The Determinants of Carbon Emissions in the Chinese Construction Industry: A Spatial Analysis

Abstract

:1. Introduction

2. Literature Review

3. Methodology

3.1. Measuring Carbon Emissions

3.2. Spatial Autocorrelation Index

3.3. Spatial Panel Econometric Model

3.4. Data

4. Results

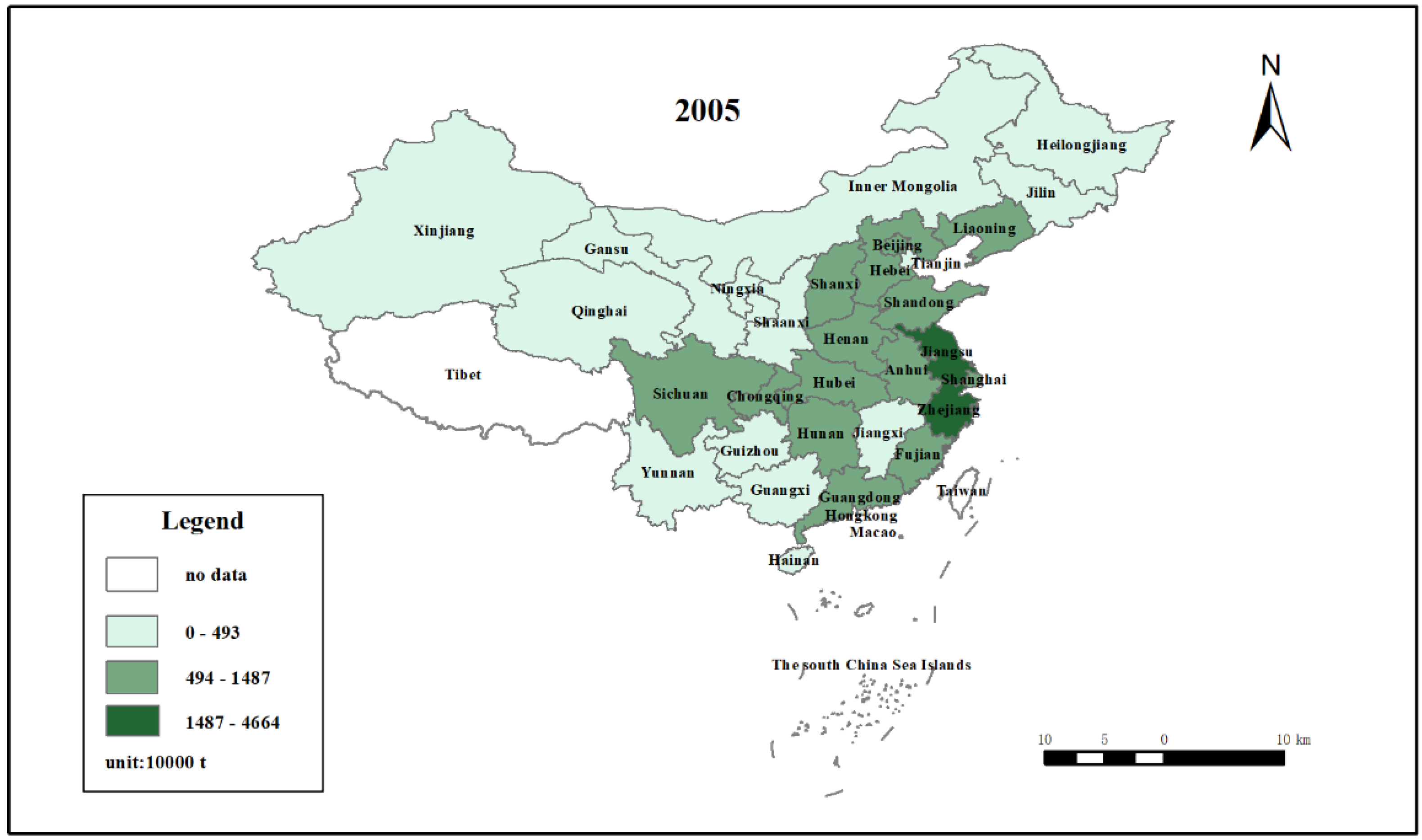

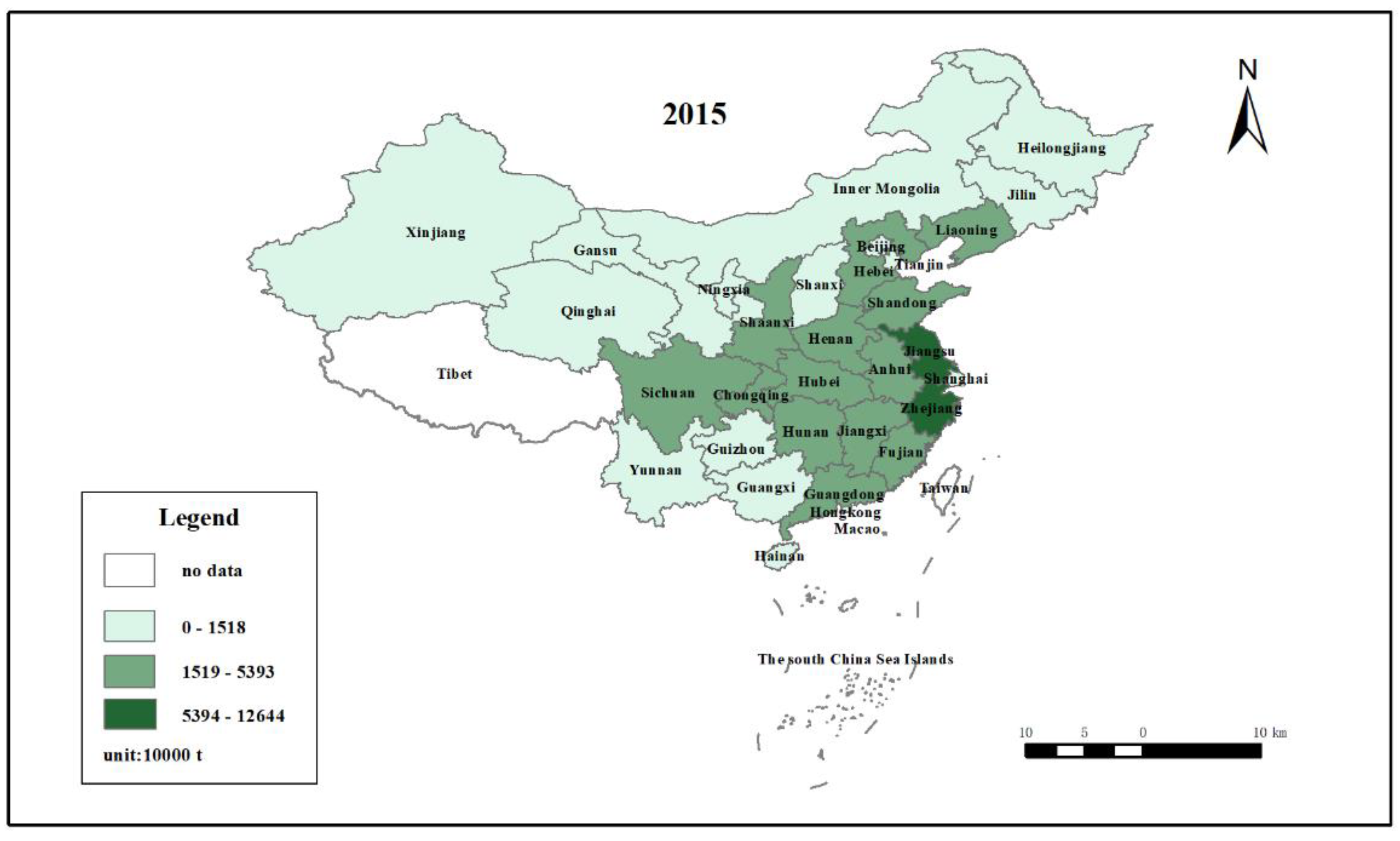

4.1. Spatial Distribution of Carbon Emissions

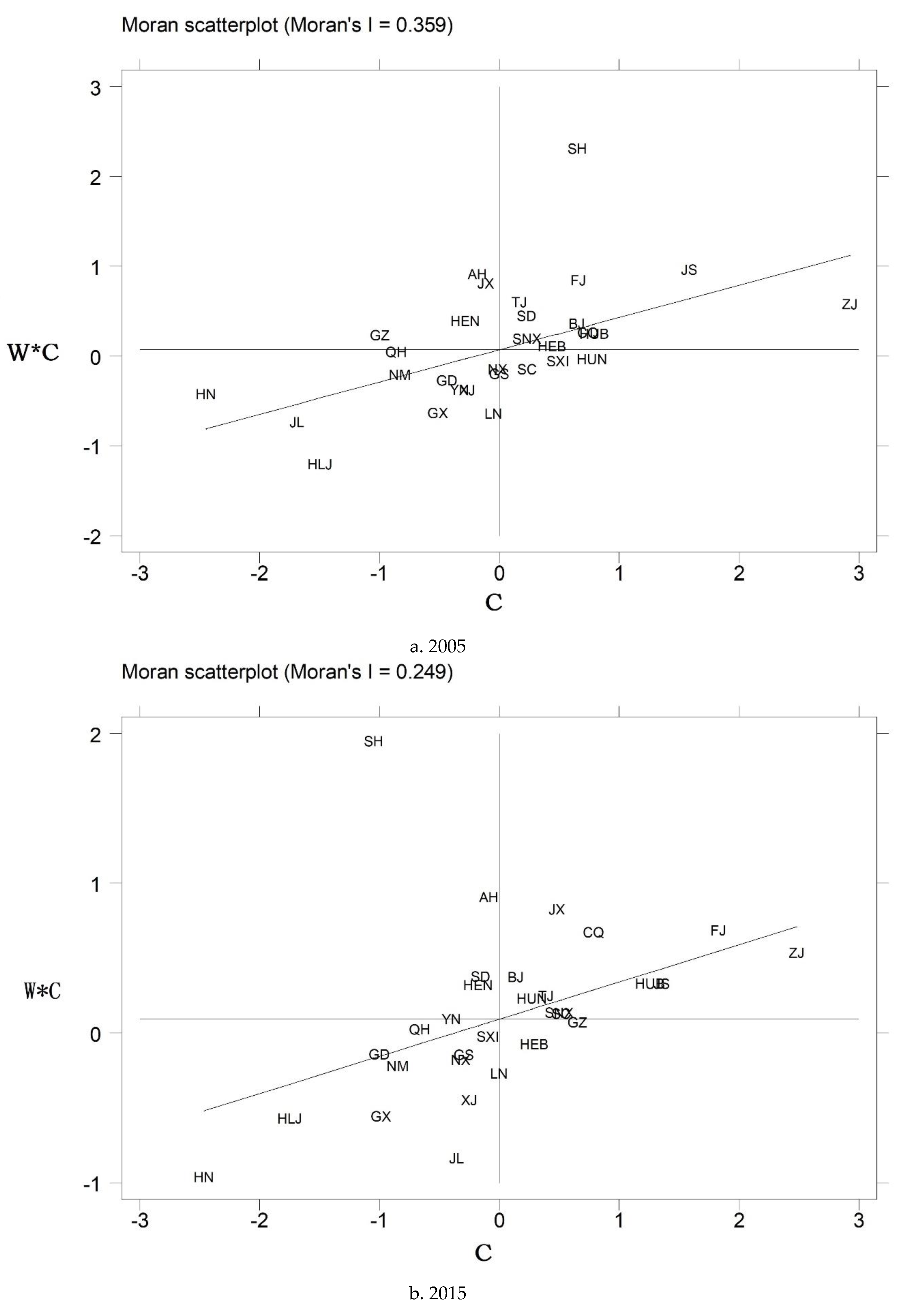

4.2. Spatial Autocorrelation Results

4.3. Choice of Spatial Econometric Models

4.4. Results from the Spatial Econometric Model

5. Discussion

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Shi, Q.; Chen, J.D.; Shen, L.Y. Driving factors of the changes in the carbon emissions in the Chinese construction industry. J. Clean Prod. 2017, 166, 615–627. [Google Scholar] [CrossRef]

- Shen, L.; Song, X.; Wu, Y.; Liao, S.; Zhang, X. Interpretive structural modeling based factor analysis on the implementation of Emission Trading System in the Chinese building sector. J. Clean Prod. 2016, 127, 214–227. [Google Scholar] [CrossRef]

- Liu, G.; Yang, Z.; Chen, B.; Zhang, Y.; Su, M.; Ulgiati, S. Prevention and control policy analysis for energy-related regional pollution management in china. Appl. Energy 2016, 166, 292–300. [Google Scholar] [CrossRef]

- Lee, P.; Wang, M.C.; Chan, E.H.W. An analysis of problems with current indicators for evaluating carbon performance in the construction industry. Procedia Eng. 2016, 164, 425–431. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Novikova, A. Potentials and costs of carbon dioxide mitigation in the world’s buildings. Energy Policy 2008, 36, 642–661. [Google Scholar] [CrossRef]

- Li, D.Z.; Chen, H.X.; Hui, E.M.; Zhang, J.B.; Li, Q.M. A methodology for estimating the life-cycle carbon efficiency of a residential building. Build. Environ. 2013, 59, 48–55. [Google Scholar] [CrossRef]

- Chuai, X.W.; Huang, X.J.; Lu, Q.L. Spatiotemporal changes of built-up land expansion and carbon emissions caused by the Chinese construction industry. Environ. Sci. Technol. 2015, 49, 13021–13030. [Google Scholar] [CrossRef]

- Li, J. Towards a low-carbon future in China’s building sector-a review of energy and climate models forecast. Energy Policy 2008, 36, 1736–1747. [Google Scholar] [CrossRef]

- Hong, J.K.; Shen, Q.P.; Xue, F. A multi-regional structural path analysis of the energy supply china in China’s construction industry. Energy Policy 2016, 92, 56–68. [Google Scholar] [CrossRef]

- Wu, P.; Song, Y.Z.; Zhu, J.B.; Chang, R.D. Analyzing the influence factors of the carbon emissions from China’s building and construction industry from 2000 to 2015. J. Clean Prod. 2019, 221, 552–566. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B. Tracking inter-regional carbon flows: A hybrid network model. Environ. Sci. Technol. 2016, 50, 4731–4741. [Google Scholar] [CrossRef]

- Liu, G.; Hao, Y.; Zhou, Y.; Yang, Z.; Zhang, Y.; Su, M. China’s low-carbon industrial transformation assessment based on logarithmic mean divisia index model. Resour. Conserv. Recycl. 2016, 108, 156–170. [Google Scholar] [CrossRef]

- Yang, Y.; Cai, W.; Wang, C. Industrial CO2 intensity, indigenous innovation and R&D spillovers in China’s provinces. Appl. Energy 2014, 131, 117–127. [Google Scholar]

- Sattary, S.; Thorpe, D. Potential carbon emission reductions in Australian construction systems through bioclimatic principles. Sustain. Cities Soc. 2016, 23, 105–113. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, L. Indirect carbon emissions in household consumption: Evidence from the urban and rural area in China. J. Clean Prod. 2014, 78, 94–103. [Google Scholar] [CrossRef]

- Lin, B.; Liu, H. CO2 mitigation potential in China’s building construction industry: A comparison of energy performance. Build. Environ. 2015, 94, 239–251. [Google Scholar] [CrossRef]

- Lu, Y.J.; Cui, P.; Li, D.Z. Carbon emissions and policies in China’s building and construction industry: Evidence from 1994 to 2012. Build. Environ. 2016, 95, 94–103. [Google Scholar] [CrossRef]

- Du, Q.; Lu, X.R.; Li, Y.; Wu, M.; Bai, L.B.; Yu, M. Carbon emissions in China’s construction industry: Calculations, factors and regions. Int. J. Environ. Res. Public Health 2018, 15, 1220. [Google Scholar] [CrossRef] [Green Version]

- Hoekstra, R.; Van den Bergh, J.C. Comparing structural decomposition analysis and index decomposition analysis. Energy Econ. 2003, 25, 39–64. [Google Scholar] [CrossRef]

- Zeng, L.; Xu, M.; Liang, S.; Zeng, S.Y.; Zhang, T.Z. Revisiting drivers of energy intensity in China during 1997–2007: A structural decomposition analysis. Energy Policy 2014, 67, 640–647. [Google Scholar] [CrossRef]

- Pan, W.; Pan, W.L.; Shi, Y.D.; Liu, S.; He, B.; Hu, C.; Tu, H.T.; Xiong, J.W.; Yu, D.Y. China’s inter-regional carbon emissions: An input–output analysis under considering national economic strategy. J. Clean Prod. 2018, 197, 794–803. [Google Scholar] [CrossRef]

- Luc, A. Spatial effects in econometric practice in environmental and resource economics. Am. J. Agric. Econ. 2001, 83, 705–710. [Google Scholar]

- Li, W.; Sun, W.; Li, G.M. Temporal and spatial heterogeneity of carbon intensity in China’s construction industry. Resour. Conserv. Recycl. 2017, 126, 162–173. [Google Scholar] [CrossRef]

- Marbuah, G.; Amuakwa-Mensah, F. Spatial analysis of emissions in Sweden. Energy Econ. 2017, 68, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.Q.; Wang, Z.Y.; Ye, X.Y. Spatiotemporal dynamics of carbon intensity from energy consumption in China. J. Geogr. Sci. 2014, 24, 631–650. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Yang, J.; Sun, Z.X.; Wu, F. Analyzing the impact factors of energy-related CO2 emissions in China: What can spatial panel regressions tell us? J. Clean Prod. 2017, 161, 1085–1093. [Google Scholar] [CrossRef]

- Han, F.; Xie, R.; Lu, Y.; Fang, J.Y.; Liu, Y. The effects of urban agglomeration economies on carbon emissions: Evidence from Chinese cities. J. Clean Prod. 2018, 172, 1096–1110. [Google Scholar] [CrossRef]

- Elhorst, J.P. Matlab software for spatial panels. Int. Reg. Sci. Rev. 2012, 37, 389–405. [Google Scholar] [CrossRef] [Green Version]

- Li, B. Research on the Technology System and the Calculation Method of Carbon Emission of Low-Carbon Building; Huazhong University of Science and Technology: Wuhan, China, 2012. [Google Scholar]

- Chen, J.D.; Shen, L.Y.; Song, X.N. An empirical study on the CO2 emissions in the Chinese construction industry. J. Clean Prod. 2017, 168, 645–654. [Google Scholar] [CrossRef]

- Qi, S.; Zhang, Y. Research on carbon footprint flow track and low-carbon development strategy in Chinese construction industry. Build. Sci. 2013, 6, 10–16. [Google Scholar]

- World Resources Institute. Global Protocol for Community-Scale Greenhouse Gas Emission Inventories—An Accounting and Reporting Standard for Cities; World Resources Institute: Washington, DC, USA, 2014. [Google Scholar]

- Wang, X. Life Cycle Assessment for Carbon Emission of Residential Building. Master’s Thesis, Tianjin University, Tianjin, China, 2011. (In Chinese). [Google Scholar]

- Chen, W.J.; Nie, Z.R.; Wang, Z.H. Life cycle inventory and characterization of flat glass in China. China Build. Mater. Sci. Technol. 2006, 15, 54–58. (In Chinese) [Google Scholar]

- Dong, S.G.; Li, X.D.; Zhang, Z.H. Life cycle environmental impact assessment of new dry process cement. Environ. Prot. 2008, 10, 39–42. (In Chinese) [Google Scholar]

- Zhong, P. Study of Building Life-Cycle Energy Use and Relevant Environmental Impacts. Master’s Thesis, Sichuan University, Chengdu, China, 2005. (In Chinese). [Google Scholar]

- Wang, B.S. Status quo, problems and suggestions on the recycling of renewable resources in China. Recycl. Resour. Circ. Econ. 2001, 3, 30–36. (In Chinese) [Google Scholar]

- Li, Z.J. Study on the Life Cycle Consumption of Energy and Resource of Air Conditioning in Urban Residential Buildings in China. Ph.D. Thesis, Tsinghua University, Beijing, China, 2007. (In Chinese). [Google Scholar]

- Anselin, L.; Bera, A.K.; Florax, R.; Yoon, M. Simple diagnostic tests for spatial dependence. Reg. Sci. Urban Econ. 1996, 26, 77–104. [Google Scholar] [CrossRef]

- Ord, J.K.; Getis, A. Local spatial autocorrelation statistics: Distributional issues and an application. Geogr. Anal. 1995, 27, 286–306. [Google Scholar] [CrossRef]

- Drukker, D.M.; Peng, H.; Prucha, I.R.; Raciborski, R. Creating and managing spatial-weighting matrices with the spmat command. Stata J. 2013, 13, 242–286. [Google Scholar] [CrossRef] [Green Version]

- Dietz, T.; Rosa, E.A. Rethinking the environmental impacts of population, affluence and technology. Hum. Ecol. Rev. 1994, 2, 277–300. [Google Scholar]

- Zhang, S.C.; Zhao, T. Identifying major influencing factors of CO2 emissions in china: Regional disparities analysis based on STIRPAT model from 1996 to 2015. Atmos. Environ. 2019, 207, 136–147. [Google Scholar] [CrossRef]

- Yang, L.X.; Xia, H.; Zhang, X.L.; Yuan, S.F. What matters for carbon emissions in regional sectors? A China study of extended STIRPAT model. J. Clean Prod. 2018, 180, 595–602. [Google Scholar] [CrossRef]

- Madu, I.A. The impacts of anthropogenic factors on the environment in Nigeria. J. Environ. Manag. 2009, 90, 1422–1426. [Google Scholar] [CrossRef]

- Vélez-Henao, J.-A.; Vivanco, D.F.; Hernández-Riveros, J.-A. Technological change and the rebound effect in the STIRPAT model: A critical view. Energy Policy 2019, 129, 1372–1381. [Google Scholar] [CrossRef]

- Jia, J.; Deng, J.; Zhao, J. Analysis of the major drivers of the ecological footprint using the STIRPAT model and the PLS method-A case study in Henan Province, China. Ecol. Econ. 2009, 68, 2818–2824. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y. Does population have a larger impact on carbon dioxide emissions than income? Evidence from a cross-regional panel analysis in China. Appl. Energy 2016, 180, 800–809. [Google Scholar] [CrossRef]

- Acs, Z.J.; Anseln, L.; Varga, A. Patents and innovation counts as measures of regional production of new knowledge. Res. Policy 2002, 31, 1069–1085. [Google Scholar] [CrossRef]

- Lanjouw, J.O.; Schankerman, M. Patent quality and research productivity: Measuring innovation with multiple indicators. Econ. J. 2004, 495, 441–465. [Google Scholar] [CrossRef]

- Wang, M.; Song, Y.; Liu, J.; Wang, J. Exploring the anthropogenic driving forces of China’s provincial environmental impacts. Int. J. Sustain. Dev. World Ecol. 2012, 19, 442–450. [Google Scholar] [CrossRef]

- Zhao, H.L.; Lin, B.Q. Will agglomeration improve the energy efficiency in China’s textile industry: Evidence and policy implications. Appl. Energy 2019, 237, 326–337. [Google Scholar] [CrossRef]

- LeSage, J.P.; Pace, R.K. Introduction to Spatial Econometrics; CRC: Boca Raton, FL, USA, 2009. [Google Scholar]

- Dong, L.; Liang, H. Spatial analysis on China’s regional air pollutants and CO2 emissions: Emission pattern and regional disparity. Atmos. Environ. 2014, 92, 280–291. [Google Scholar] [CrossRef]

- Du, Q.; Zhou, J.; Pan, T.; Sun, Q.; Wu, M. Relationship of carbon emissions and economic growth in China’s construction industry. J. Clean Prod. 2019, 220, 99–109. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, X.X. Regional carbon dioxide reduction on interaction between industrial agglomeration and technology transaction: On provincial panel data. Financ. Trade Res. 2015, 5, 33–40. (In Chinese) [Google Scholar]

- Micelli, E.; Mangialardo, A. Recycling the City. New Perspective on the Real-estate Market and Construction Industry. In Smart and Sustainable Planning for Cities and Regions. Green Energy and Technology; Bisello, A., Vettorato, D., Stephens, R., Elisei, P., Eds.; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

| Energy | Standard Coal Coefficient | CO2 Emissions Factor |

|---|---|---|

| Raw coal | 0.7143 kg ce/kg | 0.7669 kg CO2/kg ce |

| Other washed Coal | 0.45 kg ce/kg | 0.8079 kg CO2/kg ce |

| Coke | 0.9714 kg ce/kg | 0.8547 kg CO2/kg ce |

| Gasoline | 1.4714 kg ce/kg | 0.5571 kg CO2/kg ce |

| Diesel | 1.4571 kg ce/kg | 0.5913 kg CO2/kg ce |

| Fuel oil | 1.4286 kg ce/kg | 0.6176 kg CO2/kg ce |

| Liquefied petroleum gas | 1.7143 kg ce/kg | 0.5035 kg CO2/kg ce |

| Other oil | 1.20 kg ce/kg | 0.5854 kg CO2/kg ce |

| Natural gas | 1.33 kg ce/m3 | 0.4478 kg CO2/kg ce |

| Heat | 0.034 kg ce/106 J | 0.8948 kg CO2/kg ce |

| Electricity | 0.1229 kg ce/kwh | 0.277 kg CO2/kg ce |

| Building Materials | Steel | Wood | Cement | Glass | Aluminum |

|---|---|---|---|---|---|

| CO2 emissions coefficient | 1.789 kg/kg | −0.8423 t/m3 | 1.277 kg/kg | 0.02728 t/heavy box | 2.6 kg/kg |

| Recovery coefficient | 0.8 | 0.1 | - | 0.13 | 0.85 |

| Variable | Definition | Mean | Std. Dev. | Max | Min |

|---|---|---|---|---|---|

| C | carbon emissions per capita= carbon emissions/population (t/person) | 0.763 | 0.767 | 6.325 | 0.077 |

| POP | population density = urban population/built-up area (104 persons/km2) | 1.698 | 0.407 | 2.779 | 0.804 |

| PGDP | GDP per capita = GDP/total population (104 Yuan/person) | 2.928 | 1.895 | 10.294 | 0.505 |

| PAT | items of patent per unit output value = items of patent applications/construction industry output value (item/108 Yuan) | 0.074 | 0.105 | 0.346 | 0.002 |

| ES | energy structure = fossil energy (coal and oil) consumption of construction industry/total energy consumption of construction industry (%) | 0.751 | 0.147 | 0.999 | 0.116 |

| IS | industrial structure = the output value of building and civil engineering construction industry/total output value of construction industry (%) | 0.580 | 0.131 | 0.876 | 0.187 |

| EI | energy intensity = total energy consumption of construction industry/total output value of construction industry (t/104 Yuan) | 0.076 | 0.055 | 0.437 | 0.007 |

| IA | industry agglomeration (Following Zhao et al. [52], industry agglomeration was calculated as follows: , where refers to the output of industry in region , refers to the total output of region , refers to the output of industry in the nation, refers to the total output of the nation.) | 0.954 | 0.357 | 2.232 | 0.251 |

| Time | W1 | W2 | ||||

|---|---|---|---|---|---|---|

| Moran’s I | Z | p | Moran’s I | Z | p | |

| 2005 | 0.359 | 3.413 | 0.000 | 0.170 | 1.878 | 0.030 |

| 2006 | 0.275 | 2.687 | 0.004 | 0.092 | 1.167 | 0.122 |

| 2007 | 0.300 | 2.918 | 0.002 | 0.061 | 0.885 | 0.188 |

| 2008 | 0.234 | 2.298 | 0.011 | 0.064 | 0.893 | 0.186 |

| 2009 | 0.206 | 2.062 | 0.020 | 0.078 | 1.021 | 0.154 |

| 2010 | 0.183 | 1.804 | 0.036 | −0.025 | 0.085 | 0.466 |

| 2011 | 0.044 | 0.674 | 0.250 | 0.101 | 1.232 | 0.109 |

| 2012 | 0.052 | 0.729 | 0.233 | 0.094 | 1.151 | 0.125 |

| 2013 | 0.022 | 0.464 | 0.321 | 0.057 | 0.801 | 0.212 |

| 2014 | −0.010 | 0.204 | 0.419 | −0.175 | −1.231 | 0.109 |

| 2015 | 0.249 | 2.409 | 0.008 | 0.110 | 1.304 | 0.096 |

| Contents | Statistic Value | Contents | Statistic Value |

|---|---|---|---|

| LM lag | 5.924 *** | Robust-LM lag | 4.837 ** |

| LM error | 24.921 *** | Robust-LM error | 23.835 *** |

| LR-lag | 18.19 *** | LR-error | 20.60 *** |

| Hausman | 38.61 *** | ||

| Variables | Spatial–Temporal Fixed | Spatial Fixed | Temporal Fixed |

|---|---|---|---|

| LnPOP | 0.292 (0.89) | 0.013 (0.04) | 0.309 *** (2.44) |

| lnPGDP | 2.174 *** (6.19) | 1.795 *** (5.23) | 0.241 *** (3.13) |

| lnPAT | −0.065 ** (−2.27) | −0.033 (−1.16) | −0.087 *** (−2.66) |

| lnES | 0.177 * (1.71) | 0.165 * (1.52) | 0.366 *** (3.00) |

| lnIS | 0.402 * (1.58) | 0.689 *** (2.69) | 0.425 *** (4.34) |

| lnEI | −0.082 * (−1.45) | −0.031 (−0.51) | 0.045 (0.93) |

| lnIA | 1.140 *** (7.46) | 1.173 *** (7.06) | 1.030 *** (13.39) |

| W*lnPOP | 2.146 *** (3.28) | 1.720 *** (3.16) | 0.485 * (1.81) |

| W*lnPGDP | 1.331 * (1.80) | −0.633 * (−1.79) | 0.131 (0.82) |

| W*lnPAT | −0.107 * (−1.68) | 0.058 (1.25) | −0.139 * (−1.81) |

| W*lnES | −0.456 ** (−2.21) | −0.601 *** (−2.87) | 0.768 *** (3.47) |

| W*lnIS | −0.854 * (−1.59) | −0.311 (−0.73) | −0.280 (−1.26) |

| W*lnEI | 0.030 (0.23) | 0.298 ** (2.32) | −0.154 * (−1.58) |

| W*lnIA | −0.026 (−0.09) | −0.494 * (−1.67) | 0.181 (1.10) |

| C | 0.066 *** (12.78) | 0.079 *** (12.84) | 0.143 *** (12.71) |

| rho | −0.207 *** (−2.70) | 0.096 * (1.44) | −0.369 *** (−4.44) |

| log-likelihood | −22.647 | −51.7061 | −153.4802 |

| R-sq | 0.5757 | 0.6305 | 0.0006 |

| Variables | Direct Effect | Indirect Effect | Total Effect |

|---|---|---|---|

| lnPOP | 0.207 (0.61) | 1.795 *** (3.14) | 2.003 *** (3.38) |

| lnPGDP | 2.124 *** (6.71) | 0.793 (1.29) | 2.917 *** (4.55) |

| lnPAT | −0.057 ** (−2.07) | −0.079 * (−1.46) | −0.137 *** (−2.40) |

| lnES | 0.198 ** (1.96) | −0.434 *** (−2.51) | −0.235 (−1.20) |

| lnIS | 0.449 * (1.81) | −0.799 * (−1.62) | −0.349 (−0.66) |

| lnEI | −0.081 (−1.41) | 0.031 (0.27) | −0.050 (−0.40) |

| lnIA | 1.150 *** (7.08) | −0.219 (−0.86) | 0.931 *** (3.35) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, N.; Feng, S.; Liu, Z.; Wang, W.; Lu, H.; Wang, M. The Determinants of Carbon Emissions in the Chinese Construction Industry: A Spatial Analysis. Sustainability 2020, 12, 1428. https://doi.org/10.3390/su12041428

Lu N, Feng S, Liu Z, Wang W, Lu H, Wang M. The Determinants of Carbon Emissions in the Chinese Construction Industry: A Spatial Analysis. Sustainability. 2020; 12(4):1428. https://doi.org/10.3390/su12041428

Chicago/Turabian StyleLu, Na, Shuyi Feng, Ziming Liu, Weidong Wang, Hualiang Lu, and Miao Wang. 2020. "The Determinants of Carbon Emissions in the Chinese Construction Industry: A Spatial Analysis" Sustainability 12, no. 4: 1428. https://doi.org/10.3390/su12041428

APA StyleLu, N., Feng, S., Liu, Z., Wang, W., Lu, H., & Wang, M. (2020). The Determinants of Carbon Emissions in the Chinese Construction Industry: A Spatial Analysis. Sustainability, 12(4), 1428. https://doi.org/10.3390/su12041428