Abstract

The implementation of energy management over recent decades has been considered to be particularly important for companies wishing to save energy resources, to tackle the issue of climate change, and, at the same time, maintain their competitive edge in an ever-changing environment. The main objective of this article is to identify and analyse all of those critical factors that may affect the implementation of effective energy management practices by Greek enterprises. A questionnaire survey was conducted to investigate the implementation of energy management in Greek enterprises. The survey was conducted between May and September 2016. Out of the 649 questionnaires sent, 132 were collected (a response rate of 20.3%). The implementation of energy management in Greek enterprises is affected particularly positively by the implementation of a structured and integrated energy management system as far as the main findings of the survey are concerned. The use of modern technology, the involvement of the employees, and the commitment of the senior management proved to be additional critical determinants in the implementation of energy management in the operation of businesses.

1. Introduction

Over the years, energy has been a vital factor in the evolution of people and societies. Facilitating access to energy resources has been the starting point for the development of all aspects of social life and action, and a requirement in our everyday life [1,2,3]. However, maintaining the wellbeing of people and maintaining economic development has led to an increased demand for large amounts of energy. In 2018, the global energy demand grew by 2.3%, nearly twice the average rate of growth since 2010 [4]. A recent International Energy Outlook report points out that world energy consumption is expected to rise nearly 50 per cent between 2018 and 2050 and, in 2018, global energy-related CO2 emissions have risen 1.7% to reach 33.1 Gt CO2 [5]. In 2020, per capita consumption of energy in US will be 7.2 tonnes of oil equivalent per annum (toe p.a.), while the figure in Europe will be 3.5 toe., in China 2.3 toe., and in India 0.6 toe. [6]. The energy market faces many challenges, given that energy resources are limited and environmental problems are gradually emerging [7]. Currently, mankind not only seeks for ways to optimally manage energy consumption to ensure the sustainability of energy resources, but also to reduce the resulting environmental impacts [8,9,10]. In this respect, enterprises attempted, early on, to manage energy issues within their units.

The oil crisis of the 1970s was a turning point for the energy market, which gave rise to facing energy management, energy conservation, and energy security in a more systematic and organized way [11,12,13]. Climate change as a consequence of human activity and the impacts of global warming and is likely to reach 1.5 °C above the pre-industrial level determines the current energy reality [14,15,16]. The Paris Agreement in 2015, an agreement to tackle environmental issues, sets out the framework that should guide related policies of countries and businesses towards accelerating energy transformation and reducing the global energy demand [17,18,19,20].

Energy management is considered to be a sustainable approach to energy for an organization, providing a sustained competitive advantage, but, as there is no agreement on a cohesive definition [21], confusion arises as to what the term stands for. References usually cover topics such as energy efficiency, energy saving, and energy tariffs [22,23,24,25,26,27,28], which hinders the further practice and systemic implementation and measurement of energy management in organizations.

The adoption of green practices within organizations to improve energy performance is now a necessity, as the potential of total energy savings is high [29,30]. The need for a systematic approach to energy management is observed, given the great complexity of enterprises and their different views in terms of improving their energy performance [21,31] and the investigation into practical implementation is also necessary. Many studies have shown the crucial role of the management system in the implementation of effective energy practices [21,28,32,33]. Management’s commitment is a key point for the successful implementation of energy management [34,35], as energy management practices are related to all operational units and they aim to improve the business energy performance [36,37]. Another issue to be considered is the factors that may affect the implementation of energy management in businesses. Such determinants can be the use of modern technology, the engagement of the employees, and the commitment of senior management [38,39,40,41,42,43,44].

Furthermore, the establishment of an appropriate energy management system is a way to practice energy management and improve energy performance, which generally includes energy use, energy efficiency, and energy consumption [45,46]. The energy management system approach can be integrated with existing management systems and it is a successful scheme for all industry sizes and sectors [47].

The main purpose of this study is to analyse how the aforementioned key determinants affect the level of implementation of energy management in Greek enterprises. Based on literature review, three hypotheses were proposed to highlight the focus of this paper.

This work is organized as follows. The next section reviews the literature on energy management. This is followed by a description of the methodology. Subsequently, the results are presented and analysed. The paper ends with some conclusions, implications, and suggestions for further research.

2. Literature Review

2.1. Basic Energy Management Concepts

Energy management means different things to different people. Nevertheless, there are similarities among various definitions that are given by researchers [21]. According to Trianni et al. [48], definitions regarding energy management in the literature have been categorized into four main clusters: focus on energy use, strategic perspective, inclusion of managerial aspects, and relevance of people. Energy management in enterprises could be the strategy of meeting energy demand when and where it is needed by optimizing energy while using systems and procedures [28]. The adoption of energy saving measures [49] and the implementation of consistent energy management practices are other points of reference [50].

For the purpose of this study, “Energy management comprises the systematic activities, procedures and routines within a company, while taking into account the elements of strategy and planning, implementation and operation, controlling, organization, and culture, involving both productive and supportive processes that aim to continuously reduce company’s energy consumption and its related energy costs”, which is a definition given by Schulze et al. [31]. Overall, energy management can be considered to be a strategy for using energy effectively. In this context, aspects that have to be taken in consideration are energy efficiency, energy management systems, and energy standards.

The reported annual electricity savings in Stenqvist et al.’s study [39] show that energy management practices have led to real savings and this was calculated at around 3% of energy savings as compared to the base year electricity demand. Energy conservation measures (ECMs), for lighting, for heating, ventilation, and air conditioning (HVAC) (e.g., co-generation and tri-generation), or measures for improving the thermal performance of building envelope (e.g., thermal insulation, low-emissivity windows, and window overhangs), in the context of a business should be seen as having an impact on the economic fusibility of the organization that can be evaluated from an economic point of view, as part of the decision-making process in capital investment planning [51].

Catarino et al.’s study [52] highlighted the low priority that is given by firms to energy efficiency aspects, reinforcing what has already been reported by the International Energy Agency [53], that the the energy actions undertaken are limited when energy cost represents a low amount in the total production cost. Energy management, similarly in the research of Thollander and Ottosson [54], does not seem to be a priority for all of the enterprises. Energy management practices in the literature mainly emphasize barriers to adopting energy management [35]. In the Ates and Durakbasa research [41], a set of policies, such as the promotion of energy efficiency, education, training and capacity building, the facilitation of the implementation of International Management Model ISO 50001, and the strengthening and restructuring of the legal and institutional framework, is offered as a guideline to address current energy barriers. Brunke et al.’s study [43] points out that the participating enterprises are actively engaged in energy management issues, but that they should increase their prioritization and awareness of energy efficiency within the organization.

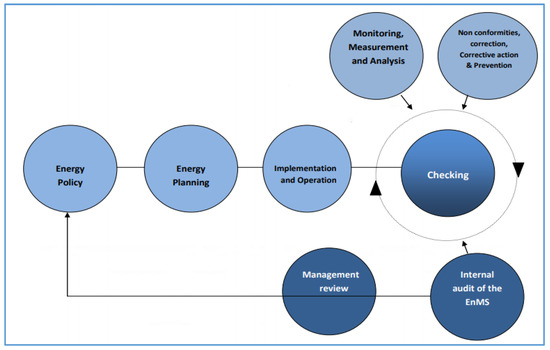

Energy efficiency is an important pillar of sustainable business strategies [55]. In practice, environmental management systems (EnMS) often manage energy efficiency. ΕnMS are expected to help remove barriers that are related to the implementation of energy management practices. An EnMS is a systematic process for continually improving energy performance and maximising energy savings [56]. Figure 1 gives the main elements of an EnMS [57]. The implementation of EnMS is not an objective itself; the main objective is the energy performance improvement [47].

Figure 1.

Main elements of an energy management system (EnMS). Source: [57].

Standards for EnMS have grown significantly [45]. ISO 50001, European Energy Standard EN 16001:2010 [45], and Energy Star (USA) are the known energy management standards [58].

The implementation of energy management varies between companies [21] and, in many cases, an energy management system has introduced new methods of monitoring energy use, which are valuable for improving energy efficiency [39]. In the context of the study, the approach of Dervitsiotis and Lagodimos was adapted, where nine components of the proposed management system can formulate an energy management system implementation framework. The nine components are energy policy, management by objectives, process based management, rational organization, systematic management of resources, systematic operational documentation, systematic audit, effective troubleshooting, and prepared/well trained and equipped employees. Energy consumption in the industrial sector and manufacturing is a considerable operating expense [59] and it consumes about 54% of the world’s total delivered energy [5]. The total final energy consumption in the eight sector groups (pulp, paper and print, iron and steel, non-metallic mineral, chemical and pharmaceutical, non-ferrous metal, petroleum refineries, food and beverage, and machinery) within EU28 was 272,487 ktoe in 2013. This accounted for 25% of the total EU28 final energy consumption (1,103,813 ktoe.) in 2013 [60]. Although, Caffal’s research [61] pointed out that industries that adopt energy management practices can save up to 40% of their total energy consumption, today, energy management is still not fully applied in practice [62]. In the literature. there are various case studies about energy management and energy efficiency in industries and small and medium enterprises [63,64,65,66,67,68]. Indicatively, Kannan and Boie’s [25] case study focus on bakeries in Germany. Gordic et al. [49,54] studied the development of the energy management system of a car manufacturing enterprise. The adaption of balanced wave technology by petrochemical production plants and industries, like the textile and clothing section, is a focal point in Chan et al.’s study [69].

In the field of tourism, regarding the supply-side, various motivations have been identified to drive achieving targets for emissions reduction [70,71] and studies that were carried out in Greece highlight the importance of energy management for tourism enterprises [72,73]. The fact that 87.5% of hotel businesses agree or fully agree that the efficient energy management can increase their profits in Zografakis et al.’s study [74] is very encouraging. In Nikolaou et al.’s research [75], 63.7% of tourism enterprises agreed that effective energy management is an important factor in their profitability, while at the same time considering themselves very well informed on issues related to energy management (68.1%).

Although there are few empirical studies regarding the implementation of energy management [54,76], a number of determinants were identified on implementation of energy management in enterprises. Whether and to what degree enterprises will choose to adopt energy management practices remains under consideration [38,43]. Overall, there is large untapped potential in achieving cleaner and more environmentally friendly production and operation in various business sectors.

Nevertheless, an energy-efficiency gap exists between the actual and optimal energy use [77]; the “energy efficiency gap” debate focuses on the reasons why profitable investments to reduce energy consumption are not realized in companies.

The assessment of energy management practices has highlighted a number of critical determinants for introducing energy efficiency improvements, but studies do not focus on how they affect the level of implementation of energy management practices.

2.2. Critical Energy Management Determinants

2.2.1. Modern Technology

The use of modern technological achievements is one of the priorities of energy management. Surveys show that enterprises estimate that most of their energy efficiency potential stems from the use of new technology, which demonstrates how important energy technology is to enterprises’ consciousness [55,76]. New measurement and monitoring technologies can enable production managers and process owners to better understand how energy resources are used in processes. There is a gap remaining between the available solutions and their actual implementation in industrial enterprises. It should be noted that the education and training of the employees and corporate culture have a key role in the successful implementation of energy management measurement and monitoring solutions and tools [55]. The use of new technologies can give the best performance curves for HVAC systems and reduce the annual energy consumption of refrigeration units by 23.2%, in the information technology sector [78]. Energy saving technologies in industrial facilities include, for example, the use of high efficiency electric motors, the reduction of the temperature of the boiler exhaust, and the use of variable speed to match the load requirement, are cost-effective energy saving measures that reduce energy consumption [28].

2.2.2. Human Resources

Promoting and communicating the value of energy efficiency to employees on a regular basis is an important aspect of their contribution to the success of the energy program [38,39]. Enterprises seek to actively involve employees in energy management by informing, motivating, and educating them in an effort to broaden their knowledge and improve their skills. At the same time, the important role of informing and raising awareness of employees regarding energy issues, with a view to creating energy consciousness and culture, is also being examined. The promotion of the value of energy efficiency to employees on a regular basis is considered to be an important aspect of energy management [43]. The staff commitment is estimated to be lower than the management’s commitment [76]. Additionally, the role of the energy management committee and the technical and steering subcommittees are crucial for a successful energy management program [79].

2.2.3. Commitment of Senior Management

The commitment of senior management has been considered as a crucial and decisive factor in most empirical studies [41,42,43,44,76,80], and this commitment is considered to be important in the successful and effective implementation of energy management [79]. The energy management practices are more effective when the vision of senior executives is to improve the energy stand of the enterprise in order to increase competitiveness and reduce environmental impacts. According to Blass et al. [42], the involvement of senior business executives in energy management increases the percentage of the conservation of energy applied on average by 13.4% and increases the possibility of adopting more innovative changes on energy processes and on the necessary energy equipment from 31% to 44%.

3. Materials and Methods

As energy consumption is increasing, energy consumption in the EU increased by 1% in 2017 and, in Greece, the change during 2016 to 2017 was 1.2% [81]. The role of energy management in organizations is an important factor for countries to reach targets for energy use and CO2 emissions. This study attempts to identify the effect of key determinates, as presented above, on the level of effective implementation of energy management in Greek enterprises. Energy management is used in this study to mean the actions of minimizing organization’s energy consumption. These actions can be focused on changes to products/services, either to changes on procedures (e.g. process modifications, changes in inputs/raw materials, use of automation, equipment replacement, better production management, better production scheduling, staff training). Sekaran’s research approach shaped the empirical research method [82] and it is analysed in four sub-steps, as follows:

- Definition of research questions.

- Definition of conceptual framework.

- Development of research hypotheses.

- Development of empirical research methodology.

3.1. Defining the Research Question

Given the state of affairs with regard to energy issues, we find it particularly important to identify those critical factors that affect the successful adoption and implementation of energy management practices in enterprises in a variety of ways, on a smaller or larger scale. These factors mainly concern the use of modern technology, the encouragement of employee participation, and the implementation of integrated energy management system.

However, there has been a discrepancy between energy efficiency improvement measures, which are considered to be critical in the international literature, and the measures actually adopted and implemented by businesses. The specific research question is as follows:

- In what way the three key determinates (modern technology, encouragement of employee participation, and the implementation of an integrated energy management system) affect the level of implementation of energy management in Greek enterprises?

3.2. Defining a Conceptual Framework

Defining the conceptual framework of the research involves identifying and naming key variables, which are examined in the context of the formulated research question. In this context, the dependent and independent variables, closely related to the specific research field, are identified, as follows.

The dependent variable of the research is the “Level of Implementation of Effective Energy Management Practices”, as energy management practices play an important role in implementing the company’s energy strategy.

As main determinants of the dependent variable examined the critical factors (which were identified through literature review) that affect the successful adoption and implementation of energy management practices in enterprises. The independent variable are defined, as follows

- The “Level of Usage of Modern Technology”.

- The “Level of Encouragement of Employees’ Involvement”.

- The “Level of Implementation of an Integrated Energy Management System”.

3.3. Main Research Hypotheses

A central issue addressed in the context of this empirical research is to examine the impact of: (a) the use of modern technology, (b) the encouragement of employees’ involvement, and (c) implementation of an integrated energy management System to the level of Implementation of effective energy management practices.

The corresponding central research hypothesis is developed, as follows:

Hypothesis 1 (H1).

The three key factors (a) of the level of use of modern technology, (b) of the level of encouragement of employees’ involvement, and (c) of the level of implementation of an integrated energy management system have a positive effect on the level of implementation of effective energy management practices in Greek businesses.

Moreover, in this research, “The Commitment of Senior Management and the existence of a clear Strategy” is considered to be an independent variable for its possible impact on (a) the level of implementation of effective energy management practices and on (b) the implementation of an integrated energy management system.

The corresponding research hypotheses are developed, as follows:

Hypothesis 2 (H2).

The Commitment of Senior Management and the Strategy influence positively the level of implementation of effective energy management practices.

Hypothesis 3 (H3).

The Commitment of Senior Management and the Strategy influence positively the level of implementation of an integrated energy management system.

3.4. Development of Empirical Research Methodology

The main elements that compose the methodology of empirical research are pooled according to the proposed research methodologies of Sekaran [82] and Saunders et al. [83].

The population of this empirical research was defined as the total number of enterprises operating in Greece, irrespective of the business sector, as long as they employ at least 10 employees, which is similar to corresponding studies on the same subject [38]. A list of the largest enterprises operating in Greece, based on a turnover for the year 2014, was used as a sampling frame for identifying the population. The sampling unit is defined as any company that is involved in the research. Cluster sampling was selected as the most appropriate sampling method for the present empirical survey and the clusters were fixed according to business size. The size of the enterprise was measured based on the number of employees.

We note that out of the population, which is 1708 enterprises, nine enterprises were excluded, for which there were no complete data. Furthermore, companies with less than 10 employees, a total of 62 enterprises, were also excluded. Consequently, the survey population is finally comprised of 1673 enterprises, which were found to be suitable to complete the questionnaire. Therefore, the final sample was 649 after applying the appropriate sampling method.

The survey was conducted between May and September 2016. Out of the 649 questionnaires sent out, 132 were filled in, setting the response rate at 20.3%, which was judged to be satisfactory, while taking the current socio-economic conditions and the specificity of the subject of this empirical research into account. The response rate before the follow-up stood at 13%. Consequently, achieving the final response rate should be largely attributable to the follow-up contribution. We note that, out of 132, 129 questionnaires were evaluated as suitable for analysis, as they did not show problematic responses to the critical variables of the survey. The questionnaire was addressed to General Managers or Technical Directors. The design of the questionnaire followed common and usual good practices [84,85,86]. The questionnaire, before final configuration, was piloted and evaluated by energy management specialists who were also potential participants of the survey.

In this survey, the most significant errors are examined and identified. The following analysis is based on Groves’ approach [85], which includes the examination of the following errors: coverage error, non-response error, sampling error, and measurement error. There was no significant problem for the research in any of these cases. All of the hypotheses of implementation of the multiple linear regression, which are analysed below, were tested. The three independent variables are continuous ratios, while they show some variability and are not highly correlated with other external variables. The individual values received by both the independent variables and the dependent variable are independent of each other. There is no problem regarding the inspection of the influential cases, the multi-collinearity, the linearity of the model, and the homoscedasticity and the regularity of the residuals.

The questionnaire was divided in six sections:

- Respondent’s & corporate identity,

- Importance of energy management,

- Factors influencing implementation of energy management practices,

- Energy management,

- Adoption of energy management practices, and

- Determinants of energy management practices.

For the analysis of the questionnaire, complex variables were created. The main variable of the study the level of implementation of effective energy management practices (PRACT) was measured while using 14 absolutely (Section 5) clear and understandable sentences, which were defined from the existing literature [38,41,43,87,88,89,90,91] (Table 1). The measurement was based on a five-point Likert scale interval.

Table 1.

Statements used for creating the variables.

The independent variables are defined, as follows. The variable level of implementation of an integrated energy management system (SYST) was defined based on the nine components of the adapted energy management system implementation framework, given above, which were translated into 12 (Section 4) fully understandable statements (Table 1). The measurement of the variable was based on a five-point Likert scale interval.

In terms of the measurement of the level of usage of modern technology (TECH) and the level of encouragement of employees’ involvement (HR) variables, their main components were identified from the literature [21,39,41,76,92] (Table 1). The measurement of the two composite variables TECH and HR (Section 6) was based on a five-point interval scale.

4. Analysis and Results

4.1. Analysis

Table 2 summarizes the key elements of the sample identity.

Table 2.

Key elements of the sample identity.

A very high percentage of the Greek enterprises under investigation—at least 89%—consider the implementation of effective energy management practices to be very important in the operation of their organization.

At the same time, an almost equally high percentage (73%) of participants monitors the current progress in energy management issues in businesses and appears to be interested in them.

More than half of companies, approximately 60% say that the current economic situation has had a major impact on the way they face energy management issues and energy saving. Furthermore, it would not be possible for businesses to remain unaffected by the current conditions of the environment within which they operate and function.

Following the delimitation of the framework for systemic energy management, we examined whether and to what extent, Greek enterprises implement an integrated and structured energy management system, as composed of its key features.

In general, it appears that enterprises are implementing some of the criteria of an integrated energy management system. However, there is certainly room for improvement if we take the average of all criteria under consideration ranging from 3 to 3.5 into account, which makes it possible to establish that in all fields, companies need to work more effectively and with greater consistency. In particular, several businesses seem to be implementing some sort of energy policy, setting clear and measurable goals, defining responsibilities, institutionalizing appropriate governance bodies, providing the necessary resources for all actions, and taking preventive measures to deal with risks. However, some of the most critical elements of an energy system, such as the existence and development of standardized energy management processes, the written documentation, the preservation of records, and the ongoing training of employees on energy issues, are among the less common elements that are found in businesses.

At the same time, Greek enterprises find themselves implementing a number of effective energy management practices, others to a greater, and others to a lesser extent. An effort being made by companies to manage the energy issues within their organization is undeniable. There is, of course, enough room for improvement to ameliorate their overall energy performance.

4.1.1. Research Hypothesis H1

To examine the H1 hypothesis, a multiple-linear regression analysis is performed:

PRACT = a + b1 TECH + b2 HR + b3 SYST, with:

- Independent Variable 1 (Predictor Variable): Level of usage of modern technology.

- Independent Variable 2 (Predictor Variable): Level of encouragement of employee involvement.

- Independent Variable 3 (Predictor Variable): Level of implementation of an integrated energy management system.

- Dependent Variable (Result): Level of implementation of effective energy management practices.

Table 3 shows the main results of the under investigation multi-linear regression model for the investigation of the H1 hypothesis.

Table 3.

Key results of the multi-linear regression model (H1 research hypothesis).

It can be seen from Table 3 that the three independent variables the level of usage of modern technology (TECH), the level of encouragement of employees’ involvement (HR), and the level of implementation of an integrated energy management system (SYST) explain at, a very high percentage (67.70%), the volatility of the dependent variable “level of implementation of effective energy management practices (PRACT)”.

Table 4 presents the ANOVA results. From this table, we conclude that the model of the multiple linear regression holds the ability to predict the result at a significant degree (F = 87.279 **, p < 0.001).

Table 4.

ANOVA results of the multiple-linear regression (research hypothesis H1).

Table 5 presents the results regarding the parameters of the multiple-linear regression model under examination.

Table 5.

Parameter results of multiple-linear regression (research hypothesis H1).

Based on these results, the multiple linear regression equation regression equation is formulated, as follows:

PRACT = 1.291 + 0.191 TECH + 0.165 HR + 0.351 SYST.

As shown by the t-test, the value of b1 (t = 3.891, p < 0.001), the value of b2 (t = 3.553 **, p < 0.01), and the value of b3 (t = 5.951, p < 0.001), significantly differ from 0. Therefore, we note that all three independent variables “level of usage of modern technology”, “level of encouragement of employees’ involvement”, and “level of implementation of an integrated energy management system” have significantly contributed to the prediction model of the dependent variable “level of implementation of effective energy management practices”.

When comparing the contribution of the three independent variables, concerning the value of the t-test criterion and the value of the adjusted beta coefficients, it appears that the variable “level of Implementation of Integrated energy management System” has a higher contribution than the other two variables the “level of usage of modern technology” and the “level of encouragement of employees’ involvement”.

The above results, with respect to the control of the H1 hypothesis, lead to the acceptance of H1 (to a 99% confidence level). Therefore, there is a statistically significant impact of the level of usae of modern technology, the level of encouragement of employees’ involvement, and the level of implementation of an integrated energy management system on the level of the implementation of effective energy management practices in Greek enterprises.

4.1.2. Research Hypothesis H2

The control of research hypothesis H2 was performed while using One-Way ANOVA Criterion (Table 6), whose value (F = 32.037 **, p < 0.001) led to the acceptance of the research hypothesis (at the 99% confidence level).

Table 6.

ANOVA results (research hypothesis H2).

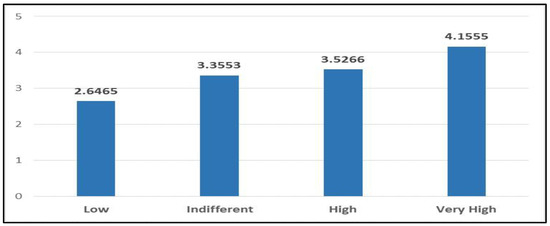

The results above lead to the conclusion that there is a statistically significant difference in the relation between the level of implementation of effective energy management practices and the commitment of top management and the existence of energy strategy in Greek enterprises. In particular, the higher the commitment of senior management in an enterprise regarding energy issues and management, the more effective energy management practices that will be implemented within this enterprise. This research hypothesis confirms, to a large extent, the existing literature [80,93]. There is no doubt that the appropriate actions are implemented in enterprises to a greater degree when the senior management decides to develop the appropriate strategy. At the same time, the energy corporate culture begins to form within the organization. Means were formed at 2.64, 3.35, 3.52, and 4.15, respectively. Figure 2 depicts the means.

Figure 2.

Representation of the responses’ means (research hypothesis H2).

4.1.3. Research Hypothesis H3

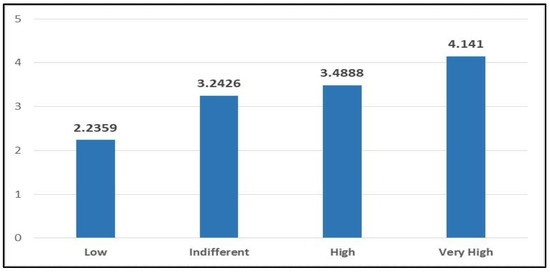

The control of the research hypothesis H3 was conducted while using One-Way ANOVA (Table 7) criterion, whose value (F = 36,504 **, p < 0.001) led to the acceptance of the research hypothesis (at the 99% confidence level).

Table 7.

ANOVA Results (research hypothesis H3).

The results above lead to the conclusion that there is a statistically significant difference in the relation between the level of implementation of an Integrated energy management System and the commitment of top management and the existence of energy strategy in Greek enterprises. More specifically, the higher the commitment of senior management in an enterprise in terms of energy issues and their management, the more improved energy management system that will be developed within this enterprise. This research hypothesis confirms the existing literature to a large extent [23,40,46,55,77]. There is no doubt that when the management decides to develop the appropriate strategy, appropriate actions are taken to build an integrated energy management system. The means were at 2.23, 3.24, 3.48, and 4.14 respectively. Figure 3 depicts the means.

Figure 3.

Representation of the responses’ means (research hypothesis H3).

4.2. Results

The results for the research hypothesis H1 suggest that the three factors (a) the use of modern technology, (b) the encouragement of employees’ involvement, and (c) the implementation of an integrated energy management system have a positive impact on the implementation of energy management practices in Greek enterprises. These three factors examined seem to interpret the implementation of energy management practices in Greek enterprises to a significant extent. The research recognizes the importance and the contribution of all three. However, the findings of the present study show that the contribution of the level of implementation of an integrated energy management system in Greek companies is greater than both the contribution of the use of modern technology and the contribution of employees’ involvement. In any case, the application of modern technology and the involvement of employees are extremely important for the implementation of energy management.

The measurement for the research hypothesis H2 shows that, the higher the commitment of senior management to an enterprise in terms of energy issues and their management is, the more effective the energy management practices that are implemented within that enterprise will be.

Additionally, the impact of senior management commitment on implementing an integrated energy management system is positive, a fact that confirms research hypothesis H3.

5. Discussion

Energy management and energy efficiency are central issues in all global energy transitions. Energy saving has become a major political priority worldwide. Energy-saving measures are very important, both to reduce costs to businesses and for the environmental benefits. The rational management of energy issues in a business can increase the value added of the products and, hence, the profitability of the business, as well as contribute to the reduction of energy consumption, and thus to the organization’s reduced environmental footprint.

Two critical potential determinants in implementing energy management have been identified in the literature, the use of modern technology and employee involvement. We confirmed that the implementation of an integrated energy management system combined with the above two main factors (modern technology and the involvement of the staff) all contribute together in the direction of improving the level of implementation of energy management practices in the context of this empirical research and in accordance with the results.

The achievements of modern technology are the starting point for a company to implement practices that will give it an impetus to improve its energy management. Likewise, employee involvement, especially when the staff is well-trained and skilled, can make a significant contribution and can ameliorate the implementation of effective energy management practices. However, these two factors, although important, cannot produce the best results if companies do not maintain an appropriate, properly structured, and organized energy management system. The system sets the structured framework and it has a decisive impact on the formulation and implementation of effective energy management practices, thus highlighting its value.

The results are also in line with the findings of the existing literature that consider the development of an energy management system to be an important tool for the effective implementation of energy practices [28,31,40,44]. In addition, studies have also documented the positive impact of modern technology on energy management [39,76]. With regard to employee involvement, the results confirm the studies of Ates and Durakbasa [41], Backlund et al. [21], and Palm and Thollander [92].

Furthermore, the findings of this research confirm the correlation between the commitment of senior management and adoption of effective energy management [38,39,41]. The commitment of senior management and the introduction of a specific strategy in energy management is judged to be important. Thus, the positive willingness of senior executives to engage in energy issues has a conceivable positive impact on both the practical and systemic implementation of the energy management. There is no doubt that, when senior management decides to develop the appropriate strategy, the necessary actions are implemented on a larger scale as it begins to form within the organization the energy corporate culture.

While considering the above results, we conclude that Greek enterprises, with regard to the way they face the implementation of energy management, appear to be more affected by endogenous than by external factors. This is based on the finding that the parameters that have a greater impact on business behavior are more closely related to the existence of top management’s commitment and strategy, the implementation of an integrated energy management system, and the involvement of human resources. All three factors are linked to the internal need and intention of the organization to take significant action in dealing with, and managing, the energy issues that arise.

6. Conclusions

To summarize, the study set out to understand the effect of key factors on the implementation of energy management in Greek companies. Three factors (integrated energy management system, commitment of senior management, and involvement of employees) were found to positively influence the level of implementation of energy management practices in Greek enterprises. The above findings of the field research provide useful information, which can be used in practice by companies and institutions that deal with energy management. However, we necessarily take into account that all measurements related to the systematic implementation of energy management use the energy management system implementation framework as a basis. In addition, all of the survey measurements were conducted in Greece and this is one limitation of the research. Lastly, we stress that all of the above findings are based on the subjective self-assessment of the companies that participated in this research, which limits the objectivity of their responses.

This research helps to update the factors that influence organizations on implementing energy management practices that will hopefully serve as additional references when planning energy policies. We also suggest conducting the same field research in a different geographical area in other European Union countries, especially in the Mediterranean, and comparing the results with those of the present survey. In addition, in a future survey, it will be of particular interest to test the importance of energy management for smaller enterprises and whether implementing energy management practices could bring positive results. Finally, it is worth noting that the field research was conducted in particularly adverse financial conditions. We expect that the current circumstances affect plenty of the findings. For this reason, repeating the same research in future, more favorable conditions are also of interest.

Author Contributions

Conceptualization, methodology, writing—review and editing E.V.T., E.A.D., D.A.G. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by University of Piraeus Research Center.

Acknowledgments

This work has been partly supported by the University of Piraeus Research Center.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Koomanoff, F.A. Energy the enabler, in our changing world. Nucl. Eng. Des. 1992, 136, 17–21. [Google Scholar] [CrossRef]

- Kats, G. Opportunity for energy reform. Energy Policy 1992, 13, 546–558. [Google Scholar] [CrossRef]

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- IEA. Global Energy & CO2 Status Report. 2018. Available online: https://webstore.iea.org/global-energy-co2-status-report-2018 (accessed on 25 July 2019).

- EIA. International Energy Outlook. 2019. Available online: https://www.eia.gov/outlooks/ieo/pdf/ieo2019.pdf (accessed on 8 November 2019).

- McKinsey Germany. Energy: A Key to Competitive Advantage-New Sources of Grouth and Productivity. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/sustainability/pdfs/energy_competitive_advantage_in_germany.ashx (accessed on 7 November 2019).

- Ali, H.M.A.; Ajmal, M.M.; Gunasekaran, A.; Helo, P.T. Managing change in constant evolving sustainable energy market: An exploratory study of motivators, enablers, and barriers. Sustain. Prod. Consum. 2019, 20, 84–97. [Google Scholar] [CrossRef]

- UNFCCC. United Nations Framework Convention on Climate Change. Available online: https://unfccc.int/files/essential_background/background_publications_htmlpdf/application/pdf/conveng.pdf (accessed on 20 October 2019).

- Sorrell, S. Reducing energy demand: A review of issues, challenges and approaches. Renew. Sustain. Energy Rev. 2015, 47, 74–82. [Google Scholar] [CrossRef]

- Reynolds, J.; Rezgui, Y.; Hippolyte, J.L. Upscaling energy control from building to districts: Current limitations and future perspectives. Sustain. Cities Soc. 2017, 35, 816–829. [Google Scholar] [CrossRef]

- Nordhaus, W.D.; Houthakker, H.S.; Sachs, J.D. Oil and Economic Performance in Industrial Countries. Brook. Pap. Econ. Act. 1980, 1980, 341. [Google Scholar] [CrossRef]

- Rüdiger, M. The 1973 Oil Crisis and the Designing of a Danish Energy Policy. Hist. Soc. Res. 2014, 39, 94–112. [Google Scholar]

- OECD. Energy. Available online: https://www.oecd.org/greengrowth/greening-energy/49157219.pdf (accessed on 5 November 2019).

- UNEP. Emissions Gap Report. 2018. Available online: http://wedocs.unep.org/bitstream/handle/20.500.11822/26895/EGR2018_FullReport_EN.pdf?sequence=1&isAllowed=y (accessed on 15 November 2019).

- UNEP. The Emissions Gap Report 2013: A UNEP Synthesis Report. Available online: https://www.oecd.org/greengrowth/greening-energy/49157219.pdf (accessed on 10 July 2019).

- IPCC. Summary for Policymakers. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/05/SR15_SPM_version_report_LR.pdf (accessed on 12 June 2019).

- UNFCCC. The Paris Agreement. Available online: http://unfccc.int/paris_agreement/items/9485.php (accessed on 9 June 2019).

- Melica, G.; Bertoldi, P.; Kona, A.; Iancu, A.; Rivas, S.; Zancanella, P. Multilevel governance of sustainable energy policies: The role of regions and provinces to support the participation of small local authorities in the Covenant of Mayors. Sustain. Cities Soc. 2018, 39, 729–739. [Google Scholar] [CrossRef]

- Núñez Collado, J.R.; Wang, H.-H.; Tsai, T.-Y. Urban Informality in the Paris Climate Agreement: Content Analysis of the Nationally Determined Contributions of Highly Urbanized Developing Countries. Sustainability 2019, 11, 5228. [Google Scholar] [CrossRef]

- Christodoulou, A.; Cullinane, K. Identifying the Main Opportunities and Challenges from the Implementation of a Port Energy Management System: A SWOT/PESTLE Analysis. Sustainability 2019, 11, 6046. [Google Scholar] [CrossRef]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the energy efficiency gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef]

- Ruteh, S.S.S. Energy management and sustainable development. WIT Trans. Ecol. Environ. 2011, 143, 159–171. [Google Scholar]

- O’Callaghan, P.W.; Probert, S.D. Energy management. Appl. Energy 1977, 3, 127–138. [Google Scholar] [CrossRef]

- Petrecca, G. Industrial Energy Management: Principles and Applications; Springer: New York, NY, USA, 1993. [Google Scholar]

- Kannan, R.; Boie, W. Energy management practices in SME––case study of a bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Thumann, A.; Mehta, D.P. Handbook of Energy Engineering, 6th ed.; Fairmont Press: Lilburn, GA, USA; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0-88173-581-9. [Google Scholar]

- Jelic, D.; Gordic, D.; Babic, M.; Koncalovic, D.; Sustersic, V. Review of existing energy management standards and possibilities for its introduction in Serbia. Therm. Sci. 2010, 14, 613–623. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Hossain, R.; Tuhin, R.A.; Sakib, T.H.; Thollander, P. Empirical Investigation of Barriers and Driving Forces for Efficient Energy Management Practices in Non-Energy-Intensive Manufacturing Industries of Bangladesh. Sustainability 2019, 11, 2671. [Google Scholar] [CrossRef]

- Ashton, W.; Russell, S.; Futch, E. The adoption of green business practices among small US Midwestern manufacturing enterprises. J. Environ. Plan. Manag. 2017, 60, 2133–2149. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L. Policy scenarios for energy efficiency improvement in industry. Energy Policy 2001, 29, 1223–1241. [Google Scholar] [CrossRef]

- Therkelsen, P.; McKane, A.; Sabouni, R.; Evans, T.; Scheihing, P. Assessing the Costs and Benefits of the Superior Energy Performance Program; Lawrence Berkeley National Lab.: Berkeley, CA, USA, 2013. [Google Scholar]

- Turner, W.C.; Doty, S. Energy Management Handbook, 6th ed.; Fairmont Press: Lilburn, GA, USA; Distributed by CRC Press/Taylor & Francis: Boca Raton, FL, USA, 2007; ISBN 978-0-88173-542-0. [Google Scholar]

- Fernando, Y.; Bee, P.S.; Jabbour, C.J.C.; Thomé, A.M.T. Understanding the effects of energy management practices on renewable energy supply chains: Implications for energy policy in emerging economies. Energy Policy 2018, 118, 418–428. [Google Scholar] [CrossRef]

- Geller, H.; Harrington, P.; Rosenfeld, A.H.; Tanishima, S.; Unander, F. Polices for increasing energy efficiency: Thirty years of experience in OECD countries. Energy Policy 2006, 34, 556–573. [Google Scholar] [CrossRef]

- Introna, V.; Cesarotti, V.; Benedetti, M.; Biagiotti, S.; Rotunno, R. Energy Management Maturity Model: An organizational tool to foster the continuous reduction of energy consumption in companies. J. Clean. Prod. 2014, 83, 108–117. [Google Scholar] [CrossRef]

- Christoffersen, L.B.; Larsen, A.; Togeby, M. Empirical analysis of energy management in Danish industry. J. Clean. Prod. 2006, 14, 516–526. [Google Scholar] [CrossRef]

- Stenqvist, C.; Nilsson, L.J.; Ericsson, K.; Modig, G. Energy management in Swedish pulp and paper industry—The daily grind that matters. In 10th eceee Summer Study-Energy Efficiency First: The Foundation of a Low-Carbon Society; eceee: Stockholm, Sweden, 2011. [Google Scholar]

- Fleiter, T.; Schleich, J.; Ravivanpong, P. Adoption of energy-efficiency measures in SMEs—An empirical analysis based on energy audit data from Germany. Energy Policy 2012, 51, 863–875. [Google Scholar] [CrossRef]

- Ates, S.A.; Durakbasa, N.M. Evaluation of corporate energy management practices of energy intensive industries in Turkey. Energy 2012, 45, 81–91. [Google Scholar] [CrossRef]

- Blass, V.; Corbett, C.J.; Delmas, M.A.; Muthulingam, S. Top management and the adoption of energy efficiency practices: Evidence from small and medium-sized manufacturing firms in the US. Energy 2014, 65, 560–571. [Google Scholar] [CrossRef]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Backlund, S.; Ottosson, M. Energy efficiency potentials and energy management practices in Swedish firms. In Proceedings of the Summer Study on Energy Efficiency in Industry (Eceee 2012), European Council for an Energy Efficient Economy, Arnhem, The Netherlands, 11–14 September 2012. [Google Scholar]

- Marimon, F.; Casadesús, M. Reasons to Adopt ISO 50001 Energy Management System. Sustainability 2017, 9, 1740. [Google Scholar] [CrossRef]

- Lee, D.; Cheng, C.-C. Energy savings by energy management systems: A review. Renew. Sustain. Energy Rev. 2016, 56, 760–777. [Google Scholar] [CrossRef]

- UNIDO. Practical Guide for Implementing an Energy Management System. Available online: https://www.unido.org/sites/default/files/2017-11/IEE_EnMS_Practical_Guide.pdf (accessed on 15 October 2019).

- Trianni, A.; Cagno, E.; Bertolotti, M.; Thollander, P.; Andersson, E. Energy management: A practice-based assessment model. Appl. Energy 2019, 235, 1614–1636. [Google Scholar] [CrossRef]

- Gordić, D.; Babić, M.; Jovičić, N.; Šušteršič, V.; Končalović, D.; Jelić, D. Development of energy management system – Case study of Serbian car manufacturer. Energy Convers. Manag. 2010, 51, 2783–2790. [Google Scholar] [CrossRef]

- Gorp, J.C.V. Maximizing energy savings with enterprise energy management systems. In Proceedings of the Conference Record of 2004 Annual Pulp and Paper Industry Technical Conference (IEEE Cat. No.04CH37523), Victoria, BC, Canada, 27 June–1 July 2004; pp. 175–181. [Google Scholar]

- Au, T.; Au, T.P. Engineering Economics for Capital Investment Analysis, 2nd ed.; PRENTICE HALL: Englewood Cliffs, NJ, USA, 1992. [Google Scholar]

- Catarino, J.; Henriques, J.; Egreja, F. Portuguese SME toward energy efficiency improvement. Energy Effic. 2015, 8, 995–1013. [Google Scholar] [CrossRef]

- International Energy Agency. Tracking Industrial Energy Efficiency and CO2 Emissions; OECD Publishing: Paris, France, 2007. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. Energy management practices in Swedish energy-intensive industries. J. Clean. Prod. 2010, 18, 1125–1133. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M. Managing Energy Efficiency in Manufacturing Processes—Implementing Energy Performance in Production Information Technology Systems. In What Kind of Information Society? Governance, Virtuality, Surveillance, Sustainability, Resilience; Berleur, J., Hercheui, M.D., Hilty, L.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 328, pp. 260–268. ISBN 978-3-642-15478-2. [Google Scholar]

- OECD. An Introduction to Energy Management Systems: Energy Savings and Increased Industrial Productivity for The Iron and Steel Sector. Available online: https://www.oecd.org/sti/ind/DSTI-SU-SC(2014)14-FINAL-ENG.pdf (accessed on 15 October 2019).

- TÜV UK Ltd. ISO 50001 (EnMS) Energy Management Systems. Available online: https://www.tuv-nord.com/fileadmin/Content/TUV_NORD_COM/TUEV_NORD_UK/pdf/iso-50001-guide-and-check-list-uk.pdf (accessed on 14 October 2019).

- ENERGY STAR|The Simple Choice for Energy Efficiency. Available online: https://www.energystar.gov/ (accessed on 17 October 2019).

- Ali, M.H.; Zailani, S.; Iranmanesh, M.; Foroughi, B. Impacts of Environmental Factors on Waste, Energy, and Resource Management and Sustainable Performance. Sustainability 2019, 11, 2443. [Google Scholar] [CrossRef]

- European Commission Directorate-General Energy/ICF. Study on Energy Efficiency and Energy Saving Potential in Industry and on Possible Policy Mechanisms. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/151201%20DG%20ENER%20Industrial%20EE%20study%20-%20final%20report_clean_stc.pdf (accessed on 17 October 2019).

- Caffal, C. Learning from experiences with Energy Management in Industry; Analysis Series 17; Centre for the Analysis and Dissemination of Demonstrated Energy Technologies: Sittard, The Netherlands, 1995. [Google Scholar]

- Sa, A.; Thollander, P.; Cagno, E.; Rafiee, M. Assessing Swedish Foundries Energy Management Program. Energies 2018, 11, 2780. [Google Scholar] [CrossRef]

- Hilger, L.; Schneiders, T.; Meyer, F.P.; Kroll, J.P. Use of smart technologies for energy efficiency, energy- and load management in small and medium sized enterprises (SMEs). In Proceedings of the 2018 7th International Energy and Sustainability Conference (IESC), Cologne, Germany, 17–18 May 2018; pp. 1–8. [Google Scholar]

- Johansson, I.; Mardan, N.; Cornelis, E.; Kimura, O.; Thollander, P. Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies 2019, 12, 1338. [Google Scholar] [CrossRef]

- Schleich, J.; Fleiter, T. Effectiveness of energy audits in small business organizations. Resour. Energy Econ. 2019, 56, 59–70. [Google Scholar] [CrossRef]

- Lu, Y.; Papagiannidis, S.; Alamanos, E. Internet of Things: A systematic review of the business literature from the user and organisational perspectives. Technol. Forecast. Soc. Chang. 2018, 136, 285–297. [Google Scholar] [CrossRef]

- Lawrence, A.; Thollander, P.; Andrei, M.; Karlsson, M. Specific Energy Consumption/Use (SEC) in Energy Management for Improving Energy Efficiency in Industry: Meaning, Usage and Differences. Energies 2019, 12, 247. [Google Scholar] [CrossRef]

- Gambini, M.; Vellini, M.; Stilo, T.; Manno, M.; Bellocchi, S. High-Efficiency Cogeneration Systems: The Case of the Paper Industry in Italy. Energies 2019, 12, 335. [Google Scholar] [CrossRef]

- Chan, M.H.E.; Chu, K.K.; Chow, H.F.; Tsang, C.W.; Ho, C.K.D.; Ho, S.K. Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer. Energies 2019, 12, 4136. [Google Scholar] [CrossRef]

- Pratt, L. Tourism in the Green Economy: Background Report Copyright © 2012; United Nations Environment Programme (UNEP) and World Tourism Organization (UNWTO): Madrid, Spain, 2012; ISBN 978-92-807-3143-9. [Google Scholar]

- Coles, T.; Dinan, C.; Warren, N. Energy practices among small- and medium-sized tourism enterprises: A case of misdirected effort? J. Clean. Prod. 2016, 111, 399–408. [Google Scholar] [CrossRef]

- Menegaki, A.N.; Agiomirgianakis, G.M. Sustainable Technologies in Greek Tourist Accommodation: A Quantitative Review. Eur. Res. Stud. J. 2018, XXI, 222–238. [Google Scholar] [CrossRef][Green Version]

- Parpairi, K. Sustainability and Energy Use in Small Scale Greek Hotels: Energy Saving Strategiesand Environmental Policies. Procedia Environ. Sci. 2017, 38, 169–177. [Google Scholar] [CrossRef]

- Zografakis, N.; Gillas, K.; Pollaki, A.; Profylienou, M.; Bounialetou, F.; Tsagarakis, K.P. Assessment of practices and technologies of energy saving and renewable energy sources in hotels in Crete. Renew. Energy 2011, 36, 1323–1328. [Google Scholar] [CrossRef]

- Nikolaou, I.E.; Vitouladitis, H.; Tsagarakis, K.P. The willingness of hoteliers to adopt proactive management practices to face energy issues. Renew. Sustain. Energy Rev. 2012, 16, 2988–2993. [Google Scholar] [CrossRef]

- Sivill, L.; Manninen, J.; Hippinen, I.; Ahtila, P. Success factors of energy management in energy-intensive industries: Development priority of energy performance measurement: Success factors of energy management: Energy performance measurement. Int. J. Energy Res. 2013, 37, 936–951. [Google Scholar] [CrossRef]

- Jaffe, A.B.; Stavins, R.N. The energy-efficiency gap What does it mean? Energy Policy 1994, 22, 804–810. [Google Scholar] [CrossRef]

- Lee, S.K.; Teng, M.C.; Fan, K.S.; Yang, K.H.; Horng, R.S. Application of an energy management system in combination with FMCS to high energy consuming IT industries of Taiwan. Energy Convers. Manag. 2011, 52, 3060–3070. [Google Scholar] [CrossRef]

- Capehart, B.L.; Turner, W.C.; Kennedy, W.J. Guide to Energy Management, 7th ed.; Fairmont Press: Lilburn, GA, USA; Distributed by Taylor & Francis: Boca Raton, FL, USA, 2012; ISBN 978-0-88173-671-7. [Google Scholar]

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry—Exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Eurostat. Energy consumption in 2017. Available online: https://ec.europa.eu/eurostat/documents/2995521/9549144/8-07022019-AP-EN.pdf/4a5fe0b1-c20f-46f0-8184-e82b694ad492 (accessed on 18 October 2019).

- Sekaran, U. Research Methods for Business: A Skill-Building Approach, 4th ed.; John Wiley & Sons: New York, NY, USA, 2003. [Google Scholar]

- Saunders, M.N.K.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 5th ed.; Prentice Hall: New York, NY, USA, 2009; ISBN 978-0-273-71686-0. [Google Scholar]

- Foddy, W. Constructing Questions for Interviews and Questionnaires: Theory and Practice in Social Research, 1st ed.; Cambridge University Press: Cambridge, UK, 1993; ISBN 978-0-521-42009-9. [Google Scholar]

- Groves, R.M. Survey Errors and Survey Costs; Wiley series in survey methodology; Wiley: Hoboken, NJ, USA, 2004; ISBN 978-0-471-67851-9. [Google Scholar]

- Mashburn, W.H. Effective energy management. In Energy Management Handbook; The Fairmont Press: Lilburn, GA, USA, 2007; pp. 9–22. [Google Scholar]

- McKane, A.; Scheihing, P.; Williams, R. Certifying Industrial Energy Efficiency Performance: Aligning Management, Measurement, and Practice to Create Market Value; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2007. [Google Scholar]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Gordić, D.; Babić, M.; Jelić, D.; Konćalović, D.; Vukašinović, V. Integrating Energy and Environmental Management in Wood Furniture Industry. Available online: https://www.hindawi.com/journals/tswj/2014/596958/ (accessed on 4 December 2019).

- Sa, A.; Paramonova, S.; Thollander, P.; Cagno, E. Classification of Industrial Energy Management Practices. Energy Procedia 2015, 75, 2581–2588. [Google Scholar] [CrossRef]

- Shrouf, F.; Miragliotta, G. Energy management based on Internet of Things: Practices and framework for adoption in production management. J. Clean. Prod. 2015, 100, 235–246. [Google Scholar] [CrossRef]

- Palm, J.; Thollander, P. An interdisciplinary perspective on industrial energy efficiency. Appl. Energy 2010, 87, 3255–3261. [Google Scholar] [CrossRef]

- Horbach, J. Determinants of environmental innovation—New evidence from German panel data sources. Res. Policy 2008, 37, 163–173. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).