Abstract

Biofuels and biochemicals play significant roles in the transition towards a fossil-free society. However, large-scale biorefineries are not yet cost-competitive with their fossil-fuel counterparts, and it is important to identify biorefinery concepts with high economic performance. For evaluating early-stage biorefinery concepts, one needs to consider not only the technical performance and process costs but also the economic performance of the full supply chain and the impacts on feedstock and product markets. This article presents and demonstrates a conceptual interdisciplinary framework that can constitute the basis for evaluations of the full supply-chain performance of biorefinery concepts. This framework considers the competition for biomass across sectors, assumes exogenous end-use product demand, and incorporates various geographical and technical constraints. The framework is demonstrated empirically through a case study of a sawmill-integrated biorefinery producing liquefied biomethane from forestry and forest industry residues. The case study results illustrate that acknowledging biomass market effects in the supply chain evaluation implies changes in both biomass prices and the allocation of biomass across sectors. The proposed framework should facilitate the identification of biorefinery concepts with a high economic performance which are robust to feedstock price changes caused by the increase in biomass demand.

1. Introduction

Lignocellulosic biorefineries producing biofuels and biochemicals are likely to play a significant role in the transition towards a fossil-free society [1,2]. This is especially true for forest-rich countries such as Sweden, Finland, and Canada, where the prevalence of forestry and forest industries provides by-products (such as sawdust, bark, and harvesting residues), which could be a potential future feedstock for large-scale biorefinery deployment. Sweden has, for example, projections of biofuels accounting for 57% by 2030, and 91% by 2045 of the energy use in the road transport sector to reach targets for greenhouse gas emission reductions [3]. The use of forest and forestry by-products makes eventual biofuel products compliant with the EU renewable energy directive (RED II), which restricts the use of primary biomass for biofuel production [4], and also makes it possible to integrate the biorefinery supply chain with the traditional forest industries. Since biomass that can be considered to be sustainable is a limited resource [5,6], it is important to optimize the environmental and economic performance of biorefineries [7]. Many technologies with a potential to contribute a significant share to greenhouse gas emission reductions are currently not available in commercial scale and are not yet cost-competitive with their fossil-fuel counterparts. Early-stage evaluations are therefore needed to identify promising low-cost biorefinery concepts. This article proposes—and demonstrates—an interdisciplinary framework for conducting such evaluations.

A variety of design variables affect the economic performance of a biorefinery, such as choice of location, feedstock, conversion technology, and final product(s). These aspects are commonly included in assessments conducted using supply chain optimization models [8,9], which minimize the system costs for a given set of constraints. Typically, feedstock and product transport costs are determined endogenously, whereas biomass-to-product yields and feedstock prices are included exogenously. However, some supply chain modeling frameworks have also included selection of key process design variables [10,11]. While all main design decision variables are considered in these cases, the output may nevertheless be misleading since market price interactions are typically not acknowledged.

Firstly, the implementation of large-capacity biorefineries will affect a variety of feedstock prices due to the increased demand for the specific feedstocks used in the process. Secondly, the price signal from increased competition for a given feedstock will lead to a re-allocation of other feedstocks in the biomass market. This will result in complex price formation mechanisms for the feedstocks included in the model, which in turn means that the feedstock prices assumed in the supply chain evaluation model may no longer be valid when the concept is assumed to be deployed in large scale. Since biomass feedstock costs generally constitute a large fraction of a biorefinery’s total production costs [12,13], unrealistic assumptions regarding cheap and abundant feedstocks risk giving rise to misleading results [14]. Previous research has also highlighted that, to fully assess the future environmental performance of emerging technologies, the system in which these will be implemented needs to be considered in full [15], this reasoning is extended to the economic performance in this work.

Uncertain price developments, if accounted for, are usually managed in supply chain modeling approaches of biorefineries or bioenergy projects through the use of various price and demand scenarios [10,16,17], or stochastic price processes to simulate future prices [18]. Both historic price data [19] and future price predictions from established analytics centers [20] have been suggested as commodity price data to be used in techno economic assessments. Relatedly, previous research has combined market analysis with techno-economic analysis [21], and vice versa [22]. However, these approaches do not consider the price dynamics caused by the change under evaluation, e.g., impacts on biomass feedstock prices resulting from the introduction of large-scale forest-based biofuel production, and/or the effects on other users. This has been acknowledged by Mustapha et al. [23], who combined economic modeling with energy system modeling to analyze the effects on the Nordic heat and power sector of large-scale forest-based biofuel production. The results showed significant impacts on the use of biomass for heat and power production, and the authors stressed the importance of accounting for the competition for biomass when evaluating large-scale introduction of bioenergy conversion technologies.

There is a current need for increased interdisciplinary efforts when assessing the performance of emerging biorefinery concepts [24], and disciplinary boundaries that limit the scope of analysis have been identified as a key challenge for sustainability assessments of biorefineries [25]. While there is a significant body of knowledge related to biomass-to-product yield estimations, supply chain evaluations, and biomass feedstock markets, there is, to the best of the authors’ knowledge, a lack of studies that combine knowledge from all three domains into a coherent analytical framework that can be used to evaluate the performance of biorefinery concepts.

In this article, we propose an interdisciplinary modeling framework for evaluating the full supply-chain performance of biorefinery concepts. It addresses techno-economic aspects as well as endogenously determined feedstock prices, and thus the competition for feedstock. The proposed framework is illustrated empirically through a case study which builds on the observation that integration of biorefinery concepts with different host industries can offer benefits regarding overall efficiency and economic performance [7,26,27,28]. In this context, existing forest industries are of particular interest due to the potential availability of biomass-derived by-products that can be used as feedstock, as well as significant experience in operating large-scale biomass supply chains. Therefore, we consider the possibility for the biorefinery to be co-located at existing industrial sites, including the need for appropriate descriptions of the integration synergy gains. The case study aims to explicate the differences in the economic performance of the biorefinery supply chain when considering endogenous instead of exogenous biomass prices.

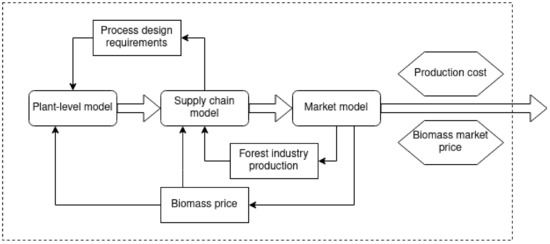

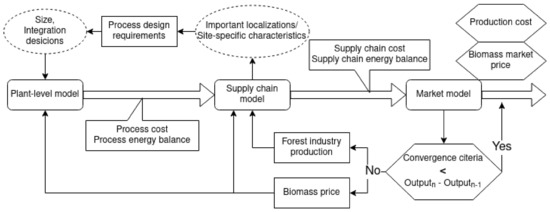

Figure 1 provides a general overview of the proposed modeling framework including the data flows between three generic models; a plant-level model for process evaluation (left), a supply chain model (in the middle), and a market model (right). The supply chain model feeds techno-economic data to the market model, which in turn provides market-based feedstock price data back to the supply chain model and to the plant-level model, for which new data are generated to the market model. After a sufficient number of iterations, the market model will generate new biomass equilibrium price. The economic performance can be assessed by testing different combinations of technologies and biomass feedstocks in an iterative process, as well as price changes in the forest and bioenergy sectors.

Figure 1.

Overview of the proposed modeling framework.

The remainder of this paper is organized as follows: Section 2 identifies and summarizes key aspects from the literature regarding the evaluation of biorefinery concepts. Section 3 presents the proposed framework for combining these aspects for modeling purposes, followed by the case study that demonstrates the framework (Section 4), and a concluding discussion (Section 5).

2. Evaluating Biorefinery Concepts: Lessons from the Literature

This section introduces the main perspectives used for evaluating the economic performance of integrated biorefineries. These perspectives include: (1) detailed plant-level process evaluation for identifying integration benefits, biomass-to-product yields and process costs, (2) supply chain considerations for identifying economically beneficial localizations and supply chain configurations, and (3) economic market modeling for identifying the biomass market impacts in terms of biomass prices. We also give a brief overview of examples of combined or integrated assessment approaches from the literature.

2.1. Techno-Economic Aspects

The full techno-economic system performance of a biorefinery concept depends on several decisions related to the supply chain configuration—from the supply side concerning the biomass feedstock to the final product. We differentiate between the methods needed to determine the plant-level performance, which relates to the choices of equipment and process parameters at each site, and the methods needed to quantify the supply chain performance. The latter includes plant-level performance but also decisions concerning, for instance, harvesting site, modes of transport, and localization of the facilities.

2.1.1. Plant-Level Aspects

A biorefinery generally includes biomass handling and pre-treatment units, followed by the main processing unit or units, which can be based on thermochemical or biochemical conversion. Thereafter, unwanted by-products are removed and the remaining components are converted to the desired end-product(s). The performance of the biorefinery will depend on the equipment and the chosen operating parameters, which determine the biomass-to-product yield and the plant’s energy and mass balances. It is also important to apprehend the plant’s investment cost as well as costs for integrating the plant at the host site.

Techno-economic evaluations are needed to assess the biomass-to-product yield, energy efficiency, and production cost [29,30,31]. Such studies typically investigate and/or optimize the production costs of a biorefinery process in a bottom-up model that includes detailed descriptions of process equipment and material and energy flows. The system boundaries are often limited to the process, thus ignoring both the supply-chain perspective and the biomass feedstock market impacts. This implies that, e.g., emissions and their related costs, and feedstock re-allocation and relative price changes that can be derived from an altered feedstock demand, are effectively excluded.

The methods used for modeling the plant-level performance of a biorefinery concept are dependent on the specific technology and technical maturity. Models of commercially available processes, or processes that have been thoroughly researched, can be validated against existing operating data. For ex-ante assessments of new biorefinery concepts, modeling is a more complex issue. Several methods aimed at modeling thermochemical biorefinery processes at the conceptual design stage have been suggested [32,33,34]. For processes with robust experimental data, a bottom-up, statistical approach can be used to validate a process model to establish the mass and energy balances of the process [35,36]. However, for processes where available experimental data are not sufficient for statistical evaluations, simulation models accounting for reaction kinetics or thermodynamic restrictions can be used to simulate the processing unit [30,33]. Using kinetic data can give satisfactory results for limited reactions, but the modeling of all physical and chemical interactions often becomes too complex. Additionally, thermodynamic or restricted thermodynamic models can be introduced in flowsheet simulation software, but this approach often deviates substantially from experimental data. Such approaches are, however, common in, e.g., gasification modeling, mainly due to a lack of better alternatives.

Plant-level models can be used for estimating the process capital costs (CAPEX) and operating costs (OPEX) including feedstock, utilities, operation and maintenance, and revenues from process by-products. The capital costs include the direct equipment purchase cost of each process unit as well as indirect costs such as costs for start-up, contingency, and installation. Biorefineries typically benefit from economies of scale, i.e., specific CAPEX costs decrease with plant size [37,38].

2.1.2. Supply Chain Aspects

The techno-economic performance of a biorefinery concept can be significantly affected by plant location. Plant-level evaluations commonly take into consideration detailed site-specific characteristics. However, these characteristics can vary significantly between different sites, e.g., in terms of feedstock availability, regional characteristics, modes of transport, localization of potential host industries for integration (and their characteristics), and the prevalence of competing biomass users, which can impact the total supply chain costs [39,40,41]. These variables affect transport costs which can constitute a significant part of the total cost of the supply chain configuration [42,43]. It is therefore important to include the decision variables affecting the biomass transport cost when evaluating the total biorefinery supply chain cost.

The configuration of the supply chain considering these decision variables can be analyzed using supply chain optimization models. These models can include a variety of components, e.g., supply chain design, planning and operation, technology selection, and different environmental sustainability metrics [41]. The aim is to capture larger fractions of the costs and emissions that occur for a biorefinery concept, and that is typically not addressed in plant-level evaluations.

The supply chain optimization models that investigate facility localization problem have mostly been implemented as mixed integer linear problems (MILP), where binary variables are used to represent the establishment of a facility at a given site, and the continuous variables represent the material flows in the studied system [44]. The MILP implementation is suitable both because it facilitates the representation of large-scale problems, and since it can be used to describe a large number of variations of the supply chain problem, including social and ecological objectives [45], as well as strategic, tactical, and operational perspectives [46,47]. However, this approach requires a large number of decision variables to describe complex problems, and can, therefore, lead to long computational times [46,48]. MILP problems also have difficulties in incorporating supply chain uncertainties, such as demand fluctuations, biomass supply variations, and biomass price changes [47]. Moreover, due to the linear nature of the modeling approach, it is difficult to account for nonlinear behavior, such as fully capturing the costs for increases in production capacity (economies-of-scale). This can be mitigated by using discrete capacity steps as inputs to the model; alternatively, the facility capacities can be determined outside the optimization procedure.

When using a supply chain model that includes not only the characteristics of potential localizations but also other industrial sites that compete for the same feedstock, it is possible to capture the changes in costs for transportation in the entire studied system [28,49,50]. Generally, such models rely on plant-level evaluations to determine the biomass-to-product yield and the investment costs (or investment cost function), which are used as exogenous input data. These types of studies typically minimize total system cost to identify economically viable biorefinery concepts.

2.2. Market Aspects

The economic performance of a biorefinery concept will depend on the prices of the biomass feedstock used. However, the introduction of a large-scale biorefinery will in turn affect these feedstock prices. For this reason, it is essential to consider the price formation in the biomass market. Biomass markets involve different types of feedstocks and products, which often serve a diverse set of industries. This leads to a competition for the feedstock, and the allocation of feedstocks and products between competing industries will be influenced by changes in relative prices.

Furthermore, the nature of the products sold in the biomass market differs. For our purposes, it is useful to distinguish between two main categories: main products and by-products. The main product alone determines the economic viability of a given plant; the by-product is instead produced in association with the main product (e.g., sawdust generated at a sawmill), and its price will not influence output decisions at the plant. This distinction is important for understanding supply behavior in the market. In particular, production of by-products is often comparatively inexpensive (since no joint costs are incurred), but since the supply is constrained by the output of the main product, the own-price elasticity of supply could be very low. For this reason, the by-product market price will increase significantly if the demand for the goods which use the by-products as inputs increases [51].

Two key points can be made concerning the competition for feedstock in the context of novel biorefinery concepts [52]. Firstly, to be economically attractive for the production of new end products, the biomass feedstock must be priced low enough so that it can compete financially with, most notably, fossil fuels as feedstock (e.g., in the transport sector). Secondly, the financial returns on biomass feedstock production must be high enough to allow the suppliers of the processed biomass-based products to compete with alternative users for the required biomass resources. In other words, if a by-product is to be allocated to the production of, e.g., liquefied biomethane (see Section 4), this sector’s willingness to pay for the by-product must be higher than the corresponding willingness to pay by actors that manufacture other products (e.g., particleboard) using the same feedstock. A high willingness to pay in one sector thus implies higher costs for these other producers, and, in the case of by-products, this price increase can be significant, as discussed above.

To analyze how the introduction of new biorefinery concepts will affect prices and resource allocation patterns in biomass markets, it is necessary to adopt an economic model that addresses the demand and supply conditions for all feedstocks and products in these markets. For this purpose, the partial equilibrium (PE) modeling approach can be adopted, which has been used extensively for the analysis of forest product markets [53,54,55,56,57,58,59]. In PE modeling, market behavior is often described using supply and demand functions with some pre-defined behavioral parameters, e.g., price elasticities. By maximizing the sum of producer and consumer surplus under certain restrictions (e.g., biomass feedstock constraints), the model is solved and endogenous feedstock prices and resource allocation patterns are generated. A common approach is the so-called activity analysis in which input–output (IO) coefficients define the inputs used to produce one unit of output [60]. A PE model can contain many IO coefficients for many combinations of feedstocks and end-use products, including also various locations.

While PE models typically address the interactions between a selection of economic sectors, so-called Computable General Equilibrium (CGE) models provide a consistent description of how all sectors of the economy interact following changes in relative prices. Such models also include the public sector and address the impacts on the national budget. CGE models can, therefore, be particularly useful when analyzing the effects of changes in economy-wide policy instruments, such as carbon and energy taxes. Thus, in studies focusing less on the specific behavior of the biomass market and more on the domestic effects of biofuel policies, CGE models are often used [61,62,63]. However, the ability to describe all feedback mechanisms in the overall economy is often associated with less-detailed representations of the key sectors of interest. For our purposes, it is important to as far as possible avoid the latter, and, for this reason, the PE modeling approach will constitute one component of the proposed framework.

2.3. Integrated Assessments

Most studies evaluating various biorefinery concepts focus on either techno-economic or environmental aspects of bioenergy projects (or a combination of the two), as concluded in a comprehensive review of forest biomass supply chains [64]. There is, nevertheless, a recent trend to also integrate social aspects to analyze trade-offs between economic, environmental, and social dimensions of sustainable forest biomass supply chains [65,66]. Multi-criteria assessment has been proposed as a suitable approach to assess the overall sustainability of biorefinery and bioenergy processes and systems; it enables the simultaneous inclusion of biophysical, economic, and social factors [67]. Multi-objective optimization approaches can be used to analyze trade-offs between different objectives in biorefinery supply chains [68,69].

However, the price dynamics of the biomass feedstock and the associated by-products, as triggered by the introduction of large-scale biorefinery production have largely been excluded in previous research. The importance of accounting for such price dynamics when evaluating forest biomass systems was demonstrated by Mustapha et al. [23], who hard-linked a PE forest sector model with a PE energy model to analyze the effects on the heat and power sector following large-scale forest-based biofuel production. The results indicated that disregarding the competition for the biomass feedstock might lead to an over-estimation of future bioenergy production levels.

When hard-linking models (“formal linking”), the models are fully integrated and used to solve a simultaneous optimization problem, i.e., the constituent models are merged into a single model with a single objective function (compare multi-objective optimization). An alternative to this approach is so-called soft-linking (“informal linking”), which is characterized by an iterative process where the models are optimized or solved separately and data are then exchanged between the models. According to [70], the main advantages of soft-linking are practicality, transparency, and learning, and those of hard-linking are productivity, uniqueness, and control. Hard-linking often implies a simplified description of one or both of the sub-models, whereas soft-linking enables the complexities of even relatively large sub-models to be kept more or less intact [71,72]. Furthermore, soft-linking provides flexibility regarding the choice of interacting models and has been shown to work successfully for the linking of marked-based (PE or CGE) models with techno-economic energy system models [73,74,75]. Soft-linking thus offers the potential to combine the respective strengths of a detailed technology representation in energy system models, with the market price formation in PE models.

As mentioned above, a biorefinery model includes many decision variables and several of these can be broken down into disaggregated models to increase the accuracy of the final results. Compared to hard-linking where the models share a common objective function, which adds much more requirements on data similarities and similar modeling structures, soft-linking has many benefits for a flexible interdisciplinary framework evaluating various biorefinery concepts. Furthermore, models can be removed in favor of another model, all depending on the research question of interest.

3. An Inter-Disciplinary Modeling Framework: A Proposal

Our proposed interdisciplinary modeling framework combines techno-economic approaches and a market approach to evaluate biorefinery concepts accounting for endogenous feedstock price formation. To illustrate key theoretical aspects in techno-economic and market evaluations, respectively, we first present three schematic modeling approaches and describe the iteration of models with different modeling structures and objective functions. While our framework and the case study focus on the evaluation of forest-based biorefineries based on thermochemical conversion pathways, other biorefinery routes could also be evaluated by adapting the included models and input data.

The framework is constructed with three central key performance indicator (KPI) categories in mind: (i) biomass feedstock prices, (ii) biomass feedstock allocation and production levels among sectors and industries, (iii) and production costs for the biorefinery products. These are chosen to provide insight into the market effects related to implementing biorefinery concepts, as well as to gain information regarding the production cost of the end-use products of interest. However, the KPIs may be exchanged depending on the purpose of the application of the framework.

3.1. Plant-Level and Supply Chain Modeling: Techno-Economic Performance

The first step to identify the full techno-economic performance is the evaluation of the plant-level process configuration, which is needed to determine both the mass and energy balances and the required capital investment. This can be challenging when evaluating emerging biorefinery technologies and concepts, where reliable data can be difficult or impossible to obtain [76]. If sufficient information about the process is available, we advocate the application of process heat integration methods (e.g., pinch analysis) to estimate the minimum net energy that needs to be added to the process [77]. This is recommended when designing integrated production systems, where special emphasis shall be put on the efficient use of energy and minimization of environmental impacts [78]. The proposed modeling framework includes the capability to account for the exchange of heat between the biorefinery process and the host industrial site. Process integration methods and tools can also be used to guide modifications to the energy system of the host process. Heat integration of a biorefinery plant at the host site can often result in a combined primary energy usage that is lower compared to stand-alone operations of the two process plants. Furthermore, some types of biorefinery may have a total heat surplus that is large enough and at a sufficiently high temperature to enable electricity generation in a high-efficiency steam turbine cycle.

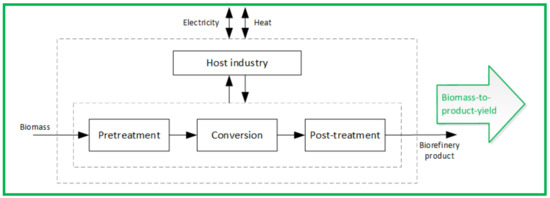

Figure 2 shows the proposed generic process model for evaluating biomass-to-product yields for a biorefinery plant integrated with a given host industry (e.g., a sawmill, refinery, or chemical cluster). The model input includes biomass feedstock composition and moisture content, as well as process unit operating parameters (e.g., reactor temperatures and pressures). The model quantifies the energy and mass balances of the plant; this is in turn required to calculate the net heat and electricity generated or required by the process, and the overall efficiencies. Generally, we suggest to not model host industries individually, since these industries already exist and are therefore not subject to design. Instead, process stream data or generalized models of different process types can be applied to capture potential process integration opportunities. Typical industries suitable for energy integration include pulp and paper mills, sawmills, petrochemical plants, and oil refineries. District heating networks could also be suitable as hosts for new biorefineries.

Figure 2.

Overview of the plant-level process model of a generic forest biomass-based biorefinery integrated with a host industrial process plant. For a stand-alone application of the plant-level model, see [26].

The output data from the plant-level process model includes biomass conversion yield, i.e., the quantity of biorefinery product(s) produced per quantity of biomass input, together with the net energy balances. Together with capital cost data and the running costs of the process, this constitutes the input data to the market and supply chain models, respectively.

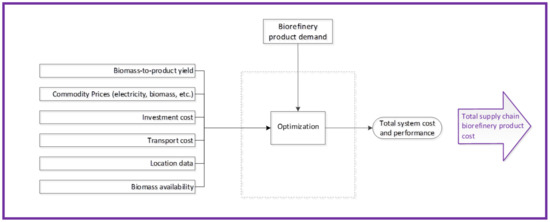

The next step is to apply a supply chain optimization model, which also considers procurement of the biomass feedstock, including transport, as well as changes in supply for other industries due to the new biomass demand of the biorefinery. We propose the use of a geographically explicit MILP model for the analysis of the localization of biorefineries, given that the model must be able to handle both geographical aspects, such as the spatial distribution of biomass supply and demand and the potential locations and plant configurations that were determined in the plant-level model. The system performance can thus be determined considering various geographical restrictions, not only due to net feedstock availability but also due to restrictions related to integration opportunities. Figure 3 presents a schematic overview of the inputs and outputs of the supply chain model.

Figure 3.

Overview of the suggested supply chain optimization model. Data in the left-hand boxes are exogenous parameters to the model. For stand-alone applications of the supply chain model, see, e.g., [28,50].

The model is driven by the exogenously specified end-use product demand for one or more biorefinery products. This demand may be determined based on, for instance, policy objectives or forecasted market demand. Based on this demand, the supply chain optimization model can identify the biorefinery supply chain configuration with the lowest total system cost, and in this way, the system performance cost of various biorefinery concepts can be determined. Depending on the design of the study, a multi- or single-technology problem can be investigated; the lowest cost solution could result in one or more biorefineries needed to satisfy the product demand.

In the proposed modeling approach, the total system cost includes all supply chain costs addressed in the model, e.g., transport costs, feedstock costs, technology costs, etc. The total transport cost is endogenously determined in the supply chain model depending on modes of transportation and transport distances. To limit the size of the total problem to be solved, we propose that the electricity market is handled exogenously and viewed as a fixed demand market. This entails that surpluses or deficits of electricity at biorefineries are assumed to be resolved by selling or purchasing electricity.

The output from the supply chain model is a set of biorefinery localizations and concepts that achieve the lowest total system cost. From this output, the system performance for each biorefinery site can be determined. The biorefinery performance costs are then used as inputs to the market model.

3.2. Market Modeling: Feedstock Allocation and Prices

The contribution of the market model in this framework is to allow for endogenous price formation of biomass feedstock considering the competition for the biomass. Key output variables from the market model are biomass feedstock allocation and prices, and biorefinery production costs and production levels. We propose to use a single-country generic PE model describing, for instance, the forestry and bioenergy sectors covering the same geographical scope as the supply chain model, to investigate price formation in the forest biomass market. The reason for choosing a PE model is that it allows for disaggregated data, which is desirable in the context of the forest biomass markets with many products and actors. The proposed modeling structure is similar to several previous PE forest sector models [23,60,79]. It is a microeconomic model focusing on a single country’s forest biomass market. The demand for end-use products and energy is exogenous, whereas production, conversion, and demand and supply of intermediate products are endogenously determined. International trade is represented through trade with one aggregate region (‘rest of the world’), which is a competitor to the domestic regions.

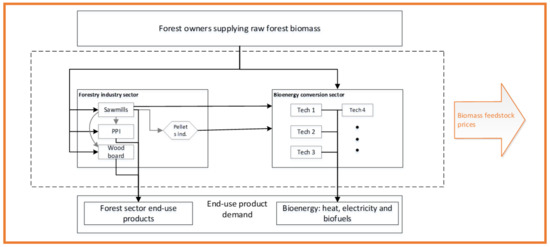

Figure 4 illustrates the main actors and biomass flows in the proposed model. In this setting, the forest industries, and the bioenergy sector both demand biomass, either as a feedstock or as fuel. The forest industries also act as suppliers of by-products both within the sector, and to the bioenergy sector. The dashed box in Figure 4 represents the interconnection between the forestry industry and the bioenergy conversion sector. The smaller boxes inside this box represent the industries and bioenergy conversion activities (representing different technology conversion options e.g., combined heat and power, heat-only production, or gasification for production of biofuels) which are represented by input–output coefficients.

Figure 4.

Overview of the suggested forest biomass market model. Supply of raw forest biomass and demand for energy and forestry end-use products are expressed exogenously to the model, shown as the upper and lower box, respectively. PPI = Pulp and paper industry. For a stand-alone application of the market model, see [53].

The objective of the market model is to maximize social welfare, i.e., the producer and consumer surplus, and to identify the corresponding optimal allocation of biomass given the exogenously given demand and supply constraints. This in turn generates endogenous feedstock prices, which can be fed back to the supply chain model and the plant-level model. For a policy scenario in which a given quota of, e.g., all transportation fuel must come from forest biofuels, the market model will choose the least-cost option to produce both forest industry and energy products given this constraint. This will lead to a reallocation of feedstocks and will therefore also affect the biomass market prices.

3.3. Integrated Assessment: Overall Economic Performance

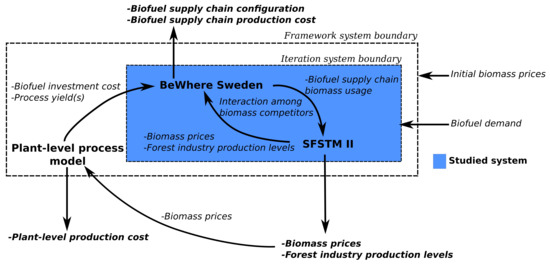

Figure 5 provides an overview of our suggested iterative model-linking process between the three different models. This enables the evaluation of the performance of various biorefinery concepts using techno-economic evaluations while at the same time considering changes in feedstock prices associated with the introduction of the biorefinery concept(s).

Figure 5.

Iteration procedure of the modeling framework.

As noted above, the respective individual models have different modeling structures, including different data aggregation levels of the data. Therefore, some data must be modified before the model integration. It is particularly important to make sure that biomass assortments are classified into the same categories in the supply chain model as in the market model. In addition, differences related to spatial resolution must be managed. In our case, the supply chain model includes exogenously determined plant-specific data and also generates plant-specific output data, whereas the market model is aggregated on sectors and large geographical regions. Our proposed solution is to adjust the output data from the supply chain model before entering the market model, by aggregating the supply chain model results per biorefinery technology and type of host. By creating a single cost for conversion for each process technology and industry type, rather than for each process technology and specific industry localization, some discrepancy between the technology representations in the supply chain and market model will occur. However, by using this approach, the specific site characteristics are implicitly included also in the market model.

The iteration procedure, as shown graphically in Figure 5, can then be summarized as follows:

- Biorefinery product yield and derived overall plant mass and energy balances are the main output data from the plant-level model. Together with the inventory of heat integration opportunities and process plant costs (CAPEX and OPEX), they constitute the input variables to the supply chain model.

- Together with biomass prices from the market model, the supply chain model will identify the technology mix that satisfies the demand for the specified biorefinery product at the lowest cost.

- The biomass prices and industrial production levels determined through the market model constitute new input data to the supply chain model through an iterative feedback loop

- The new biomass prices influence the performance cost for the different technology options in the supply chain model, which may in turn influence the lowest-cost supply chain configuration. If the new cost-minimizing supply chain differs from the previous solution, the resulting biorefinery technology choices and localizations constitute an input to the plant-level model through a second feedback loop.

- The new results from the plant-level modeling again constitute inputs to the supply chain model, and the latter will generate an updated performance cost. These new results provide updated biomass requirements and cost data to the market model that generate new biomass prices and allocation to competing sectors.

- For each iteration N, the new biomass prices and forest industry production levels determined by the market model are compared to the results generated in iteration N − 1 When the results from at iteration N differs from the results from iteration N− 1 by less than the specified convergence criterion, the solution is assumed to have converged. The biomass price, forest industry production levels, and biorefinery product costs of the last iteration are retained as the final resulting output data.

Theoretically, the data iterated between the models will eventually converge (defined as the difference between output data from iteration N and N − 1). However, given the structure of the framework, with separate models interconnected through soft-linking, convergence issues may arise. If the supply chain model responds to the changes in prices and production levels with substantial changes to supply chain configurations, the model solutions may diverge. This can be handled by applying an under-relaxation factor, by which the changes in output prices and production levels from the market model between the iterations are decreased by a specified factor. This means that if, e.g., the feedstock prices and production levels increase a lot between two iterations, the feedback to the supply chain model is lowered by a certain factor, compared to the actual output data from the market model.

4. Case Study: Demonstrating the Framework

The proposed integrated framework is demonstrated for a case study of a biorefinery concept integrated with a sawmill. The biorefinery produces liquefied biomethane (LBG) through gasification of forest biomass is followed by downstream conditioning and synthesis of the product gas. The case study aims to highlight the differences in the economic performance of the biorefinery supply chain when using exogenous biomass prices and forest industry production levels (current-exogenous biomass market scenario), and when the changes in biomass prices and forest industry production levels are endogenized (iterative-endogenous biomass market scenario)by applying the iterative soft-linking framework. The geographical scope is the national borders of Sweden, and the analysis is static over one year.

As described above, both the supply chain model and the market model are driven by an exogenously determined biorefinery product demand. We set the demand for LBG to be 4 TWh/a, assuming it to be used in the transport sector. This can be compared to future fuel usage scenarios for the Swedish transport sector, which include up to 4.2 TWh/a of gaseous biofuels by 2040 [80], and to the recent Swedish biomass market state public inquiry, which proposes a production target for non-aerobic digestion-derived biogas of 3 TWh/a by 2030 [81].

The biomass assortments allowed for the production of LBG are limited to forest and forestry industry by-products, tops and branches, industrial by-products, and wood chips. This complies with the EU renewable energy directive (RED II), which restricts the use of primary biomass for biofuel production [4].

As the focus of the case study is to demonstrate the soft-linking between the supply chain and market model, the option to modify the site-specific configuration—i.e., the “process reconfiguration” feedback loop in Figure 5—is excluded from the analysis.

4.1. Applying the Modeling Framework

4.1.1. Plant-Level Model

Two different site-specific configurations for sawmill integrated LBG production are considered. Both were pre-optimized using different heat-integration targets, as described in a previous publication by several of the authors [26]. The configurations are:

Configuration A: All sawmill residues. The LBG plant is sized to be able to process all by-products from the hosting sawmill. This allows the biorefinery to be self-sufficient regarding feedstock for LBG production and enables minimized transport costs for the LBG supply chain.

Configuration B: All sawmill residues excluding wood chips. The biorefinery is sized to be able to process all by-products from the hosting sawmill except the wood chips. This restriction recognizes that this assortment constitutes an important feedstock for the domestic pulp and paper industry.

Both biorefinery configurations are allowed to use harvesting residues (tops and branches) as feedstock. In both cases, the excess heat from the biorefinery is used to cover a portion of the hosting sawmill’s heat demand for product drying.

4.1.2. Supply Chain Model

The techno-economic supply chain performance is analyzed using the geographically explicit biorefinery localization model BeWhere Sweden. This model includes spatial data for, e.g., feedstock supply and demand, with a detailed site-specific representation of both potential host sites and competing industries, including also a description of the internal energy flows and demands of host sites for biorefinery integration. The model encompasses the national boundaries of Sweden and is divided into grid cells with a half-degree spatial resolution, resulting in 334 grid cells. It is a mixed integer linear programming (MILP) model written in GAMS using CPLEX as a solver. For a more detailed description, see [50,82,83]. The objective of the model is to minimize the total system cost to satisfy the demand for domestically produced LBG, while simultaneously satisfying the exogenously defined biomass feedstock demand in the other industries (forest industry, stationary energy sector). The total system cost includes costs for biomass, transport and distribution, electricity, as well as CAPEX and OPEX for new plants.

The objective of the model is to minimize the total system cost to satisfy the demand for domestically produced LBG, while simultaneously satisfying the exogenously defined biomass feedstock demand in the other industries (forest industry, stationary energy sector). The total system cost is dependent on the decision variables (continuous as well as binary). The decision variables included in the supply chain model were: choice of localization of facilities (binary), the flow of LBG from production sites to demand site (continuous), and the flow of biomass from harvesting sites to biomass demand sites (continuous). The LBG production capacity is dependent on the size of the hosting sawmill; therefore, the nonlinearity of the capital investment was addressed outside of the optimization.

4.1.3. Market Model

The market model used is the Swedish forest sector trade model (SFSTM II), which is a PE model that simulates the Swedish forest biomass market (based on [84,85,86], including the Swedish forest sector, and the bioenergy-using heat and power sector and transport (biofuel) sectors. The model encompasses the national borders of Sweden divided into four regions, and an additional region covering trade with the rest of the world. The model is a nonlinear programming model written in GAMS using CONOPT as the solver, and the model objective is to maximize total consumer and producer surplus to obtain equilibrium prices, industry production levels, and resource allocation; see [53,86] for a more detailed overview of the model as applied in the chosen context. The maximization of the producer and consumer surplus is dependent on the following decision variables, which are all continuous: demand of consumer goods (e.g., sawn wood, heat, and power), harvest of roundwood and harvesting residues, new industrial production, output of main products (e.g., production from forest industries), roundwood delivered, new industrial production capacity, quantity traded between regions, and quantity of energy demand. The reference year for industrial production levels and biomass prices is described in Section 4.2.2.

4.1.4. Model Linking

For the implementation of the soft-linking procedure involving BeWhere Sweden and SFSTM II, the following data are passed between the models:

- From BeWhere Sweden: biomass assortments and quantities used in the LBG production.

- From SFSTM II: forest industry production levels and new equilibrium biomass prices.

The different output parameters from the different sub-models together with the data treated as exogenous to this study are shown in Figure 6.

Figure 6.

Schematic description of the iterative framework and the system studied in this case study.

Thus, in our case study demonstration, the iterative procedure proceeds according to the following:

- Initialization of the process. Using the market model SFSTM II to generate the current industrial production and biomass prices without the introduction of the biorefinery; these data are used as inputs to the supply chain model BeWhere Sweden.

- BeWhere Sweden minimizes the total system cost while simultaneously satisfying a specified biofuel demand and the biomass demand from industries (which are dependent on their production levels). The specific biomass assortments used for producing the biofuel are used as inputs to SFSTM II to represent the biorefinery production technologies.

- SFSTM II is used to simulate new biomass prices and forest industry production levels given the new biofuel production levels.

- The iterative process (steps 2–3) continues until the convergence criteria are fulfilled.

In this case study, convergence is assumed to have been reached when the normalized outputs from SFSTM II between two iterations differed by less than .

There are differences in how biomass assortments are represented in the different models. For instance, BeWhere Sweden distinguishes between biomass assortments from final felling and thinning, but not between different species, while SFSTM II has the opposite representation. To resolve this, price differences between biomass from final felling and thinning are removed in BeWhere Sweden, and the differences in prices between biomass species in SFSTM II are averaged against harvested volumes to be used as inputs in BeWhere Sweden. Likewise, the conversion of the biomass assortments used in LBG production from BeWhere Sweden is weight-adjusted for the representation in SFSTM II.

Differences occur also in the geographical representation of the models, and therefore all biomass grid cells in BeWhere Sweden assume the same biomass prices as the corresponding region in SFSTM II to which they belong. The industrial production is aggregated to a national level rather than keeping changes in industrial production region-specific.

4.1.5. Case Study Evaluation

After the iterative procedure, the total system cost from BeWhere Sweden is used to calculate the biofuel supply cost from the total system cost. The output from SFSTM II is used to identify the impacts on the forest industry production levels and the new biomass market equilibrium prices. We then evaluate the effects of applying the framework by comparing the model outputs when using BeWhere Sweden only (current-exogenous biomass prices and production levels), versus when applying the proposed framework (iterative-endogenous prices and production levels). For this, we consider the converged industrial production levels and biomass prices from SFSTM II, as well as the total system cost and LBG cost of supply from BeWhere Sweden.

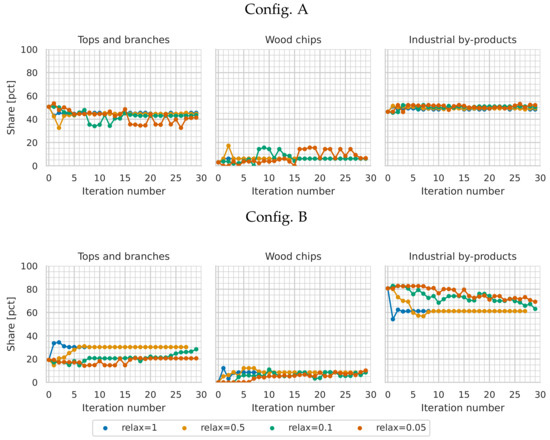

We also evaluate the effect of applying relaxation factors on the convergence of the framework by running the framework both with and without applying relaxation factors. The relaxation factors are applied on data passed in both directions. In this case, a maximum of 30 iterations is used as stopping criteria, applying relaxation factors of 1, 0.5, 0.1, and 0.05, respectively, where a relaxation factor of 1 means that no relaxation is applied. The convergence is then assessed by calculating the sum of the normalized differences in the output from SFSTM II based on the regional biomass prices and industrial production levels, with convergence defined as a change of less than .

4.2. Model Input Data

4.2.1. Biomass Availability

The “Today’s forestry” scenario from the Swedish Forest Agency’s impact assessment (SKA 15) [87] forms the basis for the theoretical potentials for future harvest (final felling and thinning) assuming current practices. The annual supply potential of sawlogs, as modeled in both BeWhere Sweden and SFSTM II, amounts to the equivalent of 89 TWh, of pulpwood to 66 TWh, and tops and branches to 37 TWh. A bottom-up approach described in detail in [40,50,82] was applied to model the spatial distribution of forest biomass. Both BeWhere Sweden and SFSTM II describe the availability of industrial by-products as functions of the production levels of the forestry industries.

4.2.2. Biomass Prices and Industrial Production

SFSTM II consists of two sub-models: one trade-cost model that calibrates prices and feedstock allocation to a reference year, and one that simulates the prices and feedstock allocation is given the introduction of new biorefinery production. The trade-cost model maximizes the sum of producer and consumer surplus and yields the market equilibrium prices, production, and biomass allocation patterns assuming competitive markets. For the calibration procedure, all production and consumption levels are fixed at the reference year values, and the other values are calculated in the model. As data reliability regarding production and consumption levels can sometimes be unreliable, manual adjustments to production levels can be necessary when observed biomass prices (in the reference year) are significantly different compared to the calibrated biomass prices, as large differences are likely to be caused by errors in underlying data. The reference year prices and industrial production levels are presented in Table 1 and Table 2, respectively.

Table 1.

Reference year (2016) market prices of biomass assortments and electricity.

Table 2.

Reference year (2016) forest industry production levels, aggregated by product category [95,96,97].

4.2.3. Technology Data

The LBG facility is based on a dual fluidized bed gasifier integrated with a generic Nordic sawmill. The facility also includes a back-pressure steam turbine. The energetic performances of the two studied LBG plant configurations are presented in Table 3.

Table 3.

Energy performance (LHV) of the biorefinery configurations, derived from [26]

Table 4 shows the overall investment cost function for the LBG facility, derived from data presented in [26].

Table 4.

Investment cost correlation depending on the size of the hosting sawmill. C is the annual production of sawn wood in m3.

For the economic evaluation in BeWhere Sweden, a capital recovery factor (used to annualize the investment cost) of 0.1 was assumed, e.g., corresponding to a discount rate of 8% and an economic lifetime of 20 years.

The biomass assortments allowed to be used for different activities in BeWhere Sweden are shown in Table 5.

Table 5.

Biomass assortments allowed to be used for different productions in BeWhere Sweden.

4.3. Case Study Results

4.3.1. Biorefinery System Performance

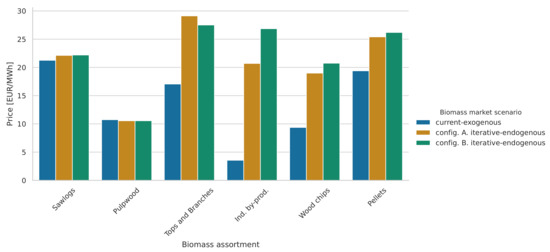

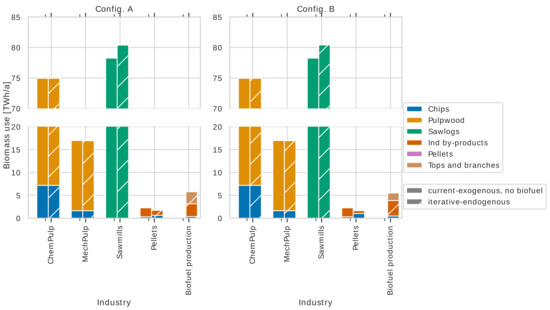

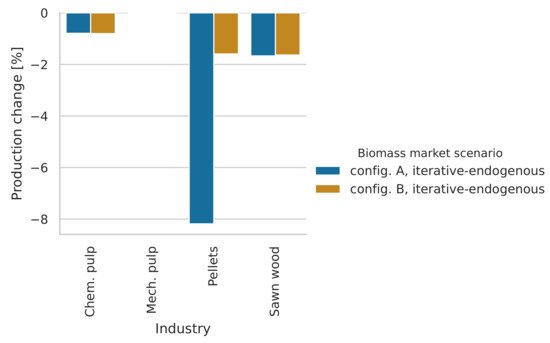

Figure 7 shows three different resulting biomass prices from STSTM II: the current exogenous prices without introduction of biorefinery production (blue bar), and the final endogenous prices at the end of the iteration procedure when considering the introduction of the two different biorefinery technology configurations (light brown and green bars). Correspondingly, Figure 8 shows the resulting biomass use in the different industries and sectors, and Figure 9 the change in industrial production resulting from introduction of the biorefinery.

Figure 7.

Biomass prices before (“current-exogenous”) and after (“iterative-endogenous”, relaxation factor = 1) the introduction of biorefinery production. Output from SFSTM II. Config. A = using all sawmill by-products, Config. B = excluding the wood chips.

Figure 8.

Biomass use (TWh/a) in the different industries before (“current-exogenous”) and after (“iterative-endogenous”, relaxation factor = 1) the introduction of biorefinery production. Output from SFSTM II. Config. A = using all sawmill by-products, Config. B = excluding the wood chips.

Figure 9.

Change in forest industry production after the introduction of biorefinery production, when applying the iterative framework. Calculated from SFSTM II output. Config. A = using all sawmill by-products, Config. B = excluding the wood chips.

Interestingly, even though both technology configurations were sized to be able to be feedstock self-sufficient using only internal by-products, the cost-minimizing solutions also include biorefineries that import feedstock in the form of tops and branches. The reason is that the usefulness of tops and branches for other uses is lower than that of the by-product assortments, since they cannot be used for pulp production or pellets production.

The most prominent effect from the biorefinery introduction on existing industries is noted for the pellets industry. This is not due to a physical shortage of industrial by-products, as those are indeed available in sufficient quantities (Figure 8). Instead, it is a result of the high feedstock market prices (Figure 7), which render pellets production unprofitable. All biomass assortments allowed for the biorefinery production, i.e., industrial by-products, wood chips, and tops and branches, show a significant price increase when the LBG production is introduced. The price of pellets also increases due to the increase in feedstock prices, despite pellets not being used as biorefinery feedstock. In contrast, the production in both the sawmills and the pulp and paper industry is relatively unaffected by the biorefinery introduction, despite the potential new competition for feedstocks.

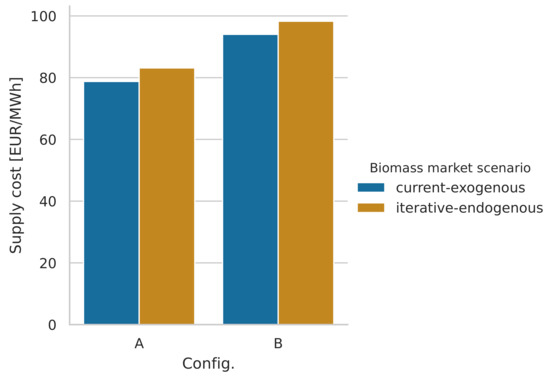

Next, let us examine the effect of applying the iterative framework on the LBG supply cost, shown in Figure 10 for the current-exogenous and iterative-endogenous scenarios, respectively. The cost shown is the total system supply cost, which includes both the direct costs related to the biorefineries, and the indirect costs in the form of increased costs for other biomass users. Unsurprisingly, the system supply cost of LBG increases when endogenous biomass prices are considered, and most significantly so for the biorefinery configuration with the higher specific biomass demand (see Table 3) and higher ultimate market prices for sawmill residues (Figure 7).

Figure 10.

Total system supply cost of produced LBG when using exogenous and endogenous biomass prices, respectively. Output from BeWhere Sweden. Config. A = using all sawmill by-products, Config. B = excluding the wood chips.

4.3.2. Convergence and Relaxation Factors

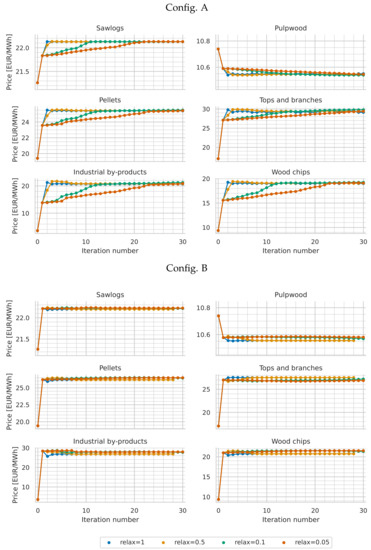

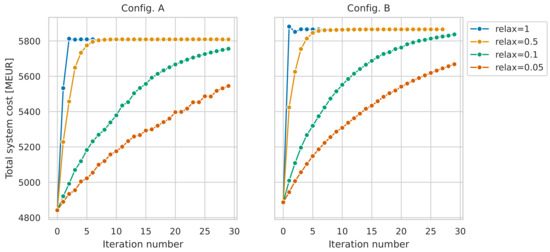

The convergence of the case study was explored by running the framework both with, and without applying relaxation factors. The same same relaxation factor was applied for both directions in the iterative process. Figure 11 displays the average national biomass prices from STSTM II at different iteration counts for the two studied biorefinery technology configurations, Figure 12 the total system cost from BeWhere Sweden at the same iteration counts, and Figure 13 the normalized biomass usage in the biorefineries.

Figure 11.

Biomass prices during the iterative process. Output from SFSTM II. (Top) Config. A = using all sawmill by-products. (Bottom) Config. B = excluding the wood chips.

Figure 12.

Total system cost during the iterative process. Output from BeWhere Sweden. Config. A = using all sawmill by-products, Config. B = excluding the wood chips.

Figure 13.

Biorefinery feedstock composition during the iterative process. Output from BeWhere Sweden. (Top) Config. A = using all sawmill by-products. (Bottom) Config. B = excluding the wood chips.

Noticeably, the relaxation factor has a modest impact on the biomass prices, which all move towards convergence. However, while the biomass prices suggest that the models have converged for all relaxation factors, the total system cost shows that this is not fully the case for the lowest relaxation factors (0.1 and 0.05). In addition, the biomass usage has not converged, as the integrated model framework oscillates between different solutions when lower relaxation factors are applied. While all different relaxation factor scenarios approach the same total system cost, 30 iterations are not enough to reach full convergence. This shows that, for the case demonstrated here, there is no benefit regarding prices and biomass allocation in applying a relaxation factor. This conclusion may, however, be different when evaluating scenarios with higher biorefinery product demand, as this might induce a geographical oscillation between model solutions.

5. Discussion and Future Research

The barriers associated with linking models from different traditions of research is a real obstacle—as not only do the models differ in structure and objective function, but the researchers representing the fields also have different agendas. The use of soft-linking enables models to be brought together representing different aspects of a topic while keeping the integrity of the models intact. The proposed framework is an example of how to soft-link models from the techno-economic tradition with the models in economics built upon market behavior.

Regarding future developments of this framework, it should be noted that so far it has been developed to improve the economic assessment of biorefinery concepts. However, as the main political interest in new biorefinery concepts lies in the possibility of substituting fossil-fuel products and energy carriers, additional variables in the form of, for example, greenhouse gas emissions related to the biorefinery supply chain can be included in the framework by attributing the different flows with the corresponding emissions. Extending the framework by including external environmental costs in the objective function enables further analysis of the cost associated with large-scale deployment of biorefinery technologies, as both the impact on the supply chain and the competing industries are captured.

Depending on the chosen system boundaries in the techno-economic evaluation of the biorefinery technology, the economic performance could be affected differently by the changing biomass market prices. To further evaluate how the proposed framework can provide additional insights into the economic performance of biorefinery technologies, it needs to be tested for case studies with a larger set of technologies and biofuel demand scenarios.

The current literature regarding economic evaluations of emerging technologies emphasizes that future market prices need to be considered. However, this is rarely done in a way that endogenizes the market price impacts from the deployment of the technology; see, for example, [8,9,10,11,28], which risks overestimating the economic performance. Combining the presented framework with scenario-based future market prices should provide a comprehensive understanding of the possible future economic performance of a technology and make it possible to reduce the risk of guiding policy support and investment towards technologies prone to future cost escalations due to changes in the feedstock market.

The framework developed and demonstrated here is particularly focused on the evaluation of lignocellulosic biorefinery concepts. However, it should be noted that the framework structure can be extended to other areas as well. This framework is particular of interest for evaluations of emerging technologies where the feedstock constitutes a significant portion of the total cost, and especially where the potential feedstock is currently traded in a competitive market, which improves data availability for formulating the market model.

Finally, to further increase the accuracy of the economic assessment, the framework may also be soft-linked with other national models covering other countries (biomass markets) to simulate trade effects as a consequence of changing feedstock prices. A more sophisticated trade analysis would also provide insights regarding the exporting possibilities for a product produced in a specific biorefinery concept, as well as contribute to a broader environmental assessment.

6. Conclusions

We have proposed and demonstrated a soft-linking framework in an attempt to bridge the gap between techno-economic modeling and market modeling in the assessment of emerging biorefinery concepts. We showed that the final price effects of introducing a new biorefinery concept at a large scale are far from straightforward to forecast, as prices are formed in markets where any price changes affect both feedstock allocation and production levels in affected industries and sectors.

Three general insights can be discerned from the case study. Firstly, the use of static supply chain optimization models and exogenous biomass prices for the analysis of the biorefinery supply chains neglects the availability of suitable feedstocks due to changed allocations on the biomass markets. Secondly, neglecting the biomass price changes that are induced by the implementation of the biorefinery leads to erroneous relative biomass market prices. This might lead to specific biomass assortments being identified as preferable to use for the biorefinery, which might not be the case given their price changes as a result of the increased demand. Thirdly, the underestimation of the effect of higher feedstock costs might lead to overestimations of the potential of forest-based biorefinery products to penetrate the market.

Based on this, we argue that the framework developed in this paper can be used to facilitate the identification of biorefinery concepts with high economic performance and that in turn are robust to feedstock price changes caused by the biorefinery introduction. Furthermore, the proposed framework complements forest sector models used to analyze exogenous shifts in biomass markets, in that it also enables the explicit inclusion of flexible technology and supply chain optimization, focused on the final biorefinery product. In contrast to a static pre-selection of technology to be included in a market model, the benefit of the iterative framework is the iteration of information between the model that generates one stable solution considering all the decision variables included. The cost-minimizing choice of technology depends on feedstock prices. The feedstock prices are in turn dependent on the technologies included. Thus, optimal technologies included in a market model may not be optimal when feedstock prices have adjusted to the new production. The proposed framework ensures that the technologies included in the market model are chosen to minimize total supply cost also when the feedstock price changes. A biorefinery has many decision variables, and ignoring some of the key aspects is likely to result in misleading conclusions, with the risk of sending out conflicting policy recommendations.

Author Contributions

Conceptualization, J.Z., E.B., and J.A.; Formal analysis, J.Z., E.B., J.A., P.S., S.H., and E.W.; Funding acquisition, P.S., S.H. and E.W.; Methodology, J.Z., E.B., and J.A.; Supervision, P.S., S.H., and E.W.; Writing—original draft, J.Z., E.B., and J.A.; Writing—review and editing, J.Z., E.B., J.A., P.S., S.H., and E.W. All authors have read and agreed to the published version of the manuscript.

Funding

The work has been carried out under the auspices of Forskarskolan Energisystem financed by the Swedish Energy Agency. Economic support from Bio4Energy, a strategic research environment appointed by the Swedish government, is also gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CAPEX | capital expenditure |

| CGE | computational general equilibrium |

| IO | input–output |

| KPI | key performance indicator |

| LBG | liquefied biomethane |

| LHV | lower heating value |

| MILP | mixed integer linear programming |

| OPEX | operational expenditure |

| PE | partial equilibrium |

References

- Connolly, D.; Mathiesen, B.; Ridjan, I. A Comparison between Renewable Transport Fuels That Can Supplement or Replace Biofuels in a 100% Renewable Energy System. Energy 2014, 73, 110–125. [Google Scholar] [CrossRef]

- Fulton, L.M.; Lynd, L.R.; Körner, A.; Greene, N.; Tonachel, L.R. The Need for Biofuels as Part of a Low Carbon Energy Future. Biofuels Bioprod. Biorefining 2015, 9, 476–483. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Kontrollstation 2019 För Reduktionsplikten; Technical Report; Swedish Energy Agency: Eskilstuna, Sweden, 2019. [Google Scholar]

- The European Parliament; The Council of the European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018, 61, 82–209. [Google Scholar]

- De Jong, J.; Akselsson, C.; Egnell, G.; Löfgren, S.; Olsson, B.A. Realizing the energy potential of forest biomass in Sweden—How much is environmentally sustainable? For. Ecol. Manag. 2017, 383, 3–16. [Google Scholar] [CrossRef]

- Eggers, J.; Melin, Y.; Lundström, J.; Bergström, D.; Öhman, K. Management strategies for wood fuel harvesting-trade-offs with biodiversity and forest ecosystem services. Sustainability 2020, 12, 4089. [Google Scholar] [CrossRef]

- Börjesson Hagberg, M.; Pettersson, K.; Ahlgren, E.O. Bioenergy Futures in Sweden—Modeling Integration Scenarios for Biofuel Production. Energy 2016, 109, 1026–1039. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Total Footprints-Based Multi-Criteria Optimisation of Regional Biomass Energy Supply Chains. Energy 2012, 44, 135–145. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Shah, N. Multi-Scale Process and Supply Chain Modelling: From Lignocellulosic Feedstock to Process and Products. Interface Focus 2011, 1, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Mansoornejad, B.; Chambost, V.; Stuart, P. Integrating Product Portfolio Design and Supply Chain Design for the Forest Biorefinery. Comput. Chem. Eng. 2010, 34, 1497–1506. [Google Scholar] [CrossRef]

- Sukumara, S.; Faulkner, W.; Amundson, J.; Badurdeen, F.; Seay, J. A Multidisciplinary Decision Support Tool for Evaluating Multiple Biorefinery Conversion Technologies and Supply Chain Performance. Clean Technol. Environ. Policy 2014, 16, 1027–1044. [Google Scholar] [CrossRef]

- Brown, T.R. A Techno-Economic Review of Thermochemical Cellulosic Biofuel Pathways. Bioresour. Technol. 2015, 178, 166–176. [Google Scholar] [CrossRef]

- European Commission; Directorate-General for Mobility and Transport; Waldheim, L.; Kalligeros, S.; Landälv, I.; Maniatis, K.; van den Heuvel, E. Building up the Future Sub Group on ADVANCED Biofuels: Final Report; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Gnansounou, E.; Dauriat, A. Techno-Economic Analysis of Lignocellulosic Ethanol: A Review. Bioresour. Technol. 2010, 101, 4980–4991. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Axelsson, E.; Harvey, S.; Berntsson, T. A Tool for Creating Energy Market Scenarios for Evaluation of Investments in Energy Intensive Industry. Energy 2009, 34, 2069–2074. [Google Scholar] [CrossRef]

- Harvey, S.; Börjesson, P.; Janssen, M.; Lundgren, J. Long-Term Sustainability Assessment of Fossil-Free Fuel Production Concepts; Technical Report 2018:13; f3 The Swedish Knowledge Centre for Renewable Transportation Fuels: Göteborg, Sweden, 2018. [Google Scholar]

- Zhao, X.; Brown, T.R.; Tyner, W.E. Stochastic Techno-Economic Evaluation of Cellulosic Biofuel Pathways. Bioresour. Technol. 2015, 198, 755–763. [Google Scholar] [CrossRef] [PubMed]

- Albrecht, F.G.; König, D.H.; Baucks, N.; Dietrich, R.U. A Standardized Methodology for the Techno-Economic Evaluation of Alternative Fuels—A Case Study. Fuel 2017, 194, 511–526. [Google Scholar] [CrossRef]

- Taal, M.; Bulatov, I.; Klemeš, J.; Stehlík, P. Cost Estimation and Energy Price Forecasts for Economic Evaluation of Retrofit Projects. Appl. Therm. Eng. 2003, 23, 1819–1835. [Google Scholar] [CrossRef]

- Britz, W.; Delzeit, R. The Impact of German Biogas Production on European and Global Agricultural Markets, Land Use and the Environment. Energy Policy 2013, 62, 1268–1275. [Google Scholar] [CrossRef]

- Kempegowda, R.S.; Skreiberg, Ø.; Tran, K.Q. Techno-Economic Evaluations of Various Biomass CHP Technologies and Policy Measures Under Norwegian Conditions. Energy Procedia 2012, 20, 1–10. [Google Scholar] [CrossRef]

- Mustapha, W.F.; Kirkerud, J.G.; Bolkesjø, T.F.; Trømborg, E. Large-Scale Forest-Based Biofuels Production: Impacts on the Nordic Energy Sector. Energy Convers. Manag. 2019, 187, 93–102. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Postawa, K. Total Chain Integration of Sustainable Biorefinery Systems. Appl. Energy 2016, 184, 1432–1446. [Google Scholar] [CrossRef]

- Palmeros Parada, M.; Osseweijer, P.; Posada Duque, J.A. Sustainable Biorefineries, an Analysis of Practices for Incorporating Sustainability in Biorefinery Design. Ind. Crop. Prod. 2017, 106, 105–123. [Google Scholar] [CrossRef]

- Ahlström, J.M.; Pettersson, K.; Wetterlund, E.; Harvey, S. Value Chains for Integrated Production of Liquefied Bio-SNG at Sawmill Sites—Techno-Economic and Carbon Footprint Evaluation. Appl. Energy 2017, 206, 1590–1608. [Google Scholar] [CrossRef]

- Holmgren, K.M.; Berntsson, T.S.; Andersson, E.; Rydberg, T. Comparison of Integration Options for Gasification-Based Biofuel Production Systems—Economic and Greenhouse Gas Emission Implications. Energy 2016, 111, 272–294. [Google Scholar] [CrossRef]

- Zetterholm, J.; Pettersson, K.; Leduc, S.; Mesfun, S.; Lundgren, J.; Wetterlund, E. Resource Efficiency or Economy of Scale: Biorefinery Supply Chain Configurations for Co-Gasification of Black Liquor and Pyrolysis Liquids. Appl. Energy 2018, 230, 912–924. [Google Scholar] [CrossRef]

- Čuček, L.; Martín, M.; Grossmann, I.E.; Kravanja, Z. Multi-Period Synthesis of Optimally Integrated Biomass and Bioenergy Supply Network. Comput. Chem. Eng. 2014, 66, 57–70. [Google Scholar] [CrossRef]

- Heyne, S.; Thunman, H.; Harvey, S. Exergy-Based Comparison of Indirect and Direct Biomass Gasification Technologies within the Framework of Bio-SNG Production. Biomass Convers. Biorefinery 2013, 3, 337–352. [Google Scholar] [CrossRef]

- Tock, L.; Gassner, M.; Maréchal, F. Thermochemical Production of Liquid Fuels from Biomass: Thermo-Economic Modeling, Process Design and Process Integration Analysis. Biomass Bioenergy 2010, 34, 1838–1854. [Google Scholar] [CrossRef]

- Alamia, A.; Magnusson, I.; Johnsson, F.; Thunman, H. Well-to-Wheel Analysis of Bio-Methane via Gasification, in Heavy Duty Engines within the Transport Sector of the European Union. Appl. Energy 2016, 170, 445–454. [Google Scholar] [CrossRef]

- Kangas, P.; Hannula, I.; Koukkari, P.; Hupa, M. Modelling Super-Equilibrium in Biomass Gasification with the Constrained Gibbs Energy Method. Fuel 2014, 129, 86–94. [Google Scholar] [CrossRef]

- Kaushal, P.; Tyagi, R. Advanced Simulation of Biomass Gasification in a Fluidized Bed Reactor Using ASPEN PLUS. Renew. Energy 2017, 101, 629–636. [Google Scholar] [CrossRef]

- Ahlström, J.M.; Alamia, A.; Larsson, A.; Breitholtz, C.; Harvey, S.; Thunman, H. Bark as Feedstock for Dual Fluidized Bed Gasifiers-Operability, Efficiency, and Economics. Int. J. Energy Res. 2019, 43, 1171–1190. [Google Scholar] [CrossRef]

- Alamia, A.; Thunman, H.; Seemann, M. Process Simulation of Dual Fluidized Bed Gasifiers Using Experimental Data. Energy Fuels 2016, 30, 4017–4033. [Google Scholar] [CrossRef]

- Moncada, B.J.; Aristizábal, M.V.; Cardona, A.C.A. Design Strategies for Sustainable Biorefineries. Biochem. Eng. J. 2016, 116, 122–134. [Google Scholar] [CrossRef]

- Wright, M.; Brown, R.C. Establishing the Optimal Sizes of Different Kinds of Biorefineries. Biofuels Bioprod. Biorefining 2007, 1, 191–200. [Google Scholar] [CrossRef]

- Blair, M.J.; Cabral, L.; Mabee, W.E. Biorefinery Strategies: Exploring Approaches to Developing Forest-Based Biorefinery Activities in British Columbia and Ontario, Canada. Technol. Anal. Strateg. Manag. 2017, 29, 528–541. [Google Scholar] [CrossRef]

- de Jong, S.; Hoefnagels, R.; Wetterlund, E.; Pettersson, K.; Faaij, A.; Junginger, M. Cost Optimization of Biofuel Production—The Impact of Scale, Integration, Transport and Supply Chain Configurations. Appl. Energy 2017, 195, 1055–1070. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-Bioenergy and Biofuel Supply Chain Optimization: Overview, Key Issues and Challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Golecha, R.; Gan, J. Biomass Transport Cost from Field to Conversion Facility When Biomass Yield Density and Road Network Vary with Transport Radius. Appl. Energy 2016, 164, 321–331. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Development of Tortuosity Factor for Assessment of Lignocellulosic Biomass Delivery Cost to a Biorefinery. Appl. Energy 2014, 119, 288–295. [Google Scholar] [CrossRef]

- Ghaderi, H.; Pishvaee, M.S.; Moini, A. Biomass Supply Chain Network Design: An Optimization-Oriented Review and Analysis. Ind. Crop. Prod. 2016, 94, 972–1000. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable Supply Chain Network Design: An Optimization-Oriented Review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Papageorgiou, L.G. Supply Chain Optimisation for the Process Industries: Advances and Opportunities. Comput. Chem. Eng. 2009, 33, 1931–1938. [Google Scholar] [CrossRef]

- Sharma, B.; Ingalls, R.; Jones, C.; Khanchi, A. Biomass Supply Chain Design and Analysis: Basis, Overview, Modeling, Challenges, and Future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; Van Orshoven, J. Methods to Optimise the Design and Management of Biomass-for-Bioenergy Supply Chains: A Review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- Natarajan, K.; Leduc, S.; Pelkonen, P.; Tomppo, E.; Dotzauer, E. Optimal Locations for Second Generation Fischer Tropsch Biodiesel Production in Finland. Renew. Energy 2014, 62, 319–330. [Google Scholar] [CrossRef]

- Pettersson, K.; Wetterlund, E.; Athanassiadis, D.; Lundmark, R.; Ehn, C.; Lundgren, J.; Berglin, N. Integration of Next,-Generation Biofuel Production in the Swedish Forest Industry—A Geographically Explicit Approach. Appl. Energy 2015, 154, 317–332. [Google Scholar] [CrossRef]

- Söderholm, P.; Lundmark, R. The Development of Forest-Based Biorefineries: Implications for Market Behavior and Policy. For. Prod. J. 2009, 59, 6–16. [Google Scholar]

- Sedjo, R.A. The Economics of Forest-Based Biomass Supply. Energy Policy 1997, 25, 559–566. [Google Scholar] [CrossRef]

- Bryngemark, E. Second Generation Biofuels and the Competition for Forest Raw Materials: A Partial Equilibrium Analysis of Sweden. For. Policy Econ. 2019, 109, 102022. [Google Scholar] [CrossRef]

- Caurla, S.; Delacote, P.; Lecocq, F.; Barkaoui, A. Stimulating Fuelwood Consumption through Public Policies: An Assessment of Economic and Resource Impacts Based on the French Forest Sector Model. Energy Policy 2013, 63, 338–347. [Google Scholar] [CrossRef]

- Geijer, E.; Bostedt, G.; Brännlund, R. Damned If You Do, Damned If You Do Not—Reduced Climate Impact vs. Sustainable Forests in Sweden. Resour. Energy Econ. 2011, 33, 94–106. [Google Scholar] [CrossRef]

- Kangas, H.L.; Lintunen, J.; Pohjola, J.; Hetemäki, L.; Uusivuori, J. Investments into Forest Biorefineries under Different Price and Policy Structures. Energy Econ. 2011, 33, 1165–1176. [Google Scholar] [CrossRef]