Mechanical and Durability Properties of Cement-Stabilized Recycled Concrete Aggregate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Aggregates

2.2. Experimental Program

2.2.1. Gradation Design

2.2.2. Unconfined Compressive Strength and Indirect Tensile Strength Tests

2.2.3. Drying Shrinkage Test

3. Test Results

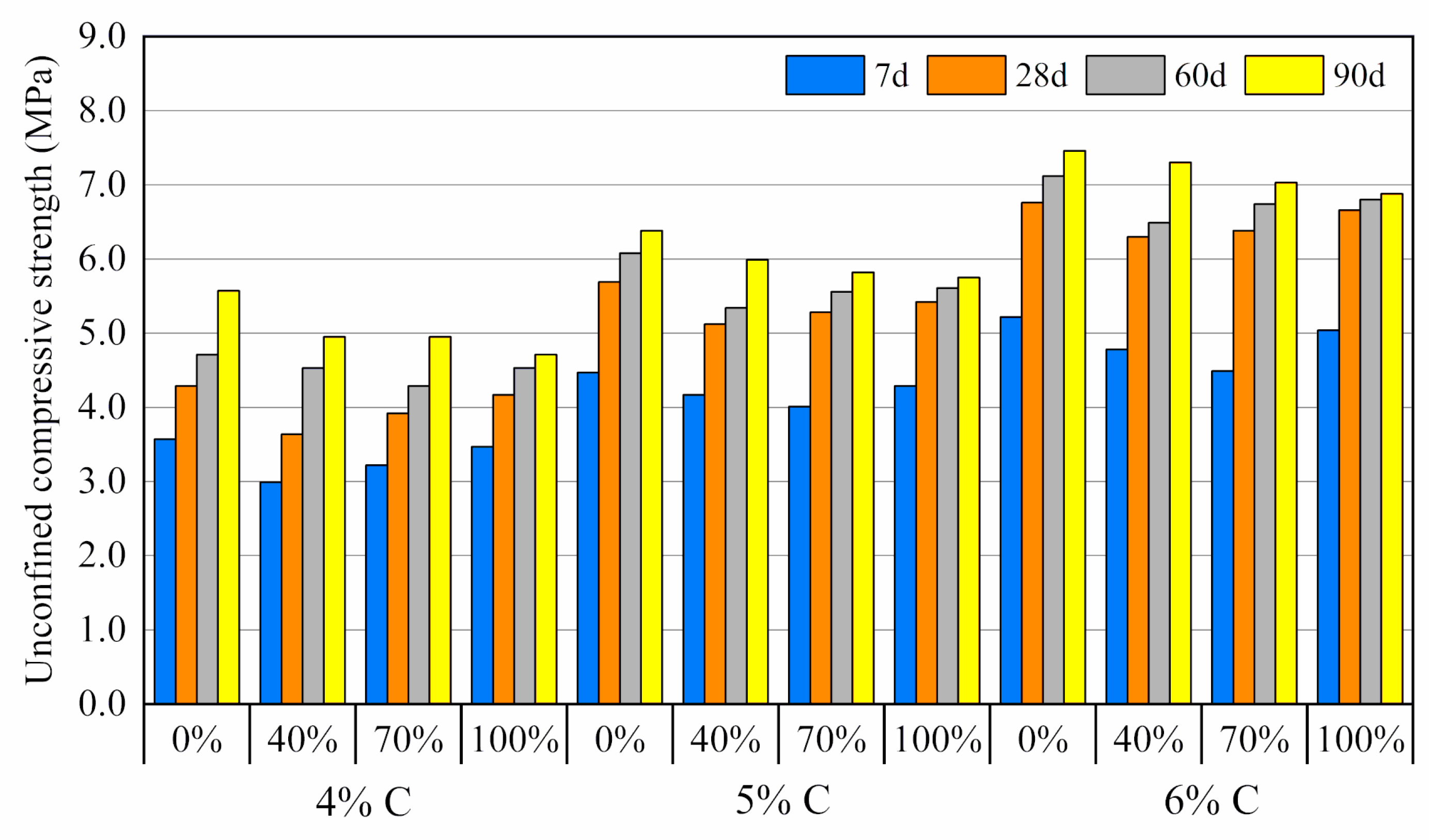

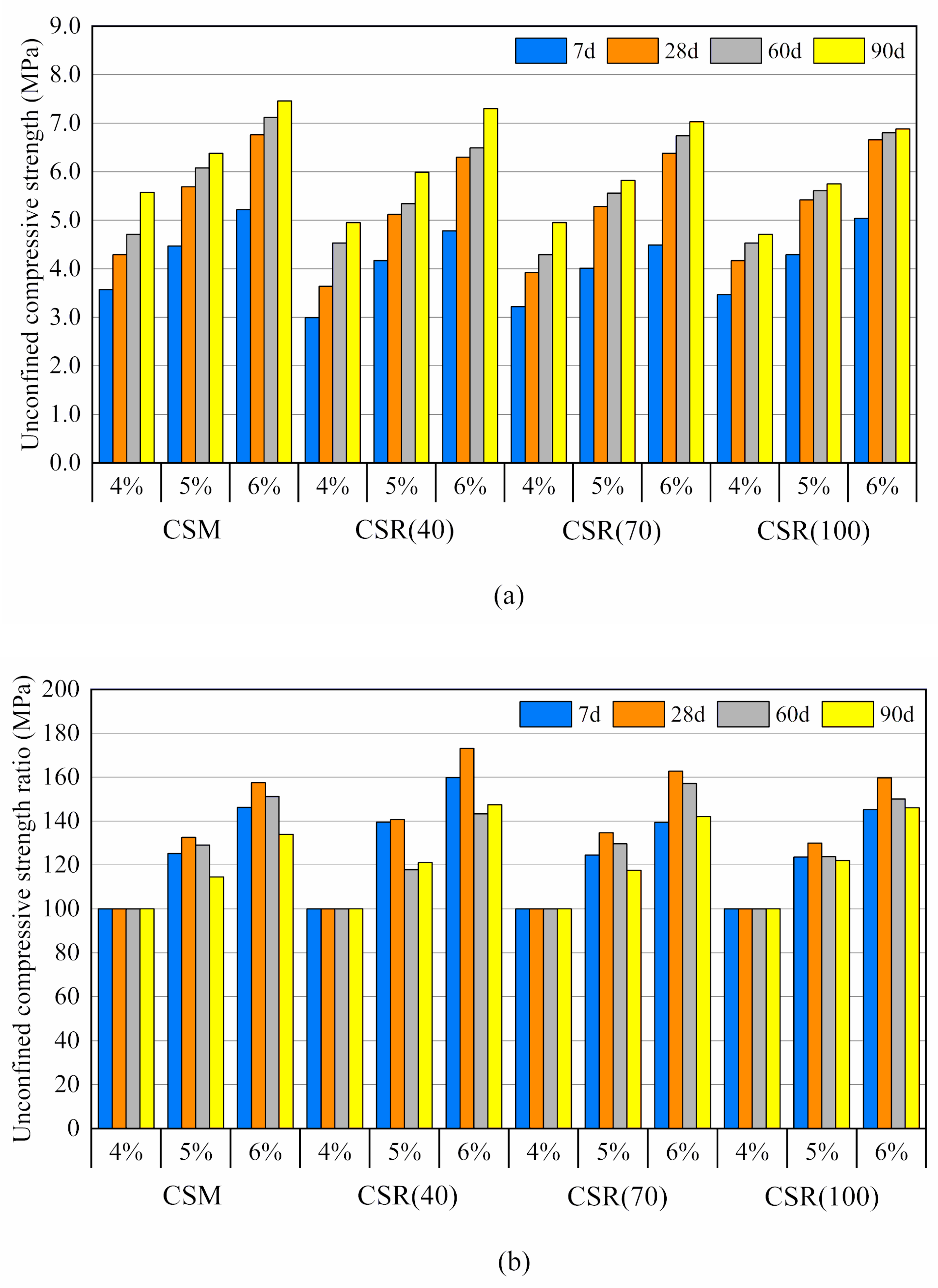

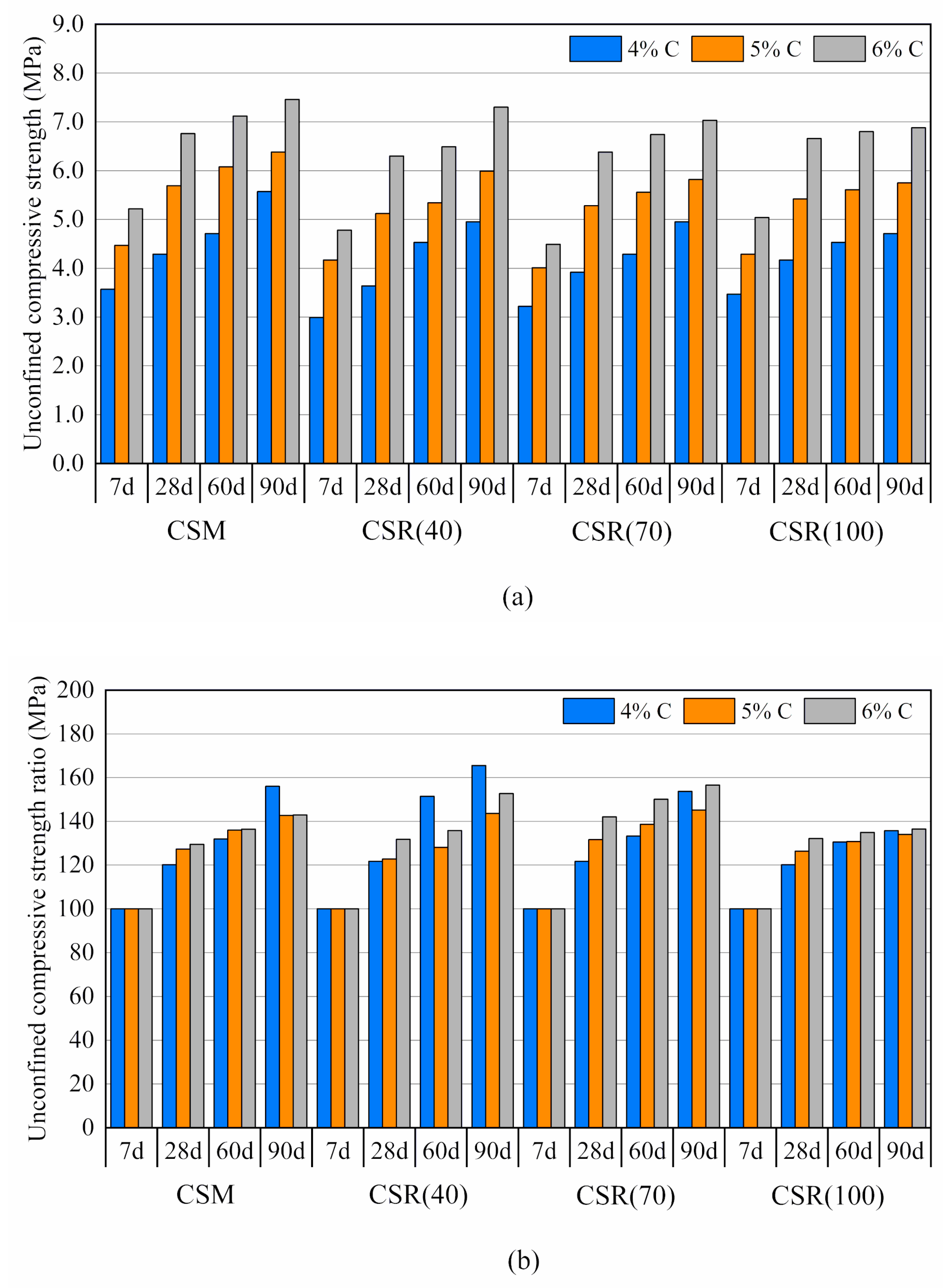

3.1. Unconfined Compressive Strength

3.1.1. Effect of the Replacement Ratio of Recycled Concrete Aggregate

3.1.2. Effect of Cement Content

3.1.3. Effect of Curing Time

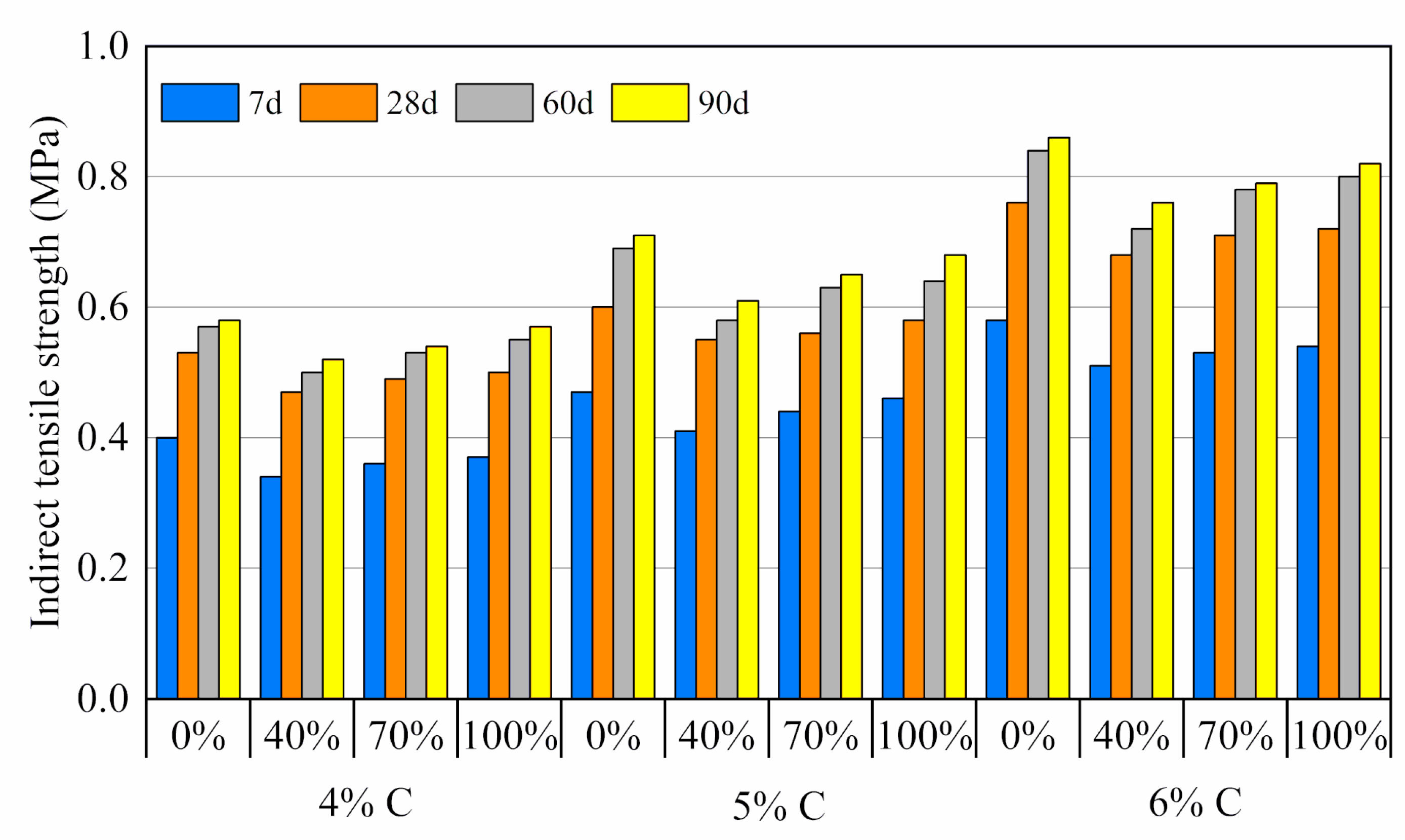

3.2. Indirect Tensile Strength

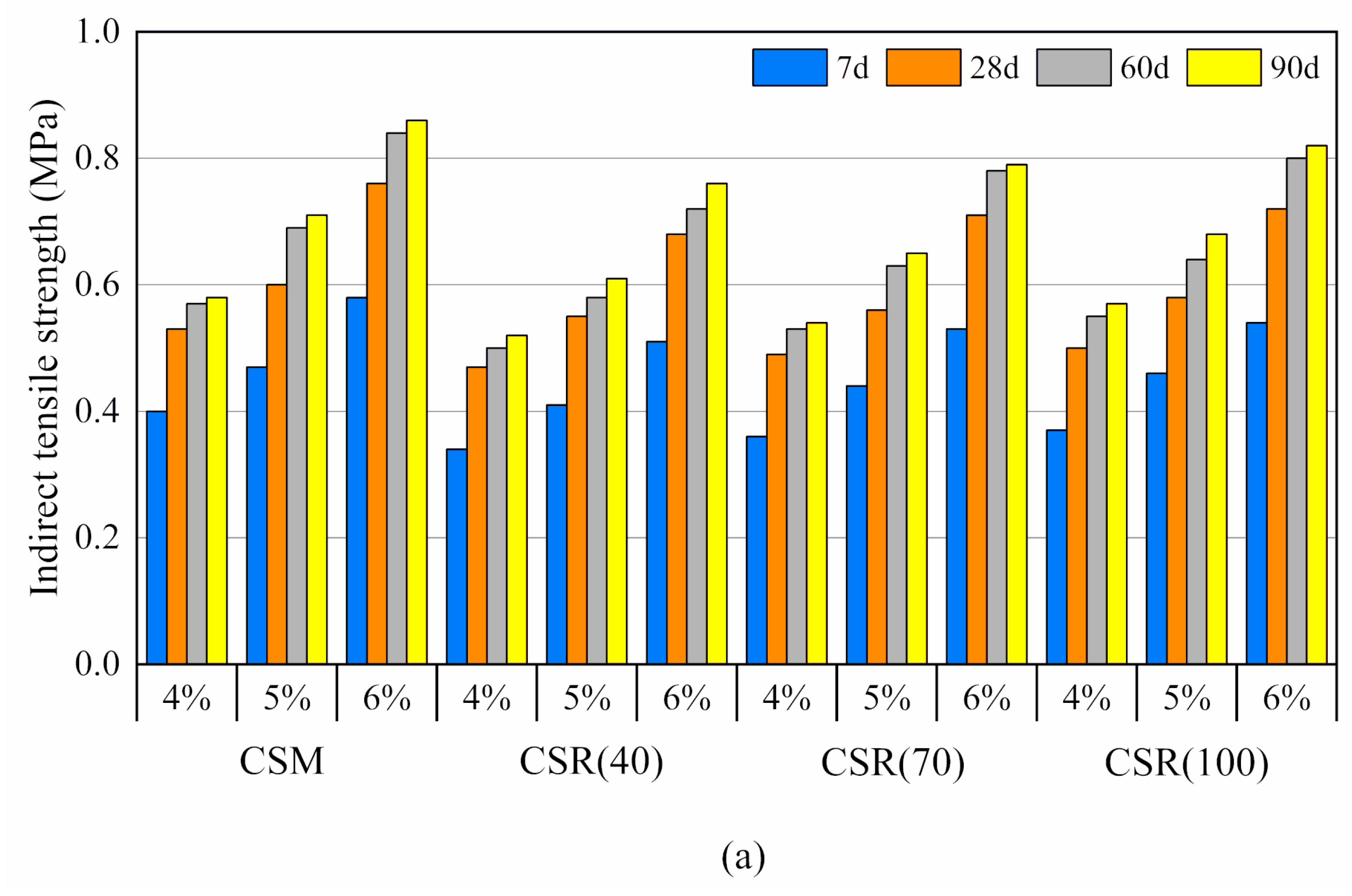

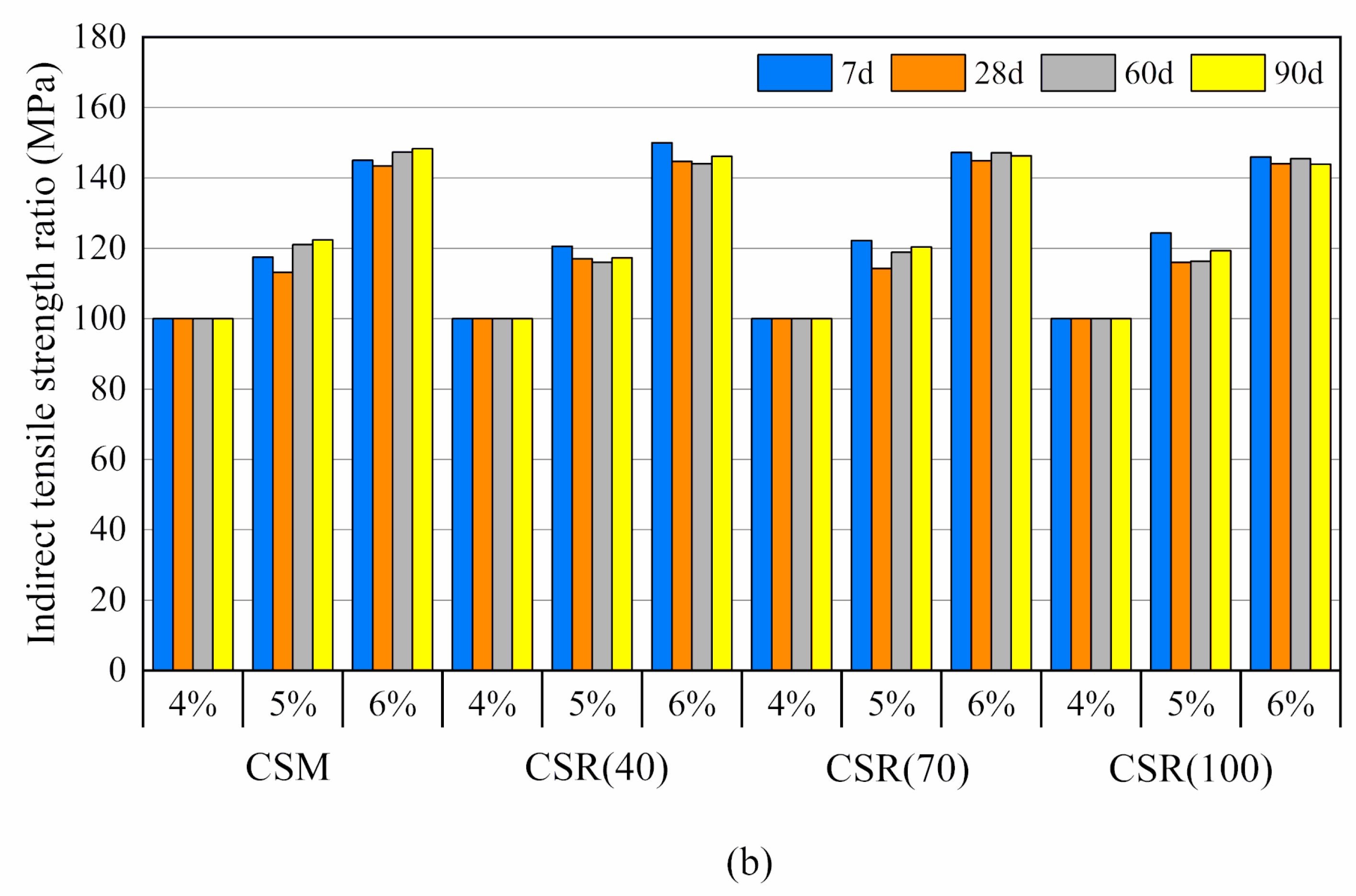

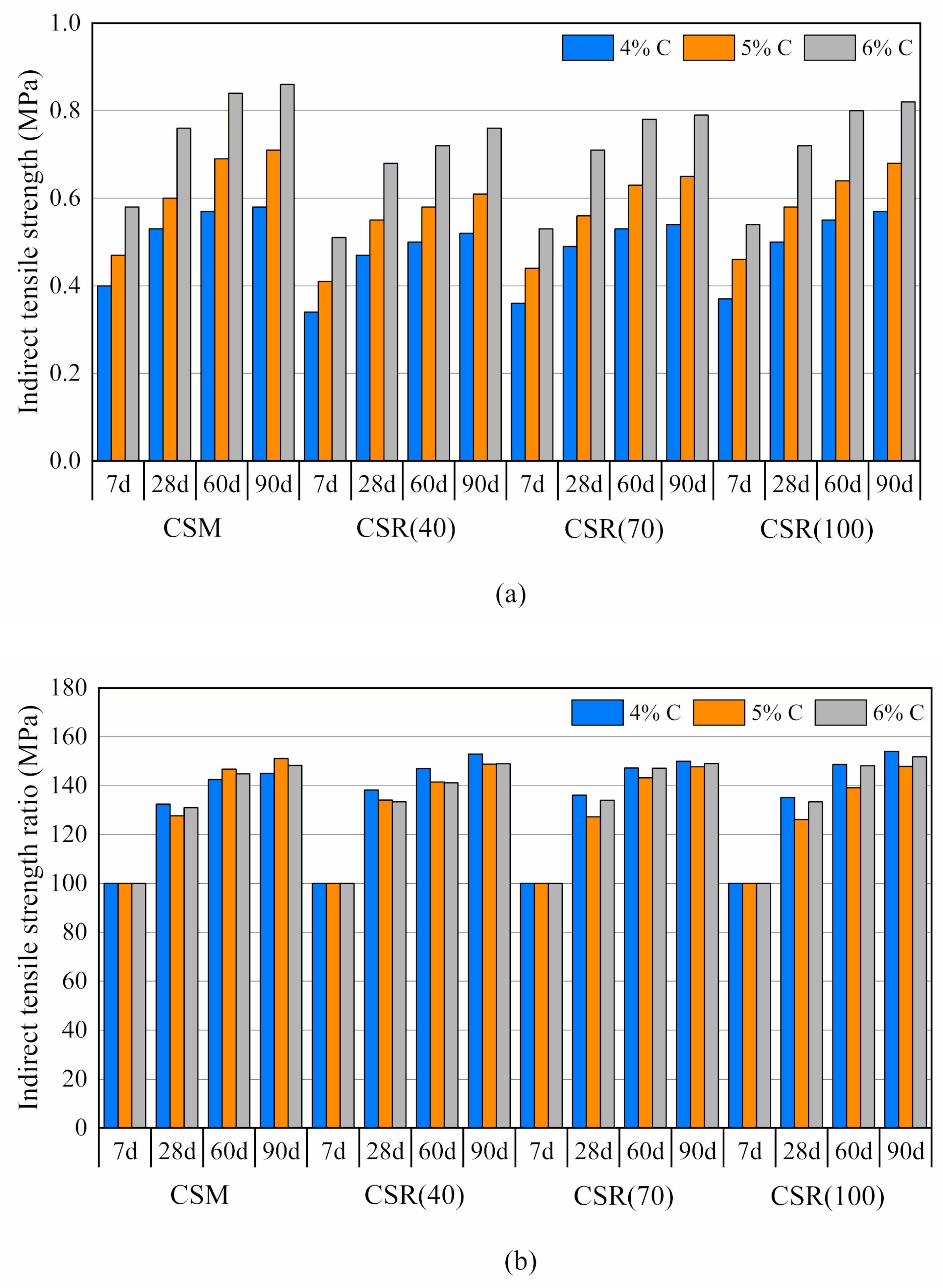

3.2.1. Effect of the Replacement Ratio of Recycled Concrete Aggregate

3.2.2. Effect of Cement Content

3.2.3. Effect of Curing Time

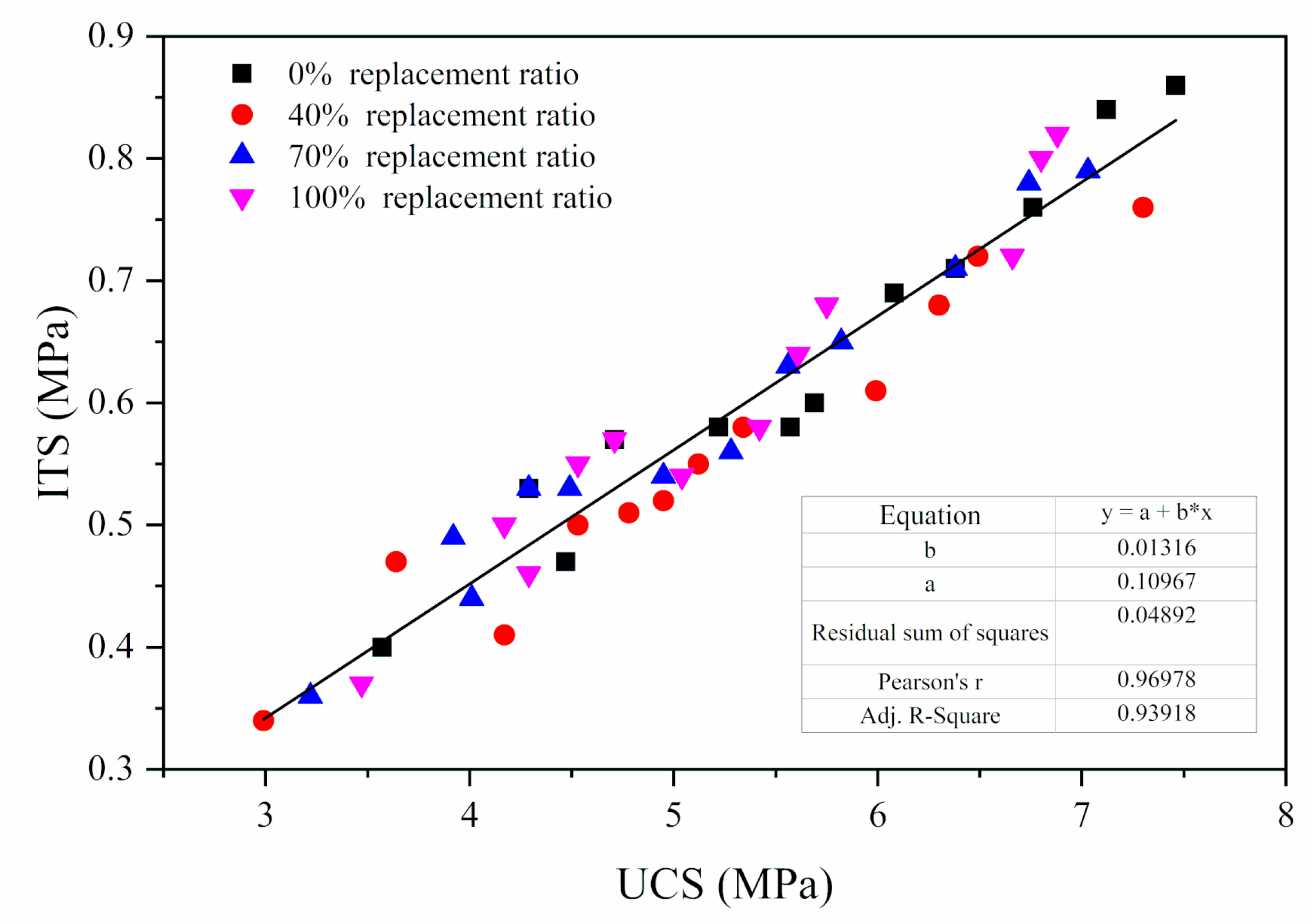

3.3. Relationship between UCS and ITS

3.4. Durability-Related Properties

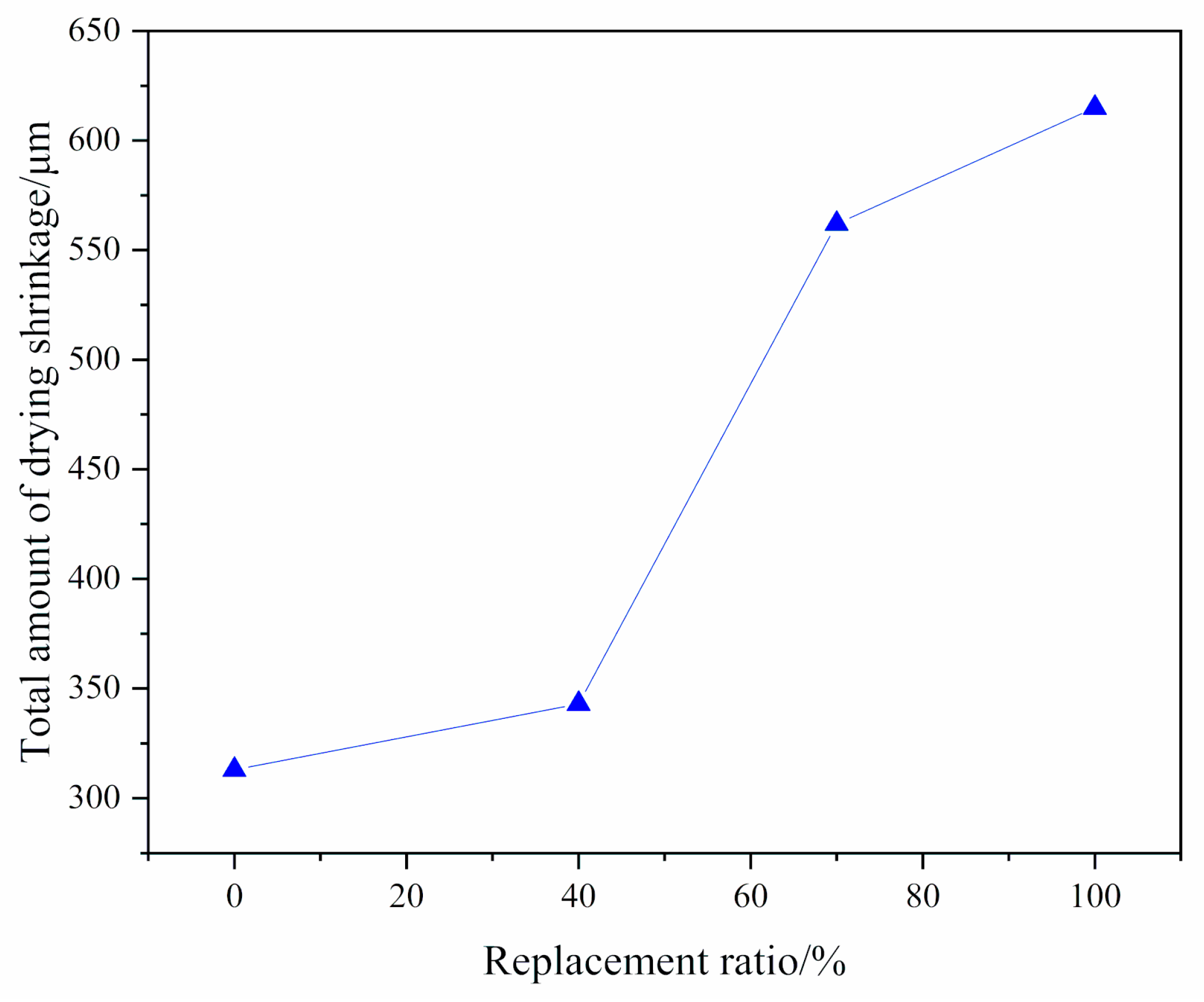

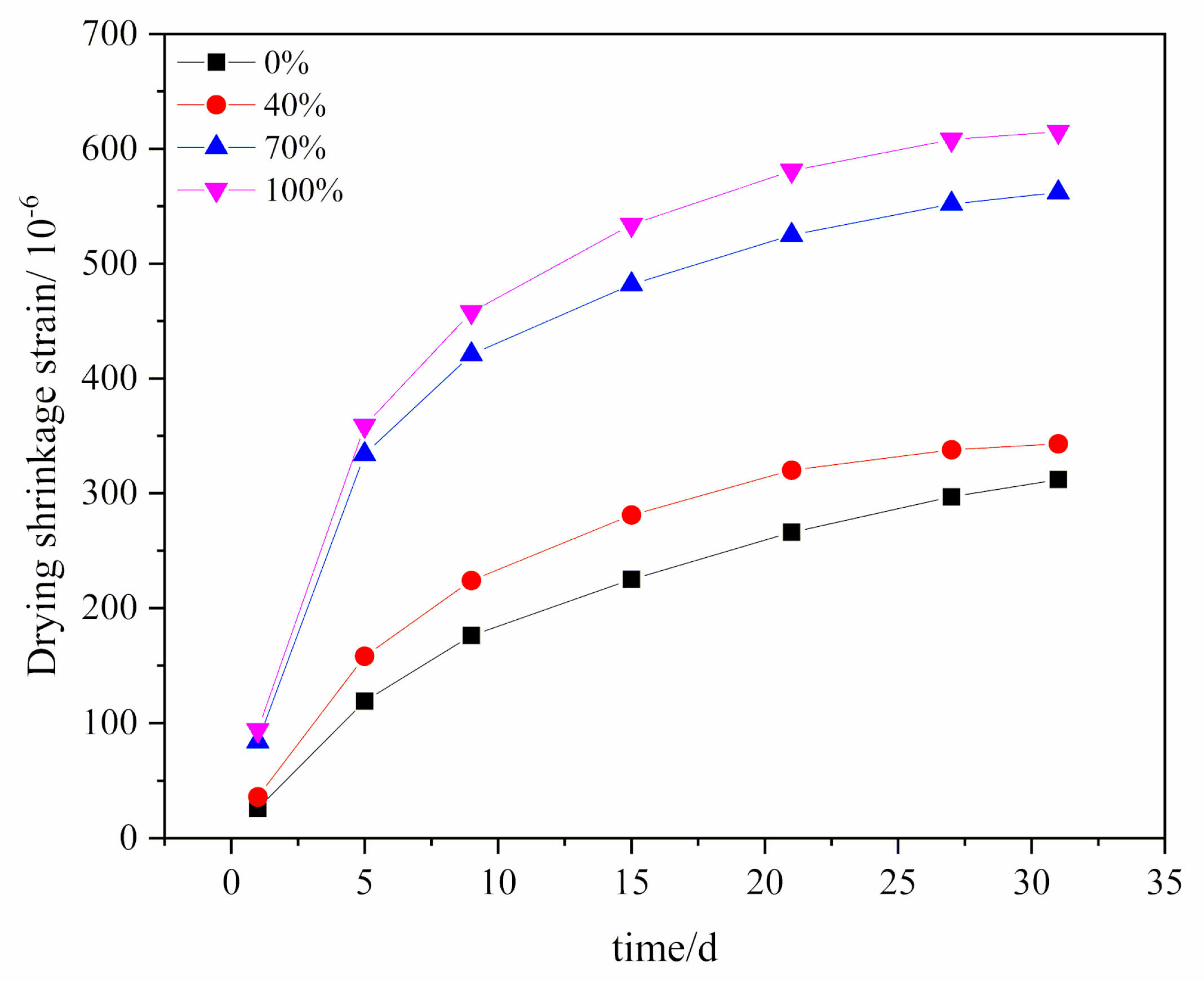

3.4.1. Drying Shrinkage

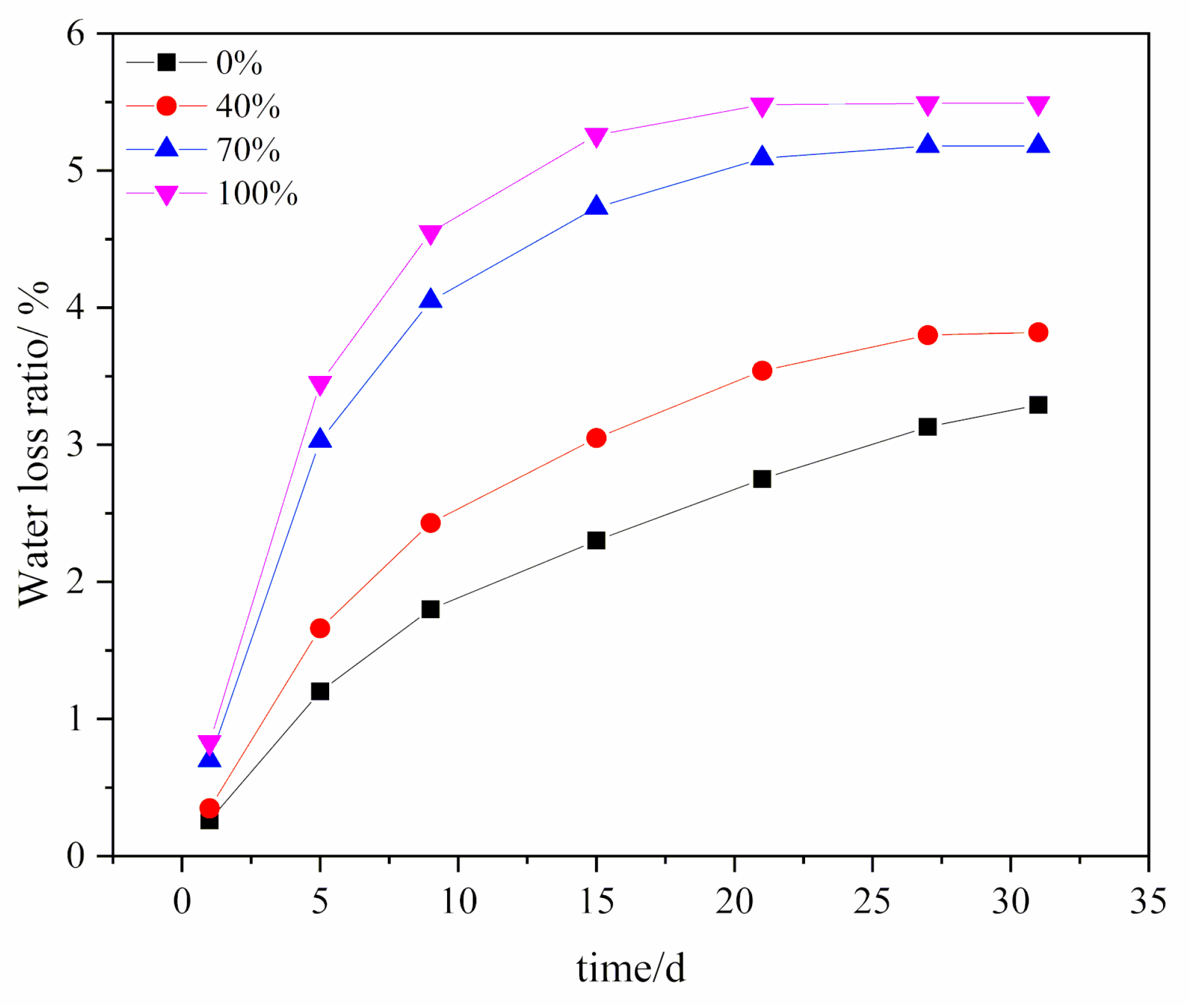

3.4.2. Water Loss Ratio

4. Conclusions

- When the curing time was fewer than 60 days, a lower replacement ratio resulted in an initial decrease in the UCS of the CSR mixture; with the increase of the replacement ratio, the UCS had a slight increase. When curing time exceeded 60 days, the UCS of the CSR mixture decreased with the replacement ratio. The seven-day UCS of the CSR mixture met the requirements for road base applications. The ITS of the CSR mixture decreased and then increased with the replacement ratio. The UCS and ITS of the CSM mixture were higher than those of the CSR mixture.

- The UCS and ITS of the CSR mixture with a higher cement content were better, and UCS was significantly increased after 28 days of curing. Compared to the CSM mixture, the CSR mixture had lower strength with the same cement content.

- For four different curing times, the development rate of the UCS and ITS of the CSR mixture from 7 to 28 days was the maximum, which then gradually decreased with curing time. Longer curing caused a further hydration reaction, thus leading to high strength levels. It is economical to use low cement content in the same age for CSR mixtures.

- The drying shrinkage strain of the CSR mixture increased with the increase of the replacement ratio but decreased with time. A high replacement ratio corresponded to high drying shrinkage strain.

- The development of the water loss ratio indicated that it was easier for the CSR mixture to lose water under dry conditions. The drying shrinkage strain and water loss ratio of the CSR mixture more obviously increased in the RCA range of 40%–70%. The higher the replacement ratio was, the shorter the water loss cycle.

Author Contributions

Funding

Conflicts of Interest

References

- Sun, Y.; Li, L. Strength assessment and mechanism analysis of cement stabilized reclaimed lime-fly ash macadam. Constr. Build. Mater. 2018, 166, 118–129. [Google Scholar] [CrossRef]

- Lv, S.T.; Yuan, J.; Liu, C.C.; Wang, J.Q.; Li, J.L.; Zheng, J.L. Investigation of the fatigue modulus decay in cement stabilized base material by considering the difference between compressive and tensile modulus. Constr. Build. Mater. 2019, 223, 491–502. [Google Scholar] [CrossRef]

- Du, S.W. Influence of chemical additives on mixing procedures and performance properties of asphalt emulsion recycled mixture with reclaimed cement-stabilized macadam. Constr. Build. Mater. 2016, 118, 146–154. [Google Scholar] [CrossRef]

- Li, W.; Lang, L.; Lin, Z.; Wang, Z.; Zhang, F. Characteristics of dry shrinkage and temperature shrinkage of cement-stabilized steel slag. Constr. Build. Mater. 2017, 134, 540–548. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Lu, W.S.; Webster, C.; Peng, Y.; Chen, X.; Zhang, X.L. Estimating and calibrating the amount of building-related construction and demolition waste in urban China. Int. J. Const. Manag. 2017, 17, 13–24. [Google Scholar] [CrossRef]

- Zhou, J.; Zeng, M.; Chen, Y.; Zhong, M. Evaluation of cement stabilized recycled concrete aggregates treated with waste oil and asphalt emulsion. Constr. Build. Mater. 2019, 199, 143–153. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete—A review. J. Clean Prod. 2020, 268. [Google Scholar] [CrossRef]

- Shaker, R.M.; Bhalala, M.; Kargar, Q.; Chang, B. Evaluation of Alternative Home-Produced Concrete Strength with Economic Analysis. Sustainability 2020, 12, 6746. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z.P. The Mechanical Properties of Asphalt Mixtures with Recycled Concrete Aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Paranavithana, S.; Mohajerani, A. Effects of recycled concrete aggregates on properties of asphalt concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Kampala, A.; Horpibulsuk, S.; Chinkullijniwat, A.; Shen, S.L. Engineering properties of recycled calcium carbide residue stabilized clay as fill and pavement materials. Constr. Build. Mater. 2013, 46, 203–210. [Google Scholar] [CrossRef]

- Lopez-Uceda, A.; Agrela, F.; Cabrera, M.; Ayuso, J.; López, M. Mechanical performance of roller compacted concrete with recycled concrete aggregates. Road Mater. Pavement Des. 2018, 19, 36–55. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Wan, H.W. Properties of concrete prepared with low-grade recycled aggregates. Constr. Build. Mater. 2012, 36, 881–889. [Google Scholar] [CrossRef]

- Kumar, R. Influence of recycled coarse aggregate derived from construction and demolition waste (CDW) on abrasion resistance of pavement concrete. Constr. Build. Mater. 2017, 142, 248–255. [Google Scholar] [CrossRef]

- Paul, S.C.; Panda, B.; Garg, A.G. A novel approach in modelling of concrete made with recycled aggregates. Measurement 2018, 115, 64–72. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Tam, C.T.; Zhang, M.H. Effects of the parent concrete properties and crushing procedure on the properties of coarse recycled concrete aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar] [CrossRef]

- Ma, K.; Li, W.B. Effect of the Aggregate Size on Strength Properties of Recycled Aggregate Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 2428576. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Xie, T. Mechanical and durability properties of recycled aggregate concrete: Effect of recycled aggregate properties and content. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Ji, X.P.; Jiang, Y.J.; Liu, Y.J. Evaluation of the mechanical behaviors of cement-stabilized cold recycled mixtures produced by vertical vibration compaction method. Mater. Struct. 2016, 49, 2257–2270. [Google Scholar] [CrossRef]

- Taha, R.; Al-Harthy, A.; Al-Shamsi, K.; Al-Zubeidi, M. Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 2002, 14, 239–245. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Haghighi, H.; Mohammadinia, A.; Horpibulsuk, S. Flexural beam fatigue strength evaluation of crushed brick as a supplementary material in cement stabilized recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 667–676. [Google Scholar] [CrossRef]

- Hou, Y.Q.; Ji, X.P.; Liu, L.Q. Study on Mechanical and Influencing Factors of Cement Stabilised Recycled Aggregate. J. Highw. Transp. Res. Dev. 2016, 33, 56–61. [Google Scholar]

- Mohammadinia, A.; Arulrajah, A.; Sanjayan, J.; Disfani, M.M.; Bo, M.W.; Darmawan, S. Laboratory Evaluation of the Use of Cement-Treated Construction and Demolition Materials in Pavement Base and Subbase Applications. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. China Professional Standard: JTG E42, Test. Methods of Aggregate for Highway Engineering; China Communication Press: Beijing, China, 2005. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. China Professional Standard: JTG E51, Test. Methods of Materials Stabilized with Inorganic Binders for Highway Engineering; China Communication Press: Beijing, China, 2009. [Google Scholar]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Ji, X.P.; Cao, H.L.; Liu, L.Q. Performance and influencing factors of cement stabilized recycled concrete aggregate. J. Build. Mater. 2016, 19, 342–346. (In Chinese) [Google Scholar]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Effect of cementation level on performance of rubberized cement-stabilized aggregate mixtures. Mater. Des. 2016, 97, 98–107. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. China Professional Standard: JTG D50, Specifications for Design of Highway Asphalt Pavement; China Communication Press: Beijing, China, 2017. [Google Scholar]

- Liu, D.; Li, L.H.; Cui, H.J. Strength performance of cement stabilized aggregate containing bottom ash aggregate (BAA). J. Build. Mater. 2014, 17, 538–542. (In Chinese) [Google Scholar]

- Du, Q.; Pan, T.; Lv, J.; Zhou, J.; Ma, Q.W.; Sun, Q. Mechanical Properties of Sandstone Cement-Stabilized Macadam. Appl. Sci. 2020, 9, 3460. [Google Scholar] [CrossRef]

- Zhang, H.W. Experimental Study on Road Performance of Recycled Aggregate for Waste Concrete Pavement. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2019. [Google Scholar]

- Gao, J.Q.; Jin, P.P.; Sheng, Y.X.; An, P. A case study on crack propagation law of cement stabilised macadam base. Int. J. Pavement Eng. 2020, 21, 516–523. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

| Type | Comparison | Physical Performance | |||||

|---|---|---|---|---|---|---|---|

| Setting Time (h) | Strength (MPa) | ||||||

| Flexural Strength | Unconfined Compressive Strength | ||||||

| Initial Set | Final Set | 3d | 28d | 3d | 28d | ||

| P.O 42.5 | Reference value Test result | ≥0.75 | ≤6 | ≥3.5 | ≥6.5 | ≥17 | ≥42.5 |

| 3 | 3.8 | 5.6 | 9.3 | 30.9 | 53.7 | ||

| Test Indicators | Natural Coarse Aggregate | Recycled Coarse Aggregate |

|---|---|---|

| Apparent density (g/cm3) | 2.729 | 2.662 |

| Crushing value (%) | 13.7 | 20.8 |

| Los Angeles abrasion value (%) | 19.7 | 26.4 |

| Water absorption (%) | 0.7 | 2.81 |

| Needle and flake content (%) | 6.4 | 8.9 |

| Mud content (%) | 0.8 | 1.4 |

| Test Indicators | Natural Fine Aggregate | Recycled Fine Aggregate |

|---|---|---|

| Apparent density (g/cm3) | 2.639 | 2.512 |

| Water absorption (%) | 2.6 | 9.2 |

| Mud content (%) | 1.6 | 4.2 |

| Fineness modulus | 3.64 | 3.12 |

| Water content (%) | 2.4 | 3 |

| Cement Content (%) | Replacement Ratio (%) | Maximum Dry Density (g/cm3) | Optimum Water Content (%) |

|---|---|---|---|

| 4 | 0 | 2.256 | 4.1 |

| 40 | 2.224 | 6.4 | |

| 70 | 2.022 | 8.1 | |

| 100 | 2.007 | 8.5 | |

| 5 | 0 | 2.286 | 4.4 |

| 40 | 2.239 | 7.3 | |

| 70 | 2.030 | 8.9 | |

| 100 | 2.015 | 9.4 | |

| 6 | 0 | 2.303 | 4.5 |

| 40 | 2.250 | 8.1 | |

| 70 | 2.049 | 9.4 | |

| 100 | 2.026 | 10.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Hu, J. Mechanical and Durability Properties of Cement-Stabilized Recycled Concrete Aggregate. Sustainability 2020, 12, 7380. https://doi.org/10.3390/su12187380

Li Q, Hu J. Mechanical and Durability Properties of Cement-Stabilized Recycled Concrete Aggregate. Sustainability. 2020; 12(18):7380. https://doi.org/10.3390/su12187380

Chicago/Turabian StyleLi, Qingfu, and Jing Hu. 2020. "Mechanical and Durability Properties of Cement-Stabilized Recycled Concrete Aggregate" Sustainability 12, no. 18: 7380. https://doi.org/10.3390/su12187380

APA StyleLi, Q., & Hu, J. (2020). Mechanical and Durability Properties of Cement-Stabilized Recycled Concrete Aggregate. Sustainability, 12(18), 7380. https://doi.org/10.3390/su12187380