1. Introduction

Over the past few decades, Italy has witnessed the rise and establishment of a new type of business in the brewing industry, the craft beer industry, which has gained great success and credibility, becoming one of the most significant phenomena in the Italian agro-food sector. The direct, indirect, and induced contribution of the craft brewing sector to the Italian economy is becoming considerable, with approximately 1371 companies (craft breweries, brewpubs, and beer firms; source—

www.microbirrifici.org) operating in the country, for an average annual beer production of approximately 483,000 hectoliters. Indeed, Italy imports almost all brewing raw materials, especially hops [

1]. However, with an ever-increasing demand for craft beer—and specifically hop-heavy IPAs—Italy has started to successfully develop its own hop industry. Hop cones, the inflorescences of the female plant of

Humulus lupulus L., play an important role as flavoring and bittering agents in the brewing industry, which uses about 98% of the world hop production [

2]. The estimated Italian hop area increased up to 80 hectares since 2006, with significant increases in the near future; the average cultivated area per farm is under 6000 m

2 [

1]. To meet the increasing demand from microbreweries, small-scale farms in Italy are trying to harvest their own cultivated hops, either by hand or with the use of hop-picking machines which are not yet optimized, consequently requiring long working times which often lead to a poor-quality product. Only a few Italian farms are self-sufficient in mechanical hop harvesting, because only a few hop farms own hop-picking machines.

Hop plants are characterized by high vegetative development and very rapidly growing bines: Can grow from 10 to 25 cm per day during their vegetative development [

3], up to 6 to 8 m in height in the classic trellis system. Hop is usually cultivated by runners, in rows 3 m apart, and every year several shoots sprout which require support [

3,

4,

5]. The supporting system is usually made of wood poles connected at their top with steel cable [

6]. From this steel cable, 2–4 slanted wires/ strings go down to the soil in a “V” formation. Two-four bines are wrapped around every wire/string [

3,

4,

5,

6,

7].

These plant morphological characteristics make it necessary to mechanize the harvesting and processing phases, even in small-size fields, in order to better preserve the aromatic characteristics of the product and reduce the time from fresh cone harvesting to the production of the final commercial products. Within the same production area in Italy, harvesting solutions have been adopted by farmers, from the hand-picking of cones to the most innovative combination of harvesting and gathering machines that can operate directly in the field [

8]. The most popular harvesting technique in the classical trellis systems is based on two different steps: First, the collection of all main bines in the field, and second, the cone picking, which frequently takes place in a shed of company area. [

9,

10,

11,

12,

13,

14,

15].

As far as both the two steps harvest, the differences in terms of efficiency, working speed, and cleaning of the product after hop-picking machines could be related to an uneven distribution of cones along the bines, caused both by yield differences in single bines and operator errors. This affects the efficiency of the second processing step, due to the increased impurities in the final product (such as stems and leaves), longer working times, greater harvest losses [

16,

17,

18], and poorer quality of the cone, with a consequent economic impact for the farmer [

19,

20,

21]. In order to preserve the quality of hop cones, it is important to reduce the time between the bine harvesting and cone separation: A result which can be achieved, for example, by increasing the working speed of the picking machine. Recent studies highlighted the need to study the entire process flow and life cycle of machine tools to detect areas for improvement in design, processing speed, and use of resources with the aim of increasing environmental awareness and more efficient use of resources [

22,

23,

24,

25]. In another study, in order to evaluate the efficiency of these mechanization systems, different types of the collection were compared, even though they were limited to experimental fields [

26]. It can be useful to compare the different settings of machines with traditional harvesting, i.e., the hand-picking of cones, considering that one bine per working hour can be collected by hand [

27,

28]. Some models are also available which adapt various techniques to farms, in order to optimize the collection/transformation process [

29].

In light of these considerations, the present study mainly aimed at assessing the workload and environment and power requirements of the main harvesting systems which are currently used for hop-harvesting in Italy, considering the fact that this crop is not yet well established. Therefore, we focused on a low mechanization level, which is not representative of the high technology available in the large professional farms of northern Europe, especially with the aim of containing costs. Picking machines are widespread where this crop is well established, but not yet in Italy; this study suggests some technical, affordable solutions for small Italian farmers. We also tested the efficiency of two different settings of a cone picking machine currently used by many European commercial growers, the WOLF 140, which offers a significant economic advantage compared to manual cone picking, a procedure frequently adopted on small-size organic hop farms. In summary, in the first part of the study, hand and mechanical hop-picking were compared, whereas the second part compared mechanical hop-picking at full speed and 75% speed.

3. Results

3.1. General Aspects

The Cascade variety grown on the two farms showed very different morphological characteristics, as shown in

Table 2. The high SD underlines the great variability, especially in the length of bines and number of side-arms.

3.2. Manual Cone Picking

The comparison involved two farms that presented the same varieties and cultivation techniques, with only a 1 m difference in the height of the hop plants. For manual collection, an old self-propelled fruit harvesting truck, functioning solely as a facilitator, was used instead of ladders. The fruit harvesting truck was driven by a small endothermic engine of limited potential (12 kW). The low consumption of the internal combustion engine (around 8 l of diesel fuel per day) makes it environmentally acceptable, also considering the greater work and effort associated with moving ladders and the logistic chain of the picked cones. The time for the manual cone picking of four plastic fruit boxes was 65 ± 5 min on average, for approximately 2 kg of fresh cones. In detail, the grams of collected cones per second ranged from 29.83 to 34.95. The quantity of the product harvested in this experience was less than 1.88 kg h−1.

3.3. Manual Bine Harvesting

It took a long time to cut ten bines by hand. On average, this operation took 325 s, i.e., 5 min and 25 s for four replications.

High variability was observed between the four replications. On average the harvesting time for each replicate was 9 ± 7, 7 ± 3, 8 ± 4, and 7 ± 5 s, respectively, with an average harvesting time of 8 ± 5 s calculated on 40 plants. The different SDs underline the difficult height positioning of the telescopic cutting system for the cut of apical bines. In detail, no significantly different manual harvesting time was observed in the four-replication process (p ≤ 0.172); however, a large difference in harvesting time was reported between individual bines, ranging from 2 up to 26 s for the minimum and maximum time for each bine.

This result might be due to a different number of bines trained per string; high correlations (r = 0.94; p ≤ 0.005) were observed among the bines per string, and seconds for main bines, confirming shorter times for a string with fewer bines: About 84 seconds were necessary to cut a string with nine bines, versus 15 s for a string with two bines. Conversely, no significant difference was observed in time as far as seconds per number of bines are concerned (data not shown). The hand-cut bines were brought to the farm center for their mechanical separation using a single-axle trailer towed by a 35 kW agricultural tractor over a distance of 140 m, with an equally low average tractor consumption of 3 l of diesel fuel per hour.

3.4. Picking Machine Settings

The settings of the picking machine were assessed by comparing their working capacity, bine yield, energy consumption, working time, and cone picking capacity.

A significant increase in the machine working capacity was observed when full speed was used. In detail, an increase of approximately 21% in terms of bines per working hour was registered between full and 75% speed, leading to an approximate 11% increase in cone yield (

Table 3). Slowing from full to 75% speed, a 5.6 W increase in power consumption per bine was recorded, which corresponds to a 5 W increase per kilo (

Table 3).

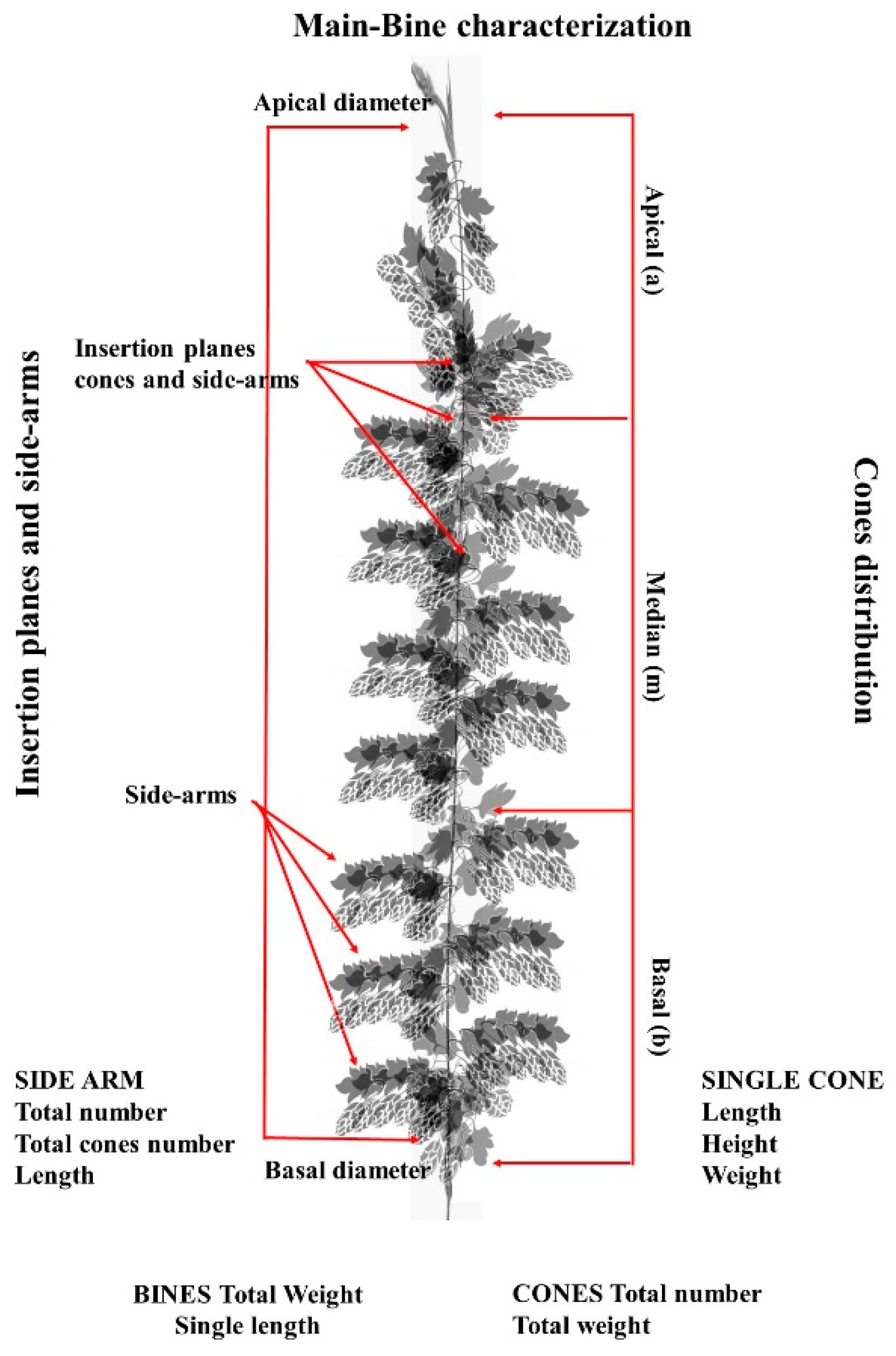

For a better assessment of the cone detachment capacity of the picking machine in relation to fixed settings, bine physical characteristics (i.e., length, basal diameter, apical diameter, weight, side-arms, cone position, and number of cones) were also evaluated in depth. On average, no statistically significant differences (

p ≤ 0.05,

Table 3) were observed among the 10 bines in full-speed engine power compared to the 10 bines in 25% speed reduction engine.

Bine characteristics were not significantly different, with an average length of approximately 3 m and SD of more than 60 cm, weight of 1300 g, and SD of 550 g. Every string had around 1000 cones with an SD of 278. The rather high standard deviations present in all data highlight a significant plant variability but do not affect the mechanical system for cone picking and cleaning. Other features are shown in

Table 3.

A similar trend was also observed on the hop bines used for setting, where there was a 25% feed chain speed reduction. In detail, bine length ranged from 401 to 120 cm in the string, whereas the basal diameter ranged from 5.5 to 3.0 cm in bine 3 and the apical diameter ranged from 2.5 to 0.8 cm. The weight ranged from 2150 to 550 g. Single bine in the same string showed the highest and lowest number of cones ranging from 1478 to 577, respectively. Furthermore, on average, in both cases, approximately 57% of cones were located along the central length of the bines (data not shown), whereas around 40% were located in the apical part of the bines. As far as side-arms are concerned, these showed a short length ranging from 8 to 78 cm with a small number of cones, on average 26 ± 15.

No significant correlations were observed among weight and apical diameter (r = 0.119; p ≤ 0.005), weight and basal diameter (r = 0.119; p ≤ 0.005), and weight and length (r = 0.681; p ≤ 0.005). The weight refers to strings, while diameter and length refer to single bines. Weight variability, on average 1305 ± 540 g, may be due to all the combined physical characteristics (length and diameter) of the bines studied. Furthermore, the total weight might also be affected by the side-arms number, which showed a 67-to-32 variability range on different bines. A high correlation was observed between the weight and number of cones (r = 0.919; p ≤ 0.005).

Figure 2 shows the performance of the picking machine with two different settings in relation to the number of picked cones, damaged cones, and intact cones not detached from bines. There were no significant differences between the two fixed settings in terms of picked cones, damaged cones, and intact unpicked cones. When the engine of the picking machine was set at full speed, 12% of the cones (on average) were not detached, and only 2% of them were damaged (

Figure 2). A high range of variability of cone losses was observed among different bines (3–20%).

When on 75% speed, an average of 10% of the cones were not picked, and 1% of them were damaged (

Figure 2). A similar range of variation among bines was observed in this case also. A high fluctuation of unpicked cones was observed (3–18%). In both cases, the unpicked cones were equally distributed at the base and in the middle of the bine.

3.5. Hop Cone Bitter Acid Content after the Picking Process

The bitter acid content of hops, mainly alpha acid, is an important quality parameter in the hops industry, as it significantly defines the overall hop supply statistics. Thus, this value is the basis for any adjustments in supply contracts containing “alpha clauses” between the brewing industry and the hop industry [

32].

Table 4 shows the bitter acid content of the analyzed hop cones

No significant differences were found among the tested samples. All samples showed a bitter acid content in line with that expected for the cultivar [

33].

4. Discussions

Regarding the first aim of the paper, the Italian trials showed that the number of cones picked manually expressed in kgh

−1 was lower than that in the mechanized system, albeit in line with the US experience of the University of Vermont, which reported on one string (characterized by three main bines) of manual cone picking per hour, not in-field/in-shed [

28]. The significantly different times for the cutting of a string might be due to the different number of shoots wrapped around the vertical supporting wire on which bines develop. The number of bines per string depends on the plant vigor and strength, as well as on the cultivation system chosen by farmers. However, if these data are compared with those of Lutz et al. [

25], much less time, around one second per bine, was needed in the mechanized harvesting of strings. Indeed, a significant time difference was observed, and the manual procedure tested in the Italian area required around 50 times the time of the mechanized procedure for strings only, without cone picking. Moreover, the mechanized harvesting times of strings are inclusive of bine loading and their transport to the shed where the picking machine is kept. In manual string harvesting, the telescopic cutting system adopted for the high cutting is also difficult to position, as confirmed by the different basal and apical cutting time of single main bines.

The results observed in achieving the second objective highlight that there was barely a 10 kg h−1 difference in the working capacity between the two settings. Therefore, this might not be considered a discriminating factor in the choice between the two settings; as for efficiency, if we consider that the manual collection does not reach 2 kg h−1, it is quite apparent that it is always necessary to choose mechanical cone separation, almost independently from the chosen working area.

The specific traits of cone harvesting in the two machine settings did not show a great difference in dimension and weight, while the average length, width, and weight values were 2.4 cm, 1.08 cm, and 0.72 g, respectively. Furthermore, the rather low SD of all values suggested the homogeneity of the cones picked.

The machine setting characterized by a greater loss at separation (full speed, 12%) is also characterized by a slightly larger cone size; in this experience, however, it is not possible to verify whether the length of the cone affected the result, as the difference in values is extremely modest.

Working time data showed that the hourly cost of this picking machine is not easy to assess, but the low market price of this second-hand (yet efficient) machine could increase the interest of Italian farmers in this emerging crop. It should be noted, however, that the total time for manual cone picking consists solely of the operator’s time—which is only quantifiable in terms of manual labor cost. Whereas, the total time and cost of the mechanical solution also includes the labor for the manual bine harvesting in the field, transport, and the time and labor for the manual feeding of the machine. A precise calculation of collection costs must always include the machine cost, which is difficult to determine for emerging supply chains, while keeping the operator cost separate.

The difference in power consumption between the two machine settings, full speed and 75% speed, is very small and it is not possible to prefer one solution over the other, when considering only one bine. However, with a large number of bines processed, a power difference could be observed.

As for the separation performance at the maximum machine speed, which is quite higher than that stated by the manufacturer (170 bines h−1 vs 140 bines h−1), the efficiency of the separation and cleaning system of the machine—in spite of being designed over 40 years ago—is remarkable.

Furthermore, the generally low power consumption both in terms of watts per bine and watts per kg of fresh product, makes this picking machine more sustainable in term of technology costs.

It should be noted that a real economic analysis has not been performed in this study because hops are an emerging crop in Italy, and essential parameters, such as adequate annual use, recovery value, and efficiency maintenance are not available. However, the market price difference between old, but efficient, machines and new hop-picking machines is fivefold, so that, unless a mass production of hop develops, it will be difficult for the best-performing solutions to spread in Italy. It must be stressed that the machine used for the test was properly maintained and in good working condition.

While very little fuel was necessary for the mechanical separation—approximately 5 kWht−1, and less than one liter of diesel fuel for the collection and transport of 100 bines, corresponding to around 20 minutes of tractor use—diesel fuel for the harvesting truck, although limited to 10 l in eight hours, only served for about 15 kg of fresh product with an incidence of 0.6 l per kg of manually collected cones.

As for picking machine settings, the two trials also yielded data both in terms of product quality and performance of the separating machine. The reported loss values remain quite high, approximately 12% for full speed and 10% for 75% speed. In different types of harvesters, lower values, around 2%, are desirable. In these operating conditions, however, this low value is difficult to achieve even below the recommended settings, probably due to the use of rather old technology.

Another aspect of being stressed is the presence of a share of damaged unseparated cones. These cones are probably well connected to the plant, so they break at an intermediate level of the cone, rather than becoming detached completely from the plant. The percentage of damaged cones not detached from the branch remained below 2% in both cases—in particular, 1.75% in full speed and 1.26% in 75% speed. These data confirm the possibility of using the machine always at its maximum potential. The machine encounters the greatest difficulties with a detachment in the experiments conducted at an intermediate position of the branch, i.e., not in the initial setting phase and not in the final release at the end of the separation cycle. These aspects should be further investigated, especially in terms of chosen varieties and harvest time.

The different machines available in other countries are not always suitable for the Italian territory, as mechanical developments are always focused solely on increasing productivity. With the hop crop, their performances currently exceed 400–600 bines h

−1, always in relation to the hectares of hop field surface area [

34]. For the crop areas available in Italy, these new picking machines encounter mostly economic and management limitations, since the timeliness of intervention and the distance of the fields make it impossible to develop an adequate contractor service. As shown in the Californian experience [

35], the option of second-hand models with similar maintenance costs could also be extended to Italy.