A General Framework for Sustainability Assessment of Sheet Metalworking Processes

Abstract

:1. Introduction

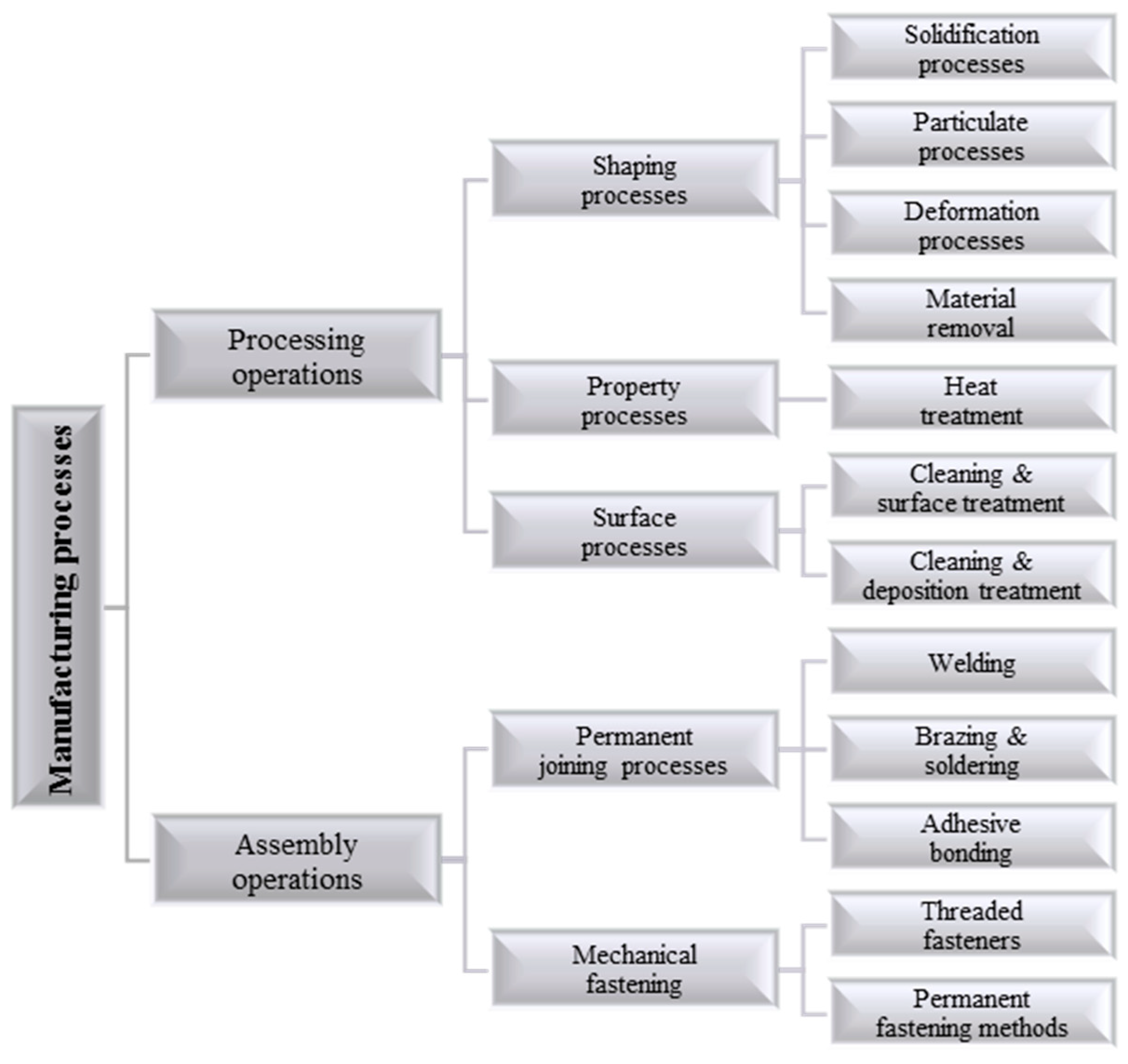

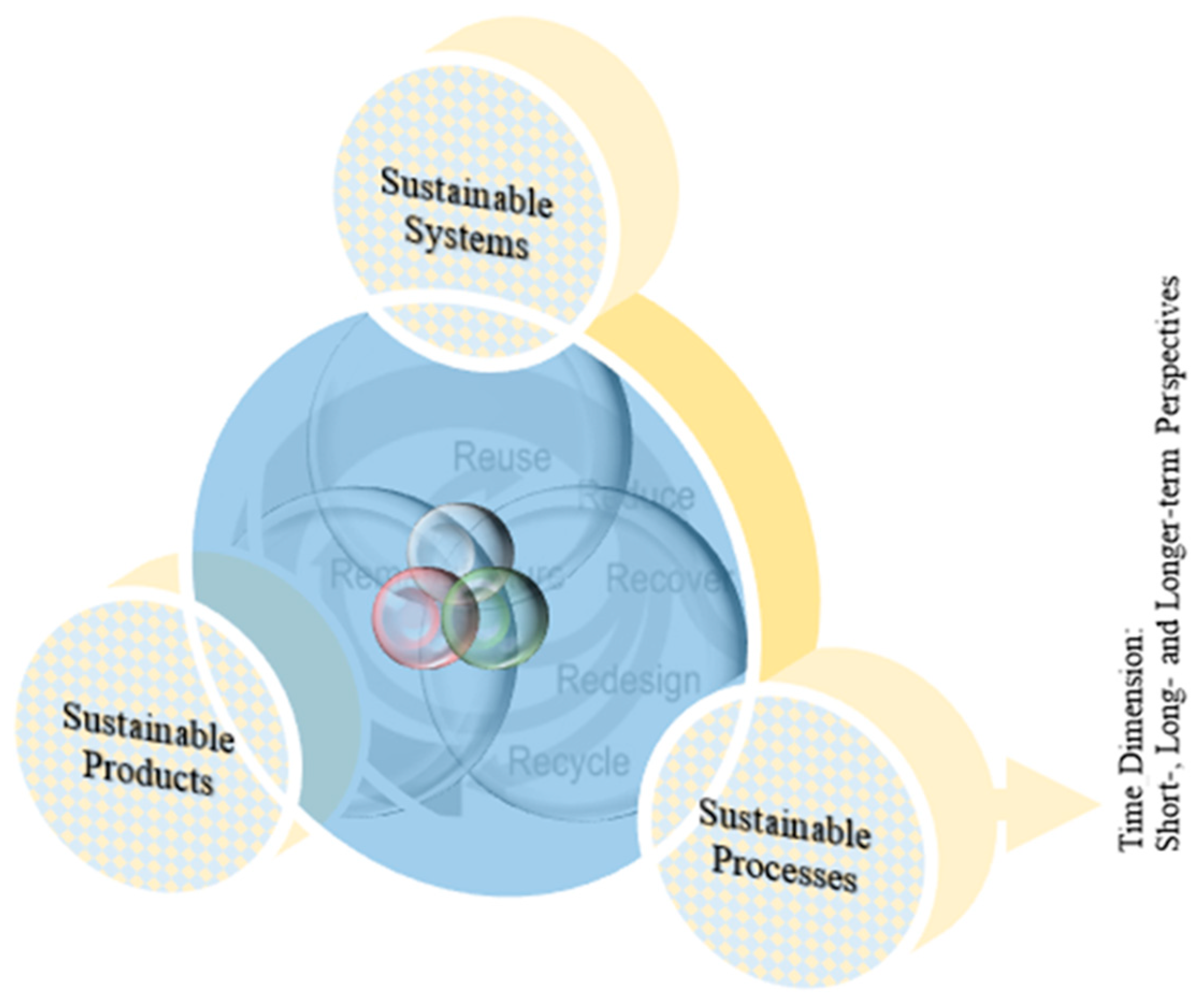

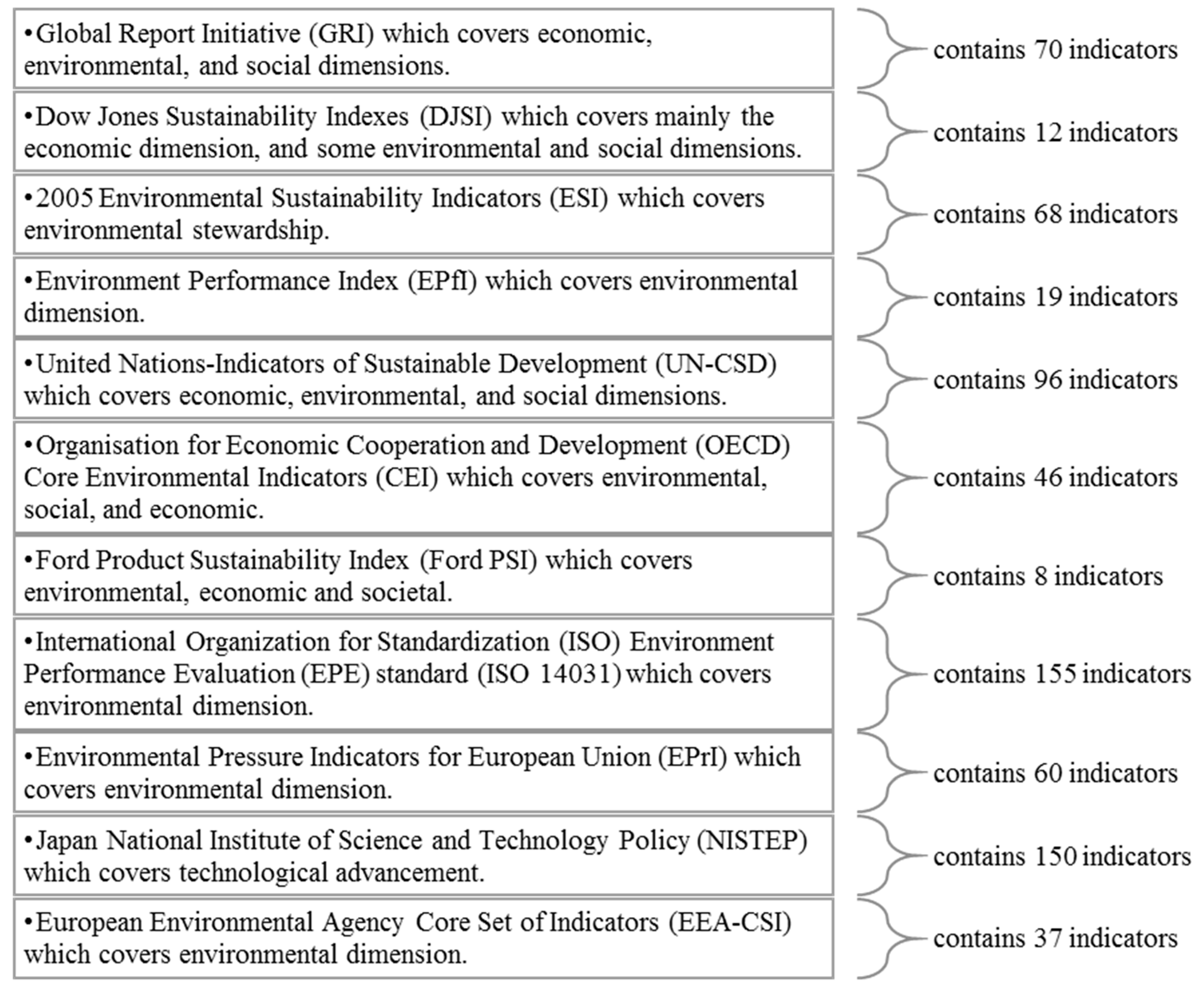

2. Literature Review

Sustainability Assessment of Manufacturing Processes

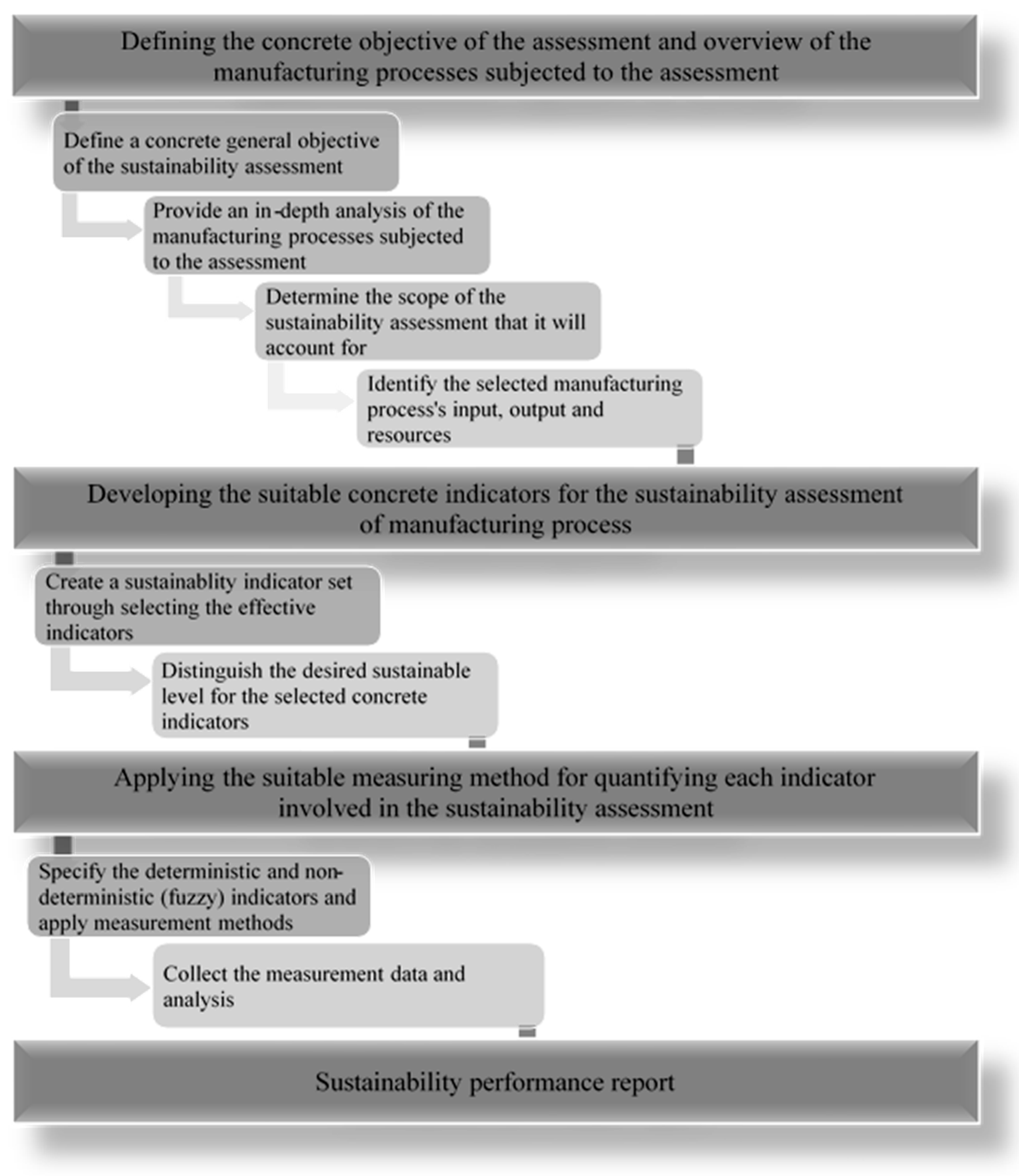

3. A Framework for Sustainability Assessment of Sheet Metalworking Processes

3.1. Step 1: Defining the Concrete Objective of the Assessment and Overview of the Manufacturing Processes Subjected to the Assessment

3.1.1. Concrete General Objective of the Sustainability Assessment

3.1.2. In-Depth Analysis of the Manufacturing Processes Subjected to the Assessment

3.1.3. Scope of the Sustainability Assessment

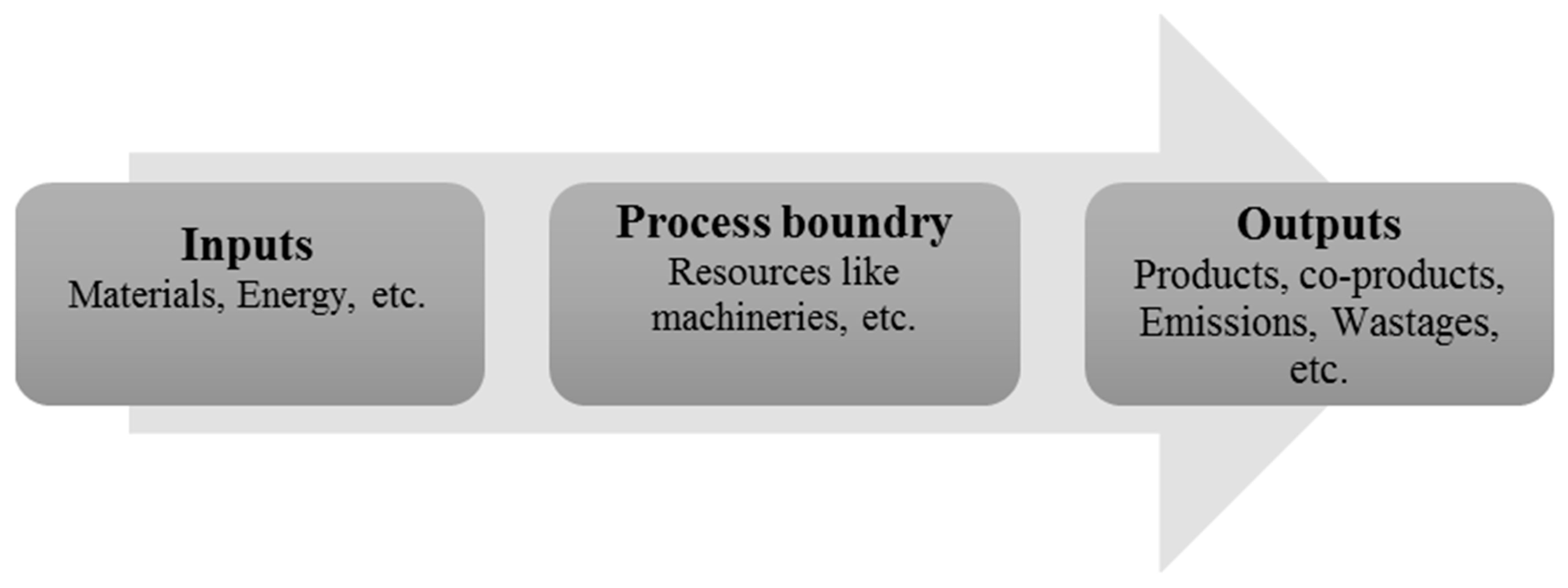

3.1.4. Identifying the Manufacturing Process’s Inputs, Outputs, and Resources

3.2. Step 2: Developing the Suitable Concrete Indicators for the Sustainability Assessment of Manufacturing Process

3.2.1. Creating a Sustainability Indicator Set through Selecting the Effective Indicators

3.2.2. Desired Sustainable Level for the Selected Concrete Indicators: Potentials to Decrease

3.3. Step 3: Applying the Suitable Measuring Methods for Quantifying Each Indicator Involved in the Sustainability Assessment

3.3.1. Deterministic and Non-Deterministic Indicators and their Measurement Methods

3.3.2. Data Collection and Analysis

3.4. Step 4: Sustainability Performance Report

4. Conclusions and Future Research Directions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Lin, L. A methodological framework for the triple bottom line accounting and management of industry enterprises. Int. J. Prod. Res. 2007, 45, 1063–1088. [Google Scholar] [CrossRef]

- Yuan, Y. A System Approach for Reducing the Environmental Impact of Manufacturing and Sustainability Improvement of Nano-Scale Manufacturing. Ph.D. Dissertation, University of Calfornia, Berkeley, CA, USA, 2009. [Google Scholar]

- Saad, M.H.; Nazzal, M.A.; Darras, B.M. A general framework for sustainability assessment of manufacturing processes. Ecol. Indic. 2019, 97, 211–224. [Google Scholar] [CrossRef]

- Sala, S.; Ciuffo, B.; Nijkamp, P. A systemic framework for sustainability assessment. Ecol. Econ. 2015, 119, 314–325. [Google Scholar] [CrossRef]

- Zaim, O. Measuring environmental performance of state manufacturing through changes in pollution intensities: A DEA framework. Ecol. Econ. 2004, 48, 37–47. [Google Scholar] [CrossRef] [Green Version]

- Moldavska, A.; Welo, T. The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. J. Clean. Prod. 2017, 166, 744–755. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W., Jr.; Jawahir, I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Ghadimi, P.; Yusof, N.M.; Saman, M.Z.M.; Asadi, M. Methodologies for measuring sustainability of product/process: A review. Pertanika J. Sci. Technol. 2013, 21, 303–326. [Google Scholar]

- US DOC. The International Trade Administration and the U.S. Department of Commerce’s Definition for Sustainable Manufacturing. 2010. Available online: http://www.trade.gov/competitiveness/sustainablemanufacturing/how_doc_defines_SM.as. (accessed on 30 January 2020).

- Gholami, H.; Jamil, N.; Zakuan, N.; Saman, M.Z.M.; Sharif, S.; Awang, S.R.; Sulaiman, Z. Social value stream mapping (Socio-VSM): Methodology to societal sustainability visualization and assessment in the manufacturing system. IEEE Access 2019, 7, 131638–131648. [Google Scholar] [CrossRef]

- Jamil, N.; Gholami, H.; Saman, M.Z.M.; Streimikiene, D.; Sharif, S.; Zakwan, N. DMAIC-based approach to sustainable value stream mapping: Towards a sustainable manufacturing system. Econ. Res. Ekonomska Istraživanja 2020, 33, 331–360. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Verlinden, B.; Cattrysse, D.; Crauwels, H.; Van Oudheusden, D. The development and application of an integrated production planning methodology for sheet metal working SMEs’. Prod. Plan. Control 2009, 20, 649–663. [Google Scholar] [CrossRef]

- Stoughton, T.B.; Yoon, J.W. A new approach for failure criterion for sheet metals. Int. J. Plast. 2011, 27, 440–459. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Araujo, J.B.; Oliveira, J.F.G. Proposal of a methodology applied to the analysis and selection of performance indicators for sustainability evaluation systems. In Collaborative Product and Service Life Cycle Management for a Sustainable World; Springer: London, UK, 2008; pp. 593–600. [Google Scholar]

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Streimikiene, D. The implementation of lean manufacturing in the furniture industry: A review and analysis on the motives, barriers, challenges, and the applications. J. Clean. Prod. 2019, 234, 660–680. [Google Scholar] [CrossRef]

- Jiran, N.S.; Gholami, H.; Mahmood, S.; Saman, M.Z.M.; Yusof, N.M.; Draskovic, V.; Javovic, R. Application of Activity-Based Costing in Estimating the Costs of Manufacturing Process. Transform. Bus. Econ. 2019, 18, 839–860. [Google Scholar]

- Ingarao, G.; Di Lorenzo, R.; Micari, F. Sustainability issues in sheet metal forming processes: An overview. J. Clean. Prod. 2011, 19, 337–347. [Google Scholar] [CrossRef]

- Badurdeen, F.; Jawahir, I.S. Strategies for value creation through sustainable manufacturing. Procedia Manuf. 2017, 8, 20–27. [Google Scholar] [CrossRef]

- Lozano, R. Envisioning sustainability three-dimensionally. J. Clean. Prod. 2008, 16, 1838–1846. [Google Scholar] [CrossRef]

- Gholami, H.; Rezaei, G.; Saman, M.Z.M.; Sharif, S.; Zakuan, N. State-of-the-art Green HRM System. J. Clean. Prod. 2016, 124, 142–163. [Google Scholar] [CrossRef]

- WCED. Our Common Future, 3rd ed.; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- UN. Agenda 21: The United Nations Programme of Action from Rio; Unite Nations: New York, NY, USA, 1993. [Google Scholar]

- Jawahir, I.S.; Wanigarathne, P.C.; Wang, X. Chapter 12: Product Design and Manufacturing Processes for Sustainability. Mechanical Engineering Handbook, 3rd ed.; Kutz, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; Volume 3, pp. 414–443. [Google Scholar]

- Wanigarathne, P.C.; Ee, K.C.; Jawahir, I.S. Near-dry machining for environmental benign manufacturing-comparison of machining performance with flood cooling and dry machining. In Proceedings of the Design and Manufacture for Sustainable Development, Homerton College, Cambridge, UK, 3–4 September 2003; pp. 39–48. [Google Scholar]

- Wanigarathne, P.C.; Liew, J.; Wang, X.; Dillon, O.W., Jr.; Jawahir, I.S. Assessment of Process Sustainability for Product Manufacture in Machining Operations. In Proceedings of the Global Conference on Sustainable Product Development and Life Cycle Engineering, Berlin, Germany, 29 September–1 October 2004; pp. 305–312. [Google Scholar]

- Jawahir, I.S.; Dillon, O.W., Jr. Sustainable Manufacturing Processes: New challenges for developing predictive models and optimisation techniques. In Proceedings of the 1st International Conference on Sustainable Manufacturing (SM1), Montreal, QC, Canada, 18–19 October 2007. [Google Scholar]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Lu, T.; Gupta, A.; Jayal, A.D.; Badurdeen, F.; Feng, S.C.; Dillon, O.W.; Jawahir, I.S. A framework of product and process metrics for sustainable manufacturing. In Advances in Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 333–338. [Google Scholar]

- Lu, T.; Rotella, G.; Feng, S.C.; Badurdeen, F.; Dillon, O.W.; Rouch, K.; Jawahir, I.S. Metrics-based sustainability assessment of a drilling process. In Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 59–64. [Google Scholar]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Metrics-based approach to evaluate sustainable manufacturing performance at the production line and plant levels. J. Clean. Prod. 2018, 192, 462–476. [Google Scholar] [CrossRef]

- Naidu, S.; Sawhney, R.; Li, X. A methodology for evaluation and selection of nanoparticle manufacturing processes based on sustainability metrics. Environ. Sci. Technol. 2008, 42, 6697–6702. [Google Scholar] [CrossRef] [PubMed]

- Martins, A.; Mata, T.M.; Costa, C.A.V.; Sikdar, S.K. Framework for Sustainability Metrics. Ind. Eng. Chem. Res. 2007, 46, 2962–2973. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. Development of Composite Sustainability Performance Index for steel industry. Ecol. Indic. 2007, 7, 565–588. [Google Scholar] [CrossRef]

- Kim, J.; Park, K.; Hwang, Y.; Park, I. Sustainable manufacturing: A case study of the forklift painting process. Int. J. Prod. Res. 2009, 48, 3061–3078. [Google Scholar] [CrossRef]

- Saidur, R.; Jahirul, M.I.; Rahim, N.A.; Masjuki, H.H.; Mekhilef, S.; Ping, H.W.; Zamaluddin, M.F. Energy Audit and Consumption Study of Malaysian Industrial Sector. 2010. Available online: http://malrep.uum.edu.my/rep/Record/my.um.eprints.8626. (accessed on 1 May 2019).

- Granados, S.; Jawahir, I.S.; Fernandez, J. A comprehensive criterion for sustainability evaluation of machining processes. In Proceedings of the 7th Global Conference on Sustainable Manufacturing, IIT Madras, Chennai, India, 2 December 2009; pp. 385–391. [Google Scholar]

- Rajemi, M.F.; Mativenga, P.T.; Aramcharoen, A. Sustainable machining: Selection of optimum turning conditions based on minimum energy considerations. J. Clean. Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production-part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Silva, N.D.; Jawahir, I.S.; Dillon, O., Jr.; Russell, M. A new comprehensive methodology for the evaluation of product sustainability at the design and development stage of consumer electronic products. Int. J. Sustain. Manuf. 2009, 1, 251. [Google Scholar] [CrossRef] [Green Version]

- Krajnc, D.; Glavic, P. A model for integrated assessment of sustainable development. Resour. Conserv. Recycl. 2005, 43, 189–208. [Google Scholar] [CrossRef]

- Krajnc, D.; Glavic, P. How to compare companies on relevant dimensions of sustainability. Ecol. Econ. 2005, 55, 551–563. [Google Scholar] [CrossRef]

- Sikdar, S.K. Sustainable Development and Sustainability Metrics. AIChE J. 2003, 49, 1928–1932. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; Van Erck, R.P.G. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef] [Green Version]

- Tugnoli, A.; Santarelli, F.; Cozzani, V. An Approach to quantitative sustainability assessment in the early stages of process design. Environ. Sci. Technol. 2008, 42, 4555–4562. [Google Scholar] [CrossRef] [PubMed]

- Tseng, M.; Divinagracia, L.; Divinagracia, R. Evaluating firm’s sustainable production indicators in uncertainty. Comput. Ind. 2009, 57, 1393–1403. [Google Scholar] [CrossRef]

- Sutherland, J.W.; Rivera, J.; Brown, K.L.; Hutchins, M.J.; Jenkins, T.L.; Haapala, K.R. Challenges for manufacturing enterprise to achieve sustainable development. In Proceedings of the 41st CIRP Conference on Manufacturing Systems, University of Tokyo, Tokyo, Japan, 26–28 May 2008. [Google Scholar]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Katholieke Universiteit Leuven, Leuven, Belguim, 31 May–2 June 2006. [Google Scholar]

- Campatelli, G. Analysis of the environmental impact for a turning operation of AISI 1040 Steel. In Proceedings of the IPROMS Conference, Cardiff, UK, 24 March 2009; pp. 6–17. [Google Scholar]

- Feng, S.C.; Joung, C.B. A measurement infrastructure for sustainable manufacturing. Int. J. Sustain. Manuf. 2011, 2, 204. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [Google Scholar] [CrossRef]

- Gupta, A.; Vangari, R.; Jayal, A.; Jawahir, I. Priority Evaluation of Product Metrics for Sustainable Manufacturing. In Global Product Development; Bernard, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Sarkar, P.; Rachuri, S.; Suh, H.W.; Lyons, K.; Sriram, R.D. A measure of product sustainability based on triple bottom line. In Proceedings of the ASME 2009 International Design Engineering Technical conferences & Computers and Information in Engineering conference, San Diego, CA, USA, 30 August–2 September 2009. [Google Scholar]

- Choi, J.K.; Ramani, K. An integrated decision analysis for sustainable product design. In Proceedings of the International Manufacturing Science and Engineering Conference, Evanston, IL, USA, 7–10 October 2008. [Google Scholar]

- Jaafar, I.H.; Venkatachalam, A.; Joshi, K.; Ungureanu, A.C.; De Silva, N.; Rouch, K.E.; Dillon, O.W., Jr.; Jawahir, I.S. Chapter 2: Product design for sustainability: A new assessment methodology and case studies. In Environmentally Conscious Mechanical Design; Kutz, M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jawahir, I.S.; Jayal, A.D. Product and process innovation for modeling of sustainable machining processes. In Advances in Sustainable Manufacturing, Proceedings of the 8th Global Conference on Sustainable Manufacturing; Seliger, G., Khraisheh, M.M.K., Jawahir, I.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 301–307. [Google Scholar]

- Linke, B.S.; Corman, G.J.; Dornfeld, D.A.; Tönissen, S. Sustainability indicators for discrete manufacturing processes applied to grinding technology. J. Manuf. Syst. 2013, 32, 556–563. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.; Jawahir, I.S. Metrics-based sustainability evaluation of cryogenic machining. Procedia CIRP 2015, 29, 520–525. [Google Scholar] [CrossRef]

- Dambhare, S.; Deshmukh, S.; Borade, A.; Digalwar, A.; Phate, M. Sustainability issues in turning process: A study in Indian machining industry. Procedia CIRP 2015, 26, 379–384. [Google Scholar] [CrossRef] [Green Version]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. An assessment of sustainability for turning process in an automobile firm. Procedia CIRP 2016, 48, 538–543. [Google Scholar] [CrossRef] [Green Version]

- Hegab, H.A.; Darras, B.; Kishawy, H.A. Towards sustainability assessment of machining processes. J. Clean. Product. 2018, 170, 694–703. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Herrmann, C.; Egede, P.; Bhakar, V.; Singer, J. Life cycle assessment of arc welding and gas welding processes. Procedia CIRP 2016, 48, 62–67. [Google Scholar] [CrossRef] [Green Version]

- Sproesser, G.; Schenker, S.; Pittner, A.; Borndörfer, R.; Rethmeier, M.; Chang, Y.J.; Finkbeiner, M. Sustainable welding process selection based on weight space partitions. Procedia CIRP 2016, 40, 127–132. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.J.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and social life cycle assessment of welding technologies. Procedia CIRP 2015, 26, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Ingarao, G.; Ambrogio, G.; Gagliardi, F.; Di Lorenzo, R. A sustainability point of view on sheet metal forming operations: Material wasting and energy consumption in incremental forming and stamping processes. J. Clean. Prod. 2012, 29, 255–268. [Google Scholar] [CrossRef]

- Ingarao, G. Manufacturing strategies for efficiency in energy and resources use: The role of metal shaping processes. J. Clean. Prod. 2017, 142, 2872–2886. [Google Scholar] [CrossRef]

- Duflou, J.R.; Kellens, K.; Dewulf, W. Environmental performance of sheet metal working processes. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 473, pp. 21–26. [Google Scholar]

- Aalbregtse, R.J.; Hejka, J.A.; Mcneley, P.K. TQM: How do you do it? Autom. August 1991, 32, 30–32. [Google Scholar]

- Popper, K.R. The Myth of the Framework. In Defence of Science and Rationality; Routledge: London, UK, 1994. [Google Scholar]

- Hacking, T.; Guthrie, P. A framework for clarifying the meaning of Triple Bottom-Line, Integrated, and Sustainability Assessment. Environ. Impact Assess. Rev. 2008, 28, 73–89. [Google Scholar] [CrossRef]

- Lin, T.; Lin, J.; Cui, S.; Cameron, S. Using a network framework to quantitatively select ecological indicators. Ecol. Indic. 2009, 9, 1114–1120. [Google Scholar] [CrossRef]

- Ragland, B. Measure, Metric or Indicator: What’s the Difference? Crosstalk 1995, 8, 29–30. [Google Scholar]

- Niemeijer, D.; de Groot, R.S. A conceptual framework for selecting environmental indicator sets. Ecol. Indic. 2008, 8, 14–25. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholami, H.; Saman, M.Z.M.; Sharif, S.; Md Khudzari, J.; Zakuan, N.; Streimikiene, D.; Streimikis, J. A General Framework for Sustainability Assessment of Sheet Metalworking Processes. Sustainability 2020, 12, 4957. https://doi.org/10.3390/su12124957

Gholami H, Saman MZM, Sharif S, Md Khudzari J, Zakuan N, Streimikiene D, Streimikis J. A General Framework for Sustainability Assessment of Sheet Metalworking Processes. Sustainability. 2020; 12(12):4957. https://doi.org/10.3390/su12124957

Chicago/Turabian StyleGholami, Hamed, Muhamad Zameri Mat Saman, Safian Sharif, Jauharah Md Khudzari, Norhayati Zakuan, Dalia Streimikiene, and Justas Streimikis. 2020. "A General Framework for Sustainability Assessment of Sheet Metalworking Processes" Sustainability 12, no. 12: 4957. https://doi.org/10.3390/su12124957

APA StyleGholami, H., Saman, M. Z. M., Sharif, S., Md Khudzari, J., Zakuan, N., Streimikiene, D., & Streimikis, J. (2020). A General Framework for Sustainability Assessment of Sheet Metalworking Processes. Sustainability, 12(12), 4957. https://doi.org/10.3390/su12124957