Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption?

Abstract

:1. Introduction

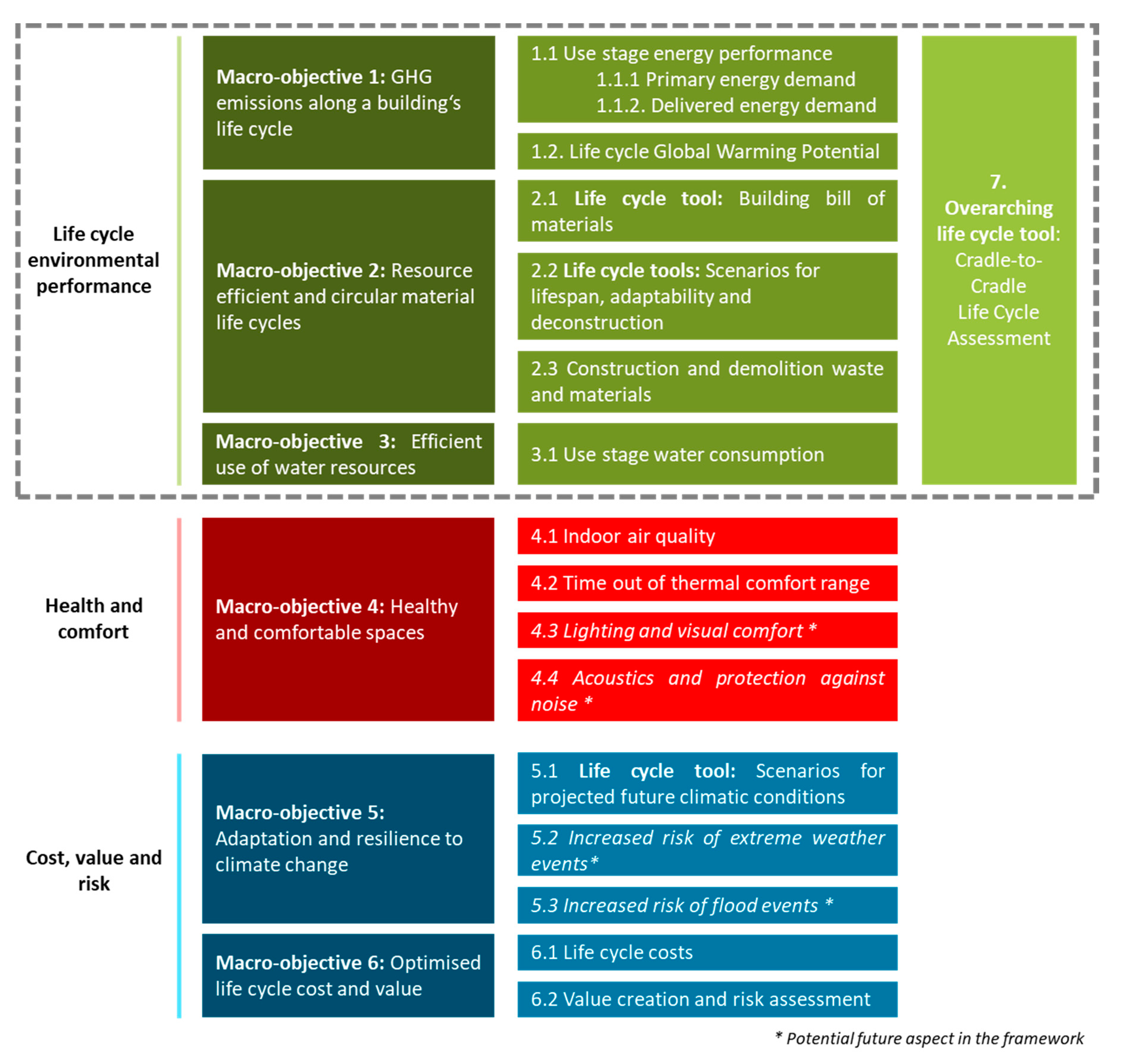

1.1. Green Building Rating Systems as Tool for Building Sustainability Assessment

1.2. Use of Environmental Product Declarations as Life-Cycle Assessment (LCA) Data Source within Green Building Rating Systems (GBRSs): Opportunities and Challenges

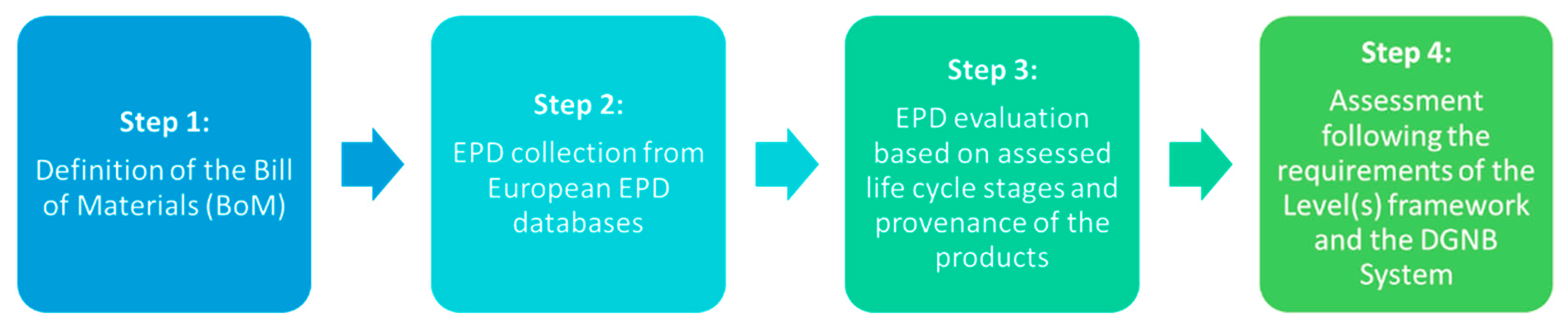

2. Materials and Methods

2.1. The Research Model

2.1.1. Step 1: Definition of the Bill of Materials

2.1.2. Step 2: Environmental Product Declarations (EPDs) Collection

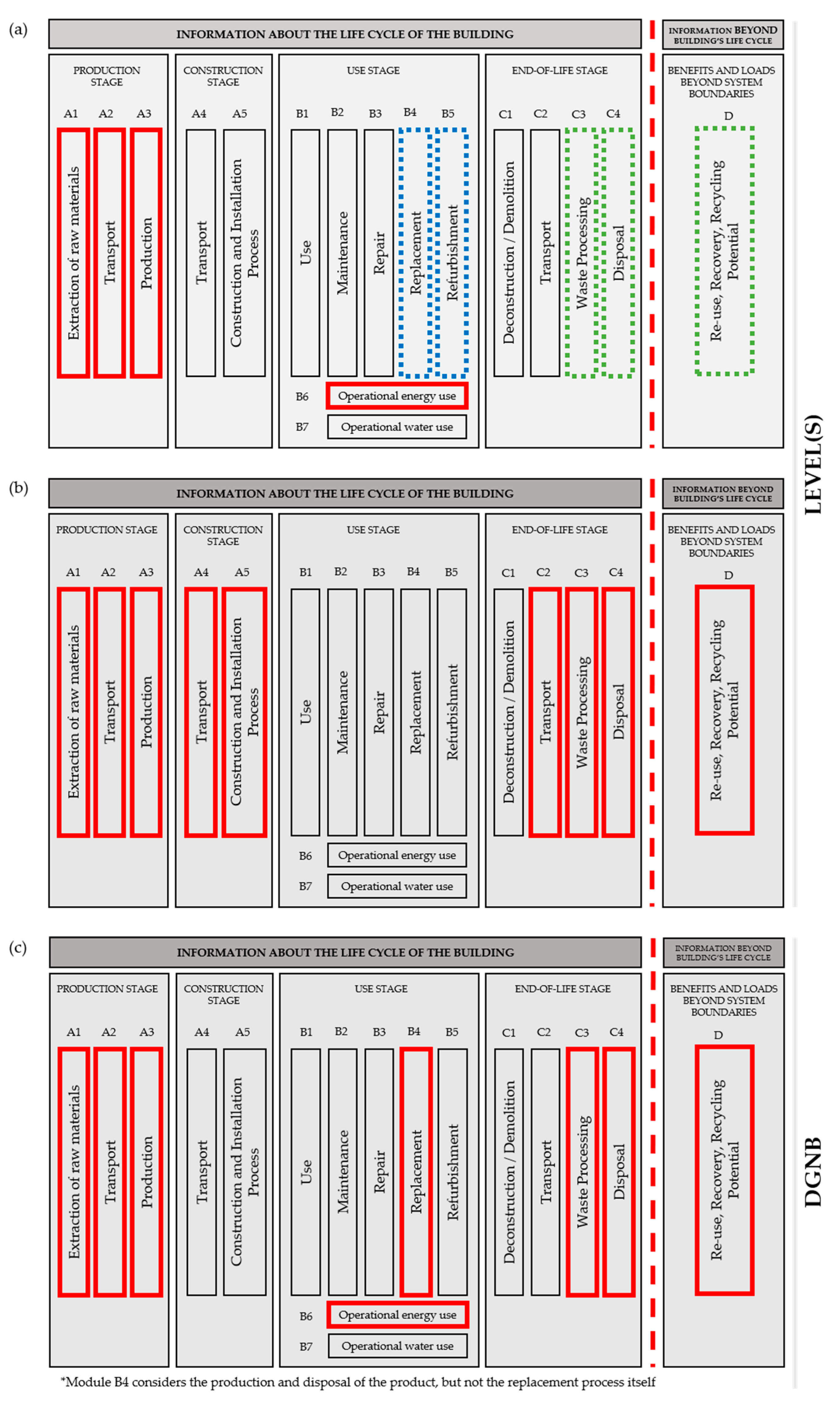

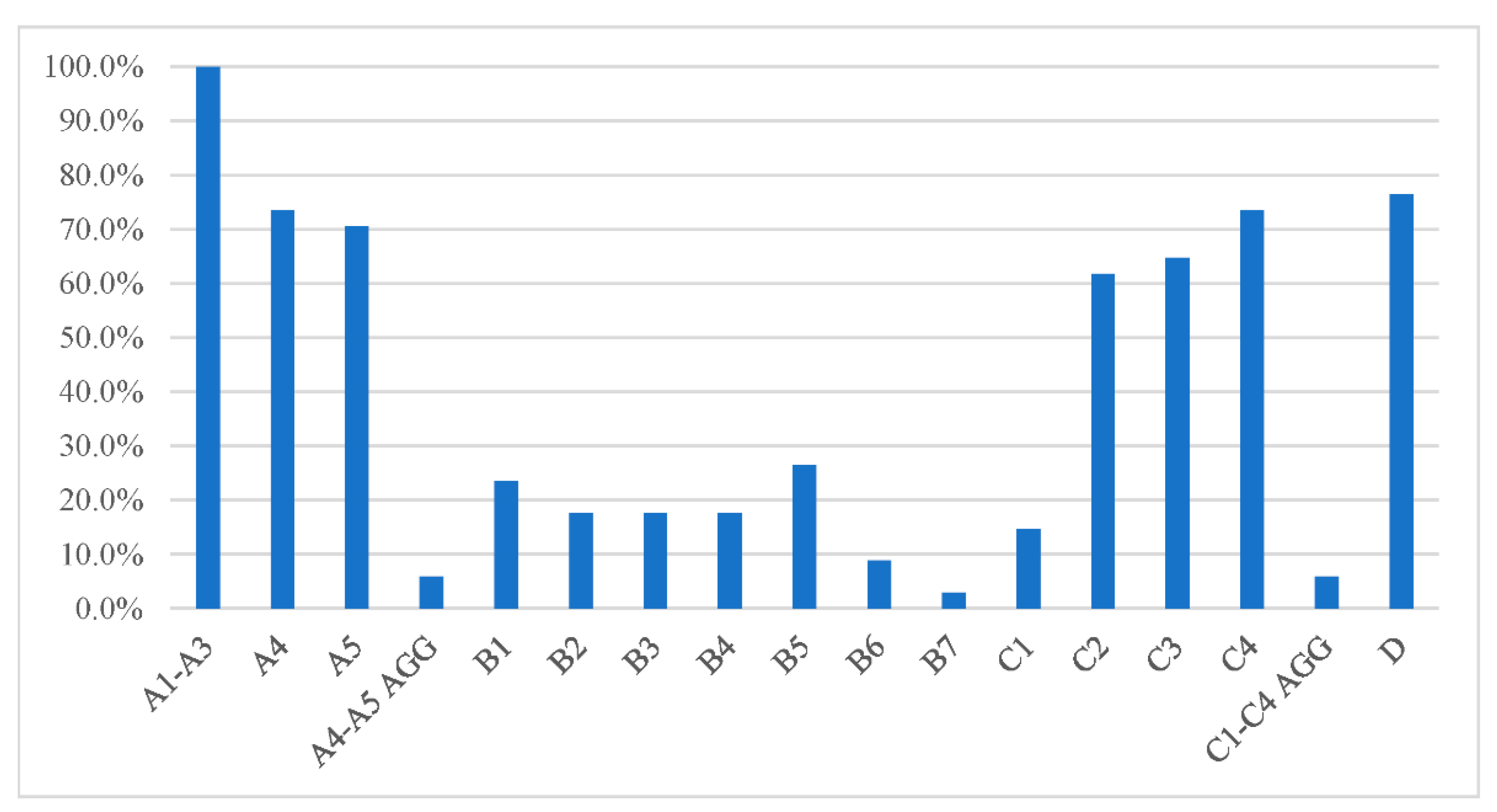

2.1.3. Step 3: EPD Evaluation

- Assessed life-cycle stages in the EPDs;

- Provenance of the product.

2.1.4. Step 4: Assessment Following the Requirements of the Level(s) Framework and the DGNB (Deutsche Gesellschaft für Nachhaltiges Bauen) System

2.2. The Case Study

3. Results

3.1. EPD Evaluation

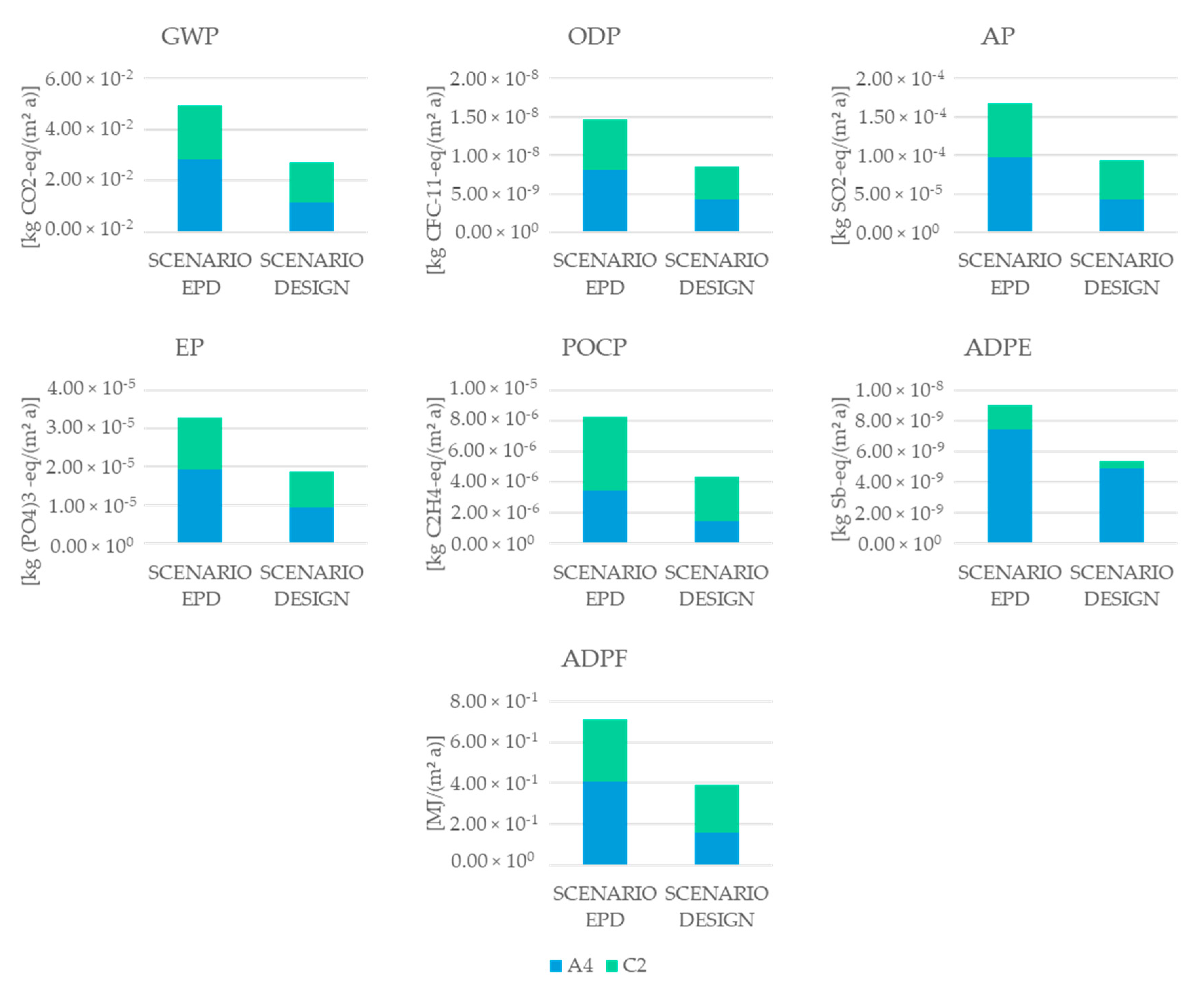

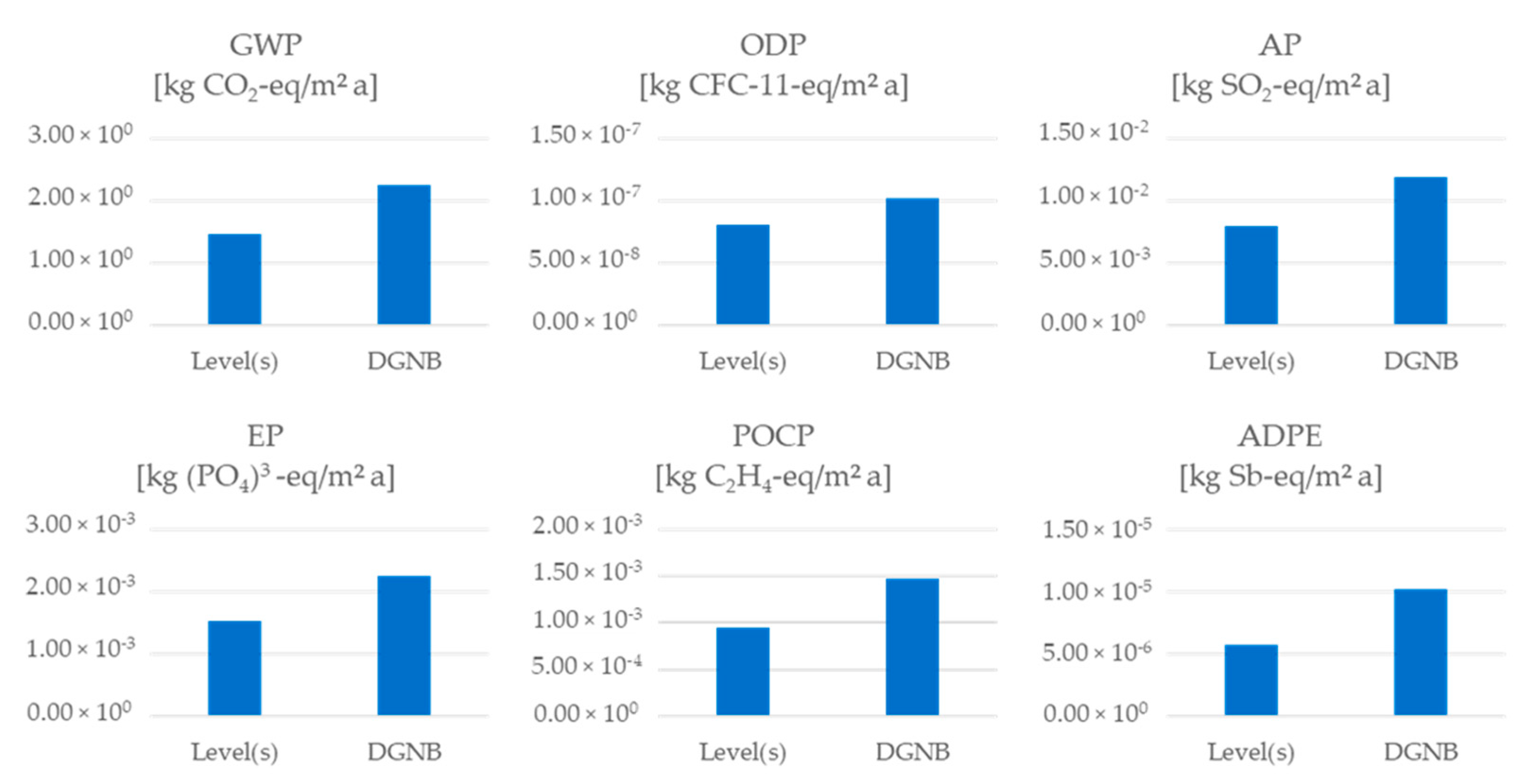

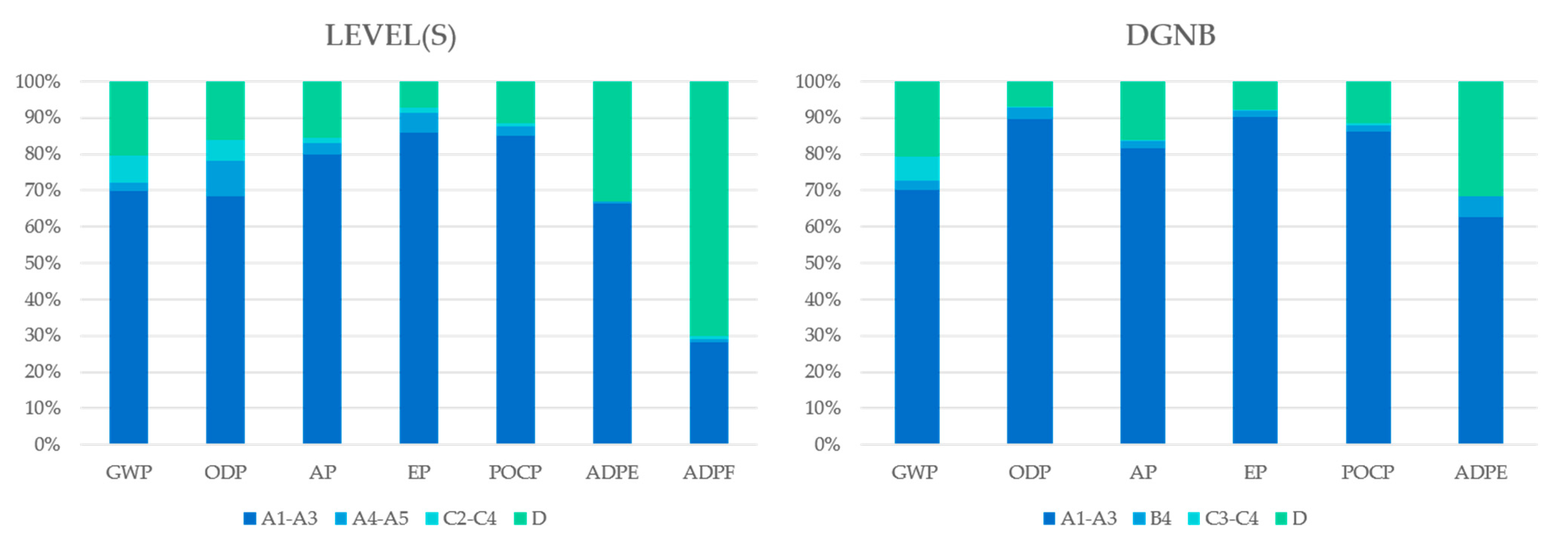

3.2. Environmental Assessment Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UN Environment and International Energy Agency. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector: Global Status Report 2017; IEA: Paris, France, 2017. [Google Scholar]

- European Commission. Construction and Demolition Waste, 2008. Environment European Commission Website. Available online: http://ec.europa.eu/environment/waste/construction_demolition.htm (accessed on 17 September 2020).

- European Commission. Sustainable Buildings for Europe’s Climate-Neutral Future. European Comission Website. Available online: https://ec.europa.eu/easme/en/news/sustainable-buildings-europe-s-climate-neutral-future (accessed on 18 June 2020).

- Venäläinen, J.; Kuittinen, M.; Huttunen, E.; le Roux, S. Level (s)—Test Report from Finland; Finland Ministry of Environment: Helsinki, Finland, 2019. [Google Scholar]

- Wen, B.; Musa, N.; Onn, C.C.; Ramesh, S.; Liang, L.; Wang, W. Evolution of sustainability in global green building rating tools. J. Clean. Prod. 2020, 259, 120912. [Google Scholar] [CrossRef]

- Mattoni, B.; Guattari, C.; Evangelisti, L.; Bisegna, F.; Gori, P.; Asdrubali, F. Critical review and methodological approach to evaluate the differences among international green building rating tools. Renew. Sustain. Energy Rev. 2018, 82, 950–960. [Google Scholar] [CrossRef]

- Khan, J.S.; Zakaria, R.; Shamsudin, S.M.; Abidin, N.I.A.; Sahamir, S.R.; Abbas, D.N.; Aminudin, E. Evolution to emergence of green buildings: A review. Adm. Sci. 2019, 9, 6. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, M. Green building rating systems as sustainability assessment tools: Case study analysis. In Sustainability Assessment at the 21st Century; Bastante-Ceca, M.J., Fuentes-Bargues, J.L., Hufnagel, L., Mihai, F.-C., Iatu, C., Eds.; IntechOpen: London, UK, 2020; Volume I. [Google Scholar]

- Li, Y.; Chen, X.; Wang, X.; Xu, Y.; Chen, P.-H. A review of studies on green building assessment methods by comparative analysis. Energy Build. 2017, 146, 152–159. [Google Scholar] [CrossRef]

- World Green Building Council. WorldGBC Annual Report 2019/20; World Green Building Council: London, UK, 2020. [Google Scholar]

- Cordero, A.S.; Melgar, S.G.; Márquez, J.M.A. Green Building rating systems and the new framework level(s): A critical review of sustainability certification within Europe. Energies 2019, 13, 66. [Google Scholar] [CrossRef] [Green Version]

- Bueno, C.; Rossignolo, J.A.; Ometto, A.R. Life cycle assessment and the environmental certification systems of buildings. Gestão Tecnol. Proj. 2013, 1, 7. [Google Scholar] [CrossRef] [Green Version]

- Herczeg, M.; McKinnon, D.; Milios, L.; Bakas, I.; Klaassens, E.; Svatikova, K.; Widerberg, O. Resource Efficiency in the Building sector: Final Report; European Commission: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Berardi, U. Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustain. Dev. 2011, 20, 411–424. [Google Scholar] [CrossRef]

- Ismaeel, W.S. Midpoint and endpoint impact categories in Green building rating systems. J. Clean. Prod. 2018, 182, 783–793. [Google Scholar] [CrossRef]

- Liu, P.C.Y.; Lo, H.-W.; Liou, J.J.H. A Combination of DEMATEL and BWM-Based ANP Methods for exploring the green building rating system in Taiwan. Sustainability 2020, 12, 3216. [Google Scholar] [CrossRef] [Green Version]

- European Commission. COM(2014) 445 final: Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on Resource Efficient Opportunities in the Building Sector; Vol. COM(2014); European Commission: Rotterdam, The Netherlands, 2014. [Google Scholar]

- European Commission. LEVEL(S): Bringing Buildings into the Circular Economy; European Commission: Rotterdam, The Netherlands, 2018. [Google Scholar]

- Dodd, N.; Cordella, M.; Traverso, M.; Donatello, S. Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings—Part 3: How to Make Performance Assessments Using Level(s); Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Kanafani, K.; Rasmussen, F.N.; Zimmermann, R.K.; Birgisdottir, H. Adopting the EU sustainable performance scheme level(s) in the Danish building sector. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 092070. [Google Scholar] [CrossRef] [Green Version]

- Bitsiou, E.; Giarma, C. Parameters related to building components’ life-cycle analysis in methods for buildings’ environmental performance assessment. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012066. [Google Scholar] [CrossRef]

- Dodd, N.; Donatello, S.; Cordella, M. Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings, Part 2: Setting Up a Project to Use the Level(s) Common Framework (Publication Version 1.0); Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- CEN EN 15978:2011. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; CEN: Belgium, Brussels, 2011. [Google Scholar]

- Lasvaux, S.; Habert, G.; Peuportier, B.; Chevalier, J. Comparison of generic and product-specific Life Cycle Assessment databases: Application to construction materials used in building LCA studies. Int. J. Life Cycle Assess. 2015, 20, 1473–1490. [Google Scholar] [CrossRef]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef] [Green Version]

- European Commission. LEVEL(S) Taking Action on the TOTAL Impact of the Construction Sector; European Commission: Rotterdam, The Netherlands, 2019. [Google Scholar]

- Arvizu-Piña, V.A.; Burgos, A.C. Promoting sustainability in Mexico’s building sector via environmental product declarations. Int. J. Life Cycle Assess. 2017, 22, 1744–1759. [Google Scholar] [CrossRef]

- Gantner, J. Projektbericht: Einfluss von EPDs im DGNB System am Beispiel eines Bürogebäudes in Massivbauweise; Fraunhofer IBP: Stuttgart, Germany, 2018; Volume 49. [Google Scholar]

- Winans, K.S. Agricultural-Based Life Cycle Assessment: Primary and Secondary Data; Industrial Ecology Seminar; College of Engineering UC Davis: Davis, CA, USA, 2017; p. 39. [Google Scholar]

- ISO. ISO 14025:2010—Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures; ISO: Genova, Switzerland, 2010. [Google Scholar]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of external thermal insulation systems. expanded polystyrene vs. mineral wool: Case study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- DIN. Nachhaltigkeit von Bauwerken—Umweltproduktdeklarationen—Grundregeln für die Produktkategorie Bauprodukte; Deutsche Fassung EN 15804:2012+A2:2019; DIN: Berlin, Germany, 2020. [Google Scholar]

- European Commission, Joint Research Centre. International Reference Life Cycle Data System (ILCD) Handbook: Specific Guide for Life Cycle Inventory Data Sets; EUR 24709 EN; Publications Office of the European Union: Luxembourg; Available online: https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/international-reference-life-cycle-data-system-ilcd-handbook-specific-guide-life-cycle#:~:text=Abstract%3A,footprinting%2CandGreenPublicProcurement (accessed on 18 August 2020).

- Palumbo, E. Effect of LCA data sources on GBRS reference values: The envelope of an Italian passive house. Energies 2021, 14, 1883. [Google Scholar] [CrossRef]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Rangelov, M.; Dylla, H.; Mukherjee, A.; Sivaneswaran, N. Use of environmental product declarations (EPDs) of pavement materials in the United States of America (U.S.A.) to ensure environmental impact reductions. J. Clean. Prod. 2021, 283, 124619. [Google Scholar] [CrossRef]

- DGNB. DGNB System—Criteria Set New Construction Building; DNGB: Stuttgart, Germany, 2018. [Google Scholar]

- Dodd, N.; Cordella, M.; Traverso, M.; Donatello, S. Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings—Parts 1 and 2: Introduction to Level(s) and How it Works; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Dodd, N.; Donatello, S.; Cordella, M. Level(s) indicator 1.2: Life cycle Global Warming Potential (GWP) User Manual: Overview, Instructions and Guidance (Publication Version 1.0); Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Palumbo, E.; Traverso, M.; Antonini, E. Comparison of Different Data Sources in Performing a Life Cycle Assessment of the Outer Envelope of a Passive House; SDEWES: Palermo, Italy, 2018. [Google Scholar]

- Strazza, C.; Del Borghi, A.; Magrassi, F.; Gallo, M. Using environmental product declaration as source of data for life cycle assessment: A case study. J. Clean. Prod. 2016, 112, 333–342. [Google Scholar] [CrossRef]

- Ylmén, P.; Peñaloza, D.; Mjörnell, K. Life cycle assessment of an office building based on site-specific data. Energies 2019, 12, 2588. [Google Scholar] [CrossRef] [Green Version]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- DGNB. DGNB System New Construction, Buildings Criteria Set; DNGB: Stuttgart, Germany, 2020. [Google Scholar]

- Al-Khalifa, F.A. International sustainability rating tools: A methodology for adoption to local contexts. KnE Eng. 2018, 3, 274–297. [Google Scholar] [CrossRef] [Green Version]

- Azari, R. Integrated energy and environmental life cycle assessment of office building envelopes. Energy Build. 2014, 82, 156–162. [Google Scholar] [CrossRef]

- Azari, R.; Garshasbi, S.; Amini, P.; Rashed-Ali, H.; Mohammadi, Y. Multi-objective optimization of building envelope design for life cycle environmental performance. Energy Build. 2016, 126, 524–534. [Google Scholar] [CrossRef]

- Gantner, J.; Wittstock, B.; Lenz, K.; Fischer, M.; Sedlbauer, K.; Anderson, J.; Saunders, T.; Gyetvai, Z.; Carter, C.; Braune, A.; et al. EeBGuide Guidance Document—Part B: Buildings—Operational Guidance for Life Cycle Assessment Studies of the Energy-Efficient Buildings Initiative; Fraunhofer Verlag: Stuttgart, Germany, 2015. [Google Scholar]

- International Property Measurement Standards (IPMS). International Property Measurement Standards: Office Buildings; IPMS: London, UK, 2014. [Google Scholar]

- Schmincke, E. Normungsaktivitäten im Rahmen der Nachhaltigen Nutzung der Natürlichen Ressourcen (BWR 7); Deutsche Gesellschaft für Nachhaltiges Bauen e.V.: Berlin, Germany, 2019. [Google Scholar]

- Öztaş, S.K.; Tanaçan, L. The importance of local factors for inventory analysis. Proc. Int. Struct. Eng. Constr. 2017, 4, 4. [Google Scholar] [CrossRef]

- SSchlanbusch, R.D.; Fufa, S.M.; Häkkinen, T.; Vares, S.; Birgisdottir, H.; Ylmén, P. Experiences with LCA in the Nordic Building Industry—Challenges, needs and solutions. Energy Procedia 2016, 96, 82–93. [Google Scholar] [CrossRef] [Green Version]

| Program Operator | EPD Program | Country |

|---|---|---|

| Building Research Establishment (BRE) Global | GreenBook Live | United Kingdom |

| The International EPD® System | ENVIRONDEC | International |

| EPDItaly | EPDItaly | Italy |

| The Norwegian EPD Foundation | EPD Norge | Norway |

| European Aluminium | European Aluminium EPD Programme | Europe |

| Institut Bauen und Umwelt e.V. (IBU) | IBU-EPD | Germany |

| Centre Scientifique et Technique du Bâtiment (CSTB) | INIES | France |

| EPD Program | Country | Number of Collected EPDs |

|---|---|---|

| GreenBook Live | United Kingdom | 0 |

| ENVIRONDEC | International | 1 |

| EPDItaly | Italy | 0 |

| EPD Norge | Norway | 3 |

| European Aluminium EPD Programme | Europe | 2 |

| IBU-EPD | Germany | 21 |

| INIES | France | 3 |

| Level(s) | DGNB | |

|---|---|---|

| LCA type | Simplified (level 1) [50] | Simplified [50] |

| Reference norms | ISO 14040/44, EN 15978 | ISO 14040/44, EN 15978 |

| Reference study period | 60 years * | 50 years |

| General | - | Consideration of data quality and simplification by safety margins. Simplified calculation method–a safety margin of 20% has to be added to the indicator results of the assessment. |

| Functional unit (FU) | 1 m2 of internal useful area per year | The FU is given through the building description. It should specify the type of building, its technical and functional properties and information. The LCA results should be given per year and referencing the net floor area SA–Surface Area. |

| LCI and LCIA datasets | As a minimum, generic data from databases or literature is required. | The use of generic and specific data is permitted, but specific data is preferred. The EPDs must correspond to the specific building materials. If not, a similar EPD must be used. In case of multiple options, the worst-case scenario is chosen. If the EPDs do not correspond to the exact materials, a safety margin of 10% is applied to the LCA results. |

| Life-cycle stages | Levels 1 and 2: Simplified reporting is permitted. Options: - A1-A3, B4, B5, B6 - A1-A3, B6, C3-C4, D Level 3: complete life cycle | A1-A3, B4, B6, C3-C4, D |

| Environmental Impact Categories | ||

| Global Warming Potential (GWP) | X ** | X |

| Ozone Depletion Potential (ODP) | X | X |

| Acidification Potential (AP) | X | X |

| Eutrophication Potential (EP) | X | X |

| Photochemical Ozone Creation Potential (POCP) | X | X |

| Abiotic Depletion Potential – Elements (ADPE) | X | X |

| Abiotic Depletion Potential – Fossil fuels (ADPF) | X | |

| Total use of renewable primary energy resources (PERT) | X | |

| Total use of non-renewable primary energy resources (PENRT) | X | |

| Proportion of renewable primary energy (PERE/PERT) | X | |

| Use of net fresh water (FW) | X | |

| Building Parts | Related Building Elements |

|---|---|

| Load-bearing structural frame | External walls |

| Non-load bearing elements | Ground floor slab |

| Façade | External wall systems Cladding and shading devices Façade openings (including windows and external walls) External paints, coatings and renders |

| Roof | Structure weatherproofing |

| Building Element | Material/Product | Description |

|---|---|---|

| Sub-base | Concrete Sub-base | Unreinforced concrete with cement CEM II/A |

| Separating layer | Polypropylene (PP) sheets, thickness: 3 mm | |

| Floor insulation | Foam glass, ventilated underfloor cavity Height: 20 cm | |

| Expanded polystyrene (EPS), thickness: 10 cm | ||

| External walls | Masonry brick | Semi-supporting blocks (24 cm × 24 cm × 12 cm) |

| Thermo-bricks (30 cm × 25 cm × 19 cm) | ||

| Insulation | Expanded polystyrene (EPS), thickness: 10 cm | |

| Plaster | Premixed plaster cement for outdoor use | |

| Façade | External insulation | Polystyrene foam slab, thickness: 10 cm |

| Internal insulation | Glass wool, thickness: 4 cm | |

| Ventilated façade cladding with stoneware | Aluminium structure and ceramic granite facing with module slabs with dimension 1206 × 606 mm, glass fibre net behind the stoneware | |

| Curtain wall with aluminium sheets | Vertical metal curtain in wall shaped in aluminium poles | |

| Continuous aluminium façade | Continuous facade of tubular uprights and crossbars with 50 mm sections in extruded aluminium alloy 6060 profiles, with 50 mm pressure die and visible outer cover. Double glazing U < 1.1 W/m2 K with laminated safety glass | |

| Aluminium window system | Facade mounted opening element consisting of tubular aluminium profiles made from extruded aluminium alloy 6060 profiles. Double glazing U < 1.1 W/m2 K with laminated safety glass | |

| Single vent aluminium window | Aluminium hinged windows made with extruded profiles in 6060 alloy. Thermal transmittance (profile): Uf < 2.8 W/m2 K. Coated flat glass | |

| Single vent aluminium window with thermal break | Aluminium hinged windows with thermal break made with extruded profiles in 6060 alloy. Fixed frame depth; 56 mm, mobile frame depth: 63 mm Thermal transmittance (profile): Uf < 2.8 W/m2 K. Coated flat glass | |

| Sunshade | Fixed protruding sunshades with extruded aluminium profile slats (10 blades of 100 mm inclined at 45° with distance between centres of 120 mm) | |

| Insulation | Glass fibre, thickness: 10 cm | |

| Roof | Crushed stone construction aggregate | Coarse gravel subgrade with small gravel, crushed stone and gravel clogging |

| Insulation | Foam glass, thermal conductivity: 0.033 W/m2 K Thicknesses: 40 mm | |

| Flexible sheets for roof waterproofing | Waterproof covering double bituminous membrane, multi-layered, fully torched | |

| Bitumen seal polymer EP4, fire retardant—4 kg/m2, multi-layered, fully torched | ||

| Plastomeric bituminous membrane, single-layered, fully torched | ||

| Roof waterproofing membrane | Polyvinyl chloride (PVC) sheet, thickness: 1.8 mm | |

| Roof and wall underlay | High-density polyethylene (HDPE) granulate (650 g/m2), extrusion plastic film | |

| Multi-pane insulating glass | Aluminium alloy (2.15 kg/m2 T-profile + L-profile) Double glazing U < 1.1 W/m2 K, Laminated safety glass | |

| Clear float glass | Uncoated flat glass | |

| Prefabricated double skin steel faced sandwich panel with a core of polyurethane | Corrugated galvanized sheet for 6/10 mm EGB Polyurethane rigid foam | |

| Laminated wood beams | Cross-laminated timber (X-LAM) | |

| Sunshade | Fixed protruding sunshades with extruded aluminium profile slats (10 blades of 100 mm inclined at 45° with distance between centres of 120 mm) | |

| Green Roof System | Green roof, plastomeric membranes, cellular glass insulation, geotextile separating layer with polypropylene fibre |

| NAME | LIFE-CYCLE STAGES | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | A5 | B1 | B2 | B3 | B4 | B5 | B6 | B7 | C1 | C2 | C3 | C4 | D | |

| FOUNDATION | |||||||||||||||||

| Concrete Sub-base | |||||||||||||||||

| Separating layer in PP sheets | |||||||||||||||||

| Floor insulation with foam glass | |||||||||||||||||

| Floor insulation with EPS | |||||||||||||||||

| EXTERNAL WALLS | |||||||||||||||||

| Masonry brick (semi-supporting blocks 24 × 24 × 12) | |||||||||||||||||

| Masonry (thermo-bricks) | |||||||||||||||||

| Expanded polystyrene (EPS) insulation | |||||||||||||||||

| Premixed plaster cement | |||||||||||||||||

| FAÇADE | |||||||||||||||||

| External insulation | |||||||||||||||||

| Internal insulation | |||||||||||||||||

| Ventilated façade cladding with stoneware | |||||||||||||||||

| Curtain wall (aluminium sheet) | |||||||||||||||||

| Continuous aluminium façade | |||||||||||||||||

| Aluminium window system | |||||||||||||||||

| Single vent aluminium window | |||||||||||||||||

| Single vent aluminium window | |||||||||||||||||

| Aluminium sunshade | |||||||||||||||||

| Fibre glass insulation | |||||||||||||||||

| ROOFS | |||||||||||||||||

| Crushed stone construction aggregate | |||||||||||||||||

| Foam glass insulation | |||||||||||||||||

| Flexible bitumen sheets for roof waterproofing–multi-layered fully torched | |||||||||||||||||

| Flexible bitumen sheets for roof waterproofing–multi-layered fully torched | |||||||||||||||||

| Flexible bitumen sheets for roof waterproofing–single-layered fully torched | |||||||||||||||||

| PVC roof waterproofing membrane | |||||||||||||||||

| Roof and wall underlay in HDPE | |||||||||||||||||

| Multi-pane insulating glass | |||||||||||||||||

| Clear float glass | |||||||||||||||||

| Prefabricated double skin steel faced sandwich panel with a core of polyurethane | |||||||||||||||||

| Cross-laminated timber (X-LAM) | |||||||||||||||||

| Aluminium sunshade | |||||||||||||||||

| Extensive Green Roof System | |||||||||||||||||

| Element | Country | EPD Transport Scenario | Design Scenario |

|---|---|---|---|

| Foundation | |||

| Concrete sub-base | France | Fuel consumption: 0.08 L/m3 km Distance to the site: 18.5 km Truck capacity: 8 m3 Avg. capacity utilization (with empty returns): 50% | Return: 80% Distance: 14 km |

| Polypropylene sheets | France | Vehicle: average truck trailer with a 24 t payload, diesel consumption 38 L/100 km Distance: 1560 km Capacity utilization (including empty returns): 100% of capacity, 30% empty returns Bulk density of transported product: 2520 m2/pallet and 10 pallet/truck Volume capacity utilization factor: 1 | Return: 50% Distance: 46 km |

| Floor insulation with foam glass | Germany | Distance: 350 km Capacity utilization and energy consumption from Ecoinvent dataset for average truck transport in EU | Return: 50% Distance: 46 km |

| Floor insulation with EPS | Germany | Transport distance: 200 km Capacity utilization (including empty runs): 70% Gross density of products transported: 15 kg/m3 Capacity utilization volume factor: 25 | Return: 50% Distance: 46 km |

| EXTERNAL WALLS | |||

| Masonry brick (semi-supporting blocks 24 × 24 × 12) | Germany | Fuel: 1.2 L/100 km Transport distance:121 km Utilization (including empty runs): 85% Bulk density of transp. Products: 550–2000 kg/m3 | Return: 80% Distance: 46 km |

| Masonry brick (thermo-bricks) | France | Vehicle: EURO 4 truck with a capacity of 24 t, diesel Distance: 300 km Capacity of utilization: 33% Density of the transported product: 669 kg/m3 | Return: 80% Distance: 46 km |

| Expanded polystyrene (EPS) insulation | Germany | Transport distance: 200 km Capacity utilization (including empty runs): 70% Gross density of products transported:15 kg/m3 Capacity utilization volume factor: 25 | Return: 50% Distance: 46 km |

| Premixed plaster cement | Germany | No data available | Return: 80% Distance: 46 km |

| FAÇADE | |||

| Exterior insulation | Germany | Transport distance: 200 km Capacity utilization (including empty runs): 70% Gross density of products transported:15 kg/m3 Capacity utilization volume factor: 25 | Return: 50% Distance: 46 km |

| Interior insulation | Sweden | Vehicle: Average truck trailer with a 24 t payload, diesel consumption 38 litres for 100 km Distance: 500 km Capacity utilization (including empty returns): 95% of the capacity in volume, 50% of empty returns Bulk density of transported products: 50–100 kg/m3 Volume capacity utilization factor: 1 (by default) | Return: 50% Distance: 46 km |

| Ventilated façade cladding with stoneware | Germany | No data available | Return: 80% Distance: 46 km |

| Curtain wall (aluminium sheet) | Germany | Vehicle: truck (34–40 t total weight/27 t payload; EURO 4). Transport distance: 450 km Occupancy rate (including empty runs): 85%. | Return: 80% Distance: 46 km |

| Continuous aluminium façade | Germany | Vehicle: Truck 7.5 (Diesel), 0.00591 L/100 km Transport Distance: 10.00 km Utilization (including empty runs): 40% Volume utilization factor:1 | Return: 80% Distance: 46 km |

| Aluminium window system | Germany | Vehicle: Truck 7.5 (Diesel), 0.00591 L/100 km Transport Distance: 10.00 km Utilization (including empty runs): 40% Volume utilization factor: 1 | Return: 80% Distance: 46 km |

| Single vent aluminium window | Belgium | No data available | Return: 80% Distance: 46 km |

| Single vent aluminium window | Belgium | No data available | Return: 80% Distance: 46 km |

| Aluminium sunshade | France | Distance: 1000 km Vehicle: truck, without empty return (Ecoinvent data, including loading rate of 50% by weight). | Return: 80%Distance: 46 km |

| Fibre glass insulation | Germany | Means of transport: Truck 17.3 t payload, Euro 3 Transport distance: 400 km Occupancy rate (including empty runs): 85%. Bulk density: 21.8 kg/m3 | Return: 80% Distance: 46 km |

| ROOFS | |||

| Crushed stone construction aggregate | Norway | Type: truck, 16–32 t, EURO 5 Capacity utilization (incl. return): max. load one way, 50% Distance: 12.5 km Fuel consumption: 0.031 L/t km or 0.38 L/t | Return: 80% Distance: 46 km |

| Foam glass insulation | Germany | Distance: 350 km Capacity utilization and energy consumption were taken from the Ecoinvent data set for average truck transport in Europe and were not changed. | Return: 50% Distance: 46 km |

| Flexible bitumen sheets for roof waterproofing–multi-layered fully torched | Europe | Vehicle: 32 t truck Distance: 300 km | Return: 50% Distance: 46 km |

| Flexible bitumen sheets for roof waterproofing–multi-layered fully torched | Europe | Vehicle: 32 t truck Distance: 300 km | Return: 50% Distance: 46 km |

| Flexible bitumen sheets for roof waterproofing–single-layered fully torched | Europe | Vehicle: 32 t truck Distance: 300 km | Return: 50% Distance: 46 km |

| PVC roof waterproofing membrane | Norway | Capacity utilization (including return): 75.0% Vehicle type: Truck, lorry over 32 t, EURO 6, CU 75% Distance: 300 km Fuel consumption: 0.0141 L/t km Unit value: 4.23 L/t | Return: 50% Distance: 46 km |

| Roof and wall underlay in HDPE | Luxemburg | Transport distance (weighted average): 2667 km Transport (train): 1.86 × 10−2 tkm Transport (road): 7.69 × 10−2 tkm Transport (water): 8.34 × 10−2 tkm | Return: 50% Distance: 46 km |

| Multi-pane insulating glass | Germany | No data available | Return: 80% Distance: 46 km |

| Clear float glass | Turkey | No data available | Return: 80% Distance: 46 km |

| Prefabricated double skin steel faced sandwich panel with a core of polyurethane | Germany | Transport distance 100 km Capacity utilisation (including empty runs): 85% | Return: 80% Distance: 46 km |

| Cross-laminated timber (X-LAM) | Germany | No data available | Return: 80% Distance: 46 km |

| Aluminium sunshade | France | 1000 km, by truck, without empty return (Ecoinvent data used, including a loading rate of approximately 50% by weight that cannot be modified). | Return: 80% Distance: 46 km |

| Extensive green roof system | Belgium | Distance: 600 km Capacity utilization: 70%. Fuel consumption: 0.025 L/100 km Transport distance: 600 km Capacity utilization (including empty runs): 70% Capacity utilization volume: 90% | Return: 80% Distance: 46 km |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Rosario, P.; Palumbo, E.; Traverso, M. Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption? Sustainability 2021, 13, 6143. https://doi.org/10.3390/su13116143

Del Rosario P, Palumbo E, Traverso M. Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption? Sustainability. 2021; 13(11):6143. https://doi.org/10.3390/su13116143

Chicago/Turabian StyleDel Rosario, Pamela, Elisabetta Palumbo, and Marzia Traverso. 2021. "Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption?" Sustainability 13, no. 11: 6143. https://doi.org/10.3390/su13116143

APA StyleDel Rosario, P., Palumbo, E., & Traverso, M. (2021). Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption? Sustainability, 13(11), 6143. https://doi.org/10.3390/su13116143