Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector

Abstract

1. Introduction

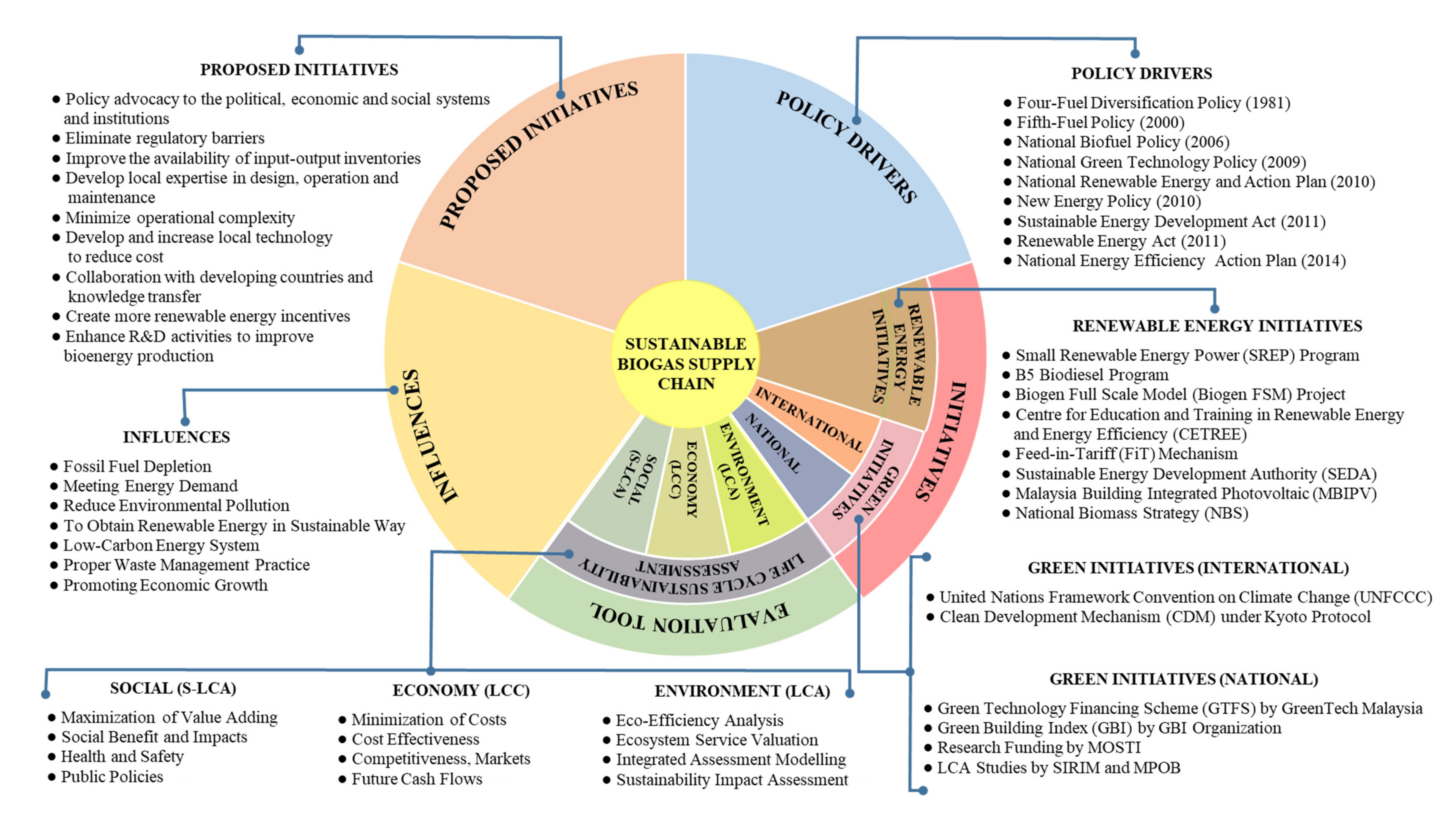

2. Sustainable Biogas Production

2.1. Policy Drivers

2.2. The Green Initiatives in Malaysia

2.3. Life Cycle Sustainability Assessment

2.4. Influences and Proposed Actions

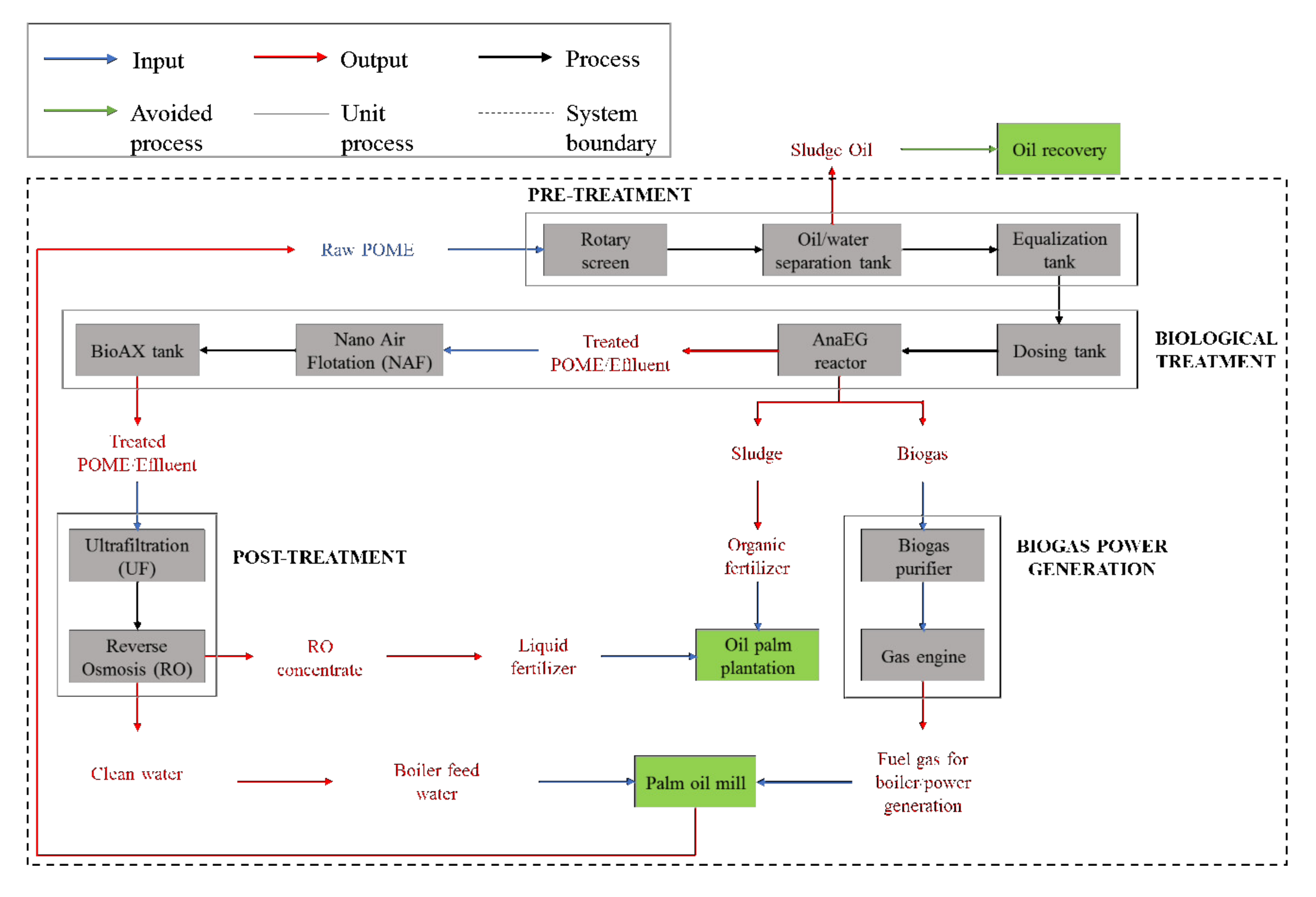

3. Promoting Biogas Production from a Palm Oil Mill Effluent as a Renewable Energy Source in Malaysia

4. Life Cycle Assessment of Zero Discharge Treatment

4.1. Material and Methods

4.1.1. Goal and Scope, Unit Process, Functional Unit and System Boundaries

4.1.2. Database and Analysis Methods

4.1.3. Life Cycle Inventory

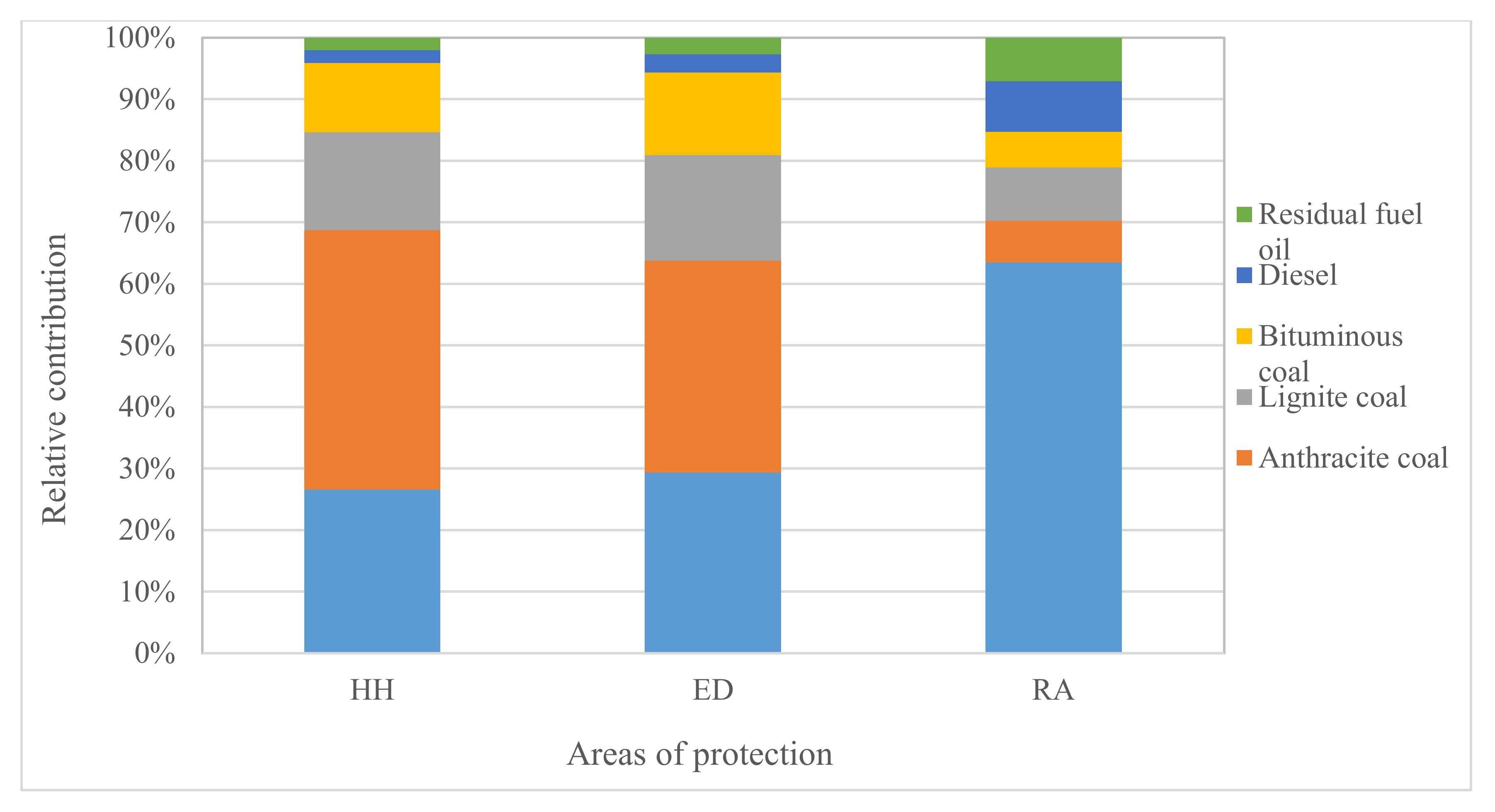

4.2. Results and Discussion

Life Cycle Impact Assessment

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GWP | global warming |

| ODP | stratospheric ozone depletion |

| IRP | ionizing radiation |

| HOFP | ozone formation (human health) |

| PMFP | fine particulate matter formation |

| EOFP | ozone formation (terrestrial ecosystems) |

| TAP | terrestrial acidification |

| FEP | freshwater eutrophication |

| MEP | marine eutrophication |

| TETP | terrestrial ecotoxicity |

| FETP | freshwater ecotoxicity |

| METP | marine ecotoxicity |

| HTPc | human carcinogenic toxicity |

| HTPnc | human non-carcinogenic toxicity |

| SOP | mineral resource scarcity |

| FFP | fossil resource scarcity |

| WCP | water consumption |

References

- Hezri, A.A.; Hasan, M.N. Towards sustainable development? The evolution of environmental policy in Malaysia. Nat. Resour. Forum 2006, 30, 37–50. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Lee, K.T. Energy for sustainable development in Malaysia: Energy policy and alternative energy. Energy Policy 2006, 34, 2388–2397. [Google Scholar] [CrossRef]

- Seman, S.Z.A.; Idris, I.; Abdullah, A.; Samsudin, I.K.; Othman, M.R. Optimizing purity and recovery of biogas methane enrichment process in a closed landfill. Renew. Energy 2019, 131, 1117–1127. [Google Scholar] [CrossRef]

- Griggs, D.; Stafford-Smith, M.; Gaffney, O.; Rockström, J.; Öhman, M.C.; Shyamsundar, P.; Steffen, W.; Glaser, G.; Kanie, N.; Noble, I. Policy: Sustainable development goals for people and planet. Nature 2013, 495, 305–307. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Mohamed Ali, M.Y.; Abdul Aziz, N.I.H.; Ashraf, M.A.; Halim, A.A.; Lee, K.E.; Idris, M. Biogas production from goat and chicken manure in Malaysia. Appl. Ecol. Environ. Res. 2017, 15, 529–535. [Google Scholar] [CrossRef]

- Nagy, V.; Szabó, E. Biogas from organic wastes. Studia Univ. Vasile Goldis Arad Ser. Stiintele Vietii Life Sci. Ser. 2011, 21, 887–891. [Google Scholar]

- Aziz, N.I.H.A.; Hanafiah, M.M. Anaerobic digestion of palm oil mill effluent (POME) using bio-methane potential (BMP) test. AIP Conf. Proc. 2018, 1940, 020026. [Google Scholar]

- Horváth, I.S.; Tabatabaei, M.; Karimi, K.; Kumar, R. Recent updates on biogas production—A review. Biofuel Res. J. 2016, 3, 394–402. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. The potential of palm oil mill effluent (POME) as a renewable energy source. J. Green Energy 2017, 1, 323–346. [Google Scholar] [CrossRef]

- Bujang, A.; Bern, C.; Brumm, T. Summary of energy demand and renewable energy policies in Malaysia. Renew. Sustain. Energy Rev. 2016, 53, 1459–1467. [Google Scholar] [CrossRef]

- Roubík, H.; Mazancová, J. Small-scale biogas plants in central Vietnam and biogas appliances with a focus on a flue gas analysis of biogas cook stove. Renew. Energy 2019, 131, 1138–1145. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Eriksson, O.; Bisaillon, M.; Haraldsson, M.; Sundberg, J. Enhancement of biogas production from food waste and sewage sludge–environmental and economic life cycle performance. J. Environ. Manag. 2016, 175, 33–39. [Google Scholar] [CrossRef]

- Yasar, A.; Rasheed, R.; Tabinda, A.B.; Tahir, A.; Sarwar, F. Life cycle assessment of a medium commercial scale biogas plant and nutritional assessment of effluent slurry. Renew. Sustain. Energy Rev. 2017, 67, 364–371. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Hanafiah, M.M. Quantifying Effects of Physical, Chemical and Biological Stressors in Life Cycle Assessment. Ph.D Thesis, Radboud University, Nijmegen, The Netherlands, 2013. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment: Part 1: Framework, goal and scope definition, inventory analysis and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: Principles and Practice; United States Environmental Protection Agency: Washington, DC, USA, 2006. [Google Scholar]

- Heijungs, R.; Goedkoop, M.; Struijs, J.; Effting, S.; Sevenster, M.; Huppes, G. Towards a Life Cycle Impact Assessment Method Which Comprises Category Indicators at the Midpoint and the Endpoint Level. Report of the First Project Phase: Design of the New Method VROM Report. 2003. Available online: http://www.leidenuniv.nl/cml/ssp/publications/recipe_phase1.pdf (accessed on 1 March 2019).

- Huijbregts, M. A critical view on scientific consensus building in life cycle impact assessment. Int. J. Life Cycle Assess. 2014, 19, 477–479. [Google Scholar] [CrossRef]

- Talve, S. The life cycle assessment management tool for technologies in Eastern Europe: Why and how. Int. J. Life Cycle Assess. 2001, 6, 181–183. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Feasibility study of biogas production and utilization as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 2013, 19, 454–462. [Google Scholar] [CrossRef]

- Ali, M.Y.M.; Hanafiah, M.M.; Wen, Y.H.; Idris, M.; Aziz, N.I.H.A.; Halim, A.A.; Lee, K.E. Biogas production from different substrates under anaerobic conditions. In Proceedings of the 3rd International Conference on Agricultural and Medical Sciences (CAMS-2015), Singapore, 10–11 December 2015; pp. 54–56. [Google Scholar]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Ali, M.Y.M. Sustainable biogas production from agrowaste and effluents–a promising step for small-scale industry income. Renew. Energy 2019, 132, 363–369. [Google Scholar] [CrossRef]

- Choo, Y.M.; Muhamad, H.; Hashim, Z.; Subramaniam, V.; Puah, C.W.; Tan, Y. Determination of GHG contributions by subsystems in the oil palm supply chain using the LCA approach. Int. J. Life Cycle Assess. 2011, 16, 669–681. [Google Scholar] [CrossRef]

- SIRIM. LCA Projects. 2016. Available online: http://lcamalaysia.sirim.my/index.php/project (accessed on 5 March 2019).

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2020, 145, 847–857. [Google Scholar] [CrossRef]

- Lamnatou, C.; Nicolai, R.; Chemisana, D.; Cristofari, C.; Cancelleiri, D. Biogas production means of an anaerobic-digestion plant in France: LCA of greenhouse-gas emissions and other environmental indicators. Sci. Total Environ. 2019, 670, 1226–1239. [Google Scholar] [CrossRef]

- Lauer, M.; Dotzauer, M.; Hennig, C.; Lehmann, M.; Nebel, E.; Postel, J.; Szarka, N.; Thrän, D. Flexible power generation scenarios for biogas plants operated in Germany: Impacts on economic viability and GHG emissions. Int. J. Energy Res. 2017, 41, 63–80. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311–313. [Google Scholar] [CrossRef]

- Hussein, M.E.; Alam, R.Z.; Siwar, C.; Ludin, N.A. Green economy models and energy policies towards sustainable development in Malaysia: A review. Int. J. Green Econ. 2016, 10, 89–106. [Google Scholar] [CrossRef]

- Yatim, P.; Mamat, M.N.; Mohamad Zailani, S.H.; Ramlee, S. Energy policy shifts towards sustainable energy future for Malaysia. Clean Technol. Environ. Policy 2016, 18, 1685–1695. [Google Scholar]

- Chen, W.M.; Kim, H.; Yamaguchi, H. Renewable energy in eastern Asia: Renewable energy policy review and comparative SWOT analysis for promoting renewable energy in Japan, South Korea and Taiwan. Energy Policy 2014, 74, 319–329. [Google Scholar] [CrossRef]

- Hua, Y.; Oliphant, M.; Hu, E.J. Development of renewable energy in Australia and China: A comparison of policies and status. Renew. Energy 2016, 85, 1044–1051. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Policy and Measures, Renewable Energy. 2019. Available online: www.iea.org (accessed on 17 March 2019).

- Alam, S.S.; Nor, N.F.M.; Ahmad, M.; Hashim, N.H.N. A survey on renewable energy development in Malaysia: Current status, problems and prospects. Environ. Climate Technol. 2016, 17, 5–17. [Google Scholar] [CrossRef]

- Fang, T.P.; Daud, W.R.W.; Halim, L.; Masdar, M.S. How ready is renewable energy? A review on renewable energy and fuel cell teaching in schools. In Proceedings of the 7th World Engineering Education Forum (WEEF), Kuala Lumpur, Malaysia, 13–16 November 2017; pp. 236–244. [Google Scholar]

- Brundtland, G. Our Common Future; Brundtland Report; United Nations World Commission on Environment and Development: Geneva, Switzerland, 1987. [Google Scholar]

- Heijungs, R.; Huppes, G.; Guinée, J.B. Life cycle assessment and sustainability analysis of products, materials and technologies. Toward a scientific framework for sustainability life cycle analysis. Polym. Degrad. Stab. 2010, 95, 422–428. [Google Scholar] [CrossRef]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89. [Google Scholar] [CrossRef]

- Mälkki, H.; Alanne, K. An overview of life cycle assessment (LCA) and researched-based teaching in renewable and sustainable energy education. Renew. Sustain. Energy Rev. 2017, 69, 218–231. [Google Scholar] [CrossRef]

- Coyle, E.; Rebow, M. Sustainable Design: A Case Study in Energy Systems. In Engineering in Context; Dublin Institute of Technology: Dublin, Ireland, 2009; pp. 1–17. [Google Scholar]

- Jürgensen, L.; Ehimen, E.A.; Born, J.; Holm-Nielsen, J.B. A combination anaerobic digestion scheme for biogas production from dairy effluent—CSTR and ABR, and biogas upgrading. Biomass Bioenergy 2018, 111, 241–247. [Google Scholar] [CrossRef]

- Ertem, F.C.; Martínez-Blanco, J.; Finkbeiner, M.; Neubauer, P.; Junne, S. Life cycle assessment of flexibly fed biogas processes for an improved demand-oriented biogas supply. Bioresour. Technol. 2016, 219, 536–544. [Google Scholar] [CrossRef]

- Styles, D.; Dominguez, E.M.; Chadwick, D. Environmental balance of the of the UK biogas sector: An evaluation by consequential life cycle assessment. Sci. Total Environ. 2016, 560, 241–253. [Google Scholar] [CrossRef]

- Curran, M. A Review of Life-Cycle Based Tools Used to Assess the Environmental Sustainability of Biofuels in the United States; Life Cycle Assessment Research Center; US Environmental Protection Agency: Cincinnati, OH, USA, 2013; Volume 1, p. 61. [Google Scholar]

- Sala, S.; Farioli, F.; Zamagni, A. Progress in sustainability science: Lessons learnt from current methodologies for sustainability assessment: Part 1. Int. J. Life Cycle Assess. 2013, 18, 1653–1672. [Google Scholar] [CrossRef]

- Takeda, S.; Keeley, A.R.; Sakurai, S.; Managi, S.; Norris, C.B. Are renewables as friendly to humans as to the environment? A social life cycle assessment of renewable electricity. Sustainability 2019, 11, 1370. [Google Scholar] [CrossRef]

- Markevičius, A.; Katinas, V.; Perednis, E.; Tamašauskienė, M. Trends and sustainability criteria of the production and use of liquid biofuels. Renew. Sustain. Energy Rev. 2010, 14, 3226–3231. [Google Scholar] [CrossRef]

- Milazzo, M.; Spina, F.; Cavallaro, S.; Bart, J. Sustainable soy biodiesel. Renew. Sustain. Energy Rev. 2013, 27, 806–852. [Google Scholar] [CrossRef]

- Turconi, R.; Boldrin, A.; Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef]

- Bößner, S.; Devisscher, T.; Suljada, T.; Ismail, C.J.; Sari, A.; Mondamina, N.W. Barriers and opportunities to bioenergy transitions: An integrated, multi-level perspective analysis of biogas uptake in Bali. Biomass Bioenergy 2019, 122, 457–465. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Basiron, Y. Palm oil production through sustainable plantations. Eur. J. Lipid Sci. Technol. 2007, 109, 289–295. [Google Scholar] [CrossRef]

- Ming, T.C.; Ramli, N.; Lye, O.T.; Said, M.; Kasim, Z. Strategies for decreasing the pour point and cloud point of palm oil products. Eur. J. Lipid Sci. Technol. 2005, 107, 505–512. [Google Scholar] [CrossRef]

- Mukherjee, I.; Sovacool, B.K. Palm oil-based biofuels and sustainability in Southeast Asia: A review of Indonesia, Malaysia, and Thailand. Renew. Sustain. Energy Rev. 2014, 37, 1–12. [Google Scholar] [CrossRef]

- Tan, C.; Man, Y.C. Differential scanning calorimetric analysis of palm oil, palm oil based products and coconut oil: Effects of scanning rate variation. Food Chem. 2002, 76, 89–102. [Google Scholar] [CrossRef]

- Teh, S.S.; Ong, A.S.H.; Mah, S.H. Recovery and utilization of palm oil mill effluent source as value-added food products. J. Oleo Sci. 2017, 66, 1183–1191. [Google Scholar] [CrossRef]

- Awalludin, M.F.; Sulaiman, O.; Hashim, R.; Nadhari, W.N.A.W. An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renew. Sustain. Energy Rev. 2015, 50, 1469–1484. [Google Scholar] [CrossRef]

- Bazmi, A.A.; Zahedi, G.; Hashim, H. Progress and challenges in utilization of palm oil biomass as fuel for decentralized electricity generation. Renew. Sustain. Energy Rev. 2011, 15, 574–583. [Google Scholar] [CrossRef]

- Basri, M.F.; Yacob, S.; Hassan, M.A.; Shirai, Y.; Wakisaka, M.; Zakaria, M.R.; Phang, L.Y. Improved biogas production from palm oil mill effluent by a scaled-down anaerobic treatment process. World J. Microbiol. Biotechnol. 2010, 26, 505–514. [Google Scholar] [CrossRef]

- Oswal, N.; Sarma, P.; Zinjarde, S.; Pant, A. Palm oil mill effluent treatment by a tropical marine yeast. Bioresour. Technol. 2002, 85, 35–37. [Google Scholar] [CrossRef]

- Mekhilef, S.; Barimani, M.; Safari, A.; Salam, Z. Malaysia’s renewable energy policies and programs with green aspects. Renew. Sustain. Energy Rev. 2014, 40, 497–504. [Google Scholar] [CrossRef]

- Shafie, S.M.; Mahlia, T.M.I.; Masjuki, H.H.; Andriyana, A. Current energy usage and sustainable energy in Malaysia: A review. Renew. Sustain. Energy Rev. 2011, 15, 4370–4377. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Drupady, I.M. Examining the small renewable energy power (SREP) program in Malaysia. Energy Policy 2011, 39, 7244–7256. [Google Scholar] [CrossRef]

- Umar, M.S.; Jennings, P.; Urmee, T. Strengthening the palm oil biomass renewable energy industry in Malaysia. Renew. Energy 2013, 60, 107–115. [Google Scholar] [CrossRef]

- Umar, M.S.; Jennings, P.; Urmee, T. Sustainable electricity generation from oil palm biomass wastes in Malaysia: An industry survey. Energy 2014, 67, 496–505. [Google Scholar] [CrossRef]

- Haris, A.H. Renewable Energy Bill and Subsidiary Legislations, Ministry of Energy, Green Technology and Water. 2011. Available online: Seda.gov.my (accessed on 13 March 2019).

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H. A review on life cycle assessment of biogas production: Challenges and future perspectives in Malaysia. Biomass Bioenergy 2019, 122, 361–374. [Google Scholar] [CrossRef]

- Abdurahman, N.; Rosli, Y.; Azhari, N. The performance evaluation of anaerobic methods for palm oil mill effluent (POME) treatment: A review. In International Perspectives on Water Quality Management and Pollutant Control; Quinn, N.W.T., Ed.; IntechOpen: London, UK, 2013; pp. 87–106. [Google Scholar]

- Ahmed, Y.; Yaakob, Z.; Akhtar, P.; Sopian, K. Production of biogas and performance evaluation of existing treatment processes in palm oil mill effluent (POME). Renew. Sustain. Energy Rev. 2015, 42, 1260–1278. [Google Scholar] [CrossRef]

- Wu, T.Y.; Mohammad, A.W.; Jahim, J.M.; Anuar, N. Pollution control technologies for the treatment of palm oil mill effluent (POME) through end-of-pipe processes. J. Environ. Manag. 2010, 91, 1467–1490. [Google Scholar] [CrossRef]

- Yuniarto, A.; Noor, Z.Z.; Ujang, Z.; Olsson, G.; Aris, A.; Hadibarata, T. Bio-fouling reducers for improving the performance of an aerobic submerged membrane bioreactor treating palm oil mill effluent. Desalination 2013, 316, 146–153. [Google Scholar] [CrossRef]

- Durham, B.; Mierzejewski, M. Water reuse and zero liquid discharge: A sustainable water resource solution. Water Sci Tech. Water Supply 2003, 3, 97–103. [Google Scholar] [CrossRef]

- Heins, W.; Schooley, K. Achieving zero liquid discharge in SAGD heavy oil recovery. J. Can. Petrol. Technol. 2004, 43, 1–8. [Google Scholar] [CrossRef]

- Katsoyiannis, I.; Castellana, M.; Cartechini, F.; Vaccarella, A.; Zouboulis, A.; Grinias, K. Application of zero liquid discharge water treatment units for wastewater reclamation: Possible application in marine ports. In Sustainable Development of Sea-Corridors and Coastal Waters; Springer: Cham, Switzerland, 2015; pp. 39–45. [Google Scholar]

- Mu, C.; Lin, W.; Zhang, M.; Zhu, Q. Towards zero discharge of chromium-containing leather waste through improved alkali hydrolysis. Waste Manag. 2003, 23, 835–843. [Google Scholar] [CrossRef]

- Wang, J.; Mahmood, Q.; Qiu, J.P.; Li, Y.S.; Chang, Y.S.; Chi, L.N.; Li, X.D. Zero discharge performance of an industrial pilot-scale plant treating palm oil mill effluent. BioMed Res. Int. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Rajakumari, S.P.; Kanmani, S. Environmental life cycle assessment of zero liquid discharge treatment technologies for textile industries, Tirupur: A case study. J. Sci. Ind. Res. 2008, 67, 461–467. [Google Scholar]

- Grant, S.B.; Saphores, J.D.; Feldman, D.L.; Hamilton, A.J.; Fletcher, T.D.; Cook, P.L.; Stewardson, M.; Sanders, B.F.; Levin, L.A.; Ambrose, R.F. Taking the “waste” out of “wastewater” for human water security and ecosystem sustainability. Science 2012, 337, 681–686. [Google Scholar] [CrossRef]

- Madaki, Y.S.; Seng, L. Pollution control: How feasible is zero discharge concepts in Malaysia palm oil mills. Am. J. Engineer. Res. 2013, 2, 239–252. [Google Scholar]

- Tong, T.; Elimelech, M. The global rise of zero liquid discharge for wastewater management: Drivers, technologies and future directions. Environ. Sci. Technol. 2016, 50, 6846–6855. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.; Wernet, G. Overview and Methodology: Data Quality Guideline for the Ecoinvent Database Version 3; Ecoinvent Report 1 (v3); The Ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Durlinger, B.; Tyszler, M.; Scholten, J.; Broekema, R.; Blonk, H.; Beatrixstraat, G. Agri-footprint: A life cycle inventory database covering food and feed production and processing. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014; pp. 310–317. [Google Scholar]

- Norris, G.A. Simapro Database Manual: The Franklin US LCI Library; Pré Consultants and Sylvatica: Amersfoort, The Netherlands, 2004; pp. 1–30. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.; Elshout, P.; Stam, G.; Verones, F.; Vieira, M.; Hollander, A.; Zijp, M.; Van Zelm, R. Recipe 2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; RIVM Report 2016–0104; National Institute for Human Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar]

- ISO 14044. Environmental Management—Life Cycle Assessment—Requirements and Guidelines, European Committee for Standardization; International Organization for Standardization ISO Central Secretariat: Geneva, Switzerland, 2006. [Google Scholar]

- Lee, K.E.; Mokhtar, M.; Mohd Hanafiah, M.; Abdul Halim, A.; Badusah, J. Rainwater harvesting as an alternative water resource in Malaysia: Potential, policies and development. J. Clean. Prod. 2016, 126, 218–222. [Google Scholar] [CrossRef]

- Loh, S.K.; Lai, M.E.; Ngatiman, M.; Lim, W.S.; Choo, Y.M.; Zhang, Z.; Salimon, J. Zero discharge treatment technology of palm oil mill effluent. J. Oil Palm Res. 2013, 25, 273–281. [Google Scholar]

- Tabassum, S.; Zhang, Y.; Zhang, Z. An integrated method for palm oil mill effluent (POME) treatment for achieving zero liquid discharge: A pilot study. J. Clean. Prod. 2015, 95, 148–155. [Google Scholar] [CrossRef]

- International Energy Agency. CO2 Emissions from Fuel Combustion—Highlights; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Energy Commission. 2016. Available online: https://www.st.gov.my/ (accessed on 3 January 2019).

- Oh, T.H.; Hasanuzzaman, M.; Selvaraj, J.; Teo, S.C.; Chua, S.C. Energy policy and alternative energy in Malaysia: Issues and challenges for sustainable growth–an update. Renew. Sustain. Energy Rev. 2017, 81, 3021–3031. [Google Scholar] [CrossRef]

- Mahlia, T. Emissions from electricity generation in Malaysia. Renew. Energy 2002, 27, 293–300. [Google Scholar] [CrossRef]

- Shafie, S.; Mahlia, T.; Masjuki, H.; Ahmad-Yazid, A. A review on electricity generation based on biomass residue in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5879–5889. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life cycle assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Wang, Q.L.; Li, W.; Gao, X.; Li, S.J. Life cycle assessment on biogas production from straw and its sensitivity analysis. Bioresour. Technol. 2016, 201, 208–214. [Google Scholar] [CrossRef]

- Roux, C.; Schalbart, P.; Peuportier, B. Accounting for temporal variation of electricity production and consumption in the LCA of an energy-efficient house. J. Clean. Prod. 2016, 113, 532–540. [Google Scholar] [CrossRef]

- Wang, J.; Mahmood, Q.; Qiu, J.P.; Li, Y.S.; Chang, Y.S.; Li, X.D. Anaerobic treatment of palm oil mill effluent in pilot-scale anaerobic EGSB reactor. BioMed Res. Int. 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Ali, R.; Daut, I.; Taib, S. A review on existing and future energy sources for electrical power generation in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 4047–4055. [Google Scholar] [CrossRef]

- Khor, C.S.; Lalchand, G. A review on sustainable power generation in Malaysia to 2030: Historical perspective, current assessment, and future strategies. Renew. Sustain. Energy Rev. 2014, 29, 952–960. [Google Scholar] [CrossRef]

- Jaramillo, P.; Griffin, W.M.; Matthews, H.S. Comparative life-cycle air emissions of coal, domestic natural gas, lng, and sng for electricity generation. Environ. Sci. Technol. 2007, 41, 6290–6296. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Kwon, H.T.; Choi, K.H.; Hyun Cho, J.; Lim, W.; Moon, I. Current status and future projections of LNG demand and supplies: A global prospective. Energy Policy 2011, 39, 4097–4104. [Google Scholar] [CrossRef]

- Tilton, J.E. On Borrowed Time? Assessing the Threat of Mineral Depletion; Routledge: New York, NY, USA, 2010; pp. 1–158. [Google Scholar]

- International Gas Union. 2017. Available online: https://www.igu.org/ (accessed on 3 January 2019).

- Hengeveld, E.J.; Bekkering, J.; Van Gemert, W.J.T.; Broekhuis, A.A. Biogas infrastructures from farm to regional scale, prospects of biogas transport grids. Biomass Bioenergy 2016, 86, 43–52. [Google Scholar] [CrossRef]

- Trummer, D.R. Biomass-Fired CHP in Palm Oil Mills. In Malaysian-Danish Country Programme for Cooperation in Environment and Sustainable Development (2002–2006); Royal Danish Embassy: Kuala Lumpur, Malaysia, 2001. [Google Scholar]

- Cervi, W.R.; Lamparelli, R.A.C.; Seabra, J.E.A.; Junginger, M.; Van Der Hilst, F. Bioelectricity potential from ecologically available sugarcane straw in Brazil: A spatially explicit assessment. Biomass Bioenergy 2019, 122, 391–399. [Google Scholar] [CrossRef]

- Gigliucci, G.; Petruzzi, L.; Cerelli, E.; Garzisi, A.; La Mendola, A. Demonstration of a residential CHP system based on PEM fuel cells. J. Power Sources 2004, 131, 62–68. [Google Scholar] [CrossRef]

- Parsaee, M.; Kiani, M.K.D.; Karimi, K. A review of biogas production from sugarcane vinasse. Biomass Bioenergy 2019, 122, 117–125. [Google Scholar] [CrossRef]

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Chin, M.J.; Poh, P.E.; Tey, B.T.; Chan, E.S.; Chin, K.L. Biogas from palm oil mill effluent (POME): Opportunities and challenges from Malaysia’s perspective. Renew. Sustain. Energy Rev. 2013, 26, 717–726. [Google Scholar] [CrossRef]

| Country | Legislation and Regulation |

|---|---|

| Developed Countries | |

| Germany | 2017 Amendment of the Renewable Energy Sources Act (EEG 2017) |

| Subsidy for solar PV with storage installations | |

| Ground-Mounted PV Auction Ordinance (2015) | |

| 2014 Amendment of the Renewable Energy Sources Act (EEG 2014) | |

| CHP Agreements with Industry | |

| KfW Program Offshore Wind Energy | |

| Law on Energy and Climate Fund | |

| "Energy of the Future" monitoring process | |

| Sixth Energy Research Program | |

| Biofuels Quota Act (2010) | |

| Energy Concept | |

| National Energy Action Plan (NREAP) (2010) | |

| KfW Renewable Energies Program | |

| KfW Program Energy-Efficient Rehabilitation | |

| Renewable Energies Heat Act (2009) | |

| Climate Legislation Package Enacted under the Integrated Climate Change and Energy Program (2008) | |

| Integrated Climate Change and Energy Program | |

| Funding for Solar Power Development Center | |

| Energy Industry Act (2005) (amended 2012) | |

| Law to Amend the Mineral Oil Tax Law and Renewable Energy Law (2002) | |

| Combined Heat and Power Law (2002) | |

| Eco-Tax Reform (1999) | |

| Market Incentive Program | |

| Preferential Loan Program offered by the Reconstruction Loan Corporation (KfW) | |

| Federal Building Codes for Renewable Energy Production | |

| Green Power | |

| Ordinance on the Fee Schedule for Architects and Engineers (1995) | |

| Federal States Support for Renewable Energy (1985) | |

| Australia | Renewable Energy (Electricity) Act 2000 |

| Renewable Energy (Electricity) (Small-Scale Technology Shortfall Charge) Act 2010 | |

| Renewable Energy (Electricity) (Large-Scale Generation Shortfall Charge) Act 2000 | |

| Renewable Energy (Electricity) Regulation 2001, | |

| Renewable Energy Certificates (RECs) | |

| Japan | Law Concerning the Promotion of the Development and Introduction of Alternative Energy |

| Long-Term Energy Supply and Demand Outlook (2015) | |

| Strategic Energy Plan (2014) | |

| Feed-in Tariff for Renewable Electricity and Solar PV Auction (2012) | |

| Global Methane Initiative (2010) | |

| Cool Earth-Energy Innovative Technology Plan (2008) | |

| Seaway Signals Converted to Use Renewable Energy (2000) | |

| Promotion of New and Renewable Energy (1997) | |

| Special Measures Law for Promoting the Use of New Energy (1997) | |

| Projects for Development and Deployment of New and Renewable Energy by NEDO and by NEPC (1980) | |

| Law on Establishment of NEDO (1980) | |

| Developing Countries | |

| China | Renewable Energy Law |

| Regulation on Administration of Power Generation from Renewable Energy | |

| Measures on Supervision and Administration of Grid Enterprises in the Purchase of Renewable Energy Power | |

| Trial Management Measures for Renewable Power Pricing and Cost Share | |

| Trial Management Measure for Allocation of Renewable Energy Tariff Surplus Revenue | |

| Notice of Strengthening the Construction and Management of Biofuel Ethanol and Promoting Sound Industrial Development | |

| Trial Management Measures for the Special Development Fund Implementation | |

| Guidelines on Promoting Wind Power Industry | |

| Guides to Renewable Energy Development | |

| Thailand | Thailand Alternative Energy Development Plan (AEDP 2015-2036) |

| Feed-in Tariff for Very Small Power Producers (VSPP) (excluding solar PV) | |

| Feed-in tariff for distributed solar systems | |

| Biodiesel blending mandate | |

| Renewable Energy Development Plan (REDP) 2008-2022 | |

| Small and Very Small Power Purchase Agreements | |

| Energy Conservation Program (ENCON) | |

| Vietnam | National Power Development Plan 7 (PDPD7 – revised) (2016) |

| Vietnam Renewable Energy Development Strategy 2016-2030 with outlook until 2050 (REDS) | |

| Decision on support mechanisms for the development of biomass power project in Vietnam (biomass feed-in tariff) | |

| Decision on support mechanisms for the development of waste-to-energy power projects in Vietnam (feed-in tariff) | |

| Accelerated depreciation tax relief for renewable energy projects | |

| Electricity Law (2005) | |

| Decree No. 45/2001/ND-CP on electric power operation and use (2001) |

| Input/Output | Unit | Amount | Data Source | Link process/substance in SimaPro 8.5.0 |

|---|---|---|---|---|

| Input from technosphere | ||||

| Materials and fuels | ||||

| Palm oil mill effluent (POME) | t | 1 | On-site data | Palm oil mill effluent |

| Energy | ||||

| Electricity from grid | kWh | 0.385 | On-site data | Electricity mix, AC, consumption mix, at consumer, < 1 kV/MY Mass |

| Electricity from biogas | kWh | 0.321 | On-site data | Biogas, zero discharge treatment plant/MY |

| Output to technosphere | ||||

| Products and co-products | ||||

| Clean water | t | 0.75 | On-site data | Clean water |

| Biogas | m3 | 28 | On-site data | Biogas, zero discharge treatment plant/MY |

| Sludge oil | kg | 4.70 | On-site data | Sludge oil |

| Organic solid sludge | kg | 28.98 | On-site data | Organic solid sludge |

| RO concentrate (K2O & MgO) | kg | 3.41 | On-site data | RO concentrate (K2O & MgO) |

| Input from environment | ||||

| Resource | ||||

| Water | m3 | 0.0002 | On-site data | Water, rain |

| Parameter | Unit | Raw POME | EQ | AnaEG Effluent | Nano Clarifier | BioAX Effluent | UF/RO Permeate |

|---|---|---|---|---|---|---|---|

| pH | 4.30 | 4.00 | 7.00 | 7.50 | 8.00 | 9.48 | |

| COD | mg/L | 75000 | 65000 | 4500 | 2000 | 1100 | ND |

| BOD5 | mg/L | 27000 | NM | NM | 820 | <20 | ND |

| TS | mg/L | 100000 | 48600 | 22600 | 8200 | 5650 | NM |

| SS | mg/L | 50000 | 22778 | 13840 | 350 | 191 | ND |

| TVS | mg/L | 80000 | 40200 | 14300 | 3000 | 1600 | NM |

| Dissolved solids | mg/L | 50000 | 25882 | 8760 | 7850 | 5459 | NM |

| VFA | mg/L | 2184 | NM | 413 | NM | NM | NM |

| Total Alkalinity | mg/L | 536 | NM | 4100 | NM | NM | NM |

| Turbidity | NTU | NM | NM | NM | 700 | 110.0 | 0.4 |

| Impact Category | Unit | Total |

|---|---|---|

| GWP | kg CO2-eq | 4.42 × 102 |

| ODP | kg CFC11-eq | 7.75 × 10−9 |

| IRP | kBq Co-60-eq | 4.80 × 10−7 |

| HOFP | kg NOx-eq | 2.15 × 10−4 |

| PMFP | kg PM2.5-eq | 1.49 × 10−3 |

| EOFP | kg NOx-eq | 2.17 × 10−4 |

| TAP | kg SO2-eq | 1.00 × 10−2 |

| FEP | kg P-eq | 6.65 × 10−12 |

| MEP | kg N-eq | 2.42 × 10−7 |

| TETP | kg 1,4-DCB | 3.08 × 10−2 |

| FETP | kg 1,4-DCB | 1.82 × 10−4 |

| METP | kg 1,4-DCB | 2.49 × 10−4 |

| HTPc | kg 1,4-DCB | 7.93 × 10−5 |

| HTPnc | kg 1,4-DCB | 8.50 × 10−3 |

| SOP | kg Cu-eq | 1.32 × 10−7 |

| FFP | kg oil-eq | 4.06 × 10−2 |

| WCP | m3 | 2.02 × 10−4 |

| Area of protection | Unit | Total |

|---|---|---|

| Human Health | ||

| GWP, Human health | DALY | 4.12 × 10−4 |

| ODP | DALY | 4.11 × 10−12 |

| HOFP | DALY | 1.96 × 10−10 |

| PMFP | DALY | 9.38 × 10−7 |

| HTPc | DALY | 2.63 × 10−10 |

| HTPnc | DALY | 1.94 × 10−9 |

| Total | DALY | 4.13 × 10−4 |

| Ecosystem Damage | ||

| GWP, Terrestrial ecosystems | species.yr | 1.24 × 10−6 |

| GWP, Freshwater ecosystems | species.yr | 3.39 × 10−11 |

| EOFP | species.yr | 2.80 × 10−11 |

| TAP | species.yr | 2.13 × 10−9 |

| MEP | species.yr | 4.12 × 10−16 |

| TETP | species.yr | 3.51 × 10−13 |

| FETP | species.yr | 1.26 × 10−13 |

| METP | species.yr | 2.62 × 10−14 |

| Total | species.yr | 1.24 × 10−6 |

| Resource Availability | ||

| FFP | USD | 9.00 × 10−3 |

| Total | USD | 9.00 × 10−3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H.; Ismail, H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability 2020, 12, 3213. https://doi.org/10.3390/su12083213

Aziz NIHA, Hanafiah MM, Gheewala SH, Ismail H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability. 2020; 12(8):3213. https://doi.org/10.3390/su12083213

Chicago/Turabian StyleAziz, Nur Izzah Hamna A., Marlia M. Hanafiah, Shabbir H. Gheewala, and Haikal Ismail. 2020. "Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector" Sustainability 12, no. 8: 3213. https://doi.org/10.3390/su12083213

APA StyleAziz, N. I. H. A., Hanafiah, M. M., Gheewala, S. H., & Ismail, H. (2020). Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability, 12(8), 3213. https://doi.org/10.3390/su12083213