Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains

Abstract

1. Introduction

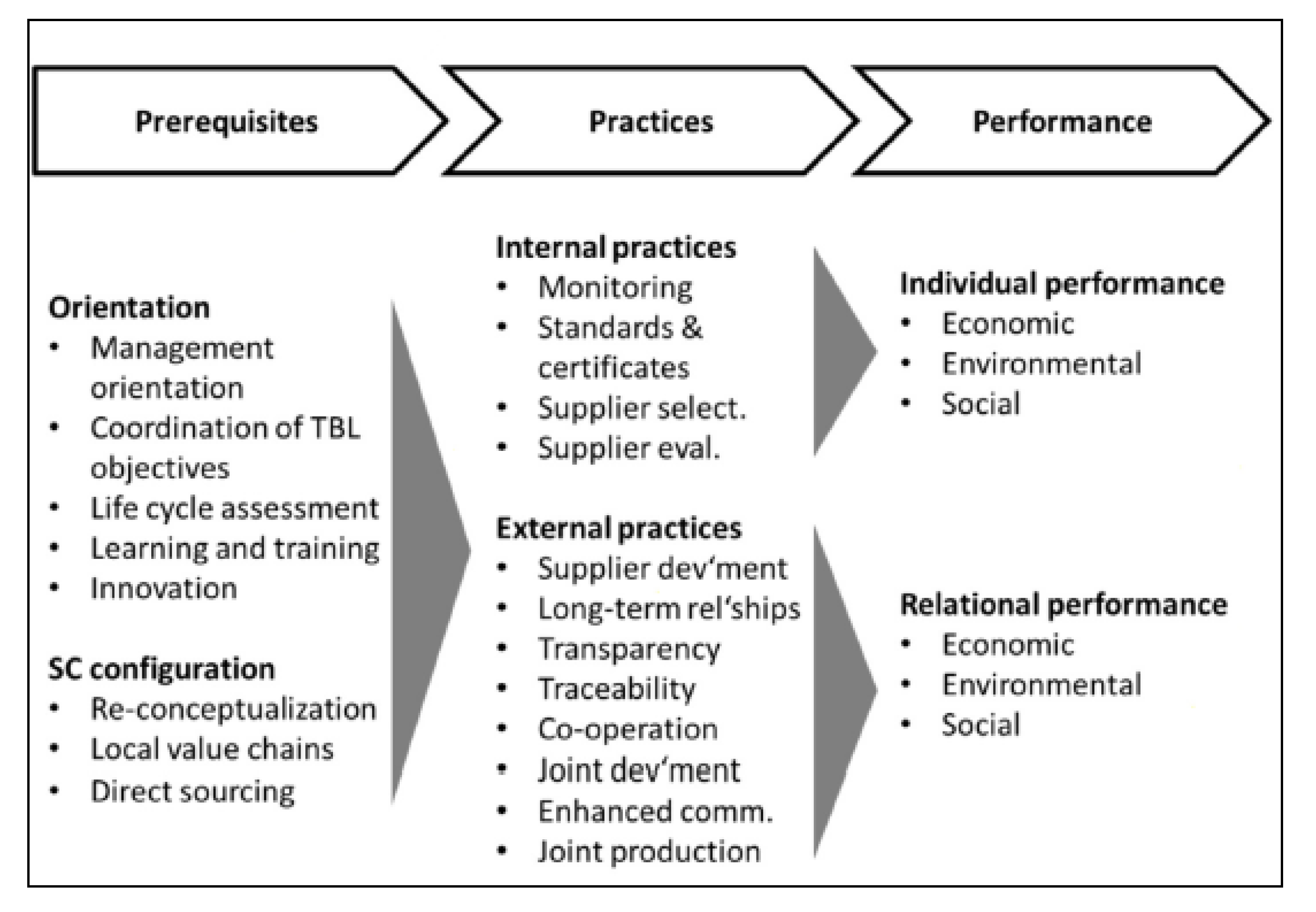

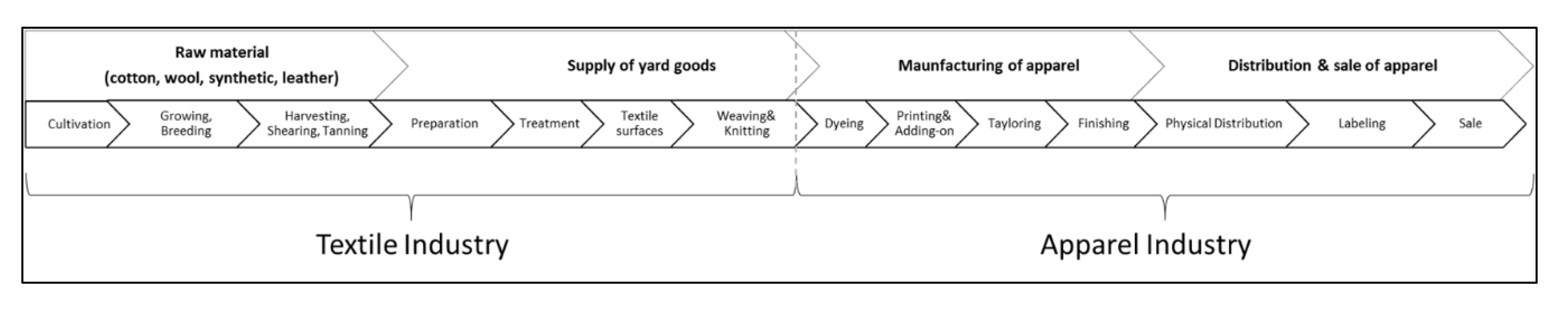

2. Background

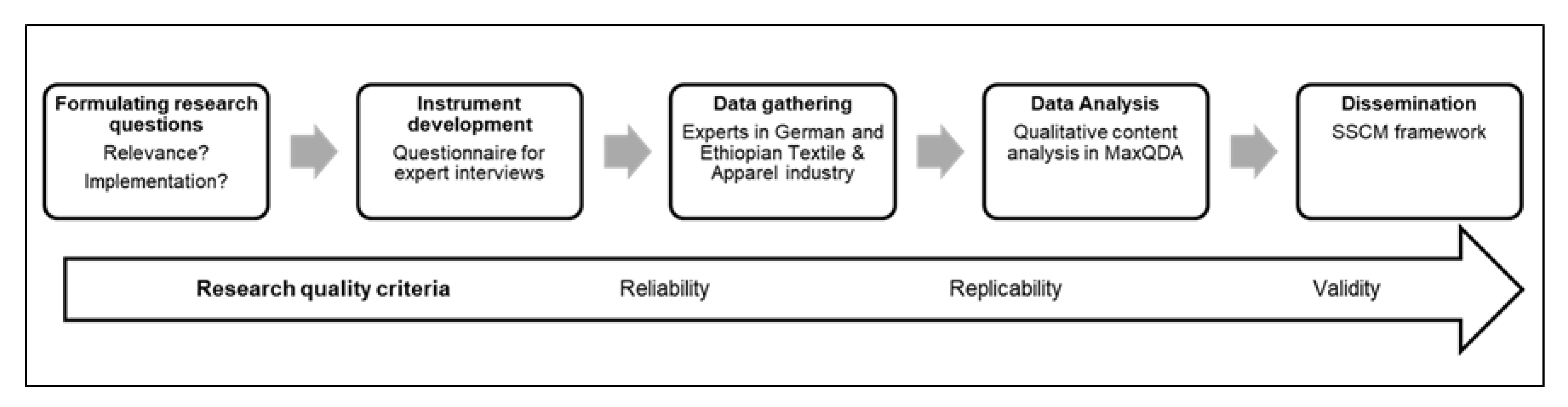

3. Research Method and Scientific Rigor

3.1. Formulating the Research Question

“What prerequisites and practices drive and enable sustainability in T&A SCs?”

3.2. Instrument Development

- (a)

- Managerial orientation toward sustainability;

- (b)

- Depiction of the value chain and its shareholders;

- (c)

- Sustainability rules and regulations within the company;

- (d)

- Procurement/purchasing and product design;

- (e)

- Sustainability standards and certificates;

- (f)

- Cooperation, communication, coordination and supplier relationship in supply networks;

- (g)

- Sustainability practices.

3.3. Data Gathering

3.4. Data Analysis

3.5. Dissemination

3.6. Scientific Rigor

4. Results

4.1. Prerequisites of SC Sustainability in the T&A Industry

“[…] we are the only group […] who publishes this sort of papers each and every year. But there is no pressure from any authorities to publish such report, but we are doing it. Because we know how important these things are to us. So, particularly for Company G this is very important. We do have a certain particular department […] with - I think - more than two hundred persons over there who are only working regarding sustainability.” (G1)

“[…] the consumer holds a ballot card with every sales slip in their hand. […] because I believe one has an incredible market force. With every purchase they declare “that’s what I want “. And for every piece you buy a new one gets manufactured. That’s where the consumer has an incredible power position.” (C1)

“The first criterium for my sustainability strategy is the proximity to my production location. This means short distances are crucial. Then I look at the working conditions of the supplier. We work with an Austrian supplier for example.” (A1)

“[…] suppose something is coming from Egypt, or China it will take up to 21 days to the port in Djibouti. Djibouti is not in Ethiopia.” (F1)

“Yes, some customers, they push too much. Sometimes they also take the commitment to help in the certification process […] directly or indirectly. […] Some of them, they even go to the extent that […] can support on the fee, certification fee or something. There are also some partners like GIZ (Deutsche Gesellschaft für internationale Zusammenarbeit, German organization for global collaboration) who also motivate us, support us to be a worldwide competitor […].” (F1)

“To add something, for our sustainability our workforce, there are training centres here.” (G2)

“[…] so, we have to develop them. And that’s why we feel always like the training is more important. Because we have to train them about their legal rights, safety standards, securities, and at the same time productivity. At the same time, their role in responsibility and how they can add their value in this. How they can add their contributions in the total company. The several trainings are more important.” (G3)

4.2. Internal Sustainability Practices in T&A SCs

“Sometimes we audit ourselves and sometimes the customers send their transparency auditors. […] They do have their own audit team.” (G1)

“Already we are WRAP (Worldwide Responsible Accredited Production certificate in sewn-product sector) certified and BSCI (Business Social Compliance Initiative, system that helps companies to gradually improve working conditions in their supply chain) certified. First of all, WRAP and BSCI we are maintaining and buyer requirements we are maintaining.” (G3)

“And yes, many customers like to see a certificate and think certificates are great but hardly anyone questions the values the certificate represents.” (E1)

I believe it is important to be able to feature certificates, that you can say […] customer can buy it with a clean conscience.” (C1)

“For cotton we have a very strict guideline. If it is a pure cotton product it has to be GOTS (Global Organic Textile Standard) certified, otherwise it won’t be sold in our store. […] we are quite consequent about that.” (C1)

“The certification organisations […] I have previously mentioned, supervise the social and environmental conditions of production.” (B1)

“[…] we do not select suppliers. Sometimes we need to source from outside. That is nominated by the customers.” (G1)

“There are also cases where we deal with what you call nominated suppliers. These are customer nominated suppliers.” (F1)

“At the beginning of the business we just want to know: Have you nominated your own supplier or can we propose you the same thing. […] or other customers have approved it, definitively they have audited the project. They have checked every single inch of the project, then they have approved it. So, we just buy from them.” (G1)

4.3. External Sustainability Practices in T&A SCs

“So, we have to be transparent. It is very important to get their [customers’] confidence and getting their assistance. So, it is very important.” (G4)

“That’s a main requirement because first of all, a buyer’s requirement is transparency.” (G3)

“We pick sustainably produced goods on a daily basis and communicate this through our social media accounts and our newsletter but also on the shop floor daily. We try to get it as close as possible to our customer.” (C1)

“[…] there are customers that strongly, consistently require to barcode all the products. […] to use RFID labels. And […] the transmission from that label could detect which item is where and where it is produced or which item-number it is.” (F1)

“So that most of all us, as entrepreneurs have the overview. Where are our products coming from, how are they produced, and under which circumstances? We do that […] by means of certifications. ”(D1)

“[…] in terms of cost saving. Also, in terms of trust and relationships. You know nowadays business has turned to be […] just transactional; it is about relationships.” (F1)

“This is not something you achieve from one season to the next but it is an opportunity and really depends on long-term relationships, long-term supplier commitment and not just chasing the lowest price.” (A1)

“[…] but we have the trust now and we know some of the producers for more than ten years and we sense, we’re on the same page regarding our mindset and actions.” (B1)

“[…] we are always trying to change with our third buyer or customer perspective. This is our motor [for] sustainability. If we are not running with them […] then, we cannot give them, work with them. We cannot keep them. In fact, the buyers will change us. So, for sustainability we can always care.” (G2)

“My opinion is first of all, dialogue. Sitting together and work together.” (G3)

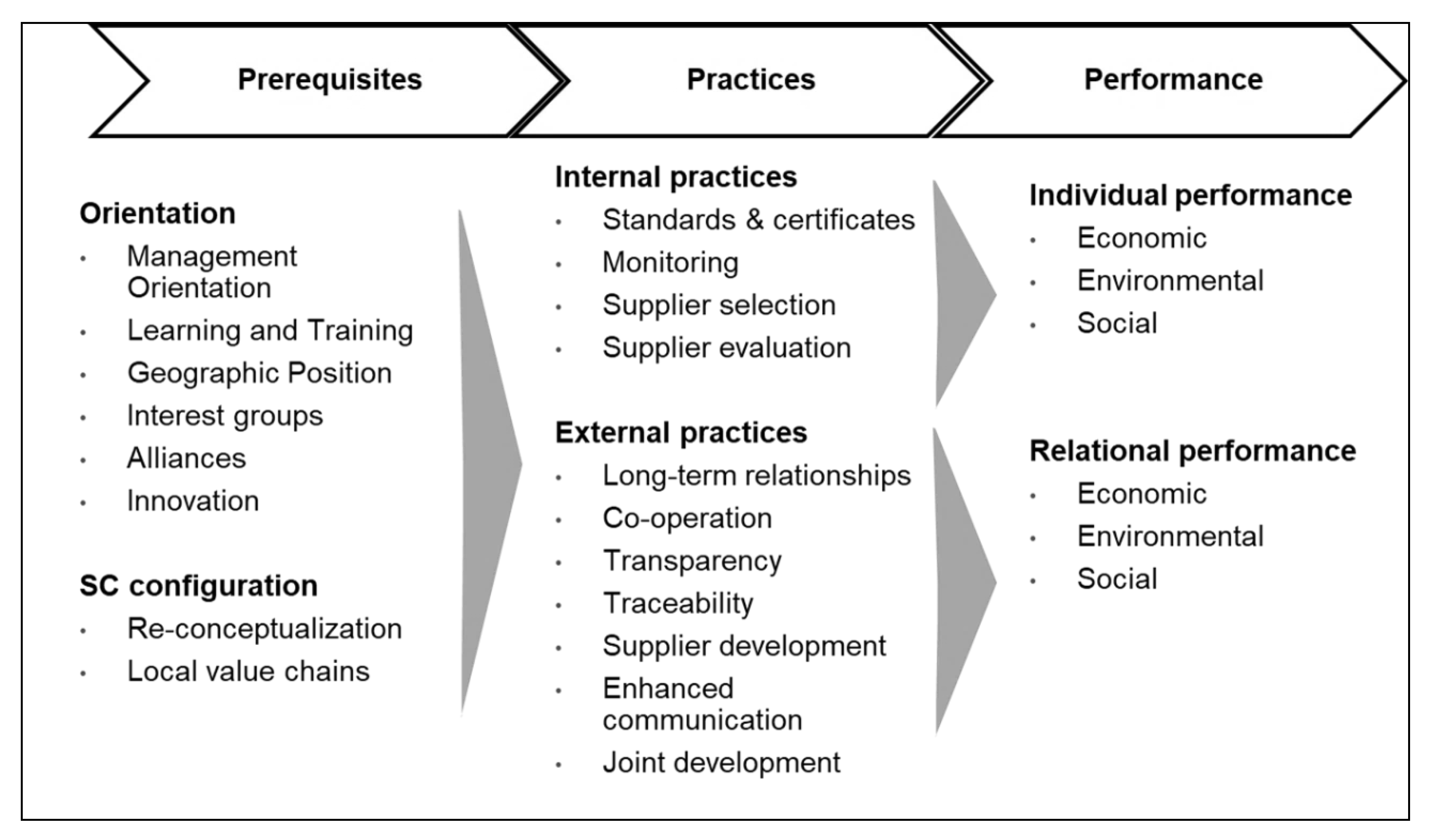

4.4. Framing the Constructs

5. Discussion

5.1. Summarized Findings

5.2. Research Contribution

5.3. Managerial Implications

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Questionnaire

- Name

- Company’s name

- Which position do you hold in your company?

- What are your responsibilities within the company? How does your daily work look like?

- Since when does the company exist?

- What are the primary business activities and objectives?

- Which products are sold?

- Through which channels are those distributed? (online shop, retail, wholesale?)

- How many stores are there in how many countries?

- How would you define sustainability?

- Which importance does sustainability have in relation with the textile industry?

- How important is this topic for your company/in your daily business?

- Is sustainability communicated to the lower management level/operations field? (How?)

- Who is responsible for a sustainable development in your company?

- Who are your customers and who is your target group?

- Who are your partners and your suppliers?

- With how many suppliers do you work together?

- Has there already been a transformation towards sustainability of your supply chains or parts of those? If yes, why?

- How does your competitive environment affect your sustainable practices?

- Which role do interest groups play e.g., customers, investors implementing sustainable practices?

- Do you work together with NGOs, competitors, and/or regulators to achieve sustainability along your supply chains?

- Is your company a member of initiatives or alliances regarding sustainability?

- In which countries are your clothes are produced? How many facilities are involved in the manufacturing process?

- Where are your raw materials from? Which materials are used for your clothes?

- How important is traceability of the products during each step and way of the manufacturing process?

- How does your company control this?

- Are there standards, rules and regulations regarding working conditions and health of workers (child labour, working hours, wages), environment (water, chemicals used, disposal), safety conditions.

- How do you ensure that the facilities and the companies that control these really comply with standards, rules and regulations? Who controls the conditions?

- Are there any approaches to minimize the carbon footprint and the ecological damage of the textile industry from your company?

- Do you work together with logistic providers including sustainable aspects?

- Purchasing/Procurement and product design

- Do you think of sustainability aspects by choosing the material?

- Does longevity play an important role? If yes, what are you doing to create this?

- How important is the material selection regarding product life cycle and the recyclability?

- Are your products marked with seals of approval?

- What kind of sustainability-related standards and certificates are used within your supply chain?

- Are there any standards that are only used within your company?

- Network cooperation, communication, coordination and supplier relationship

- How do you select your suppliers? Do you have specific sustainable-related criteria?

- How do you control that your suppliers comply with your criteria?

- Do you use supplier development and audits regarding sustainability?

- Did you define common goals with your suppliers achieving sustainability?

- To what extent can supplier relationships contribute to a sustainable development?

- Which sustainable-related practices can easily be implemented from other companies within the industry sector and which are company-specific?

- Which material and non-material profit result from implementing sustainable practices in the supply chain?

- What are/were essential success factors and barriers implementing sustainable standards along the supply chain?

- What are the most important prerequisites designing sustainable supply chains?

- Which importance does transparency have regarding the whole supply chain network and how can this be achieved?

- Are there any sustainable-related projects, campaigns or transformations planned? (social, economic, ecological)

References

- Iannone, R.; Martino, G.; Miranda, S.; Riemma, S. Modeling Fashion Retail Supply Chain through Causal Loop Diagram. IFAC-PapersOnLine 2015, 48, 1290–1295. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L.; Towers, N. Lean or Agile: A Solution for Supply Chain Management in the Textiles and Clothing Industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Dicken, P. Global Shift: Mapping the Changing Contours of the World Economy, 7th ed.; The Guilford Press: New York, NY, USA, 2015. [Google Scholar]

- Gold, S.; Awasthi, A. Sustainable Global Supplier Selection Extended Towards Sustainability Risks from (1+n)th Tier Suppliers Using Fuzzy AHP Based Approach. IFAC-PapersOnLine 2015, 43, 111–116. [Google Scholar] [CrossRef]

- Kumar, N.; Agrahari, R.P.; Roy, D. Review of Green Supply Chain Processes. IFAC-PapersOnLine 2015, 48, 374–381. [Google Scholar] [CrossRef]

- Kobza, N.; Schuster, A. Building a Responsible Europe—The Value of Circular Economy. IFAC-PapersOnLine 2016, 49, 111–116. [Google Scholar] [CrossRef]

- Andersen, M.; Skjoett-Larsen, T. Corporate Social Responsibility in Global Supply Chains. Supply Chain Manag. Int. J. 2009, 14, 75–86. [Google Scholar] [CrossRef]

- LoMonaco-Benzing, R.; Ha-Brookshire, J. Sustainability as Social Contract: Textile and Apparel Professionals’ Value Conflicts within the Corporate Moral Responsibility Spectrum. Sustainability 2016, 8, 1278. [Google Scholar] [CrossRef]

- Sauer, C.; Seuring, S. Extending the Reach of Multi-Tier Sustainable Supply Chain Management –Insights from Mineral Supply Chains. Int. J. Prod. Econ. 2018, 217, 31–43. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Yadlapalli, A.; Rahman, S.; Gunasekaran, A. Socially Responsible Governance Mechanisms for Manufacturing Firms in Apparel Supply Chains. Int. J. Prod. Econ. 2018, 196, 135–149. [Google Scholar] [CrossRef]

- Winter, S.; Lasch, R. Environmental and Social Criteria in Supplier Evaluation - Lessons from the Fashion and Apparel Industry. J. Clean. Prod. 2016, 139, 175–190. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone Publishing: Oxford, UK, 1997. [Google Scholar]

- Brandenburg, M.; Gruchmann, T.; Oelze, N. Sustainable Supply Chain Management–A Conceptual Framework and Future Research Perspectives. Sustainability 2019, 11, 7239. [Google Scholar] [CrossRef]

- Brömer, J.; Brandenburg, M.; Gold, S. Transforming Chemical Supply Chains toward Sustainability—A Practice-Based View. J. Clean. Prod. 2019, 236, 117701. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10 Exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

- Suchanek, A. Ökonomische Ethik; Mohr Siebeck: Tübingen, Germany, 2001. [Google Scholar]

- Seuring, S. Integrated Chain Management and Supply Chain Management Comparative Analysis and Illustrative Cases. J. Clean. Prod. 2004, 12, 1059–1071. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An Inter-Sectoral Comparison of Green Supply Chain Management in China: Drivers and Practices. J. Clean. Prod. 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Beske, P.; Seuring, S. Putting Sustainability into Supply Chain Management. Supply Chain Manag. Int. J. 2014, 19, 322–331. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Kot, S.; Haque, A.U.; Kozlovski, E. Strategic SCM’s Mediating Effect on the Sustainable Operations: Multinational Perspective. Organizacija 2019, 52, 219–235. [Google Scholar] [CrossRef]

- Khurana, K.; Ricchetti, M. Two Decades of Sustainable Supply Chain Management in the Fashion Business, an Appraisal. J. Fash. Mark. Manag. 2016, 20, 89–104. [Google Scholar] [CrossRef]

- Muthukumarana, T.T.; Karunathilake, H.P.; Punchihewa, H.K.; Manthilake, M.M.; Hewage, K.N. Life Cycle Environmental Impacts of the Apparel Industry in Sri Lanka: Analysis of the Energy Sources. J. Clean. Prod. 2018, 172, 1346–1357. [Google Scholar] [CrossRef]

- Köksal, D.; Strähle, J.; Müller, M.; Freise, M. Social Sustainable Supply Chain Management in the Textile and Apparel Industry—A Literature Review. Sustainability 2017, 9, 100. [Google Scholar] [CrossRef]

- Oelze, N. Implementierung von Umwelt und Sozialstandards entlang der Wertschöpfungskette: Lernen aus Erfahrungen führender Unternehmen. In CSR und Beschaffung; Fröhlich, E., Ed.; Springer Gabler: Berlin/Heidelberg, Germany, 2015; pp. 37–54. [Google Scholar] [CrossRef]

- Haseeb, M.; Kot, S.; Hussain, H.I.; Mihardjo, L.W.W.; Saluga, P.W. Modelling the Non-Linear Energy Intensity Effect Based on a Quantile-on-Quantile Approach: The Case of Textiles Manufacturing in Asian Countries. Energies 2020, 13, 2229. [Google Scholar] [CrossRef]

- Bottani, E.; Tebaldi, L.; Lazzari, I.; Casella, G. A Model for Assessing Economic and Environmental Sustainability Dimensions of a Fashion Supply Chain and a Case Study. IFAC-PapersOnLine 2019, 52, 261–366. [Google Scholar] [CrossRef]

- Fletcher, K.; Grose, L. Fashion and Sustainability: Design for Change; Laurence King Publishing: London, UK, 2012. [Google Scholar]

- Warasthe, R.; Brandenburg, M. Sourcing Organic Cotton from African Countries-Potentials and Risks for the Apparel Industry Supply Chain. IFAC-PapersOnLine 2018, 51, 297–301. [Google Scholar] [CrossRef]

- Paul, D. Die Textil- und Bekleidungsindustrie der EU: Strukturen, Strategien, Perspektiven; Igel Verlag: Hamburg, Germany, 2008. [Google Scholar]

- Freise, M.; Seuring, S. Social and Environmental Risk Management in Supply Chains. Logist. Res. 2015, 8, 2. [Google Scholar] [CrossRef]

- Nash International, BV. Business Opportunity Report Ethiopia- Textile & Apparel Industry; Nash International BV: Rotterdam, The Netherlands, 2019; Available online: https://www.academia.edu/29355486/BUSINESS_OPPORTUNITY_REPORT_ETHIOPIA_TEXTILE_and_APPAREL_INDUSTRY (accessed on 20 September 2020).

- American Bar Association Rule of Law Initiative. Case Study: Ethiopian Textile Industry; American Bar Association Rule of Law Initiative, 2017. Available online: https://www.verite.org/wp-content/uploads/2017/12/ABA-ROLI-Case-Study-Ethiopia-Aug-2017.pdf (accessed on 3 September 2020).

- Khurana, K. An Overview of Textile and Apparel Business Advances in Ethiopia. Res. J. Text. Appar. 2018, 22, 212–223. [Google Scholar] [CrossRef]

- Mukendi, A.; Davies, I.; Glozer, S.; McDonagh, P. Sustainable Fashion: Current and Future Research Directions. Eur. J. Mark. 2020. [Google Scholar] [CrossRef]

- Kunz, J.; May, S.; Schmidt, H.J. Sustainable Luxury: Current Status and Perspectives for Future Research. Bus. Res. 2020, 13, 541–601. [Google Scholar] [CrossRef]

- Yang, S.; Song, Y.; Tong, S. Sustainable Retailing in the Fashion Industry: A Systematic Literature Review. Sustainability 2017, 9, 1266. [Google Scholar] [CrossRef]

- Garcia-Torres, S.; Albareda, L.; Rey-Garcia, M.; Seuring, S. Traceability for Sustainability–Literature Review and Conceptual Framework. Supply Chain Manag. Int. J. 2019, 24, 85–106. [Google Scholar] [CrossRef]

- Sirilertsuwan, P.; Ekwall, D.; Hjelmgren, D. Proximity Manufacturing for Enhancing Clothing Supply Chain Sustainability. Int. J. Logist. Manag. 2018, 29, 1346–1378. [Google Scholar] [CrossRef]

- Karaosman, H.; Morales-Alonso, G.; Brun, A. From a Systematic Literature Review to a Classification Framework: Sustainability Integration in Fashion Operations. Sustainability 2017, 9, 30. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. Circular Economy in Textile and Apparel Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Stuart, I.; McCutcheon, D.; Handfield, R.; McLachlin, R. Effective Case Research in Operations Management: A Process Perspective. J. Oper. Manag. 2002, 20, 419–433. [Google Scholar] [CrossRef]

- Bryman, A.; Bell, E. Business Research Methods, 5th ed.; Oxford University Press: New York, NY, USA, 2019. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage Publishing: Los Angeles, CA, USA, 2018. [Google Scholar]

- Kuckartz, U.; Dresing, T.; Rädiker, S.; Stefer, C. Qualitative Evaluation: Der Einstieg in die Praxis, 1st ed.; VS Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2007. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Content Analysis: Theoretical Foundation, Basic Procedures and Software Solution; Beltz: Klagenfurt, Austria, 2014. [Google Scholar]

- Seuring, S.; Müller, M.; Westhaus, M.; Morana, R. Conducting a Literature Review—The Example of Sustainability in Supply Chains. In Research Methodologies in Supply Chain Management; Kotzab, H., Seuring, S., Müller, M., Reiner, G., Eds.; Physica-Verlag: Heidelberg, Germany, 2005; pp. 91–106. [Google Scholar] [CrossRef]

- Oelze, N.; Gruchmann, T.; Brandenburg, M. Motivating Factors for Implementing Apparel Certification Schemes—A Sustainable Supply Chain Management Perspective. Sustainability 2020, 12, 4823. [Google Scholar] [CrossRef]

- Berg, A.; Hedrich, S. East Africa: The Next Hub for Apparel Sourcing; McKinsey and Company—Retail Practice: Frankfurt, Germany, 2015; Available online: https://www.mckinsey.com/industries/retail/our-insights/east-africa-the-next-hub-for-apparel-sourcing (accessed on 23 September 2020).

- Oelze, N. Sustainable Supply Chain Management Implementation–Enablers and Barriers in the Textile Industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef]

- Raut, R.; Gardas, B.B.; Narkhede, B. Ranking the Barriers of Sustainable Textile and Apparel Supply Chains. Benchmarking Int. J. 2019, 26, 371–394. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Umme, N.J.; Nuruzzaman, M. Strategies for Mitigating Supply-Side Barriers in the Apparel Supply Chain: A Study on the Apparel Industry of Bangladesh. Glob. J. Flex. Syst. Manag. 2018, 19, 41–52. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Barriers to Environmentally-Friendly Clothing Production among Chinese Apparel Companies. Asian Bus. Manag. 2011, 10, 425–452. [Google Scholar] [CrossRef]

- Rundassa, M.W.; Azene, D.K.; Berhan, E. Comparative Advantage of Ethiopian Textile and Apparel Industry. Res. J. Text. Appar. 2019, 23, 244–256. [Google Scholar] [CrossRef]

- Wakeford, J.J.; Gebreeyesus, M.; Ginbo, T.; Yimer, K.; Manzambi, O.; Okereke, C.; Black, M.; Mulugetta, Y. Innovation for Green Industrialisation: An Empirical Assessment of Innovation in Ethiopia’s Cement, Leather and Textile Sectors. J. Clean. Prod. 2017, 166, 503–511. [Google Scholar] [CrossRef]

- Georgise, F.B.; Thoben, K.-D.; Seifert, M. Application of the Adapted SCOR Model to the Leather Industry: An Ethiopian Case Study. In Dynamics in Logistics, Lecture Notes in Logistics; Kotzab, H., Pannek, J., Thoben, K.-D., Eds.; Springer: Heidelberg, Germany, 2016; pp. 441–451. [Google Scholar] [CrossRef]

- Prasad, S.; Jaffe, J.; Bhattacharyya, K.; Tata, J.; Marshall, D. Value Supply Chains at the Base of the Pyramid: Studies of Past and Present Textile Networks. J. Humanit. Logist. Supply Chain Manag. 2017, 7, 304–323. [Google Scholar] [CrossRef]

| Interview No. | Interviewee | Position | Company | Position | Country |

|---|---|---|---|---|---|

| 1 | A.1 | Founder and owner | A | Fair fashion brand | Germany |

| 2 | B.1 | Marketing manager | B | Fair organic fashion brand | |

| 3 | C.1 | Co-owner | C | Fair organic fashion brand | |

| 4 | D.1 | Managing director | D | Sustainable work clothing brand | |

| 5 | E.1 | Founder and owner | E | Fair fashion brand | |

| 6 | F.1 | General manager (GM) | F | T&A manufacturer | Ethiopia |

| 7 | G.1 | Assistant GM—Merchandising | G | Apparel manufacturer | |

| 8 | G.2 | Assistant GM—Plant logistics | |||

| 9 | G.3 | Assistant GM—Compliance Mgr | |||

| 10 | G.4 | Assistant GM—Head of Human Resource Management (HR) |

| Analytic Category | GER Retailers | ETH Manufacturers | Total |

|---|---|---|---|

| Management orientation | 29 (28%) | 75 (38%) | 104 (34%) |

| Interest groups | 20 (19%) | 50 (25%) | 70 (23%) |

| Geographical position | 16 (15%) | 26 (13%) | 42 (14%) |

| Alliances | 16 (15%) | 22 (11%) | 38 (13%) |

| Learning and training | 5 (5%) | 18 (9%) | 23 (8%) |

| Re-conceptualization | 11 (11%) | 2 (1%) | 13 (4%) |

| Local value chains | 6 (6%) | 3 (2%) | 9 (3%) |

| Innovation | 1 (1%) | 4 (2%) | 5 (2%) |

| Total | 104 (100%) | 200 (100%) | 304 (100%) |

| n = Interviews | 5 | 5 | 10 |

| Analytic Category | GER Retailers | ETH Manufacturers | Total |

|---|---|---|---|

| Standards and Certifications | 20 (56%) | 18 (42%) | 38 (48%) |

| Monitoring | 5 (14%) | 14 (33%) | 19 (24%) |

| Supplier Selection | 7 (19%) | 6 (14%)) | 13 (16%) |

| Supplier Evaluation | 4 (11%) | 5 (11%) | 9 (12%) |

| Total | 36 (100%) | 43 (100%) | 79 (100%) |

| n = Interviews | 5 | 5 | 10 |

| Analytic Category | GER Retailers | ETH Manufacturers | Total |

|---|---|---|---|

| Transparency | 10 (23%) | 5 (22%) | 15 (23%) |

| Traceability | 6 (14%) | 6 (26%) | 12 (18%) |

| Long-term rel’ships | 9 (21%) | 3 (13%) | 12 (18%) |

| Supplier dev’ment | 11 (26%) | 0 (0%) | 11 (17%) |

| Co-operation | 1 (2%) | 5 (22%) | 6 (9%) |

| Enhanced communic. | 3 (7%) | 3 (13%) | 6 (9%) |

| Joint development | 3 (7%) | 1 (4%) | 4 (6%) |

| Total | 43 (100%) | 23 (100%) | 66 (100%) |

| n = Interviews | 5 | 5 | 10 |

| Sector | Prerequisites | Practices |

|---|---|---|

| T&A only |

| n/a |

| Both sectors |

|

|

| Chemicals only |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warasthe, R.; Schulz, F.; Enneking, R.; Brandenburg, M. Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains. Sustainability 2020, 12, 9960. https://doi.org/10.3390/su12239960

Warasthe R, Schulz F, Enneking R, Brandenburg M. Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains. Sustainability. 2020; 12(23):9960. https://doi.org/10.3390/su12239960

Chicago/Turabian StyleWarasthe, Ronak, Finja Schulz, Ralf Enneking, and Marcus Brandenburg. 2020. "Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains" Sustainability 12, no. 23: 9960. https://doi.org/10.3390/su12239960

APA StyleWarasthe, R., Schulz, F., Enneking, R., & Brandenburg, M. (2020). Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains. Sustainability, 12(23), 9960. https://doi.org/10.3390/su12239960