An Evaluation Study of the Capabilities of Civilian Manufacturing Enterprises Entering the Military Products Market under the Background of China’s Civil–Military Integration

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Development

2.2. Civil–Military Integration

2.3. Military Products Market

3. Model Framework

3.1. Proposed Indicator System

3.2. Determine the Indicator Weights

3.3. Multilevel Fuzzy Comprehensive Evaluation

4. Application

4.1. Company Background

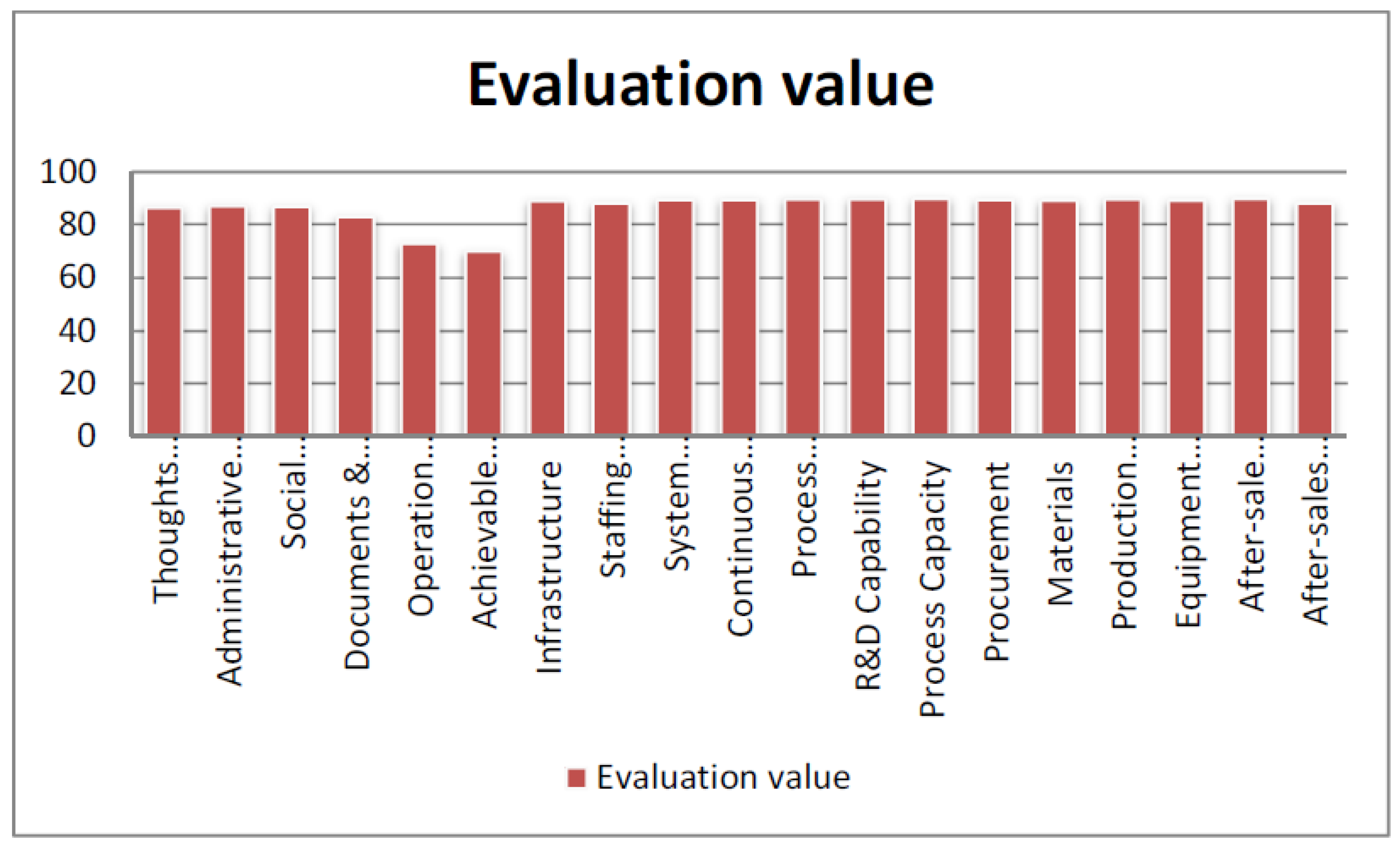

4.2. Application Results

5. Discussions

- The controllability of production documents is poor. Uncontrolled documents appear in the production workshop and are used by field personnel.

- The guidance of production documents is poor. It is difficult to realize the operation content in individual documents under the existing conditions.

- The consistency of production documents is poor. The same or similar content sometimes appears in different documents, but due to the documents being drawn up at different times, the content is inconsistent and even conflicting.

- The traceability of records is poor. The production records for individual parts cannot be traced back to their process processors.

- A meeting regarding document and record problem rectification was held and decided to establish the rectification team, with the top manager as the team leader and the heads of each department as team members; this meeting also clarified the self-inspection content of each department’s documents.

- All departments checked the existing documents of their departments and summarized the existing problems within the limited period.

- The top manager held the second meeting regarding document and record problem rectification to confirm the cleaning, cancellation and revision content of the problem documents and to assign each task to a specific responsible person.

- The quality department recycled and voided the existing documents and records of each department, reissued the revised documents and records, and tracked the operation effect of the feedback documents and records.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| The Goal | Category | Constraint | Criterion | Index |

|---|---|---|---|---|

| The CMEE-MPM capabilities | Service support process | Integrated management capacity | Thoughts integration | Management’s willingness to enter military products market |

| Employees’ ideological understanding to enter the military products market | ||||

| Administrative management | Completeness of internal management system | |||

| Perfect situation about organizational structure of enterprises | ||||

| Emergency response capability | ||||

| Social recognition | Position of enterprises in the industry | |||

| Enterprise’s prestige | ||||

| Value of enterprise customer satisfaction | ||||

| Documents &records management | Acquisition of military standard documents | |||

| Completeness of production operation instructions | ||||

| Traceability of process file records | ||||

| Enterprise financial capacity | Operation capacity | Proportion of R&D investment in military-related products | ||

| Inventory input ratio of military-related products | ||||

| Achievable economic benefits | Current economic benefits | |||

| Long-term economic benefits | ||||

| Resource allocation capacity | Infrastructure | Production and operation environment | ||

| Production equipment allocation situation | ||||

| Test equipment allocation situation | ||||

| Maintenance equipment allocation situation | ||||

| Staffing allocation | R&D staffing allocation situation | |||

| Production staffing allocation situation | ||||

| Test personnel allocation situation | ||||

| Maintenance staffing allocation situation | ||||

| Quality management capacity | System execution capacity | Management review | ||

| Internal audit | ||||

| External audit | ||||

| Continuous improvement capacity | Completion rate of corrective and preventive measures | |||

| Continuous improvement project completion rate on schedule | ||||

| Process management capacity | Misjudgment rate of raw material inspection | |||

| Non-conformity control rate of delivered products | ||||

| Qualification rate of one-time inspection of reworked and repaired products | ||||

| Product realization process | R&D and process capacity | R&D capacity | Qualification rate of disposable sample delivery | |

| Transforming ability of scientific and technological achievements | ||||

| Design schedule punctuality rate | ||||

| Design error rate | ||||

| Process capacity | Timeliness of contract review | |||

| Error rate of contract review | ||||

| Purchasing and warehousing capacity | Procurement | Qualification rate of raw material purchase | ||

| Timely arrival rate of raw materials | ||||

| Materials | Accuracy of raw material distribution | |||

| Stock error rate of raw materials | ||||

| Production and manufacturing capacity | Production process | Process rework rate | ||

| Product delivery rate on time | ||||

| Qualification rate of one-time delivery of products | ||||

| Equipment management | Failure rate of key equipment | |||

| Failure rate of main equipment | ||||

| Maintenance and after-sales service guarantee capacity | After-sale service | Serving on time | ||

| Post-service satisfaction | ||||

| After-sales guarantee | Reserve of after-sales spare parts | |||

| Reserve of after-sale finished products |

| The Goal | Category | weights | Constraint | weights | Criterion | weights | Index | weights |

|---|---|---|---|---|---|---|---|---|

| CMEE-MPM capabilities | Service support process | 0.2759 | Integrated management capacity | 0.3708 | Thoughts integration | 0.0675 | Management’s willingness to enter military products market | 0.8806 |

| Employees’ ideological Understanding to enter military products market | 0.1194 | |||||||

| Administrative management | 0.5252 | Completeness of internal management system | 0.5745 | |||||

| Perfect situation about organizational structure of enterprises | 0.2633 | |||||||

| Emergency response capability | 0.1622 | |||||||

| Social recognition | 0.1539 | Position of enterprises in the industry | 0.1544 | |||||

| Enterprise’s prestige | 0.4160 | |||||||

| Value of enterprise customer satisfaction | 0.4297 | |||||||

| Documents &records management | 0.2534 | Acquisition of military standard documents | 0.1200 | |||||

| Completeness of production operation instructions | 0.3351 | |||||||

| Traceability of process file records | 0.5449 | |||||||

| Enterprise financial capacity | 0.1205 | Operation capacity | 0.3038 | Proportion of R&D investment in military-related products | 0.8261 | |||

| Inventory input ratio of military-related products | 0.1739 | |||||||

| Achievable economic benefits | 0.6962 | Current economic benefits | 0.1702 | |||||

| Long-term economic benefits | 0.8298 | |||||||

| Resource allocation capacity | 0.1205 | Infrastructure | 0.5000 | Production and operation environment | 0.4082 | |||

| Production equipment allocation situation | 0.3122 | |||||||

| Test equipment allocation situation | 0.1528 | |||||||

| Maintenance equipment allocation situation | 0.1267 | |||||||

| Staffing allocation | 0.5000 | R&D staffing allocation situation | 0.5527 | |||||

| Production staffing allocation situation | 0.2415 | |||||||

| Test personnel allocation situation | 0.1175 | |||||||

| Maintenance staffing allocation situation | 0.0884 | |||||||

| Quality management capacity | 0.3013 | System execution capability | 0.3333 | Management review | 0.5792 | |||

| Internal audit | 0.0899 | |||||||

| External audit | 0.3309 | |||||||

| Continuous improvement capability | 0.3333 | Completion rate of corrective and preventive measures | 0.7681 | |||||

| Continuous improvement project completion rate on schedule | 0.2319 | |||||||

| Process management capability | 0.3333 | Misjudgment rate of raw material inspection | 0.0845 | |||||

| Non-conformity control rate of delivered products | 0.7489 | |||||||

| Qualification rate of one-time inspection of reworked and repaired products | 0.1665 | |||||||

| Product realization process | 0.7241 | R&D and process capability | 0.4041 | R&D capability | 0.7333 | Qualification rate of disposable sample delivery | 0.4110 | |

| Transforming ability of scientific and technological achievements | 0.0695 | |||||||

| Design schedule punctuality rate | 0.1120 | |||||||

| Design error rate | 0.4075 | |||||||

| Process capacity | 0.2667 | Timeliness of contract review | 0.1649 | |||||

| Error rate of contract review | 0.8351 | |||||||

| Purchasing and warehousing capacity | 0.0960 | Procurement | 0.7419 | Qualification rate of raw material purchase | 0.6863 | |||

| Timely arrival rate of raw materials | 0.3137 | |||||||

| Materials | 0.2581 | Accuracy of raw material distribution | 0.6667 | |||||

| Stock error rate of raw materials | 0.3333 | |||||||

| Production and manufacturing capacity | 0.3019 | Production process | 0.5000 | Process rework rate | 0.0752 | |||

| Product delivery rate on time | 0.3836 | |||||||

| Qualification rate of one-time delivery of products | 0.5412 | |||||||

| Equipment management | 0.5000 | Failure rate of key equipment | 0.7746 | |||||

| Failure rate of main equipment | 0.2254 | |||||||

| Maintenance and after-sales service guarantee capability | 0.1980 | After-sale service | 0.5000 | Serving on time | 0.5897 | |||

| Post-service satisfaction | 0.4103 | |||||||

| After-sales guarantee | 0.5000 | Reserve of after-sales spare parts | 0.8049 | |||||

| Reserve of after-sales finished products | 0.1951 |

References

- Zhang, Y.; Liu, J.; Zhang, J.; Wang, R. Emergy-based evaluation of system sustainability and ecosystem value of a large-scale constructed wetland in North China. Environ. Monit. Assess. 2013, 185, 5595–5609. [Google Scholar] [CrossRef]

- Morandín-Ahuerma, I.; Contreras-Hernández, A.; Ayala-Ortiz, D.A.; Pérez-Maqueo, O. Socio-Ecosystemic Sustainability. Suatainability 2019, 11, 3354. [Google Scholar] [CrossRef]

- Yang, D.; Chen, S.; Niu, W. A Comment on Four Representative Indexes of Sustainable Development. Sci. Manag. Res. 2001, 58–61, 72. [Google Scholar] [CrossRef]

- Masocha, R. Social Sustainability Practices on Small Businesses in Developing Economies: A Case of South Africa. Sustainability 2019, 11, 3257. [Google Scholar] [CrossRef]

- da Silva, J.; Fernandes, V.; Limont, M.; Dziedzic, M.; Andreoli, C.; Rauen, W.B. Water sustainability assessment from the perspective of sustainable development capitals: Conceptual model and index based on literature review. J. Environ. Manag. 2020, 254. [Google Scholar] [CrossRef]

- Lein, J.K. Toward a Remote Sensing Solution for Regional Sustainability Assessment and Monitoring. Sustainability 2014, 6, 2067–2086. [Google Scholar] [CrossRef]

- Zeng, Z.; Gu, P.; Zhang, M. The Application of Data Envelopment Analysis in the Evaluation of Sustainable Development. Syst. Eng. Theor. Pract. 2000, 8, 114–118. [Google Scholar] [CrossRef]

- Zang, X.; Wang, Q.; Chen, T. The Construction of Sustainable Development Indicator System for Green Blocks in Eco-cities. City Plan Rev. 2017, 41, 68–75. [Google Scholar] [CrossRef]

- Yan, M.; Odum, H.T. A Study on EmergyEvalution and Sustainabe Development of Tibetan Eco-economic System. J. Nat. Resour. 1998, 13, 116–125. [Google Scholar] [CrossRef]

- Wang, J.; Geng, J. Empirical Study on Resources Exhausted City, Cability of Sustainable Development. Econ. Probl. 2012, 1, 46–49. [Google Scholar] [CrossRef]

- Polonenko, L.M.; Hamouda, M.A.; Mohamed, M.M. Essential components of institutional and social indicators in assessing the sustainability and resilience of urban water systems: Challenges and opportunities. Sci. Total Environ. 2020, 708. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J. Dynamic simulation of regional sustainable tourism development system. Syst. Eng. Theor. Pract. 2011, 31, 2101–2107. [Google Scholar] [CrossRef]

- Doukas, H.; Karakosta, C.; Psarras, J. Computing with words to assess the sustainability of renewable energy options. Expert Syst. Appl. 2010, 37, 5491–5497. [Google Scholar] [CrossRef]

- Feng, Y.; Han, W.; Wang, H.; Lian, J. Study on the Sustainable Development Oriented Optimal Allocation to Region Water Resources. Syst. Eng. Theor. Pract. 2003, 2, 133–138. [Google Scholar] [CrossRef]

- Wagner, M. The role of corporate sustainability performance for economic performance: A firm-level analysis of moderation effects. Ecol. Econ. 2010, 69, 1553–1560. [Google Scholar] [CrossRef]

- Tomšič, N.; Bojnec, Š.; Simčič, B. Corporate sustainability and economic performance in small and medium sized enterprises. J. Clean. Prod. 2015, 108. [Google Scholar] [CrossRef]

- Cai, W. Research on the cultivation of financial ability based on the sustainable development of enterprises. Hubei Soc. Sci. 2011, 3, 71–74. [Google Scholar] [CrossRef]

- Moffat, A.; Auer, A. Corporate Environmental Innovation (CEI): A government initiative to support corporate sustainability leadership. J. Clean. Prod. 2006, 14, 589–600. [Google Scholar] [CrossRef]

- Li, R.; Peng, C.; Yang, X. Dual Innovation and Corporate Sustainable Development: The Mediating Role of Short-Term Financial Performance and Long-Term Competitive Advantage. Sci. Technol. Prog. Policy 2019, 36, 81–89. [Google Scholar] [CrossRef]

- Lodhia, S.; Martin, N. Corporate Sustainability Indicators: An Australian Mining Case Study. J. Clean. Prod. 2014, 84, 107–115. [Google Scholar] [CrossRef]

- Liern, V.; Pérez-Gladish, B. Ranking corporate sustainability: A flexible multidimensional approach based on linguistic variables. Int. Trans. Oper. Res. 2017, 25, 1–20. [Google Scholar] [CrossRef]

- Garcia, S.; Cintra, Y.; Rita de Cássia, S.R.; Lima, F.G. Corporate sustainability management: A proposed multi-criteria model to support balanced decision-making. J. Clean. Prod. 2016, 136, 181–196. [Google Scholar] [CrossRef]

- Long, Y.; Pan, J.; Feng, T. The Impact Research of the Lean Production and Corporate Environmental Management on Manufacturing’s Sustainability Performance. Soft Sci. 2018, 220, 68–71. [Google Scholar] [CrossRef]

- Kitsios, F.; Kamariotou, M.; Talias, M.A. Corporate Sustainability Strategies and Decision Support Methods: A Bibliometric Analysis. Sustainability 2020, 12, 521. [Google Scholar] [CrossRef]

- Strachan, H. Making strategy: Civil-military relations after Iraq. Survival 2006, 48, 59–82. [Google Scholar] [CrossRef]

- Huntington, S.P. The Soldier and the State: The Theory and Politics of Civil-Military Relations; Harvard University Press: Cambridge, MA, USA, 1957. [Google Scholar]

- Feaver, P.D. Armed Servants: Agency, Oversight and Civil-Military Relations; Harvard University Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Feaver, P.; Kohn, R. (Eds.) Soldiers and Civilians: The Civil-Military Gap and American National Security; MIT Press: Cambridge, MA, USA, 2001; pp. 289–324. [Google Scholar]

- Egnell, R. Explaining US and British performance in complex expeditionary operations: The civil-military dimension. J. Strateg. Stud. 2006, 29, 1041–1075. [Google Scholar] [CrossRef]

- Edwards, J.R. Accounting for Fair Competition between Private and Public Sector Armaments Manufacturers in Victorian Britain. Abacus 2015, 51, 412–436. [Google Scholar] [CrossRef][Green Version]

- Byrne, E.F. Assessing Arms Makers’ Corporate Social Responsibility. J. Bus. Ethics 2007, 74, 201–217. [Google Scholar] [CrossRef]

- Akcinaroglu, S.; Radziszewski, E. Private Military Companies, Opportunities, and Termination of Civil Wars in Africa. J. Confl. Resolut. 2013, 57, 795–821. [Google Scholar] [CrossRef]

- Mahoney, C.W. Buyer Beware: How Market Structure Affects Contracting and Company Performance in the Private Military Industry. Secur. Stud. 2017, 26, 30–59. [Google Scholar] [CrossRef]

- Vie, L.L.; Scheier, L.M.; Lester, P.B.; Ho, T.E.; Labarthe, D.R.; Seligman, M.E.P. The U.S. Army Person-Event Data Environment: A Military-Civilian Big Data Enterprise. Big Data 2015, 3, 67–79. [Google Scholar] [CrossRef]

- Moore, E.E.; Knudson, M.M.; Schwab, C.W.; Trunkey, D.D.; Johannigman, J.A.; Holcomb, J.B. Military-civilian collaboration in trauma care and the senior visiting surgeon program. N. Engl. J. Med. 2007, 357, 2723–2727. [Google Scholar] [CrossRef]

- Schwab, C.W. Winds of War: Enhancing Civilian and Military Partnerships to Assure Readiness: White Paper. J. Am. Coll. Surg. 2015, 221, 235–254. [Google Scholar] [CrossRef]

- TeKulve, H.; Smit, W.A. Civilian-military co-operation strategies in developing new technologies. Res. Policy 2003, 32, 955–970. [Google Scholar] [CrossRef]

- Watkins, T.A. Beyond guns and butter: Managing dual-use technologies. Technovation 1990, 10, 389–406. [Google Scholar] [CrossRef]

- Cronberg, T. Civil Reconstructions of Military Technology: The United States and Russia. J. Peace Res. 1994, 31, 205–218. [Google Scholar] [CrossRef]

- Brandt, L. Defense Conversion and Dual-Use Technology: The Push toward Civil-Military Integration. Policy Stud. J. 1994, 22, 359–370. [Google Scholar] [CrossRef]

- Molas-Gallart, J. Which way to go? Defence technology and the diversity of ‘dual-use’ technology transfer. Res. Policy 1997, 26, 367–385. [Google Scholar] [CrossRef]

- Lee, B.K.; Sohn, S.Y. Exploring the effect of dual use on the value of military technology patents based on the renewal decision. Scientometrics 2017, 112, 1203–1227. [Google Scholar] [CrossRef]

- Wilhite, A.; Burns, L.; Patnayakuni, R.; Tseng, F. Military supply chains and closed-loop systems: Resource allocation and incentives in supply sourcing and supply chain design. Int. J. Prod. Res. 2014, 52, 1926–1939. [Google Scholar] [CrossRef]

- Sanchez-Andres, A. Arms exports and restructuring in the Russian defence industry. Eur. Asia Stud. 2004, 56, 687–706. [Google Scholar] [CrossRef][Green Version]

- Zhao, C.; Ji, P.; Liu, J.; Zhang, H.; Wang, Y. Civil-Military Integration in Some Typical Countries. Sci. Sci. Manag. S. &T. 2005, 10, 26–31. [Google Scholar] [CrossRef]

- Peng, Z.; Han, R. International reference and policy options about civil-military integration driving the development of recently emerging industries. Reform. 2017, 9, 27–37. [Google Scholar]

- Tan, Q.; Yang, L.; Ng, J.C.Y. References and Implications of Foreign Civil-Military Integration Models. J. Nanjing Univ. Sci. Technol. (Soc. Sci. Ed.). 2018, 31, 12–15. [Google Scholar]

- Zhu, Z. On the Enactment of the Basic Law of the Civil-military Integration Development in China. J. Beijing Inst. Technol. (Soc. Sci. Ed.) 2016, 18, 133–139. [Google Scholar] [CrossRef]

- You, G.; Yan, H.; Zhao, X. The Policy System Construction on the Development of Civil-military Integration: Quo Status, Problems and Countermeasures. Forum Sci. Technol. China 2017, 1, 150–156. [Google Scholar] [CrossRef]

- Chen, H.; Huang, C.; Zhao, L.; Wang, J.; Wei, P. Science and technology policy of military and civilian integration. Def. Technol. Rev. 2018, 39, 62–69. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L. The Unification of Military-Civilian Integration and National Strategic System. Theor. Reform. 2018, 4, 70–78. [Google Scholar] [CrossRef]

- Du, R.; Ma, Y. Research on Military and Civilian Integration Level Measurement and countermeasures in Defense Industry. Sci. Technol. Prog. Policy 2016, 33, 108–116. [Google Scholar] [CrossRef]

- Du, R.; Guo, W. Research on Military and Civilian Integration Efficiency and Measurement in the Defense Industry. Sci. Technol. Prog. Policy 2017, 34, 106–111. [Google Scholar] [CrossRef]

- Du, R. Civil-Military integration system of defense industry equipment construction and its building. Forum Sci. Technol. China 2018, 5, 113–120. [Google Scholar]

- Zhang, L.; Hu, H.; Li, Z. Research and Development Policies of China’s Dual-Use Technology under Civil-Military Integration. Forum Sci. Technol. China 2018, 5, 121–127. [Google Scholar] [CrossRef]

- Cheung, T.M. Innovation in China’s Defense Technology Base: Foreign Technology and Military Capabilities. J. Strateg. Stud. 2016, 39, 1–34. [Google Scholar] [CrossRef]

- Fang, W.; Wang, C. The Cooperative Stability Evolutionary Game Analysis of the Military-Civilian Collaborative Innovation for China’s Satellite Industry. Math. Probl. Eng. 2019, 3, 1–17. [Google Scholar] [CrossRef]

- Du, D.; Kang, M.; Yang, X. Research on the Construction of Innovative Driving System in the Development of Military and Civilian Integration. Econ. Rev. 2017, 4, 48–53. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, W. On impetus of collaborative innovation of Dual-use technological industrial cluster. Sci. Manag. Res. 2014, 32, 1–5. [Google Scholar] [CrossRef]

- Zhao, L.-M.; Sun, J.-H.; Zhang, H.-B. Technology sharing behavior in civil-military integration collaborative innovation system based on differential game. J. Ind. Eng. Eng. Manag. 2017, 31, 183–191. [Google Scholar] [CrossRef]

- Suo, C. The Evaluation Research on the Scientific and Technological Collaborative Innovation Mechanism in Military and Civilian Integration Enterprises. Sci. Technol. Manag. Res. 2018, 9, 1–8. [Google Scholar] [CrossRef]

- Fang, W.; Xiao, L.; Yang, B.; Wang, L. An empirical study of influencing factors on civil-involved military knowledge transfer: A perspective of civil-military integration collaborative innovation. Stud. Sci. Sci. 2019, 37, 664–678. [Google Scholar]

- Li, Y.L.; Guo, A.D.; Luo, S.J. Research on Management of Emergency Supplies Reserves for Integrated Military-Civilian. Appl. Mech. Mater. 2012, 201–202, 987–990. [Google Scholar] [CrossRef]

- Zheng, Y.-J.; Wang, Y.; Ling, H.-F.; Xue, Y.; Chen, S.-Y. Integrated civilian-military pre-positioning of emergency supplies: A multiobjective optimization approach. Appl. Soft Comput. 2017, 58, 732–741. [Google Scholar] [CrossRef]

- Weidenbaum, M.L. The military market in the 1960’s. Bus. Horiz. 1961, 4, 61–68. [Google Scholar] [CrossRef]

- Weidenbaum, M.L. The Scope of the Military Market. J. Mark. 1959, 24, 17–20. [Google Scholar] [CrossRef]

- Desjardins, D.D.; Hopper, D.G. Military market for flat panel displays. Proc. SPIE 1997, 3057, 39–50. [Google Scholar] [CrossRef]

- Petersohn, U. The social structure of the market for force. Coop. Confl. 2015, 50, 269–285. [Google Scholar] [CrossRef]

- Wu, X. Constraints and Countermeasures of world military trade. Manag. World. 1992, 6, 179–182. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, X. A Game Analysis for Oligopoly Military Products Market. Syst. Eng. 2010, 28, 54–57. [Google Scholar]

- Bai, F.; Du, W.; Li, H.; Wang, X. Research on the Military Products Market Access System in China. J. Acad. Equip. 2013, 24, 29–32. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, F.; Lu, S. Study on Marketing Strategy for Aviation Manufacturing Enterprise Based on Domestic Military Market. Ind. Eng. Manag. Rec. 2015, 543–546. [Google Scholar] [CrossRef]

- Jiang, Y.; Xie, W.; Qu, L. Game-based Profit Analysis for Private Enterprises in Military Market. J. Acad.Equip. 2016, 27, 80–84. [Google Scholar] [CrossRef]

- Li, M.; Chen, B. Government Investment, the Military-Civilian Industrial Standards Discrepancy, and the Plight of Civil Manufacturer Entering the Military Product Market. Nankai Econ. Stud. 2019, 1, 25–45. [Google Scholar] [CrossRef]

- Parente, F.; Anderson, P.J. Delphi inquiry systems. In Judgmental Forecasting; John Wiley and Sons: New York, NY, USA, 1987; pp. 129–156. [Google Scholar]

- Liu, P.; Wu, M. Fuzzy Theory and Its Application; National University of Defense Technology Press: Changsha, China, 1998; pp. 201–209. [Google Scholar]

| Source of Experts | Members | Quantity | Percentage |

|---|---|---|---|

| Academic circles | Two members of academic institutions | 2 | 12.50 |

| Government circles | Two members from the office of civil military integration and two members of Gu Zhenkou military–civilian integration innovation demonstration zone in Qingdao | 4 | 25.00 |

| Business circles | Two members of the science and technology park, three members of A company, and three members of B company * | 8 | 50.00 |

| Military circles | Two members from the military | 2 | 12.50 |

| Total | 16 | 100 |

| Scale | Meaning |

|---|---|

| 1 | the two factors Bi and Bj have the same importance as each other |

| 3 | Bi is slightly more important than Bj |

| 5 | Bi is obviously more important than Bj |

| 7 | Bi is strongly more important than Bj |

| 9 | Bi is extremely more important than Bj |

| 2,4,6,8 | the median value of the adjacent judgment mentioned above |

| Reciprocal | if Bi/bj = aij, then Bj/Bi = 1/aij |

| Ak | B1 | B2 | … | Bn |

|---|---|---|---|---|

| B1 | b11 | b12 | … | b1n |

| B2 | b21 | b22 | … | b2n |

| … | … | … | … | … |

| Bn | bn1 | bn2 | … | bnn |

| Matrix Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| Source of Survey Respondents | Members | Quantity | Percentage |

|---|---|---|---|

| Strategic planning level | Four members are the general manager, vice president of production, vice president of design, and vice president of finance | 4 | 13.33 |

| Tactical planning level | Ten members of the middle level leaders from the whole process of product realization, including administration, finance, design, production, planning, procurement, sales, after-sales, quality management, and human resources | 10 | 33.33 |

| Operation management level | One member of administration, one member of finance, five members of R&D, five members of production, one member of procurement, two members of after-sales, and one member of quality | 16 | 53.33 |

| Total | 30 | 100.00 |

| First-Level Indicators | Comment Level Set | Weights | Second-Level Indicators | Judgement Vector | ||||

|---|---|---|---|---|---|---|---|---|

| Management’s willingness to enter military products market | 0.0000 | 0.0800 | 0.9200 | 0.8806 | Thoughts integration | 0.0000 | 0.1684 | 0.8316 |

| Employees’ ideological understanding to enter military products market | 0.0000 | 0.8200 | 0.1800 | 0.1194 | ||||

| Completeness of internal management system | 0.0000 | 0.0200 | 0.9800 | 0.5745 | Administrative management | 0.0000 | 0.1429 | 0.8571 |

| Perfect situation about organizational structure of enterprises | 0.0000 | 0.0800 | 0.9200 | 0.2633 | ||||

| Emergency response capability | 0.0000 | 0.6800 | 0.3200 | 0.1622 | ||||

| Position of enterprises in the industry | 0.0000 | 0.9644 | 0.0356 | 0.1544 | Social recognition | 0.0000 | 0.1527 | 0.8473 |

| Enterprise’s prestige | 0.0000 | 0.0000 | 1.0000 | 0.4160 | ||||

| Value of enterprise customer satisfaction | 0.0000 | 0.0089 | 0.9911 | 0.4297 | ||||

| Acquisition of military standard documents | 0.9800 | 0.0200 | 0.0000 | 0.1200 | Documents &records management | 0.1176 | 0.1071 | 0.7753 |

| Completeness of production operation instructions | 0.0000 | 0.2222 | 0.7778 | 0.3351 | ||||

| Traceability of process file records | 0.0000 | 0.0556 | 0.9444 | 0.5449 | ||||

| Proportion of R&D investment in military-related products | 0.0000 | 0.8200 | 0.1800 | 0.8261 | Operation capacity | 0.0000 | 0.8509 | 0.1491 |

| Inventory input ratio of military-related products | 0.0000 | 0.9978 | 0.0022 | 0.1739 | ||||

| Current economic benefits | 0.0000 | 0.0800 | 0.9200 | 0.1702 | Achievable economic benefits | 0.1494 | 0.6940 | 0.1566 |

| Long-term economic benefits | 0.1800 | 0.8200 | 0.0000 | 0.8298 | ||||

| Production and operation environment | 0.0000 | 0.0556 | 0.9444 | 0.4082 | Infrastructure | 0.0000 | 0.0500 | 0.9500 |

| Production equipment allocation situation | 0.0000 | 0.0200 | 0.9800 | 0.3122 | ||||

| Test equipment allocation situation | 0.0000 | 0.0200 | 0.9800 | 0.1528 | ||||

| Maintenance equipment allocation situation | 0.0000 | 0.1422 | 0.8578 | 0.1267 | ||||

| R&D staffing allocation situation | 0.0000 | 0.1089 | 0.8911 | 0.5527 | Staffing allocation | 0.0000 | 0.0952 | 0.9048 |

| Production staffing allocation situation | 0.0000 | 0.0556 | 0.9444 | 0.2415 | ||||

| Test personnel allocation situation | 0.0000 | 0.1422 | 0.8578 | 0.1175 | ||||

| Maintenance staffing allocation situation | 0.0000 | 0.0556 | 0.9444 | 0.0884 | ||||

| Management review | 0.0000 | 0.0089 | 0.9911 | 0.5792 | System execution capability | 0.0000 | 0.0267 | 0.9733 |

| Internal audit | 0.0000 | 0.0356 | 0.9644 | 0.0899 | ||||

| External audit | 0.0000 | 0.0556 | 0.9444 | 0.3309 | ||||

| Completion rate of corrective and preventive measures | 0.0000 | 0.0200 | 0.9800 | 0.7681 | Continuous improvement capability | 0.0000 | 0.0200 | 0.9800 |

| Continuous improvement project completion rate on schedule | 0.0000 | 0.0200 | 0.9800 | 0.2319 | ||||

| Misjudgment rate of raw material Inspection | 0.0000 | 0.0089 | 0.9911 | 0.0845 | Process management capability | 0.0000 | 0.0161 | 0.9839 |

| Non-conformity control rate of delivered products | 0.0000 | 0.0200 | 0.9800 | 0.7489 | ||||

| Qualification rate of one-time inspection of reworked and repaired products | 0.0000 | 0.0022 | 0.9978 | 0.1665 | ||||

| Qualification rate of disposable sample delivery | 0.0000 | 0.0089 | 0.9911 | 0.4110 | R&D capability | 0.0000 | 0.0160 | 0.9840 |

| Transforming ability of scientific and technological achievements | 0.0000 | 0.0356 | 0.9644 | 0.0695 | ||||

| Design schedule punctuality rate | 0.0000 | 0.0800 | 0.9200 | 0.1120 | ||||

| Design error rate | 0.0000 | 0.0022 | 0.9978 | 0.4075 | ||||

| Timeliness of contract review | 0.0000 | 0.0089 | 0.9911 | 0.1649 | Process capacity | 0.0000 | 0.0033 | 0.9967 |

| Error rate of contract review | 0.0000 | 0.0022 | 0.9978 | 0.8351 | ||||

| Qualification rate of raw material purchase | 0.0000 | 0.0200 | 0.9800 | 0.6863 | Procurement | 0.0000 | 0.0249 | 0.9751 |

| Timely arrival rate of raw materials | 0.0000 | 0.0356 | 0.9644 | 0.3137 | ||||

| Accuracy of raw material distribution | 0.0000 | 0.0556 | 0.9444 | 0.6667 | Materials | 0.0000 | 0.0400 | 0.9600 |

| Stock error rate of raw materials | 0.0000 | 0.0089 | 0.9911 | 0.3333 | ||||

| Process rework rate | 0.0000 | 0.0089 | 0.9911 | 0.0752 | Production process | 0.0000 | 0.0192 | 0.9808 |

| Product delivery rate on time | 0.0000 | 0.0200 | 0.9800 | 0.3836 | ||||

| Qualification rate of one-time delivery of products | 0.0000 | 0.0200 | 0.9800 | 0.5412 | ||||

| Failure rate of key equipment | 0.0000 | 0.0200 | 0.9800 | 0.7746 | Equipment management | 0.0000 | 0.0280 | 0.9720 |

| Failure rate of main equipment | 0.0000 | 0.0556 | 0.9444 | 0.2254 | ||||

| Serving on time | 0.0000 | 0.0089 | 0.9911 | 0.5897 | After-sale service | 0.0000 | 0.0089 | 0.9911 |

| Post-service satisfaction | 0.0000 | 0.0089 | 0.9911 | 0.4103 | ||||

| Reserve of after-sales spare parts | 0.0000 | 0.0356 | 0.9644 | 0.8049 | After-sales guarantee | 0.0000 | 0.0911 | 0.9089 |

| Reserve of after-sale finished products | 0.0000 | 0.3200 | 0.6800 | 0.1951 | ||||

| Second-Level Indicators | Comment Level Set | Weights | Third-Level Indicators | Judgement Vector | ||||

|---|---|---|---|---|---|---|---|---|

| Thoughts integration | 0.0000 | 0.1684 | 0.8316 | 0.0675 | Integrated management capacity | 0.0298 | 0.1370 | 0.8332 |

| Administrative management | 0.0000 | 0.1429 | 0.8571 | 0.5252 | ||||

| Social recognition | 0.0000 | 0.1527 | 0.8473 | 0.1539 | ||||

| Documents &records management | 0.1176 | 0.1071 | 0.7753 | 0.2534 | ||||

| Operation capacity | 0.0000 | 0.8509 | 0.1491 | 0.3038 | Enterprise financial capacity | 0.1040 | 0.7417 | 0.1543 |

| Achievable economic benefits | 0.1494 | 0.6940 | 0.1566 | 0.6962 | ||||

| Infrastructure | 0.0000 | 0.0500 | 0.9500 | 0.5000 | Resource allocation capacity | 0.0000 | 0.0726 | 0.9274 |

| Staffing allocation | 0.0000 | 0.0952 | 0.9048 | 0.5000 | ||||

| System execution capability | 0.0000 | 0.0267 | 0.9733 | 0.3333 | Quality management ability | 0.0000 | 0.0209 | 0.9791 |

| Continuous improvement capability | 0.0000 | 0.0200 | 0.9800 | 0.3333 | ||||

| Process management capability | 0.0000 | 0.0161 | 0.9839 | 0.3333 | ||||

| R&D capability | 0.0000 | 0.0160 | 0.9840 | 0.7333 | R&D and process capability | 0.0000 | 0.0126 | 0.9874 |

| Process capacity | 0.0000 | 0.0033 | 0.9967 | 0.2667 | ||||

| Procurement | 0.0000 | 0.0249 | 0.9751 | 0.7419 | Purchasing and warehousing capacity | 0.0000 | 0.0288 | 0.9712 |

| Materials | 0.0000 | 0.0400 | 0.9600 | 0.2581 | ||||

| Production process | 0.0000 | 0.0192 | 0.9808 | 0.5000 | Production and manufacturing capacity | 0.0000 | 0.0236 | 0.9764 |

| Equipment management | 0.0000 | 0.0280 | 0.9720 | 0.5000 | ||||

| After-sale service | 0.0000 | 0.0089 | 0.9911 | 0.5000 | Maintenance and after-sales service guarantee capability | 0.0000 | 0.0500 | 0.9500 |

| After-sales guarantee | 0.0000 | 0.0911 | 0.9089 | 0.5000 | ||||

| Third-Level Indicators | Comment Level Set | Weights | Forth-Level Indicators | Judgement Vector | ||||

|---|---|---|---|---|---|---|---|---|

| Integrated management capacity | 0.0298 | 0.1370 | 0.8332 | 0.3708 | Service support process | 0.0236 | 0.1616 | 0.8148 |

| Enterprise financial capacity | 0.1040 | 0.7417 | 0.1543 | 0.1205 | ||||

| Resource allocation capacity | 0.0000 | 0.0726 | 0.9274 | 0.2073 | ||||

| Quality management ability | 0.0000 | 0.0209 | 0.9791 | 0.3013 | ||||

| R&D and process capability | 0.0000 | 0.0126 | 0.9874 | 0.4041 | Product realization process | 0.0000 | 0.0249 | 0.9751 |

| Purchasing and warehousing capacity | 0.0000 | 0.0288 | 0.9712 | 0.0960 | ||||

| Production and manufacturing capacity | 0.0000 | 0.0236 | 0.9764 | 0.3019 | ||||

| Maintenance and after-sales service guarantee capability | 0.0000 | 0.0500 | 0.9500 | 0.1980 | ||||

| Forth-Level Indicators | Comment Level Set | Weights | Fifth-Level Indicators | Judgement Vector | ||||

|---|---|---|---|---|---|---|---|---|

| Service support process | 0.0236 | 0.1616 | 0.8148 | 0.27586 | The capabilities of enterprises entering military products market | 0.0065 | 0.0626 | 0.9309 |

| Product realization process | 0.0000 | 0.0249 | 0.9751 | 0.72414 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zhang, S. An Evaluation Study of the Capabilities of Civilian Manufacturing Enterprises Entering the Military Products Market under the Background of China’s Civil–Military Integration. Sustainability 2020, 12, 2416. https://doi.org/10.3390/su12062416

Xu J, Zhang S. An Evaluation Study of the Capabilities of Civilian Manufacturing Enterprises Entering the Military Products Market under the Background of China’s Civil–Military Integration. Sustainability. 2020; 12(6):2416. https://doi.org/10.3390/su12062416

Chicago/Turabian StyleXu, Jianzhong, and Song Zhang. 2020. "An Evaluation Study of the Capabilities of Civilian Manufacturing Enterprises Entering the Military Products Market under the Background of China’s Civil–Military Integration" Sustainability 12, no. 6: 2416. https://doi.org/10.3390/su12062416

APA StyleXu, J., & Zhang, S. (2020). An Evaluation Study of the Capabilities of Civilian Manufacturing Enterprises Entering the Military Products Market under the Background of China’s Civil–Military Integration. Sustainability, 12(6), 2416. https://doi.org/10.3390/su12062416