Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials

Abstract

:1. Introduction

2. Assumption of the Mechanism for Stabilization BOF Slags in Geopolymer System

3. Experimental

3.1. Materials

3.2. Methods

4. Results and Discussion

4.1. BOF Slags Expansion Behavior and Powdering Rate

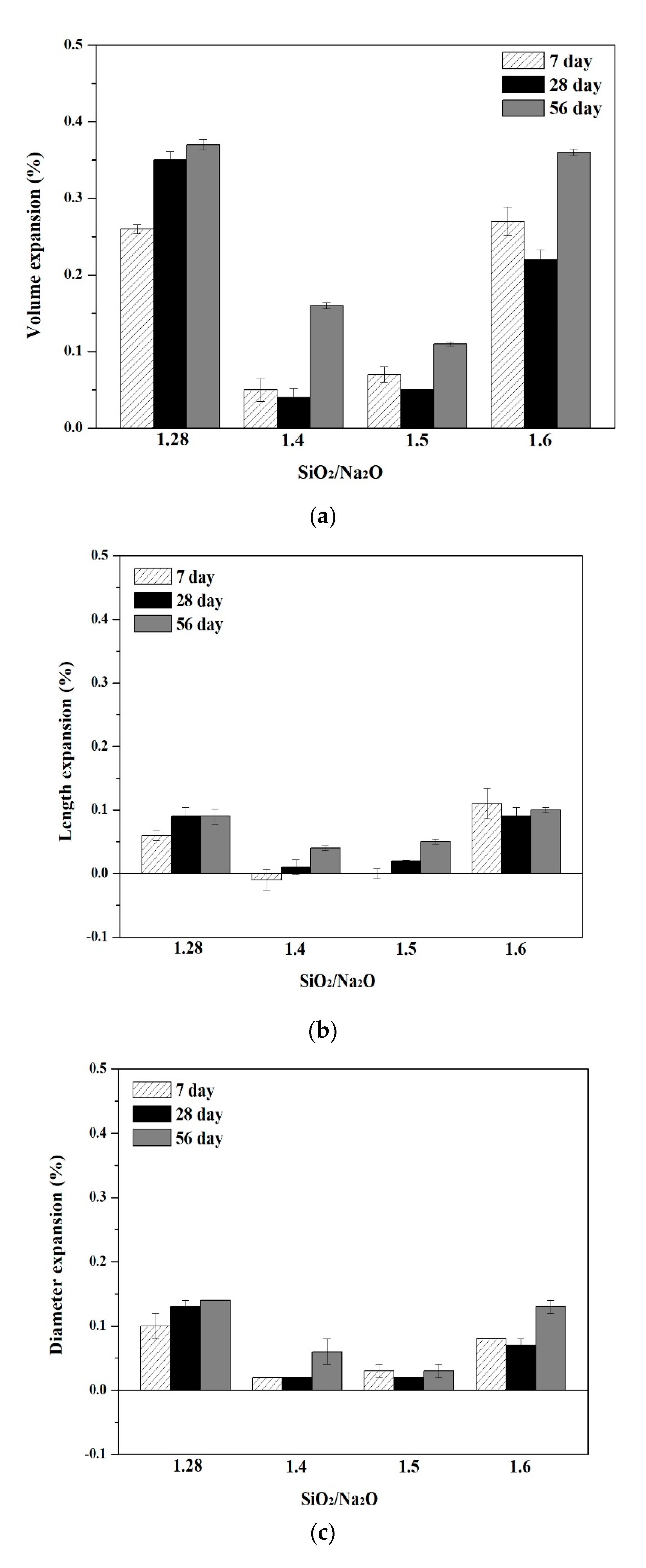

4.2. Effect of SiO2/Na2O Molar Ratio on the Properties of BOF Slag-Based Geopolymer Mortar

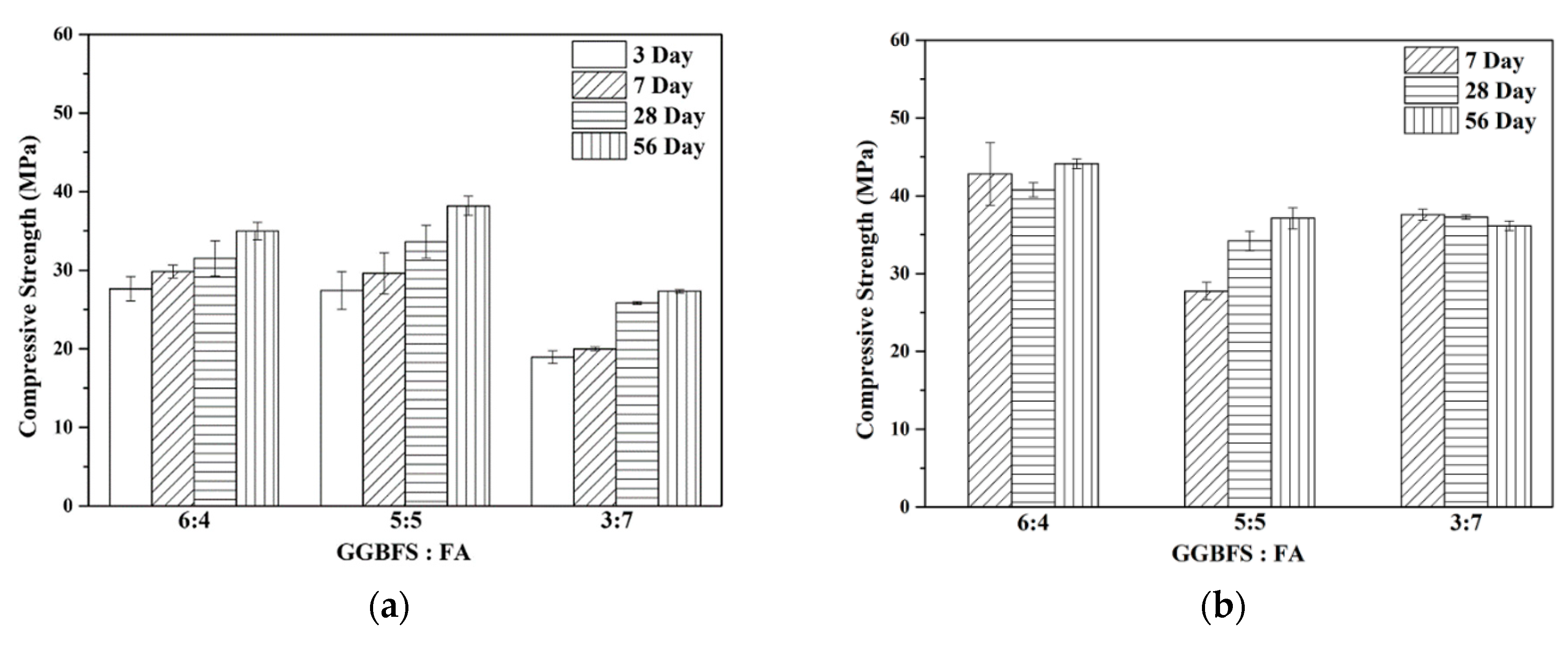

4.3. Effect of GGBS/FA Ratio on the Properties of BOF Slag-Based Geopolymer Mortar

4.4. Laboratory Horizontal Double Shaft Mixer Tests

4.5. BOF Slag-Based Geopolymer Mortar Tests in Ready-Mixed Plant

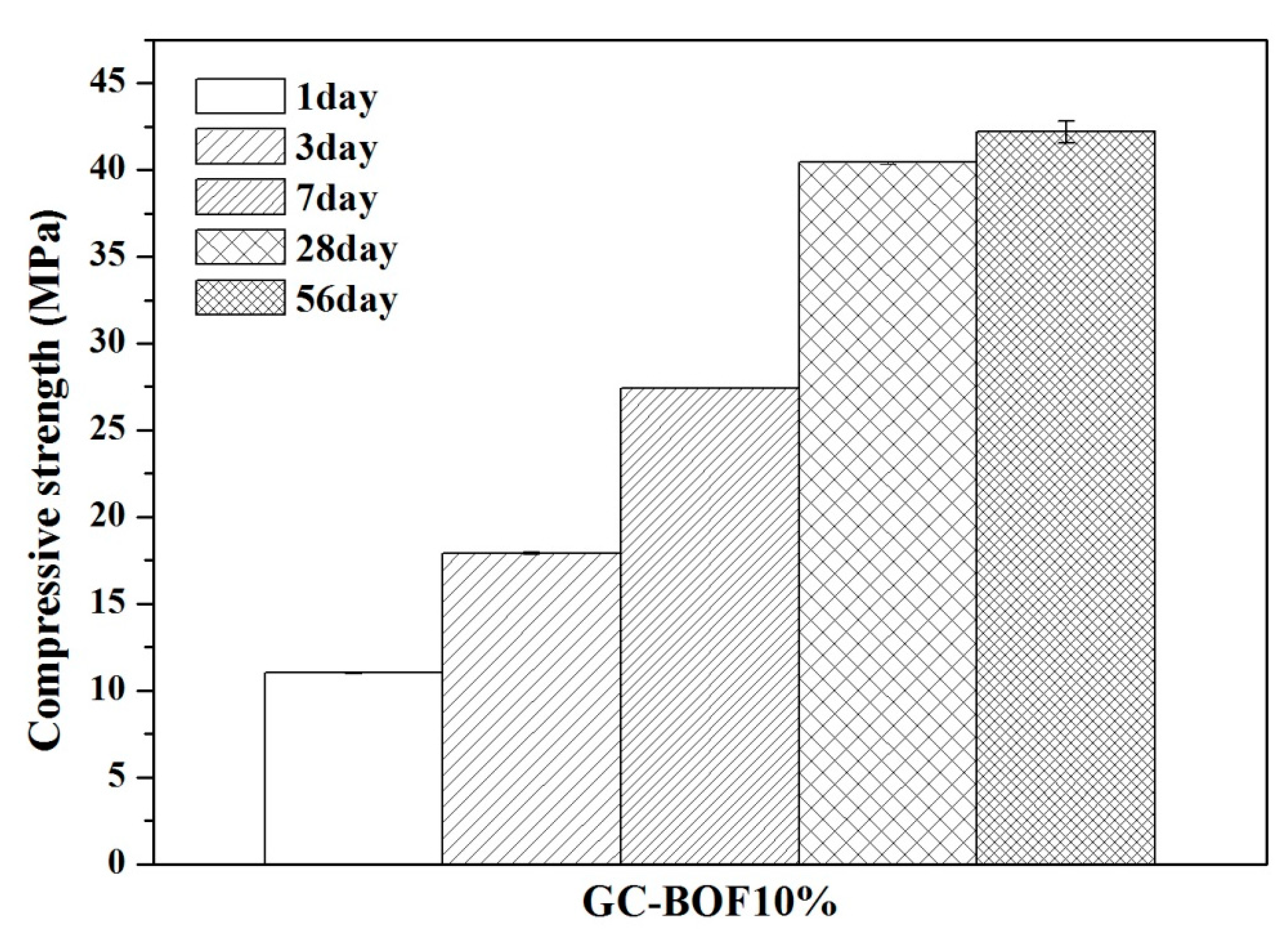

4.5.1. Ready-Mixed Plant Small Scale Tests

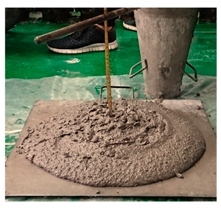

4.5.2. Ready-Mixed Plant Pilot-Scale Tests

5. Conclusions

- Reduction concerning CO2 emissions and consumption of copiously available BOF slag wastes is possible by employing geopolymer technology. Not merely that, it stabilizes the BOF slag production absolutely by turning them into valuable products.

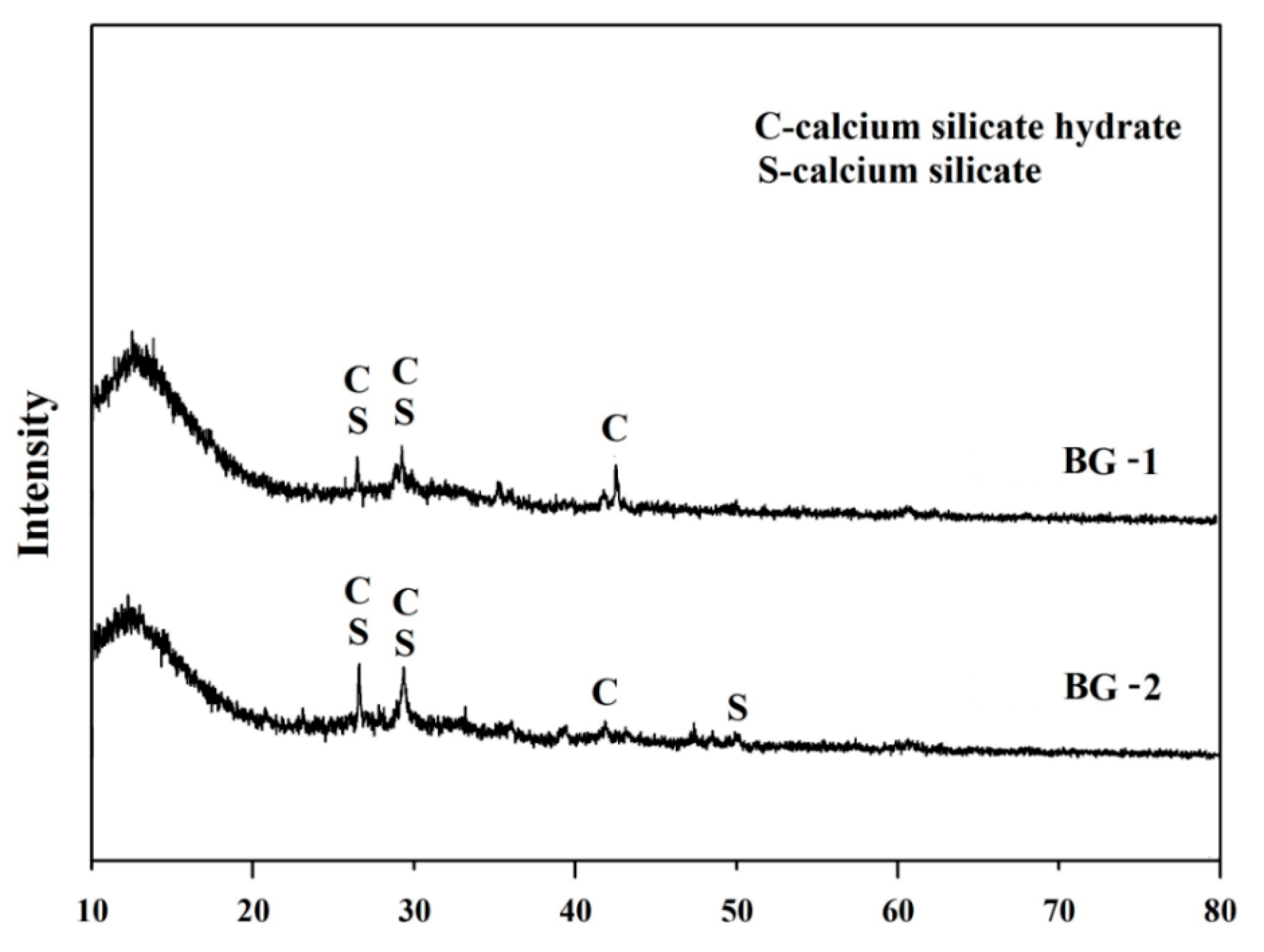

- Stabilization of the BOF slag through geopolymer technology is successfully determined, since their matrix encompasses a large amount of free silicon (Si) which can react with free CaO and free MgO to form stable silicate compounds leading to the addressing of the quandary of BOF slag expansion.

- Lab-scale and ready-mixed plant pilot-scale experimental upshots unveiled that the compressive strength of fine BOF slag-based geopolymer mortar achieved the compressive strength of 30–40 MPa after 28 days, and increased compressive strength. The expansion can be controlled also, less than 0.5% after ASTM C151 autoclave testing.

- A systematic solution for the disposal of the waste accumulation of BOF slags is extended through this novel geopolymer technology since its incorporation is possible in manufacturing, user and eco-friendly green geopolymer composites, otherwise filling land spaces and causing the contamination of environments, ecology, soils, surface and subsurface waters as well as health hazards.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, C.C. Engineering Characteristics of Basic Oxygen Furnace Slag and Used as Base Layer Material. Ph.D. Thesis, National Cheng Kung University, Taiwan, 2005. [Google Scholar]

- Shi, C. Steel slag—Its production, processing, characteristics, and cementitious properties. J. Mater. Civ. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Wang, G. Determination of the expansion force of coarse steel slag aggregate. Constr. Build. Mater. 2010, 24, 1961–1966. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Steel furnace slag aggregate expansion and hardened concrete properties. Cem. Concr. Compos. 2015, 60, 1–9. [Google Scholar] [CrossRef]

- Ding, Y.C.; Cheng, T.W.; Liu, P.C.; Lee, W.H. Study on the treatment of BOF slag to replace fine aggregate in concrete. Constr. Build. Mater. 2017, 146, 644–651. [Google Scholar] [CrossRef]

- Kambole, C.; Paige-Green, P.; Kupolati, W.K.; Ndambuki, J.M.; Adeboje, A.O. Basic oxygen furnace slag for road pavements: A review of material characteristics and performance for effective utilisation in southern Africa. Constr. Build. Mater. 2017, 148, 618–631. [Google Scholar] [CrossRef]

- Lu, T.H.; Chen, Y.L.; Shih, P.H.; Chang, J.E. Use of basic oxygen furnace slag fines in the production of cementitious mortars and the effects on mortar expansion. Constr. Build. Mater. 2018, 167, 768–774. [Google Scholar] [CrossRef]

- Blanco, I.; Molle, P.; Saenz de Miera, L.E.; Ansola, G. Basic Oxygen Furnace steel slag aggregates for phosphorus treatment. Evaluation of its potential use as a substrate in constructed wetlands. Water Res. 2016, 89, 355–365. [Google Scholar] [CrossRef]

- Bodor, M.; Santos, R.M.; Cristea, G.; Salman, M.; Cizer, O.; Iacobescu, R.I.; Chiang, Y.W.; van Balen, K.; Vlad, M.; van Gerven, T. Laboratory investigation of carbonated BOF slag used as partial replacement of natural aggregate in cement mortars. Cem. Concr. Compos. 2016, 65, 55–66. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.H.; Lin, D.F.; Luo, H.L.; Lin, Z.Y. Application of reclaimed basic oxygen furnace slag asphalt pavement inroad base aggregate. Constr. Build. Mater. 2017, 157, 647–653. [Google Scholar] [CrossRef]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Santos, R.M.; Ling, D.; Sarvaramini, A.; Guo, M.; Elsen, J.; Larachi, F.; Beaudoin, G.; Blanpain, B.; Van Gerven, T. Stabilization of basic oxygen furnace slag by hot-stage carbonation treatment. Chem. Eng. J. 2012, 203, 239–250. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Zhang, C.; Wang, G.; Yang, J.; Cai, Y.; Zhao, C. Free CaO stabilisation by mixing of BF slag and BOF slag in molten state. Ironmak. Steelmak. 2018, 45, 969–977. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, C.; Wang, G.; Cai, Y.; Zhao, C. Stabilization of free CaO in molten BOF slag by addition of silica at high temperature. Metall. Res. Technol. 2018, 115, 414. [Google Scholar] [CrossRef] [Green Version]

- Pan, S.Y.; Chiang, P.C.; Chen, Y.H.; Tan, C.S.; Chang, E.E. Ex Situ CO2 Capture by Carbonation of Steelmaking Slag Coupled with Metalworking Wastewater in a Rotating Packed Bed. Environ. Sci. Technol. 2013, 47, 3308–3315. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.W.; Pan, S.Y.; Chen, C.T.; Chen, Y.H.; Chiang, P.C. High-gravity carbonation of basic oxygen furnace slag for CO2 fixationand utilization in blended cement. J. Clean. Prod. 2016, 124, 350–360. [Google Scholar] [CrossRef]

- Singh, N.K.; Mishra, P.C.; Singh, V.K.; Narang, K.K. Effects of hydroxyethyl cellulose and oxalic acid on the properties of cement. Cem. Concr. Res. 2003, 33, 1319–1329. [Google Scholar] [CrossRef]

- Lin, P.C.; Hsieh, H.C.; Ou, M.Y.; Huang, C.H.; Hsueh, W.H. Water Immersing and Aging Treatment of Steel-making Slag (CHC Resources Corp., Taiwan; China Steel Corp., Taiwan). Taiwan Patent TW-I275647, 11 March 2007. [Google Scholar]

- Louati, S.; Hajjaji, W.; Baklouti, S.; Samet, B. Structure and properties of new eco-material obtained by phosphoric acid attack of natural Tunisian clay. Appl. Clay Sci. 2014, 101, 60–67. [Google Scholar] [CrossRef]

- Ferone, C.; Capasso, I.; Bonati, A.; Roviello, G.; Montagnaro, F.; Santoro, L.; Turco, R.; Cioffi, R. Sustainable management of water potabilization sludge by means of geopolymers production. J. Clean. Prod. 2019, 229, 1–9. [Google Scholar] [CrossRef]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of mining waste as aggregates in fly ash-based geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Swanepoel, J.C.; Strydom, C.A. Utilisation of fly ash in a geopolymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- Boca Santa, R.A.A.; Soares, C.; Riella, H.G. Geopolymers with a high percentage of bottom ash for solidification/immobilization of different toxic metals. J. Hazard. Mater. 2016, 318, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Yaseri, S.; Hajiaghaei, G.; Mohammadi, F.; Mahdikhani, M.; Farokhzad, R. The role of synthesis parameters on the workability, setting and strength properties of binary binder based geopolymer paste. Constr. Build. Mater. 2017, 157, 534–545. [Google Scholar] [CrossRef]

- Wang, W.C. Feasibility of stabilizing expanding property of furnace slag by autoclave method. Constr. Build. Mater. 2014, 68, 552–557. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, H.H.; Wang, Y.C.; Xu, D.L. Geopolymer Microstructure and Hydration Mechanism of Alkali-activated Fly Ash-based Geopolymer. Adv. Mater. Res. 2012, 374–377, 1481–1484. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008. [Google Scholar]

- Wang, G.C. The Utilization of Slag in Civil Infrastructure Construction; Woodhead Publishing Series in Civil Engineering; Woodhead Publishing: Duxford, UK, 2016. [Google Scholar]

- Ghosh, S.N. Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and Use; Elsevier: New Delhi, India, 2014. [Google Scholar]

- Cho, Y.K.; Yoo, S.W.; Jung, S.H.; Lee, K.M.; Kwon, S.J. Effect of Na2O content, SiO2/Na2O molar ratio, and curing conditions on the compressive strength of FA-based geopolymer. Constr. Build. Mater. 2017, 145, 253–260. [Google Scholar] [CrossRef]

- Kazemian, H.; Naghdali, Z.; Ghaffari Kashani, T.; Farhadi, F. Conversion of high silicon fly ash to Na-P1 zeolite: Alkaline fusion followed by hydrothermal crystallization. Adv. Powder Technol. 2010, 21, 279–283. [Google Scholar] [CrossRef]

- Yijin, L.; Shiqiong, Z.; Jian, Y.; Yingli, G. The effect of fly ash on the fluidity of cement paste, mortar and concrete. In Proceedings of the International Workshop on Sustainable Development of Concrete Technology, Beijing, China, 20–21 May 2004. [Google Scholar]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various byproduct materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

| Composition | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | f-CaO | LOI. | Others | |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | |||||||||

| BOF Slag | 9.4 | 37.1 | 4.2 | 24.1 | 7.1 | 4.7 | 0.8 | 12.6 | |

| GGBS | 27.7 | 57.9 | 11.2 | 0.4 | – | – | – | 2.8 | |

| FA | 60.2 | 2.7 | 19.1 | 8.7 | – | – | 2.9 | 6.4 | |

| Particle Size Range | Powdering Rate (%) |

|---|---|

| 3/8 inch–#4 mesh | 29.9 |

| 3/4 inch–3/8 inch | 27.8 |

| >3/4 inch | 17.4 |

| BOF Slag in Different System | Before Autoclave Test | After Autoclave Test | |

|---|---|---|---|

| Portland Cement System |  |  | |

| Geopolymer System |  |  | |

| Ave height change | 0.18% | ||

| Ave diameter change | 0.07% | ||

| Ave volume change | 0.35% | ||

| GGBS: FA | Diameter Expansion (%) | Length Expansion (%) | Volume Expansion (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 7d | 28d | 56d | 7d | 28d | 56d | 7d | 28d | 56d | |

| 6:4 | 0.18 | 0.18 | 0.18 | 0.24 | 0.22 | 0.15 | 0.62 | 0.59 | 0.53 |

| 5:5 | 0.03 | 0.02 | 0.02 | 0.01 | 0.02 | 0.03 | 0.07 | 0.05 | 0.10 |

| 3:7 | 0.24 | 0.21 | 0.26 | 0.16 | 0.19 | 0.19 | 0.66 | 0.63 | 0.71 |

| Mix No. | Source Materials | Binder: Aggregate | Wollastonite | L/S | BOF Slags Water Content | |

|---|---|---|---|---|---|---|

| FA | GGBS | |||||

| GC-BOF10% | 5 | 5 | 1:2.75 | 5% | 0.49 | 10% |

| Mix No. | Setting Time | |

|---|---|---|

| Initial | Final | |

| GC-BOF10% | 3 h 15 min | 8 h 40 min |

| Test Specimen GC-BOF10% | Before Autoclave Test | After Autoclave Test | Volume Changed |

|  | 0.27% | |

| Compressive Strength (MPa) | 28.4 | 35.6 |

| NO. | L/S | Binder : Aggregate | Mixture Proportion (kg) | Total Weight (kg) | |||

|---|---|---|---|---|---|---|---|

| GGBS | FA | BOF (15% water) | Alkali Solution | ||||

| Test-1 | 0.41 | 1:2.90 | 15.12 | 15.12 | 100.85 (87.70) | 12.50 | 143.59 |

| Test-2 | 0.38 | 1:1.98 | 19.70 | 19.70 | 90.00 (78.26) | 15.00 | 144.40 |

| NO. | Initial | After 45 Min | ||

|---|---|---|---|---|

| Test-1 | Slump | Slump flow | Slump | Slump flow |

| 265 mm | 540*580 mm | 250 mm | 520*520 mm | |

|  | |||

| Test-2 | Initial | After 45 min | ||

| Slump | Slump flow | Slump | Slump flow | |

| 260 mm | 470*480 mm | 250 mm | 440*440 mm | |

|  | |||

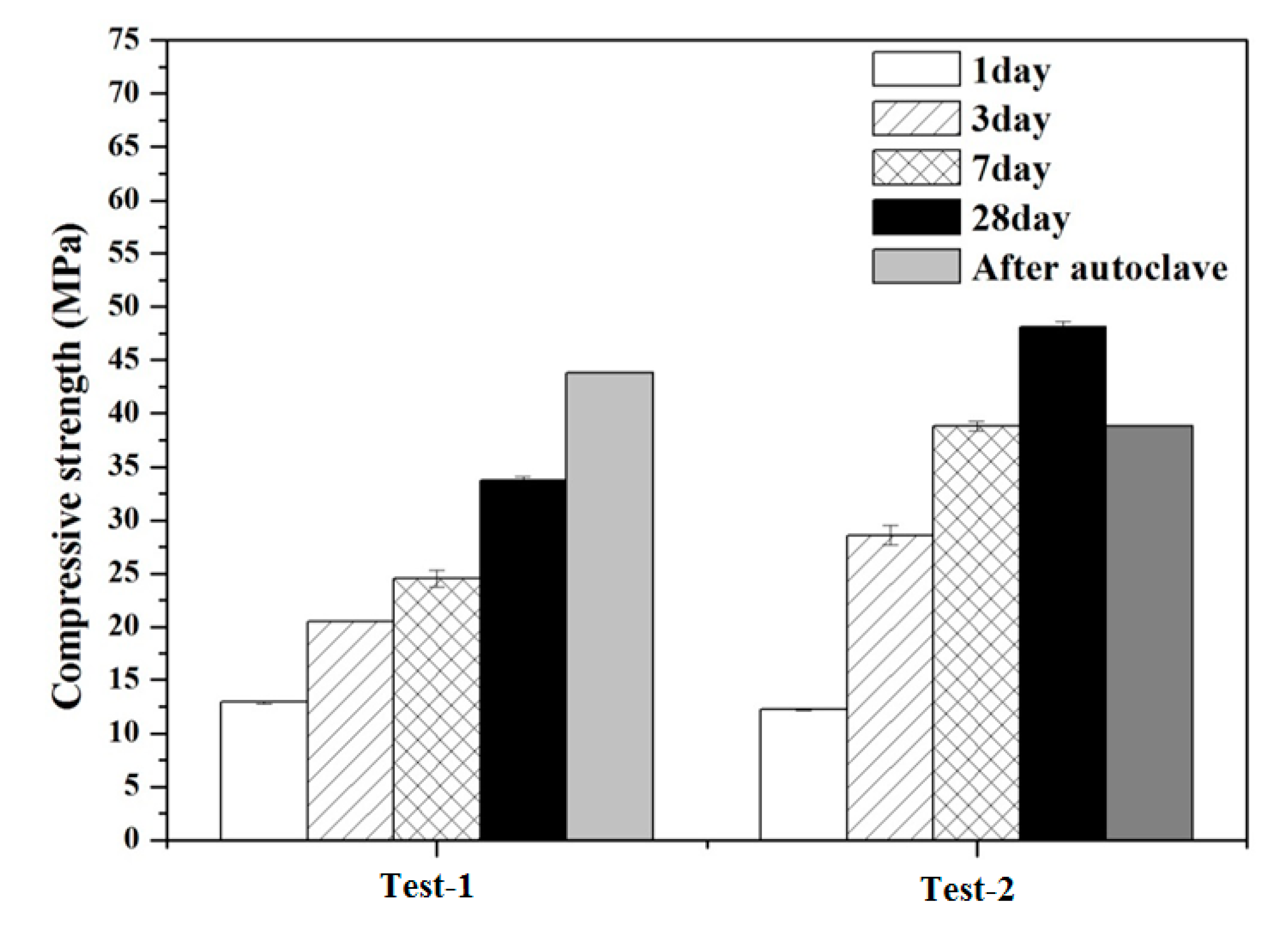

| NO. | Test Time | Compressive Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1d | Ave | 3d | Ave | 7d | Ave | 28d | Ave | After Autoclave Test | ||

| Test-1 | 0 min | 13.2 | 12.9 | 20.4 | 20.5 | 22.9 | 24.5 | 32.9 | 33.7 | 43.8 |

| 45 min | 12.7 | 20.5 | 26.1 | 34.5 | ||||||

| Test-2 | 0 min | 12.1 | 12.2 | 26.8 | 28.6 | 39.7 | 38.8 | 49.3 | 48.1 | 38.8 |

| 45 min | 12.3 | 30.4 | 38.0 | 47.0 | ||||||

| NO. | FA : GGBS | L/S | Binder : Aggregate | Mixture Proportion (kg) | Total Volume and Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Alkali Solution | GGBS | FA | BOF Slag (Wet) | BOF Slag Water Content | Water Added | |||||

| Test-3 | 5:5 | 0.50 | 1:2.936 | 374 | 375 | 375 | 2,400 | 9.0% | 20.0 | 1.5 m3 3544 kg |

| Test-4 | 6:4 | 0.52 | 1:3.575 | 349 | 267 | 400 | 2,560 | 7.4% | 60.0 | 1.5 m3 3636 kg |

| NO. | FA:GGBS | Slump | Slump Flow |

|---|---|---|---|

| Test-3 | 5:5 |  |  |

| 260 mm | 380*390 mm | ||

| Test-4 | 6:4 |  |  |

| 270 mm | 510*490 mm |

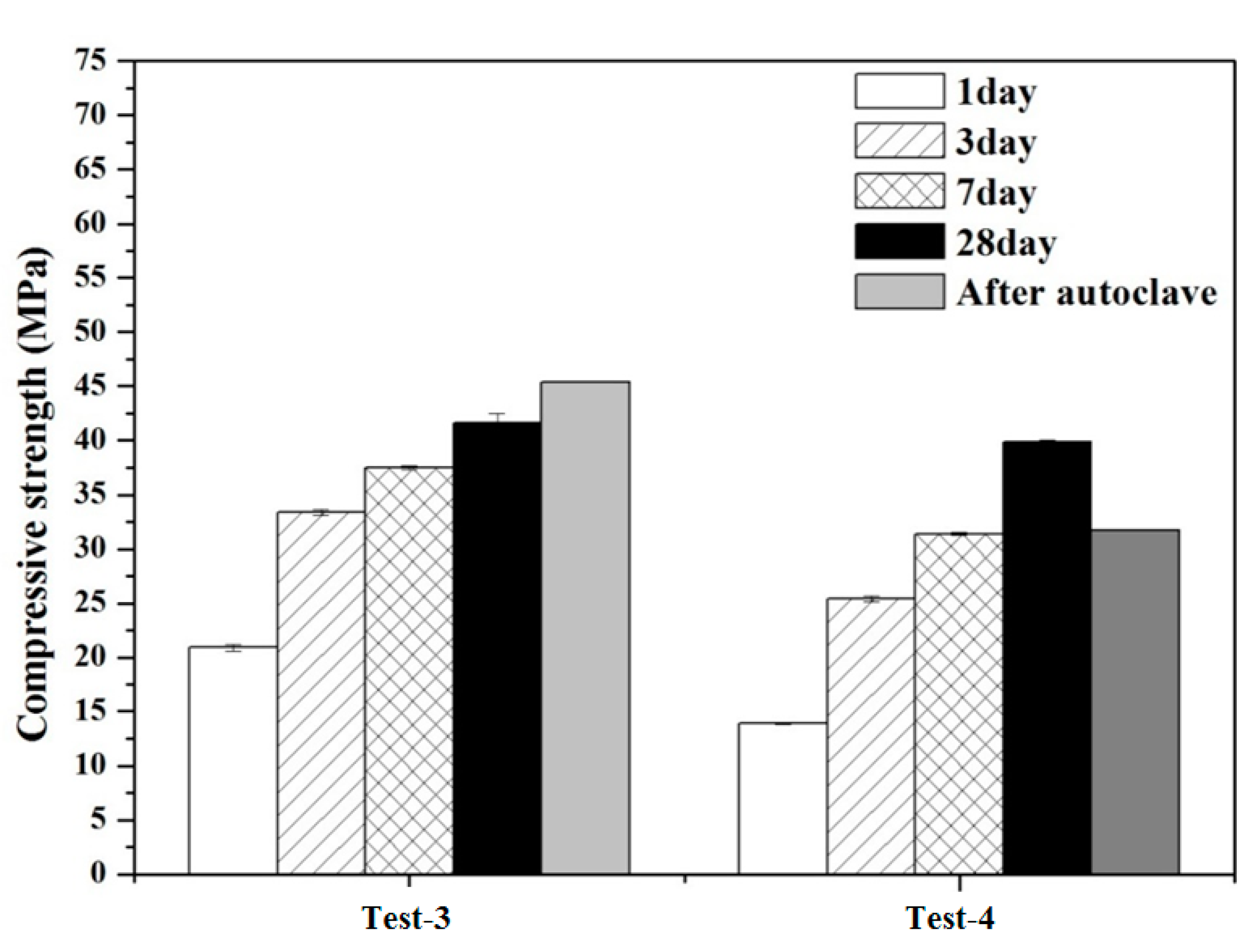

| NO. | FA : GGBS | Compressive Strength (MPa) | Autoclave Test | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1d | Ave | 3d | Ave | 7d | Ave | 28d | Ave | 28d | ||

| Test-3 | 5:5 | 20.3 | 20.9 | 33.9 | 33.4 | 37.2 | 37.5 | 39.7 | 41.6 | 45.4 |

| 21.5 | 32.8 | 37.9 | 43.4 | |||||||

| Test-4 | 6:4 | 13.8 | 13.9 | 24.9 | 25.4 | 31.6 | 31.4 | 39.7 | 39.9 | 31.7 |

| 14.1 | 26.0 | 31.1 | 40.4 | |||||||

| NO. | Expansion Ratio After Autoclave Test (%) | |

|---|---|---|

| Diameter Change | Length Change | |

| Test-3 | −0.41 | −0.41 |

| Test-4 | −0.41 | −0.41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, W.-H.; Cheng, T.-W.; Lin, K.-Y.; Lin, K.-L.; Wu, C.-C.; Tsai, C.-T. Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials. Sustainability 2020, 12, 5002. https://doi.org/10.3390/su12125002

Lee W-H, Cheng T-W, Lin K-Y, Lin K-L, Wu C-C, Tsai C-T. Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials. Sustainability. 2020; 12(12):5002. https://doi.org/10.3390/su12125002

Chicago/Turabian StyleLee, Wei-Hao, Ta-Wui Cheng, Kuan-Yu Lin, Kae-Long Lin, Chia-Cheng Wu, and Chih-Ta Tsai. 2020. "Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials" Sustainability 12, no. 12: 5002. https://doi.org/10.3390/su12125002

APA StyleLee, W.-H., Cheng, T.-W., Lin, K.-Y., Lin, K.-L., Wu, C.-C., & Tsai, C.-T. (2020). Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials. Sustainability, 12(12), 5002. https://doi.org/10.3390/su12125002