Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.3. Research Objectives

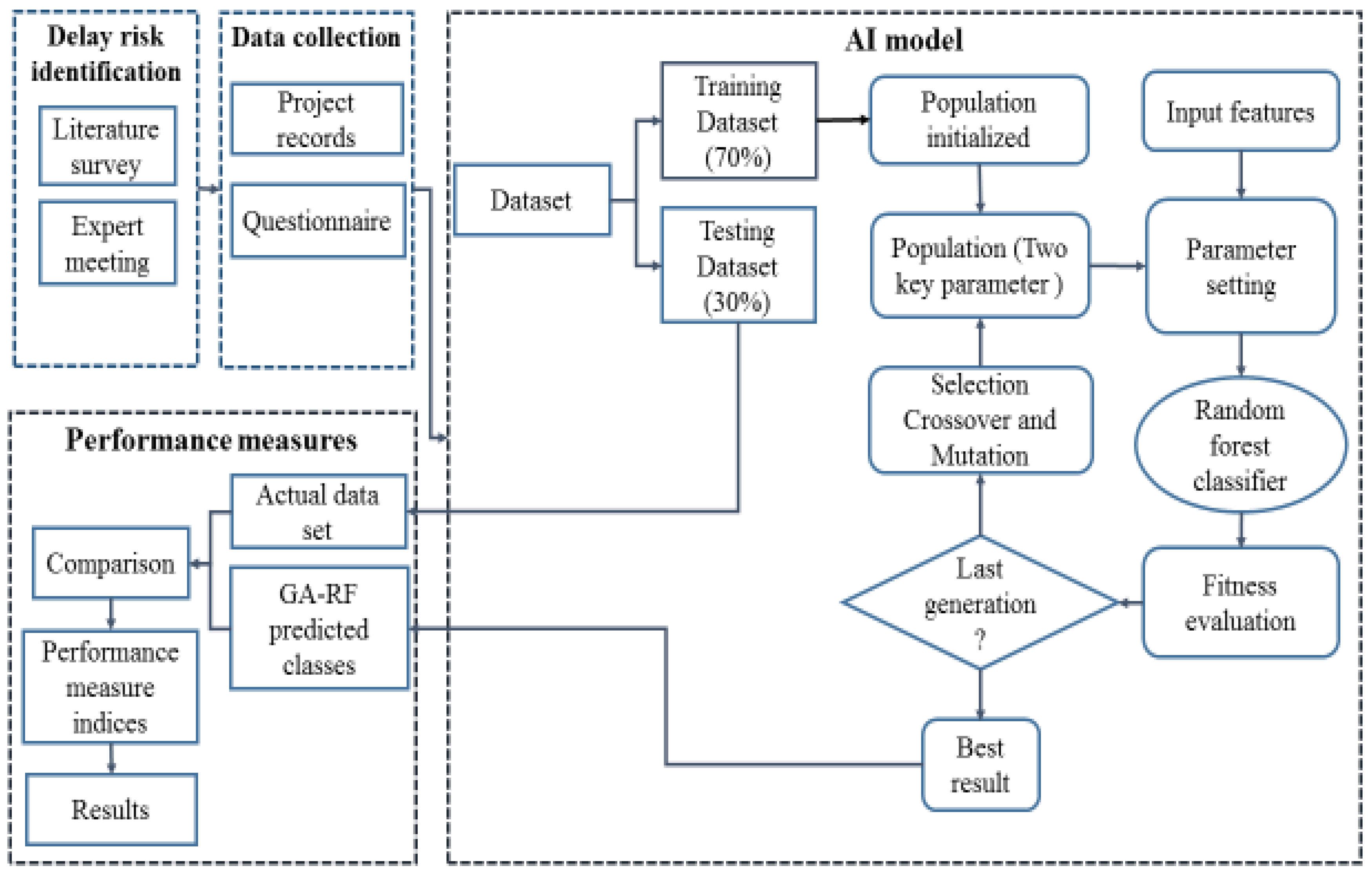

2. Research Methodology

2.1. Random Forest Model

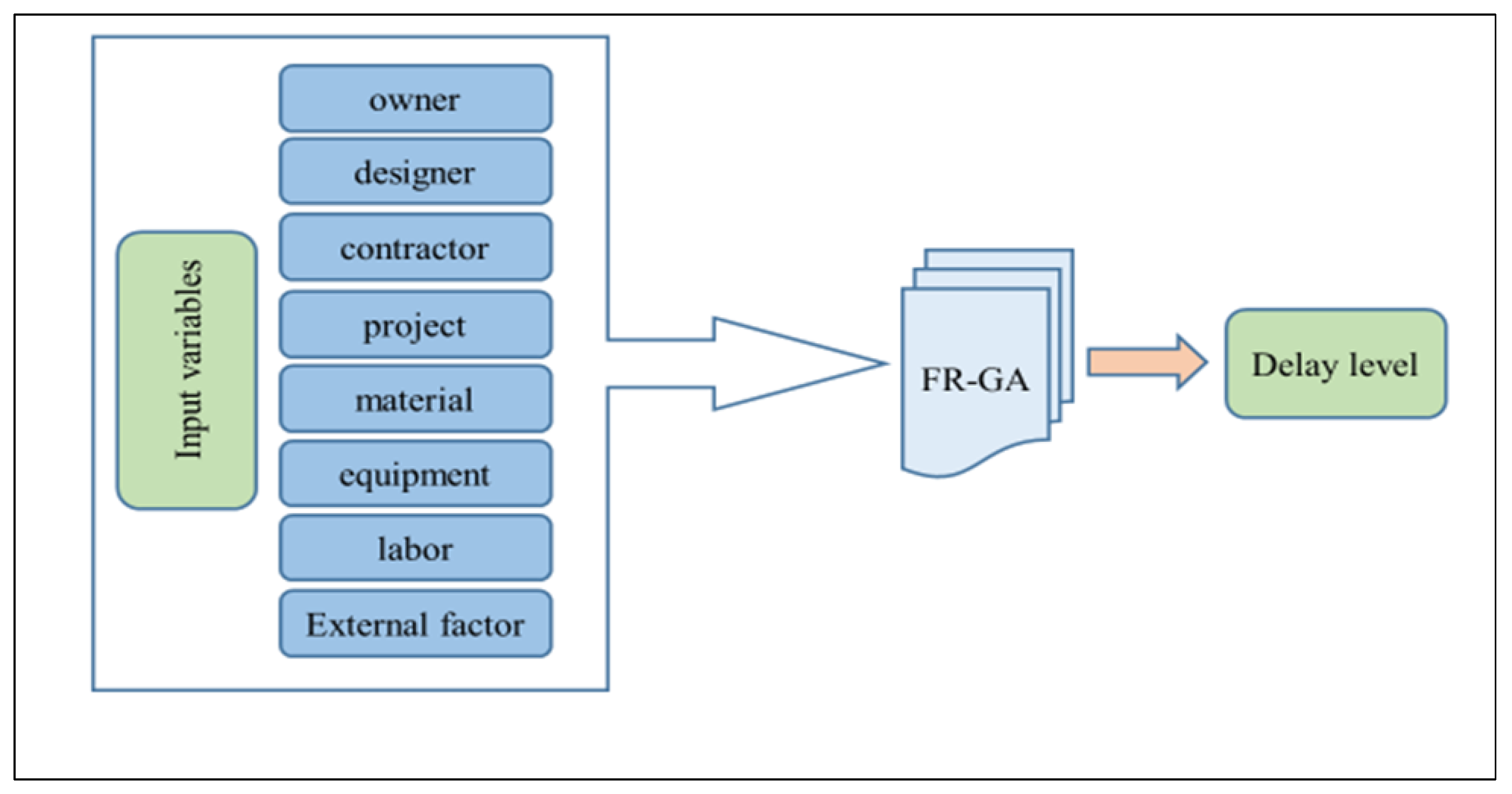

2.2. The Hybrid RF-GA Model

2.3. Identification of Delay Sources and Factors in Construction Projects

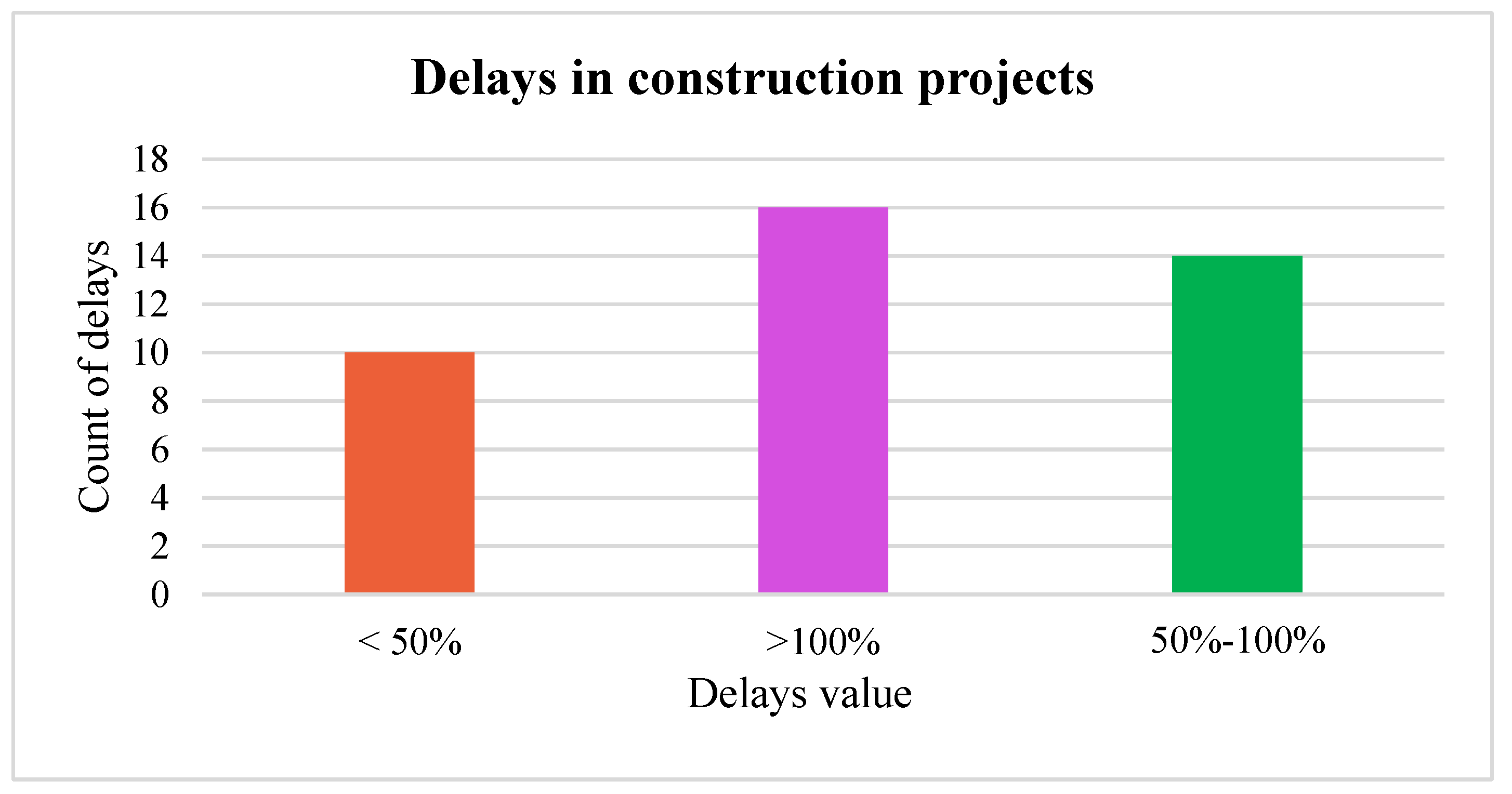

2.4. Data Collection

2.5. Model Development Procedure

2.6. Model Performance Measures

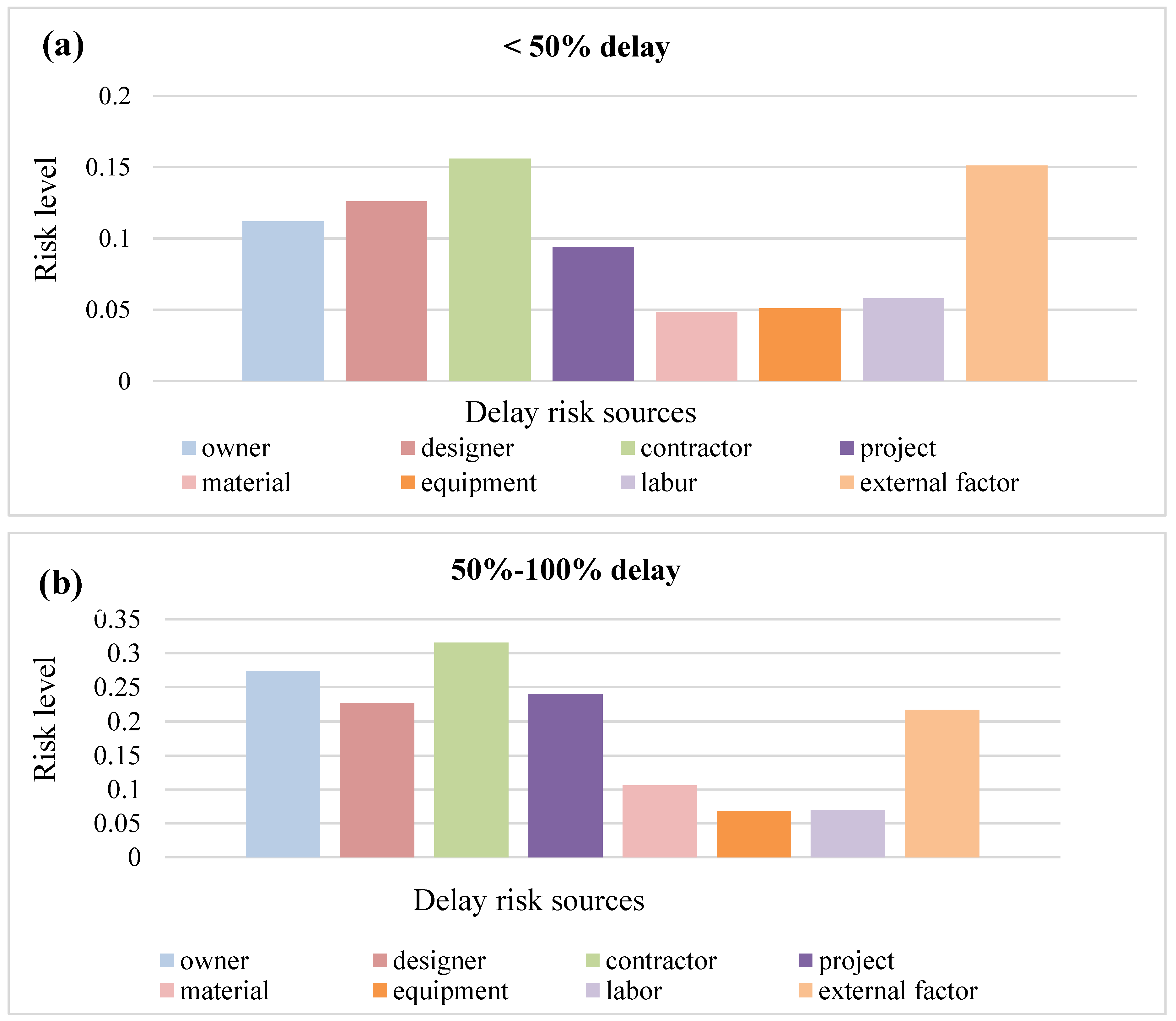

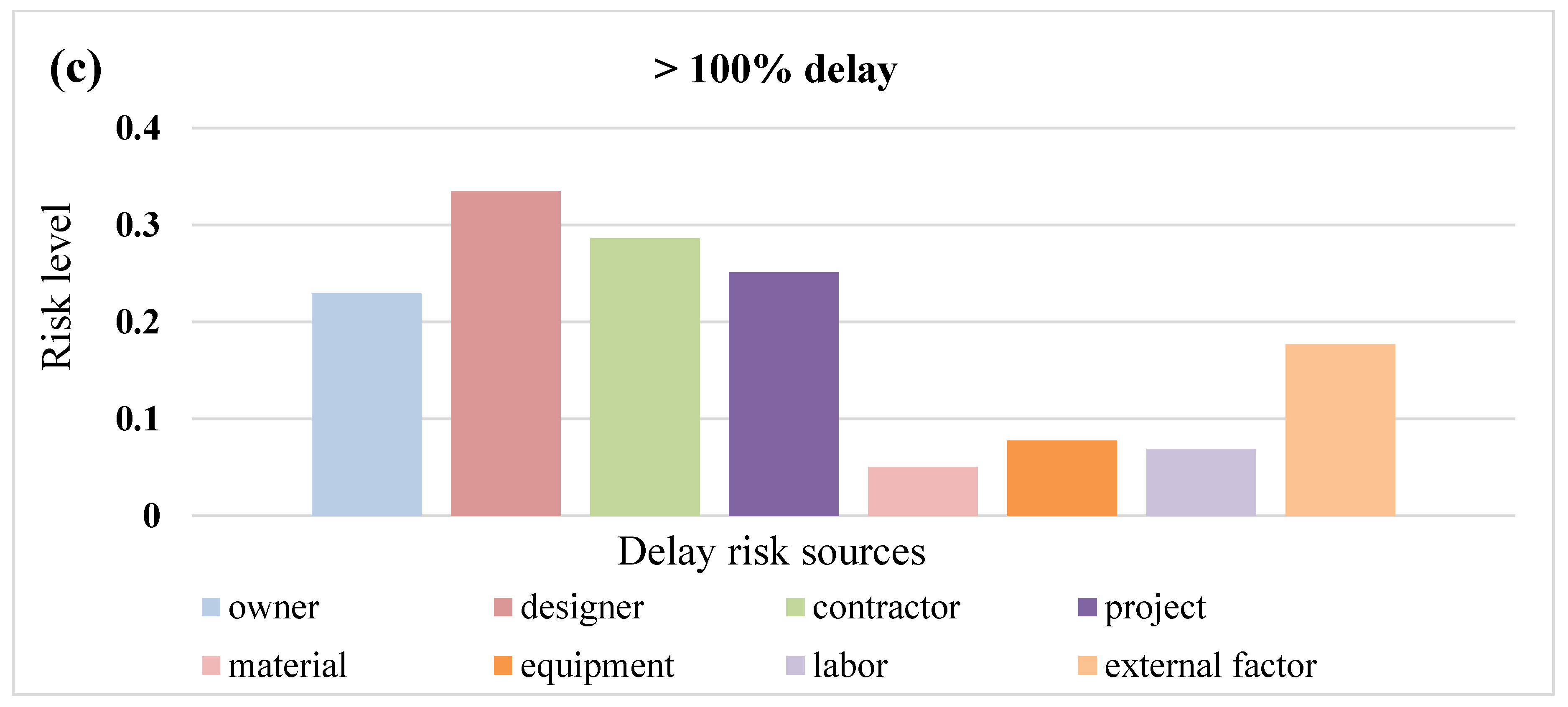

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vorakulpipat, C.; Rezgui, Y.; Hopfe, C.J. Value creating construction virtual teams: A case study in the construction sector. Autom. Constr. 2010, 19, 142–147. [Google Scholar] [CrossRef]

- Chan, A.P. Time-cost relationship of public sector projects in Malaysia. Int. J. Proj. Manag. 2001, 19, 223–229. [Google Scholar] [CrossRef]

- Assaf, S.A.; Al-Hejji, S. Causes of delay in large construction projects. Int. J. Proj. Manag. 2006, 24, 349–357. [Google Scholar] [CrossRef]

- Sambasivan, M.; Soon, Y.W. Causes and effects of delays in Malaysian construction industry. Int. J. Proj. Manag. 2007, 25, 517–526. [Google Scholar] [CrossRef]

- Aibinu, A.; Jagboro, G. The effects of construction delays on project delivery in Nigerian construction industry. Int. J. Proj. Manag. 2002, 20, 593–599. [Google Scholar] [CrossRef]

- Odeh, A.M.; Battaineh, H.T. Causes of construction delay: traditional contracts. Int. J. Proj. Manag. 2002, 20, 67–73. [Google Scholar] [CrossRef]

- Fugar, F.D.; Agyakwah-Baah, A.B. Delays in Building Construction Projects in Ghana. Australas. J. Constr. Econ. Build. 2010, 10, 103–116. [Google Scholar] [CrossRef]

- Aziz, R.F. Ranking of delay factors in construction projects after Egyptian revolution. Alex. Eng. J. 2013, 52, 387–406. [Google Scholar] [CrossRef]

- Al-Momani, A.H. Construction delay: a quantitative analysis. Int. J. Proj. Manag. 2000, 18, 51–59. [Google Scholar] [CrossRef]

- Jing, W.; Naji, H.I.; Zehawi, R.N.; Ali, Z.; Al-Ansari, N.; Yaseen, Z.M. System Dynamics Modeling Strategy for Civil Construction Projects: The Concept of Successive Legislation Periods. Symmetry 2019, 11, 677. [Google Scholar] [CrossRef]

- Gondia, A.; Siam, A.; El-Dakhakhni, W.; Nassar, A.H. Machine Learning Algorithms for Construction Projects Delay Risk Prediction. J. Constr. Eng. Manag. 2020, 146, 04019085. [Google Scholar] [CrossRef]

- Mahamid, I.; Bruland, A.; Dmaidi, N. Causes of delay in road construction projects. J. Manag. Eng. 2011, 28, 300–310. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Chan, D.W. Developing a benchmark model for project construction time performance in Hong Kong. Build. Environ. 2004, 39, 339–349. [Google Scholar] [CrossRef]

- Rezaie, K.; Amalnik, M.; Gereie, A.; Ostadi, B.; Shakhseniaee, M. Using extended Monte Carlo simulation method for the improvement of risk management: Consideration of relationships between uncertainties. Appl. Math. Comput. 2007, 190, 1492–1501. [Google Scholar] [CrossRef]

- Hammad, A.A.A.; Ali, S.M.A.; Sweis, G.J.; Bashir, A. Prediction model for construction cost and duration in Jordan. Jordan J. Civ. Eng. 2008, 2, 250–266. [Google Scholar]

- Mohamed, D.; Srour, F.; Tabra, W.; Zayed, T. A prediction model for construction project time contingency. In Construction Research Congress 2009: Building a Sustainable Future; ASCE: Reston, VA, USA, 2009; pp. 736–745. [Google Scholar]

- Abu Hammad, A.; Ali, S.M.A.; Sweis, G.J.; Sweis, R. Statistical Analysis on the Cost and Duration of Public Building Projects. J. Manag. Eng. 2010, 26, 105–112. [Google Scholar] [CrossRef]

- Dursun, O.; Stoy, C. Time–cost relationship of building projects: statistical adequacy of categorization with respect to project location. Constr. Manag. Econ. 2011, 29, 97–106. [Google Scholar] [CrossRef]

- Kokkaew, N.; Wipulanusat, W. Completion delay risk management: A dynamic risk insurance approach. KSCE J. Civ. Eng. 2014, 18, 1599–1608. [Google Scholar] [CrossRef]

- Brunette, E.S.; Flemmer, R.C.; Flemmer, C.L. A review of artificial intelligence. In Proceedings of the 2009 4th International Conference on Autonomous Robots and Agents, Wellington, New Zealand, 10–12 February 2009; pp. 385–392. [Google Scholar]

- Elazouni, A. Classifying Construction Contractors Using Unsupervised-Learning Neural Networks. J. Constr. Eng. Manag. 2006, 132, 1242–1253. [Google Scholar] [CrossRef]

- Chao, L.-C.; Chien, C.-F. Estimating Project S-Curves Using Polynomial Function and Neural Networks. J. Constr. Eng. Manag. 2009, 135, 169–177. [Google Scholar] [CrossRef]

- Desai, V.S.; Joshi, S. Application of decision tree technique to analyze construction project data. In Communications in Computer and Information Science, Proceedings of the International Conference on Information Systems, Technology and Management, Bangkok, Thailand, 11–13 March 2010; Springer: Piscataway, NJ, USA, 2010; pp. 304–313. [Google Scholar]

- Shin, Y.-S. Formwork System Selection Model for Tall Building Construction Using the Adaboost Algorithm. J. Korea Inst. Build. Constr. 2011, 11, 523–529. [Google Scholar] [CrossRef]

- Chou, J.-S.; Lin, C. Predicting disputes in public-private partnership projects: Classification and ensemble models. J. Comput. Civ. Eng. 2012, 27, 51–60. [Google Scholar] [CrossRef]

- Rudžianskaitė–Kvaraciejienė, R.; Apanaviciene, R.; Gelzinis, A. modelling the effectiveness of ppp road infrastructure projects by applying random forests. J. Civ. Eng. Manag. 2015, 21, 290–299. [Google Scholar] [CrossRef]

- Heravi, G.; Eslamdoost, E. Applying Artificial Neural Networks for Measuring and Predicting Construction-Labor Productivity. J. Constr. Eng. Manag. 2015, 141, 04015032. [Google Scholar] [CrossRef]

- Gerassis, S.; Martín, J.E.; García, J.T.; Saavedra, A.; Taboada, J. Bayesian decision tool for the analysis of occupational accidents in the construction of embankments. J. Constr. Eng. Manag. 2016, 143, 4016093. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.; Qadir, J.; Munir, K.; Ajayi, S.; Akinade, O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Asadi, A.; Alsubaey, M.; Makatsoris, C. A machine learning approach for predicting delays in construction logistics. Int. J. Adv. Logist. 2015, 4, 115–130. [Google Scholar] [CrossRef]

- Hassan, Z.; Ibrahim, A.M.; Naji, H. Evaluation of Legislation Adequacy in Managing Time and Quality Performance in Iraqi Construction Projects- a Bayesian Decision Tree Approach. Civ. Eng. J. 2018, 4, 993. [Google Scholar] [CrossRef]

- Yaseen, Z.; Mohtar, W.H.M.W.; Ameen, A.M.S.; Ebtehaj, I.; Razali, S.F.M.; Bonakdari, H.; Salih, S.Q.; Al-Ansari, N.; Shahid, S. Implementation of univariate paradigm for streamflow simulation using hybrid data-driven model: Case study in tropical region: Implementation of univariate paradigm for streamflow simulation using hybrid data-driven model: Case study in tropical region. IEEE Access 2019, 7, 74471–74481. [Google Scholar] [CrossRef]

- Chou, J.-S.; Pham, A.-D. Hybrid computational model for predicting bridge scour depth near piers and abutments. Autom. Constr. 2014, 48, 88–96. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Ehteram, M.; Hossain, S.; Chow, M.F.; Koting, S.; Mohd, N.S.; Jaafar, W.B.; Afan, H.A.; Hin, L.S.; Zaini, N.; et al. A Novel Hybrid Evolutionary Data-Intelligence Algorithm for Irrigation and Power Production Management: Application to Multi-Purpose Reservoir Systems. Sustainability 2019, 11, 1953. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Ebtehaj, I.; Kim, S.; Sanikhani, H.; Asadi, H.; Ghareb, M.I.; Bonakdari, H.; Mohtar, W.H.M.W.; Al-Ansari, N.; Shahid, S. Novel Hybrid Data-Intelligence Model for Forecasting Monthly Rainfall with Uncertainty Analysis. Water 2019, 11, 502. [Google Scholar] [CrossRef]

- Breiman, L.; Cutler, A. State of the art of data mining using Random forest. In Proceedings of the Salford Data Mining Conference, San Diego, CA, USA, 24–25 May 2012. [Google Scholar]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Ruppert, D. The Elements of Statistical Learning: Data Mining, Inference, and Prediction. J. Am. Stat. Assoc. 2004, 99, 567. [Google Scholar] [CrossRef]

- Catani, F.; Lagomarsino, D.; Segoni, S.; Tofani, V. Landslide susceptibility estimation by random forests technique: sensitivity and scaling issues. Nat. Hazards Earth Syst. Sci. 2013, 13, 2815–2831. [Google Scholar] [CrossRef]

- Naghibi, S.A.; Ahmadi, K.; Daneshi, A. Application of Support Vector Machine, Random Forest, and Genetic Algorithm Optimized Random Forest Models in Groundwater Potential Mapping. Water Resour. Manag. 2017, 31, 2761–2775. [Google Scholar] [CrossRef]

- Alipour, M.; Harris, D.K.; Barnes, L.E.; Ozbulut, O.; Carroll, J. Load-Capacity Rating of Bridge Populations through Machine Learning: Application of Decision Trees and Random Forests. J. Bridg. Eng. 2017, 22, 04017076. [Google Scholar] [CrossRef]

- Liaw, A.; Wiener, M. Classification and regression by randomforest. R News 2002, 2, 18–22. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Azar, A.T.; Vaidyanathan, S. Computational Intelligence Applications in Modeling and Control; Springer: Piscataway, NJ, USA, 2015. [Google Scholar]

- Kandil, A.; El-Rayes, K. Parallel Genetic Algorithms for Optimizing Resource Utilization in Large-Scale Construction Projects. J. Constr. Eng. Manag. 2006, 132, 491–498. [Google Scholar] [CrossRef]

- Senouci, A.; Eldin, N.N. Use of Genetic Algorithms in Resource Scheduling of Construction Projects. J. Constr. Eng. Manag. 2004, 130, 869–877. [Google Scholar] [CrossRef]

- Long, L.D.; Ohsato, A. A genetic algorithm-based method for scheduling repetitive construction projects. Autom. Constr. 2009, 18, 499–511. [Google Scholar] [CrossRef]

- Rogalska, M.; Bozejko, W.; Hejducki, Z. Time/cost optimization using hybrid evolutionary algorithm in construction project scheduling. Autom. Constr. 2008, 18, 24–31. [Google Scholar] [CrossRef]

- Chou, J.-S.; Cheng, M.-Y.; Wu, Y.-W.; Pham, A.-D. Optimizing parameters of support vector machine using fast messy genetic algorithm for dispute classification. Expert Syst. Appl. 2014, 41, 3955–3964. [Google Scholar] [CrossRef]

- Xia, N.; Zhong, R.; Wu, C.; Wang, X.; Wang, S. Assessment of Stakeholder-Related Risks in Construction Projects: Integrated Analyses of Risk Attributes and Stakeholder Influences. J. Constr. Eng. Manag. 2017, 143, 04017030. [Google Scholar] [CrossRef]

- Ismail, I.; Memon, A.H.; Rahman, I.A. Expert opinion on risk level for factors affecting time and cost overrun along the project lifecycle in Malaysian construction projects. Int. J. Constr. Technol. Manag. 2013, 1, 2289. [Google Scholar]

- Thomas, S.J. Using Web and Paper Questionnaires for Data-Based Decision Making: From Design to Interpretation of the Results; Corwin Press: Thousand Oaks, CA, USA, 2004. [Google Scholar]

- Helmer, G.; Wong, J.; Honavar, V.G.; Miller, L. Automated discovery of concise predictive rules for intrusion detection. J. Syst. Softw. 2002, 60, 165–175. [Google Scholar] [CrossRef]

- Davis, J.; Goadrich, M. The relationship between Precision-Recall and ROC curves. In Proceedings of the 23rd International Conference on Machine Learning; ACM: New York, NY, USA, 2006; pp. 233–240. [Google Scholar]

- Smeeton, N.C. Early history of the kappa statistic. Biometrics 1985, 41, 795. [Google Scholar]

- Pontius, R.G.; Millones, M. Death to Kappa: birth of quantity disagreement and allocation disagreement for accuracy assessment. Int. J. Remote Sens. 2011, 32, 4407–4429. [Google Scholar] [CrossRef]

- Tabassum, M.; Mathew, K. A genetic algorithm analysis towards optimization solutions. Int. J. Digit. Inf. Wirel. Commun. 2014, 4, 124–142. [Google Scholar] [CrossRef]

| Delay Source | Delay Factors |

|---|---|

| 1. Owner | 1.1 Owner financial problems |

| 1.2 Payment delay by the owner | |

| 1.3 Choosing of inefficient design team | |

| 1.4 Inadequate experience of the owner | |

| 1.5 Issuing of change orders by the owner | |

| 1.6 Delay in location delivery to the contractor | |

| 1.7 Choice of inefficient contractor | |

| 1.8 Delay in decision making procedure | |

| 2. Designer | 2.1 Inadequate experience of design members |

| 2.2 Delay in the preparation of design documents | |

| 2.3 Defects in the design and ambiguity of design drawings | |

| 3. Contractor | 3.1 Ineffective project planning |

| 3.2 Financial contractor difficulties | |

| 3.3 Inadequacy of contractor | |

| 3.4 Rework due to defects in executed work | |

| 3.5 Ineffective supervision and site management | |

| 3.6 Many changes in subcontractor parties | |

| 3.7 Poor communication between contractor and project parties | |

| 4. Project | 4.1 Awarding the contract to an inadequate contractor |

| 4.2 Disputes between project parties | |

| 4.3 Period of contract is very short | |

| 4.4 Errors in contract documents | |

| 5. Material | 5.1 Deficiency of materials in the market |

| 5.2 Delay in supplying materials | |

| 5.3 Ineffective quality of materials | |

| 5.4 Poor storage of materials | |

| 6. Equipment | 6.1 Poor efficiency of equipment |

| 6.2 Unsuitable type of equipment | |

| 7. Labor | 7.1 Poor labor productivity |

| 7.2 Inadequacy of workforce | |

| 7.3 Lack of labor | |

| 8. External factors | 8.1 Political situation and terrorism |

| 8.2 Inflation | |

| 8.3 Legislation changes in the country | |

| 8.4 Unpredicted surface conditions | |

| 8.5 Neighbor problems | |

| 8.6 Bad weather conditions |

| Scale | Probability | Impact |

|---|---|---|

| Very low | 0.1 | 0.05 |

| Low | 0.3 | 0.1 |

| Medium | 0.5 | 0.2 |

| High | 0.7 | 0.4 |

| Very high | 0.9 | 0.8 |

| Actual Class | ||||

|---|---|---|---|---|

| Predicted Class | ˂50% | 50%–100% | ˃100% | Total |

| ˂50% | 2 | 0 | 1 | 3 |

| 50%–100% | 0 | 0 | 3 | 3 |

| ˃100% | 1 | 4 | 1 | 6 |

| Total | 3 | 4 | 5 | |

| Actual Class | ||||

|---|---|---|---|---|

| Predicted Class | ˂50% | 50%–100% | ˃100% | Total |

| ˂50% | 2 | 0 | 0 | 2 |

| 50%–100% | 1 | 5 | 0 | 6 |

| ˃100% | 0 | 0 | 4 | 4 |

| Total | 3 | 5 | 4 | |

| RF | RF-GA | |||||

|---|---|---|---|---|---|---|

| Performance Index | ˂50% Delay | 50%–100% Delay | ˃100% Delay | ˂50% Delay | 50%–100% Delay | ˃100% Delay |

| Precision | 87.5 | 100 | 90 | 87.5 | 100 | 100 |

| Sensitivity | 87.5 | 83.33 | 90 | 100 | 91.67 | 90 |

| Specificity | 95 | 100 | 94.44 | 95.2 | 100 | 100 |

| Accuracy | 92.86 | 96.43 | ||||

| Classification error | 7.41 | 3.57 | ||||

| Kappa | 89.2 | 94.6 | ||||

| RF | RF-GA | |||||

|---|---|---|---|---|---|---|

| Performance Index | ˂50% Delay | 50%–100% Delay | ˃100% Delay | ˂50% Delay | 50%–100% Delay | ˃100% Delay |

| Precision | 66.67 | 100 | 90 | 66.67 | 83.33 | 100 |

| Sensitivity | 50 | 50 | 90 | 80 | 100 | 80 |

| Specificity | 87.5 | 100 | 94.44 | 71.4 | 85.7 | 100 |

| Accuracy | 75 | 91.67 | ||||

| Classification error | 25 | 8.33 | ||||

| Kappa | 62.5 | 87 | ||||

| Author | Methods | Results |

|---|---|---|

| [30] | Questionnaire survey, decision tree and Naive Bayes | Accuracy of decision tree 79.41% is higher than Naive Bayes by 5.81% |

| [31] | Questionnaire and Bayesian decision tree | Bayesian decision tree gained an accuracy of 86.7% |

| [11] | Records of construction projects, meeting with experts, decision tree and Naive Bayes | Accuracy of Naive Bayes, 51.2%, is higher than decision tree by 4% |

| The current study | Records of construction projects, meetings and questionnaire survey, classical Random Forest, hybrid genetic Random Forest | Accuracy of genetic Random Forest, 91.76%, is higher than classical Random Forest by 16.67% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaseen, Z.M.; Ali, Z.H.; Salih, S.Q.; Al-Ansari, N. Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability 2020, 12, 1514. https://doi.org/10.3390/su12041514

Yaseen ZM, Ali ZH, Salih SQ, Al-Ansari N. Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability. 2020; 12(4):1514. https://doi.org/10.3390/su12041514

Chicago/Turabian StyleYaseen, Zaher Mundher, Zainab Hasan Ali, Sinan Q. Salih, and Nadhir Al-Ansari. 2020. "Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model" Sustainability 12, no. 4: 1514. https://doi.org/10.3390/su12041514

APA StyleYaseen, Z. M., Ali, Z. H., Salih, S. Q., & Al-Ansari, N. (2020). Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability, 12(4), 1514. https://doi.org/10.3390/su12041514