Sustainable Water Use Considering Three Hungarian Dairy Farms

Abstract

1. Introduction

“Not doing so often underlies the general failure of programs or policies aimed at enhancing farmers’ resilience through intensification of production and can lead to otherwise avoidable and unintended negative environmental consequences. In many cases, intensification initially increases production but decreases it in the long run” [11].

2. Materials and Methods

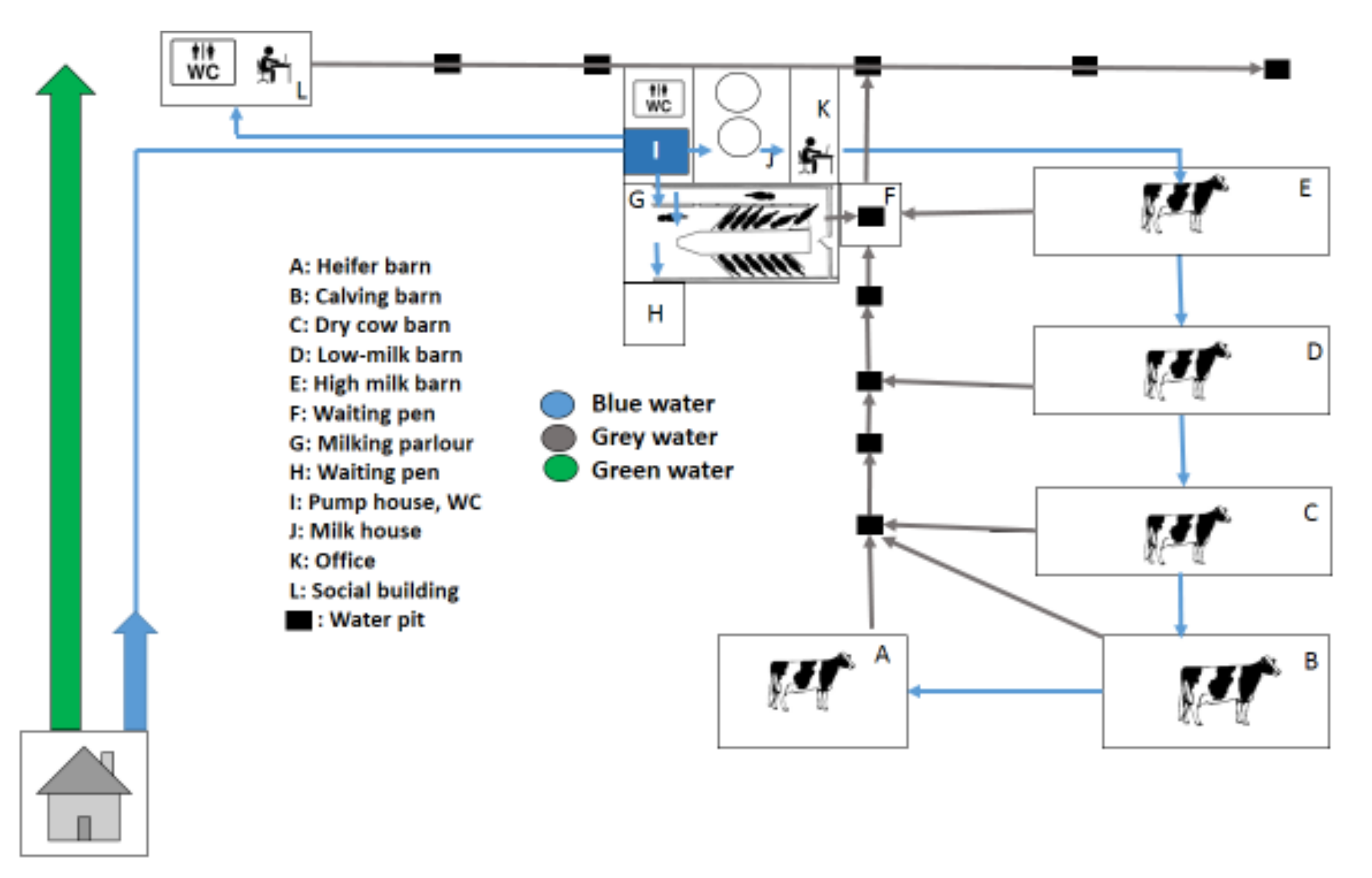

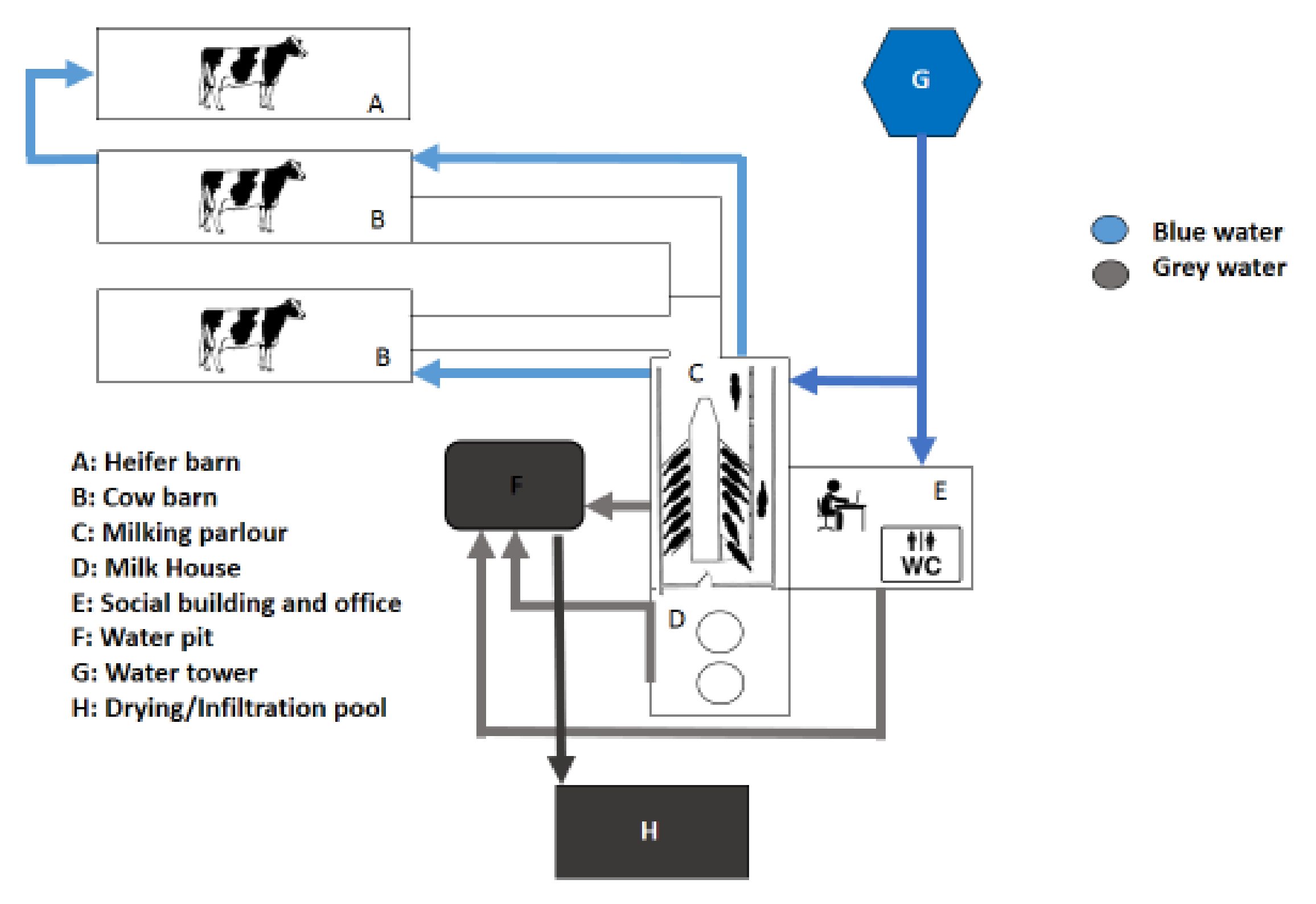

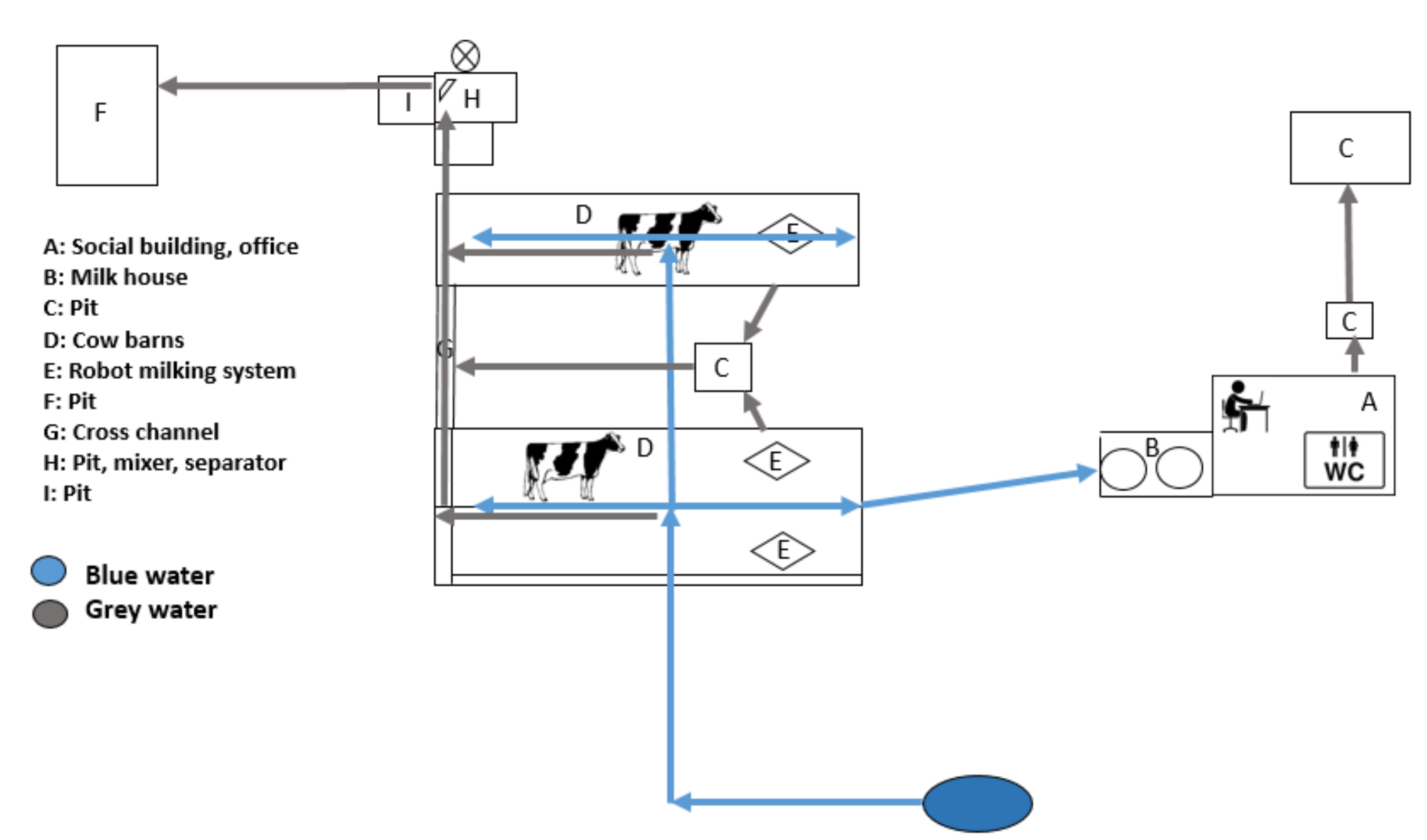

2.1. Animal Housing

2.2. Water Use of Dairy Farms

3. Results

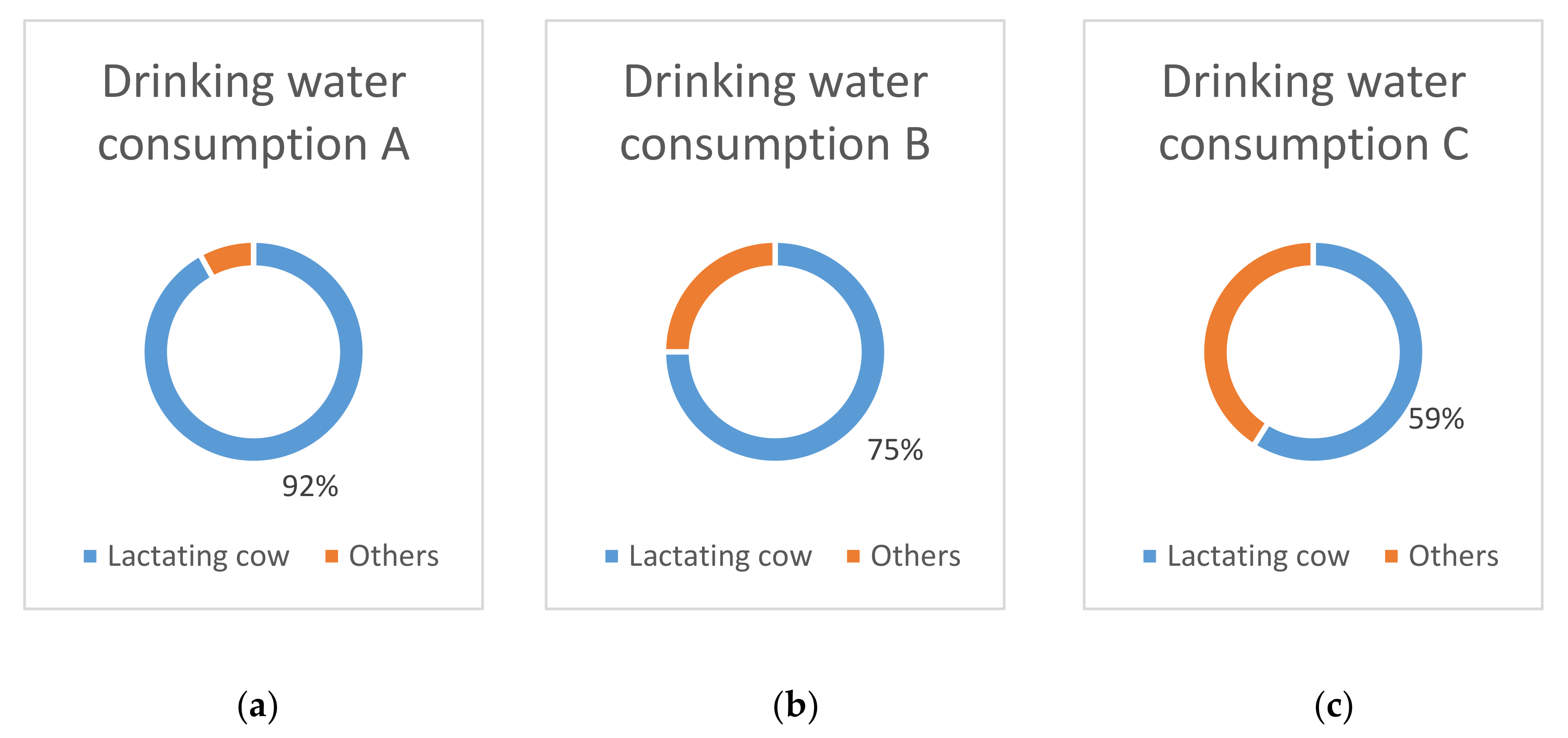

3.1. Drinking Water Consumption of the Farms

3.2. Technological Water Use

3.3. Total Water Use of the Farms

3.4. WU Considering Milking System

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- UNIS. Sustainable Development Goals. 2019. Available online: http://www.unis.unvienna.org/unis/hu/topics/sustainable_development_goals.html (accessed on 13 January 2020).

- Ridoutt, B.; Williams, S.; Baud, S.; Fraval, S.; Marks, N. Short communication: The water footprint of dairy products: Case study involving skim milk powder. J. Dairy Sci. 2010, 93, 5114–5117. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, D.P.; Knee, J.E.; Doyle, P.T.; Pritchard, K.E.; Gyles, O.A. Water-use efficiency on irrigated dairy farms in northern Victoria and southern NSW. Anim. Prod. Sci. 2000, 40, 643–653. [Google Scholar] [CrossRef]

- Lin, J.C.; Moss, B.R.; Koon, J.L.; Flood, C.A.; Smith, R.C., III; Cummins, K.A.; Coleman, D.A. Comparison of various fan, sprinkler, and mister systems in reducing heat stress in dairy cows. Appl. Eng. Agric. 1998, 14, 177–182. [Google Scholar] [CrossRef]

- Drastig, K.; Prochnow, A.; Kraatz, S.; Klauss, H.; Plochl, M. Water footprint analysis for the assessment of milk production in Brandenburg–Germany. Adv. Geosci. 2010. Available online: http://www.adv-geosci.net/27/65/2010/adgeo-27-65-2010.html (accessed on 14 February 2020).

- Legrand, A.; Schültz, K.E.; Tucker, C.B. Using water to cool cattle: Behavioral and physiological changes associated with voluntary use of cow showers. J. Dairy Sci. 2011, 94, 3376–3386. [Google Scholar] [CrossRef] [PubMed]

- Le Riche, E.L.; Vanderzaag, A.C.; Burtt, S.; Lapen, D.; Gordon, R.J. Water Use and Conservation on a Free-Stall Dairy Farm. Water 2017, 9, 977. [Google Scholar] [CrossRef]

- SAI. Water Stewardship in Sustainable Agriculture beyond the Farm Towards a Catchment. 2013. Available online: https://saiplatform.org/uploads/SAI%20Platform%20Water%20Stewardship%20report.pdf (accessed on 14 February 2020).

- De Boer, I.J.M.; Hoving, I.E.; Vellinga, T.; Van De Ven, G.W.J.; Leffelaar, P.A.; Gerber, P.J. Assessing Environmental Impacts Associated with Freshwater Consumption along the Life Cycle of Animal Products: The Case of Dutch Milk Production In Noord-brabant. Int. J. Life Cycle Assess. 2013, 18, 193–203. [Google Scholar] [CrossRef]

- Palhares, J.C.P.; Pezzopane, J.R.M. Water footprint accounting and scarcity indicators of conventional and organic dairy production systems. J. Clean. Prod. 2015, 93, 299–307. [Google Scholar] [CrossRef]

- Bosire, C.K.; Rao, J.; Muchenje, V.; Van Wijk, M.; Ogutu, J.O.; Mekonnen, M.M.; Hammond, J. Agriculture, ecosystems and environment adaptation opportunities for smallholder dairy farmers facing resource scarcity: Integrated livestock, water and land management. Agric. Ecosyst. Environ. 2019, 284, 106592. [Google Scholar] [CrossRef]

- Gerber, P.; Velligna, T.; Opio, C.; Henderson, B.; Steinfeld, H. Greenhouse Gas Emissions from theDairy SectorA Life Cycle Assessment. 2010. Available online: http://www.fao.org/3/k7930e/k7930e00.pdf (accessed on 10 March 2020).

- FAO. Water Use of Livestock Production Systems and Supply Chains. 2018. Available online: http://www.fao.org/3/I9692EN/i9692en.pdf (accessed on 7 March 2019).

- Usva, K.; Virtanen, E.; Hyvärinen, H.; Nousiainen, J.; Sinkko, T.; Kurppa, S. Water in an LCA framework–applying the methodology to milk production in Finland. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco, CA, USA, 8–10 October 2014; Schenck, R., Huizenga, D., Eds.; ACLCA: Vashon, WA, USA, 2014. [Google Scholar]

| Category | Number of Animals in the Category | ||

|---|---|---|---|

| Farm A | Farm B | Farm C | |

| High-yield cow | 160 | 560 | 580 |

| Low-yield cow | 70 | ||

| Dry cow | 25 | 80 | 120 |

| Heifers | 25 | 500 | 1300 |

| Calves | 30 | 100 | 160 |

| Cow before calving | 10 | 160 | 50 |

| Total | 320 | 1400 | 2210 |

| Category | Farm A | Farm B | Farm C | |||||

|---|---|---|---|---|---|---|---|---|

| Number of Animals | Water Consumption [L] | No of Animals | Water Consumption [L] | No of Animals | Water Consumption [L] | |||

| High-yield cow | 160 | 20 000 | 560 | 70 000 | 580 | 58 000 | ||

| Low-yield cow | 70 | 7210 | ||||||

| Dry cow | 25 | 1050 | 80 | 3360 | 120 | 5040 | ||

| Heifers | 25 | 625 | 500 | 12 500 | 1300 | 32 500 | ||

| Calves | 30 | 210 | 100 | 700 | 160 | 1120 | ||

| Cow before calving | 10 | 450 | 160 | 7200 | 50 | 2250 | ||

| Total | 320 | 29 535 | 1400 | 93 760 | 2210 | 98 910 | ||

| A | B | C | |

|---|---|---|---|

| Category | (L/day) | ||

| Milk tank washing | 500 | 1200 | 370 |

| Washing udder | 100 | Dry preparation | 326 |

| Washing robotic milking system | - | - | 754 |

| Washing platform and milking equipment | 300 | 6500 | - |

| Total | 900 | 7700 | 1450 |

| (m3) | A | B | C | |||

|---|---|---|---|---|---|---|

| Cold Period | Hot Period | Cold Period | Hot Period | Cold Period | Hot Period | |

| Average total WU/month | 925 | 1025 | 2925 | 3249 | 3024 | 3390 |

| Average total WU m3 month−1 milking cow−1 | 4.02 | 4.45 | 5.22 | 5.80 | 5.21 | 5.84 |

| Average total WU/day | 30.3 | 34.6 | 97.7 | 108.6 | 100.8 | 113 |

| Drinking water/day | 29 | 33 | 94 | 104 | 99 | 109 |

| Technical water/day | 0.9 | 0.9 | 2.9 | 2.9 | 1.4 | 1.4 |

| Social water/day | 0.4 | 0.5 | 0.8 | 1.5 | 0.4 | 2.3 |

| Humidifier/day | - | 0.15 | - | 0.2 | - | 0.3 |

| Farm | A | B | C |

|---|---|---|---|

| Number of lactating cows (cows day−1) | 230 | 560 | 580 |

| FPCM (kg cow−1 day−1) | 29.84 | 35.96 | 34.97 |

| Technological water use of milking (liter day−1) | 900 | 7700 | 1450 |

| Technological water use of milking (kgwater cow−1 day−1) | 3.91 | 13.75 | 2.5 |

| Technological water use for a cow to produce 1 kg milk (kgwater cow−1 kg milk−1) | 0.13 | 0.38 | 0.071 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagypál, V.; Mikó, E.; Hodúr, C. Sustainable Water Use Considering Three Hungarian Dairy Farms. Sustainability 2020, 12, 3145. https://doi.org/10.3390/su12083145

Nagypál V, Mikó E, Hodúr C. Sustainable Water Use Considering Three Hungarian Dairy Farms. Sustainability. 2020; 12(8):3145. https://doi.org/10.3390/su12083145

Chicago/Turabian StyleNagypál, Virág, Edit Mikó, and Cecilia Hodúr. 2020. "Sustainable Water Use Considering Three Hungarian Dairy Farms" Sustainability 12, no. 8: 3145. https://doi.org/10.3390/su12083145

APA StyleNagypál, V., Mikó, E., & Hodúr, C. (2020). Sustainable Water Use Considering Three Hungarian Dairy Farms. Sustainability, 12(8), 3145. https://doi.org/10.3390/su12083145