Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools

Abstract

1. Introduction

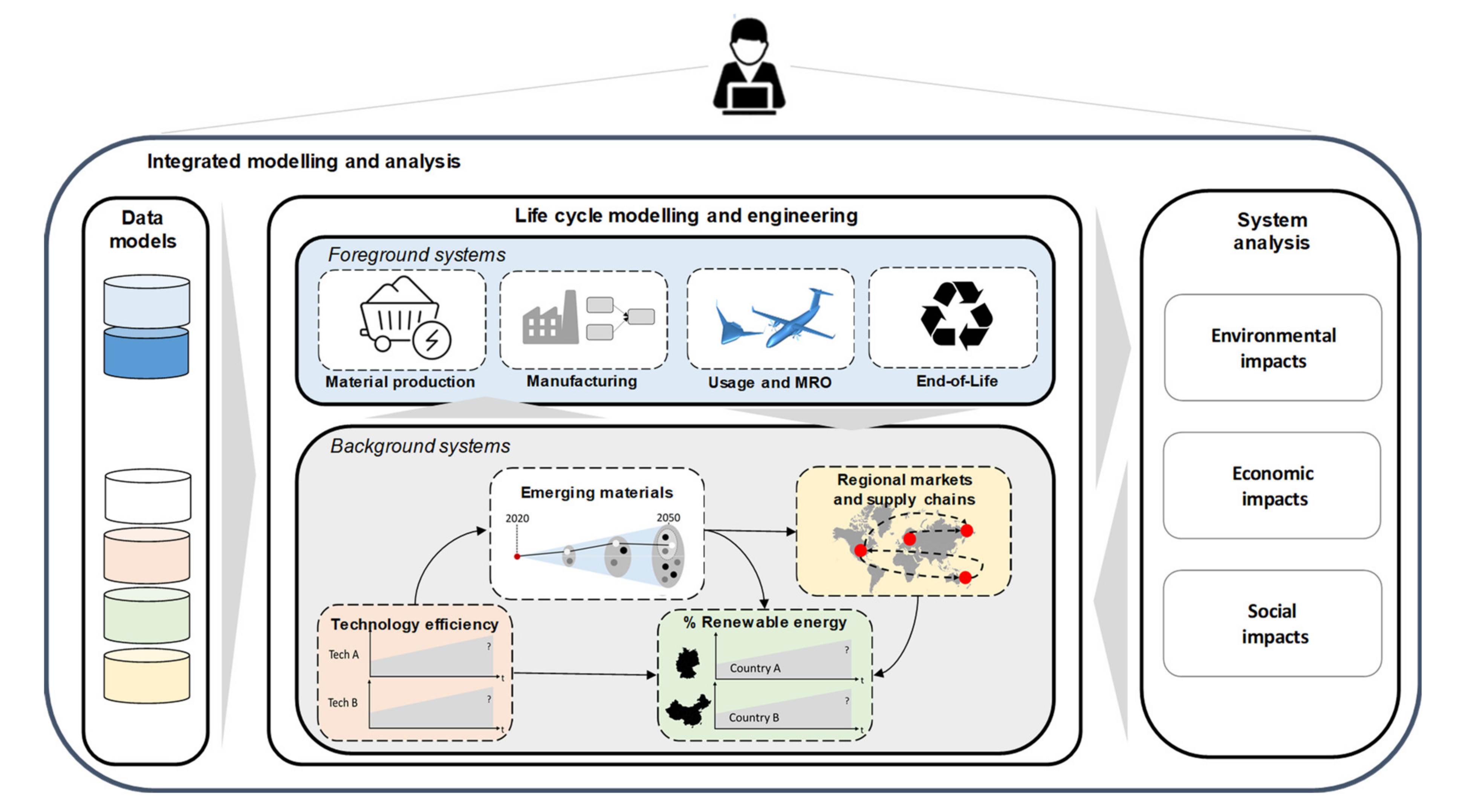

2. Framework for Sustainability Modelling and Assessment of Emerging Aircraft Concepts and Propulsion Systems

2.1. Data Models

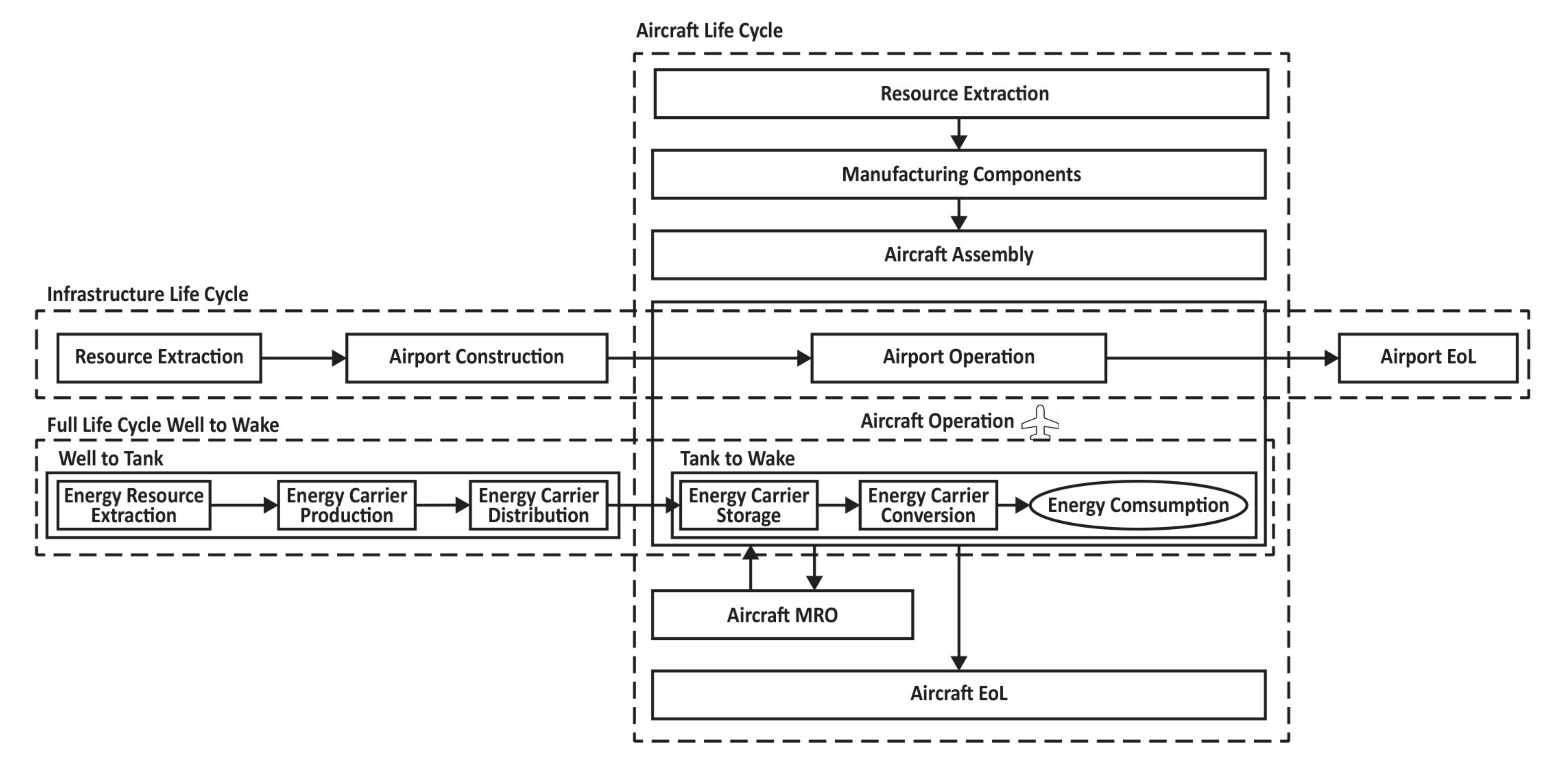

2.2. Life Cycle Modelling and Engineering

2.3. System Analysis

2.3.1. Environmental Assessment Methods

2.3.2. Economic Assessment Methods

2.3.3. Social Assessment Methods

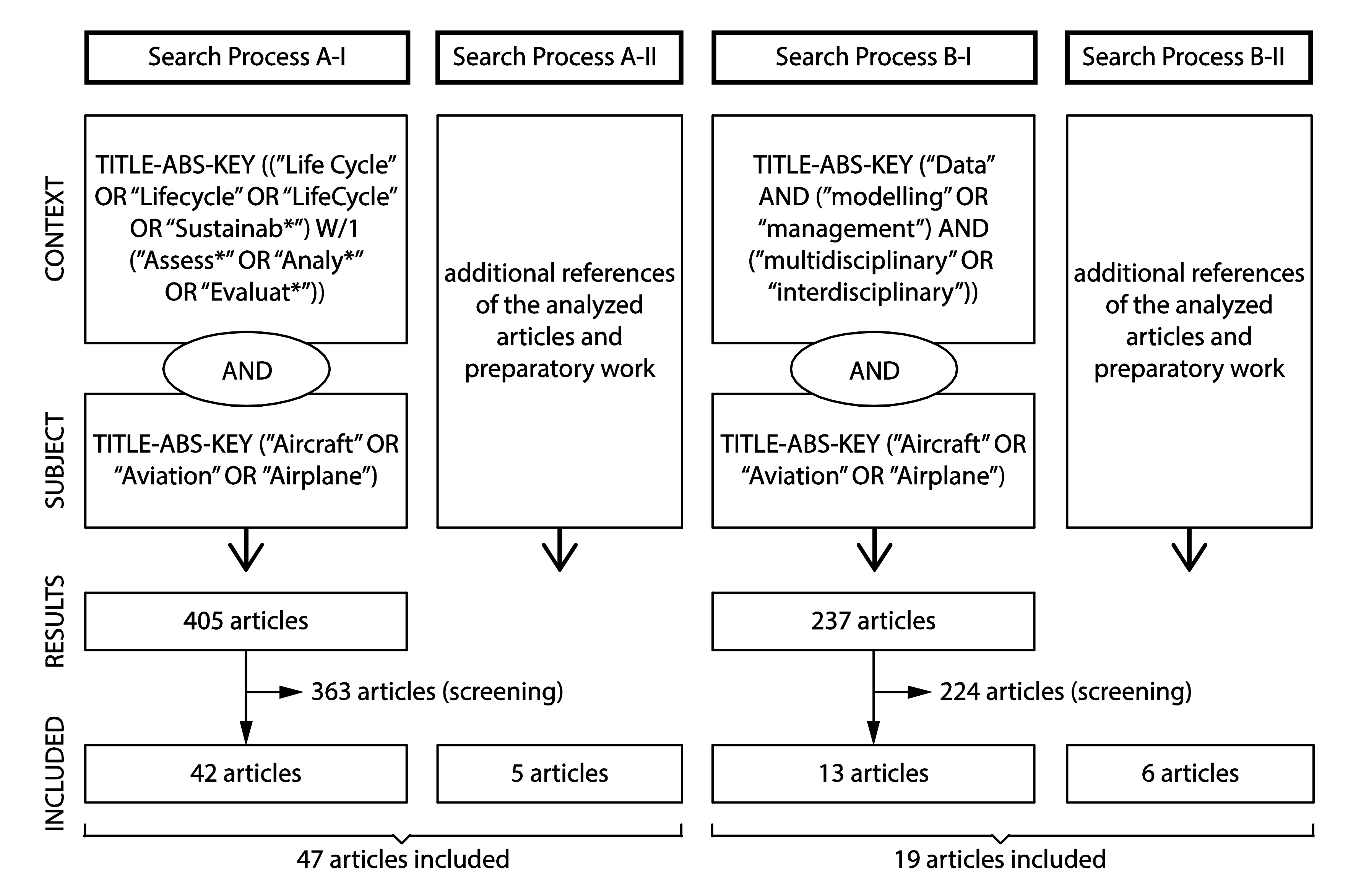

3. Review Methodology

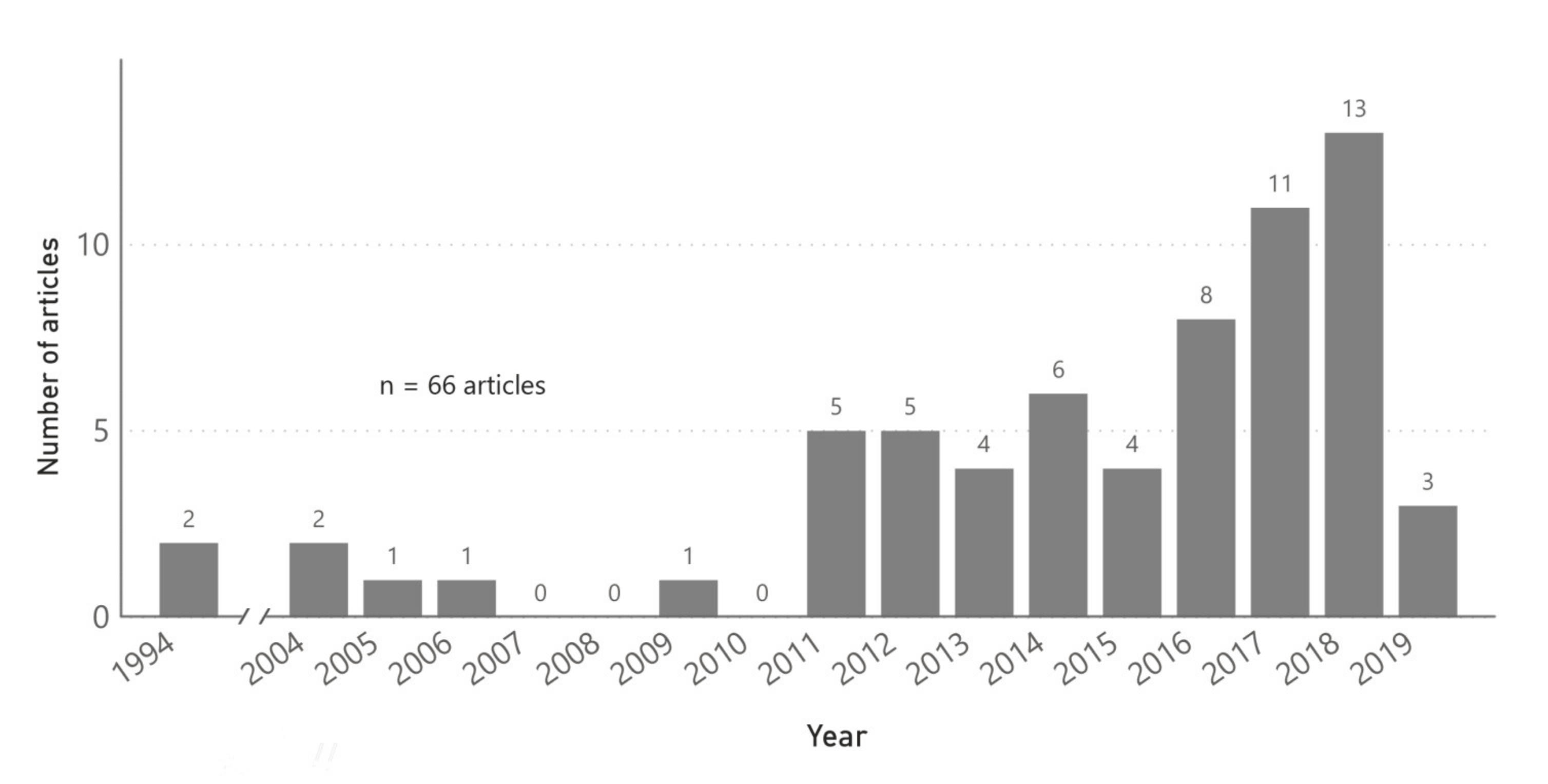

4. Descriptive Analysis of the Selected Literature

4.1. Technologies for a More Sustainable Aircraft Propulsion System

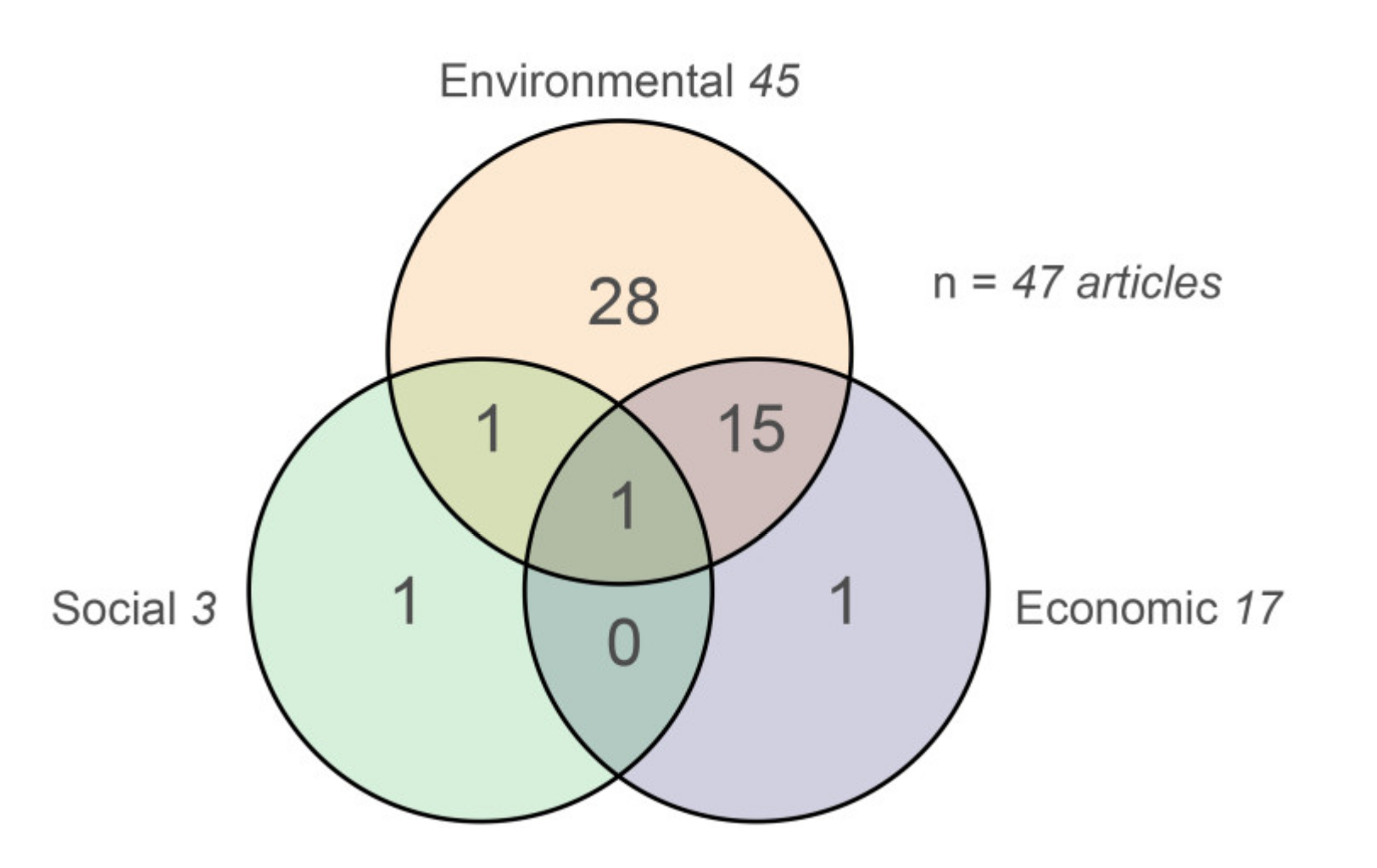

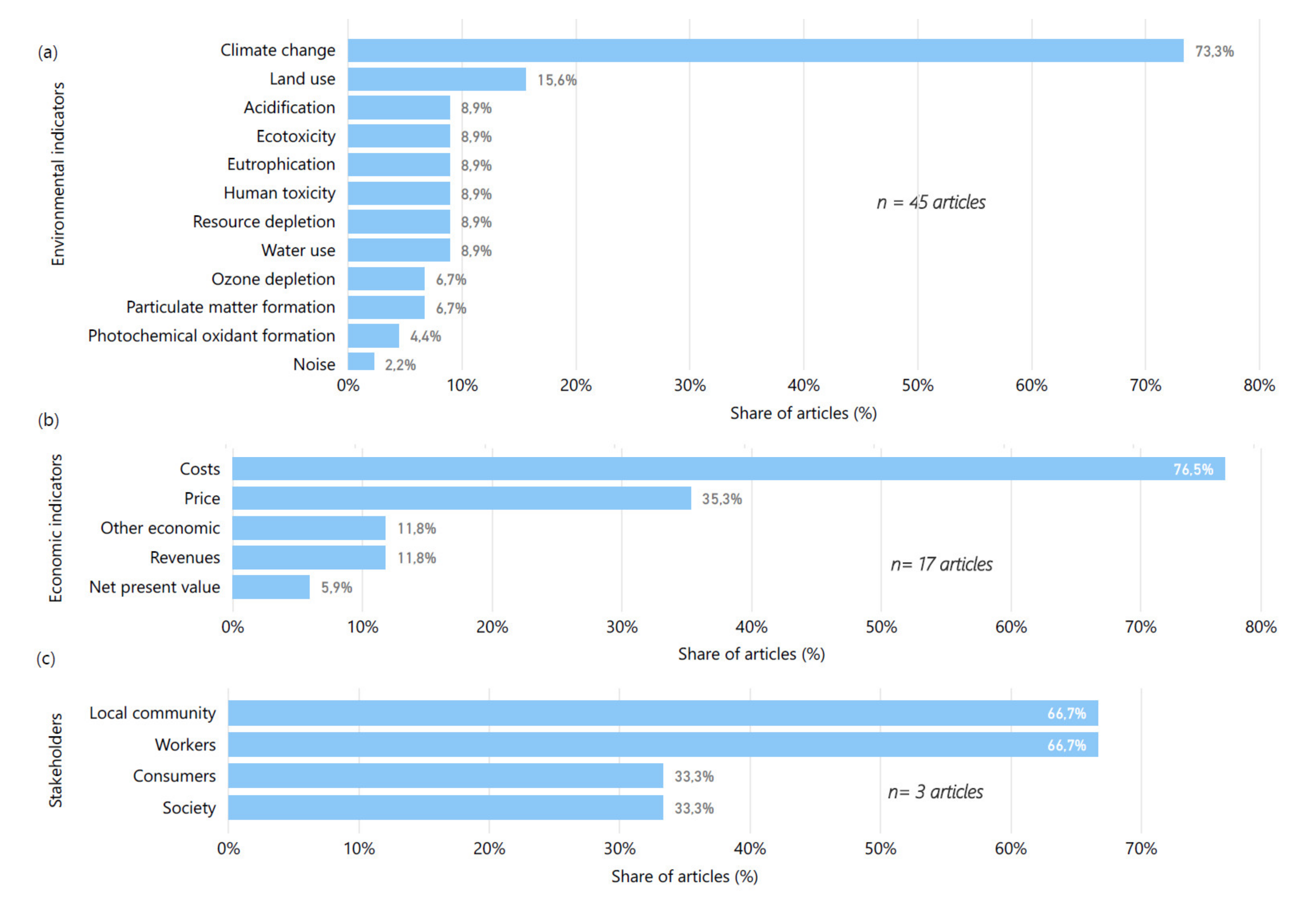

4.2. Sustainability Dimensions and Indicators

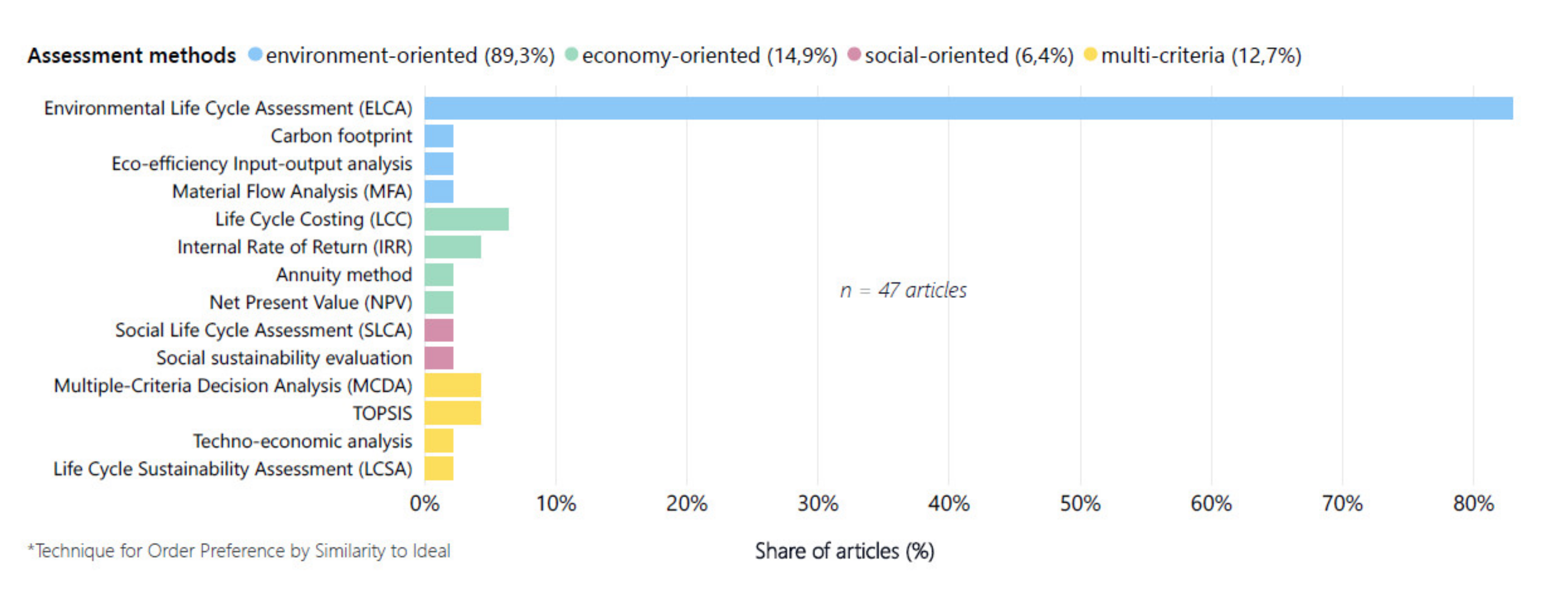

4.3. Assessment Methods

5. Detailed Analysis of the Articles and Key Insights

5.1. Management of Multidisciplinary Data

5.2. Life Cycle Modelling and System Analysis Towards a More Sustainable Aviation

5.2.1. Biofuels

5.2.2. Electrofuels

5.2.3. Alternative Powertrains

6. Research Gaps and Future Research Directions

6.1. Data Models

6.2. Life Cycle Modelling and System Analysis

7. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sims, R.; Schaeffer, F.R.; Creutzig, X.; Cruz-Núñez, M.; D’Agosto, D.; Dimitriu, M.J.; Figueroa Meza, L.; Fulton, S.; Kobayashi, O.; Lah, A.; et al. 2014: Transport. In Climate Change 2014: Mitigation of Climate Change: Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Lee, D.S.; Fahey, D.W.; Forster, P.M.; Newton, P.J.; Wit, R.C.N.; Lim, L.L.; Owen, B.; Sausen, R. Aviation and global climate change in the 21st century. Atmos. Environ. 2009, 43, 3520–3537. [Google Scholar] [CrossRef] [PubMed]

- Airbus. Cities, Airports & Aircraft: Global Market Forecast 2019–2038. Available online: https://gmf.airbus.com/ (accessed on 25 September 2019).

- Boeing. Commercial Market Outlook 2019–2038. Available online: https://www.boeing.com/commercial/market/commercial-market-outlook/ (accessed on 25 September 2019).

- International Civil Aviation Organization (ICAO). On Board: A Sustainable Future—2016 Environmental Report. Available online: https://www.icao.int/environmental-protection/Pages/env2016.aspx (accessed on 25 September 2019).

- Gnadt, A.R.; Speth, R.L.; Sabnis, J.S.; Barrett, S.R.H. Technical and environmental assessment of all-electric 180-passenger commercial aircraft. Prog. Aerosp. Sci. 2019, 105, 1–30. [Google Scholar] [CrossRef]

- Gössling, S.; Upham, P. Climate Change and Aviation: Issues, Challenges and Solutions; Earthscan: London, UK; Sterling, VA, USA, 2009. [Google Scholar]

- Ploetner, K.O.; Miltner, L.; Jochem, P.; Kuhn, H.; Hornung, M. Environmental life cycle assessment of universally-electric powered transport aircraft. In Proceedings of the Deutscher Luft- Und Raumfahrt Kongress, Braunschweig, Germany, 14 September 2016. [Google Scholar]

- Timmis, A.J.; Hodzic, A.; Koh, L.; Bonner, M.; Soutis, C.; Schäfer, A.W.; Dray, L. Environmental impact assessment of aviation emission reduction through the implementation of composite materials. Int. J. Life Cycle Assess. 2015, 20, 233–243. [Google Scholar] [CrossRef]

- Toyota Motor Corporation. The MIRAI: Life Cycle Assessment for Communication. 2015, pp. 1–31. Available online: https://global.toyota/en/sustainability/esg/challenge2050/challenge2/lca-and-eco-actions/ (accessed on 10 November 2019).

- Thies, C.; Kieckhäfer, K.; Spengler, T.S.; Sodhi, M.S. Assessment of social sustainability hotspots in the supply chain of lithium-ion batteries. Procedia CIRP 2019, 80, 292–297. [Google Scholar] [CrossRef]

- Wang, Z.; Osseweijer, P.; Duque, J.P. Assessing Social Sustainability for Biofuel Supply Chains: The Case of Aviation Biofuel in Brazil. In Proceedings of the IEEE Conference on Technologies for Sustainability (SusTech), Phoenix, AZ, USA, 12–14 November 2017; pp. 1–5. [Google Scholar]

- Hauschild, M.Z.; Herrmann, C.; Kara, S. An Integrated Framework for Life Cycle Engineering. Procedia CIRP 2017, 61, 2–9. [Google Scholar] [CrossRef]

- Wheatcraft, L.; Ryan, M. Integrated Data as a Foundation of Systems Engineering: Whitepaper by the Requirements Working Group; International Council on Systems Engineering (INCOSE): San Diego, CA, USA, 2018. [Google Scholar]

- Titscher, P.; Schön, P.; Horst, M.; Krewer, U.; Kwade, A. Increasing Energy Densities of Sulfur Cathodes using Dispersing and Calendering Processes for Lithium-Sulfur Batteries. Energy Technol. 2018, 6, 1139–1147. [Google Scholar] [CrossRef]

- Cerdas, F.; Thiede, S.; Herrmann, C. Integrated Computational Life Cycle Engineering—Application to the case of electric vehicles. CIRP Ann. 2018, 67, 25–28. [Google Scholar] [CrossRef]

- UNEP/SETAC Life Cycle Initiative. Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products. 2011. Available online: http://hdl.handle.net/20.500.11822/8001 (accessed on 10 November 2019).

- Costa, D.; Quinteiro, P.; Dias, A.C. A systematic review of life cycle sustainability assessment: Current state, methodological challenges, and implementation issues. Sci. Total Environ. 2019, 686, 774–787. [Google Scholar] [CrossRef] [PubMed]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment; Springer: Cham, Germany, 2018; ISBN 978-3-319-56474-6. [Google Scholar]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Swarr, T.E.; Hunkeler, D.; Klöpffer, W.; Pesonen, H.-L.; Ciroth, A.; Brent, A.C.; Pagan, R. Environmental life-cycle costing: A code of practice. Int. J. Life Cycle Assess. 2011, 16, 389–391. [Google Scholar] [CrossRef]

- Kicherer, A.; Schaltegger, S.; Tschochohei, H.; Pozo, B.F. Eco-efficiency. Int. J. Life Cycle Assess. 2007, 12, 537–543. [Google Scholar] [CrossRef]

- Müller-Langer, F.; Tzimas, E.; Kaltschmitt, M.; Peteves, S. Techno-economic assessment of hydrogen production processes for the hydrogen economy for the short and medium term. Int. J. Hydrogen Energy 2007, 32, 3797–3810. [Google Scholar] [CrossRef]

- Leontief, W. Environmental Repercussions and the Economic Structure: An Input-Output Approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- UNEP/SETAC Life Cycle Initiative. Guidelines for Social Life Cycle Assessment of Products. 2009. Available online: https://www.oeko.de/oekodoc/908/2009-023-en.pdf (accessed on 10 November 2019).

- Harzing, A.-W.; Alakangas, S. Google Scholar, Scopus and the Web of Science: A longitudinal and cross-disciplinary comparison. Scientometrics 2016, 106, 787–804. [Google Scholar] [CrossRef]

- Moed, H.F.; Bar-Ilan, J.; Halevi, G. A new methodology for comparing Google Scholar and Scopus. J. Informetr. 2016, 10, 533–551. [Google Scholar] [CrossRef]

- Scheelhaase, J.; Maertens, S.; Grimme, W.; Jung, M. EU ETS versus CORSIA—A critical assessment of two approaches to limit air transport’s CO 2 emissions by market-based measures. J. Air Transp. Manag. 2018, 67, 55–62. [Google Scholar] [CrossRef]

- Meltzer, J. Climate Change and Trade—The EU Aviation Directive and the WTO. J. Int. Econ. Law 2012, 15, 111–156. [Google Scholar] [CrossRef]

- Lindenthal, A. Aviation and climate protection: EU leadership within the International Civil Aviation Organization. Environ. Politics 2014, 23, 1064–1081. [Google Scholar] [CrossRef]

- U.S. Life Cycle Inventory Database Roadmap; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2009. Available online: https://www.nrel.gov/docs/fy09osti/45153.pdf (accessed on 10 November 2019).

- Wang, C. A multidisciplinary design and analysis environment and its application to aircraft flight dynamics analysis. J. Ind. Inf. Integr. 2016, 1, 14–19. [Google Scholar] [CrossRef]

- Stevens, D.; Striz, A.; Yurkovich, R. An interactive model generator/preprocessor for the multidisciplinary optimization of aircraft. In Proceedings of the 5th Symposium on Multidisciplinary Analysis and Optimization, Panama City Beach, FL, USA, 7–9 September 1994; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1994. [Google Scholar]

- Ireman, T.; Holmberg, G.; Edlund, A. Aspects on design and analysis of composite structures in an integrated analysis environment. Compos. Struct. 1994, 29, 181–189. [Google Scholar] [CrossRef]

- Hwang, H.Y.; Jung, K.J.; Kang, I.M.; Kim, M.S.; Park, S.I.; Kim, J.H. Multidisciplinary aircraft design and evaluation software integrating CAD, analysis, database, and optimization. Adv. Eng. Softw. 2006, 37, 312–326. [Google Scholar] [CrossRef]

- Li, N.; Tan, R.; Huang, Z.; Tian, C.; Gong, G. Agile Decision Support System for Aircraft Design. J. Aerosp. Eng. 2016, 29, 04015044. [Google Scholar] [CrossRef]

- Welstead, J.R.; Caldwell, D.; Condotta, R.; Monroe, N. An Overview of the Layered and Extensible Aircraft Performance System (LEAPS) Development. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2018; p. 395, ISBN 978-1-62410-524-1. [Google Scholar]

- Tristl, C.; Karcher, A.; Klenk, H.; Haubach-Lippmann, C. Towards a Framework for Synchronization of Systems- and Mechanical, Electrical Engineering Processes on Multiple Dimensions; Springer: London, UK, 2013. [Google Scholar]

- Reitenbach, S.; Krumme, A.; Behrendt, T.; Schnoes, M.; Schmidt, T.; Hönig, S.; Mischke, R.; Mörland, E.; Moerland, E. Design and application of a multidisciplinary predesign process for novel engine concepts. J. Eng. Gas Turbines Power 2018, 141, 011017. [Google Scholar] [CrossRef]

- Bryson, D.E.; Haimes, R.; Dannenhoffer, J. Toward the Realization of a Highly Integrated, Multidisciplinary, Multifidelity Design Environment. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2019; p. 541, ISBN 978-1-62410-578-4. [Google Scholar] [CrossRef]

- Moerland, E.; Deinert, S.; Fernaß Daoud, J.D. Collaborative aircraft design using an integrated and distributed multidisciplinary product development process. In Proceedings of the 30th Congress of the Internatinal Council of the Aeronautical Sciences, Daejeon, Korea, 26–30 September 2016. [Google Scholar]

- Silberschatz, A.; Korth, H.F.; Sudarshan, S. Data Models. In Computer Science Handbook, 2nd ed.; Tucker, A.B., Ed.; Taylor & Francis Group, CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Lin, R.; Afjeh, A.A. An XML-Based Integrated Database Model for Multidisciplinary Aircraft Design. J. Aerosp. Comput. Inf. Commun. 2004, 1, 154–172. [Google Scholar] [CrossRef]

- Nagel, B.; Bohnke, D.; Gollnick, V.; Schmollgruber, P.; Alonso, J.J.; Rizzi, A.; La Rocca, G. Communication in Aircraft Design: Can We Establish a Common Language? In Proceedings of the 28th Congress of the International Council of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; pp. 1–13. [Google Scholar]

- Common Parametric Aircraft Configuration Schema (CPACS). Available online: https://github.com/DLR-LY/CPACS (accessed on 29 October 2019).

- Schwinn, D.B.; Kohlgrüber, D.; Scherer, J.; Siemann, M.H. A parametric aircraft fuselage model for preliminary sizing and crashworthiness applications. CEAS Aeronaut. J. 2016, 7, 357–372. [Google Scholar] [CrossRef]

- Li, M.Z.; Ryerson, M.S. Reviewing the DATAS of aviation research data: Diversity, availability, tractability, applicability, and sources. J. Air Transp. Manag. 2019, 75, 111–130. [Google Scholar] [CrossRef]

- Hazen, B.T.; Weigel, F.K.; Ezell, J.D.; Boehmke, B.C.; Bradley, R.V. Toward understanding outcomes associated with data quality improvement. Int. J. Prod. Econ. 2017, 193, 737–747. [Google Scholar] [CrossRef]

- Cox, B.; Jemiolo, W.; Mutel, C. Life cycle assessment of air transportation and the Swiss commercial air transport fleet. Transp. Res. Part D Transp. Environ. 2018, 58, 1–13. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 24008. [Google Scholar] [CrossRef]

- Johanning, A.; Scholz, D. A First Step Towards the Integration of Life Cycle Assessment into Conceptual Aircraft Design; Deutsche Gesellschaft für Luft- und Raumfahrt—Lilienthal-Oberth e.V.: Bonn, Germany, 2013. [Google Scholar]

- Koroneos, C.; Dompros, A.; Roumbas, G.; Moussiopoulos, N. Advantages of the use of hydrogen fuel as compared to kerosene. Resour. Conserv. Recycl. 2005, 44, 99–113. [Google Scholar] [CrossRef]

- Schmidt, P.; Batteiger, V.; Roth, A.; Weindorf, W.; Raksha, T. Power-to-Liquids as Renewable Fuel Option for Aviation: A Review. Chem. Ing. Tech. 2018, 90, 127–140. [Google Scholar] [CrossRef]

- Niklaß, M.; Lührs, B.; Grewe, V.; Dahlmann, K.; Luchkova, T.; Linke, F.; Gollnick, V. Potential to reduce the climate impact of aviation by climate restricted airspaces. Transp. Policy 2019, 83, 102–110. [Google Scholar] [CrossRef]

- Teoh, R.; Schumann, U.; Majumdar, A.; Stettler, M.E.J. Mitigating the Climate Forcing of Aircraft Contrails by Small-Scale Diversions and Technology Adoption. Environ. Sci. Technol. 2020, 54, 2941–2950. [Google Scholar] [CrossRef]

- Hileman, J.I.; Stratton, R.W. Alternative jet fuel feasibility. Transp. Policy 2014, 34, 52–62. [Google Scholar] [CrossRef]

- Schmidt, P.; Weindorf, W.; Roth, A.; Batteiger, V.; Riegel, F. Power-to-Liquids: Potentials and Perspectives for the Future Supply of Renewable Aviation Fuel; German Environment Agency: Dessau-Roßlau, Germany, 2016. [Google Scholar]

- Yilmaz, N.; Atmanli, A. Sustainable alternative fuels in aviation. Energy 2017, 140, 1378–1386. [Google Scholar] [CrossRef]

- Han, J.; Elgowainy, A.; Cai, H.; Wang, M.Q. Life-cycle analysis of bio-based aviation fuels. Bioresour. Technol. 2013, 150, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; Cardoso, T.D.F.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Han, J.; Tao, L.; Wang, M. Well-to-wake analysis of ethanol-to-jet and sugar-to-jet pathways. Biotechnol. Biofuels 2017, 10, 21. [Google Scholar] [CrossRef]

- Neuling, U.; Kaltschmitt, M. Techno-economic and environmental analysis of aviation biofuels. Fuel Process. Technol. 2018, 171, 54–69. [Google Scholar] [CrossRef]

- Lokesh, K. Life Cycle Greenhouse Gas Analysis of Biojet fuels with a Technical Investigation into their Impact on Jet Engine. Biomass Bioenergy 2015, 77, 26–44. [Google Scholar] [CrossRef]

- Capaz, R.; Posada John, A.; Osseweijer, P.; Seabra, J.E.A. Life Cycle Assessment of Renewable Jet Fuel from ethanol: An analysis from consequential and attributional approaches. In Proceedings of the 26th European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–18 May 2018; pp. 1336–1343, ISBN 978-88-89407-18-9. [Google Scholar] [CrossRef]

- Tao, L.; Milbrandt, A.; Zhang, Y.; Wang, W.-C. Techno-economic and resource analysis of hydroprocessed renewable jet fuel. Biotechnol. Biofuels 2017, 10, 261. [Google Scholar] [CrossRef] [PubMed]

- Rye, L.; Batten, D. Alternative Aviation Fuel Feedstock: The Microalgae Solution? In Bioenergy Australia 2011; Bioenergy Australia: Sunshine Coast, Australia, 2011. [Google Scholar]

- Crossin, E. Life cycle assessment of a mallee eucalypt jet fuel. Biomass Bioenergy 2017, 96, 162–171. [Google Scholar] [CrossRef]

- Chao, H.; DeLaurentis, D.A.; Agusdinata, B. Sensitivity Analysis of Fleet-level Life Cycle Carbon Emissions to Biofuel Options and Emission Policy Schemes for the U.S. Commercial Airlines. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017; pp. 1–11. [Google Scholar] [CrossRef]

- Johanning, A. Comparison of the potential environmental impact improvements of future aircraft concept using life cycle assessment. In Proceedings of the 5th Ceas Air & Space Conference, Delft, NL, USA, 7–11 September 2015. [Google Scholar]

- Agusdinata, D.B.; Zhao, F.; Ileleji, K.; DeLaurentis, D. Life cycle assessment of potential biojet fuel production in the United States. Environ. Sci. Technol. 2011, 45, 9133–9143. [Google Scholar] [CrossRef] [PubMed]

- Collier, Z.A.; Connelly, E.B.; Polmateer, T.L.; Lambert, J.H. Value chain for next-generation biofuels: Resilience and sustainability of the product life cycle. Environ. Syst Decis. 2017, 37, 22–33. [Google Scholar] [CrossRef]

- Warshay, B.; Brown, J.J.; Sgouridis, S. Life cycle assessment of integrated seawater agriculture in the Arabian (Persian) Gulf as a potential food and aviation biofuel resource. Int. J. Life Cycle Assess. 2017, 22, 1017–1032. [Google Scholar] [CrossRef]

- Jagtap, S.S. Sustainability assessment of hydro-processed renewable jet fuel from algae from market-entry year 2020: Use in passenger aircrafts. In Proceedings of the 16th AIAA Aviation Technology, Integration, and Operations Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Goldmann, A.; Sauter, W.; Oettinger, M.; Kluge, T.; Schröder, U.; Seume, J.; Friedrichs, J.; Dinkelacker, F. A Study on Electrofuels in Aviation. Energies 2018, 11, 392. [Google Scholar] [CrossRef]

- Pereira, S.R.; Fontes, T.; Coelho, M.C. Can hydrogen or natural gas be alternatives for aviation?—A life cycle assessment. Int. J. Hydrogen Energy 2014, 39, 13266–13275. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle evaluation of hydrogen and other potential fuels for aircrafts. Int. J. Hydrogen Energy 2017, 42, 10722–10738. [Google Scholar] [CrossRef]

- Cox, K.; Renouf, M.; Dargan, A.; Turner, C.; Klein-Marcuschamer, D. Environmental life cycle assessment (LCA) of aviation biofuel from microalgae, Pongamia pinnata, and sugarcane molasses. Biofuels Bioprod. Biorefining 2014, 8, 579–593. [Google Scholar] [CrossRef]

- Hunkeler, D.; Lichtenvort, K.; Rebitzer, G. Environmental Life Cycle Costing; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinheiro Melo, S.; Barke, A.; Cerdas, F.; Thies, C.; Mennenga, M.; Spengler, T.S.; Herrmann, C. Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability 2020, 12, 5663. https://doi.org/10.3390/su12145663

Pinheiro Melo S, Barke A, Cerdas F, Thies C, Mennenga M, Spengler TS, Herrmann C. Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability. 2020; 12(14):5663. https://doi.org/10.3390/su12145663

Chicago/Turabian StylePinheiro Melo, Sofia, Alexander Barke, Felipe Cerdas, Christian Thies, Mark Mennenga, Thomas S. Spengler, and Christoph Herrmann. 2020. "Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools" Sustainability 12, no. 14: 5663. https://doi.org/10.3390/su12145663

APA StylePinheiro Melo, S., Barke, A., Cerdas, F., Thies, C., Mennenga, M., Spengler, T. S., & Herrmann, C. (2020). Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability, 12(14), 5663. https://doi.org/10.3390/su12145663