Research on Teaching a Welding Implementation Course Assisted by Sustainable Virtual Reality Technology

Abstract

1. Introduction

2. Literature Review

2.1. Development and Application of Welding Technology

2.2. Electric Welding Technology Training

2.3. VR Technology Development

2.3.1. Interactivity

2.3.2. Integration

2.3.3. Imagination

2.4. Application of VR in Engineering Education

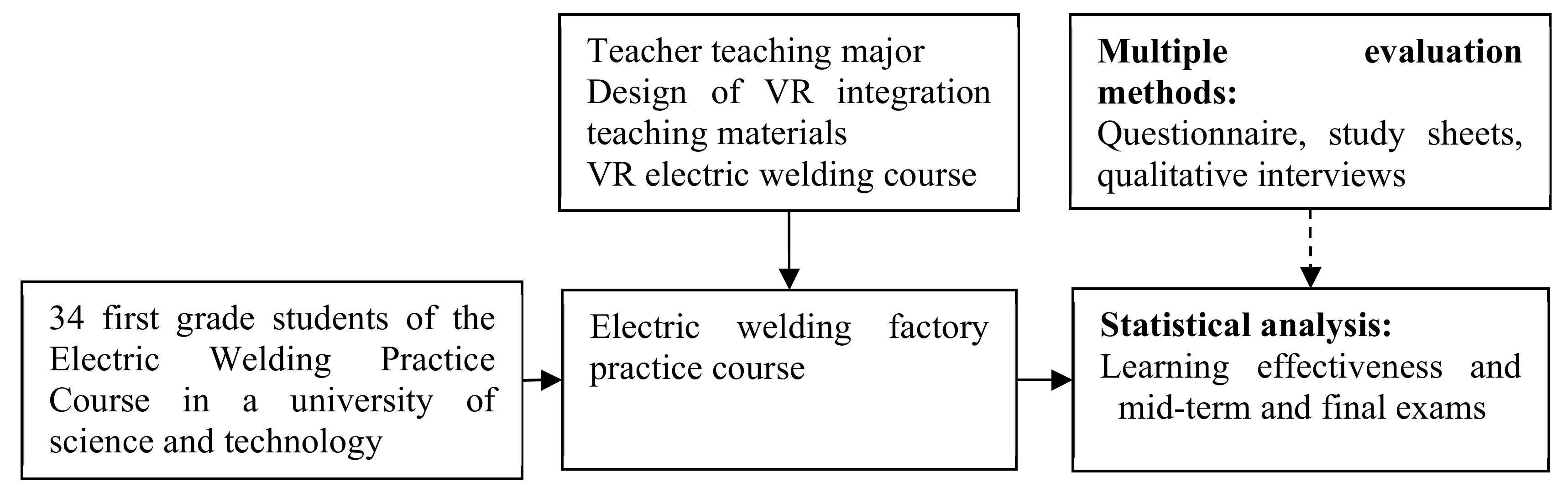

3. Research Design

3.1. Research Structure

3.2. Research Method

3.3. Research Subjects

3.4. Research Tools

3.5. Validity and Reliability

3.6. Research Limitations

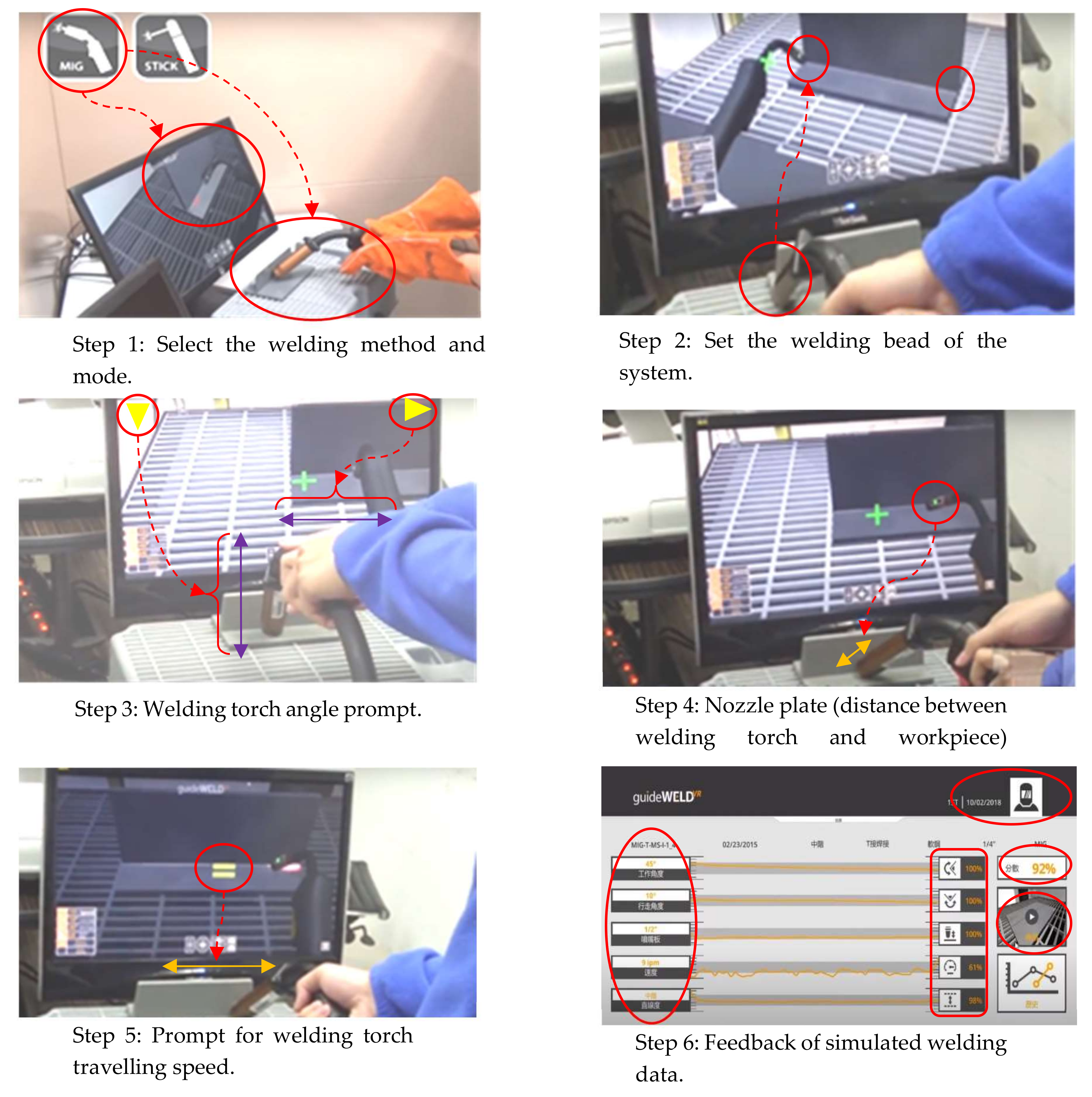

3.7. Curriculum Design and Teaching

4. Results and Analysis

4.1. Analysis of Student Welding Practice Tests

4.2. Analysis of Students’ Learning Effect of VR Welding Course

4.3. Analysis of Feedback from Students Learning VR Welding Course

4.3.1. Implement Virtual Reality Safety Advocacy for Welding Field and Practical Courses

S0203: “In the first class of the electric welding course, the teacher talked a lot about electric welding related equipment knowledge, electric welding operation safety regulations, and related protective measures.”

4.3.2. Provide Practice and Guidance for Diversified Virtual and Reality Integrated Welding Practice

S0301: “This was the first time for me to do actual welding. Although there was a teaching assistant demonstration, I was afraid of welding by myself. The welding bead was crooked and the welding rod was often stuck, such as in Figure 8. Fortunately, there is VR welding equipment for us to practice first.”

S0602: “VR welding equipment allows us to experience electric welding operations and become familiar with the welding steps and postures. The most important thing is to repeat the practice without fear of injury, let alone damage the equipment.”

4.3.3. Apply VR-Assisted Teaching to Strengthen Students’ Proficiency and Application Ability of Welding Skills

S0503: “In addition to flat welding and horizontal welding, the VR welding equipment can also set the thickness of the plate, so that we can practice a variety of welding modes. This ‘practice makes perfect’ affects the actual welding, and good works can be produced, as shown in Figure 10.”

S0104: “In addition to the practice mode, the VR welding equipment also has a test mode, which can test the stability of our welding, the walking speed of the electrode, and the welding angle, and let us repeat the exercise.”

4.3.4. Demonstrate Students’ Problem-Solving Ability and Creation Results of the Actual Application of Welding Skills

S0202: Our final project was to design a multi-functional iron frame, which can hold our weekly welding works. The design drawing should be designed according to the size of the plate to facilitate storage and reduce weight.

S0403: Although we have learned the skills of electric welding, it is still difficult to actually make the product, because we need to design the product by ourselves, prepare the materials according to the size, and integrate the various welding modes we have learned. Fortunately, the students worked together with labor division, and we actually completed the product.

5. Comprehensive Discussion

6. Conclusions and Suggestions

6.1. Conclusions

6.1.1. The Final Test Scores of Most Students in Welding Practice Were Significantly Higher Than the Mid-Term Test Scores

6.1.2. Most Students Positively Affirmed the Effectiveness of VR-Assisted Welding Course Teaching

6.1.3. Most Students Showed Significant Positive Affirmation of Their Learning Satisfaction with VR-Assisted Welding Course Teaching

6.1.4. VR Welding Course with Four Key Implementation Points

6.2. Suggestions

6.2.1. Take the VR Welding Course, as Summarized and Developed in This Study, as an Important Reference for Welding Course Planning

6.2.2. Cultivate Teachers’ VR Knowledge and Skills to Assist in Practical Teaching

6.2.3. Have Discussions on Experimental Teaching of Related Research Topics

Author Contributions

Funding

Conflicts of Interest

References

- Information Technology & Services. Virtual Reality Industry Development White Paper. 2019. Available online: https://www.ponews.net/tech/yfgwzejqpl.html (accessed on 25 May 2020).

- Bellini, H.; Chen, W.; Sugiyama, M.; Shin, M.; Alam, S.; Takayama, D. Virtual & augmented reality: Understanding the race for the next computing platform. Profiles Innov. 2016, 1, 1–30. [Google Scholar]

- Howard, S.; Serpanchy, K.; Lewin, K. Virtual reality content for higher education curriculum. In Proceedings of the 19th Biennial Conference and Exhibition, VALA Libraries, Melbourne, Australia, 13–15 February 2018; pp. 1–15. [Google Scholar]

- Bucea-Manea-Țoniş, R.; Bucea-Manea-Țoniş, R.; Simion, V.E.; Ilic, D.; Braicu, C.; Manea, N. Sustainability in Higher Education: The Relationship between Work-Life Balance and XR E-Learning Facilities. Sustainability 2020, 12, 5872. [Google Scholar] [CrossRef]

- Cheng, K.-H.; Tsai, C.-C. Affordances of augmented reality in science learning: Suggestions for future research. J. Sci. Educ. Technol. 2013, 22, 449–462. [Google Scholar] [CrossRef]

- Fan, L.; Ma, J. Review on hotspots of virtual reality in 2019. Sci. Technol. Rev. 2020, 38, 158–169. [Google Scholar]

- Abulrub, A.-H.G.; Attridge, A.N.; Williams, M.A. Virtual reality in engineering education: The future of creative learning. In Proceedings of the 2011 IEEE Global Engineering Education Conference (EDUCON), Amman, Jordan, 4–6 April 2011. [Google Scholar]

- Kriz, Z.; Prochaska, R.; Morrow, C.A.; Vasquez, C.; Wu, H. Unreal III based 3-D virtual models for training at nuclear power plants. In Proceedings of the 2010 1st International Nuclear & Renewable Energy Conference (INREC), Amman, Jordan, 21–24 March 2010. [Google Scholar]

- Li, X.; Yi, W.; Chi, H.L.; Wang, X.; Chan, A.P. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Zhao, D.; Lucas, J. Virtual reality simulation for construction safety promotion. Int. J. Inj. Control. Saf. Promot. 2015, 22, 57–67. [Google Scholar] [CrossRef]

- Lave, J.; Wenger, E. Situated Learning: Legitimate Peripheral Participation; Cambridge University Press: Cambridge, UK, 1991. [Google Scholar]

- Meng, X. Formal analysis and application of the new mode of “VR+ Education”. ITM Web. Conf. 2019, 26, 01014. [Google Scholar] [CrossRef]

- Ministry of Labor. 2019 Labor Statistics Report. 2020. Available online: https://reurl.cc/q8bzb3 (accessed on 20 June 2020).

- Chen, T.-S. Talking about welding safety and health. Ind. Saf. Health Mon. 1995, 11, 44–49. [Google Scholar]

- Hopkins, L.E.; Laing, E.A.; Peake, J.L.; Uyeminami, D.; Mack, S.M.; Li, X.; Smiley-Jewell, S.; Pinkerton, K.E. Repeated Iron–Soot Exposure and Nose-to-brain Transport of Inhaled Ultrafine Particles. Toxicol. Pathol. 2018, 46, 75–84. [Google Scholar] [CrossRef]

- Skill Evaluation Center of Workforce Development Agency. Skill Evaluation 2011–2019 Number of Applicants, Qualified, and Qualification Rate of Applicants. 2020. Available online: https://www.wdasec.gov.tw/News_Content.aspx?n=23A105FE84353704&sms=CA0630966F34DA45&s=20430C8A27225B18. (accessed on 20 June 2020).

- Wells, T.; Miller, G. The Effect of Virtual Reality Technology on Welding Skill Performance. J. Agric. Educ. 2020, 61, 152–171. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Cheng, S. Application of welding simulator trainer in aluminum welder training. Electr. Weld. Mach. 2016, 46, 127–130. [Google Scholar]

- Le, Q.T.; Pedro, A.; Park, C.-S. A Social Virtual Reality Based Construction Safety Education System for Experiential Learning. J. Intell. Robot. Syst. 2015, 79, 487–506. [Google Scholar] [CrossRef]

- Chen, Y.Z. Welding; New Wun Ching Developmental Publishing: Taipei, Taiwan, 2005. [Google Scholar]

- Common Wealth Magazine. The rise of offshore wind power-to create a new level of energy in Taiwan. Common Wealth Mag. 2019, 673, 10. [Google Scholar]

- David, D.; Monroe, R.; Thomas, E. Exploring the Need to Include Cast Carbon Steels in Welding Procedure Specifications; AMER WELDING SOC 550 NW LEJEUNE RD: Miami, FL, USA, 2015. [Google Scholar]

- Antonini, J.M.; Santamaria, A.B.; Jenkins, N.T.; Albini, E.; Lucchini, R. Fate of manganese associated with the inhalation of welding fumes: Potential neurological effects. Neurotoxicology 2006, 27, 304–310. [Google Scholar] [CrossRef]

- Meo, S.A.; Al-Khlaiwi, T. Health hazards of welding fumes. Saudi Med. J. 2003, 24, 1176–1182. [Google Scholar]

- Torres-Treviño, L.M.; Reyes-Valdes, F.A.; López, V.; Praga-Alejo, R. Multi-objective optimization of a welding process by the estimation of the Pareto optimal set. Expert Syst. Appl. 2011, 38, 8045–8053. [Google Scholar] [CrossRef]

- Psotka, J. Immersive training systems: Virtual reality and education and training. Instr. Sci. 1995, 23, 405–431. [Google Scholar] [CrossRef]

- Mazuryk, T.; Gervautz, M. Virtual Reality-History, Applications, Technology and Future; Vienna University of Technology: Vienna, Austria, 1996. [Google Scholar]

- Burdea, G.C.; Coiffet, P. Virtual Reality Technology; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Monahan, T.; McArdle, G.; Bertolotto, M. Virtual reality for collaborative e-learning. Compt. Educ. 2008, 50, 1339–1353. [Google Scholar] [CrossRef]

- Temkin, B.; Acosta, E.; Hatfield, P.; Onal, E.; Tong, A. Web-based Three-dimensional Virtual Body Structures: W3D-VBS. J. Am. Med. Inform. Assoc. 2002, 9, 425–436. [Google Scholar] [CrossRef]

- Chou, H.J.; Lin, H.C. Applying Virtual Reality Application with 6E Instructional Model in Living Technology at High School: A Case Study of Construction Design. J. Technol. Hum. Res. Educ. 2018, 4, 67–89. [Google Scholar]

- Ting, L. Application of virtual reality technology to sports. In Proceedings of the 2015 AASRI International Conference on Circuits and Systems (CAS 2015), Paris, France, 9–10 August 2015. [Google Scholar]

- Mousas, C.; Anastasiou, D.; Spantidi, O. The effects of appearance and motion of virtual characters on emotional reactivity. Comput. Hum. Behav. 2018, 86, 99–108. [Google Scholar] [CrossRef]

- Wei, W.; Dongsheng, L.; Chun, L. Fixed-wing aircraft interactive flight simulation and training system based on XNA. In Proceedings of the 2013 International Conference on Virtual Reality and Visualization, Xi’an, China, 14–15 September 2013; pp. 191–198. [Google Scholar] [CrossRef]

- Gil-Quintana, J.; Osuna-Acedo, S. Citizenship Training through sMOOCs: A Participative and Intercreative Learning. Sustainability 2020, 12, 8301. [Google Scholar] [CrossRef]

- Chen, Y.S. Integration of augmented reality into multimedia teaching materials: A study of an interactive ebook for visual arts education. Res. Educ. Commun. Technol. 2020, 122, 57–70. [Google Scholar] [CrossRef]

- Freina, L.; Ott, M. A literature review on immersive virtual reality in education: State of the art and perspectives. In Proceedings of the International Scientific Conference eLearning and Software for Education, Bucharest, Romania, 23–24 April 2015. [Google Scholar]

- Ausburn, L.J.; Ausburn, F.B. Desktop virtual reality: A powerful new technology for teaching and research in industrial teacher education. J. Ind. Teach. Educ. 2004, 41, 1–16. [Google Scholar]

- Price, A.H.; Kuttolamadom, M.; Obeidat, S. Using virtual reality welding to improve manufacturing process education. In Proceedings of the 2019 Conference for Industry and Education Collaboration, American Society for Engineering Education, New Orleans, LA, USA, 30 Janaury–1 February 2019. [Google Scholar]

- Sampaio, A.Z.; Martins, O.P. The application of virtual reality technology in the construction of bridge: The cantilever and incremental launching methods. Autom. Const. 2014, 37, 58–67. [Google Scholar] [CrossRef]

- Wang, S.B. Command ships driving simulation system based on virtual reality technology teaching model research. App. Mech. Mater. 2013, 373, 1231–1236. [Google Scholar] [CrossRef]

- Häfner, P.; Häfner, V.; Ovtcharova, J. Teaching methodology for virtual reality practical course in engineering education. Proced. Comput. Sci. 2013, 25, 251–260. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Duh, H.B.-L.; Li, N.; Lin, T.-J.; Tsai, C.-C. An Investigation of University Students’ Collaborative Inquiry Learning Behaviors in an Augmented Reality Simulation and a Traditional Simulation. J. Sci. Educ. Technol. 2014, 23, 682–691. [Google Scholar] [CrossRef]

- Di Serio, A.; Ibáñez, M.B.; Kloos, C.D. Impact of an augmented reality system on students’ motivation for a visual art course. Comput. Educ. 2013, 68, 586–596. [Google Scholar] [CrossRef]

- Chiang, T.H.; Yang, S.J.; Hwang, G.-J. Students’ online interactive patterns in augmented reality-based inquiry activities. Comput. Educ. 2014, 78, 97–108. [Google Scholar] [CrossRef]

- Yilmaz, R.M. Educational magic toys developed with augmented reality technology for early childhood education. Comput. Hum. Behav. 2015, 54, 240–248. [Google Scholar] [CrossRef]

- Chiou, Y.J. Rethinking the Learning Outcome of E-learning. J. Educ. Media Libr. Sci. 2004, 41, 561–581. [Google Scholar]

- Shao, D.; Lee, I.J. Acceptance and Influencing Factors of Social Virtual Reality in the Urban Elderly. Sustainability 2020, 12, 9345. [Google Scholar] [CrossRef]

- Byrd, A.P.; Anderson, R.; Stone, R. The use of virtual welding simulators to evaluate experienced welders. Weld. J. 2015, 94, 389–395. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods; Sage Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Denzin, N.K. Sociological Methods: A Sourcebook; Routledge: Abingdon-on-Thames, UK, 2017. [Google Scholar]

- Morel, M.; Bideau, B.; Lardy, J.; Kulpa, R. Advantages and limitations of virtual reality for balance assessment and rehabilitation. Neurophysiol. Clin. Neurophysiol. 2015, 45, 315–326. [Google Scholar] [CrossRef]

- Stone, R.T.; Watts, K.P.; Zhong, P. Virtual reality integrated welder training. Weld. J. 2011, 90, 136–141. [Google Scholar]

| Item | Quantitative Analysis | Qualitative Analysis | |

|---|---|---|---|

| Welding practice test | Significantly positive | Students have the skills to apply electric welding and the ability to solve problems | |

| Learning effectiveness | Master the learning progress | Significantly positive | VR-assisted teaching allows students to understand their own learning progress |

| Improve learning efficiency | Significantly positive | Integrated VR welding practice improves learning efficiency | |

| Strengthen welding skills | Significantly positive | VR-assisted teaching strengthens students’ welding skills | |

| Enhance learning interest | Significantly positive | Integrated VR welding practice training increases learning interest | |

| Learning satisfaction | Improve learning safety | Significantly positive | VR-assisted teaching improves the safety of students in the field of welding practice |

| Reduce learning pollution | Significantly positive | VR-assisted teaching can be repeated many times to reduce pollution sources | |

| Lower learning costs | Significantly positive | VR-assisted teaching can be repeated many times to reduce learning costs | |

| Increase evaluation of learning effectiveness | Significantly positive | Diversified display of student learning effectiveness | |

| Strengthen traditional welding teaching | Significantly positive | Integrated VR welding practice teaching can assist traditional welding teaching | |

| Week | Course Outline | VR Assisted Teaching |

|---|---|---|

| Weekly | Site preparation, including: turn off the power of the machine, maintain and return tools, clean up the workbench, remove waste, clean the environment, use the equipment carefully, and cherish public property | VR understanding of the welding factory environment and equipment layout to establish students’ safety and health recognition concepts. |

| The 1st and 2nd weeks | 1. Brief introduction of AC welding machines, functions and comparison of AC welding machines 2. Brief introduction of CNS mild steel electrode numbering principles, and the application of mild steel electrodes 3. Introduction of the selection of personal appliances and safety lenses for welding operations 4. Explanation of the safety rules of electric welding operation and introduction of equipment relevant to a welding workshop | VR welding equipment operation teaching and welding operation safety simulations to provide students with learning opportunities. |

| The 3rd to 4th weeks | 1. Protective equipment, welding posture (including electrode chuck holding method, electrode holding method) 2. Electric welding machine operation, current adjustment, arc initiation method, and flat weld straight line welding 3. Electric welding arc damage and protective measures, electric shock hazard and prevention methods 4. Demonstration, explanation, and practice | VR-assisted welding skills and basic posture stability teaching, linking students’ prior knowledge of electric welding for proficiency in electric welding methods. |

| The 5th to 8th week | 1. Proper welding arc length 2. The angle that the base metal and the welding rod should maintain during welding 3. The welding points of flat welding, horizontal welding, vertical welding, and overhead welding 4. Demonstration, explanation, and practice | VR-assisted advanced teaching of welding skills and weld stability to strengthen students’ welding methods, and ensure that students acquire practical welding skills. |

| The 9th week | Mid-term exam: 1. Finished product review, joint evaluation by teachers and students 2. Answering students’ questions and summarizing the key points of this course | VR simulation welding test, in order that teachers and students can understand the learning effectiveness of welding knowledge and skills. |

| The 10th to 17th weeks | 1. Types and causes of weld bead defects 2. Prevention and improvement methods of weld bead defects Operation practice: (Teachers give individual guidance to correct students’ welding posture) 1. Strengthening the welding exercises demonstrated by the teacher 2. Completing the assignments on the work order | VR-assisted welding practice, remedial teaching and VR simulation welding test to correct students’ misconceptions, and ensure that students’ welding skills can be widely applied. |

| The 18th week | Final exam: 1. Finished-product review, joint evaluation by teachers and students 2. Answering students’ questions and summarizing the key points of this course | VR simulation welding test, in order that teachers and students can understand the learning effectiveness and application results of welding knowledge and skills. |

| Category | Mean | Standard Deviation | t | Df | p-Value |

|---|---|---|---|---|---|

| pre-test | 82.824 | 1.783 | −8.489 | 33 | 0.000 |

| post-test | 85.618 | 0.739 |

| Construct | Item | Average Mean | Standard Deviation | t |

|---|---|---|---|---|

| Learning effectiveness | (1) VR-assisted welding teaching allows me to master the learning process more accurately | 4.03 | 0.85 | 7.41 *** |

| (2) VR-assisted welding teaching makes my learning more efficient | 4.05 | 0.87 | 7.47 *** | |

| (3) VR-assisted welding teaching made me get used to welding muscle memory | 3.95 | 0.87 | 6.73 *** | |

| (4) The immersion of VR-assisted welding teaching can stimulate my interest in learning | 3.92 | 0.85 | 6.68 *** | |

| Learning satisfaction | (1) VR-assisted welding teaching can improve the personal safety of welding training | 4.08 | 0.97 | 6.86 *** |

| (2) VR-assisted electric welding teaching has low pollution and is very environmentally friendly | 4.08 | 0.91 | 7.29 *** | |

| (3) VR-assisted welding teaching saves costs | 4.05 | 0.87 | 7.47 *** | |

| (4) VR-assisted welding teaching makes it easier to evaluate students’ welding skills | 4.00 | 0.84 | 7.35 *** | |

| (5) VR-assisted welding teaching can strengthen traditional welding training | 3.95 | 0.80 | 7.27 *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-Y.; Lou, S.-J.; Cheng, Y.-M.; Chung, C.-C. Research on Teaching a Welding Implementation Course Assisted by Sustainable Virtual Reality Technology. Sustainability 2020, 12, 10044. https://doi.org/10.3390/su122310044

Huang C-Y, Lou S-J, Cheng Y-M, Chung C-C. Research on Teaching a Welding Implementation Course Assisted by Sustainable Virtual Reality Technology. Sustainability. 2020; 12(23):10044. https://doi.org/10.3390/su122310044

Chicago/Turabian StyleHuang, Chuang-Yeh, Shi-Jer Lou, Yuh-Ming Cheng, and Chih-Chao Chung. 2020. "Research on Teaching a Welding Implementation Course Assisted by Sustainable Virtual Reality Technology" Sustainability 12, no. 23: 10044. https://doi.org/10.3390/su122310044

APA StyleHuang, C.-Y., Lou, S.-J., Cheng, Y.-M., & Chung, C.-C. (2020). Research on Teaching a Welding Implementation Course Assisted by Sustainable Virtual Reality Technology. Sustainability, 12(23), 10044. https://doi.org/10.3390/su122310044