Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives

Abstract

1. Introduction

2. Materials and Methods

2.1. Composting Materials

2.2. Experiment Design

2.3. Sampling and Analytical Methods

2.4. Statistical Analysis

3. Results and Discussion

3.1. Changes in Gas Emissions during Composting

3.2. Changes in Temperature and pH during Composting

3.3. Compost Chemical Characteristics

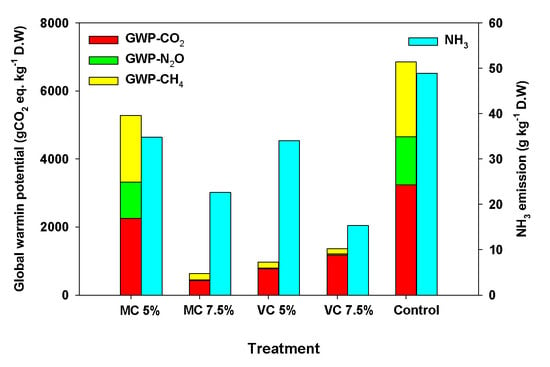

3.4. Total Gas Fluxes and Global Warming Potential

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Korea Ministry of Environment. Study on Preparation of Enhancement of Domestic Management System of the Waste in International Trade; Final Report, KME Report; Korea Ministry of Environment: Seoul, Korea, 2019. [Google Scholar]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life cycle assessment of a food waste composting system: Environmental impact hotspots. J. Clean. Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- Hodge, K.L.; Levis, J.W.; DeCarolis, J.F.; Barlaz, M.A. Systematic evaluation of industrial, commercial and institutional food waste management strategies in the United States. Environ. Sci. Technol. 2016, 50, 8444–8452. [Google Scholar] [CrossRef] [PubMed]

- Solomon, S. Climate Change 2007: The Physical Science Basis: Contribution of Working Group I to the Fourth Assessment Report of the Inter-Governmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Belyaeva, O.N.; Haynes, R.J. Chemical, microbial and physical properties of manufactured soils produced by co-composting municipal green waste with coal fly ash. Bioresour. Technol. 2009, 100, 5203–5209. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Pandey, A.K.; Bundela, P.S.; Wong, J.W.C.; Li, R.; Zhang, Z. Co-composting of gelatin industry sludge combined with organic fraction of municipal solid waste and poultry waste employing zeolite mixed with enriched nitrifying bacterial consortium. Bioresour. Technol. 2016, 213, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Chan, M.T.; Selvam, A.; Wong, J.W.C. Reducing nitrogen loss and salinity during ‘struvite’ food waste composting by zeolite amendment. Bioresour. Technol. 2016, 200, 838–844. [Google Scholar] [CrossRef]

- He, Z.; Lin, H.; Hao, J.; Kong, X.; Tian, K.; Bei, Z.; Tian, X. Impact of vermiculite on ammonia emissions and organic matter decomposition of food waste during composting. Bioresour. Technol. 2018, 263, 548–554. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Duan, Y.; Liu, T.; Awasthi, S.K.; Zhang, Z. Relevance of biochar to influence the bacterial succession during pig manure composting. Bioresour. Technol. 2020, 304, 122962. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Duan, Y.; Liu, T.; Awasthi, S.K.; Zhang, Z. Influence of bamboo biochar on mitigating greenhouse gas emissions and nitrogen loss during poultry manure composting. Bioresour. Technol. 2020, 303, 122952. [Google Scholar] [CrossRef]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef]

- Yang, F.; Li, Y.; Han, Y.; Qian, W.; Li, G.; Luo, W. Performance of mature compost to control gaseous emissions in kitchen waste composting. Sci. Total Environ. 2019, 657, 262–269. [Google Scholar] [CrossRef]

- Jack, A.L.H.; Thies, J.E. Compost and vermicompost as amendments promoting soil health. In Biological Approaches to Sustainable Soil Systems; Uphof, N., Ball, A.S., Fernandes, E., Herren, H., Husson, O., Laing, M., Palm, C., Pretty, J., Sanchez, P., Sanginga, N., et al., Eds.; Routledge: Abingdon, UK, 2006; pp. 453–466. [Google Scholar]

- Yang, Y.; Awasthi, M.K.; Ren, X.; Guo, H.; Lv, J. Effect of bean dregs on nitrogen transformation and bacterial dynamics during pig manure composting. Bioresour. Technol. 2019, 288, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Li, G.X.; Yang, Q.Y.; Luo, W.H. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting. Chemosphere 2013, 93, 1393–1399. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.Y.; Kim, S.H.; Kim, M.S.; Park, S.J.; Lee, C.H. Co-composting of chicken manure with organic wastes: Characterization of gases emissions and compost quality. Appl. Biol. Chem. 2020, 63, 1–10. [Google Scholar] [CrossRef]

- RDA (Rural Development Administration, Korea). Quality Control and Utilization of Livestock Manure; National Institute of Agricultural Sciences: WanJu, Korea, 2012. [Google Scholar]

- Zhang, H.; Li, G.; Gu, J.; Wang, G.; Li, Y.; Zhang, D. Influence of aeration on volatile sulfur compounds (VSCs) and NH3 emissions during aerobic composting of kitchen waste. Waste Manag. 2016, 58, 369–375. [Google Scholar] [CrossRef] [PubMed]

- Kits, K.D.; Campbell, D.J.; Rosana, A.R.; Stein, L.Y. Diverse electron sources support denitrification under hypoxia in the obligate methanotroph Methylomicrobium album strain BG8. Front. Microbiol. 2015, 6, 1072. [Google Scholar] [CrossRef]

- Mohammadi, S.S.; Pol, A.; Alen, T.V.; Jetten, M.S.M.; Op den Camp, H.J.M. Ammonia oxidation and nitrite reduction in the verrucomicrobial methanotroph Methylacidiphilum fumariolicum SolV. Front. Microbiol. 2017, 8, 1901. [Google Scholar] [CrossRef]

- Campbell, M.A.; Nyerges, G.; Kozlowski, J.A.; Poret-Peterson, A.T.; Stein, L.Y.; Klotz, M.G. Model of the molecular basis for hydroxylamine oxidation and nitrous oxide production in methanotrophic bacteria. FEMS Microbiol. Lett. 2011, 322, 82–89. [Google Scholar] [CrossRef]

- Jiang, T.; Ma, X.; Tang, Q.; Li, G.; Schuchardt, F. Combined use of nitrification inhibitor and struvite crystallization to reduce the NH3 and N2O emissions during composting. Bioresour. Technol. 2016, 217, 210–218. [Google Scholar] [CrossRef]

- Zeng, Y.; Amaury, D.G.; Patrick, D. Improving composting as a post-treatment of anaerobic digestate. Bioresour. Technol. 2016, 201, 293–303. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Changes in physical, chemical, and microbiological properties during the two-stage co-composting of green waste with spent mushroom compost and biochar. Bioresour. Technol. 2014, 171, 274–284. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.; Alburquerque, J.A.; Sanchwz-Mondero, M.A.; Roig, A.; Cayuela, M.L. Biochar accelerates organic matter degradation and enhances N mineralisation during composting of poultry manure without a relevant impact on gas emissions. Bioresour. Technol. 2015, 192, 272–279. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Huang, G.H. Effect of sodium acetate as a pH control amendment on the composting of food waste. Bioresour. Technol. 2009, 100, 2005–2011. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.; Li, Y.; Li, J.; Chen, Q.; Zhao, H.; Qi, Z. Influences of the Thermophilic Period on Biodegradation and Nitrogen Loss in Stimulated Vegetable Waste Composting. Glob. Ecol. Conserv. 2019, 18, e00623. [Google Scholar] [CrossRef]

- Ameen, A.; Ahmad, J.; Raza, S. Effect of pH and moisture content on composting of Municipal solid waste. Int. J. Sci. Res. Publ. 2016, 6, 35–37. [Google Scholar]

- Zhang, D.; Luo, W.; Yuan, J.; Li, G.; Luo, Y. Effects of woody peat and superphosphate on compost maturity and gaseous emissions during pig manure composting. Waste Manag. 2017, 68, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of composting on phytotoxicity of spent pig-manure sawdust litter. Environ. Pollut. 1996, 93, 249–256. [Google Scholar] [CrossRef]

- Kato, K.; Miura, N. Effect of matured compost as a bulking and inoculating agent on the microbial community and maturity if cattle manure compost. Bioresour. Technol. 2008, 99, 3372–3380. [Google Scholar] [CrossRef]

- Ren, L.M.; Schuchardt, F.; Shen, Y.J.; Li, G.X.; Li, C.P. Impact of struvite crystallization on nitrogen losses during composting of pig manure and cornstalk. Waste Manag. 2010, 30, 885–892. [Google Scholar] [CrossRef]

- Sanchez-Monedero, M.A.; Roig, A.; Paredes, C.; Bernal, M.P. Nitrogen transformation during organic waste composting by the Rutgers system and its effects on pH, EC and maturity of the composting mixtures. Bioresour. Technol. 2001, 78, 301–308. [Google Scholar] [CrossRef]

- Kim, D.J.; Lee, D.I.; Keller, J. Effect of temperature and free ammonia on nitrification and nitrite accumulation in landfill leachate and analysis of its nitrifying bacterial community by FISH. Bioresour. Technol. 2006, 97, 459–468. [Google Scholar] [CrossRef]

- Santos, A.; Bustamante, M.A.; Tortosa, G.; Moral, R.; Bernal, M.P. Gaseous emissions and process development during composting of pig slurry: The influence of the proportion of cotton gin waste. J. Clean. Prod. 2016, 112, 81–90. [Google Scholar] [CrossRef]

- Pathma, J.; Sakthivel, N. Microbial Diversity of Vermicompost Bacteria That Exhibit Useful Agricultural Traits and Waste Management Potential; Springer Plus: Berlin/Heidelberg, Germany, 2012; Volume 1, p. 26. [Google Scholar]

- Lazcano, C.; Domínguez, J. Effects of vermicompost as a potting amendment of two commercially-grownornamental plant species. Span. J. Agric. Res. 2010, 8, 1260–1270. [Google Scholar] [CrossRef]

- Lim, S.L.; Wu, T.Y. Determination of maturity in the vermicompost produced from palm oil mill effluent using spectroscopy, structural characterization and thermogravimetric analysis. Ecol. Eng. 2015, 84, 515–519. [Google Scholar] [CrossRef]

- Chang, J.I.; Chen, Y.J. Effects of bulking agents on food waste composting. Bioresour. Technol. 2010, 101, 5917–5924. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Food Waste | Mature Compost | Vermicompost | Sawdust |

|---|---|---|---|---|

| Total C (%) | 44.9 ± 0.1 | 39.3 ± 0.3 | 8.1 ± 0.2 | 48.7 ± 0.3 |

| Total N (%) | 5.1 ± 0.03 | 1.1 ± 0.05 | 0.79 ± 0.07 | 0.12 ± 0.00 |

| C/N ratio | 8.8 ± 0.1 | 35.1 ± 1.7 | 10.2 ± 0.8 | 400 ± 17.7 |

| DOC (g kg−1) 1 | 107 ± 13 | 6.3 ± 0.22 | 1.2 ± 0.05 | 5.6 ± 0.08 |

| DON (g kg−1) 1 | 16.4 ± 2.1 | 2.8 ± 0.04 | 2.1 ± 0.08 | 0.27 ± 0.004 |

| HWEC (g kg−1) 1 | 25.2 ± 3.0 | 4.2 ± 0.12 | 1.7 ± 0.09 | 3.8 ± 0.13 |

| HWEN (g kg−1) 1 | 3.2 ± 0.36 | 1.1 ± 0.02 | 0.32 ± 0.002 | 0.11 ± 0.003 |

| EC (dS m−1) 1 | 7.0 ± 0.1 | 2.6 ± 0.07 | 2.2 ± 0.03 | 0.25 ± 0.02 |

| pH | 4.9 ± 0.1 | 7.4 ± 0.1 | 7.0 ± 0.1 | 5.3 ± 0.1 |

| Treatment 1 | Composting Cycle | Mass (kg) | Content (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TOC | TN | C/N | K | Ca | Mg | Na | |||

| MC 5% | Initial | 21.0 | 40.1 | 1.08 | 37.1 | 0.40 | 2.50 | 0.25 | 0.59 |

| Final | 18.7 | 37.2 | 1.00 | 37.2 | 0.43 | 2.97 | 0.32 | 0.95 | |

| MC 7.5% | Initial | 21.5 | 40.1 | 1.09 | 36.8 | 0.51 | 2.83 | 0.20 | 0.56 |

| Final | 19.4 | 38.9 | 1.07 | 36.4 | 0.46 | 9.01 | 0.5 | 1.14 | |

| VC 5% | Initial | 21.0 | 36.7 | 1.25 | 29.4 | 0.62 | 1.93 | 0.27 | 0.47 |

| Final | 18.2 | 29.5 | 1.03 | 28.6 | 0.50 | 4.14 | 0.61 | 0.88 | |

| VC 7.5% | Initial | 21.5 | 32.3 | 0.99 | 32.6 | 0.46 | 2.44 | 0.32 | 0.35 |

| Final | 19.5 | 26.8 | 0.81 | 33.1 | 0.68 | 3.03 | 0.61 | 0.62 | |

| Control | Initial | 20.0 | 45.2 | 1.18 | 38.3 | 0.31 | 0.72 | 0.08 | 0.66 |

| Final | 12.3 | 42.1 | 0.78 | 54.0 | 0.39 | 1.41 | 0.20 | 1.08 | |

| Compost 1 | NH3 | CO2 | N2O | CH4 | Total GWP |

|---|---|---|---|---|---|

| g kg−1 D.W | kg CO2 eq. kg−1 D.W | ||||

| MC 5% | 34.8 | 1885 | 0.11 | 29.8 | 2.66 |

| MC 7.5% | 22.6 | 2556 | 0.13 | 47.9 | 3.79 |

| VC 5% | 34.0 | 4206 | 0.27 | 69.5 | 6.02 |

| VC 7.5% | 15.3 | 3758 | 0.27 | 46.4 | 5.00 |

| Control | 48.9 | 3240 | 4.73 | 88.1 | 6.85 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, H.Y.; Kim, S.H.; Shim, J.; Park, S.J. Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives. Sustainability 2020, 12, 7811. https://doi.org/10.3390/su12187811

Hwang HY, Kim SH, Shim J, Park SJ. Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives. Sustainability. 2020; 12(18):7811. https://doi.org/10.3390/su12187811

Chicago/Turabian StyleHwang, Hyun Young, Seong Heon Kim, Jaehong Shim, and Seong Jin Park. 2020. "Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives" Sustainability 12, no. 18: 7811. https://doi.org/10.3390/su12187811

APA StyleHwang, H. Y., Kim, S. H., Shim, J., & Park, S. J. (2020). Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives. Sustainability, 12(18), 7811. https://doi.org/10.3390/su12187811