Assessment Methodology of Practical Configuration Management (CM) for Sustainable Nuclear Power Plants (NPPs)

Abstract

1. Introduction

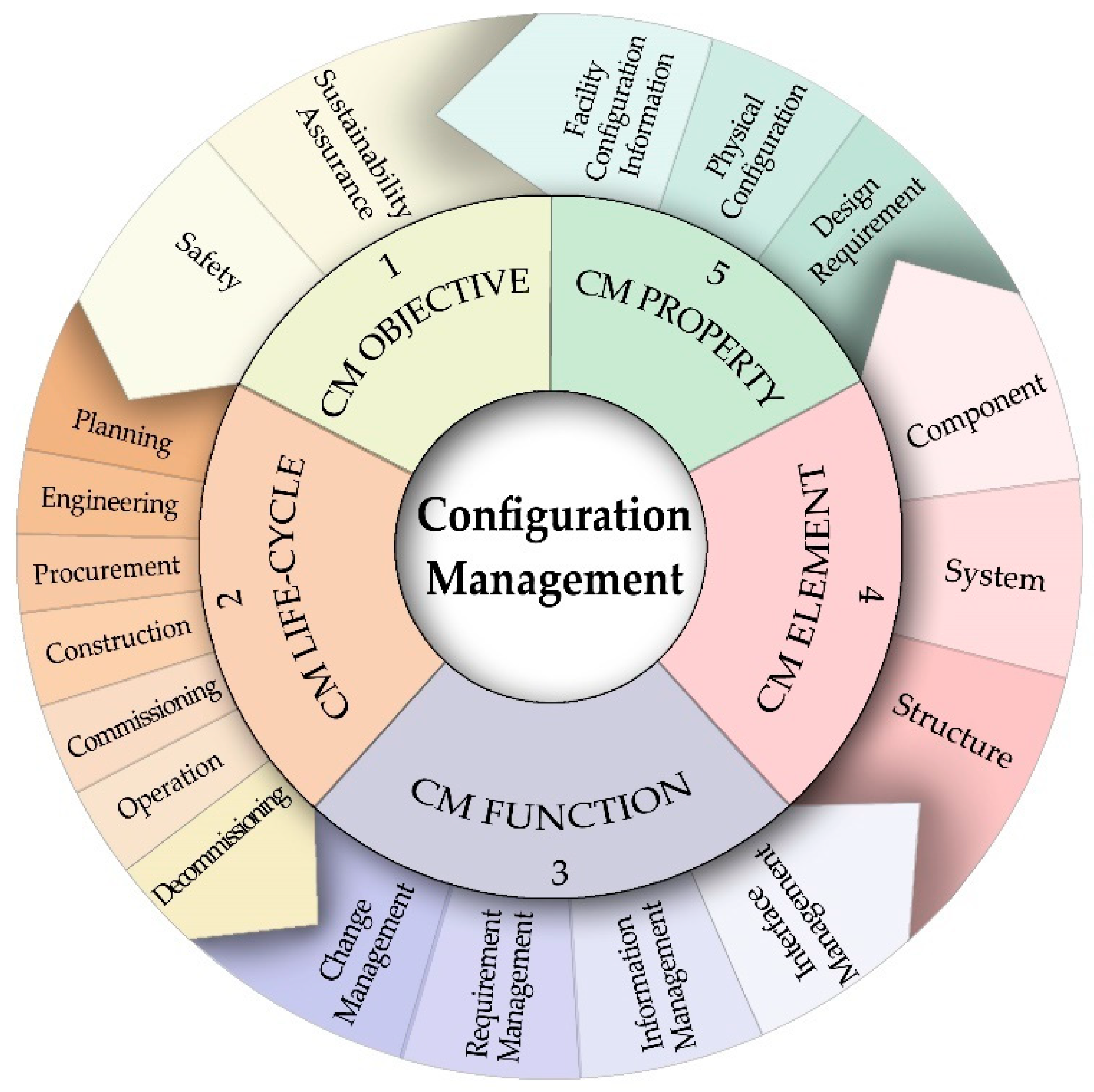

2. Framework for Configuration Management Assessment

2.1. Variables of CM Assessment Framework

2.2. Outline of CM Assessment Methodology

3. Elements for CM Assessment: Structure, System, Component (SSC)

3.1. Element Facets for Classification

3.2. Combined NPP SSCs as an Evaluation PBS

4. Criteria for CM Assessment: Change, Requirement, Information, Interface

4.1. Evaluation Criteria of Change Management (MC)

4.2. Evaluation Criteria of Requirement Management (MR)

4.3. Evaluation Criteria of Information Management (MD)

4.4. Evaluation Criteria of Interface Management (MI)

5. Assessment Methodology and a Case Study

5.1. NPP CM Evaluation Methodology

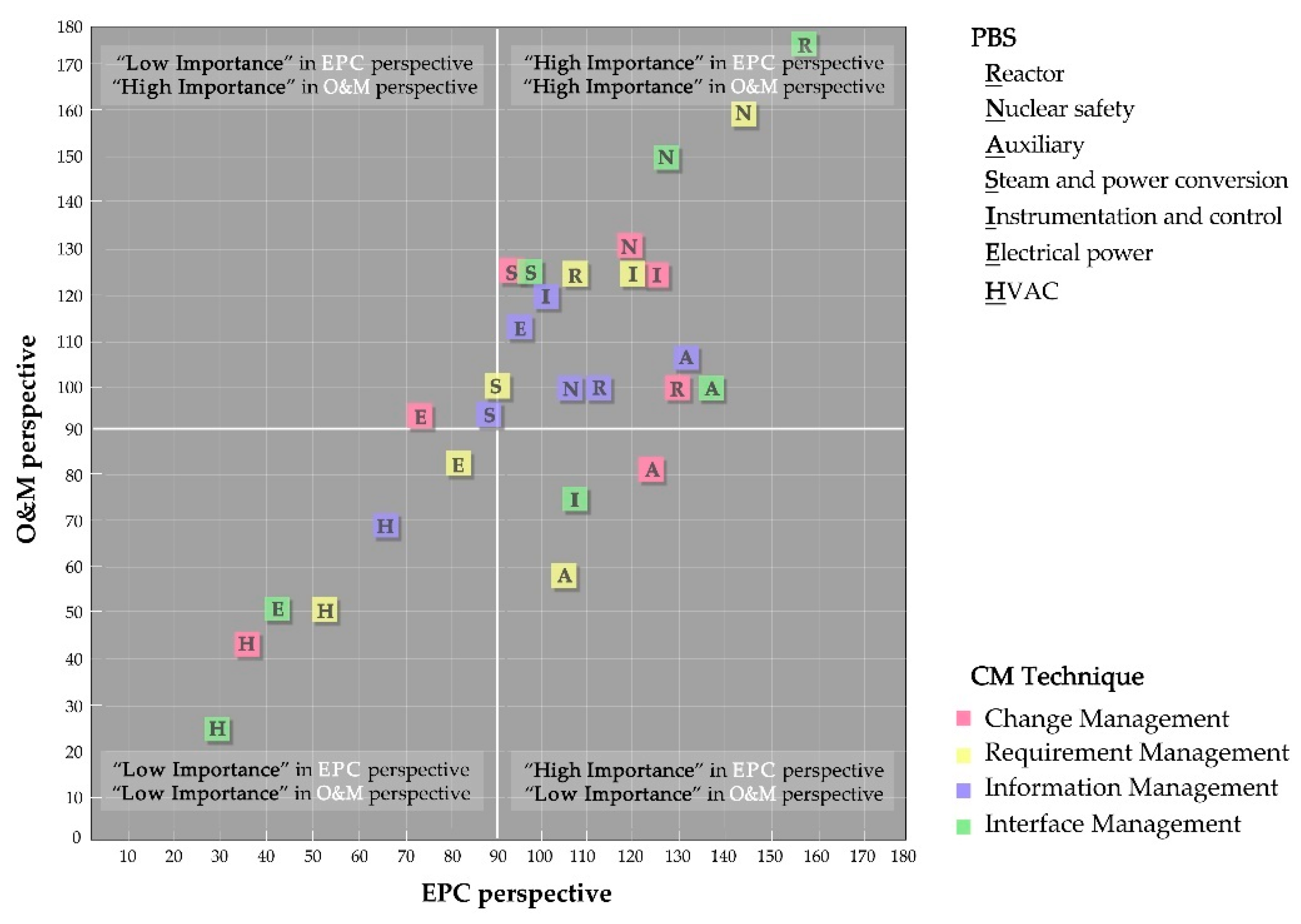

5.2. Overview of a Case Assessment

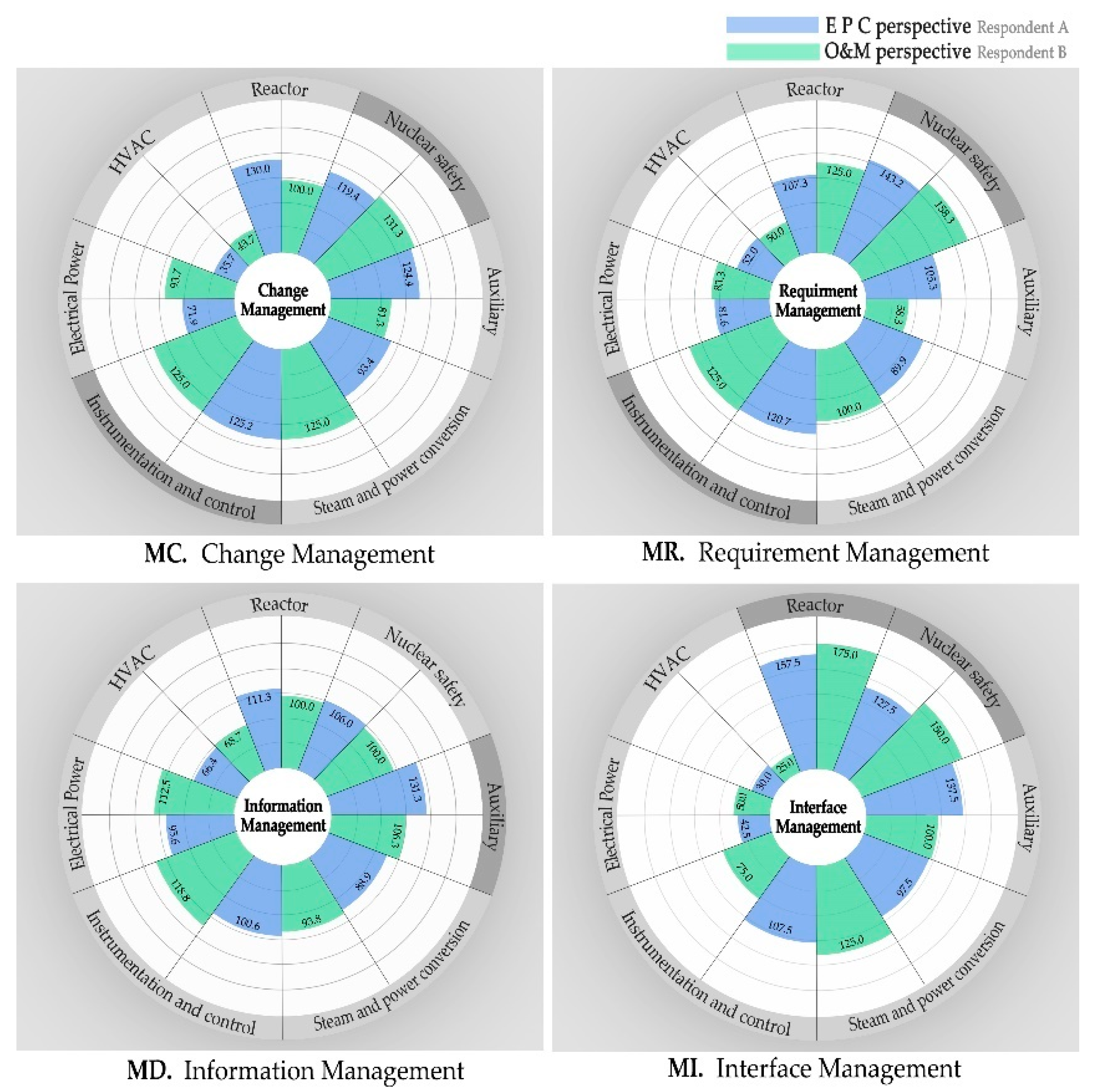

5.3. Assessment Result of Change Management Function (MC)

5.4. Assessment Result of Requirement Management Function (MR)

5.5. Assessment Result of Information Management Function (MD)

5.6. Assessment Result of Interface Management Function (MI)

5.7. Summary and Discussions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| CCS—System Level I | System Level II | |

|---|---|---|

| Reactor | FHS | Fuel Handling and Refueling System |

| RCS | Reactor Coolant System | |

| RXS | Reactor System | |

| Nuclear Safety System | CNS | Containment System |

| PCS | Passive Containment Cooling System | |

| PXS | Passive Core Cooling System | |

| SGS | Steam Generator System | |

| VES | Main Control Room Emergency Habitability System | |

| Auxiliary System | CCS | Component Cooling Water System |

| CVS | Chemical and Volume Control System | |

| DOS | Standby Diesel Fuel Oil System | |

| FPS | Fire Protection System | |

| MHS | Mechanical Handling System | |

| RNS | Normal Residual Heat Removal System | |

| SFS | Spent Fuel Pool Cooling System | |

| SWS | Service Water System | |

| VLS | Containment Hydrogen Control System | |

| WLS | Liquid Radwaste System | |

| WGS | Gaseous Radwaste System | |

| WSS | Solid Radwaste System | |

| PSS | Primary Sampling System | |

| DWS | Demineralized Water Transfer and Storage System | |

| CAS | Compressed and Instrument Air System | |

| PWS | Potable Water System | |

| WWS | Waste Water System | |

| PGS | Plant Gas System | |

| EFS | Communication System | |

| TCS | Turbine Building Closed Cooling Water System | |

| SSS | Secondary Sampling System | |

| VUS | Containment Leak Rate Test System | |

| DWS | Demineralized Water Treatment System | |

| RDS | Gravity and Roof Drain Collection System | |

| SDS | Sanitary Drainage System | |

| TDS | Turbine Island Vents, Drains and Relief System | |

| WRS | Radioactive Waste Drain System | |

| DRS | Storm Drain System | |

| RWS | Raw Water System | |

| Steam and Power Conversion System | FWS | Main and Startup Feedwater System |

| MTS | Main Turbine System | |

| MSS | Main Steam System | |

| BDS | Steam Generator Blowdown System | |

| CMS | Condenser Air Removal System | |

| CDS | Condensate System | |

| CWS | Circulating Water System | |

| ASS | Auxiliary Steam Supply System | |

| CES | Condenser Tube Cleaning System | |

| CFS | Turbine Island Chemical Feed System | |

| CPS | Condensate Polishing System | |

| GSS | Gland Seal System | |

| HCS | Generator Hydrogen and CO2 System | |

| HDS | Heater Drain System | |

| HSS | Hydrogen Seal Oil System | |

| LOS | Main Turbine and Generator Lube Oil System | |

| Instrumentation and Control System | DAS | Diverse Actuation System |

| PMS | Protection and Safety Monitoring System | |

| PLS | Plant Control System | |

| DDS | Data Display and Processing System | |

| IIS | In-Core Instrumentation System | |

| SMS | Special Monitoring System | |

| OCS | Operation and Control Centers System | |

| RMS | Radiation Monitoring System | |

| SJS | Seismic Monitoring System | |

| TOS | Main Turbine Control and Diagnostic System | |

| Electrical Power System | ECS | Main ac Power System |

| EDS | Non-Class 1E dc and Uninterruptible Power Supply System | |

| IDS | Class 1E dc and Uninterruptible Power Supply System | |

| ZOS | Onsite Standby Power System | |

| ELS | Lighting System | |

| EGS | Grounding and Lighting Protection System | |

| SHT | Special Process Heat Tracing System | |

| CAP | Cathodic Protection System | |

| PSE | Plant Security System | |

| ZAS | Main Generation System | |

| EVR | Excitation and Voltage Regulation System | |

| HVAC System | VBS | Nuclear Island Nonradioactive Ventilation System |

| VWS | Central Chilled Water System | |

| VXS | Annex/Auxiliary Building Nonradioactive Ventilation System | |

| VZS | Diesel Generator Building Ventilation System | |

| VAS | Radiologically Controlled Area Ventilation System | |

| VFS | Containment Air Filtration System | |

| VCS | Containment Recirculation Cooling System | |

| VRS | Radwaste Building HVAC System | |

| VHS | Health Physics and Hot Machine Shop HVAC System | |

| VYS | Hot Water Heating System | |

| VTS | Turbine Building Ventilation System | |

Appendix B

| CM Function | X * | (p1) Reactor | (p2) Nuclear Safety | (p3) Auxiliary | (p4) Steam and Power Conversion | (p5) Instrumentation & Control | (p6) Electrical Power | (p7) HVAC | |

|---|---|---|---|---|---|---|---|---|---|

| Change Management | MC.A1 | A | 148.5 | 127.3 | 106.1 | 84.8 | 148.5 | 63.6 | 21.2 |

| B | 175.0 | 150.0 | 50.0 | 125.0 | 100.0 | 75.0 | 25.0 | ||

| MC.A2 | A | 148.5 | 127.3 | 106.1 | 84.8 | 148.5 | 63.6 | 21.2 | |

| B | 175.0 | 150.0 | 50.0 | 125.0 | 100.0 | 75.0 | 25.0 | ||

| MC.A3 | A | 113.5 | 113.5 | 132.4 | 94.6 | 94.6 | 94.6 | 56.8 | |

| B | 25.0 | 175.0 | 100.0 | 150.0 | 125.0 | 75.0 | 50.0 | ||

| MC.A4 | A | 109.4 | 109.4 | 153.2 | 109.4 | 109.4 | 65.7 | 43.8 | |

| B | 25.0 | 50.0 | 125.0 | 100.0 | 175.0 | 150.0 | 75.0 | ||

| Requirement Management | MR.A1 | A | 25.0 | 175.0 | 125.0 | 100.0 | 150.0 | 75.0 | 50.0 |

| B | 25.0 | 175.0 | 125.0 | 100.0 | 150.0 | 75.0 | 50.0 | ||

| MR.A2 | A | 148.5 | 127.3 | 106.1 | 84.8 | 106.1 | 84.8 | 42.4 | |

| B | 175.0 | 150.0 | 25.0 | 125.0 | 100.0 | 75.0 | 50.0 | ||

| MR.A3 | A | 148.5 | 127.3 | 84.8 | 84.8 | 106.1 | 84.8 | 63.6 | |

| B | 175.0 | 150.0 | 25.0 | 75.0 | 125.0 | 100.0 | 50.0 | ||

| Information Management | MD.A1 | A | 175.0 | 150.0 | 125.0 | 50.0 | 25.0 | 75.0 | 100.0 |

| B | 175.0 | 150.0 | 125.0 | 50.0 | 25.0 | 75.0 | 100.0 | ||

| MD.A2 | A | 25.0 | 50.0 | 125.0 | 100.0 | 175.0 | 150.0 | 75.0 | |

| B | 25.0 | 50.0 | 125.0 | 100.0 | 175.0 | 150.0 | 75.0 | ||

| MD.A3 | A | 96.5 | 96.5 | 169.0 | 120.7 | 96.5 | 72.4 | 48.3 | |

| B | 25.0 | 50.0 | 125.0 | 100.0 | 175.0 | 150.0 | 75.0 | ||

| MD.A4 | A | 148.5 | 127.3 | 106.1 | 84.8 | 106.1 | 84.8 | 42.4 | |

| B | 175.0 | 150.0 | 50.0 | 125.0 | 100.0 | 75.0 | 25.0 | ||

| Interface Management | MI.A1 | A | 140.0 | 105.0 | 175.0 | 70.0 | 140.0 | 35.0 | 35.0 |

| B | 175.0 | 150.0 | 100.0 | 125.0 | 75.0 | 50.0 | 25.0 | ||

| MI.A2 | A | 175.0 | 150.0 | 100.0 | 125.0 | 75.0 | 50.0 | 25.0 | |

| B | 175.0 | 150.0 | 100.0 | 125.0 | 75.0 | 50.0 | 25.0 | ||

Appendix C. Glossary of Terms

| CM | Configuration Management |

| COL | Combined Operation License |

| DCD | Design Control Document |

| DoD | Department of Defense |

| EBS | Equipment Breakdown Structure |

| EPC | Engineering, Procurement, Construction |

| EPRI | Electric Power Research Institute |

| FCI | Facility Configuration Information |

| IAEA | International Atomic Energy Agency |

| INPO | Institute of Nuclear Power Operations |

| MC | Evaluation Criteria for Change Management |

| MD | Evaluation Criteria for Information Management |

| MI | Evaluation Criteria for Interface Management |

| MR | Evaluation Criteria for Requirement Management |

| NPP | Nuclear Power Plant |

| NRC | Nuclear Regulatory Commission |

| O&M | Operation and Maintenance |

| PBS | Physical Breakdown Structure |

| PRA | Probabilistic Risk Assessment |

| PSA | Probabilistic Safety Assessment |

| SDC | Standard Design Certification |

| SSC | Structures, Systems, Components |

References

- KINS. Study on Establishment of Regulation Policy for the Reinforcement of Configuration Management and Application in Nuclear Power Plants; Nuclear Safety and Security Commission (NSSC): Seoul, Korea, 2013.

- DoD. Configuration Management Guidance; Department of Defense (DoD): Washington, DC, USA, 2001.

- IAEA. Configuration Management in Nuclear Power Plants; IAEA: Vienna, Austria, 2003; ISBN 92-0-100503-2. [Google Scholar]

- INPO. Configuration Management Process Description; Institute of Nuclear Power Operations (INPO): Atlanta, GA, USA, 2005; AP-929 Revision 1. [Google Scholar]

- IAEA. Information Technology for Nuclear Power Plant Configuration Management; IAEA: Vienna, Austria, 2010; ISBN 978-92-0-106310-6. [Google Scholar]

- EPRI. Elements of Pre-Operational and Operational Configuration Management for a New Nuclear Facility; EPRI: Palo Alto, CA, USA, 2011; 1022684. [Google Scholar]

- Kang, M.-Y.; Jung, Y. Framework & Functions of Configuration Management (CM) in Nuclear Power Plants (NPP). Korean J. Constr. Eng. Manag. 2015, 16, 101–112. [Google Scholar]

- Jung, Y.; Woo, S. Flexible Work Breakdown Structure for Integrated Cost and Schedule Control. J. Constr. Eng. Manag. 2004, 130, 616–625. [Google Scholar] [CrossRef]

- Jung, Y.; Moon, B.-S.; Kim, Y.-M.; Kim, W. Integrated Cost and Schedule Control Systems (EVMS) for Nuclear Power Plant (NPP) Construction. Sci. Technol. Nucl. Install. 2015, 2015. [Google Scholar] [CrossRef]

- Kim, M.; Lee, I.; Jung, Y. International Project Risk Management for Nuclear Power Plant (NPP) Construction: Featuring Comparative Analysis with Fossil and Gas Power Plants. Sustainability 2017, 9, 469. [Google Scholar] [CrossRef]

- Westinghouse. Westinghouse AP1000 Design Control Document Rev. 19; Nuclear Regulatory Commission: Rockville, MA, USA, 2011; Accession Number: ML11171A500. [Google Scholar]

- IAEA. Managing Change in Nuclear Utilities; IAEA: Vienna, Austria, 2001; ISSN 1011-4289. [Google Scholar]

- IAEA. Management of Procurement Activities in a Nuclear Installation; IAEA: Vienna, Austria, 1996; ISSN 1011-4289. [Google Scholar]

- IAEA. Maintenance, Periodic Testing and Inspection of Research Reactors; IAEA Safety Standards Series No. NS-G-4.2; IAEA: Vienna, Austria, 2006; ISBN 92-0-109806-5. [Google Scholar]

- IAEA. Commissioning for Nuclear Power Plants: Training and Human Resource Considerations; IAEA Nuclear Energy Series NG-T-2.2; IAEA: Vienna, Austria, 2008; ISBN 978-92-0-103608-7. [Google Scholar]

- IAEA. Project Management in Nuclear Power Plant Construction: Guidelines and Experience; IAEA Nuclear Energy Series NP-T-2.7; IAEA: Vienna, Austria, 2012; ISBN 978-92-0-122210-7. [Google Scholar]

- IAEA. Safety of Nuclear Power Plant: Design; IAEA Safety Standards Series No. SSR-2/1; IAEA: Vienna, Austria, 2012; ISBN 978-92-0-121510-9. [Google Scholar]

- Nuclear Regulatory Commission. Part 50: Domestic Licensing of Production and Utilization Facilities-50.2 Definition; Nuclear Regulatory Commission: Rockville, MA, USA, 2011; Title 10, Code of Federal Regulations. [Google Scholar]

- EPRI. Advanced Nuclear Technology: New Nuclear Power Plant Information Handover Guide; EPRI: Palo Alto, CA, USA, 2016; 1019221. [Google Scholar]

- Kim, Y.M.; Bae, Y.K.; Yang, M.D. A Study on Engineering/Construction Impact and Improvement against the Delay of BOP Vender Design Data in Nuclear Plant Project of Korea; KEPCO E&C: Gimcheon, Korea, 2012. [Google Scholar]

- IAEA. Commissioning for Nuclear Power Plants; IAEA Safety Standards Series No. SSG-28; IAEA: Vienna, Austria, 2014; ISBN 978-92-0-140110-6. [Google Scholar]

- Kim, W.; Ryu, D.; Jung, Y. Application of Linear Scheduling Method (LSM) for Nuclear Power Plant (NPP) Construction. Nucl. Eng. Des. 2014, 270, 65–75. [Google Scholar] [CrossRef]

| Variable | Constituent | Issues for Assessment | This Study |

|---|---|---|---|

| Objective | Safety, Sustainability | Objective setting | 2 objectives |

| Life-cycle | Planning, Engineering, Procurement, Construction, Commissioning, Operation, Decommissioning | Integration of processes & data | 7 phases |

| Function | Change mgmt., Requirement mgmt., Information mgmt., Interface mgmt. a | Quantifiable measures | 13 criteria |

| Element | Structures, Systems, Components b | Top-down breakdown (PBS) | 7 elements (1st level) |

| Property | Design requirements, Physical configuration, Facility configuration information c | Detail data properties | Details not defined |

| SSC | Level I * | Breakdown * | No. of Components |

|---|---|---|---|

| Structure (8) | Nuclear island | Base mat, Containment interior, Shield building, Auxiliary building, Containment air baffle | 5 |

| Containment vessel | Containment vessel | 1 | |

| Plant vent and stair structure | Plant vent and stair structure | 1 | |

| Turbine building | Turbine building | 1 | |

| Annex building | Annex building | 1 | |

| Rad-waste building | Rad-waste building | 1 | |

| Diesel-generator building | Diesel-generator building | 1 | |

| Circulating water pump house and towers | Circulating water pump house and towers | 1 | |

| System (7) | Reactor | FHS, RCS, RXS | 3 |

| Nuclear safety system | CNS, PCS, PXS, SGS, VES | 5 | |

| Auxiliary system | CCS, CVS, DOS, FPS, MHS, RNS, SFS, SWS, VLS, WLS, WGS, WSS, PSS, DWS, CAS, PWS, WWS, PGS, EFS, TCS, SSS, VUS, DWS, RDS, SDS, TDS, WRS, DRS, RWS | 29 | |

| Steam and power conversion system | FWS, MTS, MSS, BDS, CMS, CDS, CWS, ASS, CES, CFS, CPS, GSS, HCS, HDS, HSS, LOS | 16 | |

| Instrumentation and control system | DAS, PMS, PLS, DDS, IIS, SMS, OCS, RMS, SJS, TOS | 10 | |

| Electrical power system | ECS, EDS, IDS, ZOS, ELS, EGS, SHT, CAP, PSE, ZAS, EVR | 11 | |

| HVAC system | VBS, VWS, VXS, VZS, VAS, VFS, VCS, VRS, VHS, VYS, VTS | 11 | |

| Component (7) | Reactor | 733 components | 733 |

| Nuclear Safety System | 576 components | 576 | |

| Auxiliary System | 480 components | 480 | |

| Steam and Power Conversion System | 46 components | 46 | |

| Instrumentation and Control System | 38 components | 38 | |

| Electrical Power System | 157 components | 157 | |

| HVAC System | 227 components | 227 |

| PBS Level I (7) | PBS Level II (97) | PBS Level III (2257) |

|---|---|---|

| P1: Reactor | FHS, RCS, RXS Base mat, Containment interior, Shield building, Auxiliary building, Containment air baffle | 733 components |

| P2: Nuclear safety | CNS, PCS, PXS, SGS, VES Containment Vessel | 576 components |

| P3: Auxiliary | CCS, CVS, DOS, FPS, MHS, RNS, SFS, SWS, VLS, WLS, WGS, WSS, PSS, DWS, CAS, PWS, WWS, PGS, EFS, TCS, SSS, VUS, DWS, RDS, SDS, TDS, WRS, DRS, RWS Annex building, Rad-waste building, Plant vent and stair structure | 480 components |

| P4: Steam and power conversion | FWS, MTS, MSS, BDS, CMS, CDS, CWS, ASS, CES, CFS, CPS, GSS, HCS, HDS, HSS, LOS Turbine building, Circulating water pump house and towers | 46 components |

| P5: Instrumentation and control (I&C) | DAS, PMS, PLS, DDS, IIS, SMS, OCS, RMS, SJS, TOS | 38 components |

| P6: Electrical power | ECS, EDS, IDS, ZOS, ELS, EGS, SHT, CAP, PSE, ZAS, EVR Diesel generator building | 157 components |

| P7: HVAC | VBS, VWS, VXS, VZS, VAS, VFS, VCS, VRS, VHS, VYS, VTS | 227 components |

| CM Function | CM Sub-Functions * | |

|---|---|---|

| Change Management (MC) | MC1. | Maintaining the conformance of three elements (SSCs) |

| MC2. | Analyses and documentation of expected changes | |

| MC3. | Managing change processes based on safety, regulations, economy | |

| MC4. | Safety and risk analyses based on changes (PSA/PRA ** methods) | |

| MC5. | Integration with cost and schedule control | |

| MC6. | Traceability of change | |

| Requirement Management (MR) | MR1. | Documentation and conformance with regulations and permits |

| MR2. | Application requirements of industry standards | |

| MR3. | Economic impact and PRA/PSA requirements | |

| MR4. | Owner’s requirements | |

| MR5. | Definition and documentation of design requirements | |

| MR6. | Tolerance requirements | |

| Information Management (MD) | MD1. | Documentation of facility data throughout the entire lifecycle |

| MD2. | Linkage with SSCs by using numbering systems | |

| MD3. | Document management system | |

| MD4. | Traceability of information | |

| MD5. | Version and revision management | |

| MD6. | Reconstitution of design documentation | |

| Interface Management (MI) | MI1. | Organization interface management |

| MI2. | Process interface control | |

| MI3. | Activity information control | |

| CM Function | CM Assessment Criteria | Remark | ||

|---|---|---|---|---|

| MC. | Change Management | MC.A1 | Mutual impact by the change | Workload |

| MC.A2 | Cost impact from the change | Impact | ||

| MC.A3 | Complexity of change procedures | Complexity | ||

| MC.A4 | Frequency of changes | Frequency | ||

| MR. | Requirement Management | MR.A1 | Number of specifications | Frequency |

| MR.A2 | Relevance to the capability by design bases | Impact | ||

| MR.A3 | Safety impact caused by the non-conformance between SSC | Impact | ||

| MD. | Information Management | MD.A1 | Complexity of the elements (SSCs) | Complexity |

| MD.A2 | Quantity of documents | Workload | ||

| MD.A3 | Frequency of document retrieval | Frequency | ||

| MD.A4 | Importance of document in the O&M phase | Impact | ||

| MI. | Interface Management | MI.A1 | Required manpower | Workload |

| MI.A2 | Number of related activities | Frequency | ||

| CM Function | Assessment Criteria | Score | Remarks | ||

|---|---|---|---|---|---|

| Change Management (MC) | MC.A1. | 7-point scale | 1/4 | 100 (Normalized) | Workload |

| MC.A2. | 7-point scale | 1/4 | Impact | ||

| MC.A3. | 7-point scale | 1/4 | Complexity | ||

| MC.A4. | 7-point scale | 1/4 | Frequency | ||

| Requirement Management (MR) | MR.A1. | 7-point scale | 1/3 | 100 (Normalized) | Frequency |

| MR.A2. | 7-point scale | 1/3 | Impact | ||

| MR.A3. | 7-point scale | 1/3 | Impact | ||

| Information Management (MD) | MD.A1. | 7-point scale | 1/4 | 100 (Normalized) | Complexity |

| MD.A2. | 7-point scale | 1/4 | Workload | ||

| MD.A3. | 7-point scale | 1/4 | Frequency | ||

| MD.A4. | 7-point scale | 1/4 | Impact | ||

| Interface Management (MI) | MI.A1. | % | 1/2 | 100 (Normalized) | Workload |

| MI.A2. | 7-point scale * | 1/2 | Frequency | ||

| No. | Notation | Formula/Example | Description |

|---|---|---|---|

| N1 | pi | p1: reactor | An element of the PBS for NPP CM |

| N2 | X * | A: EPC, B: O&M, T: all (A + B) | A group of different respondents |

| N3 | Xpi | A p1: score of reactor from group A | An evaluation from a group for an element |

| F1 | MC.A1.Xpi | MC.A1.Ap1 = (MC.A1.Ap1)/∑(MC.A1.Api) × 100 × n | Score of an element for one criterion, (e.g., score of p1 for MC.A1 from A: EPC) |

| F2 | MC.Xpi | MC.Ap1 = (MC.Ap1)/∑(MC.Api) × 100 × n | Score of an element for one CM function, where n is the total number of elements |

| F3 | M.Xpi | M.Ap1 = (MC.Ap1 + MR.Ap1 + MD.Ap1 + MI.Ap1)/4 | Score of an element for all four CM functions, which is a single index for CM effectiveness |

| CM Function | X * | (p1) Reactor | (p2) Nuclear Safety | (p3) Auxiliary | (p4) Steam and Power Conversion | (p5) Instrumentation & Control | (p6) Electrical Power | (p7) HVAC | (∑pi) Row Total |

|---|---|---|---|---|---|---|---|---|---|

| CM Index (M.Xpi) | T | 125.8 | 129.4 | 105.5 | 101.7 | 112.2 | 78.9 | 46.5 | 700 |

| A | 126.5 | 124.0 | 124.6 | 92.4 | 113.5 | 72.9 | 46.0 | 700 | |

| B | 125.0 | 134.9 | 86.5 | 111.0 | 110.9 | 84.9 | 46.9 | 700 | |

| |A − B| | 1.5 | 10.9 | 38.2 | 18.5 | 2.6 | 12.0 | 0.8 | 0 | |

| Change Management (MC.Xpi) | T | 115.0 | 125.3 | 102.8 | 109.2 | 125.1 | 82.8 | 39.7 | 700 |

| A | 130.0 | 119.4 | 124.4 | 93.4 | 125.2 | 71.9 | 35.7 | 700 | |

| B | 100.0 | 131.3 | 81.3 | 125.0 | 125.0 | 93.7 | 43.7 | 700 | |

| |A − B| | 30.0 | 11.9 | 43.2 | 31.6 | 0.2 | 21.9 | 8.0 | 0 | |

| Requirement Management (MR.Xpi) | T | 116.2 | 150.8 | 81.8 | 95.0 | 122.9 | 82.4 | 51.0 | 700 |

| A | 107.3 | 143.2 | 105.3 | 89.9 | 120.7 | 81.6 | 52.0 | 700 | |

| B | 125.0 | 158.3 | 58.3 | 100.0 | 125.0 | 83.3 | 50.0 | 700 | |

| |A − B| | 17.7 | 15.2 | 47.0 | 10.1 | 4.3 | 1.8 | 2.0 | 0 | |

| Information Management (MD.Xpi) | T | 105.6 | 103.0 | 118.8 | 91.3 | 109.7 | 104.0 | 67.6 | 700 |

| A | 111.3 | 106.0 | 131.3 | 88.9 | 100.6 | 95.6 | 66.4 | 700 | |

| B | 100.0 | 100.0 | 106.3 | 93.8 | 118.8 | 112.5 | 68.7 | 700 | |

| |A − B| | 11.3 | 6.0 | 25.0 | 4.9 | 18.1 | 16.9 | 2.3 | 0 | |

| Interface Management (MI.Xpi) | T | 166.3 | 138.8 | 118.8 | 111.3 | 91.2 | 46.2 | 27.5 | 700 |

| A | 157.5 | 127.5 | 137.5 | 97.5 | 107.5 | 42.5 | 30.0 | 700 | |

| B | 175.0 | 150.0 | 100.0 | 125.0 | 75.0 | 50.0 | 25.0 | 700 | |

| |A − B| | 17.5 | 22.5 | 37.5 | 27.5 | 32.5 | 7.5 | 5.0 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.-Y.; Jeong, Y.; Jung, Y. Assessment Methodology of Practical Configuration Management (CM) for Sustainable Nuclear Power Plants (NPPs). Sustainability 2019, 11, 2391. https://doi.org/10.3390/su11082391

Kang M-Y, Jeong Y, Jung Y. Assessment Methodology of Practical Configuration Management (CM) for Sustainable Nuclear Power Plants (NPPs). Sustainability. 2019; 11(8):2391. https://doi.org/10.3390/su11082391

Chicago/Turabian StyleKang, Mi-Yeon, Yeheun Jeong, and Youngsoo Jung. 2019. "Assessment Methodology of Practical Configuration Management (CM) for Sustainable Nuclear Power Plants (NPPs)" Sustainability 11, no. 8: 2391. https://doi.org/10.3390/su11082391

APA StyleKang, M.-Y., Jeong, Y., & Jung, Y. (2019). Assessment Methodology of Practical Configuration Management (CM) for Sustainable Nuclear Power Plants (NPPs). Sustainability, 11(8), 2391. https://doi.org/10.3390/su11082391