Integrator’s Coordination on Technological Innovation Performance in China: The Dual Moderating Role of Environmental Dynamism

Abstract

:1. Introduction

2. Research Context and Hypothesis Development

2.1. Research Context

2.1.1. Integrator’s Coordination in the Context of CoPS Innovation

2.1.2. Environmental Conditions

2.2. The Effect of Integrator’s Coordination on Its Technological Innovation Performance in CoPS

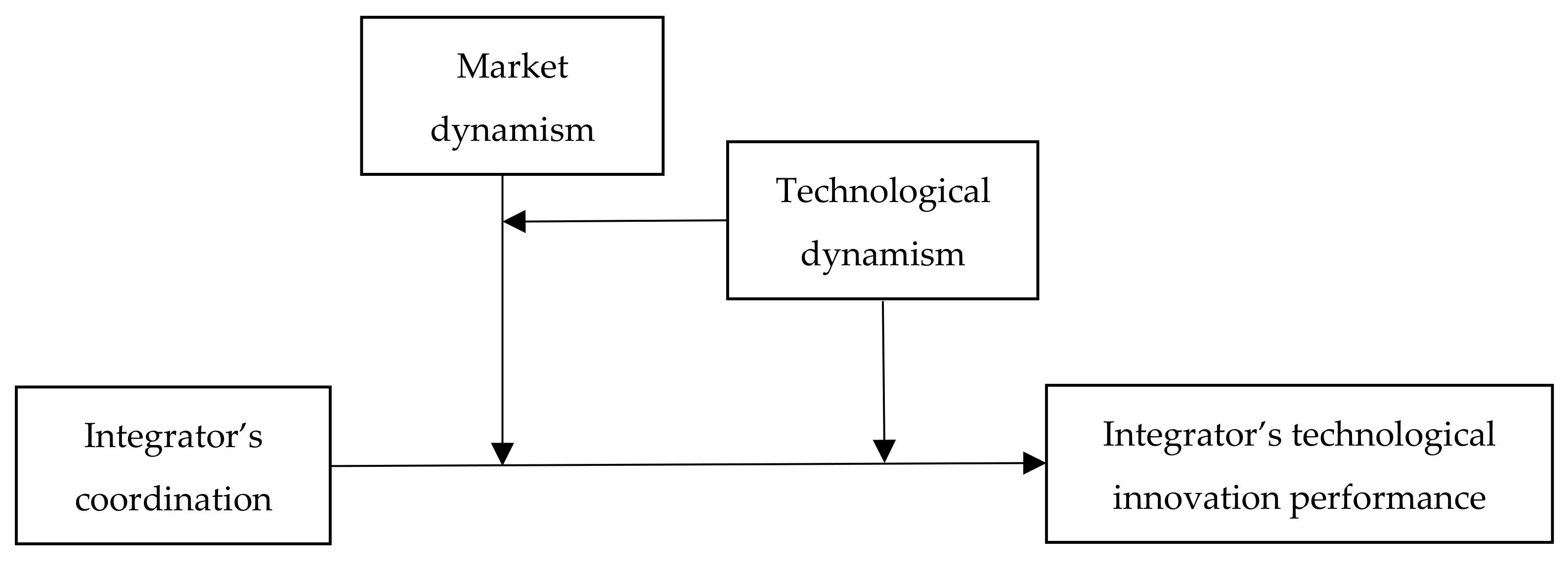

2.3. The Moderating Effect of Environmental Dynamism

2.3.1. The Moderating Effect of Technological Dynamism

2.3.2. The Moderating Effect of Market Dynamism

2.3.3. The Dual Moderating Effect of Market and Technological Dynamism

3. Research Methods

3.1. Data Collection and Sample

3.2. Measures

3.2.1. Dependent Variable

3.2.2. Independent Variable

3.2.3. Moderating Variable

3.2.4. Control Variables

Firm Age

Firm Size

Industry Type

Cooperation Duration

Specific Assets

The Importance of This CoPS Project to Key Suppliers

Integrator’s Technological Integration

3.3. Reliability, Validity, and Common Method Variance

4. Regression Analysis Results

4.1. Direct Effect

4.2. Moderating Effect

5. Discussion

5.1. Discussion

5.2. Theoretical Contribution

5.3. Practical Implication

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, J.J.; Yoon, H. A comparative study of technological learning and organizational capability development in complex products systems: Distinctive paths of three latecomers in military aircraft industry. Res. Policy 2015, 44, 1296–1313. [Google Scholar] [CrossRef] [Green Version]

- Park, T.Y. How a latecomer succeeded in a complex product system industry: Three case studies in the Korean telecommunication systems. Ind. Corp. Chang. 2013, 22, 363–396. [Google Scholar] [CrossRef]

- Majidpour, M. Technological catch-up in complex product systems. J. Eng. Technol. Manag. 2016, 41, 92–105. [Google Scholar] [CrossRef]

- Davies, A.; Hobday, M. The Business of Projects: Managing Innovation in Complex. Products and Systems; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Brusoni, S.; Prencipe, A. Patterns of modularization: The dynamics of product architecture in complex systems. Eur. Manag. Rev. 2011, 8, 67–80. [Google Scholar] [CrossRef]

- Kiamehr, M.; Hobday, M.; Hamedi, M. Latecomer firm strategies in complex product systems (CoPS): The case of Iran’s thermal electricity generation systems. Res. Policy 2015, 44, 1240–1251. [Google Scholar] [CrossRef]

- Safdari Ranjbar, M.; Park, T.; Kiamehr, M. What happened to complex product systems literature over the last two decades: Progresses so far and path ahead. Technol. Anal. Strateg. 2018, 30, 948–966. [Google Scholar] [CrossRef]

- Naghizadeh, M.; Manteghi, M.; Ranga, M.; Naghizadeh, R. Managing integration in complex product systems: The experience of the IR-150 aircraft design program. Technol. Forecast. Soc. 2017, 122, 253–261. [Google Scholar] [CrossRef]

- Olausson, D.; Berggren, C. Managing uncertain, complex product development in high-tech firms: In search of controlled flexibility. R&D Manag. 2010, 40, 383–399. [Google Scholar] [CrossRef]

- Gil, N. On the value of project safeguards: Embedding real options in complex products and systems. Res. Policy 2007, 36, 980–999. [Google Scholar] [CrossRef]

- Li, Y.; Chu, X.; Chu, D.; Liu, Q. An integrated module partition approach for complex products and systems based on weighted complex networks. Int. J. Prod. Res. 2013, 52, 4608–4622. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Mondragon, C.E.C. Managing complex, modular products: How technological uncertainty affects the role of systems integrators in the automotive supply chain. Int. J. Prod. Res. 2018, 56, 6628–6643. [Google Scholar] [CrossRef]

- Gholz, E.; James, A.D.; Speller, T.H. The second face of systems integration: An empirical analysis of supply chains to complex product systems. Res. Policy 2018, 47, 1478–1494. [Google Scholar] [CrossRef]

- Appio, F.P.; Lacoste, S. B2B relationship management in complex product systems (CoPS). Ind. Market. Manag. 2018, 79, 53–57. [Google Scholar] [CrossRef]

- Townsend, D.M.; Hunt, R.A.; Mcmullen, J.S.; Sarasvathy, S.D. Uncertainty, knowledge problems, and entrepreneurial action. Acad. Manag. Ann. 2018, 12, 659–687. [Google Scholar] [CrossRef]

- Tee, R.; Davies, A.; Whyte, J. Modular designs and integrating practices: Managing collaboration through coordination and cooperation. Res. Policy 2019, 48, 51–61. [Google Scholar] [CrossRef]

- Crespin-Mazet, F.; Romestant, F.; Salle, R. The co-development of innovative projects in CoPS activities. Ind. Market. Manag. 2019, 79, 71–83. [Google Scholar] [CrossRef]

- Frandsen, T. Evolution of modularity literature: A 25-year bibliometric analysis. Int. J. Oper. Prod. Manag. 2017, 37, 703–747. [Google Scholar] [CrossRef]

- Belvedere, V.; Cuttaia, F.; Rossi, M.; Stringhetti, L. Mapping wastes in complex projects for lean product development. Int. J. Proj. Manag. 2019, 37, 410–424. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.; Jeon, M. The technical efficiency of French regional airports and low-cost carrier terminals. Sustainability 2019, 11, 5107. [Google Scholar] [CrossRef] [Green Version]

- Taddeo, R.; Simboli, A.; Di Vincenzo, F.; Ioppolo, G. A bibliometric and network analysis of lean and clean(er) production research (1990/2017). Sci. Total Environ. 2019, 653, 765–775. [Google Scholar] [CrossRef]

- Jacobs, M.; Droge, C.; Vickery, S.K.; Calantone, R. Product and process modularity’s effects on manufacturing agility and firm growth performance. J. Prod. Innov. Manag. 2011, 28, 123–137. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, S.L.; Ouyang, T.H.; Chou, T. Achieving IT-enabled enterprise agility in China: An IT organizational identity perspective. IEEE Trans. Eng. Manag. 2014, 61, 182–195. [Google Scholar] [CrossRef]

- Hong, Y.; Pearson, J.N.; Carr, A.S. A typology of coordination strategy in multi-organizational product development. Int. J. Oper. Prod. Manag. 2009, 29, 1000–1024. [Google Scholar] [CrossRef]

- Consoli, D.; Patrucco, P.P. Complexity and the coordination of technological knowledge: The case of innovation platforms. In Handbook on the Economic Complexity of Technological Change; Edward Elgar Publishing: Cheltenham, UK, 2011; pp. 201–220. [Google Scholar]

- Brusoni, S.; Prencipe, A.; Pavitt, K. Knowledge specialization, organizational coupling, and the boundaries of the firm: Why do firms know more than they make? Admin. Sci. Q. 2001, 46, 597–621. [Google Scholar] [CrossRef]

- Brusoni, S.; Prencipe, A. The organization of innovation in ecosystems: Problem framing, problem solving, and patterns of coupling. In Collaboration and Competition in Business Ecosystems; Emerald Group Publishing Limited: Bingley, UK, 2014; Volume 1, pp. 167–194. [Google Scholar]

- Brusoni, S. The limits to specialization: Problem solving and coordination in ‘modular networks’. Organ. Stud. 2005, 26, 1885–1907. [Google Scholar] [CrossRef]

- França, J.A. The coordination of complex product systems projects: A case study of an R&D multi-party alliance. Int. J. Innov. Manag. 2019, 23, 1–25. [Google Scholar]

- Gulati, R.; Wohlgezogen, F.; Zhelyazkov, P. The two facets of collaboration: Cooperation and coordination in strategic alliances. Acad. Manag. Ann. 2012, 6, 1–53. [Google Scholar] [CrossRef]

- Vayvay, Ö.; Cruz-Cunha, M.M. Supplier involvement in new product development: A case study from the semiconductor industry. Econ. Manag. 2016, 19, 123–141. [Google Scholar] [CrossRef]

- Zeschky, M.; Daiber, M.; Widenmayer, B.; Gassmann, O. Coordination in global R&D organizations: An examination of the role of subsidiary mandate and modular product architectures in dispersed R&D organizations. Technovation 2014, 34, 594–604. [Google Scholar]

- Zanfei, A. Transnational firms and the changing organisation of innovative activities. Camb. J. Econ. 2000, 24, 515–542. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Han, Q.; Zhou, J.; Yuan, C. The influence of environmental management practices and supply chain integration on technological innovation performance-evidence from China’s manufacturing industry. Sustainability 2015, 7, 15342–15361. [Google Scholar] [CrossRef] [Green Version]

- Perez-Luno, A.; Gopalakrishnan, S.; Cabrera, R.V. Innovation and performance: The role of environmental dynamism on the success of innovation choices. IEEE Trans. Eng. Manag. 2014, 61, 499–510. [Google Scholar] [CrossRef]

- Danneels, E.; Sethi, R. New product exploration under environmental turbulence. Organ. Sci. 2004, 22, 1026–1039. [Google Scholar] [CrossRef]

- Uzkurt, C.; Kumar, R.; Kimzan, H.S.; Sert, H. The impact of environmental uncertainty dimensions on organisational innovativeness: An empirical study on SMEs. Int. J. Innov. Manag. 2012, 16, 1–23. [Google Scholar] [CrossRef]

- Fleming, L.; Sorenson, O. Technology as a complex adaptive system: Evidence from patent data. Res. Policy 2001, 30, 1019–1039. [Google Scholar] [CrossRef]

- Revilla, A.; Fernández, Z. Environmental dynamism, firm size and the economic productivity of R&D. Ind. Innov. 2013, 22, 503–522. [Google Scholar]

- Rodrigo-Alarcón, J.; García-Villaverde, P.M.; Parra-Requena, G.; Ruizortega, M.J. Innovativeness in the context of technological and market dynamism: The conflicting effects of network density. J. Organ. Chang. Manag. 2017, 30, 548–568. [Google Scholar] [CrossRef]

- Yang, H. Does familiarity foster innovation? The impact of alliance partner repeatedness on breakthrough innovations. J. Manag. Stud. 2015, 52, 213–230. [Google Scholar]

- Choi, Y.; Lim, U. Contextual factors affecting the innovation performance of manufacturing SMEs in Korea: A structural equation modeling approach. Sustainability 2017, 9, 1193. [Google Scholar] [CrossRef] [Green Version]

- Gulati, R.; Singh, H. The architecture of cooperation: Managing coordination costs and appropriation concerns in strategic alliances. Admin. Sci. Q. 1998, 43, 781–814. [Google Scholar] [CrossRef]

- Becker, G.S.; Murphy, K.S. The division of labor, coordination costs, and knowledge. Q. J. Econ. 1992, 107, 1137–1160. [Google Scholar] [CrossRef]

- Colfer, L.J.; Baldwin, C.Y. The mirroring hypothesis: Theory, evidence, and exceptions. Ind. Corp. Chang. 2016, 25, 709–738. [Google Scholar] [CrossRef]

- Marengo, L.; Dosi, G. Division of labor, organizational coordination and market mechanisms in collective problem-solving. J. Econ. Behav. Organ. 2005, 58, 303–326. [Google Scholar] [CrossRef] [Green Version]

- Almirall, E.; Casadesus-Masanell, R. Open versus closed innovation: A model of discovery and divergence. Acad. Manag. Rev. 2017, 35, 27–47. [Google Scholar]

- Ogbeibu, S.; Emelifeonwu, J.; Senadjki, A.; Gaskin, J.; Kaivo-Oja, J. Technological turbulence and greening of team creativity, product innovation, and human resource management: Implications for sustainability. J. Clean. Prod. 2020, 244, 1–15. [Google Scholar] [CrossRef]

- Hung, K.; Chou, C. The impact of open innovation on firm performance: The moderating effects of internal R&D and environmental turbulence. Technovation 2013, 33, 368–380. [Google Scholar]

- Pérez-Luño, A.; Wiklund, J.; Cabrera, R.V. The dual nature of innovative activity: How entrepreneurial orientation influences innovation generation and adoption. J. Bus. Ventur. 2011, 26, 555–571. [Google Scholar] [CrossRef]

- Martinez-Conesa, I.; Soto-Acosta, P.; Carayannis, E.G. On the path towards open innovation: Assessing the role of knowledge management capability and environmental dynamism in SMEs. J. Knowl. Manag. 2017, 21, 553–570. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D. Managing firm resources in dynamic environments to create value: Looking inside the black box. Acad. Manag. Rev. 2007, 32, 273–292. [Google Scholar] [CrossRef] [Green Version]

- Eroglu, C.; Hofer, C. The effect of environmental dynamism on returns to inventory leanness. J. Oper. Manag. 2014, 32, 347–356. [Google Scholar] [CrossRef]

- Söderholm, P.; Hellsmark, H.; Frishammar, J.; Hansson, J.; Mossberg, J.; Sandström, A. Technological development for sustainability: The role of network management in the innovation policy mix. Technol. Forecast. Soc. 2019, 138, 309–323. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, Y.; Yang, Q.; Maksimov, V.; Hou, J. Improving performance and reducing cost in buyer-supplier relationships: The role of justice in curtailing opportunism. J. Bus. Res. 2015, 68, 607–615. [Google Scholar] [CrossRef]

- Zhang, L.; Qian, Q. How mediated power affects opportunism in owner-contractor relationships: The role of risk perceptions. Int. J. Proj. Manag. 2017, 35, 516–529. [Google Scholar] [CrossRef]

- Xie, X.; Wang, L.; Zeng, S. Inter-organizational knowledge acquisition and firms’ radical innovation: A moderated mediation analysis. J. Bus. Res. 2018, 90, 295–306. [Google Scholar] [CrossRef]

- Whipple, J.M.; Wiedmer, R.; Boyer, K.K. A dyadic investigation of collaborative competence, social capital, and performance in buyer-supplier relationships. J. Supply Chain Manag. 2015, 51, 3–21. [Google Scholar] [CrossRef]

- Schreiner, M.; Kale, P.; Corsten, D. What really is alliance management capability and how does it impact alliance outcomes and success? Strateg. Manag. J. 2009, 30, 1395–1419. [Google Scholar] [CrossRef]

- Kim, K.K.; Park, S.; Ryoo, S.Y.; Park, S.K. Inter-organizational cooperation in buyer-supplier relationships: Both perspectives. J. Bus. Res. 2010, 63, 863–869. [Google Scholar] [CrossRef]

- Lu, L.Y.Y.; Yang, C. The R&D and marketing cooperation across new product development stages: An empirical study of Taiwan’s IT industry. Ind. Market. Manag. 2004, 33, 593–605. [Google Scholar]

- Chen, J. Innovation Management of Complex Product Systems; Science Press: Beijing, China, 2008. [Google Scholar]

- Luo, Y. Are joint venture partners more opportunistic in a more volatile environment? Strateg. Manag. J. 2007, 28, 39–60. [Google Scholar] [CrossRef]

- Huo, B.; Wang, Z.; Tian, Y. The impact of justice on collaborative and opportunistic behaviors in supply chain relationships. Int. J. Prod. Econ. 2016, 177, 12–23. [Google Scholar] [CrossRef]

- Malik, K. Aiding the technology manager: A conceptual model for intra-firm technology transfer. Technovation 2002, 22, 427–436. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Mackenzie, S.B.; Lee, J.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Aiken, L.S.; West, S.G. Multiple Regression: Testing and Interpreting Interactions; Sage: Newbury Park, CA, USA, 1991. [Google Scholar]

- Glazer, J.; Rubinstein, A. Coordinating with a “problem solver”. Manag. Sci. 2019, 65, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Haans, R.F.J.; Pieters, C.; He, Z. Thinking about U: Theorizing and testing U- and inverted U-shaped relationships in strategy research. Strateg. Manag. J. 2016, 37, 1177–1195. [Google Scholar] [CrossRef]

- Shimizu, K. Prospect theory, behavioral theory, and the threat-rigidity thesis: Combinative effects on organizational decisions to divest formerly acquired units. Acad. Manag. J. 2007, 50, 1495–1514. [Google Scholar] [CrossRef]

- Shi, W.; Connelly, B.L.; Cirik, K. Short seller influence on firm growth: A threat rigidity perspective. Acad. Manag. J. 2018, 61, 1892–1919. [Google Scholar] [CrossRef]

- Aversa, P.; Guillotin, O. Firm technological responses to regulatory changes: A longitudinal study in the Le Mans prototype racing. Res. Policy 2018, 47, 1655–1673. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.M. Synergy, coordination costs, and diversification choices. Strateg. Manag. J. 2011, 32, 624–639. [Google Scholar] [CrossRef]

- Wang, C. A multidisciplinary design and analysis environment and its application to aircraft flight dynamics analysis. J. Ind. Inf. Integr. 2016, 1, 14–19. [Google Scholar] [CrossRef]

- Hansen, K.L.; Rush, H. Hotspots in complex product systems: Emerging issues in innovation management. Technovation 1998, 18, 555–561. [Google Scholar] [CrossRef]

| Construct and Measuring Items | CITC | SFL |

|---|---|---|

| Integrator coordination effort (Cronbach’s α = 0.816; AVE = 0.530; CR = 0.8183). | ||

| COR1: We will learn from previous experience working with key suppliers. | 0.633 | 0.74 |

| COR2: We will identify and resolve conflicts arising from cooperation with key suppliers. | 0.650 | 0.74 |

| COR3: Processes within the organization will be established to monitor and manage the collaborative process with key suppliers. | 0.587 | 0.68 |

| COR4: Coordination mechanisms will be established among enterprises to supervise and manage the cooperation process with key suppliers. | 0.685 | 0.75 |

| Integrator technological innovation performance (Cronbach’s α = 0.809; AVE =0.5916; CR = 0.8119) | ||

| TIP1: Work with key suppliers helps to shorten the product development, production time, or extend the life of the product. | 0.614 | 0.68 |

| TIP2: Work with key suppliers helps us advance in technology. | 0.718 | 0.82 |

| TIP3: Work with key suppliers contributes to the accumulation of technology to improve our enterprise internal innovation success rate. | 0.646 | 0.80 |

| Market dynamism (Cronbach’s α = 0.748; AVE = 0.5067; CR = 0.7540) | ||

| M.D.1: Users continuously put forward new functional requirements for the product/system. | 0.542 | 0.69 |

| M.D.2: Competition for similar products in the market is fierce. | 0.657 | 0.78 |

| M.D.3: Policies related to project development are changing rapidly. | 0.530 | 0.66 |

| Technological dynamism (Cronbach’s α = 0.862; AVE = 0.6177; CR = 0.8657) | ||

| T.D.1: How likely will major changes occur regarding functionality improvements during the next three years? | 0.705 | 0.77 |

| T.D.2: How likely will major changes occur regarding price/performance improvements during the next three years? | 0.715 | 0.77 |

| T.D.3: How likely will major changes occur regarding major product innovations during the next three years? | 0.768 | 0.85 |

| T.D.4: How likely will major changes occur regarding major manufacturing innovations during the next three years? | 0.655 | 0.75 |

| Model fit index | ||

| χ2/df = 2.123; p= 0.000; RMSEA = 0.073, TLI = 0.917, CFI = 0.935, IFI = 0.936. | ||

| Classification | Item | Number | Percentage (%) | Classification | Item | Number | Percentage (%) |

|---|---|---|---|---|---|---|---|

| Firm Size | <50 | 42 | 20.1 | R&D personnel intensity | < 5% | 16 | 7.66 |

| 50–99 | 32 | 15.31 | (5–10%) | 31 | 14.83 | ||

| 100–499 | 60 | 28.71 | 10–20% | 70 | 33.49 | ||

| 500–999 | 21 | 10.05 | 20–30% | 39 | 18.66 | ||

| 1000–4999 | 33 | 15.79 | 30–50% | 39 | 18.66 | ||

| ≥5000 | 21 | 10.05 | >50% | 14 | 6.7 | ||

| Industry | EQUIP | 165 | 78.95 | Ownership | SOEs | 24 | 11.48 |

| TRANS | 9 | 14.83 | PEs | 163 | 77.99 | ||

| IT | 4 | 4.31 | FIEs | 10 | 4.79 | ||

| Others | 31 | 1.91 | CREs | 12 | 5.74 | ||

| Respondent’s information | Senior manager | 40 | 19.14 | Ranking of R&D investment within industry | Far higher | 41 | 19.62 |

| MM/EP in SC | 33 | 15.79 | Little bit higher | 96 | 45.93 | ||

| MM/EP in E | 42 | 20.09 | Middle level | 57 | 27.27 | ||

| MM/EP in R&D | 39 | 18.66 | Little bit lower | 13 | 6.22 | ||

| others | 55 | 26.32 | Far lower | 2 | 0.96 | ||

| Firm Age (Year) | ≤5 | 39 | 18.66 | Geographical Location | Northeast China | 68 | 32.53 |

| 6–10 | 37 | 17.7 | Yangtze river delta | 94 | 44.98 | ||

| 11–15 | 60 | 28.71 | Pearl river delta | 19 | 9.09 | ||

| 16–20 | 20 | 9.57 | Others | 28 | 13.40 | ||

| >20 | 53 | 25.36 | Total | 209 | 100% |

| Mean | S.D. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. TIP | 3.89 | 0.819 | 0.769 | |||||||||||||

| 2. COOR | 4.086 | 0.712 | 0.550 *** | 0.728 | ||||||||||||

| 3. M.D. | 3.54 | 0.866 | 0.181 ** | 0.373 *** | 0.712 | |||||||||||

| 4. T.D. | 3.91 | 0.858 | 0.185 ** | 0.299 *** | 0.407 *** | 0.786 | ||||||||||

| 5. Firm Age | 17.21 | 17.886 | −0.087 | −0.043 | −0.069 | −0.188 ** | 1 | |||||||||

| 6. Firm Size | 2.42 | 0.928 | −0.038 | 0.058 | 0.026 | −0.268 *** | 0.364 *** | 1 | ||||||||

| 7. Coop_Duration | 3.39 | 1.497 | 0.044 | 0.111 | −0.007 | −0.175 * | 0.309 *** | 0.310 *** | 1 | |||||||

| 8. Specific Asset | 3.10 | 1.201 | 0.237 *** | 0.260 *** | 0.266 *** | 0.100 | 0.100 | 0.050 | 0.102 | 1 | ||||||

| 9. Program’s Percentage | 3.61 | 1.096 | 0.148 * | 0.084 | −0.057 | −0.040 | −0.131 † | 0.017 | −0.029 | −0.008 | 1 | |||||

| 10. Key Supplier’s Percentage | 2.80 | 1.064 | 0.090 | 0.117 † | 0.027 | 0.061 | −0.006 | 0.037 | 0.086 | 0.308 *** | 0.431 *** | 1 | ||||

| 11. EQUIP | 0.79 | 0.409 | −0.028 | −0.024 | 0.080 | 0.143 * | 0.035 | −0.006 | 0.120 † | 0.178 ** | −0.067 | 0.057 | 1 | |||

| 12. TRANS | 0.04 | 0.203 | −0.040 | −0.084 | 0.031 | −0.103 | 0.116 † | 0.158 * | 0.039 | −0.056 | −0.204 ** | −0.071 | −0.411 *** | 1 | ||

| 13. IT | 0.02 | 0.137 | −0.110 | 0.008 | −0.061 | −0.027 | −0.076 | −0.026 | −0.060 | −0.040 | −0.078 | −0.072 | −0.271 *** | −0.030 | 1 | |

| 14. Technological Integration | 4.13 | 0.696 | 0.420 *** | 0.430 *** | 0.348 *** | 0.439 *** | −0.208 ** | −0.121 † | −0.078 | 0.088 | 0.079 | 0.001 | 0.083 | −0.126 † | −0.052 | 1 |

| VARIABLES | M1 | M2 | M3 | M4 | M5 | M6 |

|---|---|---|---|---|---|---|

| Control Variables | ||||||

| Firm Age | −0.002 | −0.001 | −0.001 | −0.002 | −0.002 | −0.002 |

| (−0.50) | (−0.45) | (−0.40) | (−0.60) | (−0.68) | (−0.59) | |

| Firm Size | −0.013 | −0.052 | −0.058 | −0.044 | −0.046 | −0.058 |

| (−0.21) | (−0.91) | (−1.01) | (−0.77) | (−0.81) | (−1.03) | |

| Coop Duration | 0.048 | 0.013 | 0.012 | 0.016 | 0.019 | 0.018 |

| (1.29) | (0.38) | (0.36) | (0.47) | (0.56) | (0.53) | |

| Specific Asset | 0.155 *** | 0.100 ** | 0.102 ** | 0.091 ** | 0.090 ** | 0.097 ** |

| (3.29) | (2.29) | (2.34) | (2.08) | (2.05) | (2.21) | |

| Program’s Percentage | 0.087 | 0.076 | 0.079 | 0.081 | 0.076 | 0.089 * |

| (1.58) | (1.52) | (1.58) | (1.62) | (1.53) | (1.77) | |

| Key Supplier’s Percentage | −0.031 | −0.037 | −0.034 | −0.036 | −0.034 | −0.040 |

| (−0.55) | (−0.72) | (−0.65) | (−0.70) | (−0.66) | (−0.78) | |

| EQUIP | −0.277 * | −0.125 | −0.110 | −0.129 | −0.120 | −0.129 |

| (−1.85) | (−0.91) | (−0.79) | (−0.94) | (−0.87) | (−0.95) | |

| TRANS | −0.054 | 0.128 | 0.123 | 0.093 | 0.089 | 0.126 |

| (−0.18) | (0.48) | (0.46) | (0.35) | (0.33) | (0.48) | |

| IT | −0.654 * | −0.677 * | −0.684 * | −0.653 * | −0.670 * | −0.672 * |

| (−1.66) | (−1.89) | (−1.92) | (−1.83) | (−1.89) | (−1.90) | |

| Technological Integration | 0.450 *** | 0.282 *** | 0.288 *** | 0.276 *** | 0.280 *** | 0.303 *** |

| (5.34) | (3.48) | (3.56) | (3.43) | (3.50) | (3.77) | |

| Market Dynamism | 0.005 | −0.049 | −0.047 | −0.055 | −0.065 | −0.101 |

| (0.07) | (−0.77) | (−0.74) | (−0.87) | (−1.03) | (−1.56) | |

| Technology Dynamism | 0.019 | −0.045 | −0.050 | −0.047 | −0.039 | −0.085 |

| (0.26) | (−0.67) | (−0.75) | (−0.71) | (−0.59) | (−1.20) | |

| Independent variable | ||||||

| Integrator’s Coordination | 0.504 *** | 0.436 *** | 0.545 *** | 0.520 *** | 0.494 *** | |

| (6.47) | (4.76) | (6.71) | (6.33) | (5.81) | ||

| Coordination × Sqr | −0.083 | |||||

| (−1.41) | ||||||

| COOR × T.D. | 0.125 * | 0.186 ** | 0.280 *** | |||

| (1.69) | (2.28) | (3.02) | ||||

| COOR × M.D. | −0.145 * | −0.089 | ||||

| (−1.73) | (−0.99) | |||||

| T.D. × M.D. | −0.047 | |||||

| (−0.76) | ||||||

| COOR × T.D. × M.D. | 0.182 ** | |||||

| (2.06) | ||||||

| Constant | 2.993 *** | 3.032 *** | 3.046 *** | 3.067 *** | 3.064 *** | 3.030 *** |

| (7.54) | (8.39) | (8.45) | (8.52) | (8.55) | (8.41) | |

| Observations | 209 | 209 | 209 | 209 | 209 | 209 |

| R-squared | 0.256 | 0.388 | 0.394 | 0.397 | 0.406 | 0.419 |

| r2_a | 0.211 | 0.347 | 0.350 | 0.353 | 0.360 | 0.368 |

| F | 5.630 *** | 9.495 *** | 9.002 *** | 9.105 *** | 8.784 *** | 8.109 *** |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, L.; Li, J.; Guo, C. Integrator’s Coordination on Technological Innovation Performance in China: The Dual Moderating Role of Environmental Dynamism. Sustainability 2020, 12, 308. https://doi.org/10.3390/su12010308

Mao L, Li J, Guo C. Integrator’s Coordination on Technological Innovation Performance in China: The Dual Moderating Role of Environmental Dynamism. Sustainability. 2020; 12(1):308. https://doi.org/10.3390/su12010308

Chicago/Turabian StyleMao, Lina, Jinghua Li, and Changwei Guo. 2020. "Integrator’s Coordination on Technological Innovation Performance in China: The Dual Moderating Role of Environmental Dynamism" Sustainability 12, no. 1: 308. https://doi.org/10.3390/su12010308

APA StyleMao, L., Li, J., & Guo, C. (2020). Integrator’s Coordination on Technological Innovation Performance in China: The Dual Moderating Role of Environmental Dynamism. Sustainability, 12(1), 308. https://doi.org/10.3390/su12010308