Abstract

Pneumatic separation is one of the available methods for cleaning seed mixtures. Variously shaped seeds, including spherical (vetch), elongated (wheat), and pyramid-shaped seeds (buckwheat), were analyzed in this study. A seed mixture containing 80% of main crop seeds and 20% of other crop seeds imitating impurities was separated in a pneumatic separator with the shape of an inverted cone in a stream of air. The regression equations describing the separation efficiency of the main crop seeds and other crop seeds imitating impurities (η) and the separation efficiency index (ε) were characterized by high and very high fit to empirical data. The coefficient of determination for the analyzed seed mixtures ranged from 0.71 to 0.99. The conical separator supported effective separation of seed mixture components in a stream of air.

1. Introduction

Seeds often fail to meet the qualitative criteria for processing in the food industry and are frequently disqualified. Therefore, seed cleaning methods are continuously optimized, and new equipment and devices that meet stringent industrial requirements and consumer expectations are being developed [1,2,3,4,5,6]. High qualitative standards are imposed not only on the principal cereal species, but also on buckwheat, which has emerged as an important source material for the production of gluten-free foods in recent years [7]. Seeds that are uniform in terms of the desired attributes can be effectively processed and used in the production of high-quality foods [8,9,10]. Modern sowing technologies also require seeds characterized by high viability and germination capacity, as well as seeds that are homogeneous, cleaned, and sorted [11,12]. Apart from the seeds of crop plants, the seeds of forest trees and shrubs are also difficult to separate due to considerable variation in size and shape. Wings and cone remnants have to be removed from the seed mixture, and the separated seed lots are usually small [13,14].

The separation traits that differentiate seeds from impurities are used in seed cleaning and sorting processes. They include geometric parameters, aerodynamic properties, mass, density, electrostatic and mechanical properties. The use of various machines and devices in separation processes compromises the accuracy of seed classification [15,16].Conventional seed cleaning machines and devices (winnowers, grain graders, separators, aspirators) that rely on a single seed attribute generally do not produce satisfactory results, and the purified material fails to meet the relevant industrial standards. Therefore, seed sorting methods are being continuously improved by searching for new separation traits and designing new equipment [17]. Seed mixtures are separated in a stream of air in specialized pneumatic cleaners as well as in simpler threshing machines [18,19,20,21,22]. Air flow is frequently used to separate seeds because pneumatic devices have a simple structure and are easy to operate. [23,24]. Seeds are also dried, aired, and transported by a stream of air. Pneumatic devices are popular due to their high separation efficiency, versatility, and low operating cost.

This group of devices includes separators where the separating screen has the shape of a truncated cone. Unlike the most popular types of seed separators, devices with a conical screen improve the quality and efficiency of the separation process. Conical separators are also characterized by a simple structure, small size, and low energy requirements (relative to the achieved effect), which makes them worth further development.

Theoretical research into the separation of seed mixtures across conical surfaces where seeds travel in curvilinear motion was conducted by Gołąb [25,26,27], Pankowski [28], and Wierzbicki and Reszczyński [29]. Their findings confirmed that an inverted truncated cone effectively separates seeds into different fractions. However, in the analyzed solutions, seeds were separated by setting the cone into rotary motion. Reszczyński and Wierzbicki [29] designed a stationary cone where seeds were separated and transported by a stream of air.

The aim of this study was to develop a stationary seed separator with the shape of a truncated cone, where seeds are set into motion by a stream of air to enable effective separation and purification of a seed mixture composed of spherical, elongated, and pyramid-shaped seeds.

2. Materials and Methods

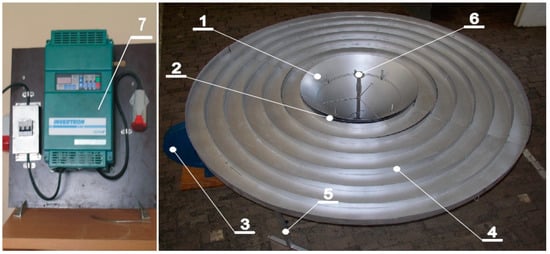

The model seed mixtures analyzed in this study were composed of three seed species: common vetch cv. Hanka, spring bread wheat cv. Tybalt, and common buckwheat cv. Panda, which were purchased in a seed store in Olsztyn. The relative moisture content of the purchased seeds was estimated at 12.00%. The seeds were selected for the experiment based on their shape: spherical (vetch), elongated (wheat), and pyramid-shaped (buckwheat). The seed mixture with a mass of 100 g contained 80% of main crop seeds and 20% of other crop seeds imitating impurities in six combinations: vetch with buckwheat and wheat, wheat with buckwheat and vetch, and buckwheat with wheat and vetch. The seed mixture was separated in a pneumatic conical separator [30]. The test stand with a power inverter is presented in Figure 1.

Figure 1.

Test stand: 1—inner cone, 2—outer cone, 3—fan, 4—troughs, 5—base, 6—control knob, 7—power inverter [31].

The experimental factors were:

- Fixed factors:

- width of the grain inlet, w = 10 mm;

- sample mass, ms = 100 g;

- length of the cone’s generating line, L = 500 mm;

- trough width, tw = 100 mm;

- cone’s apex angle, 2β = 90°;

- Variable factors:

- air stream velocity, V= 18.79 ÷ 19.56 m · s−1;

- moisture content of the seed mixture, M = 10.1 ÷ 17.3%;

- seed mixture variant mw/b—wheat and buckwheat, mw/v—wheat and vetch, mv/w—vetch and wheat, mv/b—vetch and buckwheat, mb/w—buckwheat and wheat, mb/v—buckwheat and vetch.

The moisture content of seeds was increased to 10%, 14%, and 17%, separately for each seed species. The target moisture content was achieved by adding the required amount to water based on the following equation [32]:

where:

- Mw—the mass of water required to increase the moisture content of seeds, g;

- M0—the initial moisture content of seeds, %;

- M1—the required moisture content of seeds after water addition, %;

- m—the sample mass, g.

After the addition of water, seeds were stirred, placed in air-tight containers and stored in a refrigerator at a temperature of around 4 °C for 48 h. The samples were stirred several times to uniformly distribute moisture. The samples were removed from the refrigerator one hour before the experiment to bring seeds to room temperature. Samples with the target moisture content of around 10.00% were left to dry at room temperature for 48 h. The moisture content of seed samples was determined at 10.10%, 13.70%, and 17.30% by the oven-drying method.

In the first step of the experiment, the width of the grain inlet was set to the preset value. Fan speed was controlled with the inverter. The seed mixture was poured into the inner cone. Air stream velocity was determined by measuring the time when the seeds left the outer cone and fell outside the troughs.

To determine seed separation efficiency, seeds deposited in troughs were manually separated and weighed on the WPS 3100/C/2 scale to the nearest 0.01 g. The measurements were conducted for all combinations of variable factors.

The separation efficiency of main crop seeds and other crop seeds imitating impurities (η) was determined based on the mass of seed mixture components deposited in troughs. The separation efficiency of each component was calculated with the formula below [33]:

where:

- mz—the mass of impurities separated from the seed mixture, g;

- mc—the mass of all impurities in the seed mixture, g;

The separation efficiency index (ε) was calculated for the entire separation process as the most reliable measure of separation quality [7,33,34,35,36]. The closer the value of ε to 1, the higher the separation efficiency. The value of ε for the preset separation parameters was calculated with the formula below:

The partial values of the separation efficiency index, (ε1) and (ε2), were determined with the following formula [36]:

where:

- mz—the mass of impurities separated from the seed mixture, g;

- mc—the mass of all impurities in the seed mixture, g;

- mo—the mass of main crop seeds that were not separated from the mixture, g;

- mn—the mass of main crop seeds in the mixture before separation, g.

The separation efficiency of seed mixture components (η) and the separation efficiency index (ε) were processed statistically with the use of a quadratic polynomial multiple regression model. The results were processed statistically and visualized in Statistica PL v. 13.1 with a graphics module [37].

3. Results

The average mass of the main crop seeds and the average mass of impurities separated from the model mixtures are presented in Table 1.

Table 1.

The average mass of fractions of the model seed mixture.

The statistical parameters describing the separation efficiency of seed mixture components (η) and the separation efficiency index (ε) are presented in Table 2. The separation efficiency of wheat (ηw) from the vetch and wheat mixture was characterized by the highest variation (approx. 40.00%). The smallest variation (approx. 1.00%) was noted in the separation efficiency of wheat (ηw) from the buckwheat and wheat mixture. The highest average separation efficiency (η) was observed for wheat (ηw) (approx. 97.00%) separated from the buckwheat and wheat mixture. The lowest average separation efficiency (η) was noted for wheat (ηw) (approx. 16.00%) separated from the vetch and wheat mixture.

Table 2.

Statistical parameters of the separation efficiency of seed mixtures.

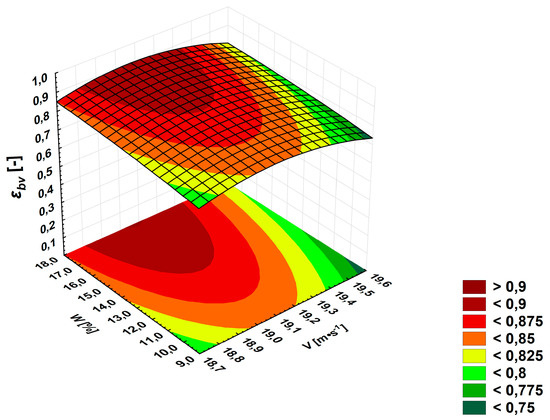

The average value of the separation efficiency index (ε) was lowest in the vetch and wheat mixture at εvw = 0.15. The highest average value of the separation efficiency index (ε) was noted in two mixtures: vetch with buckwheat (εvb = 0.82) and buckwheat with vetch (εbv = 0.82). In a study by Konopka [7], buckwheat seeds were separated from a mixture containing wild radish siliques and rye, wheat, oat, and barley kernels in an indented cylinder separator, and seed separation efficiency reached 0.63. The seed separation efficiency in a cylinder with nonindented walls was 0.92. In a study by Kaliniewicz [38], the separation efficiency of a mixture containing buckwheat nutlet seeds and the seeds of the four main crop species seeds in a grain grader with indented pockets with a depth of 2.4 mm and a 25° inclination angle of the edge of trough was determined at 0.78.

Table 3 presents the statistical parameters describing a functional relationship between the separation efficiency of main crop seeds and other crop seeds imitating impurities (η) and the separation efficiency index (ε) in a pneumatic conical separator versus the moisture content of the seed mixture and air stream velocity.

Table 3.

Regression equations describing the separation efficiency of main crop seeds and other crop seeds imitating impurities (η) and the separation efficiency index (ε).

The results of the polynomial multiple regression analysis indicate that the regression equations describing the separation efficiency of main crop seed and other crop seeds imitating impurities (η) and the separation efficiency index (ε) were characterized by high and very high fit to empirical data. The coefficient of determination for the analyzed seed mixtures ranged from 0.71 to 0.99.

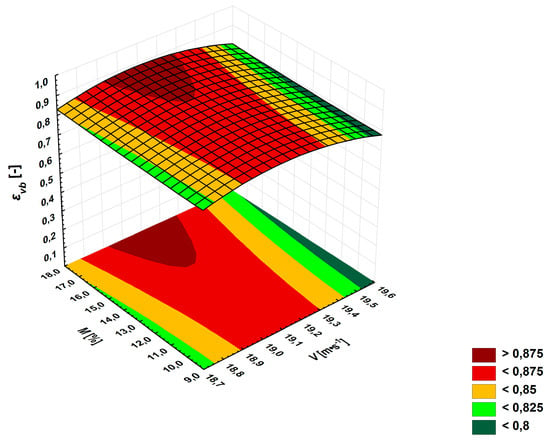

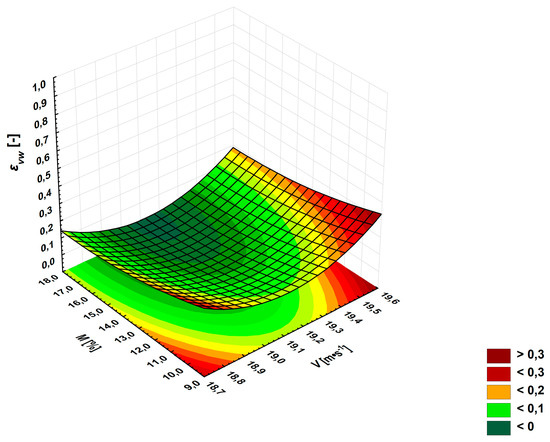

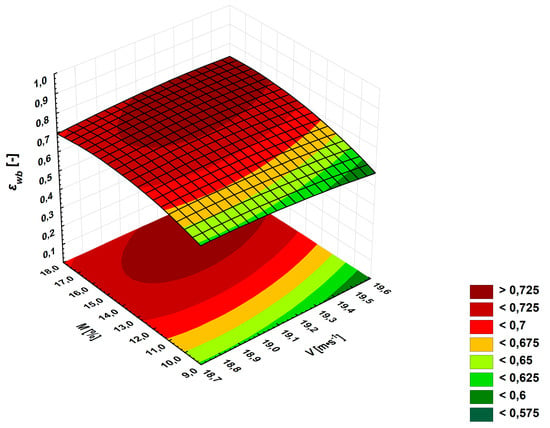

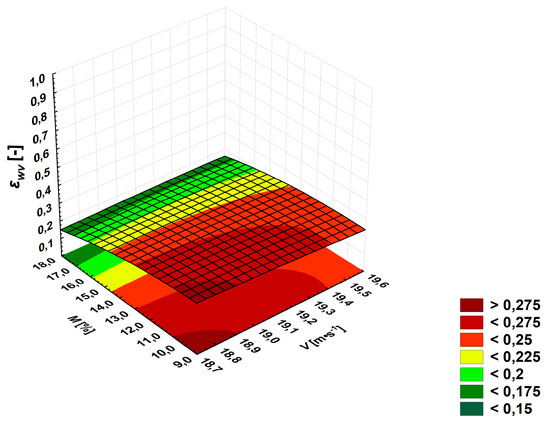

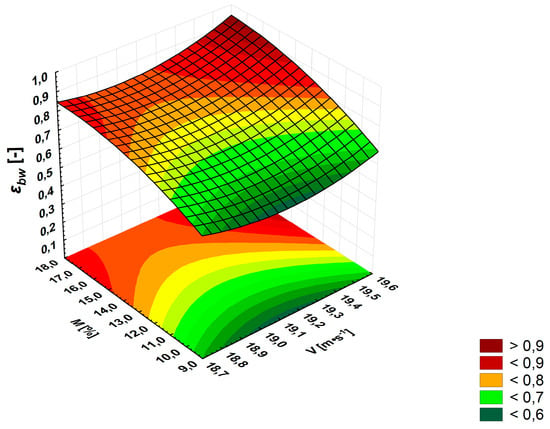

The quadratic equations describing the relationships between the separation efficiency index of the seed mixture (ε) versus moisture content M and air stream velocity V are presented in Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7. Seed mixtures composed of vetch and buckwheat, as well as buckwheat and vetch, were most efficiently separated at a moisture content of M = 18.00% and air stream velocity of V = 19.00 m · s−1. In seed mixtures combining wheat and buckwheat as well as buckwheat and wheat, separation efficiency was highest at the highest moisture content and maximum air stream velocity. The vetch and wheat seed mixture was most efficiently separated at the lowest moisture content and maximum air stream velocity. In the wheat and vetch seed mixture, separation efficiency was highest at the lowest moisture content and minimum air stream velocity.

Figure 2.

Separation efficiency of the vetch and buckwheat mixture (εvb) subject to moisture content (M) and air stream velocity (V).

Figure 3.

Separation efficiency of the vetch and wheat mixture (εvw) subject to moisture content (M) and air stream velocity (V).

Figure 4.

Separation efficiency of the wheat and buckwheat mixture (εwb) subject to moisture content (M) and air stream velocity (V).

Figure 5.

Separation efficiency of the wheat and vetch mixture (εwv) subject to moisture content (M) and air stream velocity (V).

Figure 6.

Separation efficiency of the buckwheat and wheat mixture (εbw) subject to moisture content (M) and air stream velocity (V).

Figure 7.

Separation efficiency of the buckwheat and vetch mixture (εbv) subject to moisture content (M) and air stream velocity (V).

Most seed cleaning and sorting processes rely on the basic properties of seeds (geometric parameters, mass, and aerodynamic characteristics), which generates reliable results in the majority of plant species. When the differences between the main crop seeds and impurities are small, successive cleaning and sorting processes are conducted based on various separation traits. Seed separation efficiency can be optimized by selecting a trait that maximally shortens the technological process of separating a seed mixture [33].

4. Conclusions

The separation efficiency index (ε) of two-component seed mixtures in a pneumatic conical separator exceeded 80%. These results indicate that the evaluated device can be used for preliminary seed cleaning in typical processing lines.

The indicators for evaluating the quality of the separation process can be described with a multivariate quadratic polynomial. Probabilistic mathematical equations formulated a posteriori to describe changes in the values of dependent variables, i.e., the relationships between the separation efficiency index (ε) and the separation efficiency of main crop seeds and other crop seeds imitating impurities (η) versus the values of independent variables, support accurate predictions of the parameters describing the quality of the seed mixture separation process.

The geometric and aerodynamic properties of seeds should be determined before the seed mixture is separated in a pneumatic conical separator.

Author Contributions

P.S.R. and D.J.C. conceived and carried out calculations; P.S.R. performed the experiments; S.K., E.K., and A.L. contributed to the literature study; S.K. and E.K. analyzed the data; D.J.C., A.L., and S.K. wrote the paper; S.K., D.J.C., and E.K. critically revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Giyevskiy, A.M.; Orobinsky, V.I.; Tarasenko, A.P.; Chernyshov, A.V.; Kurilov, D.O. Substantiation of basic scheme of grain cleaning machine for preparation of agricultural crops seeds. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327. [Google Scholar] [CrossRef]

- Saitov, V.E.; Farafonov, V.G.; Gataullin, R.G.; Saitov, A.V. Research of a diametrical fan with suction channel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 457. [Google Scholar] [CrossRef]

- Dal-Pastro, E.; Facco, P.; Bezzo, E.; Zamprogna, E.; Barolo, M. Data-driven modelling of milling and sieving operations in wheat milling process. Food Bioprod. Process. 2016, 99, 99–108. [Google Scholar] [CrossRef]

- Mudarisov, S.; Khasanov, E.; Rakhimov, Z.; Gabitov, I.; Badretdinov, I.; Farchutdinov, I.; Gallyamov, F.; Davletshin, M.; Aipov, R.; Jarullin, R. Specifying Two-Phase Flow in Modeling Pneumatic Systems Performance of Farm Machines. J. Mech. Eng. Res. Dev. 2017, 40, 706–715. [Google Scholar] [CrossRef]

- Wierzbicki, K.; Reszczyński, P. Wstępne czyszczenie mieszaniny ziarnistej z wykorzystaniem powierzchni stożkowej i strumienia powietrza (Preliminary cleaning of a seed mixture with a cone separator in a stream of air). Probl. Inż. Roln. 2003, 4, 51–58. (In Polish) [Google Scholar]

- Kaliniewicz, Z.; Markowski, P.; Rawa, T. Analysis of distributions of basic physical features of buckwheat seed and “świrzepa” radish hulls in aspect of modelling of distributive processes. Inżynieria Rol. 2005, 1, 85–91. (In Polish) [Google Scholar]

- Konopka, S. An analysis of buckweat seed separation process using trieur bar-type working surfaces. Inżynieria Rol. 2006, 8. (In Polish) [Google Scholar]

- Evers, T. A matter of size. World Grain 2002, 8, 33–35. [Google Scholar]

- Smith, G.P.; Gooding, M.J. Models of wheat grain quality considering climate, cultivar and nitrogen effects. Agric. For. Meteorol. 1999, 94, 159–170. [Google Scholar] [CrossRef]

- Troccoli, A.; di Fonzo, N. Relationship between size features and test weight in “Tricum durum”. Coreal Chem. 1999, 76, 45–49. [Google Scholar] [CrossRef]

- Ammer Ch Mosandl, R.; El Kateb, H. Direct seeding of beech (Fagus Sylvatica L.) in Norway spruce (Picea abies [L.] Karst.) stands-effects of canopy density and fine root biomass on seed germination. For. Ecol. Manag. 2002, 159, 59–72. [Google Scholar] [CrossRef]

- Suszka, B. Zagadnienia nasiennictwa w szkółkarstwie górskim (Seed production in nurseries of mountain plants). Sylwan 1999, 1, 37–42. (In Polish) [Google Scholar]

- Kaliniewicz, Z.; Poznański, A. Variability and correlation of selected physical attributes of small−leaved lime (Tilia cordata Mill.) seeds. Publishing House of UWM: Olsztyn, Poland. Sylwan 2013, 1, 39–46. (In Polish) [Google Scholar]

- Tylek, P. Analysis of aerodynamic properties of common fir and common beech. Inżynieria Rol. 2011, 6, 247–253. (In Polish) [Google Scholar]

- Gregg, B.R.; Billups, G.L. Seed Conditioning, Vol. 2: Technology; Taylor and Francis: New York, NY, USA, 2010. [Google Scholar]

- Gregg, B.R.; Billups, G.L. Seed Conditioning, Vol. 3: Crop Seed Conditioning; Taylor and Francis: New York, NY, USA, 2010. [Google Scholar]

- Konopka, S.; Choszcz, D.; Wierzbicki, K. Wpływ wilgotności mieszaniny na skuteczność procesu rozdziału gryki od zanieczyszczeń w obrotowym sicie szczelinowym (The effect of the moisture content of a seed mixture on the separation efficiency of buckwheat seeds and impurities in a rotary groove separator). Inżynieria Rol. 2000, 9, 119–125. [Google Scholar]

- Saitov, V.E.; Kurbanov, R.F.; Suvorov, A.N. Assessing the Adequacy of Mathematical Models of Light Impurity Fractionation in Sedimentary Chambers of Grain Cleaning Machines. Procedia Eng. 2016, 150, 107–110. [Google Scholar] [CrossRef][Green Version]

- Savinyh, P.; Sychugov, Y.; Kazakov, V.; Ivanovs, S. Development and Theoretical Studies of Grain Cleaning Machine for Fractional Technology of Flattening Forage Grain. Eng. Rural Dev. 2018, 124–130. [Google Scholar]

- Xu, L.; Wei, C.; Liang, Z.; Chai, X.; Li, Y.; Liu, Q. Development of rapeseed cleaning loss monitoring system and experiments in a combine harvester. Biosyst. Eng. 2019, 178, 118–130. [Google Scholar] [CrossRef]

- Bulgakov, V.; Holovach, I.; Bandura, V.; Ivanovs, S.A. A theoretical research of the grain milling technological process for roller mills with two degrees of freedom. INMATEH-Agric. Eng. 2017, 52, 99–106. [Google Scholar]

- Sysuev, V.; Ivanovs, S.; Savinyh, P.; Kazakov, V. Movement and transformation of grain in two-stage crusher. Eng. Rural Dev. Proc. 2015, 14, 22–27. [Google Scholar]

- Stepanenko, S. Research pneumatic gravity separation grain materials. Mech. Agric. Conserv. Resour. 2017, 63, 54–56. [Google Scholar]

- Badretdinov, I.; Mudarisov, S.; Tuktarov, M.; Dick, E.; Arslanbekova, S. Mathematical modeling of the grain material separation in the pneumatic system of the grain-cleaning machine. J. Appl. Eng. Sci. 2017, 17, 529–534. [Google Scholar] [CrossRef]

- Gołąb, J. Badania ruchu ziarna, gleby i płodów rolnych na elementach wirujących metodą stroboskopową (An analysis of the rotational movement of seeds, soil and agricultural products under stroboscopic light). IBMER 1961–1962, XXV/28. (In Polish) [Google Scholar]

- Gołąb, J. Teoria zachowania się ziaren na wirujących powierzchniach stożkowych (Theoretical behavior of seeds on rotating conical surfaces). Biul. Pr. Nauk.-Badaw. IBMER 1964, 3, 181–207. (In Polish) [Google Scholar]

- Gołąb, J. Badania ruchu cząstek kulistych i płaskich na wirujących stożkach w aspekcie separacji i wysiewu (An analysis of the movement of spherical and flat particles on rotating cone elements for seed separation and sowing). Biul. Pr. Nauk.-Badaw. IBMER 1974, 11, 3–75. (In Polish) [Google Scholar]

- Pankowski, Z. Separacja produktów sieczko-młotu przy wykorzystaniu ruchu po zakrzywionym torze (Separation of the materials processed by a chaff cutter with a hammer mill based on curvilinear motion). Biul. Pr. Nauk.-Badaw. IBMER 1974, 11, 3–17. (In Polish) [Google Scholar]

- Reszczyński, P.; Wierzbicki, K. Wstępne wyniki badań ziaren pszenicy i nasion wyki na nieruchomej powierzchni stożkowej (A preliminary analysis of wheat grain and vetch seeds on an immobile conical surface). Inżynieria Rol. 2004, 4, 171–180. (In Polish) [Google Scholar]

- Choszcz, D.; Reszczyński, P. Urządzenie do Pneumatycznego Rozdzielania Nasion (A Pneumatic Device for Seed Separation). Patent Application No. P.403348, 28 March 2013. [Google Scholar]

- Reszczyński, P.S. Analiza Procesu Rozdziału Mieszaniny Ziarnistej przy Zastosowaniu Stożkowej Powierzchni Roboczej i Strumienia Powietrza (Analysis of the Process of Granular Mixture Separation Using a Tapered Work Surface and an Air Flow). Ph.D. Thesis, Uniwersytet Warmińsko-Mazurki w Olsztynie, Wydział Nauk Technicznych, Olsztyn, Poland, 2013. (In Polish). [Google Scholar]

- Kania, M.; Andrejko, D.; Samborski, A.; Rydzak, L. Wpływ ogrzewania ziarna pszenicy promieniami podczerwonymi na właściwości fizyczne produktów przemiału (Influence of infrared radiation heat treatment of wheat seed on physical properties of milling products). Inżynieria Przetwórstwa Spożywczego 2012, 1, 19–21. (In Polish) [Google Scholar]

- Grochowicz, J. Maszyny do czyszczenia i sortowania nasion (Seed Cleaning and Sorting Machines). AR Lublin 1994. (In Polish) [Google Scholar]

- Kaliniewicz, Z.; Rawa, T. Laboratorium z Maszyn Rolniczych (Agricultural Machine Workshop); Publishing House of UWM: Olsztynie, Poland, 2000. (In Polish) [Google Scholar]

- Rawa, T. Studia nad skutecznością czyszczenia ziarna gryki (An analysis of the separation efficiency of buckwheat seeds). Acta Acad. Agricult. Tech. Olst. Aedif. Mech. 1992, 22. (In Polish) [Google Scholar]

- Choszcz, D.J. Efektywność rozdzielania mieszaniny nasion rzepaku i przytulii czepnej w separatorze z taśmą pętelkową (Separation efficiency for mixture of rape and cleavers seeds in separator with looped belt). Inżynieria Rolnicza 2009, 7. (In Polish) [Google Scholar]

- Stanisz, A. Przystępny Kurs Statystyki w Oparciu o Program STATISTICA PL na Przykładach z Medycyny. Tom 1. Statystyki Podstawowe (Accessible Course in Statistics Based on the STATISTICA PL Software on Examples from Medicine. Tome 1. Basic Statistics); StatSoft Polska: Kraków, Poland, 2007. (In Polish) [Google Scholar]

- Kaliniewicz, Z. Skuteczność rozdzielania mieszaniny ziarniaków zbóż i orzeszków gryki w tryjerze z wgłębieniami kieszonkowymi (Separation efficiency for the mixture of corn seeds and buckwheat nuts in a trieur with pocket pits). Inżynieria Rol. 2009, 6. (In Polish) [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).