New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals

Abstract

1. Introduction

- Sustainability. According to the social role that organisations are requested to play as providers of good, services, respectful environmental behaviour and social wellness, Sustainable Business Model (SBM) requirements need to be considered.

- Innovation. The innovative dimension is rather intrinsic to the BM creation, therefore, consideration of Business Model Innovation (BMI) becomes natural.

- Organisational. PcrM requires to develop an ecosystem of agents cooperating in a long term engagement through different workflows, while they can involve either human or Artificial Intelligence (AI) based agents. Such dynamic ecosystem is deeply innovative, and it can have a significant impact over the institutional logic for most of the involved agents/organisations.

- When PcrM BMs are considered, which framework and perspectives for the analysis on the interaction inside the built ecosystem are meaningful?

- Which are the significant factors or elements allowing to transform data into value inside the ecosystem?

- When PcrM BMs are considered, what are the expected impacts in terms of innovation, sustainability, social effects, and organisational design for the involved agents?

2. Literature Review

2.1. Prescriptive Maintenance and Shared Value

2.2. Business Model Innovation

- Sustainable value should incorporate economic, social and environmental benefits,

- SBMs require a system of sustainable value flows among multiple stakeholders including the natural environment and society as primary stakeholders,

- SBMs require a value network with a new purpose, design and governance, conceptualized as value forms,

- SBMs require a systemic consideration of stakeholder interests and responsibilities for mutual value creation, and

- Internalizing externalities through PSS enables innovation towards SBMs.

2.3. Overview and Research Gap

3. Methodology

- Understand the BM. This stage requires to identify the BM from different angles, as well as the relevant factors. Then the core of the BM as well as reinforcing and balancing feedback loops can be defined.

- Identify Technology Influence. The central activity for this stage is to identify the key technological aspects for the BM. It also involves the analysis of the possibilities of the forthcoming changes, and finally, the stage requires to elaborate the value proposal.

- Assessment. In this stage all the value related aspects need to be analysed, but also relevant strengths and connections with key concepts must be described. In the present case this stage becomes particularly relevant as ecosystem interactions are essential in the BM proposal.

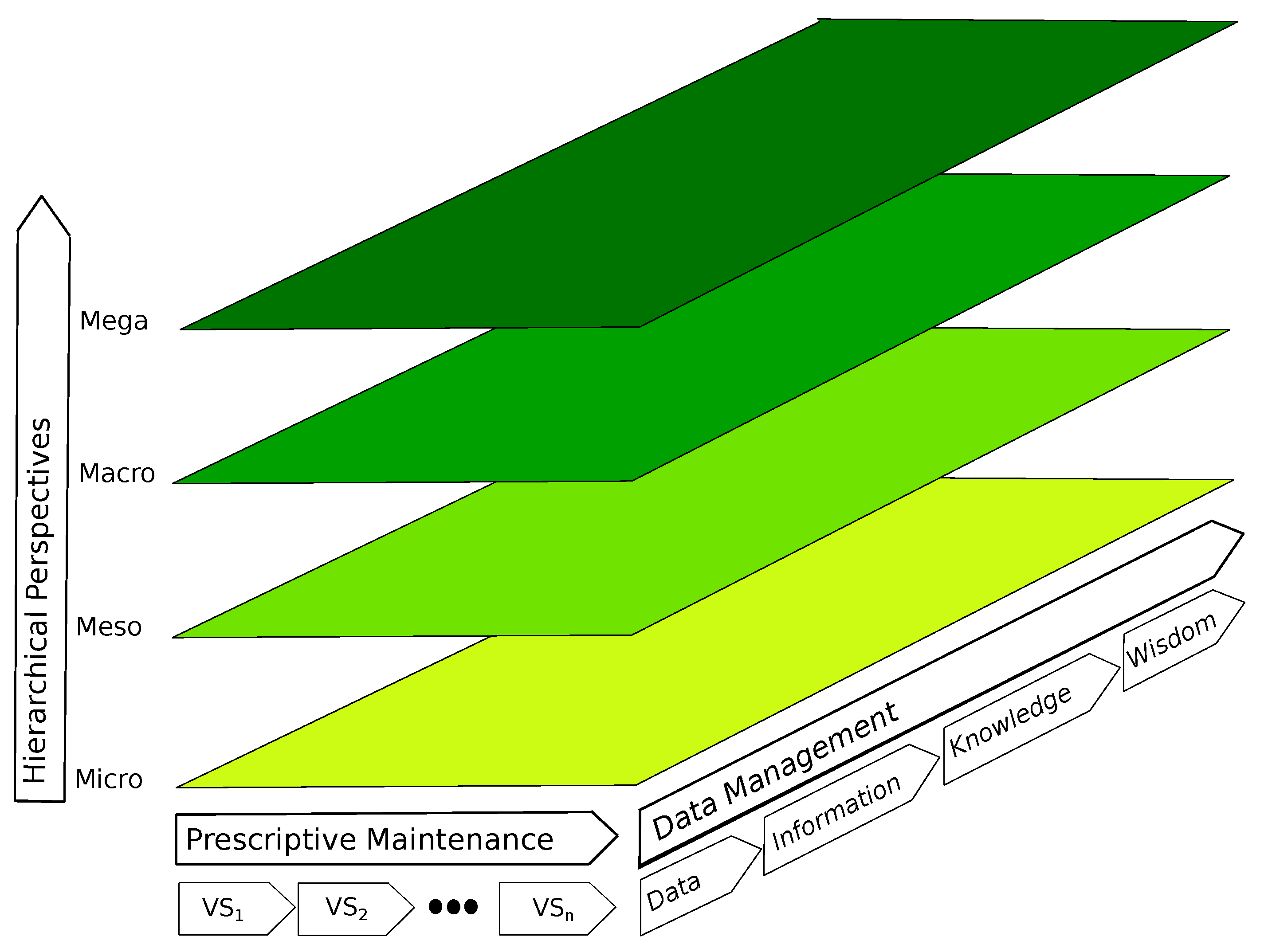

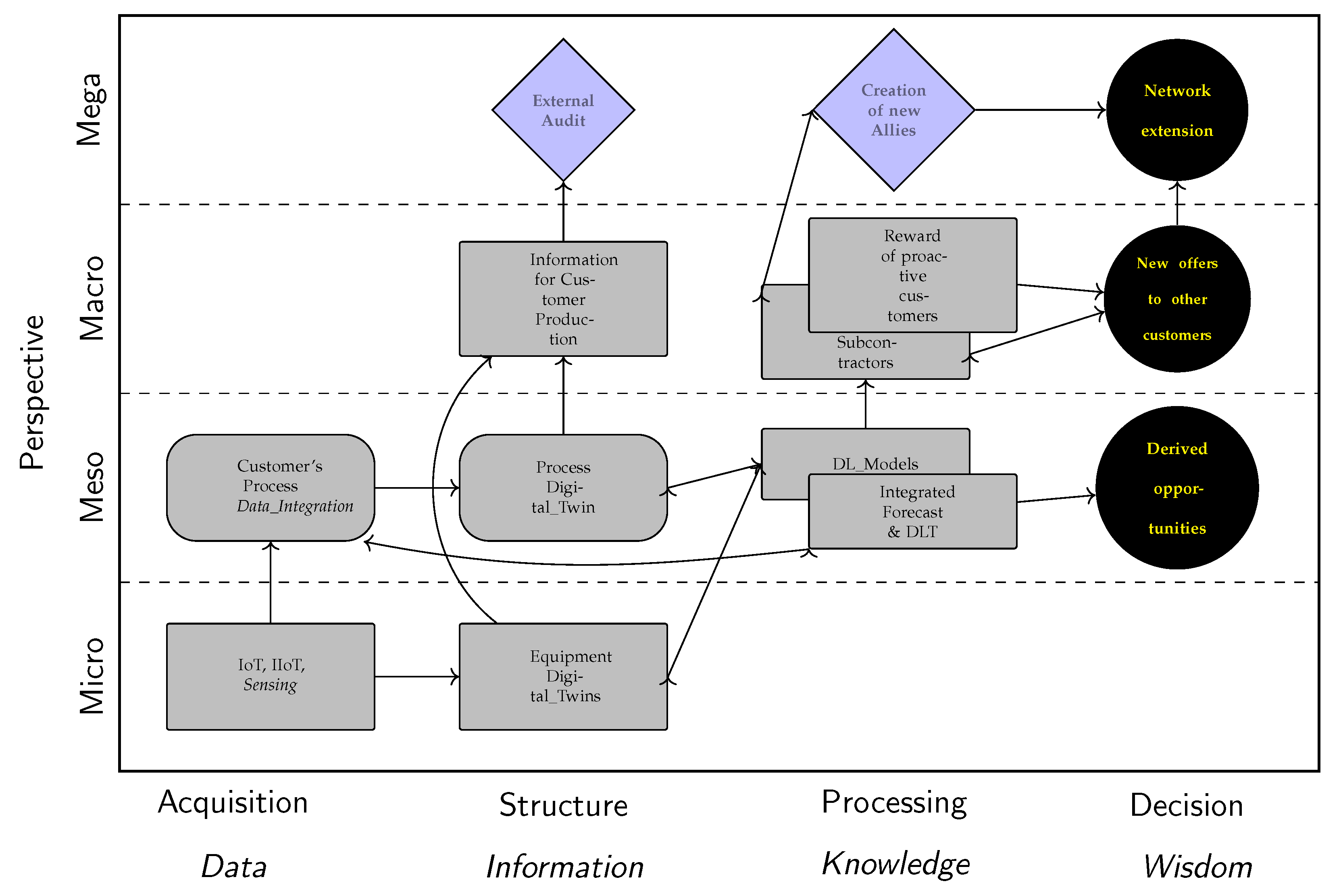

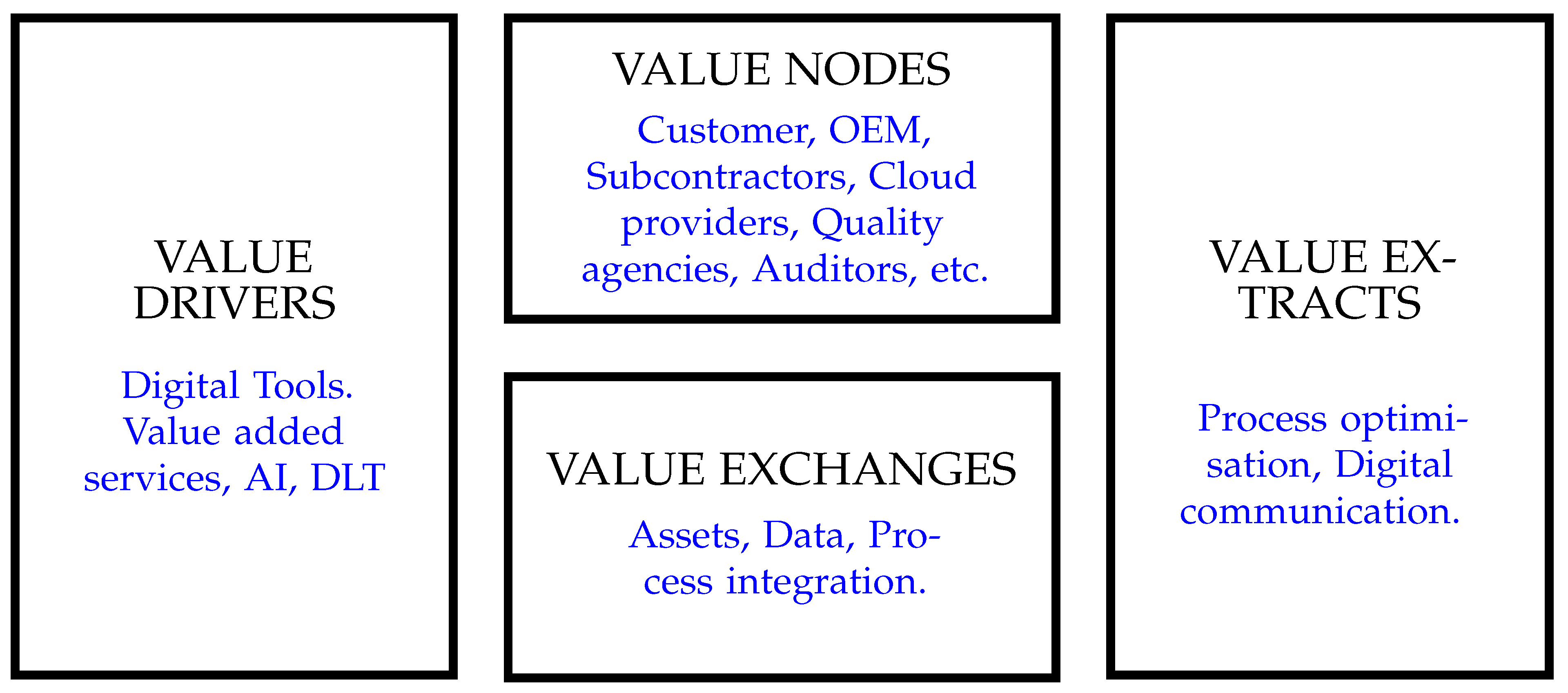

4. Business Model Creation

- Systematic data acquisition: In this phase, data collection is ensured by placing smart sensors on the network nodes. At the different hierarchical levels this presents different challenges that must be dealt with in different ways.

- Information: To allow proper data processing into information, the structure in which the data is located is as important as the data itself. The topology in which the data is found will largely determine the methods needed to convert this information into actionable knowledge. That is why this BM proposes standardisation processes for these structures.

- Knowledge:

- Data processing. The data are processed to be transformed into knowledge. This treatment takes place by means of AI algorithms on distributed platforms to ensure its robustness and reliability.

- Business Analytics. Data analysis is performed in semi- or fully supervised processes by experts. However, the trend shown by Industry 4.0 is to delegate more and more processes to unsupervised algorithms based on Big Data and technologies such as Deep Learning.

- Value:

- Decision making. Depending on the strategic objectives of the organisation, corresponding decisions will be made. For this purpose, the management must have an adequate management system that supports the BM.

- Operationalisation. The implementation of the decisions taken, carries with it an implicit commitment by the management that allows not only the achievement of objectives, but also that these are sustainable over time.

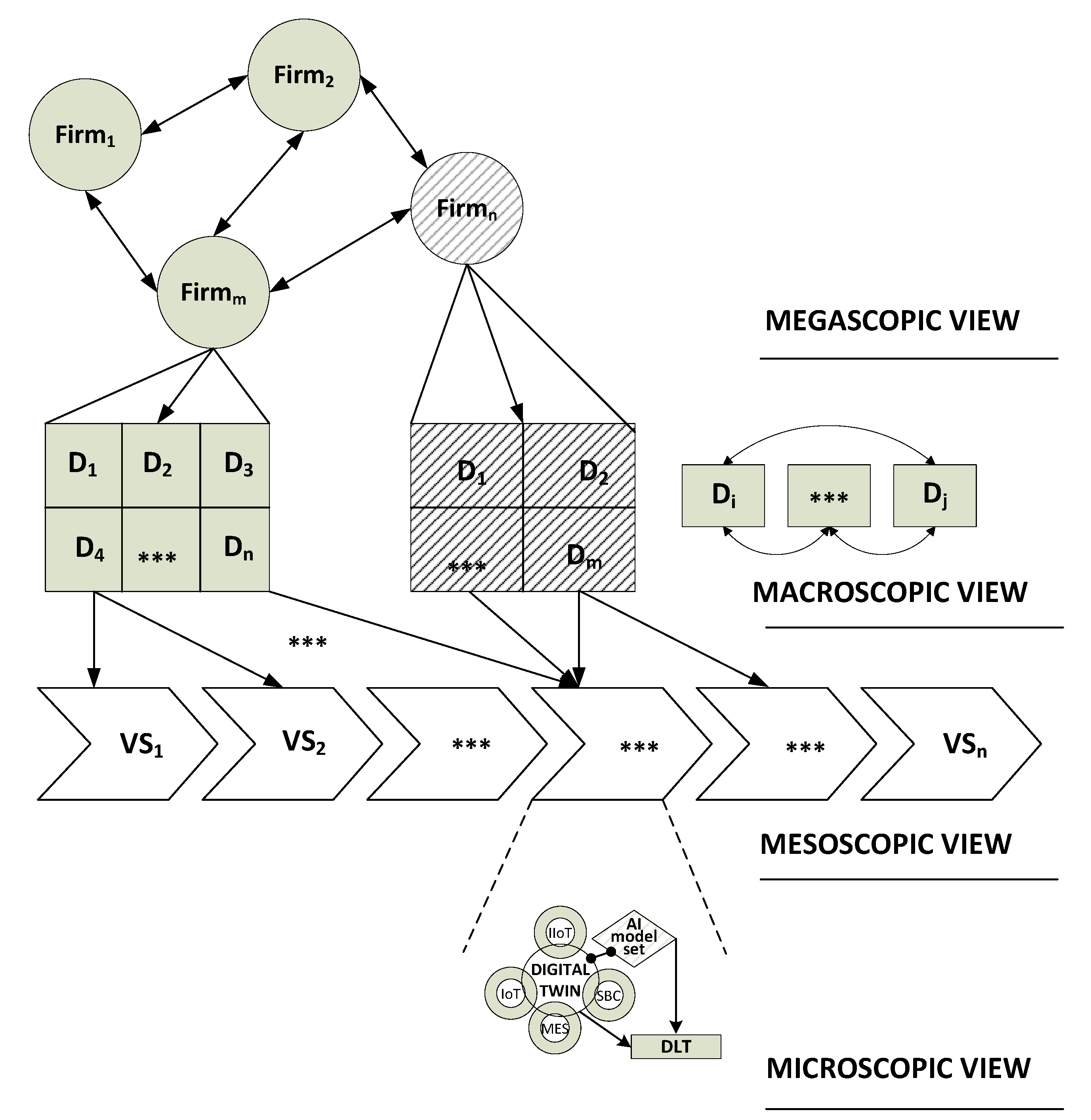

- Mega, the development of capabilities looking for understanding how actors within the ecosystem are making money or could make money,

- Macro, the role of data or how the data is processed for creating value of existing products, at the same time enabling other services,

- Meso, path to profit or how information asymmetry reduced and sustainable cost efficiency developed by transforming operating models,

- Micro, from push to pull or how to address real time and emerging needs in a predictive manner.

5. Discussion

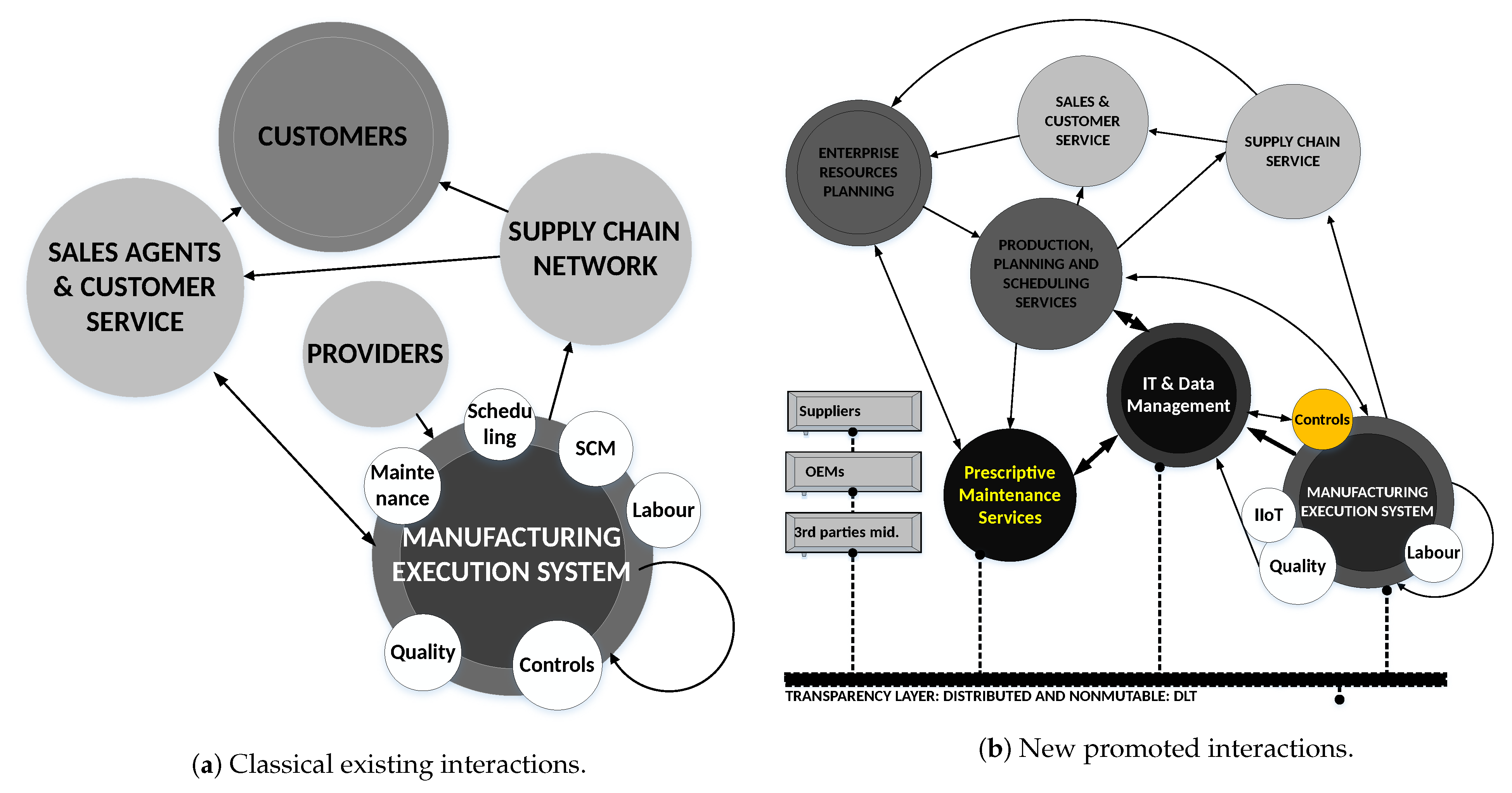

5.1. Innovative Content

- Including new actors in service ecosystem: This way is one of the most powerful ways for innovation, not only by adding customers but also technology providers among others. Within service ecosystems, actors cannot avoid the institutional arrangements guiding their behaviour even when innovating [91]. However, it is possible to redefine parts of “how things are done” by adding diversity to the institutionalised rules.In order to visualise main conceptual differences between classical strategies and prescriptive maintenance, Figure 1a was introduced. Major differences arise because of the technical IT management component, requested to deal with real time data coming from the production processes, including events, and in cooperation with the Deep Learning based modelling and the Digital Twin technologies, but also working as a hub by enabling other functions to benefit from such datasets, such as system to system information through DLT solutions.This entire paradigm relies on the value for different applications of data collected from the production system both, product related as well as process related. It can provide context for equipment related data allowing to describe the degradation in the quality of service.Prescriptive maintenance scenario clearly will require a considerable standardisation effort to harmonise [92]

- (i)

- communication protocols as well as configuration management,

- (ii)

- modelling methodologies,

- (iii)

- big data architecture, tools, and applications with different kind of technical platforms (local, cloud, private, public, virtualised, etc.) as well as

- (iv)

- different tools to feed-in the collected data in streaming way.

In some specific sectors, like maintenance of services in buildings, the management of the decision making can also be integrated through the existing standards like BIM, which plays the role of MES system and changes both the ways of working and the business structure [36]. In this case, stakeholders carry out their work on one share platform which creates enormous possibilities that allow controlled decisions to be made within the design team and among clients, contractors and designers. In this particular application the Digital Twin is the natural contributor for integrating BIM with sensors and service data, where DLT becomes central keeping the different decision makers updated. Furthermore, when the social relevance of the project is significant, these digital and virtual models can be opened to the public and to the authorities. - Redefining roles of actors in service ecosystems: In addition to adding new actors, institutional reconfiguration in service ecosystems often also manifest themselves as redefined roles of both the existing and new actors [93]. Prescriptive maintenance promotes changes on the role of the customer from a traditional passive to a more engaged and active learner and doer.As the customer acquires additional perspective on the production because of the knowledge gain from the deployed technology. It can help to evolve their role into a more active one. Instead of rehearsing or forwarding new solutions, they now participate in idea generation actively. The redefinition of roles affects also to other existing agents, such as the OEMs, now expaning their activities to develop advanced digital twins for their products, and having additional requirements for computational and communication capabilities. Indeed, new agents are invited to join the network to externally assess contractual requirements and to provide different digital based added value services.Besides, at the plant level it is particularly relevant the Maintenance function, which moves itself from being a supporting concept for the Manufacturing Execution System into an active component able to see the systems as probabilistic exposed to failures. Therefore, it will care, not only of technical procedures and their management but also of analyzing their remaining life. Because of this, it will be possible to cooperate with production planning by estimating potential damage impacts on different subsystems because of the use of different production parameter. This higher integration between system components at mesoscopic level will benefit the performance of the agent at macroscopic level.

- Reframing resources in service ecosystems: In service ecosystems, institutional arrangements act as sense-making frames for the ’resourceness’ of potential resources [39]. In other words, when partially conflicting institutional arrangements coexist, they can provide actors with alternative frames of sense-making and enable the combinatory emergence of new instances of ’resourceness’.It is argued that, the more the value of the PSS moves from the physical product to the performance, the greater the benefit is, but also the more radical is the change required to companies [94]. Now the products are owned by the manufacturers, keeping the responsibility of them along life cycle, and they are operated by customers as a service.The existing challenge is the trust, sharing critical information with third-party can be difficult [92]. Although new technologies such as DLT can help to find a solution to minimise some of the associate risks, as access to the customer IT systems are not required.One relevant aspect of prescriptive maintenance is that in order to look for failure causes, traditional approaches are focused on considering human oriented feature selection and related criteria. Cognitive system engineering techniques provide an opportunity to even utilise people acting as soft sensors. Fusing data from humans with that from electronic sensors [4,95] is another key concept in this approach.In addition, prescriptive maintenance shows that innovation becomes a process of reconfiguring the institutional structure of service ecosystem, which also results in reframed resources, and requires investments on other capabilities as well [28,96]:

- (i)

- designer system which can faster innovation, introducing improvements on user experience repairing and to upgrading components with improved technologies that can be installed on existing or future machines. Product developer is now aware of operating conditions.

- (ii)

- financial system which have to manage a new perspective over the cost and revenues arising during the product lifecycle, moving to a new frame of long-term service contract at a predetermined price. Stable and continuous cash flows from customer to manufacturer over the product lifecycle, of a smaller entity compared to product sales.

- (iii)

- commercial system which would to avoid product-cost competition to capture market shares and to growth profits by building new sources of sustainable advantage.Smart Product-Service Ecosystems as a relational, long-term process.

Obviously the process for reframing the resources reaches all the agents in the network, and it has a dynamic effect and network will continue to increase in size to cope with the increasing complexity, bringing each actor behaviour more efficient along the innovation path.

5.2. Organisational Design

- at the mega level, systems become interdependent across firm boundaries, and performance is disembodied from ownership of assets. Actors that support innovation therefore are both constrained and enabled in their actions by the structure of innovations and have to challenge the dominant institutional logic, as it is essential for its success. However institutional change is often beyond the capacity of individual actors and requires joint activities by a wide group of them on the basis of mutual interests [97,98].

- at the macro-level is not only the articulation of the newly framed problem, governance, but also in a way that is likely to resonate with the interests of firms ecosystem actors, legitimacy, which implies the creation of more complex governance practices around trust and cooperation within the firm ecosystem [31,99].

- at the micro and meso level relates to the organisational structures design and decision making procedures [100]. New equipment prescriptive maintenance innovation requires actors that contribute to the innovation process in a wide variety of ways (for instance through knowledge development of advanced forecasting models, fostering the continuous learning procedures not only internally but also for the technology, standardisation of procedures, etc.). Such contributions can include an integrative framework for the business value of the unit and the facility as a whole and use of the innovation with a dynamic cooperation between prescriptive maintenance tasks and production activities in a more integrated way (see Table 2).

5.3. Sustainable Development Goals

- Maximise material efficiency: Preservation of raw materials by predicting machinery operational capacities; also by enhancing ecological footprint; and, by decreasing spare parts since they are replaced only when needed rather than on a fixed schedule.

- Optimises energy efficiency: Preservation of energy by integration of resources optimisation through time, closing resource loops through reuse, re-manufacturing, and recycling; lower the environmental impact corresponding to greenhouse gas emissions due to the energy saving by integrating operation with maintenance activities.

- Improves worker safety: Reduction of accidents and risky works for operators by lowering incidents with assets by predicting incidents before they escalate.

- Improves working conditions: Additional Information on machine ergonomics and incidents (by virtual reality for example) to maximise people’s health and safety, satisfaction from work.

- Improves working environment: Opportunities for new service providers, specially smaller and technological oriented, not dependent of a specific localisations.

- New educational model and culture: Articulate connections between new behaviours and corporate success; create new social norms and shared values consistent with new approach.

- (i)

- actively involved groups (e.g., employees and users with individual interests such as well-being and satisfaction) as well as

- (ii)

- passively involved or “affected” groups (e.g., administrative stakeholders or future generations with collective interests such as ecological concerns).

- (i)

- G8: Decent work and Economic growth,

- (ii)

- G9: Industry, Innovation and infrastructure and

- (ii)

- G11: Sustainable communities.

- (i)

- G3: Good health and Well-being, as better work conditions are being promoted, where digitalisation can promote learning procedures at work.

- (ii)

- G4: Quality Education, as the all the technology involved can illustrate case studies highlighting advanced techniques. It will promote convenient skills for the future,

- (iii)

- G5: Gender equality, as higher level skills will be needed in the continuous innovation process, and where they can be obtained from different people, and

- (iv)

- G10: Reduced Inequality, where neutral technology can also help people suffering disabilities.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BMs | Business Models |

| BMC | Business Model Canvas |

| BMI | Business Model Innovation |

| CBM | Condition Based Monitoring |

| CPU | Central Process Unit |

| DLT | Distributed Ledger Technologies |

| EBM | Ecosystem Business Models |

| EMBMI | Equipment Maintenance Business Model Innovation |

| ICT | Information and Communication Technologies |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| OD | Organisational Design |

| OEE | Overall Equipment Effectiveness |

| OEM | Original Equipment Manufacturer |

| PcrM | Prescriptive maintenance |

| PSS | Product-Service System |

| TPM | Total Productive Maintenace |

| TRM | Teechnology Roadmap |

| SM | Smart Maintenace |

| SBM | Sustainable Business Model |

| SBMI | Sustainable Business Model Innovation |

| SPSE | Smart Product Service Ecosystem |

References

- Casadesus-Masanell, R.; Ricart, J. From Strategy to Business Models and onto Tactics. Long Range Plan. 2010, 43, 195–215. [Google Scholar] [CrossRef]

- Teece, D. Business Models, Business Strategy and Innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Lemus-Aguilar, I.; Morales-Alonso, G.; Ramirez-Portilla, A.; Hidalgo, A. Sustainable Business Models through the Lens of Organizational Design: A Systematic Literature Review. Sustainability 2019, 11, 5379. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. [Google Scholar] [CrossRef]

- Ranjbari, M.; Morales-Alonso, G.; Carrasco-Gallego, R. Conceptualizing the sharing economy through presenting a comprehensive framework. Sustainability 2018, 10, 2336. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Strategy And The Internet. Harv. Bus. Rev. 2001, 79, 62–78. [Google Scholar] [CrossRef]

- Fusko, M.; Rakyta, M.; Krajcovic, M.; Dulina, L.; Gaso, M.; Grznar, P. Basics of designing maintenance processes in industry 4.0. MM Sci. J. 2018, 3, 2252–2259. [Google Scholar] [CrossRef]

- Leseure, M.; Hudson-Smith, M.; Martinez, V.; Bastl, M.; Kingston, J.; Evans, S. Challenges in transforming manufacturing organisations into product-service providers. J. Manuf. Technol. Manag. 2010, 21, 449–469. [Google Scholar]

- Zheng, M.; Ming, X.; Wang, L.; Yin, D.; Zhang, X. Status review and future perspectives on the framework of Smart Product Service Ecosystem. Procedia CIRP 2017, 64, 181–186. [Google Scholar] [CrossRef]

- Yin, D.; Ming, X.; Zhang, X. Sustainable and Smart Product Innovation Ecosystem: An integrative status review and future perspectives. J. Clean. Prod. 2020, 274, 123005. [Google Scholar] [CrossRef]

- Passlick, J.; Dreyer, S.; Olivotti, D.; Grutzner, L.; Eilers, D.; Breitner, M.H. Predictive maintenance as an internet of things enabled business model: A taxonomy. Electron. Mark. 2020, 1–21. [Google Scholar] [CrossRef]

- Marques, H.; Giacotto, A. Prescriptive Maintenance: Building Alternative Plans for Smart Operations. In Proceedings of the 10th Aerospace Technology Congress, Stockholm, Sweden, 8–9 October 2019; Linköping University Electronic Press: Stockholm, Sweden, 2019; pp. 231–236. [Google Scholar] [CrossRef]

- Fera, M.; Greco, A.; Caterino, M.; Gerbino, S.; Caputo, F.; Macchiaroli, R.; D’Amato, E. Towards Digital Twin Implementation for Assessing Production Line Performance and Balancing. Sensors 2019, 20, 97. [Google Scholar] [CrossRef] [PubMed]

- Matyas, K.; Nemeth, T.; Kovacs, K.; Glawar, R. A procedural approach for realizing prescriptive maintenance planning in manufacturing industries. CIRP Ann. 2017, 66, 461–464. [Google Scholar] [CrossRef]

- Nemeth, T.; Ansari, F.; Sihn, W.; Haslhofer, B.; Schindler, A. PriMa-X: A reference model for realizing prescriptive maintenance and assessing its maturity enhanced by machine learning. Procedia CIRP 2018, 72, 1039–1044. [Google Scholar] [CrossRef]

- Li, M.; Tuunanen, T. Actors’ Dynamic Value Co-creation and Co-destruction Behavior in Service Systems: A Structured Literature Review. In Proceedings of the 53rd Hawaii International Conference on System Science, Hawaii, Maui, 7–10 January 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Nenonen, S.; Storbacka, K. Business model design: Conceptualizing networked value co-creation. Int. J. Qual. Serv. Sci. 2010, 2, 43–59. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Fotia, S. Classification and Mapping of PSS Evaluation Approaches. IFAC PapersOnLine 2016, 49, 1555–1560. [Google Scholar] [CrossRef]

- Parida, V.; Sjodin, D.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, R.; Wu, D. Equipment Maintenance Business Model Innovation for Sustainable Competitive Advantage in the Digitalization Context: Connotation, Types, and Measuring. Sustainability 2018, 10, 3970. [Google Scholar] [CrossRef]

- Baima, G.; Forliano, C.; Santoro, G.; Vrontis, D. Intellectual capital and business model: A systematic literature review to explore their linkages. Intellect. Cap. Bus. Model 2020, 1469–1930. [Google Scholar] [CrossRef]

- Tirabeni, L.; De Bernardi, P.; Forliano, C.; Franco, M. How can organisations and business models lead to a more sustainable society? A framework from a systematic review of the industry 4.0. Sustainability 2019, 11, 6363. [Google Scholar] [CrossRef]

- Foss, N.J.; Saebi, T. Fifteen Years of Research on Business Model Innovation: How Far Have We Come, and Where Should We Go? J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Bocken, N.; Boons, F.; Baldassarre, B. Sustainable business model experimentation by understanding ecologies of business models. J. Clean. Prod. 2019, 208, 1498–1512. [Google Scholar] [CrossRef]

- Velter, M.; Bitzer, V.; Bocken, N.; Kemp, R. Sustainable business model innovation: The role of boundary work for multi-stakeholder alignment. J. Clean. Prod. 2020, 247, 119497. [Google Scholar] [CrossRef]

- Jansson, N.; Ahokangas, P.; Iivari, M.; Perala-Heape, M.; Salo, S. The competitive advantage of an ecosystemic business model: The case of OuluHealth. Interdiscip. Stud. J. 2014, 3, 282. [Google Scholar]

- Arnaiz, A.; Léger, J.B.; Aguirregomezkorta, A.; Fernandez, S.; Revilla, O.; Peysson, F. Advanced maintenance as enabler for service oriented business models (BM)-An application in forklift trucks. IFAC-PapersOnLine 2016, 49, 144–149. [Google Scholar] [CrossRef]

- Hirano, H. JIT Implementation Manual: The Complete Guide to Just-in-Time Manufacturing, (6-Volume Set); CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Porter, M.E.; Millar, V.E. How information gives you competitive advantage. Harv. Bus. Rev. 1985, 63, 149–160. [Google Scholar]

- Amit, R.; Zott, C. Value creation in e-business. Strateg. Manag. J. 2001, 22, 493–520. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; del Olmo, J.; Ugalde, G. A Hybrid Sensor Fault Diagnosis for Maintenance in Railway Traction Drives. Sensors 2020, 20, 962. [Google Scholar] [CrossRef]

- Lee, H.; Lee, B. The Development of a State-Aware Equipment Maintenance Application Using Sensor Data Ranking Techniques. Sensors 2020, 20, 3038. [Google Scholar] [CrossRef]

- Moleda, M.; Momot, A.; Mrozek, D. Predictive Maintenance of Boiler Feed Water Pumps Using SCADA Data. Sensors 2020, 20, 571. [Google Scholar] [CrossRef] [PubMed]

- Merluzzi, A.; Brunetti, G. Metals industry: Road to digitalization. In Proceedings of the 2017 40th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 22–26 May 2017; pp. 967–973. [Google Scholar]

- Hautala, K.; Jarvenpaa, M.E.; Pulkkinen, P. Digitalization transforms the construction sector throughout asset’s life-cycle from design to operation and maintenance. Stahlbau 2017, 86, 340–345. [Google Scholar] [CrossRef]

- Ansari, F.; Glawar, R.; Nemeth, T. PriMa: A prescriptive maintenance model for cyber-physical production systems. Int. J. Comput. Integr. Manuf. 2019, 32, 482–503. [Google Scholar] [CrossRef]

- Liu, B.; Lin, J.; Zhang, L.; Kumar, U. A dynamic prescriptive maintenance model considering system aging and degradation. IEEE Access 2019, 7, 94931–94943. [Google Scholar] [CrossRef]

- Koskela-Huotari, K.; Edvardsson, B.; Jonas, J.M.; Soörhammar, D.; Witell, L. Innovation in service ecosystems—Breaking, making, and maintaining institutionalized rules of resource integration. J. Bus. Res. 2016, 69, 2964–2971. [Google Scholar] [CrossRef]

- Myllykoski, J.; Ahokangas, P. Transformation toward a cloud business model. Commun. Cloud Softw. 2013, 2, 1–11. [Google Scholar]

- Amit, R.; Zott, C. Creating value through business model innovation. MIT Sloan Manag. Rev. 2012, 53, 41–49. [Google Scholar]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley and Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Osterwalder, A.; Pigneur, Y.; Bernarda, G.; Smith, A.; Papadakosa, T. Value Proposition Design: How to Create Products and Services Customers Want; John Wiley and Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kooijman, M.; Hekkert, M.P.; van Meer, P.J.; Moors, E.H.; Schellekens, H. How institutional logics hamper innovation: The case of animal testing. Technol. Forecast. Soc. Chang. 2017, 118, 70–79. [Google Scholar] [CrossRef]

- Oliver, P.E. Formal models of collective action. Annu. Rev. Sociol. 1993, 19, 271–300. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; Fossen, K.V.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business Model Innovation for Sustainability: Towards a Unified Perspective for Creation of Sustainable Business Models. Bus. Strategy Environ. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Vendrell-Herrero, F.; Bustinza, O.F.; Parry, G.; Georgantzis, N. Servitization, digitization and supply chain interdependency. Ind. Mark. Manag. 2017, 60, 69–81. [Google Scholar] [CrossRef]

- Nosratabadi, S.; Mosavi, A.; Shamshirband, S.; Kazimieras Zavadskas, E.; Rakotonirainy, A.; Chau, K.W. Sustainable business models: A review. Sustainability 2019, 11, 1663. [Google Scholar] [CrossRef]

- Cortimiglia, M.N.; Ghezzi, A.; Frank, A.G. Business model innovation and strategy making nexus: Evidence from a cross-industry mixed-methods study. R&D Manag. 2016, 46, 414–432. [Google Scholar] [CrossRef]

- Bradley, P.; Parry, G.; O’Regan, N. A framework to explore the functioning and sustainability of business models. Sustain. Prod. Consum. 2020, 21, 57–77. [Google Scholar] [CrossRef]

- Iansiti, M.; Levien, R. The Keystone Advantage: What the New Dynamics of Business Ecosystems Mean for Strategy, Innovation, and Sustainability; Harvard Business Press: Boston, MA, USA, 2004. [Google Scholar]

- Lehto, I.; Hermes, J.; Ahokangas, P.; Myllykoski, J. Collaboration in cloud businesses–value networks and ecosystems. Commun. Cloud Softw. 2013, 2, 1–9. [Google Scholar]

- Normann, R.; Ramirez, R. From value chain to value constellation: Designing interactive strategy. Harv. Bus. Rev. 1993, 71, 65. [Google Scholar]

- Zarvic, N.; Seifert, M.; Thoben, K.D. A task-resource dependency perspective on partner selection during the formation of networked business constellations. Int. J. Netw. Virtual Organ. 2010, 7, 399–414. [Google Scholar] [CrossRef]

- Glova, J.; Sabol, T.; Vajda, V. Business models for the internet of things environment. Procedia Econ. Financ. 2014, 15, 1122–1129. [Google Scholar] [CrossRef]

- Villalba-Díez, J.; Molina, M.; Ordieres-Meré, J.; Sun, S.; Schmidt, D.; Wellbrock, W. Geometric Deep Lean Learning: Deep Learning in Industry 4.0 Cyber–Physical Complex Networks. Sensors 2020, 20, 763. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Schmidt, D.; Gevers, R.; Ordieres-Meré, J.; Buchwitz, M.; Wellbrock, W. Deep Learning for Industrial Computer Vision Quality Control in the Printing Industry 4.0. Sensors 2019, 19, 3987. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Zheng, X.; Schmidt, D.; Molina, M. Characterization of Industry 4.0 Lean Management Problem-Solving Behavioral Patterns Using EEG Sensors and Deep Learning. Sensors 2019, 19, 2841. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, D.; Diez, J.V.; Ordieres-Meré, J.; Gevers, R.; Schwiep, J.; Molina, M. Industry 4.0 Lean Shopfloor Management Characterization Using EEG Sensors and Deep Learning. Sensors 2020, 20, 2860. [Google Scholar] [CrossRef] [PubMed]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Hacklin, F.; Bjorkdahl, J.; Wallin, M.W. Strategies for business model innovation: How firms reel in migrating value. Long Range Plan. 2018, 51, 82–110. [Google Scholar] [CrossRef]

- Herskovits, R.; Grijalbo, M.; Tafur, J. Understanding the main drivers of value creation in an open innovation program. Int. Entrep. Manag. J. 2013, 9, 631–640. [Google Scholar] [CrossRef]

- Ritala, P.; Huotari, P.; Bocken, N.; Albareda, L.; Puumalainen, K. Sustainable business model adoption among S&P 500 firms: A longitudinal content analysis study. J. Clean. Prod. 2018, 170, 216–226. [Google Scholar] [CrossRef]

- Joyce, A.; Paquin, R.L. The triple layered business model canvas: A tool to design more sustainable business models. J. Clean. Prod. 2016, 135, 1474–1486. [Google Scholar] [CrossRef]

- Franceschelli, M.; Santoro, G.; Candela, E. Business model innovation far sustainability: A food start-up case study. BríTish Food J. 2018, 120, 2483–2494. [Google Scholar] [CrossRef]

- Behnam, S.; Cagliano, R.; Grijalvo, M. How should firms reconcile their open innovation capabilities for incorporating external actors in innovations aimed at sustainable development? J. Clean. Prod. 2018, 170, 950–965. [Google Scholar] [CrossRef]

- Bernardi, P.D.; Azucar, D. Innovation and Entrepreneurial Ecosystems: Structure, Boundaries, and Dynamics. In lnnovation in Food Ecosystems; Bernardi, P.D., Azucar, D., Eds.; Springer: Cham, Swizerland, 2020; Chapter 3; pp. 73–104. [Google Scholar]

- Leminen, S.; Rajahonka, M.; Westerlund, M.; Siuruainen, R. Ecosystem business models for the Internet of Things. Internet Things Finl. 2015, 1, 10–13. [Google Scholar] [CrossRef]

- Poeppelbuss, J.; Durst, C. Smart Service Canvas - A tool for analyzing and designing smart product-service systems. Procedia CIRP 2019, 83, 324–329. [Google Scholar] [CrossRef]

- Buhalis, D.; Harwood, T.; Bogicevic, V.; Viglia, G.; Beldona, S.; Hofacker, C. Technological disruptions in services: Lessons from tourism and hospitality. J. Serv. Manag. 2019, 30, 484–506. [Google Scholar] [CrossRef]

- Iivari, M.; Ahokangas, P.; Komi, M.; Tihinen, M.; Valtanen, K. Toward Ecosystemic Business Models in the Context of Industrial Internet. J. Bus. Model. 2016, 4, 42–59. [Google Scholar]

- Izquierdo, J.; Erguido, A.; Zubizarreta, P.; Uribetxebarria, J. Framework for managing the operations and maintenance of wind farms. J. Phys. Conf. Ser. 2019, 1222, 012046. [Google Scholar] [CrossRef]

- MacDonald, C. Understanding participatory action research: A qualitative research methodology option. Can. J. Action Res. 2012, 13, 34–50. [Google Scholar]

- Somekh, B. Action Research: A Methodology for Change and Development: A Methodology for Change and Development; McGraw-Hill Education: London, UK, 2005. [Google Scholar]

- Mills, G.E. Action Research: A Guide for the Teacher Researcher; ERIC: New York, NY, USA, 2000. [Google Scholar]

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Savioz, P.; Blum, M. Strategic forecast tool for SMEs: How the opportunity landscape interacts with business strategy to anticipate technological trends. Technovation 2002, 22, 91–100. [Google Scholar] [CrossRef]

- Toro-Jarrín, M.A.; Ponce-Jaramillo, I.E.; Güemes-Castorena, D. Methodology for the of building process integration of Business Model Canvas and Technological Roadmap. Technol. Forecast. Soc. Chang. 2016, 110, 213–225. [Google Scholar] [CrossRef]

- Auer, C.; Follack, M. Using action research for gaining competitive advantage out of the internet, s impact on existing business models. In Proceedings of the 15th Bled Electronic Commerce Conference eReality: Constructing the eEconomy, Bled, Slovenia, 17–19 June 2002; p. 45. [Google Scholar]

- Chesbrough, H. Business model innovation: It’s not just about technology anymore. Strategy Leadersh. 2007, 35, 12–17. [Google Scholar] [CrossRef]

- Barrett, M.; Davidson, E.; Prabhu, J.; Vargo, S. Service innovation in the digital age: Key contributions and future directions. MIS Q. Manag. Inf. Syst. 2015, 39, 155–175. [Google Scholar] [CrossRef]

- Ordieres-Meré, J.; Remón, T.P.; Rubio, J. Digitalization: An opportunity for contributing to sustainability from knowledge creation. Sustainability 2020, 12, 1460. [Google Scholar] [CrossRef]

- Nesse, P.J.; Hallingby, H.S.; Erdal, O.B.; Evjemo, B. Business Ecosystem and Internet of Things (IoT): Learnings from an Experimental Ecosystem Approach in Norway. In Economics and Finance Readings; Springer: Berlin/Heidelberg, Germany, 2020; pp. 109–124. [Google Scholar]

- Vargo, S.; Lush, R.F. Service-dominant logic: Continuing the evolution. J. Acad. Mark. Sci. 2008, 36, 1–10. [Google Scholar] [CrossRef]

- Frow, P.; McColl-Kennedy, J.R.; Hilton, T.; Payne, A.D.A.; Brozovic, D. Value propositions. Mark. Theory 2014, 14, 327–351. [Google Scholar] [CrossRef]

- Grönroos, C. Value co-creation in service logic: A critical analysis. Mark. Theory 2011, 11, 301–379. [Google Scholar] [CrossRef]

- Kim, W.C.; Mauborgne, R. Blue Ocean Shift: Beyond Competing-Proven Steps to Inspire Confidence and Seize New Growth; Hachette: London, UK, 2017. [Google Scholar]

- Rao, H.; Morrill, C.; Zald, M.N. Power plays: How social movements and collective action create new organizational forms. Res. Organ. Behav. 2000, 22, 237–281. [Google Scholar] [CrossRef]

- Tracey, P.; Phillips, N.; Jarvis, O. Bridging institutional entrepreneurship and the creation of new organizational forms: A multilevel model. Organ. Sci. 2011, 22, 60–80. [Google Scholar] [CrossRef]

- Michel, S.; Brown, S.W.; Gallan, A.S. Service-logic innovations: How to innovate customers, not products. Calif. Manag. Rev. 2008, 50, 49–65. [Google Scholar] [CrossRef]

- Lawrence, T.B.; Suddaby, R.; Leca, B. Institutional Work: Actors and Agency in Institutional Studies of Organizations; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Isaksson, A.J.; Harjunkoski, I.; Sand, G. The impact of digitalization on the future of control and operations. Comput. Chem. Eng. 2018, 114, 122–129. [Google Scholar] [CrossRef]

- Normann, R. Reframing Business: When the Map Changes the Landscape; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Xing, K.; Wang, H.F.; Qian, W. A sustainability-oriented multi-dimensional value assessment model for product-service development. Int. J. Prod. Res. 2013, 51, 5908–5933. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, P. Failure diagnosis using deep belief learning based health state classification. Reliab. Eng. Syst. Saf. 2013, 115, 124–135. [Google Scholar] [CrossRef]

- Copani, G.; Behnam, S. Remanufacturing with upgrade PSS for new sustainable business models. CIRP J. Manuf. Sci. Technol. 2018, 47, 531–536. [Google Scholar] [CrossRef]

- Wijen, F.; Ansari, S. Overcoming inaction through collective institutional entrepreneurship: Insights from regime theory. Organ. Stud. 2007, 28, 1079–1100. [Google Scholar] [CrossRef]

- Tina Dacin, M.; Goodstein, J.; Richard Scott, W. Institutional theory and institutional change: Introduction to the special research forum. Acad. Manag. J. 2002, 45, 45–56. [Google Scholar] [CrossRef]

- Rousseau, D.M.; Sitkin, S.B.; Burt, R.S.; Camerer, C. Not so different after all: A cross-discipline view of trust. Acad. Manag. Rev. 1998, 23, 393–404. [Google Scholar] [CrossRef]

- Child, J.; Rodrigues, S.B. Corporate governance and new organizational forms: Issues of double and multiple agency. J. Manag. Gov. 2003, 7, 337–360. [Google Scholar] [CrossRef]

- Fiore, M.; Galati, A.; Golebieswski, J.; Drejerska, N. Stakeholders’ involvement in establishing sustainable business models: The case of Polish dairy cooperatives. BríTish Food J. 2020, 122, 1671–1691. [Google Scholar] [CrossRef]

- Shams, S.; Vrontis, D.; Weber, Y.; Tsoukatos, E.; Galati, A. Stakeholder Engagement for A Sustainable Development of Business Models; Routledge: Abingdon, UK, 2019; pp. 1–13. [Google Scholar]

- Giacomarra, M.; Crescimanno, M.; Sakka, G.; Galati, A. Stakeholder engagement toward value co-creation in the F&B packaging industry. Euromed J. Bus. 2019, 15, 315–331. [Google Scholar]

- von Geibler, J.; Piwowar, J.; Greven, A. The SDG-Check: Guiding Open Innovation towards Sustainable Development Goals. Technol. Innov. Manag. Rev. 2019, 9, 20–37. [Google Scholar] [CrossRef]

- Wegerich, K. Institutional change: A theoretical approach. Occas. Pap. 2001, 30, 1–27. [Google Scholar]

| Main Results | Literature | |

|---|---|---|

| Business Model Innovation | Taking into account the source of value criterion two types of BMI were identified: novel BMI; and efficient BMI | [19,20,47] |

| Taking into account the innovation degree criterion classification depends on the macro (enterprises) or micro (utilities) dimension | [20] | |

| Taking into account the market perception criterion, two BMI types are identified: market-driven BMI; and driven-market BMI | [20,28,60,61] | |

| From the innovation scope criterion, the BMI identified are: closed BMI; and, open BMI | [20,24,42,62] | |

| From the source of competitive advantage criteria the BMI identified are: BMI based on production technology; and, BMI based on operating method | [20,24,47] | |

| Sustainable Business Models | Taking into account up to nine different strategies, four SBM types can be differentiated: circular BMs; social enterprises; bottom of the pyramid solutions; product-service system | [24] |

| SBM adopted by a large number of global corporation, it has been synthesized strategies that are environmentally, social and economic oriented | [63] | |

| The triple layered BMC as direct extensions of BMC is a practical tool to incorporate environmental and social dimension into BMC | [42,64] | |

| Sustainable Business Models Innovation | SBMI proposed classification types is: sustainable start-ups; SBM transformation; SBM diversification; SBM acquisition | [24,65] |

| SBMI, involves organisational boundary changes and requires multi-actor collaboration trough boundary work | [26,50,66] | |

| Ecosystem Business Models | The EBM, are characterised by high complexity, interdependence, cooperation, competition and coevolution. It can be seen as a bundle of interlinked models with interconnected processes of value cocreation, cocapture and coopetition | [16,27,42,67] |

| A EBM is composed for a set of value pillars anchored in ecosystems, which focus on both the firms methods of creating and capturing value as well as any part of the ecosystem’s method of creating and capturing value to the ecosystem | [68] | |

| Ecosystem perspective is presented as one of the pillars, in addition to value perspective and customer perspective, to the Smart Service Canvas BMs. It connects customer and the smart product-service system provider (PSS). Ecosystem perspective is a generic field describing the technical infrastructure and digital platform | [69,70] | |

| Simultaneous value cocreation and cocapture within the IoT ecosystems rises through “oblique” BMs | [27,71] | |

| Equipment Maintenance Business Model Innovation | Integrates data-structure and asset management innovations for maintenance strategy optimisation within the scope of PSS BMs which entail important benefits for the OEMs and for the operators | [72] |

| Out of an in-deep study of measurement items for EMBMI in the digitalisation context, EMBMI are classified into efficient and novel | [20] |

| Organisational Structures | Decision Making Changes | |

|---|---|---|

| Breaking | To produce a common framework holistically presenting the systems, components and factors, as well as the existing knowledge regarding the damage/degradation models. | |

| Identification and definition of a system architecture, the needed interfaces and the tools for prescriptive maintenance. It does include the analysis of the existing data to support the creation of AI based models estimationg the assets degradation. | Integration of expert’s experiences In particular it does include the identification of convenient business units and assets to perform pilot tests, making it possible to assess the implications. | |

| Compilation and integration of expert’s knowledge. In particular it does include rules for relevance of AI usage, leadership, etc. | ||

| Making | To produce a methodology to establish the advanced degradation/damage models. This methodology will enable to foresee the impact of a working order through a specific production path. | |

| Deployment and integration of the needed IIoT systems providing data about the assets status. | ||

| Use of additional technologies, like cloud data processing, and data ingestion from IoT devices and from DLT. The tools allowing to develop such models need to be deployed (such as tensorflow, python, R, web-services, etc.) and integrated in the organisation | Competence based institutional logic is needed. The employees must acquire/develop convenient skills to deal within such highly technical environment, which probably will imply to adopt different ways of cooperation (slack, trello, etc.) | |

| The assessment will consider to what end the operations at selected units will modify the damage of such components, by considering sensitiveness in regards to the operating parameters. Specific KPI indicators will be used such as LC/VC, etc. This will easy to communicate the impact of the managerial decision on the assets. This assessment tool is keystone to bring business value when prescriptive maintenance and production planning talk each other. | ||

| Increasing reliability of data from IIoT by adding trust layers from the data content but also making it easy to enable external assessment or better integration into the customer’s value streams. This objective is aimed to be developed by using Blockchain like technologies (DLT) as they only require to send information and no way back is needed. | ||

| Enable the maintenance as a service with remote tracking of device performance, without disturbances in production. (relaying on the IIoT + Blockchain contribution) | ||

| Reduction of production costs in industry by reducing production downtimes, maintenance costs and product quality deficiencies. In some cases more value is added when a decision is made considering production needs but also the impact of prolongating intervention in assets. | ||

| Competitiveness inrease for new maintenance service providers, especially the smaller and technologically oriented ones. | ||

| Maintaining | Supporting operators/management in deciding, organising and executing maintenance. Significant impact is expected on the Quality Assurance strategy at the organisation level. | |

| Reduction of maintenance effort by increasing the operating life of assets, when operational conditions become under the spotlight. An additional benefit is expected from the higher level of standardisation of operations and the connection with IoT sensors. | ||

| Reduction of accidents and risky work for operators and staff by lowering incidents with assets. | ||

| Preservation of energy and raw materials by predicting machinary operational capacities, thus improving production efficiency | ||

| Increment the level of transparency at low level operations, which enable a more constructive architecture to identify improvement areas, based on the IIoT + Blockchain contribution | ||

| Prescriptive Maintenance Firm versus Customer | Value Create Prescriptive Maintenance Firm | Value Create Customer | Value Destroy Customer | Value Exchange Customer | Value Extract Customer |

|---|---|---|---|---|---|

| MEGA | Build new alliances and partners based on trust and reputation and transactional experience. | Build new alliances and partners based on trust and reputation and transactional experience. | Incentives to co-create specialised products and services within the networked economy. | Indirect network externalities and benefits due to the positive relation between customer, PM firm and other stakeholders. | |

| MACRO | Enable the maintenance as a smart PSS focus on customer needs (relaying on the IIoT + Blockchain contribution). | Improved coordination with its customers and suppliers (transaction efficiency). Continuously optimise the existing processes, knowledge and technologies related to equipment maintenance services and data analysis. | Swiching cost due to effective barriers to imitation, customisation an increase the level of differentiation. | Highly integrated value co-creation relationships based on data and process integration. Product research is faster. Frequently improve the existing major equipment based on data analysis. | Strong integration within supply chain. Informed decisions through use of extensive information in order to invest in new equipment. Long term relationship new relationship based on pay per use. |

| MESO | Exchange mechanism that allow information becomes instantly available to their partners – ecosystem firms (DLT). | Cross functional transparency of maintenance and production process. | Swishing cost due to effective barriers to imitation, customisation an increase the level of differentiation. | Data and process integration. Combination of online and off-line resources and capabilities. | Reduction of production costs in industry by reducing: production downtime, maintenance costs and product quality deficiencies uncertainty complexity risk. Cross functional optimisation delivers new efficiency savings |

| MICRO | Transaction speed and low cost information processing power. | Reduction of production costs in industry by reducing of investment because of servitisation. | Loss of the existing Knowledge related of the specific equipment. | Higher quality services. | The maintenance process can be simplified and acelerated. Improved responsiveness. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grijalvo Martín, M.; Pacios Álvarez, A.; Ordieres-Meré, J.; Villalba-Díez, J.; Morales-Alonso, G. New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals. Sustainability 2021, 13, 216. https://doi.org/10.3390/su13010216

Grijalvo Martín M, Pacios Álvarez A, Ordieres-Meré J, Villalba-Díez J, Morales-Alonso G. New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals. Sustainability. 2021; 13(1):216. https://doi.org/10.3390/su13010216

Chicago/Turabian StyleGrijalvo Martín, Mercedes, Antonia Pacios Álvarez, Joaquín Ordieres-Meré, Javier Villalba-Díez, and Gustavo Morales-Alonso. 2021. "New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals" Sustainability 13, no. 1: 216. https://doi.org/10.3390/su13010216

APA StyleGrijalvo Martín, M., Pacios Álvarez, A., Ordieres-Meré, J., Villalba-Díez, J., & Morales-Alonso, G. (2021). New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals. Sustainability, 13(1), 216. https://doi.org/10.3390/su13010216