Safe and Ecological Speed Control for Heavy-Duty Vehicles on Long–Steep Downhill and Sharp-Curved Roads

Abstract

1. Introduction

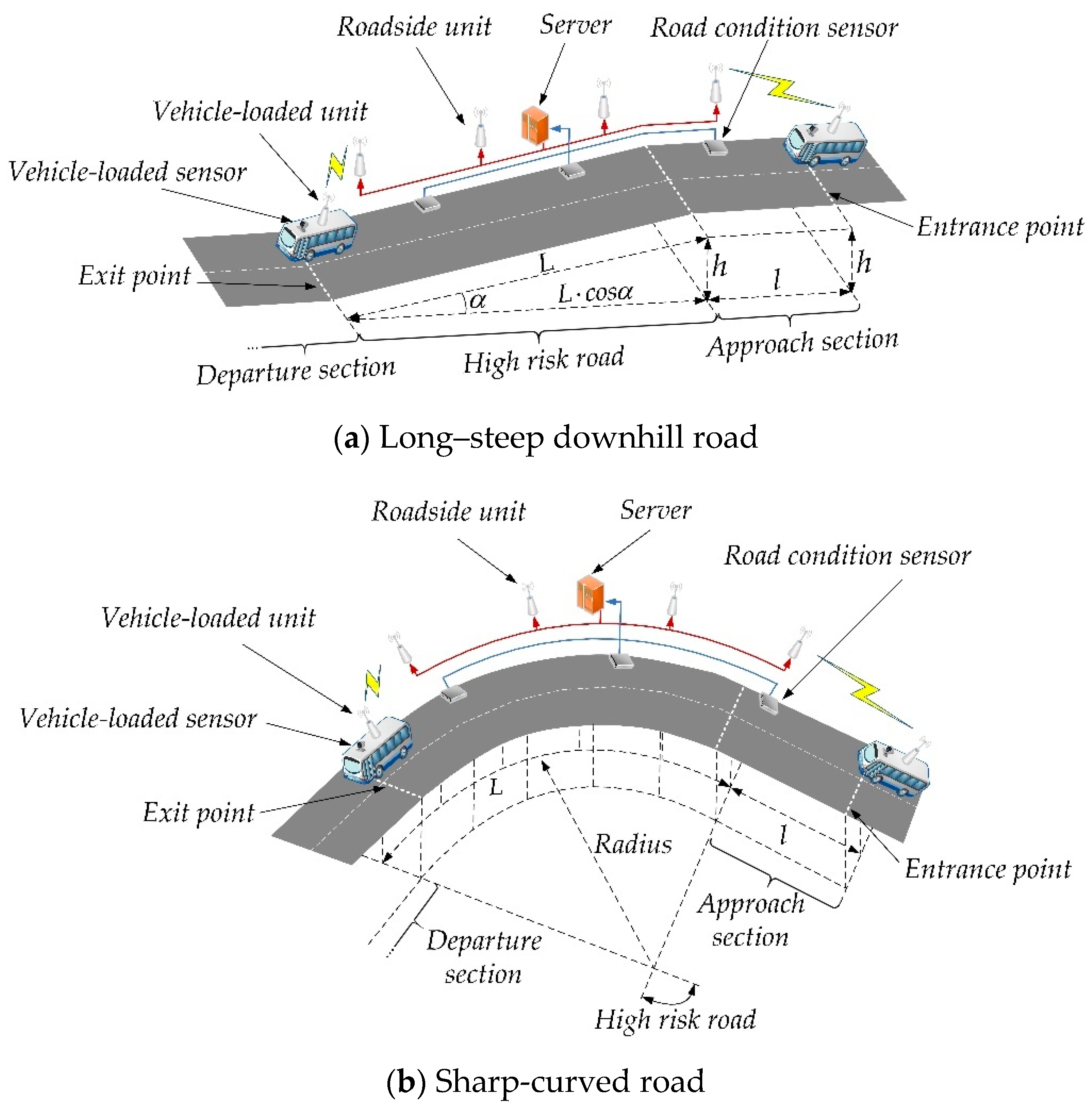

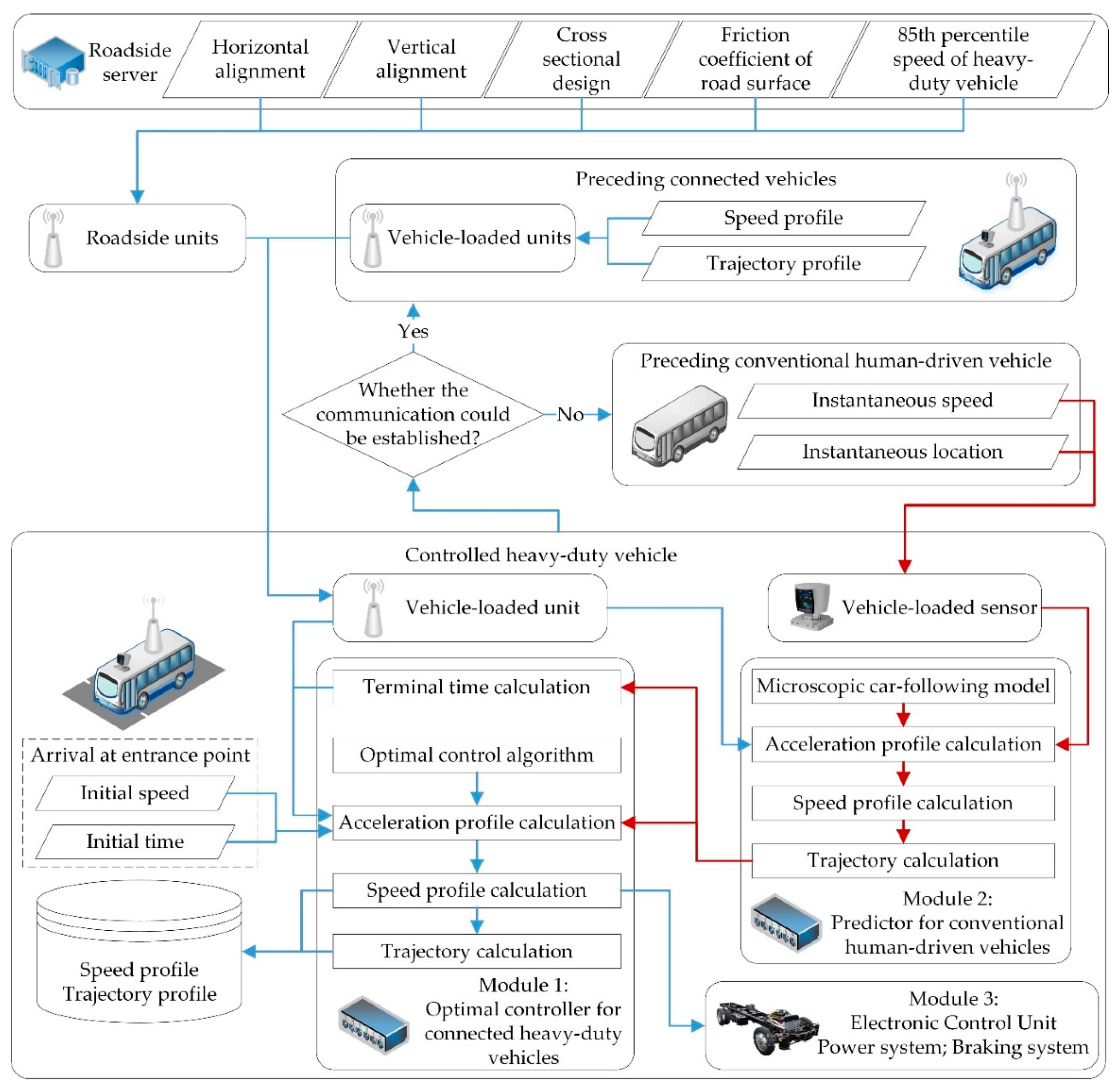

2. Control Structure

- (1)

- Road condition sensors and communication devices installed along both high-risk roads and their approaching sections. Road condition sensors monitor the friction coefficient of road surface in real-time by infrared spectral analysis technology, which is free from dependence on information of weather and temperature around the sensors. Communication devices provide information on road design and surface conditions for connected heavy-duty vehicles (CHDVs) named “Roadside units”. List format hanging 0.75.

- (2)

- Communication devices installed on CHDVs to enable communication between multiple vehicles or between vehicles and roadside units called “Vehicle-loaded units”.

- (3)

- Sensors installed on CHDVs to obtain the state of their preceding unconnected vehicles.

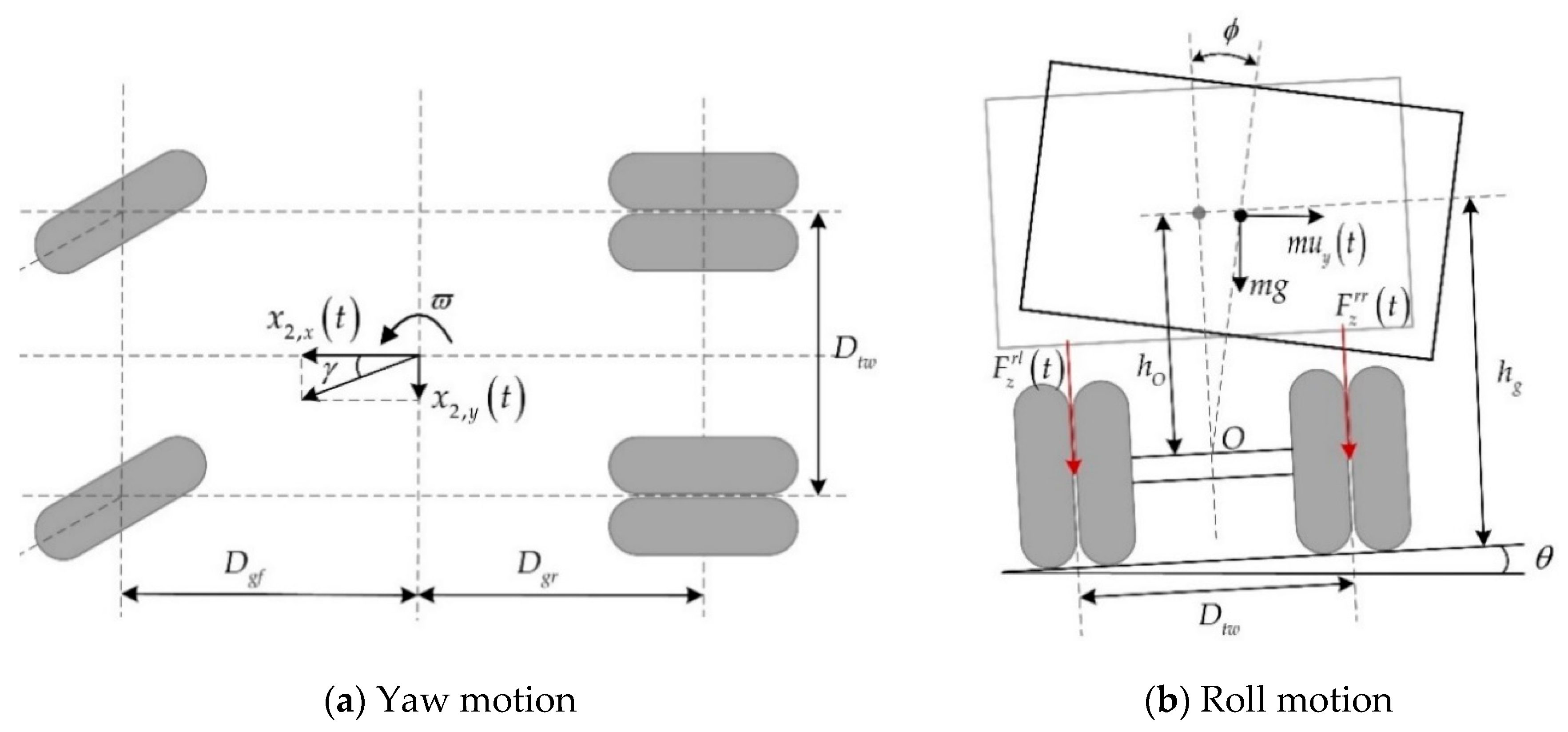

3. Mathematical Formulation

- (1)

- The optimal speed profile is adopted by the CHDV as the desired speed and can be overruled by the car-following behavior to guarantee safety.

- (2)

- The desired speed of conventional human-driven vehicles equals the 85th percentile speed of all heavy-duty vehicles that have safely driven through the high-risk roads; all the human-driven vehicles run at the desired speed unless impeded by the preceding vehicle.

- (3)

- The friction coefficient of road surface is accurately monitored by road condition sensors, and the measured values are not affected by traffic flow on the road. The wind speed equals 0 km/h.

3.1. Optimal Controller for Connected Heavy-Duty Vehicles

3.1.1. State Explanation

3.1.2. Cost Function

3.1.3. Conditions and Constraints

3.1.4. Brake Drum Temperature Rise Model

3.1.5. Lateral Stability Model

3.1.6. Solution Based on Pontryagin’s Minimum Principle

3.1.7. Iterative PMP Algorithm to Solve the Optimal Control

- Step 1: Initialize the co-state , .

- Step 2: Start the iterative solving process with the iteration number .

- Step 3: Solve Equation (43) forward in time subject to the initial conditions and constraints for state using co-state . The downhill gradient and curve radius are updated according to the vehicle’s actual position.

- Step 4: Solve Equation (42) backwards in time for co-state with .

- Step 5: Update the co-state with the weight factor that can smooth the co-state updating process, .

- Step 6: If the error , then stop the iteration; otherwise, set and loop back to step 3. is the pre-set error threshold.

3.2. Predictor for Conventional Human-Driven Vehicles

- (1)

- When the predicted conventional vehicle is driving on the approach sections connected to high-risk roads, it will prefer to gradually decelerate to a desired speed before entering said high-risk roads. The desired speed of the predicted vehicle equals its initial speed at the entrance point, . The speed and location of its virtual preceding vehicle are

- (2)

- When both the predicted conventional vehicle and its virtual preceding vehicle are traveling on high-risk roads, the predicted vehicle will maintain a stable net distance from the virtual preceding vehicle. The desired speed of the predicted vehicle is the 85th percentile speed of all heavy-duty vehicles, . The speed and location of its virtual preceding vehicle are

- (3)

- When the predicted conventional vehicle is driving on high-risk roads, and its virtual preceding vehicle is traveling on the departure section, the predicted vehicle will gradually increase speed until leaving the high-risk roads. The desired speed of the predicted vehicle remains equal to the 85th percentile speed of all heavy-duty vehicles. The speed and location of the virtual preceding vehicle can be calculated as

4. Simulation and Evaluation

4.1. Simulation Platform and Scenarios

- (1)

- MATLAB/Simulink is the master control program and is responsible for optimizing the speed profiles of the CHDVs, predicting the speed profiles of the conventional human-driven vehicles, and communicating between TruckSim and VISSIM. The optimal controller for CHDVs and the predictor for conventional human-driven vehicles of the proposed speed control system are only implemented in MATLAB/Simulink. The input of the optimal controller and predictor are information on acceleration, speed and location of CHDVs and conventional human-driven vehicles transmitted from VISSIM.

- (2)

- VISSIM establishes the test roads and conducts a microscopic traffic simulation on high-risk roads using its own microscopic car-following model called “Wiedemann 74”. To ensure the realness of the simulation results output from VISSIM, the Wiedemann 74 car-following model is calibrated according to the Highway Capacity Manual 2010, the base saturation flow rate of single lane equals 1830 veh/h. The Wiedemann 74 car-following model could simulate complex vehicle interactions realistically on a microscopic level, and thereby verify the accuracy of predictor in module 2 improved from IDM car-following model. The optimal speed advisory transmitted from MATLAB/Simulink is written to the corresponding CHDV as the “Desired Speed”. Then, the motion profiles of the CHDVs and conventional human-driven vehicles generated in VISSIM are sent to the optimal controller and predictor in MATLAB/Simulink, and are transmitted to TruckSim as the control input for the vehicles through MATLAB/Simulink.

- (3)

- TruckSim constructs a dynamics model of heavy-duty vehicles and configures the CHDVs or conventional human-driven vehicles to run according to the corresponding speed profiles obtained from VISSIM. To ensure the realness of the simulation results output from VISSIM, the dynamics model of heavy-duty vehicles is calibrated by field test data of a heavy-duty vehicle called “Sinotruk HOWO”.

4.2. Simulation Results

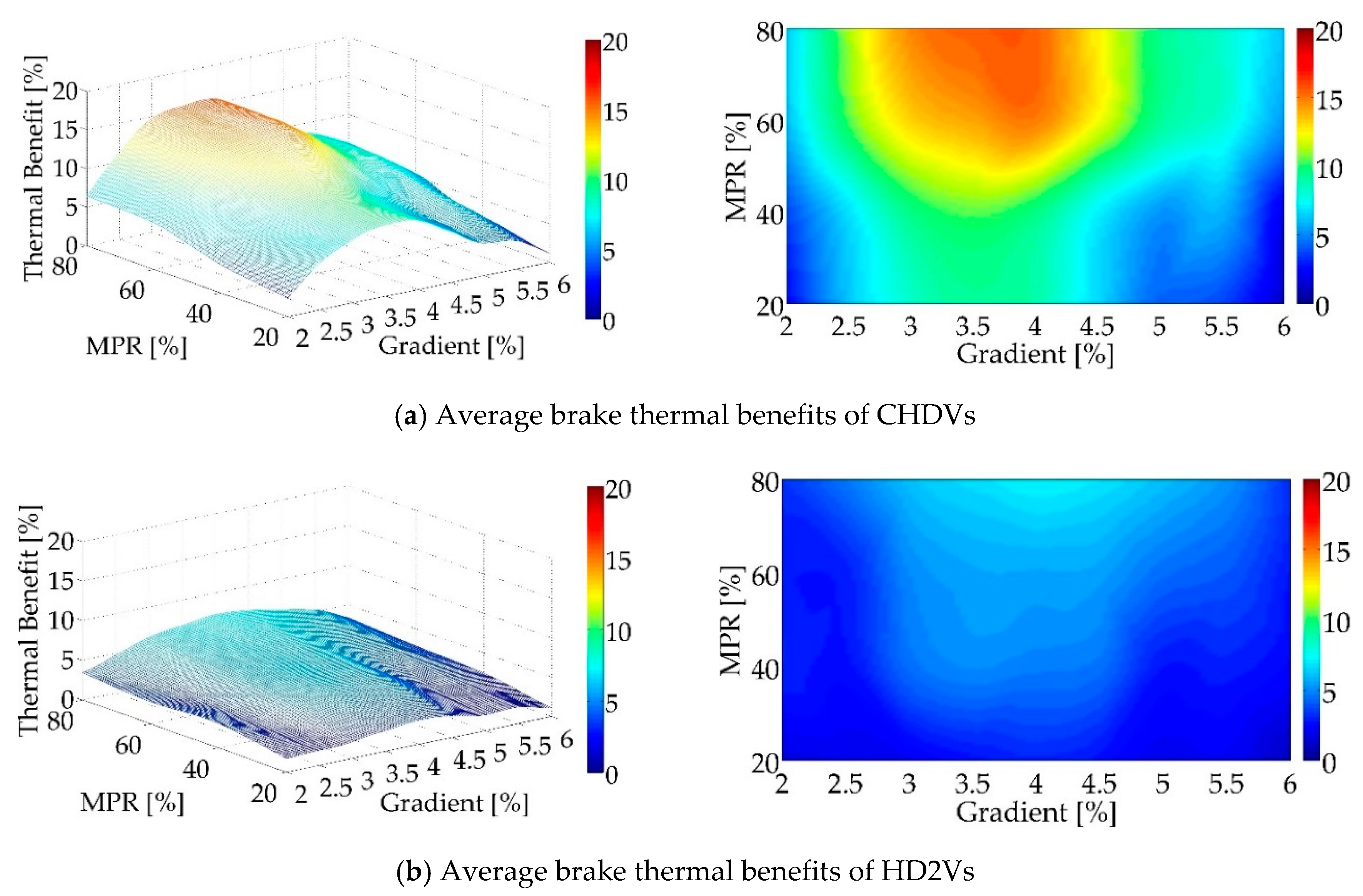

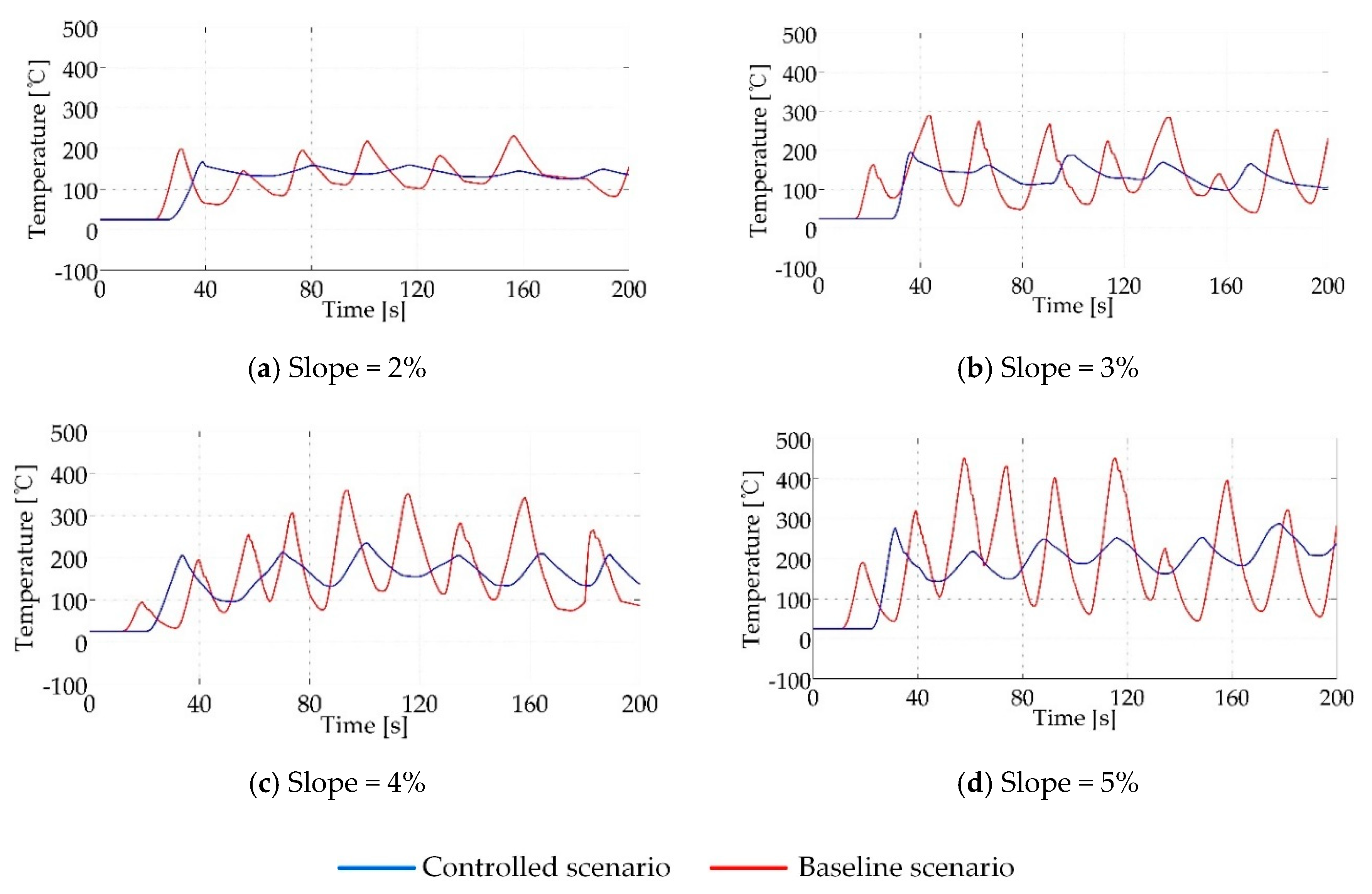

4.2.1. Brake Stability

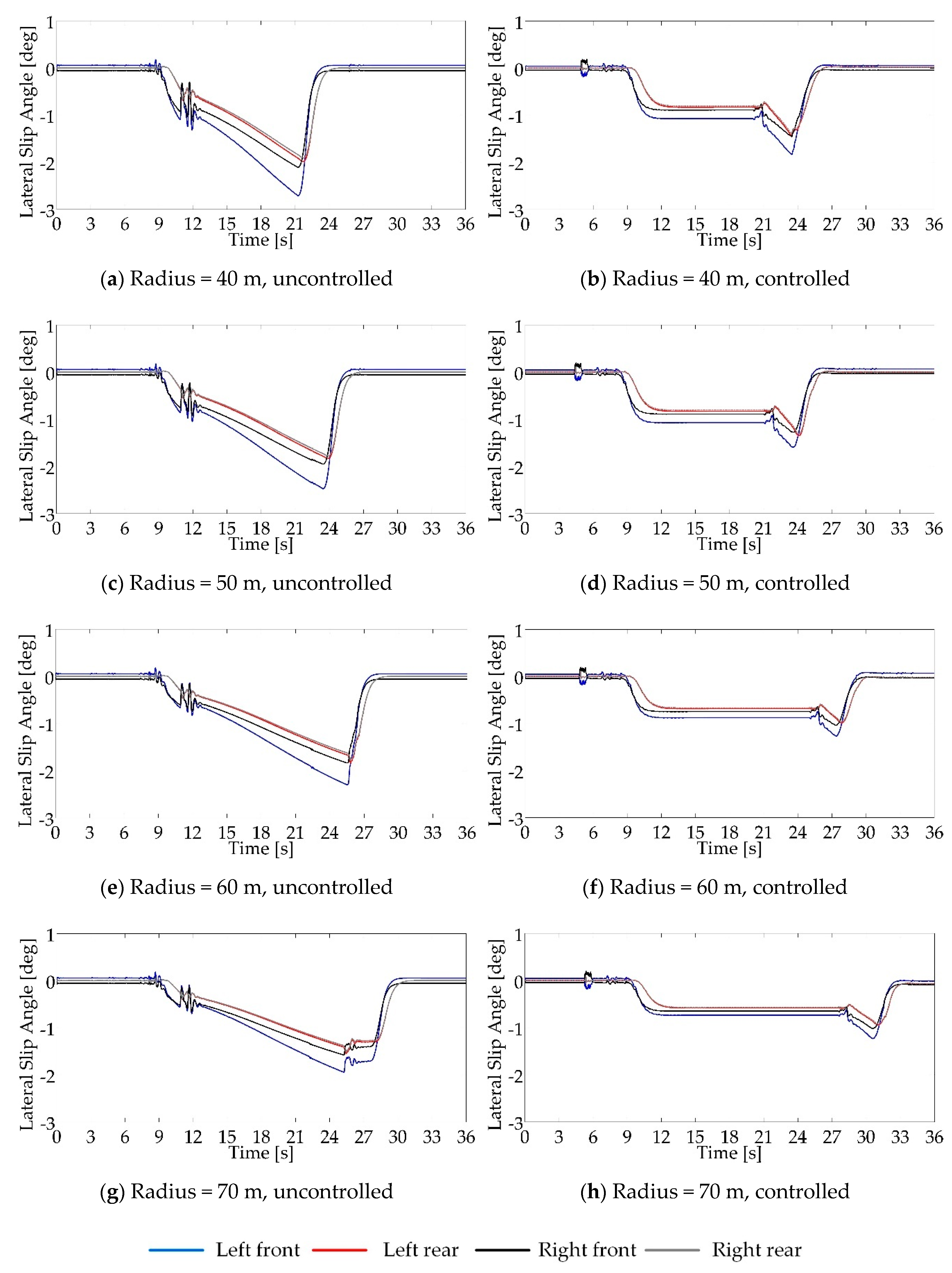

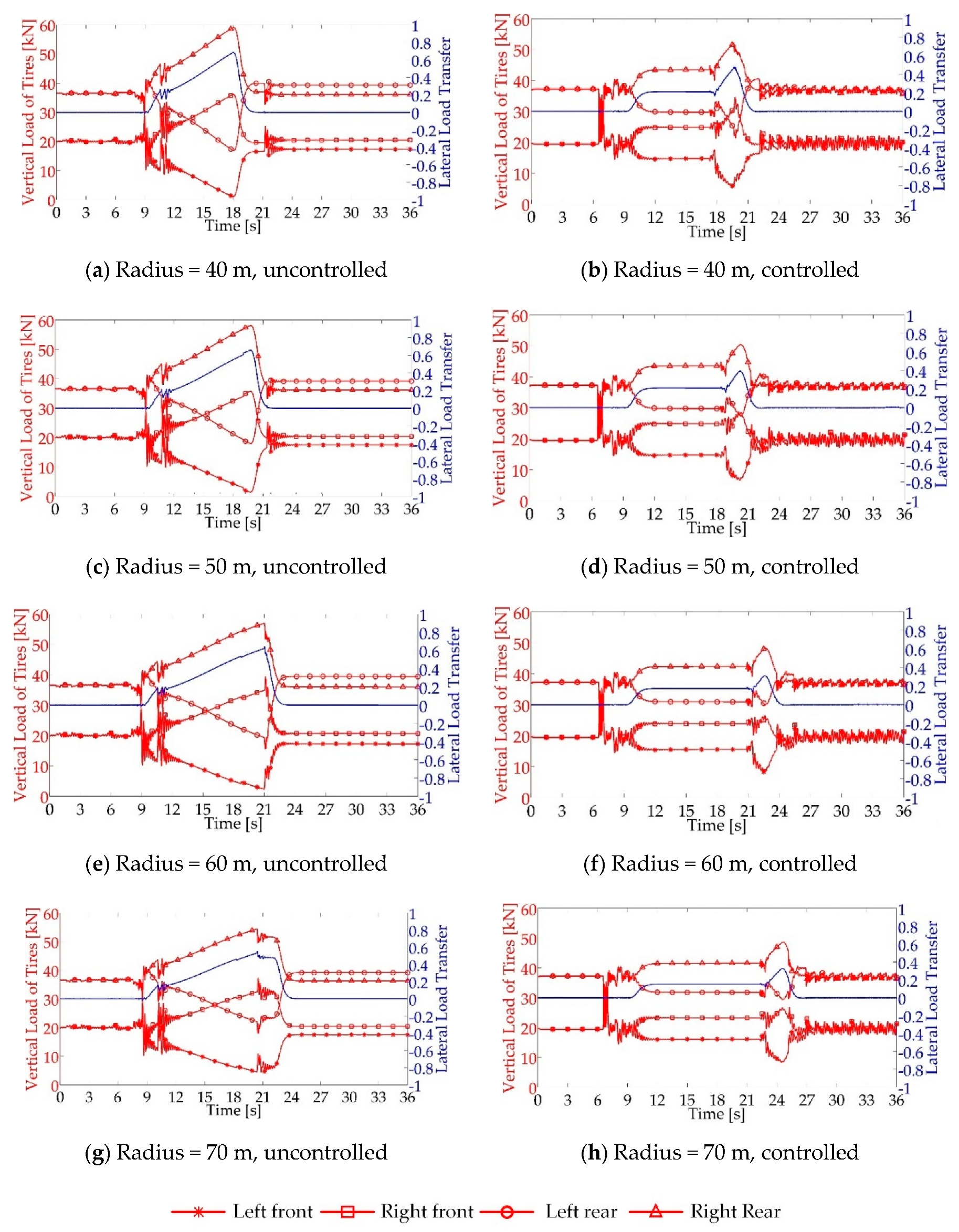

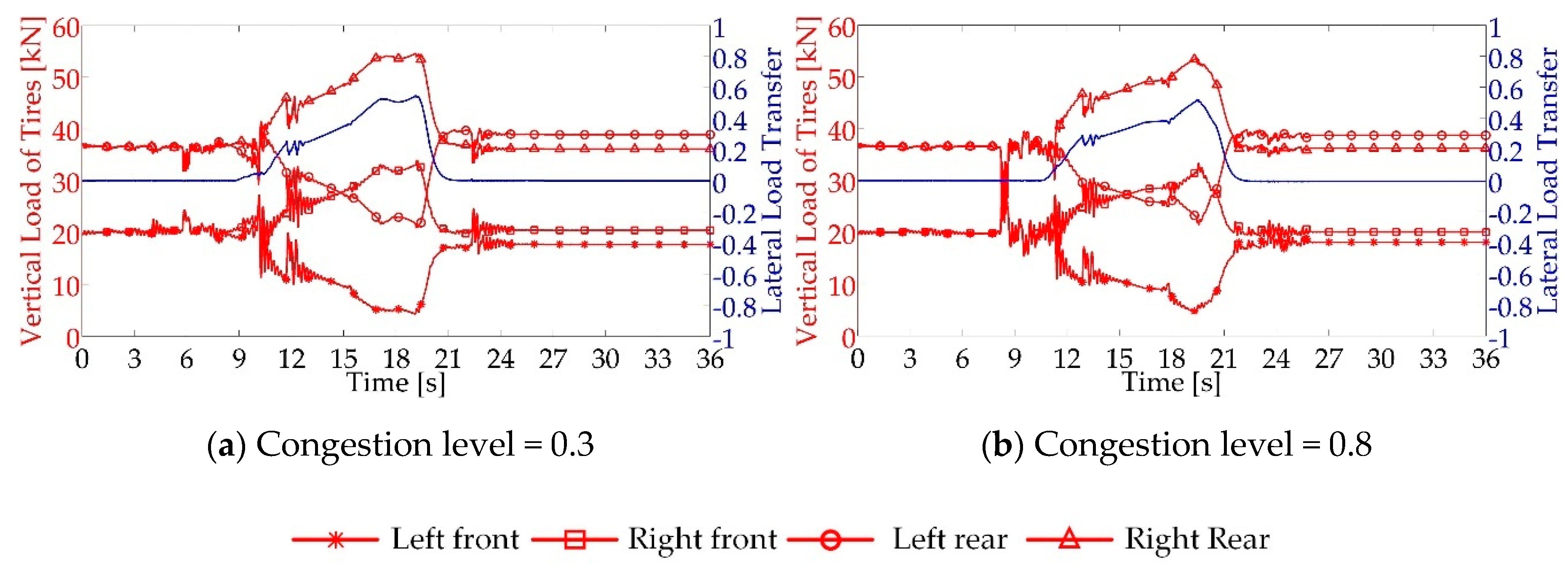

4.2.2. Lateral Stability

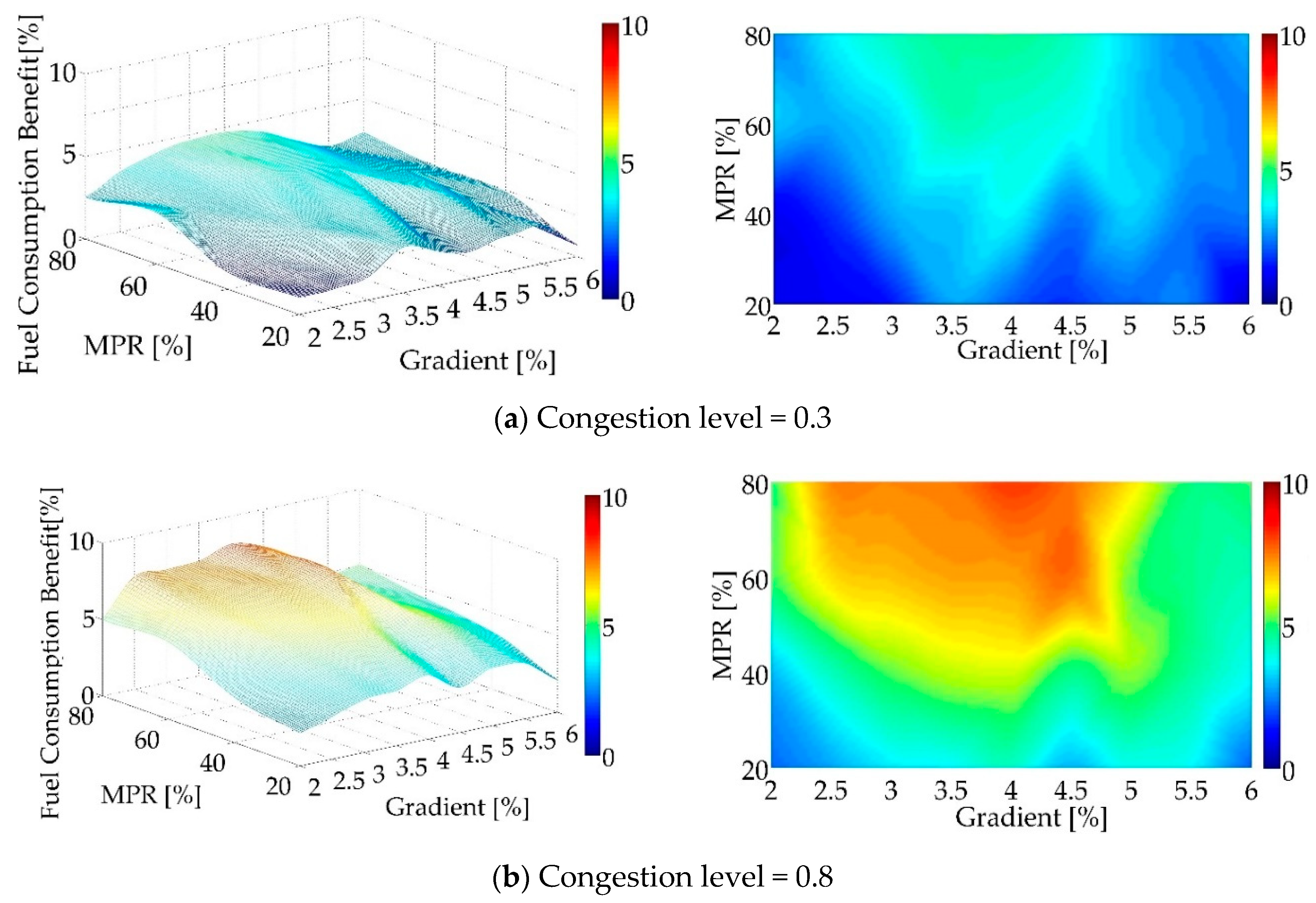

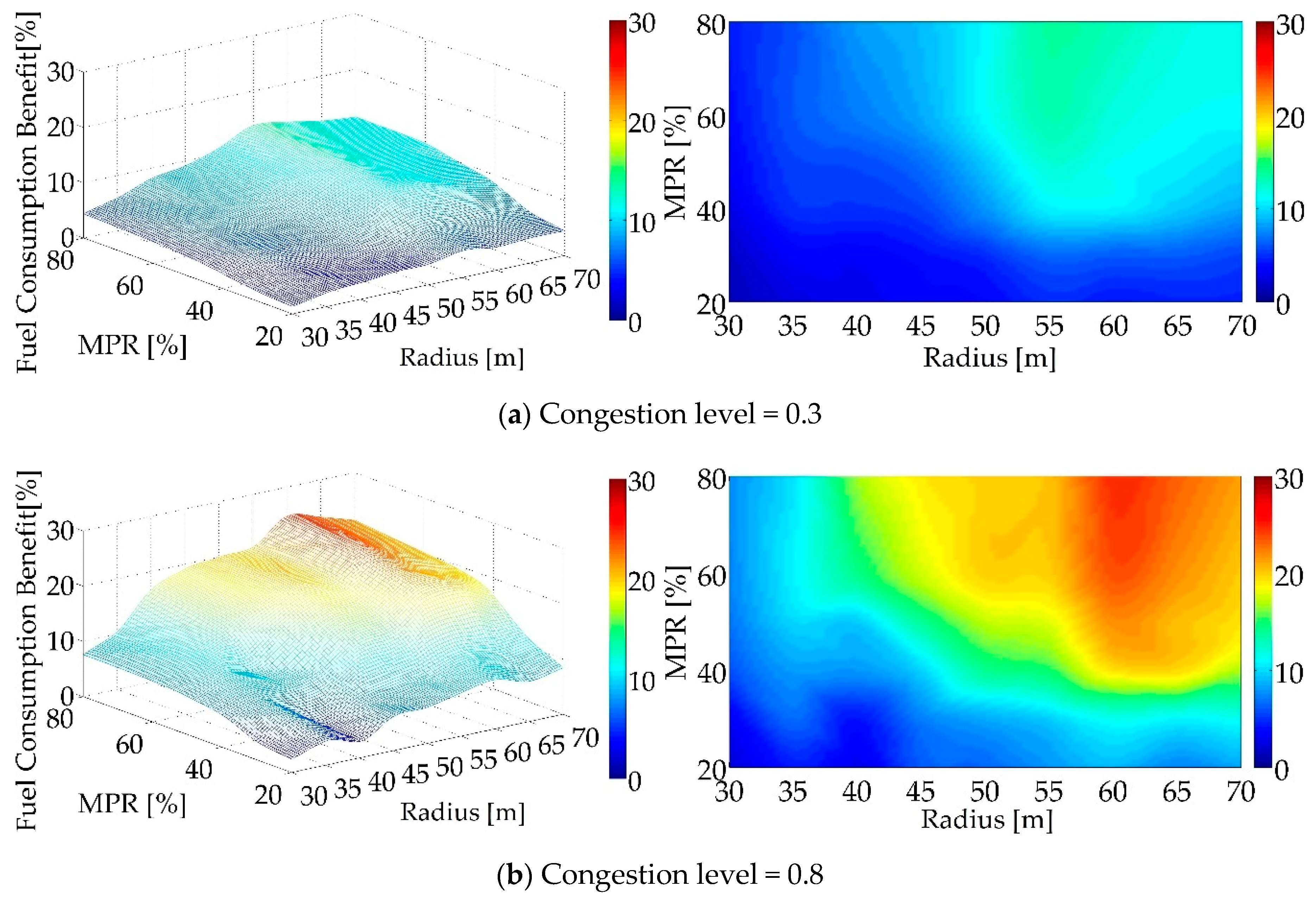

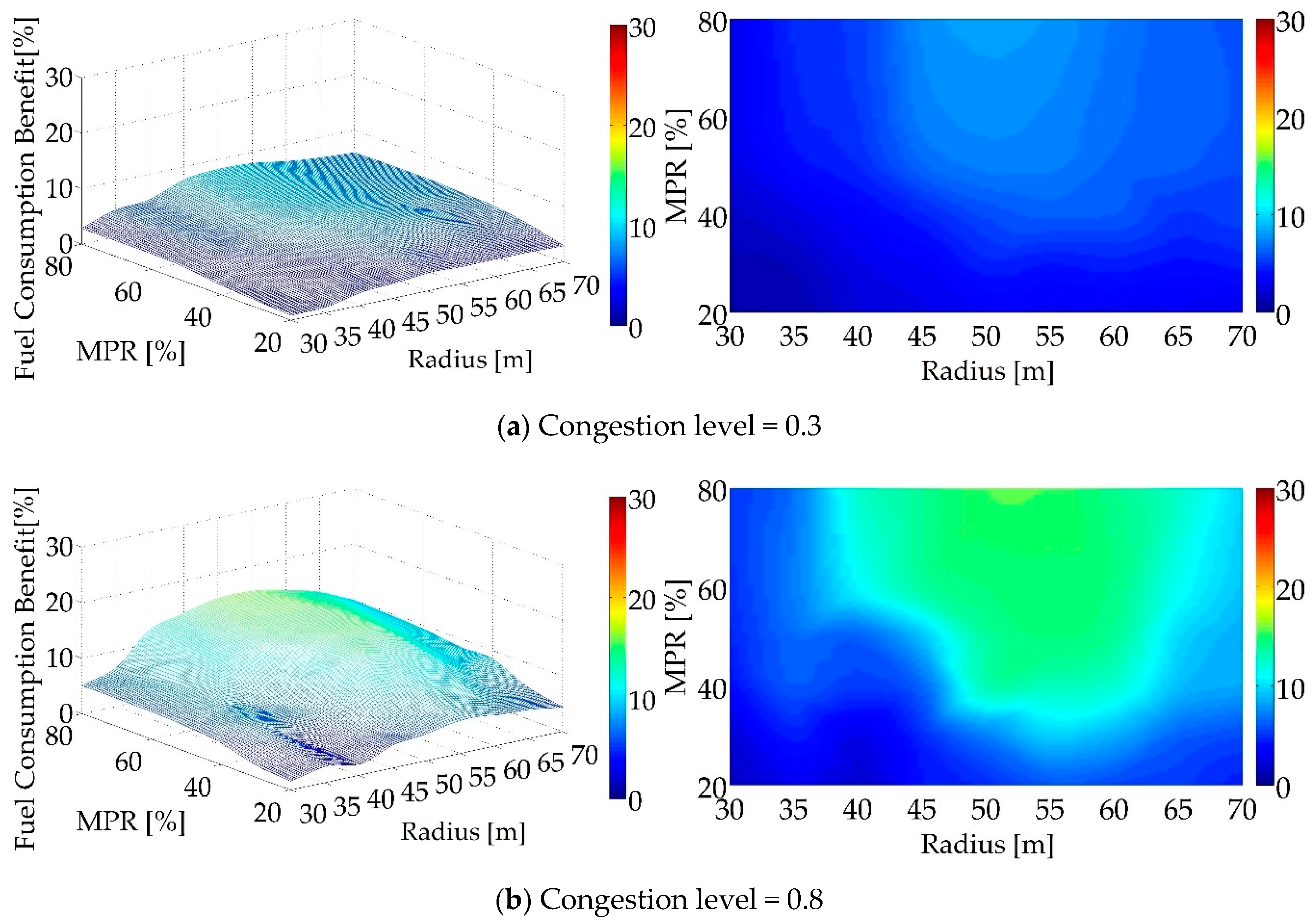

4.2.3. Fuel Economy

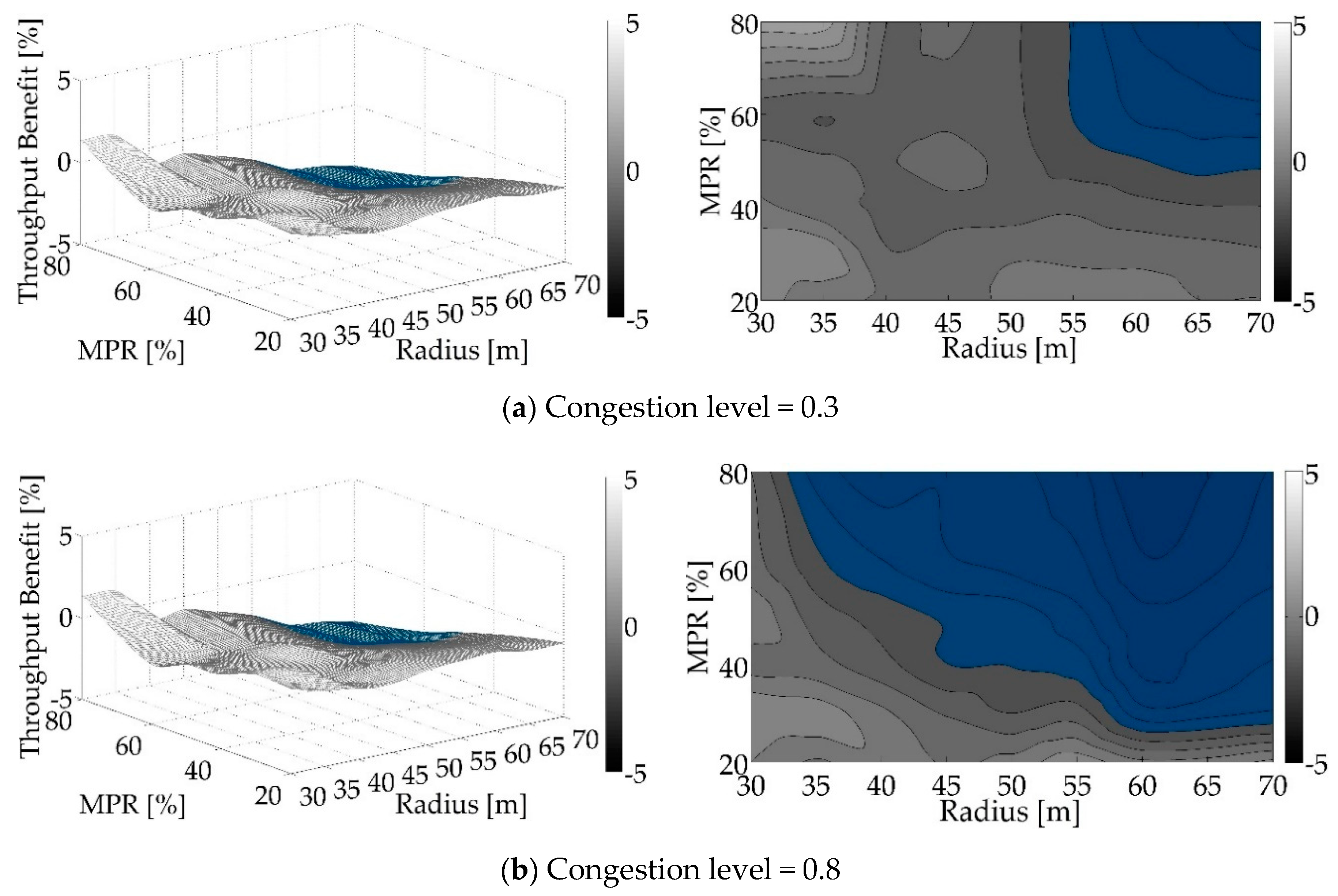

4.2.4. Mobility

5. Conclusions and Future Research

- (1)

- The brake thermal benefits of CHDVs range from 1.07% to 15.50%, and their brake drums maintain a safe temperature. The brake thermal benefits of HD2Vs range from 1.06% to 7.22%. These variations are caused by the MPR of CHDVs and the downhill gradient. The optimal gradient is 3.5%.

- (2)

- The lateral slip angles and the lateral load transfer rates of heavy-duty vehicles in controlled scenarios, including CHDVs and HD2Vs, are much lower than those in the baseline scenarios. The lateral slip angles and the lateral load transfer rates of the CHDVs in the controlled scenarios are within a safe range. The inhibition effect on the lateral slip angle and the lateral load transfer rate of the HD2Vs increase with the congestion level of road traffic.

- (3)

- The fuel consumption benefits range from 2.08% to 8.15% when the heavy-duty vehicles are driving on downhill roads and range from 1.34% to 15.49% on curved roads. These variations are caused by the MPR of CHDVs, the curve radius, and the congestion level. The benefits increase as the MPR of CHDVs and the congestion level increase.

- (4)

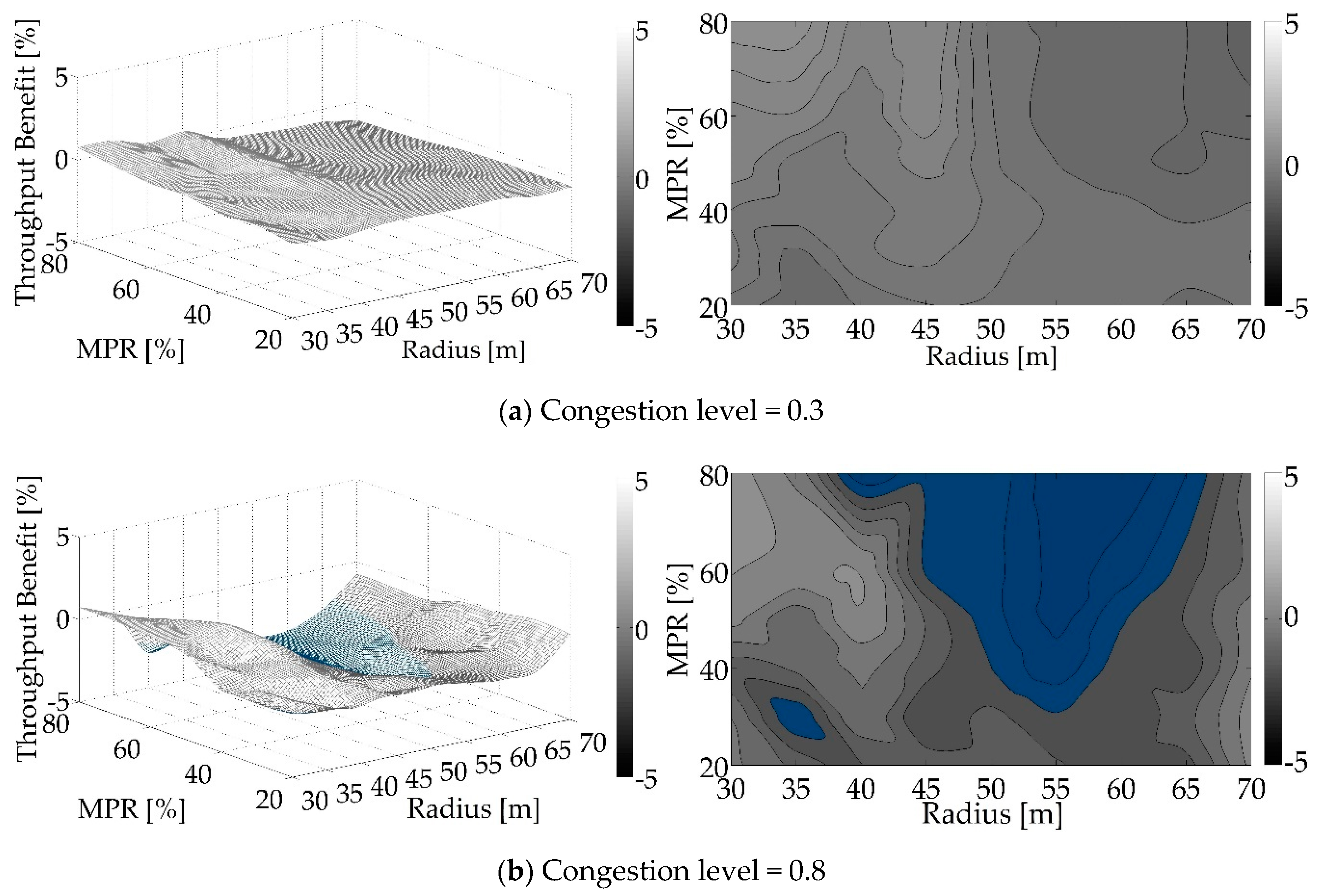

- Significant negative impacts on throughput by up to 4.97% were observed on curved roads, but this adverse effect of the proposed control system is at least 3.27% lower than that of most similar controllers without the consideration of all traffic and the stochastic driving behaviors of human-driven vehicles.

- (5)

- The brake thermal benefits, fuel consumption benefits, and control effects on the lateral slip and load transfer show increasing trends with the MPR of CHDVs. Significant benefits can be obtained as long as there are few CHDVs. Thus, the proposed speed control system has great feasibility for future implementation in the real world.

- (6)

- The fuel consumption benefits, control effects on lateral slip, and load transfer under high congestion levels are much greater that those under low congestion levels. The proposed control system offers better control over the entire traffic flow under high congestion levels.

- (7)

- The optimal downhill gradient for the proposed speed controller is 2.5~4.5%, and the optimal curve radius is 50~70 m. All benefits and control effects are at high levels under these conditions.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Notation | Meaning |

|---|---|

| Location of the heavy-duty vehicle at t time, (m) | |

| Speed of the heavy-duty vehicle at t time, (m/s) | |

| Longitudinal speed of the heavy-duty vehicle at t time, (m/s) | |

| Lateral speed of the heavy-duty vehicle at t time, (m/s) | |

| Location of the virtual preceding vehicle of the predicted vehicle at t time in Module 2, (m) | |

| Speed of the virtual preceding vehicle of the predicted vehicle at t time in Module 2, (m/s) | |

| Distance gap between the predicted vehicle and its virtual preceding vehicle at t time in Module 2, (m) | |

| Speed difference between the predicted vehicle and its virtual preceding vehicle at t time in Module 2, (m/s) | |

| Acceleration of the heavy-duty vehicle at t time, (m/s2) | |

| Longitudinal acceleration of the heavy-duty vehicle at t time, (m/s2) | |

| Lateral acceleration of the heavy-duty vehicle at t time, (m/s2) | |

| Yaw rate of the heavy-duty vehicle at t time, (rad/s) | |

| Desired yaw rate of the heavy-duty vehicle at t time, (rad/s) | |

| Thermal energy generated by the brake drums of the heavy-duty vehicle from 0 time to t time, (J) | |

| Roll angle of the vehicle at the center of gravity at t time, (rad) | |

| Energy generated by the brake and non-brake forces of the heavy-duty vehicle from 0 time to t time, (J) | |

| Kinetic energy of the heavy-duty vehicle at t time, (J) | |

| Gravitational potential energy of the heavy-duty vehicle at t time, (J) | |

| Energy of the engine braking from 0 time to t time, (J) | |

| Energy generated by the rolling resistance of all tires from 0 time to t time, (J) | |

| Energy generated by the aerodynamic drag of the vehicle from 0 time to t time, (J) | |

| Thermal energy dissipated by the convective heat transfer of the brake drum i from 0 time to t time, (J) | |

| Thermal energy dissipated by the radiative heat transfer of the brake drum i from 0 time to t time, (J) | |

| Thermal energy generated by the rolling resistance at the tire of wheel k and road surface, (J) | |

| Thermal energy generation rate of the drum-brakes of the heavy-duty vehicle at t time, (J/s) | |

| Thermal energy dissipation rate of the drum-brakes of the heavy-duty vehicle at t time, (J/s) | |

| Net thermal energy generation rate of the drum-brakes of the heavy-duty vehicle at t time, (J/s) | |

| Torque of engine braking at t time, (N·m) | |

| Instantaneous fuel consumption rate of the heavy-duty vehicle at t time, (ml/t) | |

| Lateral load transfer ratio of the heavy-duty vehicle at t time | |

| Curve radius at location , (m) | |

| Aerodynamic drag of the vehicle at time, (N) | |

| Vertical load of left front wheel of the heavy-duty vehicle at t time, (N) | |

| Vertical load of right front wheel of the heavy-duty vehicle at t time, (N) | |

| Vertical load of left rear wheel of the heavy-duty vehicle at t time, (N) | |

| Vertical load of right rear wheel of the heavy-duty vehicle at t time, (N) | |

| External surface temperature of the brake drum i at time, (°C) | |

| Ambient air temperature of the brake drum i at time, (°C) | |

| Thermodynamic temperature of the brake drum i at time, (K) | |

| Thermodynamic temperature of ambient air surrounding the brake drum i at time, (K) | |

| Terminal cost of the optimal problem in Module 1 | |

| Running cost of the optimal problem in Module 1 | |

| Engine speed of the heavy-duty vehicle at t time, (rpm) | |

| Relative speed of air and vehicle at time, (m/s) | |

| Rolling resistance of the ith wheel, (N) | |

| Maximum yaw rate of the heavy-duty vehicle, (rad/s) | |

| Initial speed of the heavy-duty vehicle when it enters the control area, (m/s) | |

| Desired speed of the heavy-duty vehicle, (m/s) | |

| 85th percentile speed of all heavy-duty vehicles that have safely driven through the downhill/curved section, (m/s) | |

| Legal speed limit of heavy-duty vehicles on high-risk roads, (m/s) | |

| Maximum acceleration of the heavy-duty vehicle, (m/s2) | |

| Minimum acceleration (maximum deceleration) of the heavy-duty vehicle, (m/s2) | |

| Desired deceleration of the heavy-duty vehicle, (m/s2) | |

| Maximum jerk of the heavy-duty vehicle, (m/s3) | |

| Minimum jerk of the heavy-duty vehicle, (m/s3) | |

| Desired jerk of the virtual preceding vehicle of the predicted vehicle in Module 2, (m/s3) | |

| Maximum lateral load transfer ratioat t time | |

| Minimum lateral load transfer ratio of the heavy-duty vehicle at t time | |

| Ratio of engine speed and vehicle speed | |

| Maximum temperature of the brake drum, (°C) | |

| Mass of the heavy-duty vehicle, (kg) | |

| Mass of brake drum i, (kg) | |

| Windward area of the vehicle, (m2) | |

| External surface area of the brake drum i, (m2) | |

| Radius of the vehicle wheels, (m) | |

| Coefficient of the torque formula for engine braking | |

| Coefficient of roll angle formula | |

| Coefficient of rolling resistance | |

| Coefficient of aerodynamic drag | |

| Specific Heat Capacity of the brake drum, (J/(kg·K)) | |

| Distance from the center of gravity to front axle, (m) | |

| Distance from the center of gravity to rear axle, (m) | |

| Track width of the heavy-duty vehicle, (m) | |

| Minimum desired net distance between the predicted vehicle and its virtual preceding vehicle in Module 2, (m) | |

| Rolling stiffness of the front suspension, (N/m) | |

| Rolling stiffness of the rear suspension, (N/m) | |

| Height of the center of gravity, (m) | |

| Height from the center of gravity to roll center O, (m) | |

| Coefficient of convection heat transfer | |

| Gravitational acceleration, (m/s2) | |

| Length of high-risk roads, (m) | |

| Length of flat and straight section connected to high-risk roads, (m) | |

| Travel distance of the vehicle, (m) | |

| Index of wheel | |

| The number of vehicle wheels | |

| Initial time when the heavy-duty vehicle reaches the entrance point of the control area, (s) | |

| Time when the heavy-duty vehicle reaches the top of the downhill road or the beginning of the sharp-curved road, (s) | |

| Terminal time when heavy-duty vehicle pulls out of the control area, (s) | |

| Terminal time when preceding vehicle pulls out of the control area, (s) | |

| Expected terminal time of the heavy-duty vehicle, (s) | |

| Pre-set headway of two consecutive vehicles, (s) | |

| Safe time headway between the predicted vehicle and its virtual preceding vehicle in Module 2, (s) | |

| Gradient of downhill, (rad) | |

| Bank angle of sharp curve, (rad) | |

| Empirical coefficient, (W/(m⋅°C)) | |

| Emissivity coefficient of the brake drum | |

| Stefan-Boltzmann Constant, (W/m2K4) | |

| Tire–road friction coefficient | |

| Thermal energy distribution coefficient of the brake drum i | |

| Load of the ith wheel, (N) | |

| Coefficient for the steering angle estimation of the front wheels | |

| Air density, (Kg/m3) | |

| Acceleration exponent of the IDM car-following model | |

| Parameters of the fuel consumption and emissions model | |

| Weighting factor for brake safety of the vehicle, (m2·s−3·J−1) | |

| Weighting factor for yaw stability of the vehicle, (m2·s−2·rad−2) | |

| Weighting factor for roll stability of the vehicle, (m2·s−4) | |

| Weighting factor for fuel efficiency of the vehicle’s power system, (m3·mL−1·s−4) |

References

- Yue, L.; Wang, H. An optimization design method of combination of steep slope and sharp curve sections for mountain highways. Math. Probl. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Burdzik, R.; Warczek, J. The influence of tyre pressure and vehicle load on evaluation of brake system effectiveness by vehicles services stations items. Sci. J. Sil. Univ. Technol. Ser. Transp. 2010, 66, 15–24. [Google Scholar]

- Garcia, L.; Wilson, F.R.; Innes, J. Heavy truck dynamic rollover: Effect of Load Distribution, Cargo Type, and Road Design Characteristics. Transp. Res. Rec. 2003, 1851, 25–31. [Google Scholar] [CrossRef]

- Li, W.L.; Zhou, W.; Gao, L.; Chen, Y. Real-time monitoring for vehicle brake temperature rise in continuous long downhill. In Applied Mechanics and Materials. Proceedings of the 2nd International Conference on Mechatronics, Hong Kong & Taipei, China, 6–9 December 2012; TTP: Zurich, Switzerland, 2012; pp. 916–919. [Google Scholar]

- Tiengo, W.; Costa, E.B.; Fechine, J.M. Reducing risk of rollover in curve for heavy-duty vehicles with an agent-based advanced driver assistance system. In Proceedings of the IEEE International Conference on Computer and Information Technology, Nadi, Fiji, 7–10 December 2016; pp. 65–72. [Google Scholar]

- Milhan, M.; Mahdi, R.; Mustaffa, N.R.; Khaled, K. Predicting injury severity and crash frequency: Insights into the impacts of geometric variables on downgrade crashes in Wyoming. J. Traffic Transp. Eng. 2020, 7, 375–383. [Google Scholar]

- Li, Y.M.; Deng, C.; Wang, Y.Z. A novel high-temperature-resistant polymeric material for cables and insulated wires via the ceramization of mica-based ceramifiable eva composites. Compos. Sci. Technol. 2016, 132, 116–122. [Google Scholar] [CrossRef]

- Jin, Z.; Li, J.; Huang, Y.; Khajepour, A. Study on rollover index and stability for a triaxle bus. Chin. J. Mech. Eng. 2019, 32, 1–15. [Google Scholar] [CrossRef]

- Jia, P. An approach for heavy-duty vehicle-level engine brake performance evaluation. SAE Int. J. Commer. Veh. 2019, 12, 57–66. [Google Scholar] [CrossRef]

- Geng, G.Q.; Tang, B.; Xu, Z. Design and energy saving analysis of heavy-duty vehicles ESC-HPS based on a new-type electromagnetic slip coupling. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Dearborn, MI, USA, 27–29 June 2016; pp. 1–5. [Google Scholar]

- Limpert, R.; Andrews, D.F. Analysis of Truck Braking Accidents. Accident Reconstruction: Automobiles, Tractor-Semitrailers, Motorcycles, and Pedestrians, Detroit USA, 23–27 February 1987; SAE: Warrendale, PA, USA, 1987; pp. 1–16. [Google Scholar]

- Bowman, B.L.; Coleman, J.A. Grade severity rating system. ITE J. 1990, 60, 19–24. [Google Scholar]

- Chuo, K. Evaluation of the Applicability of the Interactive Highway Safety Design Model to Safety Audit of Two-Lane Rural Highways. Master’s Thesis, Brigham Young University, Provo, UT, USA, 13 March 2008. [Google Scholar]

- Fancher, P.; Wider, C.; Campbell, M. The Influence of Braking Strategy on Brake Temperatures in Mountain Descents; FHWA: Washington, DC, USA, 1992; pp. 64–69.

- Bowman, B.L. Grade Severity Rating System (GSRS)—User’s Manual; FHWA: Washington, DC, USA, 1989; pp. 1–106.

- Yan, M.; Xu, J. Prediction model for brake-drum temperature of large trucks on consecutive mountain downgrade routes based on energy conservation law. Math. Probl. Eng. 2018, 2018, 1–10. [Google Scholar] [CrossRef]

- Seykens, X.L.J.; Baert, R.S.G.; Willems, F.P.T.; Vink, W.; Heuvel, I.T.M. Development of a dynamic engine brake model for control purposes. In New Trends in Engine Control, Simulation and Modelling, 2–4 October 2006; IFP: Rueil-Malmaison, France, 2007; pp. 320–329. [Google Scholar]

- Wu, C.X.; Guo, X.X.; Yang, B.; Pei, X.F.; Guo, S.J. Hydraulic retarder torque control for heavy duty vehicle longitudinal control. Int. J. Heavy Veh. Syst. 2019, 26, 854–871. [Google Scholar] [CrossRef]

- Barbieri, F.A.A.; Andreatta, E.C.; Argachoy, C.; Brandao, H. Decompression engine brake modeling and design for diesel engine application. SAE Int. J. Eng. 2010, 3, 92–102. [Google Scholar] [CrossRef]

- Zhao, L.; He, Y. An investigation of active safety control strategies for improving the lateral stability of car-trailer systems. Int. J. Veh. Syst. Model Test. 2019, 13, 295–318. [Google Scholar]

- Anwar, S. Yaw stability control of an automotive vehicle via generalized predictive algorithm. In Proceedings of the 2005 American Control Conference, Portland, OR, USA, 8–10 June 2005; pp. 435–440. [Google Scholar]

- Chen, K.; Pei, X.; Ma, G.; Guo, X. Longitudinal/Lateral Stability Analysis of Vehicle Motion in the Nonlinear Region. Math. Probl. Eng. 2016, 2016, 1–15. [Google Scholar] [CrossRef]

- Lin, C.; Xu, Z.; Zhang, R. A Yaw Stability Control Algorithm for Four-Wheel Independently Actuated Electric Ground Vehicles considering Control Boundaries. Math. Probl. Eng. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Di Cairano, S.; Tseng, H.E.; Bernardini, D.; Bemporad, A. Vehicle Yaw Stability Control by Coordinated Active Front Steering and Differential Braking in the Tire Sideslip Angles Domain. IEEE Trans. Control Syst. Technol. 2012, 21, 1236–1248. [Google Scholar] [CrossRef]

- He, P.; Hori, Y. Optimum traction force distribution for stability improvement of 4WD EV in critical driving condition. In Proceedings of the 9th IEEE International Workshop on Advanced Motion Control, Istanbul, Turkey, 27–29 March 2006; pp. 596–601. [Google Scholar]

- Paolo, F.H.; Eric, T.; Francesco, B.; Jahan, A.; Davor, H. MPC-based yaw and lateral stabilisation via active front steering and braking. Veh. Syst. Dyn. 2009, 46, 611–628. [Google Scholar]

- Ahmadi, J.; Sedigh, A.K.; Kabganian, M. Adaptive vehicle lateral-plane motion control using optimal tire friction forces with saturation limits consideration. IEEE Trans. Veh. Technol. 2009, 58, 4098–4107. [Google Scholar] [CrossRef]

- Li, L.; Lu, Y.; Wang, R.; Chen, J. A three-dimensional dynamics control framework of vehicle lateral stability and rollover prevention via active braking with MPC. IEEE Trans. Ind. Electron. 2017, 64, 3389–3401. [Google Scholar] [CrossRef]

- Yang, S.M.; Kim, J.H. Validation of the 6-dof vehicle dynamics model and its related VBA program under the constant radius turn manoeuvre. Int. J. Automot. Technol. 2012, 13, 593–605. [Google Scholar] [CrossRef]

- Dahmani, H.; Chadli, M.; Rabhi, A.; Hajjaji, A.E. Vehicle dynamic estimation with road bank angle consideration for rollover detection: Theoretical and experimental studies. Veh. Syst. Dyn. 2013, 51, 1853–1871. [Google Scholar] [CrossRef]

- Huang, H.; Yedavalli, R.K.; Guenther, D.A. Active roll control for rollover prevention of heavy articulated vehicles with multiple-rollover-index minimisation. Veh. Syst. Dyn. 2012, 50, 471–493. [Google Scholar] [CrossRef]

- Rajamani, R.; Piyabongkarn, D. New paradigms for the integration of yaw stability and rollover prevention functions in vehicle stability control. IEEE Trans. Intell. Transp. Syst. 2013, 14, 249–261. [Google Scholar] [CrossRef]

- Matthäus, B.A.; Johannes, T.; Tor, A.J. Integration of vehicle yaw stabilisation and rollover prevention through nonlinear hierarchical control allocation. Veh. Syst. Dyn. 2014, 52, 1607–1621. [Google Scholar]

- Combs, T.S.; Sandt, L.; Clamann, M.P.; Mcdonald, N.C. Automated vehicles and pedestrian safety: Exploring the promise and limits of pedestrian detection. Am. J. Prev. Med. 2019, 56, 1–7. [Google Scholar] [CrossRef]

- Wang, Z.; Amar, P.; Garmon, E.; Tanugula, S.; Hsu, Y.-P.; Vu, A.; Caballero, F.; Hao, P.; Wu, G.; Boriboonsomsin, K.; et al. Early Findings from Field Trials of Heavy-Duty Truck Connected Eco-Driving System. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference, Auckland, New Zealand, 27–30 October 2019; pp. 3037–3042. [Google Scholar]

- Wang, Z.; Wu, G.; Hao, P.; Boriboonsomsin, K.; Barth, M. Developing a platoon-wide eco-cooperative adaptive cruise control (CACC) system. In Proceedings of the 2017 IEEE Intelligent Vehicles Symposium, Redondo Beach, CA, USA, 11–14 June 2017; IEEE: New York, NY, USA, 2017; pp. 1256–1261. [Google Scholar]

- Wang, M.; Daamen, W.; Hoogendoorn, S.P.; van Arem, B. Rolling horizon control framework for driver assistance systems. Part I: Mathematical formulation and non-cooperative systems. Transp. Res. Part C 2014, 40, 271–289. [Google Scholar] [CrossRef]

- Wang, M.; Daamen, W.; Hoogendoorn, S.P.; van Arem, B. Rolling horizon control framework for driver assistance systems. Part II: Cooperative sensing and cooperative control. Transp. Res. Part C 2014, 40, 290–311. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, D.; Li, K. Enhanced eco-driving system based on V2X communication. In Proceedings of the International IEEE Conference on Intelligent Transportation Systems, Anchorage, AK, USA, 16–19 September 2012; pp. 200–205. [Google Scholar]

- Mandava, S.; Boriboonsomsin, K.; Barth, M. Arterial velocity planning based on traffic signal information under light traffic conditions. In Proceedings of the 2009 12th International IEEE Conference on Intelligent Transportation Systems, St. Louis, MO, USA, 4–7 October 2009; pp. 1–6. [Google Scholar]

- Barth, M.; Mandava, S.; Boriboonsomsin, K.; Xia, H. Dynamic ECO-driving for arterial corridors. In Proceedings of the 2011 IEEE Forum on Integrated and Sustainable Transportation System (FISTS), Vienna, Austria, 29 June–1 July 2011; pp. 182–188. [Google Scholar]

- Lee, J.; Park, B. Development and evaluation of a cooperative vehicle intersection control algorithm under the connected vehicles. IEEE Trans. Intell. Transp. Syst. 2012, 13, 81–90. [Google Scholar] [CrossRef]

- Jiang, H.; Hu, J.; An, S.; Wang, M.; Park, B.B. Eco approaching at an isolated signalized intersection under partially connected and automated vehicles environment. Transp. Res. Part C 2017, 79, 290–307. [Google Scholar] [CrossRef]

- Ma, J.; Li, X.; Zhou, F.; Hu, J.; Park, B. Parsimonious shooting heuristic for trajectory design of connected automated traffic part II: Computational issues and optimization. Transp. Res. Part B 2017, 95, 421–441. [Google Scholar] [CrossRef]

- Zhou, F.; Li, X.; Ma, J. Parsimonious shooting heuristic for trajectory design of connected automated traffic part I: Theoretical analysis with generalized time geography. Transp. Res. Part B 2017, 95, 394–420. [Google Scholar] [CrossRef]

- Jiang, H.; An, S.; Wang, J.; Cui, J. Eco-approach and departure system for left-turn vehicles at a fixed-time signalized intersection. Sustainability 2018, 10, 273. [Google Scholar] [CrossRef]

- Jiang, H.; Hu, J.; Park, B.; Wang, M.; Zhou, W. An Extensive Investigation of an Eco-Approach Controller under a Partially Connected and Automated Vehicle Environment. Sustainability 2019, 11, 6319. [Google Scholar] [CrossRef]

- Astarita, V.; Guido, G.; Mongelli, D.W.; Giofre, V.P. Ecosmart and TutorDrive: Tools for fuel consumption reduction. In Proceedings of the 2014 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Qingdao, China, 8–10 October 2014; pp. 183–187. [Google Scholar]

- Astarita, V.; Guido, G.; Mongelli, D.W.; Giofre, V.P. A co-operative methodology to estimate car fuel consumption by using smartphone sensors. Transport 2015, 30, 307–311. [Google Scholar] [CrossRef]

- Keyvanfar, A.; Shafaghat, A.; Muhammad, N.Z.; Ferwati, M.S. Driving Behaviour and Sustainable Mobility—Policies and Approaches Revisited. Sustainability 2018, 10, 1152. [Google Scholar] [CrossRef]

- Zegeye, S.K.; De Schutter, B.; Hellendoorn, J.; Breunesse, E.A. Variable speed limits for green mobility. In Proceedings of the 2011 14th International IEEE Conference on Intelligent Transportation Systems (ITSC), Washington, DC, USA, 5–7 October 2011; pp. 2174–2179. [Google Scholar]

- Li, D.; Zhao, Y.; Ranjitkar, P.; Zhao, H.; Bai, Q. Hybrid approach for variable speed limit implementation and application to mixed traffic conditions with connected autonomous vehicles. IET Intell. Transp. Syst. 2018, 12, 327–334. [Google Scholar] [CrossRef]

- Hall, F.L. Traffic stream characteristics. In Highway Capacity Manual; FHWA: Washington, DC, USA, 1994; pp. 1–36. [Google Scholar]

- Treiber, M.; Hennecke, A.; Helbing, D. Congested traffic states in empirical observations and microscopic simulations. Phys. Rev. E 2000, 62, 1805–1824. [Google Scholar] [CrossRef]

- Doumiati, M.; Victorino, A.C.; Charara, A.; Lechner, D. Lateral load transfer and normal forces estimation for vehicle safety: Experimental test. Veh. Syst. Dyn. 2009, 47, 1511–1533. [Google Scholar] [CrossRef]

- Akcelik, R. Efficiency and drag in the power-based model of fuel consumption. Transp. Res. Part B 1989, 23, 376–385. [Google Scholar] [CrossRef]

- Rakha, H.; Ahn, K.; Trani, A. Development of VT-Micro model for estimating hot stabilized light duty vehicle and truck emissions. Transp. Res. Part D Trans. Environ. 2004, 9, 49–74. [Google Scholar] [CrossRef]

- Gao, C.; Xu, J.; Jia, X.; Dong, Y.; Ru, H. Influence of large vehicles on the speed of expressway traffic flow. Adv. Civ. Eng. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

| Category | Parameters | Value |

|---|---|---|

| Simulation platform | Length of approach section (m) | 120 |

| Gradient of downhill road (%) | 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5, 6 | |

| Radius of curved road (m) | 40, 45, 50, 55, 60, 65, 70 | |

| Congestion level | 0.3, 0.8 | |

| MPR of connected vehicles | 20, 30, 40, 50, 60, 70, 80 | |

| Warming time of VISSIM (s) | 120 | |

| Optimal controller for connected heavy-duty vehicles | Legal speed limit (km/h) | 50 |

| Maximum acceleration (m/s2) | 3.5 | |

| Minimum acceleration (m/s2) | −4 | |

| Maximum jerk (m/s2) | 10 | |

| Minimum jerk (m/s2) | 0 | |

| Pre-set headway (s) | 5 | |

| Weighting factors () | (1,10,100,100,100,1) | |

| Predictor for conventional human-driven vehicles | Acceleration exponent | 4 |

| Minimum desired net distance (m) | 7 | |

| Desired speed (km/h) | 50 | |

| Minimum speed (km/h) | 0 | |

| Safe time headway (s) | 5 | |

| Desired deceleration (m/s2) | −2.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Zhou, W.; Liu, C.; Zhang, G.; Hu, M. Safe and Ecological Speed Control for Heavy-Duty Vehicles on Long–Steep Downhill and Sharp-Curved Roads. Sustainability 2020, 12, 6813. https://doi.org/10.3390/su12176813

Jiang H, Zhou W, Liu C, Zhang G, Hu M. Safe and Ecological Speed Control for Heavy-Duty Vehicles on Long–Steep Downhill and Sharp-Curved Roads. Sustainability. 2020; 12(17):6813. https://doi.org/10.3390/su12176813

Chicago/Turabian StyleJiang, Huifu, Wei Zhou, Chang Liu, Guosheng Zhang, and Meng Hu. 2020. "Safe and Ecological Speed Control for Heavy-Duty Vehicles on Long–Steep Downhill and Sharp-Curved Roads" Sustainability 12, no. 17: 6813. https://doi.org/10.3390/su12176813

APA StyleJiang, H., Zhou, W., Liu, C., Zhang, G., & Hu, M. (2020). Safe and Ecological Speed Control for Heavy-Duty Vehicles on Long–Steep Downhill and Sharp-Curved Roads. Sustainability, 12(17), 6813. https://doi.org/10.3390/su12176813