Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges

Abstract

1. Introduction

2. Life Cycle Assessment Methods

- Goal and scope definition

- Inventory analysis

- Impact assessment

- Interpretation of results

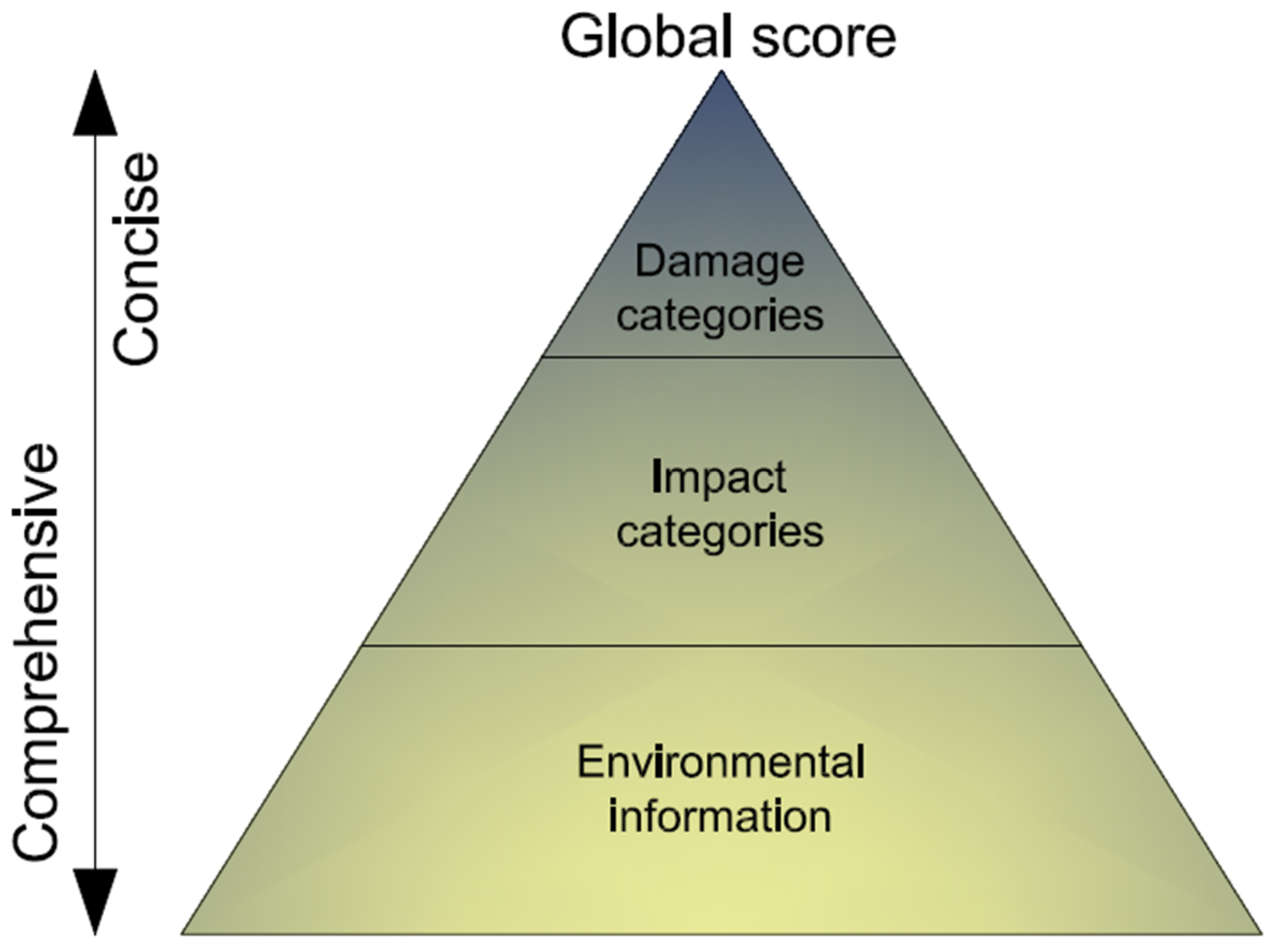

2.1. Environmental Life Cycle Impact Assessment

2.2. Social Life Cycle Impact Assessment

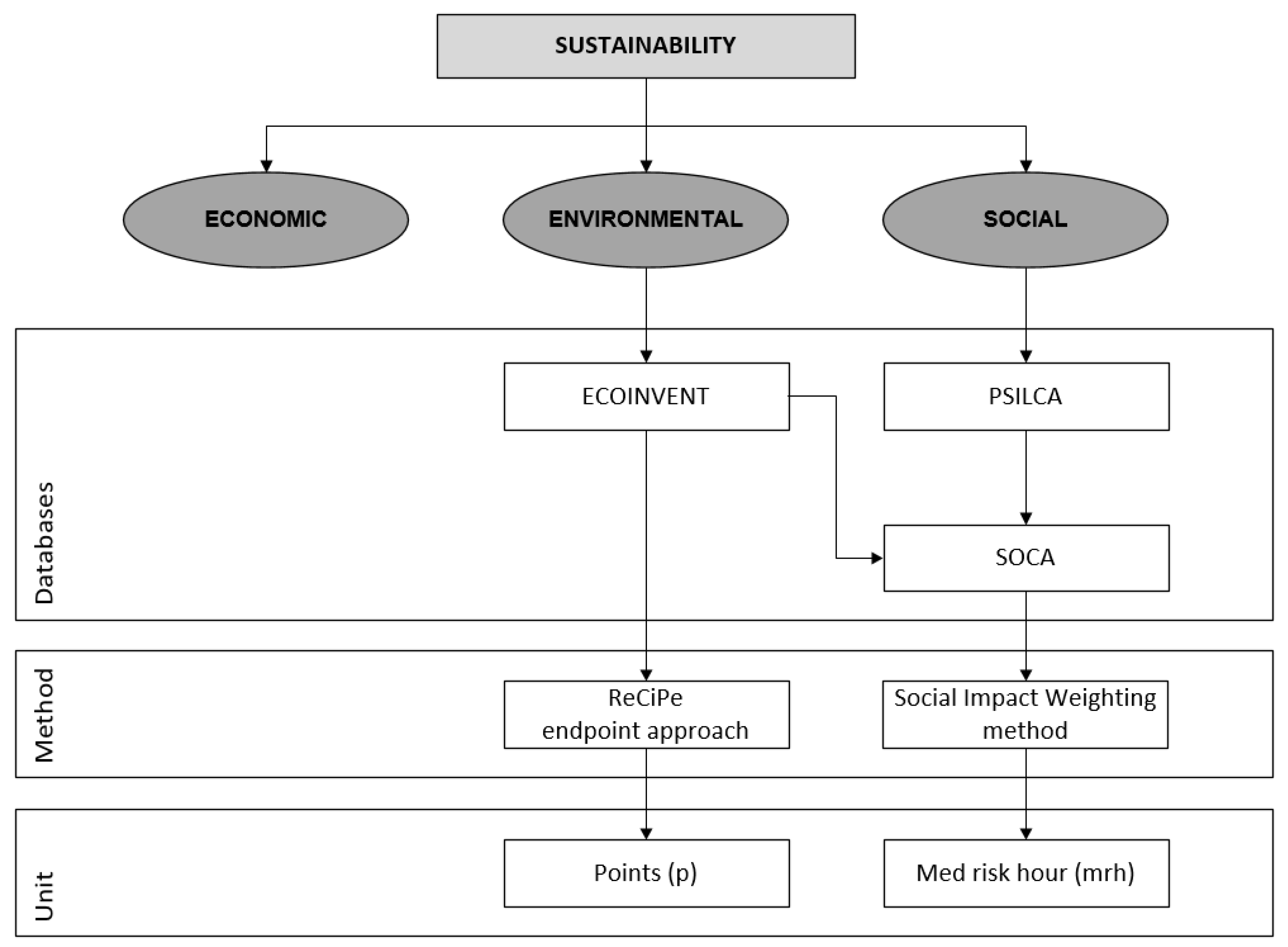

3. Methodology

4. Case Study

4.1. Goal and Scope

4.1.1. Functional Unit

4.1.2. System Boundaries

4.2. Inventory Analysis

4.3. Impact Assessment

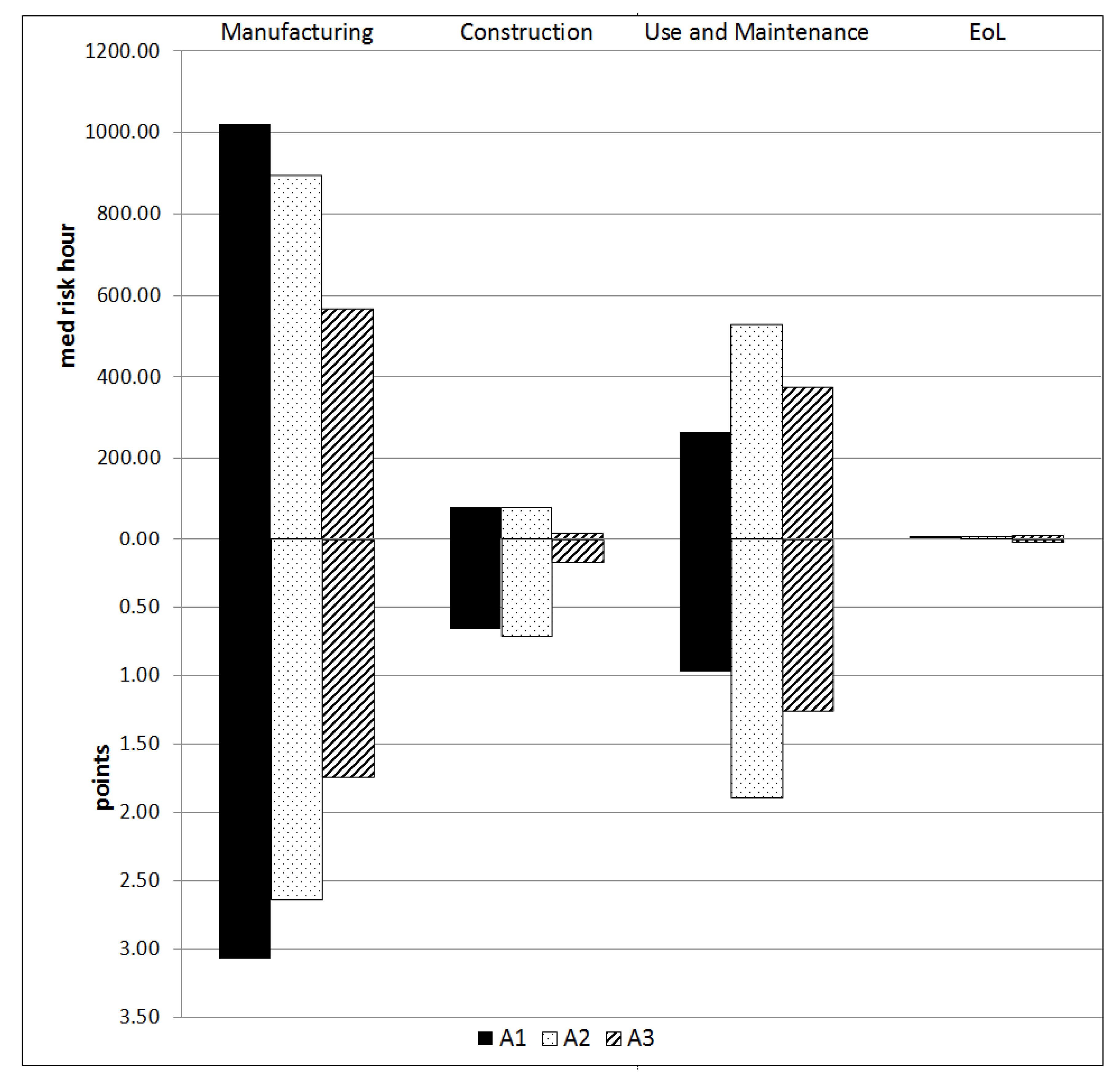

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United Nations. World Commission on Environment and Development Our Common Future; Oxford University Press: New York, NY, USA, 1987. [Google Scholar]

- United Nations. Transforming our world: The 2030 agenda for sustainable development; General Assembly: New York, NY, USA, 2015. [Google Scholar]

- Murphy, K. The social pillar of sustainable development: A literature review and framework for policy analysis. Sustain. Sci. Pract. Policy 2012, 8, 15–29. [Google Scholar] [CrossRef]

- Montalbán-Domingo, L.; García-Segura, T.; Sanz, M.A.; Pellicer, E. Social sustainability criteria in public-work procurement: An international perspective. J. Clean. Prod. 2018, 198, 1355–1371. [Google Scholar] [CrossRef]

- Vallance, S.; Perkins, H.C.; Dixon, J.E. What is social sustainability? A clarification of concepts. Geoforum 2011, 42, 342–348. [Google Scholar] [CrossRef]

- Harris, J.M.; Wise, T.A.; Gallagher, K.P.; Goodwine, N.R. A Survey of Sustainable Development: Social and Economic Dimension; Island Press: Washinton, DC, USA, 2001. [Google Scholar]

- Sierra, L.A.; Yepes, V.; Pellicer, E. Assessing the social sustainability contribution of an infrastructure project under conditions of uncertainty. Environ. Impact Assess. Rev. 2017, 67, 61–72. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. Social life cycle assessment of concrete bridge decks exposed to aggressive environments. Environ. Impact Assess. Rev. 2018, 72, 50–63. [Google Scholar] [CrossRef]

- Navarro, I.J.; Martí, J.V.; Yepes, V. Reliability-based maintenance optimization of corrosion preventive designs under a life cycle perspective. Environ. Impact Assess. Rev. 2019, 74, 23–34. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. Sustainability assessment of concrete bridge deck designs in coastal environments using neutrosophic criteria weights. Struct. Infrastruct. Eng. 2020, 16, 949–967. [Google Scholar] [CrossRef]

- Montalbán-Domingo, L.; García-Segura, T.; Amalia Sanz, M.; Pellicer, E. Social Sustainability in Delivery and Procurement of Public Construction Contracts. J. Manag. Eng. 2019, 35, 1–11. [Google Scholar] [CrossRef]

- Valdes-Vasquez, R.; Klotz, L.E. Social sustainability considerations during planning and design: Framework of processes for construction projects. J. Constr. Eng. Manag. 2013, 139, 80–89. [Google Scholar] [CrossRef]

- Almahmoud, E.; Doloi, H.K. Assessment of social sustainability in construction projects using social network analysis. Facilities 2015, 30, 152–176. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Yepes, V. Multi-criteria assessment of alternative sustainable structures for a self-promoted, single-family home. J. Clean. Prod. 2020, 258, 120556. [Google Scholar] [CrossRef]

- Navarro, I.; Yepes, V.; Martí, J. Life cycle cost assessment of preventive strategies applied to prestressed concrete bridges exposed to chlorides. Sustainability 2018, 10, 845. [Google Scholar] [CrossRef]

- Salas, J.; Yepes, V. VisualUVAM: A decision support system addressing the curse of dimensionality for the multi-scale assessment of urban vulnerability in Spain. Sustainability 2019, 11, 2191. [Google Scholar] [CrossRef]

- Kripka, M.; Yepes, V.; Milani, C.J. Selection of sustainable short-span bridge design in Brazil. Sustainability 2019, 11, 1307. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Yepes, V.; García-Segura, T. Robust decision-making design for sustainable pedestrian concrete bridges. Eng. Struct. 2020, 209, 109968. [Google Scholar] [CrossRef]

- Rasheed, A.; Farooq, S.H.; Usman, M.; Hanif, A.; Khan, N.A.; Khushnood, R.A. Structural reliability analysis of superstructure of highway bridges on China-Pakistan Economic Corridor (CPEC): A case study. J. Struct. Integr. Maint. 2018, 3, 197–207. [Google Scholar] [CrossRef]

- Hansen, M. Determination and assessment of fatigue stresses on concrete bridges. Struct. Concr. 2020, 1–12. [Google Scholar] [CrossRef]

- Sargsyan, A.; Sargsyan, G.; Resnik, B. Influence of Cracks on Frequency of the Self-Vibration of Reinforced Concrete T Beam of Road Bridges | Scientific.Net. Key Eng. Mater. 2019, 828, 9–13. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; García-Segura, T.; Martí, J.; Yepes, V. A review of multi-criteria decision-making methods applied to the sustainable bridge design. Sustainability 2016, 8, 1295. [Google Scholar] [CrossRef]

- Horvath, A.; Hendrickson, C. Steel versus steel-reinforced concrete bridges: Environmental assessment. J. Infrastruct. Syst. 1998, 4, 111–117. [Google Scholar] [CrossRef]

- Widman, J. Environmental impact assessment of steel bridges. J. Constr. Steel Res. 1998, 46, 291–293. [Google Scholar] [CrossRef]

- Stengel, T.; Schiessl, P. Life cycle assessment of UHPC bridge constructions: Sherbrooke Footbridge, Kassel Gärtnerplatz Footbridge and Wapello Road Bridge. Archit. Civ. Eng. Environ. 2009, 1, 109–118. [Google Scholar]

- Gervasio, H.; Simoes da Silva, L. Comparative life-cycle analysis of steel-concrete composite bridges. Struct. Infrastruct. Eng. 2008, 4, 251–269. [Google Scholar] [CrossRef]

- Itoh, Y.; Kitagawa, T. Using CO2 emission quantities in bridge lifecycle analysis. Eng. Struct. 2003, 25, 565–577. [Google Scholar] [CrossRef]

- Bouhaya, L.; Roy, R.L.; Feraille-Fresnet, A. Simplified environmental study on innovative bridge structure. Environ. Sci. Technol. 2009, 43, 2066–2071. [Google Scholar] [CrossRef] [PubMed]

- Steele, K.N.P.; Cole, G.; Parke, G. Application of life cycle assessment technique in the investigation of brick arch highway bridges. In Proceedings of the 6th International Masonry Conference, London, UK, 9 November 2002; pp. 1–8. [Google Scholar]

- Pang, B.; Yang, P.; Wang, Y.; Kendall, A.; Xie, H.; Zhang, Y. Life cycle environmental impact assessment of a bridge with different strengthening schemes. Int. J. Life Cycle Assess 2015, 20, 1300–1311. [Google Scholar] [CrossRef]

- Du, G.; Safi, M.; Pettersson, L.; Karoumi, R. Life cycle assessment as a decision support tool for bridge procurement: Environmental impact comparison among five bridge designs. Int. J. Life Cycle Assess. 2014, 19, 1948–1964. [Google Scholar] [CrossRef]

- Hammervold, J.; Reenaas, M.; Brattebø, H. Environmental life cycle assessment of bridges. J. Bridg. Eng. 2013, 18, 153–161. [Google Scholar] [CrossRef]

- Gervásio, H.; Simões Da Silva, L. A probabilistic decision-making approach for the sustainable assessment of infrastructures. Expert Syst. Appl. 2012, 39, 7121–7131. [Google Scholar] [CrossRef]

- Sabatino, S.; Frangopol, D.M.; Dong, Y. Sustainability-informed maintenance optimization of highway bridges considering multi-attribute utility and risk attitude. Eng. Struct. 2015, 102, 310–321. [Google Scholar] [CrossRef]

- Chen, Z.; Abdullah, A.B.; Anumba, C.J.; Li, H. ANP experiment for demolition plan evaluation. J. Constr. Eng. Manag. 2013, 140, 51–60. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). International Organization for Standardization (ISO) Environmental Managment—Life Cycle Assessment—Principles and Framework; International Organization for Standarization: Geneva, Switzerland, 2006. [Google Scholar]

- Benoît, C.; Mazijn, B. Guidelines for Social Life Cycle Assessment of Products; UNEP/SETAC Life Cycle Initiative, Sustainable Product and Consumption Branch: Paris, France, 2009; Volume 15, ISBN 9789280730210. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Wegener Sleeswijk, A.; Udo De Haes, H.A.; de Bruijn, J.A.; van Duin, R.; Huijbregts, M.A.J. Life cycle assessment: An operational guide to the ISO standards. III Sci. Backgr. 2001, 692. [Google Scholar] [CrossRef]

- Hauschild, M.; Potting, J. Background for spatial differentiation in LCA impact assessment—The EDIP2003 methodology. Environ. News 2005, 80, 1–195. [Google Scholar]

- Bare, J.C. The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- Gocdkoop, M.; Hofstetter, P.; Müller-Wenk, R.; Spriemsma, R. The Eco-Indicator 98 explained. Int. J. Life Cycle Assess. 1998, 3, 352–360. [Google Scholar] [CrossRef]

- Steen, B. A Systematic Approach to Environmental Priority Strategies in Product Development (EPS); Centre for Environmental Assessment of Products and Material System: Gothenburg, Sweeden, 1999. [Google Scholar]

- Frischknecht, R.; Steiner, R.; Jungbluth, N. Methode der ökologischen Knappheit—Ökofaktoren 2006. 2009. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008 A Life Cycle Impact Assessment Method which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ministerie van VROM: Hague, The Netherlands, 2009. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; Zelm, R. ReCiPe 2016 A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; Rijksinstituut voor Volksgezondheid en Milieu RIVM: De Bilt, The Netherlands, 2016. [Google Scholar]

- Itsubo, N.; Sakagami, M.; Washida, T.; Kokubu, K.; Inaba, A. Weighting across safeguard subjects for LCIA through the application of conjoint analysis. Int. J. Life Cycle Assess. 2004, 9, 196–205. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new Life Cycle Impact Assessment Methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- GreenDelta PSILCA v1.0 (Product Social Impact Life-Cycle Assessment); Greendelta: Berlin, Germany, 2013.

- New Earth SHDB v1.0 (Social Hotspot Database). 2009. Available online: https://www.socialhotspot.org/ (accessed on 1 October 2019).

- GreenDelta PSILCA Database. Available online: https://psilca.net/ (accessed on 1 October 2019).

- New Earth SHDB Database. Available online: https://www.socialhotspot.org/for-more-information.html (accessed on 1 October 2019).

- Du, G.; Karoumi, R. Environmental life cycle assessment comparison between two bridge types: Reinforced concrete bridge and steel composite bridge. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Hettinger, A.; Birat, J.; Hechler, O.; Braun, M. Sustainable bridge—LCA for a composite and a concrete bridge. In Economical Bridge Solutions Based on Innovative Composite Dowels and Integrated Abutments; Petzek, E., Bancila, R., Eds.; Springer Vieweg: Wiesbaden, Germany, 2015; pp. 45–54. [Google Scholar]

- Du, G.; Karoumi, R. Life cycle assessment of a railway bridge: Comparison of two superstructure designs. Struct. Infrastruct. Eng. 2012, 9, 1149–1160. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Martí, J.V.; García-Segura, T.; Yepes, V. Life-cycle assessment: A comparison between two optimal post-tensioned concrete box-girder road bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; García-Segura, T.; Martí, J.V.; Yepes, V. An optimization-LCA of a prestressed concrete precast bridge. Sustainability 2018, 10, 685. [Google Scholar] [CrossRef]

- Pons, J.J.; Penadés-Plà, V.; Yepes, V.; Martí, J.V. Life cycle assessment of earth-retaining walls: An environmental comparison. J. Clean. Prod. 2018, 192, 411–420. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 206-1 Concrete—Part1: Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- Steele, K.; Cole, G.; Parke, G.; Clarke, B.; Harding, J.; Harding, J. Highway bridges and environment-sustainable perspectives. Proc. Inst. Civ. Eng. 2003, 156, 176–182. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Lehmann, A.; Muñoz, P.; Antón, A.; Traverso, M.; Rieradevall, J.; Finkbeiner, M. Application challenges for the social Life Cycle Assessment of fertilizers within life cycle sustainability assessment. J. Clean. Prod. 2014, 69, 34–48. [Google Scholar] [CrossRef]

- Marceau, M.L.; Nisbet, M.A.; Vangeem, M.G. Life Cycle Inventory of Portland Cement Concrete; Portland Cement Association: Skokie, IL, USA, 2007. [Google Scholar]

- Ministerio de Fomento. EHE-08: Code on Structural Concrete; Ministerio de Fomento: Madrid, Spain, 2008.

- Ministerio de Fomento. IAP-11: Code on the Actions for the Design of Road Bridges; Ministerio de Fomento: Madrid, Spain, 2011.

- European Committee for Standardization. EN 1001-2:2003. Eurocode 1: Actions on Structures—Part 2: Traffic Loads Bridges; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- European Committee for Standardisation. EN1992-2:2005. Eurocode 2: Design of Concrete Structures—Part 2: Concrete Bridge-Design and Detailing Rules; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Catalonia Institute of Construction Technology. BEDEC PR/PCT ITEC Material Database. 2016. Available online: https://metabase.itec.cat/vide/ca/bedec (accessed on 1 October 2019).

- García-Segura, T.; Yepes, V.; Frangopol, D.M.; Yang, D.Y. Lifetime reliability-based optimization of post-tensioned box-girder bridges. Eng. Struct. 2017, 145, 381–391. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Radwan, N.M.; Senousy, M.B.; El, A.; Riad, D.M. Neutrosophic AHP multi criteria decision making method applied on the selection of learning management system. Int. J. Adv. Comput. Technol. 2016, 8, 95–105. [Google Scholar]

- Prascevic, N.; Prascevic, Z. Application of fuzzy AHP for ranking and selection of alternatives in construction project management. J. Civ. Eng. Manag. 2017, 23, 1123–1135. [Google Scholar] [CrossRef]

- García-Segura, T.; Penadés-Plà, V.; Yepes, V. Sustainable bridge design by metamodel-assisted multi-objective optimization and decision-making under uncertainty. J. Clean. Prod. 2018, 202, 904–915. [Google Scholar] [CrossRef]

- Pamučar, D.; Badi, I.; Sanja, K.; Obradović, R. A novel approach for the selection of power-generation technology using a linguistic neutrosophic CODAS method: A case study in Libya. Energies 2018, 11, 2489. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A comparative cradle-to-gate life cycle assessment of three concrete mix designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef]

- Sierra, L.A.; Pellicer, E.; Yepes, V. Method for estimating the social sustainability of infrastructure projects. Environ. Impact Assess. Rev. 2017, 65, 41–53. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V.; González-Vidosa, F. Life cycle impact assessment of corrosion preventive designs applied to prestressed concrete bridge decks. J. Clean. Prod. 2018, 196, 698–713. [Google Scholar] [CrossRef]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social life cycle assessment for material selection: A case study of building materials. Int. J. Life Cycle Assess. 2014, 19, 620–645. [Google Scholar] [CrossRef]

| E-LCIA Group | E-LCIA Method | Midpoint Indicators | Endpoint Indicators |

|---|---|---|---|

| Midpoint approach | CML 2000 | Obligatory impact categories: Depletion of abiotic resources, climate change, land competition, stratospheric ozone depletion, human toxicity, freshwater aquatic ecotoxicity, terrestrial ecotoxicity, marine aquatic ecotoxicity, photo-oxidant formation, acidification, and eutrophication. Optional impact categories: Loss of life support function, loss of biodiversity, marine sediment ecotoxicity, freshwater sediment ecotoxicity, impacts of ionizing radiation, waste heat, malodorous air, noise, casualties, lethal, non-lethal, depletion of biotic resources, desiccation, and malodorous water | |

| EDIP 2003 | Global warming, ozone depletion, terrestrial eutrophication, acidification, aquatic eutrophication, photochemical ozone formation, ecotoxicity, human toxicity, and noise | ||

| TRACI | Ozone depletion, global warming, smog formation, eutrophication, acidification, eco-toxicity, human health cancer, human health non-cancer, human health criteria pollutants, and fossil fuel depletion | ||

| Endpoint approach | EI99 | Climate change, ozone layer depletion, acidification, eutrophication, respiratory effects, carcinogenicity, ionizing radiation, ecotoxicity, land use, mineral resources, fossil resources | |

| EPS | Life expectancy, severe morbidity and suffering, morbidity, severe nuisance, wood production capacity, nuisance crop production capacity, fish and meat production capacity, base cation capacity, production capacity for water, share of species extinction, depletion of element reserves, depletion of fossil reserves (coal), depletion of fossil reserves (gas), depletion of fossil reserves (oil), and depletion of mineral reserves | ||

| Eco-scarcity | Ozone depletion, photochemical oxidant formation, respiratory effects, air emissions, surface water emissions, radioactive emissions, cancer caused by radionuclides emitted to the sea, emissions to groundwater, emissions to soil, radioactive wastes, landfill municipal (reactive) wastes, hazardous wastes (stored underground), water consumption, gravel consumption, primary energy resources, endocrine disruptors, and biodiversity losses | ||

| Midpoint/Endpoint approach | ReCiPe | Climate change, ozone depletion, terrestrial acidification, freshwater eutrophication, marine eutrophication, human toxicity, photochemical oxidant formation, particulate matter formation, marine ecotoxicity, terrestrial ecotoxicity, freshwater ecotoxicity, ionizing radiation, agricultural land occupation, urban land occupation, natural land transformation, water depletion, mineral resource depletion, fossil fuel depletion | Damage to human health, damage to ecosystem diversity, and damage to resource availability |

| LIME | Ozone layer depletion, global warming, acidification, photochemical oxidant formation, regional air pollution, human-toxic chemicals, ecotoxic chemicals, eutrophication, waste landfill, land use, resources, and consumption | Cataracts, skin cancer, other cancers, respiratory diseases, thermal stress, infectious diseases, agricultural production, hypoalimentation, disaster causality, forestry production, fishery production, loss of land-use, energy consumption, user cost, terrestrial ecosystem, aquatic ecosystem | |

| IMPACT 2000+ | Human toxicity, respiratory effects, ionizing radiation, ozone depletion, photochemical oxidant formation, terrestrial ecotoxicity, aquatic ecotoxicity, aquatic eutrophication, terrestrial eutrophication and acidification, land occupation, global warming, non-renewable energy, and mineral extraction | Damage to human health, damage to ecosystem quality, damage to climate change, and damage to resources |

| S-LCIA Database | CATEGORIES |

|---|---|

| Product Social Impact Life Cycle Assessment (PSILCA) | WORKERS: Child labor, fair salary, discrimination, forced labor, health and safety, social benefits and legal issues, working time, workers’ rights. VALUE CHAIN ACTORS: Corruption, promoting social responsibility, fair competition, supplier relationships. SOCIETY: Contribution to economic development, health and safety, prevention and mitigation of conflicts. LOCAL COMMUNITY: Access to material resources, respect of indigenous rights, local employment, safe and healthy living conditions, migration. CONSUMERS: Health and safety, transparency, end of life responsibility. |

| Social Hotspot Database (SHDB) | LABOR RIGHTS AND DECENT WORK: Child labor, discrimination, excessive working time, freedom of association, forced labor, labor laws, migrant labor, poverty, social benefits, unemployment, wage assessment. HUMAN RIGHTS: Indigenous rights, human health issues, gender equity, high conflicts. HEALTH AND SAFETY: Injuries and fatalities, toxins and hazards. GOVERNANCE: Legal system, corruption. COMMUNITY: Drinking water, children out of school, hospital beds, sanitation, smallholder vs. commercial farms. |

| A1 | A2 | A3 | ||

|---|---|---|---|---|

| Precast Concrete Beam | Concrete Slab | |||

| Strength (MPa) | 50 | 35 | 35 | 40 |

| Passive steel (kg/m2) | 74.67 | 66.89 | 12.52 | 23.92 |

| Active steel (kg/m2) | 19.8 | 21.98 | 10.53 | – |

| Concrete (m3/m2) | 0.67 | 0.674 | 0.1117 | 0.1797 |

| Cement (kg/m3) | 400 | 300 | 300 | 320 |

| Gravel (kg/m3) | 726 | 848 | 848 | 829 |

| Sand (kg/m3) | 1136 | 1088 | 1088 | 1102 |

| Water (kg/m3) | 160 | 160 | 160 | 162 |

| Superplasticizer (kg/m3) | 7 | 4 | 4 | 5 |

| Assessment | Unit | Manufacturing | Construction | Use and Maintenance | EoL | Total | |

|---|---|---|---|---|---|---|---|

| Environmental | HH | p | 1.33 | 0.30 | 0.42 | −0.20 | 1.86 |

| R | p | 1.05 | 0.10 | 0.36 | 0.02 | 1.53 | |

| E | p | 0.69 | 0.26 | 0.18 | −0.13 | 1.01 | |

| Total | 4.40 | ||||||

| Social | W | mrh | 227.17 | 20.27 | 57.87 | 2.25 | 307.56 |

| LC | mrh | 273.58 | 22.03 | 71.49 | 2.54 | 369.65 | |

| S | mrh | 320.67 | 25.05 | 79.56 | 2.98 | 428.26 | |

| VCA | mrh | 199.67 | 14.09 | 56.44 | 1.90 | 272.11 | |

| Total | 1377.58 |

| Assessment | Unit | Manufacturing | Construction | Use and Maintenance | EoL | Total | |

|---|---|---|---|---|---|---|---|

| Environmental | HH | p | 1.13 | 0.32 | 0.86 | −0.15 | 2.16 |

| R | p | 0.93 | 0.11 | 0.72 | 0.01 | 1.77 | |

| E | p | 0.57 | 0.28 | 0.31 | −0.10 | 1.06 | |

| Total | 4.98 | ||||||

| Social | W | mrh | 197.63 | 20.68 | 115.75 | 2.26 | 336.31 |

| LC | mrh | 238.77 | 22.36 | 142.98 | 2.55 | 406.67 | |

| S | mrh | 285.49 | 25.42 | 159.12 | 3.00 | 473.02 | |

| VCA | mrh | 174.01 | 14.34 | 112.87 | 1.91 | 303.14 | |

| Total | 1519.14 |

| Assessment | Unit | Manufacturing | Construction | Use and Maintenance | EoL | Total | |

|---|---|---|---|---|---|---|---|

| Environmental | HH | p | 0.74 | 0.08 | 0.56 | 0.00 | 1.38 |

| R | p | 0.64 | 0.05 | 0.46 | 0.03 | 1.17 | |

| E | p | 0.36 | 0.04 | 0.23 | −0.01 | 0.63 | |

| Total | 3.19 | ||||||

| Social | W | mrh | 124.88 | 4.02 | 82.27 | 2.81 | 213.97 |

| LC | mrh | 151.20 | 5.08 | 101.62 | 3.44 | 261.34 | |

| S | mrh | 182.92 | 5.93 | 113.08 | 4.05 | 305.98 | |

| VCA | mrh | 109.66 | 4.11 | 80.22 | 2.73 | 196.72 | |

| Total | 978.02 |

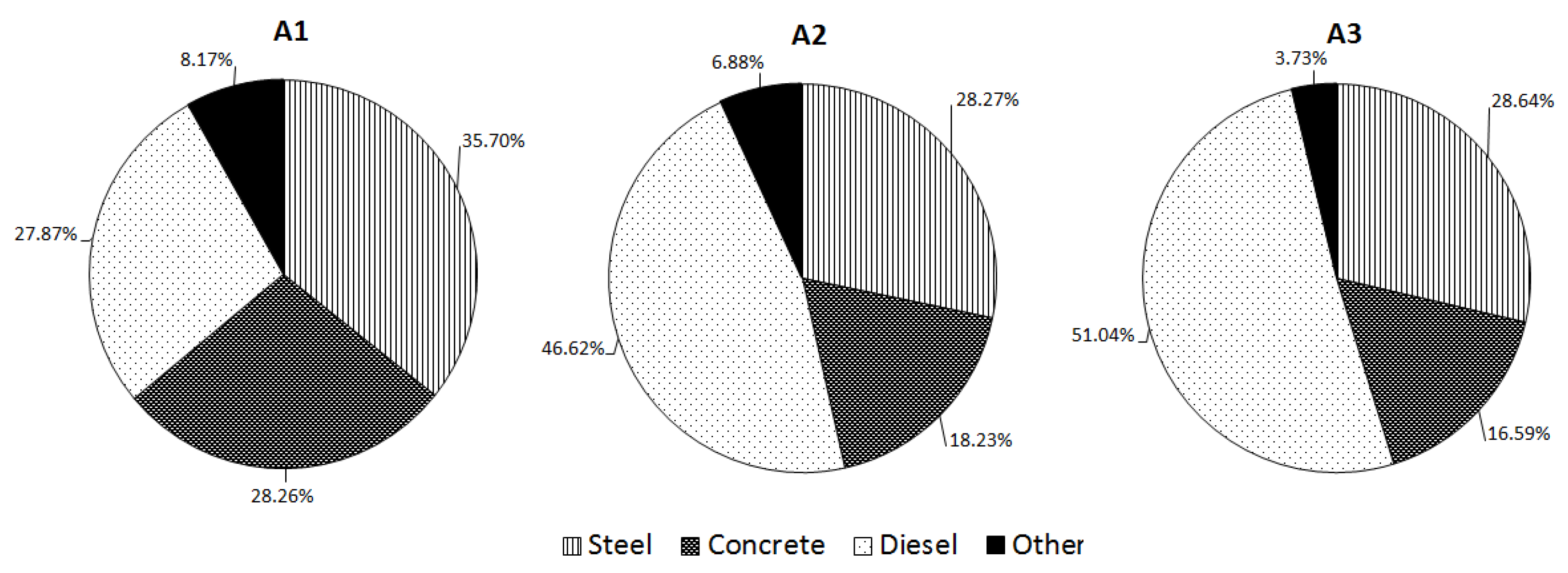

| A1 | A2 | A3 | ||||

|---|---|---|---|---|---|---|

| Steel | Concrete | Steel | Concrete | Steel | Concrete | |

| FL | 57.93% | 24.11% | 53.04% | 17.82% | 54.82% | 16.46% |

| FS | 55.63% | 29.60% | 53.14% | 22.73% | 55.42% | 21.10% |

| WH | 49.90% | 27.02% | 43.92% | 19.26% | 45.12% | 17.74% |

| GW | 41.82% | 42.58% | 42.18% | 34.56% | 48.36% | 34.60% |

| NFA | 31.87% | 49.36% | 30.03% | 37.22% | 31.67% | 34.12% |

| FA | 35.70% | 28.26% | 28.27% | 18.23% | 28.64% | 16.59% |

| SM | 24.51% | 49.95% | 23.15% | 36.30% | 26.02% | 36.09% |

| ND | 51.76% | 28.34% | 46.35% | 20.56% | 47.38% | 18.65% |

| SS | 50.01% | 27.31% | 44.01% | 19.49% | 45.21% | 17.88% |

| VL | 53.19% | 29.07% | 49.35% | 21.92% | 51.51% | 20.32% |

| ACB | 58.06% | 29.96% | 57.53% | 23.94% | 62.05% | 22.52% |

| TU | 48.20% | 29.57% | 42.91% | 21.32% | 44.28% | 19.64% |

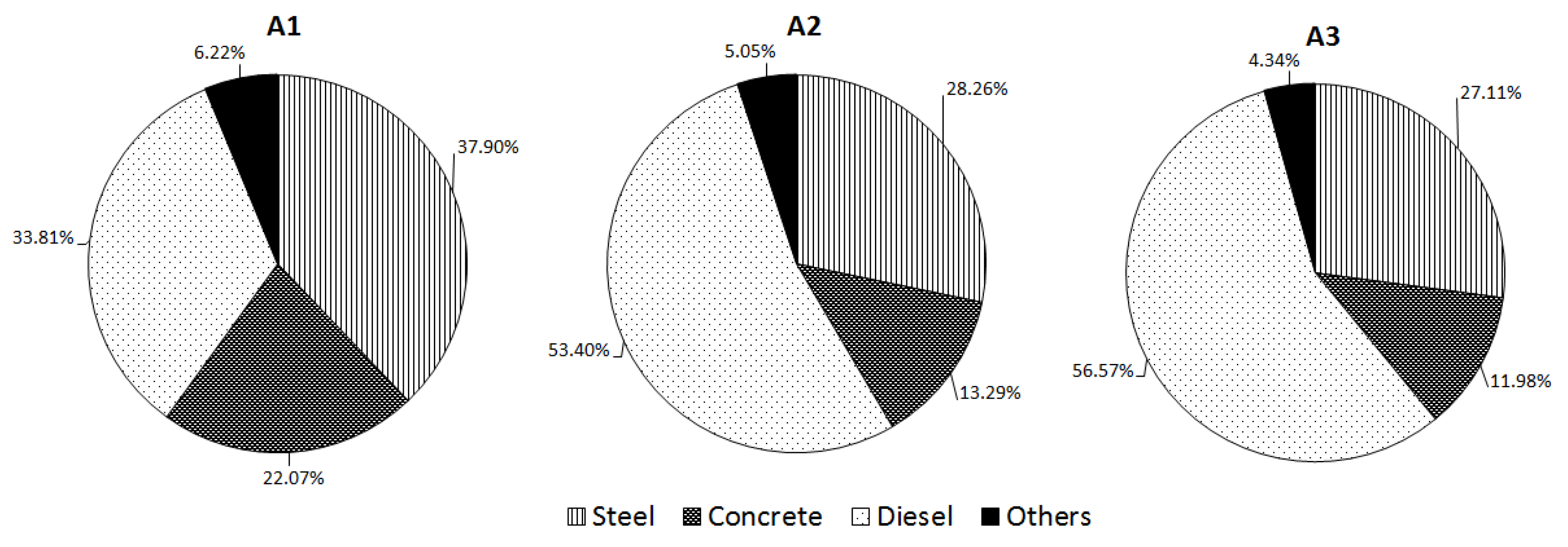

| IMW | 37.90% | 22.07% | 28.26% | 13.29% | 27.11% | 11.98% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penadés-Plà, V.; Martínez-Muñoz, D.; García-Segura, T.; Navarro, I.J.; Yepes, V. Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges. Sustainability 2020, 12, 4265. https://doi.org/10.3390/su12104265

Penadés-Plà V, Martínez-Muñoz D, García-Segura T, Navarro IJ, Yepes V. Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges. Sustainability. 2020; 12(10):4265. https://doi.org/10.3390/su12104265

Chicago/Turabian StylePenadés-Plà, Vicent, David Martínez-Muñoz, Tatiana García-Segura, Ignacio J. Navarro, and Víctor Yepes. 2020. "Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges" Sustainability 12, no. 10: 4265. https://doi.org/10.3390/su12104265

APA StylePenadés-Plà, V., Martínez-Muñoz, D., García-Segura, T., Navarro, I. J., & Yepes, V. (2020). Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges. Sustainability, 12(10), 4265. https://doi.org/10.3390/su12104265