1. Introduction

Upgrading the energy efficiency of buildings has become a global issue; many governments have established goals for the reduction of greenhouse gas (GHG) emissions and energy use. In the construction sector, buildings account for 24% of total energy consumption [

1,

2]. The environmental performance of new buildings has been continuously improved due to consistent updating of regulations and green building certification standards. However, the majority of existing buildings, which make up 99% of the building sector, demonstrate relatively poor energy performance and thus have a negative impact on the energy consumption of the building sector [

3]. It has been reported that newly built homes emit 0.86 tons of carbon dioxide on average, while existing homes produce 1.6 tons [

4]. Additionally, the environmental impact of extending the life cycles of buildings is significantly less than that of demolition and new construction [

5]. Regarding these issues, Sunikka [

6] has argued that the real potential for sustainable construction and CO

2 reduction lies in the management of existing buildings in the residential sector.

To address this issue, many countries and organizations have tried to increase energy efficiency in the existing building sector over the last decade. The U.S. federal government has financially supported the refurbishment of existing buildings, and Australia has also invested a significant amount of money into increasing the energy efficiency of existing buildings [

3]. In 2014, the Korean government set the goal of reducing GHG emissions by 37%, relative to the business-as-usual (BAU) standard of 851,000,000 tons, by 2030 [

2] and initiated a project supporting “green remodeling” to improve the energy performance of existing buildings. The Ministry of Land, Infrastructure, and Transport (MOLIT) and the Korea Land and Housing Corporation (LH) are supporting this project, which involves both the public and private construction sectors.

Many researchers have examined various aspects of green refurbishment. Numerous studies have investigated the current status and methodologies related to green refurbishment in various local environments. Methodologies and state-of-the-art techniques for retrofitting existing buildings have been investigated, as well as future directions in the field [

3,

7]. Some research has also focused on the impact of the green refurbishment of local historic buildings on real estate markets [

8].

At present, the largest benefit of building refurbishment is considered to be energy savings. To maximize the effects of green refurbishment, many factors must be considered, proper decision-making processes must be employed, and appropriate tools must be used [

9,

10]. Thus, research has been conducted on decision-making methods and tools for green refurbishment to achieve optimum energy efficiency [

11,

12]. Some studies have focused on the hierarchy of refurbishment strategies to achieve zero-carbon buildings [

13]. Korean researchers have also developed decision-making frameworks for green refurbishment, considering the government-funded Green Remodeling project, and investigated their applicability [

14,

15].

To achieve maximum energy efficiency for buildings, performance evaluation has been studied as a key factor for green refurbishment. Building energy simulation studies have been conducted as a common tool for pre-performance evaluation at the design stage [

16,

17,

18]. Many researchers have used diverse building energy simulation programs to evaluate refurbishment settings, the performance of different design strategies, the performance of new materials, and economic feasibility in different local and climatic conditions [

1,

19,

20,

21]. Additionally, emphasis has been placed on the importance of field measurement as a post-performance evaluation method [

22,

23,

24]. Various green refurbishment factors have been investigated to evaluate performance, such as airtightness, insulation, and building envelope, and many researchers have reported specific energy saving results based on field measurements in diverse countries [

23,

25,

26]. The Korean government has developed a national building energy management system, based on which comparative performance evaluations have been conducted considering performance before and after green refurbishment [

2,

27,

28,

29]. Additionally, Ascione et al. [

24] proposed a performance analysis methodology for green refurbishment based on the comprehensive evaluation methods of field measurement and energy simulation. In this context, The purpose of this study is to verify the heating energy reduction and to improve the indoor thermal environment via green refurbishment of an existing building (though passive house-level insulation, high performance windows, and an increase in air-tightness). To achieve this, one of two identical rooms in the existing building, with the same size and orientation, were refurbished to conduct comparative analysis. The indoor environment and heating energy consumption were monitored, and the data were analyzed.

Many studies have investigated the enhancement of performance through green refurbishment, but field studies on the improvement of thermal performance require further investigation regarding performance evaluation and variation across different climatic conditions. Therefore, this paper discusses the improvement and evaluation of performance through green refurbishment. An existing building (85 m2) that met the size requirements for the reception of government funding for a green refurbishment project was selected as the test site. The building’s energy performance was initially analyzed using an energy simulation program (DesignBuilder), after which refurbishment construction was conducted on the building. Multiple monitoring experiments were then performed to measure the building’s heating performance in winter, and a comparative analysis was conducted.

2. Materials and Methods

2.1. Test Building

The test building was constructed in 2006 and is located in Yangji-meon, Cheoin-gu, Yong-In City, South Korea, which is 40 km to the South-East of Seoul. The site is located in a rural area and is far enough from the neighboring houses that they will not be affected physically. It is a two-story residential building with a reinforced concrete structure, and the test rooms are on the first floor of the building. Although the building was registered as a residential building, the whole building was designed as a testbed for the research. In particular, two rooms on the first floor were designed to compare the building performances in terms of different materials, design, etc.

The building code for insulation in 2006 was much lower than that of the current requirements, and the windows and finishing materials have aged. Therefore, this building was selected as a test site to validate the performance improvement created by green refurbishment. Two rooms in the building were selected to compare and verify the thermal performance of green refurbishment.

2.2. Energy Simulation

An energy simulation was initially conducted on rooms in the building to analyze the performance improvement of green refurbishment, and the DesignBuilder software (using the EnergyPlus engine) was selected for energy simulation. Various combinations of different materials were analyzed, and final materials were selected considering energy performance improvement as well as economic feasibility. A climate data file (EPW) for Yong-In city (the building site) was obtained from the national weather station and applied in the energy simulation.

2.3. Test Building and Green Refurbishment

Green refurbishment construction was conducted based on the results of the simulation and material selections. One room was selected as the control site and remained in its original state. The other room was used as the experimental site for green refurbishment elements. The existing reinforced concrete structure and doors were reused in both units. To enhance the thermal performance of the green refurbishment site, additional insulation material was applied inside the walls, the existing windows were replaced with high-performance windows, and seals were installed around the windows. The inner partition wall between the two test rooms was also augmented with additional insulation to prevent thermal interference. The green refurbishment was completed on 28 January 2016, and the test sites were stabilized without any residents or use before the monitoring experiments.

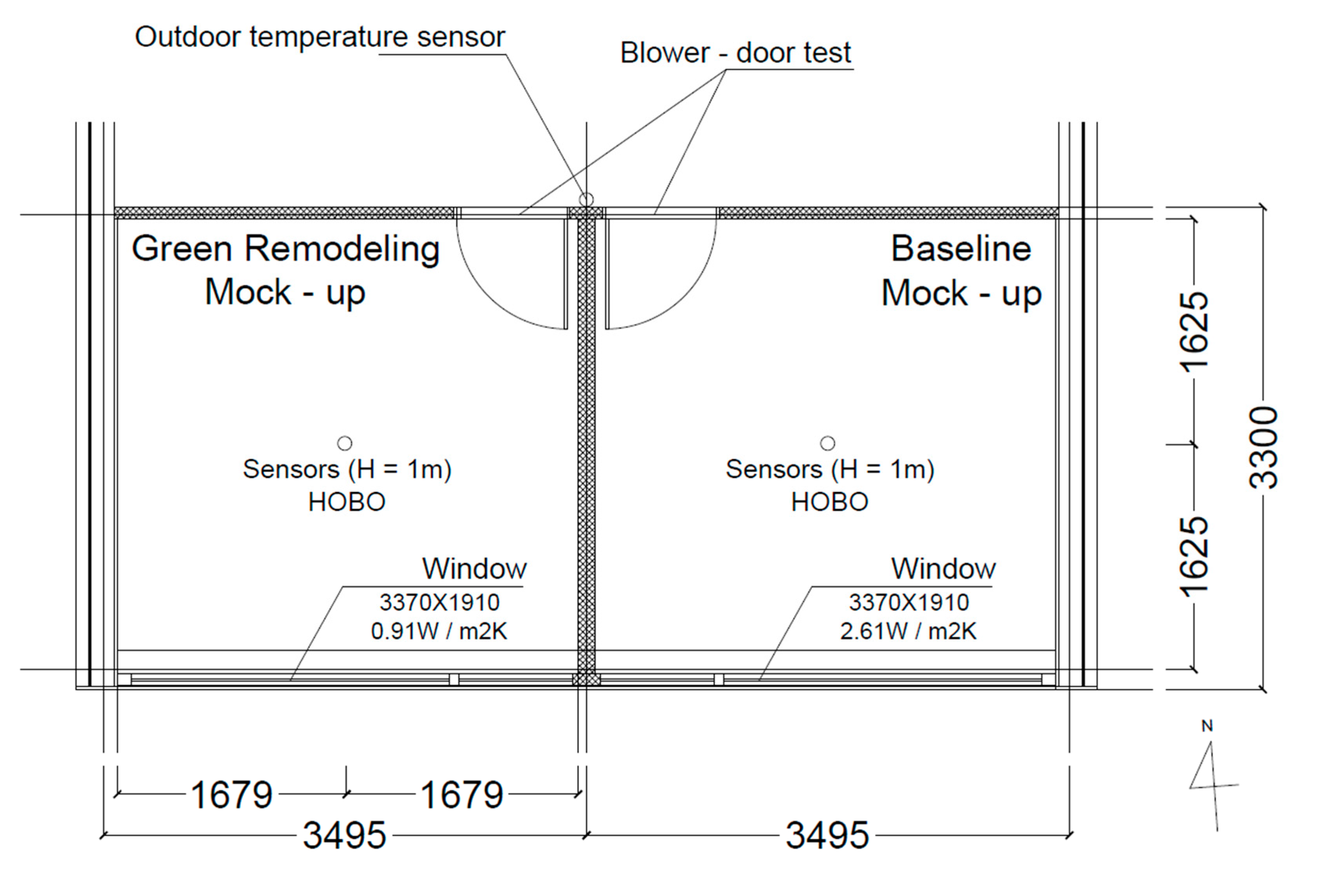

The two test rooms in the building faced south for optimum passive solar use. The east room was selected as a baseline (BL) room (control group), and the west room was selected as a green refurbishment (GR) room (experimental group). The rooms were identical in size and plans, with measurements of 3.495 m (W) × 3.3 m (D) × 2.4 m (H) and a floor area of 11.53 m

2. The rooms were also separated from the common area by an insulated partition wall to minimize impact caused by the adjacent space (

Figure 1).

The outer wall of the existing building is 404 mm and consists of drywall on the inside, a 180 mm reinforced concrete structure, 100 mm extruded polystyrene insulation with an air gap, and a lightweight soil block outside. The inner partition wall was planned with 70 mm glass wool insulation and drywall on each side (89 mm), and the U-value was 0.426 W/m

2K. The floor of both sites consists of 100 mm of leveling concrete, 300 mm of reinforced concrete, and 120 mm of cement mortar. The thickness of the floor is 520 mm, and the U-value was 2.142 W/m

2K. The ceiling consists of 300 mm of reinforced concrete, 120 mm of cement mortar, and 30 mm of wood siding (making a total of 450 mm), and the U-value was 1.448 W/m

2K. The material property of the outer wall, floor, ceiling, and inner wall are demonstrated in

Table 1,

Table 2,

Table 3 and

Table 4.

The existing windows in the test rooms were installed on the south wall, and the entrance doors were located on the north inner walls, which were connected to the indoor corridor. A double-glazed window with poly vinyl chloride (PVC) frames, which was previously installed, remained in the baseline test room, and the window in the green refurbishment test room was replaced with a triple low-E window with a PVC frame (U-value: 0.91 m

2K). The plan and specifications of the window are shown in

Figure 2 and

Table 5.

2.4. Monitoring Equipment and Method

Blower-door tests were conducted to measure the airtightness of the rooms following the KS L ISO 9972 regulation. The blower door test determines the average air infiltration under a certain atmospheric pressure and shows the indoor air changes that occur within an hour (1/h). In a German passive house, 60% indoor air changes per hour at 50 Pa is the standard, which is presented as 50 Pa = 0.6 (1/h). The Minneapolis Blower Door

TM DG-700: Model 3 blower door fan of TEC Co. was used in the experiment and was manufactured according to the DIN EN 13829 standard. TECTITE

TM building airtightness software was used for airtightness data analysis. Compression and decompression tests were conducted separately for each room, and the average value between the two tests was determined to validate the airtightness of each room. Specifications concerning the blower door test equipment are shown in

Table 6.

HOBO type data loggers by Onset computer were used to measure indoor and outdoor temperature (Model: UX100-011). The measurement range is 20~70 °C with ± 0.21 °C accuracy (at 0~50 °C). All sensors were installed on 30 January 2016, and were tested before the start of the monitoring experiments. Indoor temperature sensors were placed at a height of one meter in the center of the floor in each room. Outdoor temperature sensors were installed on the north side of the building, and a shading cover was installed on each sensor to prevent direct solar radiation while providing ventilation around the sensor. The temperature was measured and recorded every 60 seconds, and data were collected after each experiment.

2.5. Test Method

The monitoring experiments were conducted from February 10th to 29th, 2016, which is late winter in Korea. Heating experiments were conducted to validate indoor thermal performance improvement. An electric fan heater (power consumption: 2500 W) set to 18 °C was used for heating. The heater was placed in the center of the room, 50 cm lower than the indoor temperature sensor to prevent interference. The heater operated 24 h a day during the heating experiment. A watt-hour meter was connected to the heater to measure electricity usage, and results for the BL room and GR room were compared.

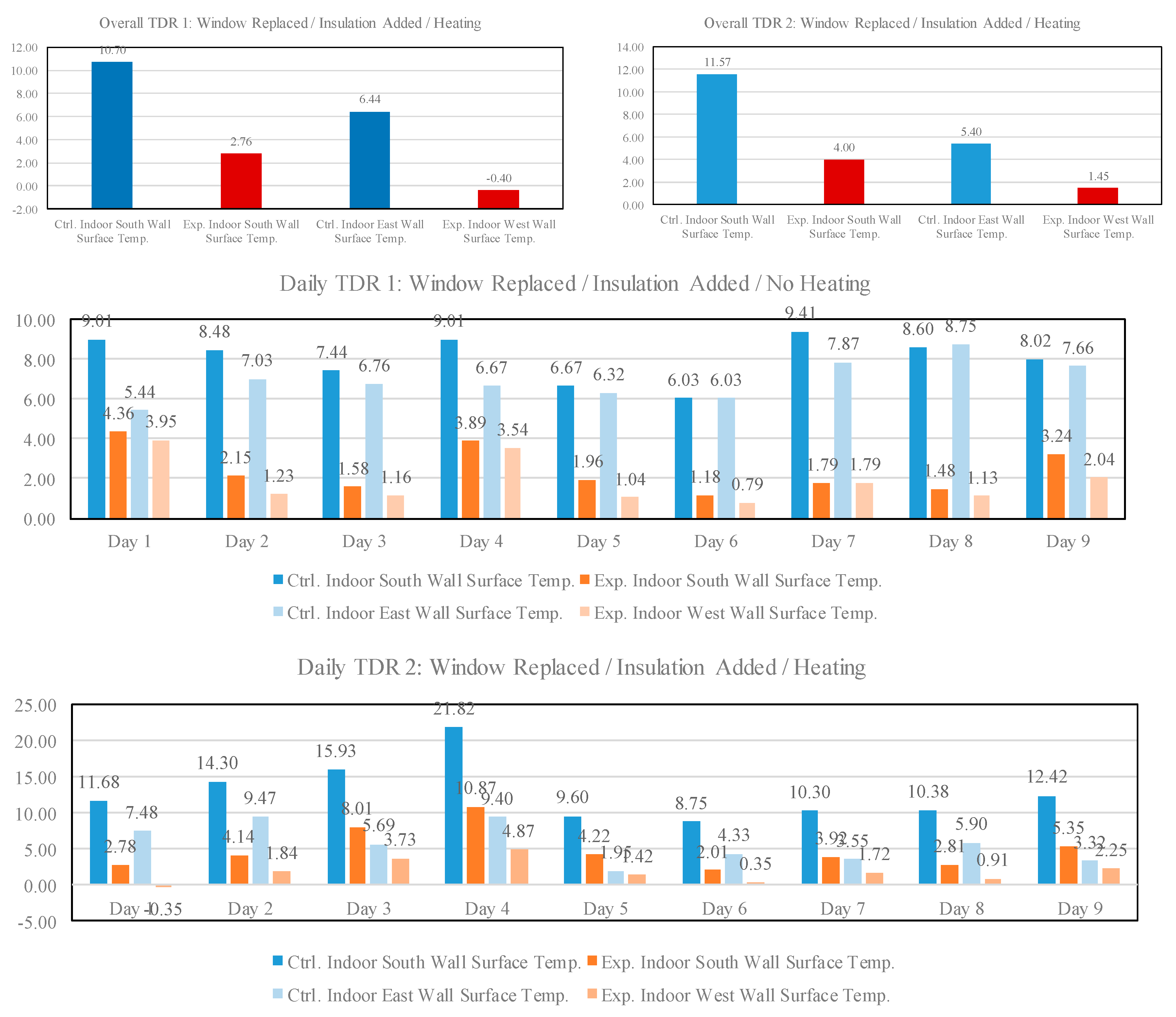

The collected data were analyzed using various statistical tools and methods. Minitab 17.0 and Microsoft Excel were used for data analysis, and statistical analysis was conducted at a 95% significance level. Multiple statistical methods, such as a paired

t-test, two sample

t-tests, and TDR (Time difference Ratio) were used to verify and compare the thermal performance of the two rooms. The procedure used in the study is illustrated in

Figure 3.

5. Conclusions

This study investigated the improvement of an indoor thermal environment through green refurbishment in Korea. An existing building was selected as a test site, and multiple monitoring experiments were conducted to measure and compare actual heating performance in winter. The results validated the significant improvement in heating performance created by green refurbishment. The green refurbishment process decreased heating load significantly in the simulation results, and the field measurement for electricity use in the heating experiment and the airtightness verified this result. Simulation results by DesignBuilder showed that 42–43% of heating energy consumption was decreased by the green refurbishment, however, the monitoring result showed 51~68% energy consumption. Additionally, the indoor temperature of the GR room was 4.22 °C lower than the other one so that it maintained a more stable indoor thermal environment. This result indicates that indoor thermal environment quality can be improved by the green refurbishment, and heating energy consumption can be reduced by more than 50%.

Regarding minimum indoor temperature and indoor temperature swing, the stability of the indoor thermal environment was enhanced by the green refurbishment process. This study also developed a simple equation to predict the indoor minimum temperature of the refurbished room using TDR. The methodology used to derive the empirical equation can be applied to other buildings, allowing the calculation of minimum indoor temperature as a function of outdoor temperature swing.

The findings of this study contribute to the understanding of thermal performance improvement created by green refurbishment. This technical result can be considered in green refurbishment projects to identify performance augmentation as well as differences between simulation results and field measurements.

Although the findings of this study are significant, the limitations of the research should be taken into account. First, more field measurement should be conducted to increase the accuracy of the results. Monitoring experiments in other seasons (e.g., summer) and extreme conditions will provide additional information about performance improvement and the limitations of green refurbishment. The application of other heating systems and different levels of airtightness will also increase the accuracy of the results. In addition, other simulation programs should be considered for further study. Finally, other green refurbishment factors need to be investigated using simulations and field measurement, which will help validate the accuracy of the differences between simulations and filed measurements.