Effect of Substrate Concentration on Photo-Fermentation Bio-Hydrogen Production Process from Starch-Rich Agricultural Leftovers under Oscillation

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Substrate

2.2. Microorganisms and Medium

2.3. Procedures of Bio-Hydrogen Production Process

2.4. Analytical Methods

3. Results and Discussion

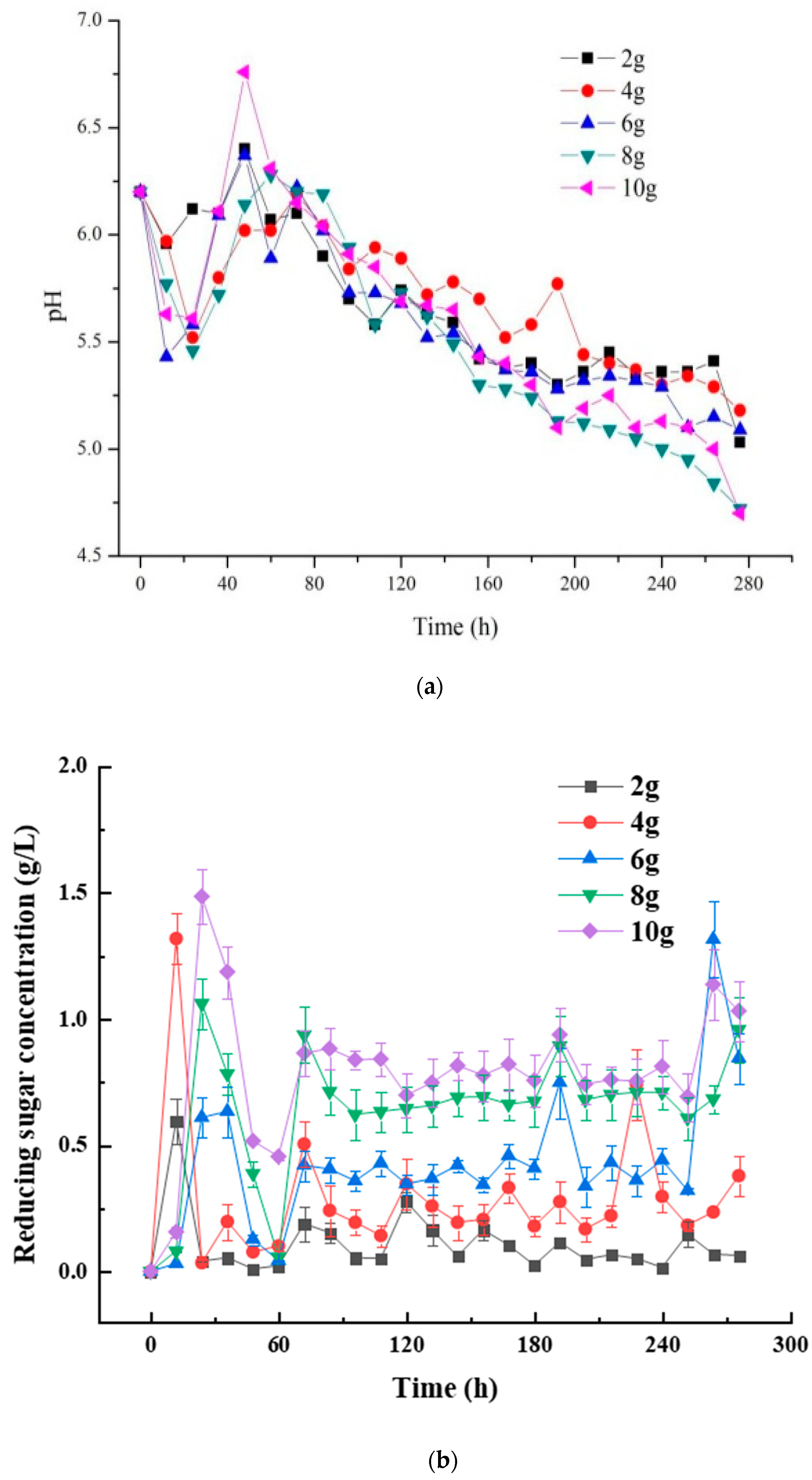

3.1. Evaluation of pH and RSC Changes under Diverse Substrate Concentrations

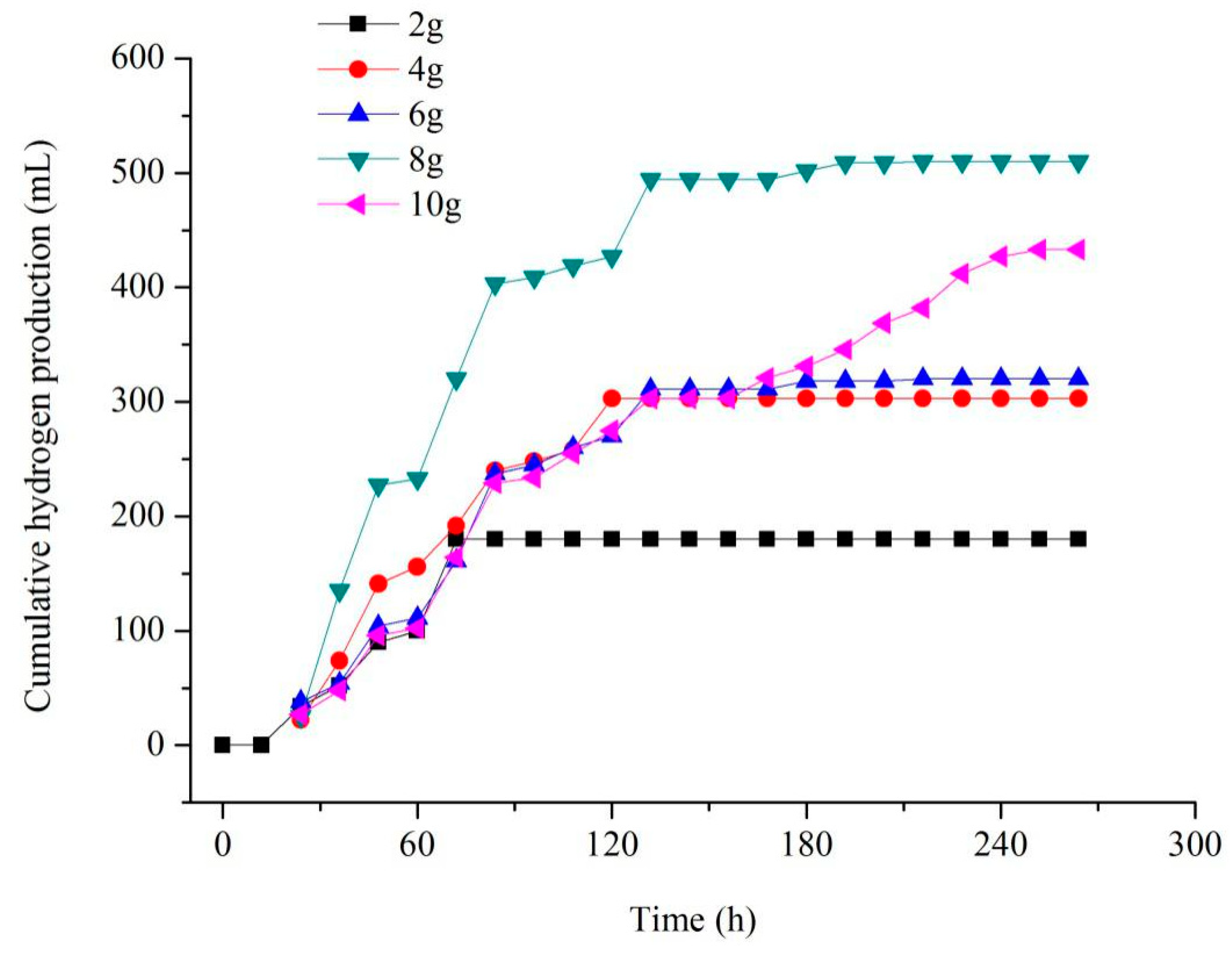

3.2. Variation of Bio-Hydrogen Yield under Diverse Substrate Concentrations

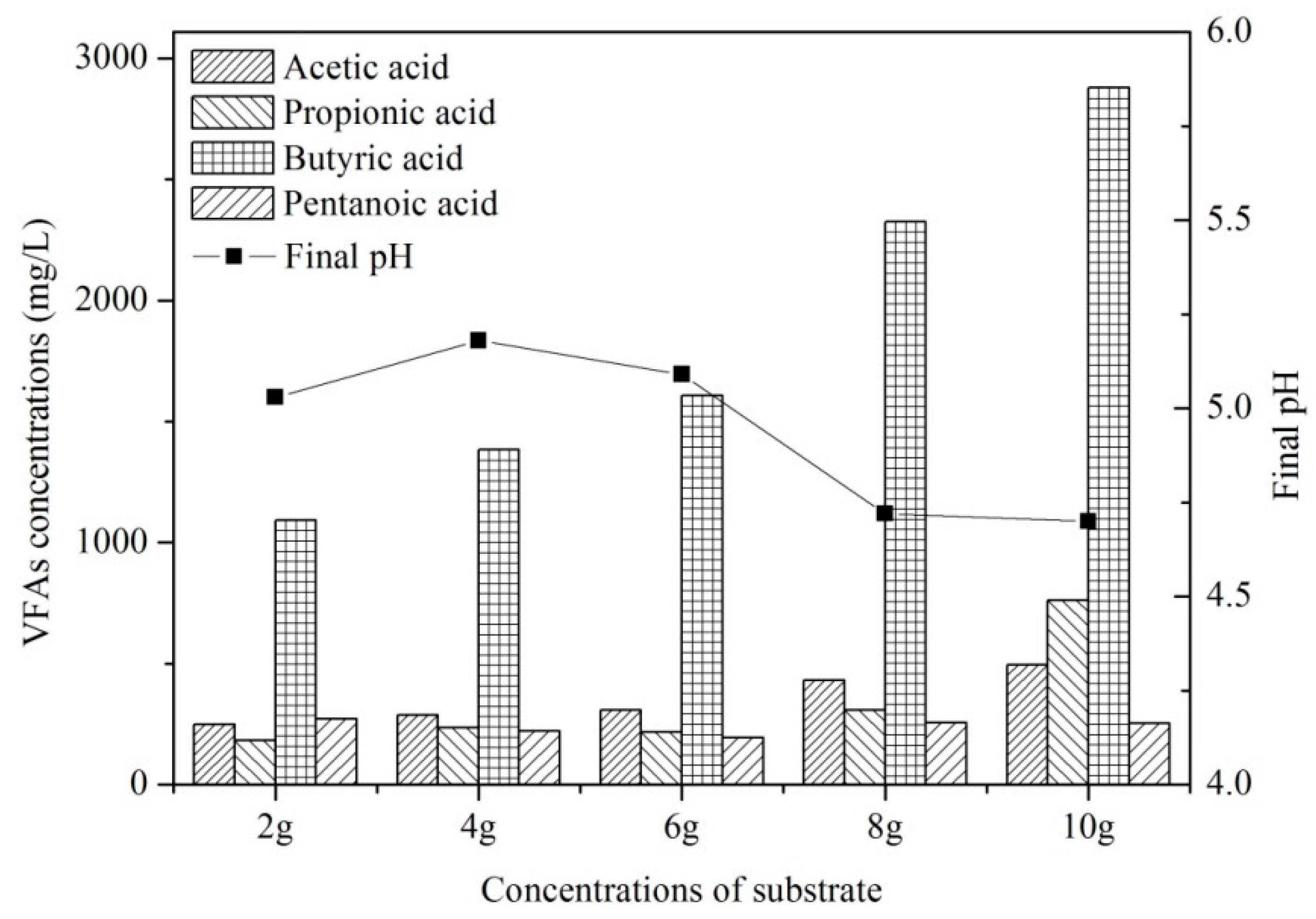

3.3. Evaluation of the Byproducts of Photo-Fermentation Bio-Hydrogen Production from Potato Starch Under Diverse Substrate Concentrations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, N.; Lior, N.; Jin, H. The energy situation and its sustainable development strategy in China. Energy 2011, 36, 3639–3649. [Google Scholar] [CrossRef]

- Cheng, C.X.; Tian, Y.J.; Wang, F.; Wu, X.H.; Zheng, J.L.; Zhang, J.; Li, L.W.; Yang, P.L. Experimental study on the morphology and memory effect of methane hydrate reformation. Energy Fuels 2019, 33, 3439–3447. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Nadeem, T.; Li, Y.M.; Zhang, T.; Zhu, S.N.; Zhang, Q.G. Tailoring of structural and optical parameters of corncobs through ball milling pretreatment. Renew. Energy 2019, 141, 298–304. [Google Scholar] [CrossRef]

- Guevara-López, E.; Buitrón, G. Evaluation of different support materials used with a photo-fermentative consortium for hydrogen production. Int. J. Hydrog. Energy 2015, 40, 17231. [Google Scholar] [CrossRef]

- Kumar, G.; Bakonyi, P.; Periyasamy, S.; Kim, S.H.; Nemestóthy, N.; Bélafi-Bakó, K. Lignocellulose biohydrogen: Practical challenges and recent progress. Renew. Sust. Energ. Rev. 2015, 44, 728–737. [Google Scholar] [CrossRef]

- Singh, L.; Wahid, Z.A. Methods for enhancing bio-hydrogen production from biological process: A review. J. Ind. Eng. Chem. 2015, 21, 70–80. [Google Scholar] [CrossRef]

- Urbaniec, K.; Bakker, R.R. Biomass residues as raw material for dark hydrogen fermentation-A review. Int. J. Hydrog. Energy 2015, 40, 3648–3658. [Google Scholar] [CrossRef]

- Wang, Y.H.; Wu, D.Y.; Chi, J. The status and development current of hydrogen energy and its application technology. Chem. Ind. Eng. Prog. 2001, 20, 6–8. [Google Scholar]

- Xie, G.J.; Liu, B.F.; Wang, R.Q. Bioaggregate of photo-fermentative bacteria for enhancing continuous hydrogen production in a sequencing batch photobioreactor. Sci. Rep. 2015, 5, 16174. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Yue, J.Z.; Zhou, X.H.; Jing, Y.Y.; Jiang, D.P.; Zhang, Q.G. Photo-fermentative bio-hydrogen production from agricultural residue enzymatic hydrolyzate and the enzyme reuse. Bioresources 2014, 9, 2299–2310. [Google Scholar] [CrossRef]

- Cheng, J.; Su, H.B.; Zhou, J.H.; Song, W.L.; Cen, K.F. Hydrogen production by mixed bacteria through dark and photo-fermentation. Int. J. Hydrog. Energy 2011, 36, 450–457. [Google Scholar] [CrossRef]

- Hoffmann, R.A.; Garcia, M.L.; Veskivar, M. Effect of shear on performance and microbial ecology of continuously stirred anaerobic digesters treating animal manure. Biotechnol. Bioeng. 2008, 100, 38–48. [Google Scholar] [CrossRef] [PubMed]

- Eker, S.; Sarp, M. Hydrogen gas production from waste paper by dark fermentation: Effects of initial substrate and biomass concentrations. Int. J. Hydrog. Energy 2017, 42, 2562–2568. [Google Scholar] [CrossRef]

- Jiang, D.P.; Ge, X.M.; Zhang, T.; Zhang, Q.G. Photo-fermentative hydrogen production from enzymatic hydrolysate of corn stalk pith with a photosynthetic consortium. Int. J. Hydrog. Energy 2016, 41, 16778. [Google Scholar] [CrossRef]

- Kaparaju, P.; Buendia, I.; Ellegaard, L. Effects of mixing on methane production during thermophilic anaerobic digestion of manure: Lab-scale and pilot-scale studies. Bioresour. Technol. 2008, 99, 4919–4928. [Google Scholar] [CrossRef] [PubMed]

- Ong, H.K.; Greenfield, P.F.; Pullammanappallil, P.C. Effect of mixing on biomethanation of cattle-manure slurry. Environ. Technol. 2002, 23, 1081. [Google Scholar] [CrossRef]

- Tian, J.C.; Hu, X.Y.; Tian, S.L.; Ge, X.; Li, M. Analysis of Nutrient Composition of 19 Variety Potatoes. Acta Nutr. Sin. 2017, 39, 102–104. [Google Scholar]

- Zhang, Z.P.; Li, Y.M.; Zhang, H.; He, C.; Zhang, Q.G. Potential use and the energy conversion efficiency analysis of fermentation effluents from photo and dark fermentative bio-hydrogen production. Bioresour. Technol. 2017, 245, 884–889. [Google Scholar] [CrossRef]

- Lindmark, J.; Thorin, E.; Fdhila, R.B. Effects of mixing on the result of anaerobic digestion: Review. Renew. Sust. Energy 2014, 40, 1030–1047. [Google Scholar] [CrossRef]

- Oncel, S.; Sabankay, M. Microalgal biohydrogen production considering light energy and mixing time as the two key features for scale-up. Bioresour. Technol. 2012, 121, 228–234. [Google Scholar] [CrossRef]

- Li, Y.M.; Zhang, P.; Jing, Y.Y.; Zhang, Q.G. Statistical optimization of simultaneous saccharification fermentative hydrogen production from Platanus orientalis leaves by photosynthetic bacteria HAU-M1. Int. J. Hydrog. Energy 2017, 42, 5804–5811. [Google Scholar] [CrossRef]

- Miller, G. Use of dinitrosalicylic acid reagent of determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Phowan, P.; Danvirutai, P. Hydrogen production from cassava pulp hydrolysate by mixed seed cultures: Effects of initial pH, substrate and biomass concentrations. Biomass Bioenergy 2014, 64, 1–10. [Google Scholar] [CrossRef]

- Guo, X.M.; Trably, E.; Latrille, E.; Carrère, H.; Steyer, J.P. Hydrogen production from agricultural waste by dark fermentation: A review. Int. J. Hydrog. Energy 2010, 35, 10660–10673. [Google Scholar] [CrossRef]

- Hu, B.; Li, Y.M.; Zhang, H.R.; Jing, Y.Y.; Jiang, D.P.; He, C.; Zhang, Z.P. Evaluation of biohydrogen yield potential and electron balance in the photo-fermentation process with different initial pH from starch agricultural leftover. Bioresource Techonol. 2020, 305, 122900–122904. [Google Scholar] [CrossRef] [PubMed]

| Name | Corn | Soybean | Potato | Peanut |

|---|---|---|---|---|

| Carbohydrate content (g/100g) | 22.8 | 18.7 | 17.2 | 13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, J.; Zhang, Q.; Zhu, S.; Yang, S.; Zhang, Z. Effect of Substrate Concentration on Photo-Fermentation Bio-Hydrogen Production Process from Starch-Rich Agricultural Leftovers under Oscillation. Sustainability 2020, 12, 2700. https://doi.org/10.3390/su12072700

Zhang H, Li J, Zhang Q, Zhu S, Yang S, Zhang Z. Effect of Substrate Concentration on Photo-Fermentation Bio-Hydrogen Production Process from Starch-Rich Agricultural Leftovers under Oscillation. Sustainability. 2020; 12(7):2700. https://doi.org/10.3390/su12072700

Chicago/Turabian StyleZhang, Haorui, Jiaolin Li, Quanguo Zhang, Shengnan Zhu, Shuai Yang, and Zhiping Zhang. 2020. "Effect of Substrate Concentration on Photo-Fermentation Bio-Hydrogen Production Process from Starch-Rich Agricultural Leftovers under Oscillation" Sustainability 12, no. 7: 2700. https://doi.org/10.3390/su12072700

APA StyleZhang, H., Li, J., Zhang, Q., Zhu, S., Yang, S., & Zhang, Z. (2020). Effect of Substrate Concentration on Photo-Fermentation Bio-Hydrogen Production Process from Starch-Rich Agricultural Leftovers under Oscillation. Sustainability, 12(7), 2700. https://doi.org/10.3390/su12072700