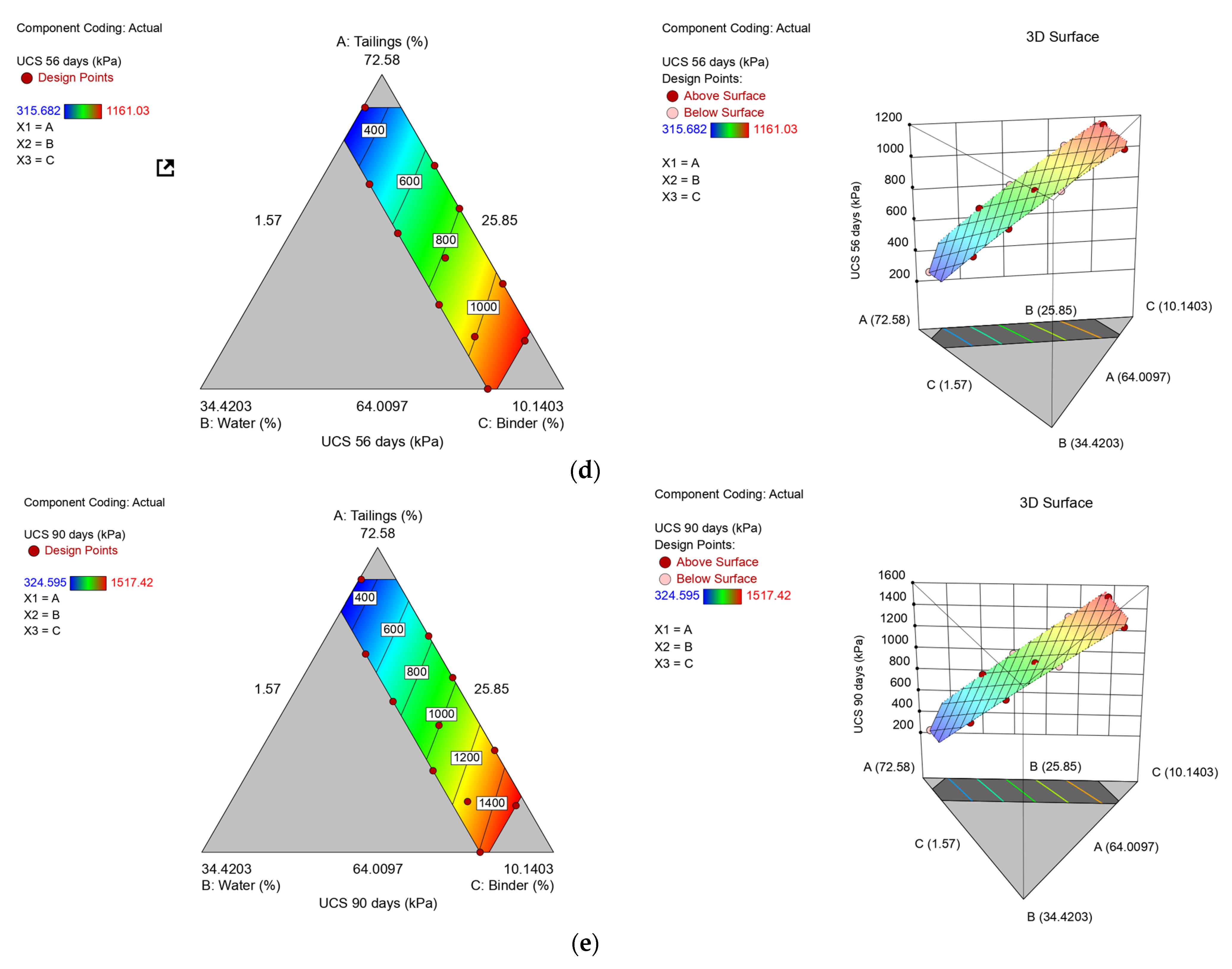

4.1. Interpretation of Model Output

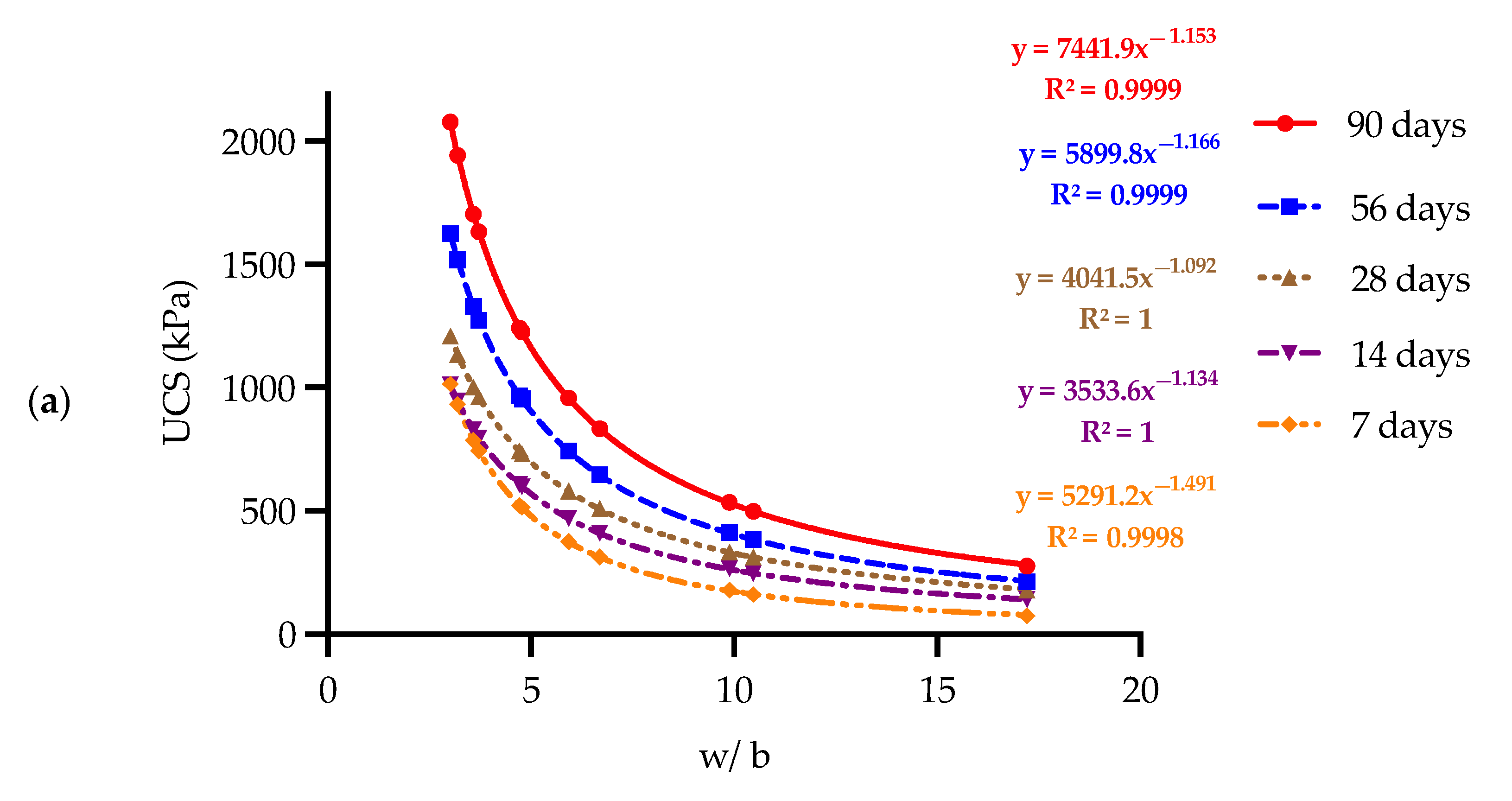

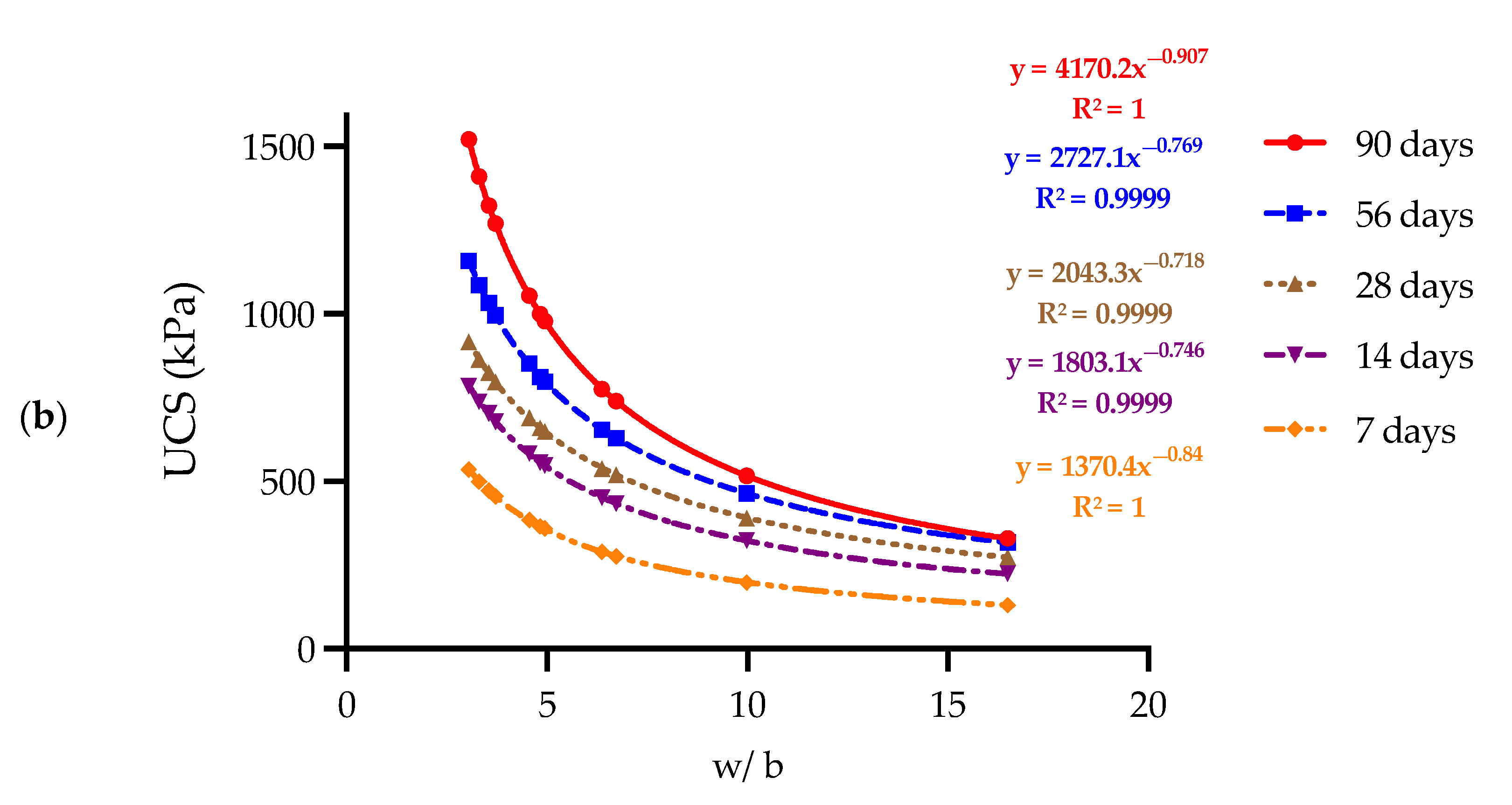

4.2. Effect of Water-to-Binder Ratio on UCS

5. Policy Implications

- Environment: the re-use of tailings in backfilling applications will support the implementation of clean mining technology to manage mine tailings in such a way as to protect the environment and to minimize the storage of tailings on the surface.

- Mine closure: the practice of mine backfilling is a part of progressive rehabilitation, which will not only facilitate closure, but also reduce closure costs and ensure sustainable land use after closure.

- Occupational health and safety: the implementation of backfill technology will help to reduce the number of accidents associated with the storage of tailings on the surface and enhance the safety of the working environment. For example, backfill technology implemented in a Chinese coal mine resolved issues related to surface subsidence caused by underground mining activities [71].

- Social responsibility: the Saudi regulations require applicants for a mining license to conduct an environmental and social impact study. Mine backfilling with tailings will minimize the negative impacts on surrounding communities who are directly affected by mining activities.

6. Conclusions

- The statistical design of the experiments was effective for developing models to predict backfill UCS as a function of tailings, water, and binder content and interactions among these factors.

- The UCS values for CPB increased with curing time. The maximum UCS after 90 days depended on CPB composition. UCS development (and possible degradation) after 90 days should be a focus of future studies.

- The pozzolanic cement used as a binder affected the maximum UCS achieved. Future research is encouraged to investigate other environmentally friendly binders that could improve the mechanical properties of the CPB and lower operational costs.

- The selected Saudi copper tailings can be used in mine backfill: the CPB samples developed UCS typical for CPB (<2 MPa), making them useful for various purposes (e.g., cut and fill mining and free-standing applications).

- These bench-scale experimental results are promising for the use of selected copper tailings in mine backfill. However, field trials are required to demonstrate their application to an operational setting.

- Microstructural studies are encouraged to better understand the effect of different recipes at the microscopic level, for example, using scanning electron microscopy.

- In Saudi Arabia, the number of mines and range of target minerals is expected to increase to achieve the Saudi 2030 vision. Therefore, future research should also focus on the re-use of other tailings (e.g., gold tailings) for mine backfilling.

- Mine backfilling can contribute to complying with regulatory requirements in Saudi Arabia and promote sustainability in the mining sector. It is a practical method to minimize the environmental damage caused by the surface disposal of mine tailings, especially those containing sulfide-bearing minerals.

- Site-specific quantitative and qualitative (expert opinion) techno-economic assessments addressing technical, technological, economic, social, and environmental factors (per [22]) should be conducted for all stages of new and existing mine operations prior to the implementation of mine backfilling or other techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Wang, C.; Harbottle, D.; Liu, Q.; Xu, Z. Current state of fine mineral tailings treatment: A critical review on theory and practice. Miner. Eng. 2014, 58, 113–131. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Tang, X.; Zhang, Q.; Gao, R. Data-driven modelling of the flocculation process on mineral processing tailings treatment. J. Clean. Prod. 2018, 196, 505–516. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Y.; Li, S.; Wei, Z. Improvement of traditional mining tailings storage facilities. J. Residuals Sci. Technol. 2016, 13, S11–S14. [Google Scholar] [CrossRef]

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards mine tailings valorization: Recovery of critical materials from Chilean mine tailings. J. Clean. Prod. 2019, 263, 121555. [Google Scholar] [CrossRef]

- Kinnunen, P.H.M.; Kaksonen, A.H. Towards circular economy in mining: Opportunities and bottlenecks for tailings valorization. J. Clean. Prod. 2019, 228, 153–160. [Google Scholar] [CrossRef]

- Kinnunen, P.; Obenaus-Emler, R.; Raatikainen, J.; Guignot, S.; Guimerà, J.; Ciroth, A.; Heiskanen, K. Review of closed water loops with ore sorting and tailings valorisation for a more sustainable mining industry. J. Clean. Prod. 2021, 278, 123237. [Google Scholar] [CrossRef]

- Bellenfant, G.; Guezennec, A.-G.; Bodenan, F.; D’Hugues, P.; Cassard, D. Reprocessing of mining waste: Combining environmental management and metal recovery? In Proceedings of the Eighth International Seminar on Mine Closure, Cornwall, UK, 18–20 September 2013. [Google Scholar] [CrossRef] [Green Version]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Carneiro, A.; Fourie, A. Assessing the impacts of uncertain future closure costs when evaluating strategies for tailings management. J. Clean. Prod. 2020, 247, 119173. [Google Scholar] [CrossRef]

- Mamelkina, M.A.; Heraiz-Carboné, M.; Cotillas, S.; Lacasa, E.; Sáez, C.; Tuunila, R.; Sillanpää, M.; Häkkinen, A.; Rodrigo, M.A. Treatment of mining wastewater polluted with cyanide by coagulation processes: A mechanistic study. Sep. Purif. Technol. 2020, 237, 116345. [Google Scholar] [CrossRef]

- Skorohodov, V.; Nikitin, R.; Biryukov, V.; Kitaev, A. A mining-industrial waste water treatment technology: Justification of parametres using computer simulation. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying, Geology and Mining, Ecology and Management, SGEM, Albena, Bulgaria, 16–25 August 2020. [Google Scholar] [CrossRef]

- Modoi, O.C.; Roba, C.; Török, Z.; Ozunu, A. Environmental risks due to heavy metal pollution of water resulted from mining wastes in NW Romania. Environ. Eng. Manag. J. 2014, 13, 2325–2336. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef] [Green Version]

- Taha, Y.; Benzaazoua, M. Editorial for special issue ‘Towards a sustainable management of mine wastes: Reprocessing, reuse, revalorization, and repository. Minerals 2020, 10, 21. [Google Scholar] [CrossRef] [Green Version]

- Pličanič, S.; Mladenović, A.; Pranjić, A.M.; Vrhovnik, P. Mining waste in circular economy—Legislative aspect. Geol. Maced. 2020, 34, 149–156. [Google Scholar] [CrossRef]

- Breitenbach, A.J. Overview: Tailings disposal and dam construction practices in the 21 st century. In Proceedings of the Tailings and Mine Waste’10—14th International Conference on Tailings and Mine Waste, Vail, CO, USA, 17–20 October 2010. [Google Scholar]

- Fourie, A. Preventing catastrophic failures and mitigating environmental impacts of tailings storage facilities. Procedia Earth Planet. Sci. 2009, 1, 1067–1071. [Google Scholar] [CrossRef] [Green Version]

- Oberle, B.; Brereton, D.; Mihaylova, A. Towards Zero Harm: A Compendium of Papers Prepared for the Global Tailings Review; GRID-Arendal: Arendal, Norway, 2020. [Google Scholar]

- Lottermoser, B.G. Mine Wastes Characterization, Treatment and Environmental Impacts, 2nd ed.; Springer: New York, NY, USA; Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Songolo, M.; Moono, W.S.; Mwenya, W.M. Achieving Sustainable Mine Waste Management Practices through Capacity Building of Stakeholder Engagement the Case of the Zambian Minerals Industry. Am. Sci. Res. J. Eng. Technol. Sci. 2016, 26, 39–51. [Google Scholar]

- Rakhmangulov, A.; Burmistrov, K.; Osintsev, N. Sustainable open pit mining and technical systems: Concept, principles, and indicators. Sustainability 2021, 13, 1101. [Google Scholar] [CrossRef]

- Segura-Salazar, J.; Tavares, L.M. Sustainability in the minerals industry: Seeking a consensus on its meaning. Sustainability 2018, 10, 1429. [Google Scholar] [CrossRef] [Green Version]

- D’Adamo, I.; Lupi, G. Sustainability and resilience after COVID-19: A circular premium in the fashion industry. Sustainability 2021, 13, 1861. [Google Scholar] [CrossRef]

- Lottermoser, B.G. Mine Wastes: Characterization, Treatment and Environmental Impacts, 3rd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Karaoglu, K.; Yilmaz, E. Cemented paste backfill pressure monitoring and field testing. In Paste Tailings Management; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Yilmaz, E.; Kesimal, A.; Erçikdi, B. The factors affecting strength and stability of paste backfill|Macun doglu dayanimini ve durayliliǧini etkileyen faktörler. Yerbilimleri Bull. Earth Sci. 2003, 28, 155–169. [Google Scholar]

- Panchal, S.; Deb, D.; Sreenivas, T. Mill tailings based composites as paste backfill in mines of U-bearing dolomitic limestone ore. J. Rock Mech. Geotech. Eng. 2018, 10, 310–322. [Google Scholar] [CrossRef]

- Ercikdi, B.; Külekci, G.; Yilmaz, T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings. Constr. Build. Mater. 2015, 93, 573–583. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Deveci, H.; Erdemir, F. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: Effect of activator nature, concentration and slag properties. Miner. Eng. 2015, 83, 117–127. [Google Scholar] [CrossRef]

- Hefni, M.A. The potential use of pumice in mine backfill. Exp. Results 2020, 1, e56. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, Ì. Effect of natural pozzolans as mineral admixture on the performance of cemented-paste backfill of sulphide-rich tailings. Waste Manag. Res. 2010, 28, 430–435. [Google Scholar] [CrossRef] [PubMed]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of viscosity, strength and microstructural properties of cemented tailings backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, E.; Yilmaz, E. Sustainability and Tailings Management in the Mining Industry: Paste Technology. Mugla J. Sci. Technol. 2018, 4, 16–26. [Google Scholar] [CrossRef]

- Yilmaz, E.; Fall, M. Paste Tailings Management; Springer: Cham, Switzerland, 2017; ISBN 9783319396828. [Google Scholar]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-thinking mining waste through an integrative approach led by circular economy aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef] [Green Version]

- Gayana, B.C.; Chandar, K.R. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements—A review. Adv. Concr. Constr. 2018, 6, 221–243. [Google Scholar] [CrossRef]

- Hirschi, J.C.; Chugh, Y.P. Sustainable coal waste disposal practices. In Advances in Productive, Safe, and Responsible Coal Mining; Woodhead: Cambridge, UK, 2018. [Google Scholar]

- Ivannikov, A.L.; Kongar-Syuryun, C.; Rybak, J.; Tyulyaeva, Y. The reuse of mining and construction waste for backfill as one of the sustainable activities. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 362. [Google Scholar] [CrossRef]

- Tariq, A.; Yanful, E.K. A review of binders used in cemented paste tailings for underground and surface disposal practices. J. Environ. Manag. 2013, 131, 138–149. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Belem, T.; Bussière, B. Chemical factors that influence the performance of mine sulphidic paste backfill. Cem. Concr. Res. 2002, 32, 1133–1144. [Google Scholar] [CrossRef]

- Hefni, M.; Ali, M.A. The Potential to Replace Cement with Nano-Calcium Carbonate and Natural Pozzolans in Cemented Mine Backfill. Adv. Civ. Eng. 2021, 2021, 5574761. [Google Scholar] [CrossRef]

- Eshun, S.N.; Gidigasu, S.S.R.; Gawu, S.K.Y. The Effect of Clay Pozzolana-Cement-Composite on the Strength Development of a Hydraulic Backfill. Ghana Min. J. 2018, 18, 32–38. [Google Scholar] [CrossRef]

- Rosca, E.; Arnold, M.; Bendul, J.C. Business models for sustainable innovation—An empirical analysis of frugal products and services. J. Clean. Prod. 2017, 162, S133–S145. [Google Scholar] [CrossRef]

- Sivakugan, N.; Rankine, R.M.; Rankine, K.J.; Rankine, K.S. Geotechnical considerations in mine backfilling in Australia. J. Clean. Prod. 2006, 14, 1168–1175. [Google Scholar] [CrossRef]

- Niroshan, N.; Sivakugan, N.; Veenstra, R.L. Laboratory Study on Strength Development in Cemented Paste Backfills. J. Mater. Civ. Eng. 2017, 29, 04017027. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.K. High-performance, high-volume fly ash concrete for sustainable development. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004. [Google Scholar]

- Yang, K.H.; Jung, Y.B.; Cho, M.S.; Tae, S.H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Hefni, M.; Hassani, F. Effect of air entrainment on cemented mine backfill properties: Analysis based on response surface methodology. Minerals 2021, 11, 81. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Sp. Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Wu, A.; Wang, Y.; Wang, H.; Yin, S.; Miao, X. Coupled effects of cement type and water quality on the properties of cemented paste backfill. Int. J. Miner. Process. 2015, 143, 65–71. [Google Scholar] [CrossRef]

- Mahlaba, J.S.; Kearsley, E.P.; Kruger, R.A.; Pretorius, P.C. Evaluation of workability and strength development of fly ash pastes prepared with industrial brines rich in so 4 = and Cl- to expand brine utilisation. Miner. Eng. 2011, 24, 1077–1081. [Google Scholar] [CrossRef]

- ASTM International. ASTM D2166/D2166M-16, Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Hassani, F.; Archibald, J. Mine Backfill; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 1998. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014; Available online: https://www.accessengineeringlibrary.com/content/book/9780071797870 (accessed on 18 May 2021).

- Potvin, Y.; Thomas, E.; Fourie, A. Handbook on Mine Fill; Australian Centre for Geomechanics: Nedlands, Western Australia, Australia, 2005. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Third Edition Prentice; Hall, Inc.: Englewood Cliffs, NJ, USA, 2006. [Google Scholar]

- Liu, J.; Li, G.; Yang, S.; Huang, J. Prediction models for evaluating the strength of cemented paste backfill: A comparative study. Minerals 2020, 10, 1041. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Peyronnard, O.; Belem, T.; Stephant, A.; Dublet, G. Key issues related to behaviour of binders in cemented paste backfilling. In Proceedings of the Thirteenth International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 May 2010. [Google Scholar] [CrossRef] [Green Version]

- Walker, R.; Pavía, S. Physical properties and reactivity of pozzolans, and their influence on the properties of lime-pozzolan pastes. Mater. Struct. Constr. 2011, 44, 1139–1150. [Google Scholar] [CrossRef] [Green Version]

- Mahedi, M.; Cetin, B.; White, D.J. Cement, Lime, and Fly Ashes in Stabilizing Expansive Soils: Performance Evaluation and Comparison. J. Mater. Civ. Eng. 2020, 32, 04020177. [Google Scholar] [CrossRef]

- Amaratunga, L.M.; Yaschyshyn, D.N. Development of a high modulus paste fill using fine gold mill tailings. Geotech. Geol. Eng. 1997, 15, 205–219. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Zhang, X.; Li, J. A Novel Prediction Model of Strength of Paste Backfill Prepared from Waste-Unclassified Tailings. Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Salvoldi, B.; van der Spuy, B.; Wilson, S. Optimisation of cemented aggregate backfill at New Luika Gold Mine. In Proceedings of the 22nd International Conference on Paste, Thickened and Filtered Tailings, Cape Town, South Africa, 8–10 May 2019. [Google Scholar] [CrossRef] [Green Version]

- Chang, Q.; Chen, J.; Zhou, H.; Bai, J. Implementation of paste backfill mining technology in Chinese coal mines. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

| Cumulative Passing (wt.%) | SG | Cu 1 | Cc 2 | ||||

|---|---|---|---|---|---|---|---|

| D10 | D30 | D50 | D60 | D90 | |||

| 14.70 | 29.91 | 36.89 | 40.04 | 48.69 | 2.95 | 2.72 | 1.52 |

| SiO2 | FeO | Al2O3 | SO3 | MgO | CaO | Na2O | NiO | K2O | Cu | Cr2O3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 49.78 | 13.89 | 11.97 | 9.55 | 9.13 | 3.89 | 0.90 | 0.27 | 0.25 | 0.23 | 0.13 |

| Property | Value |

|---|---|

| Appearance | Clear |

| pH @ 20 °C | 7.4 |

| Electrical conductivity @ 25 °C (µS/cm) | 1320 |

| Total dissolved solids (mg/L) | 806 |

| Turbidity (NTU) | 0.2 |

| Total hardness (mg/L) | 159 |

| Bicarbonate (mg/L) | 144 |

| Carbonate (mg/L) | <1 |

| Total alkalinity (mg/L CaCO3) | 118 |

| Oxide | PPC1 (wt.%) | PPC2 (wt.%) |

|---|---|---|

| CaO | 55.43 | 49.42 |

| SiO2 | 23.80 | 24.94 |

| Al2O3 | 5.48 | 7.52 |

| Fe2O3 | 5.83 | 6.49 |

| MgO | 4.97 | 3.31 |

| SO3 | 2.29 | 2.75 |

| K2O | 0.34 | 0.51 |

| Na2O | 0.57 | 1.21 |

| Code | Ingredient | PPC1 | PPC2 | ||

|---|---|---|---|---|---|

| Low (wt.%) | High (wt.%) | Low (wt.%) | High (wt.%) | ||

| A | Tailings | 64.01 | 71.68 | 64.01 | 71.68 |

| B | Water | 25.85 | 27.64 | 25.85 | 27.64 |

| C | Binder | 1.57 | 8.57 | 1.62 | 8.57 |

| Recipe | PPC1 | PPC2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Tailings (wt.%) | Water (wt.%) | Binder (wt.%) | w/b | Tailings (wt.%) | Water (wt.%) | Binder (wt.%) | w/b | |

| 1 | 65.58 | 25.85 | 8.57 | 3.02 | 69.59 | 27.64 | 2.77 | 9.98 |

| 2 | 66.93 | 25.85 | 7.22 | 3.58 | 65.44 | 27.23 | 7.33 | 3.71 |

| 3 | 65.39 | 27.27 | 7.33 | 3.72 | 67.58 | 26.85 | 5.56 | 4.83 |

| 4 | 66.50 | 27.64 | 5.86 | 4.72 | 68.93 | 25.85 | 5.22 | 4.95 |

| 5 | 71.41 | 27.02 | 1.57 | 17.21 | 66.30 | 27.64 | 6.06 | 4.56 |

| 6 | 68.23 | 27.64 | 4.13 | 6.69 | 71.68 | 26.70 | 1.62 | 16.48 |

| 7 | 71.68 | 25.85 | 2.47 | 10.47 | 66.88 | 25.85 | 7.27 | 3.56 |

| 8 | 67.84 | 26.60 | 5.56 | 4.78 | 70.10 | 25.85 | 4.05 | 6.38 |

| 9 | 69.79 | 25.85 | 4.36 | 5.93 | 64.01 | 27.64 | 8.35 | 3.31 |

| 10 | 64.01 | 27.42 | 8.57 | 3.20 | 68.25 | 27.64 | 4.11 | 6.73 |

| 11 | 69.81 | 27.42 | 2.77 | 9.90 | 65.32 | 26.11 | 8.57 | 3.05 |

| Model | 7 Day | 14 Day | 28 Day | 56 Day | 90 Day |

|---|---|---|---|---|---|

| R2 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Adjusted R2 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 |

| Predicted R2 | 0.99 | 0.99 | 1.00 | 0.99 | 0.99 |

| p value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| F value | 2.313 × 104 | 1.002 × 105 | 2.347 × 105 | 8.813 × 104 | 1.002 × 105 |

| CV% | 0.5887 | 0.2311 | 0.1449 | 0.2485 | 0.2311 |

| Standard deviation | 3.00 | 1.32 | 1.02 | 2.29 | 2.73 |

| PRESS | 247.69 | 50.42 | 30.09 | 150.78 | 215.22 |

| Model | 7 Day | 14 Day | 28 Day | 56 Day | 90 Day |

|---|---|---|---|---|---|

| R2 | 1.00 | 0.99 | 0.99 | 1.00 | 1.00 |

| Adjusted R2 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 |

| Predicted R2 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 |

| p value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| F value | 3.512 × 104 | 1.792 × 104 | 1.197 × 104 | 2.187 × 104 | 2.298 × 105 |

| CV% | 0.2609 | 0.3429 | 0.3992 | 0.3170 | 0.1125 |

| Standard deviation | 0.9625 | 1.87 | 2.62 | 2.54 | 1.11 |

| PRESS | 48.97 | 184.88 | 361.57 | 340.41 | 65.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia. Sustainability 2021, 13, 6204. https://doi.org/10.3390/su13116204

Hefni M, Ahmed HAM, Omar ES, Ali MA. The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia. Sustainability. 2021; 13(11):6204. https://doi.org/10.3390/su13116204

Chicago/Turabian StyleHefni, Mohammed, Hussin A. M. Ahmed, Ebaa Shaikh Omar, and Maaz A. Ali. 2021. "The Potential Re-Use of Saudi Mine Tailings in Mine Backfill: A Path towards Sustainable Mining in Saudi Arabia" Sustainability 13, no. 11: 6204. https://doi.org/10.3390/su13116204