1.1. The Problem of Scrap Tires

The management of waste associated with end-of-life products is a public concern and a priority of policy debates. The end-of-life scrap tires represent an important issue notably for the implications they hold for public health and environment. Tires are made of non-biodegradable material, i.e. styrene-butadiene rubber (SBR), and for this reason there is a growing concern among developed economies about the need to prevent harmful environmental effects associated with tire waste. One option for improving the management of the scrap tires is processing end-of-life items for recovering its material. The recovery of scrap tires is done by rubber crumb (fine-grained or granulated tire rubber) and removal of fiber and steel elements, and by using the resulting outputs for new rubber products, such as playgrounds, sports surfacing, and rubber-modified asphalt. An alternative for addressing end-of-life waste tires is subjecting them to processes that yield outputs that are suitable for energy applications [

1].

The amount of scrap tires is increasing significantly as result of rapid economic growth and development of the transport industry. According to statistics reported by Wang et al. [

2] and Li et al. [

3], approximately 3.0 billion tires are generated globally, with a predicted growth rate of at least 1.0 billion tires each year. North America, Europe, and Asia generate many scrap tires, accounting for almost 90% of global tire production [

4,

5]. The estimated growth for the worldwide tire demand is about 4.3% per year, and reached 2.9 billion units in 2017, while waste tire disposal in 2015 reached nearly 1 billion units [

6,

7,

8]. In this scenario, recycling end-of-life tires becomes an urgent need because the accumulation of discarded tires holds serious environmental risks. While some end-of-life tires are recapped or ground for particular reuses, a great volume is simply dumped in rural areas or in landfills. When buried in landfills, they can eventually float to the surface. In piles, the non-biodegradable rubber can cause serious harm if ignited. Likewise, tires infested with mosquitoes are a subject of increasing concern [

2,

5].

Most countries do not yet have specific legislation concerning the collection of waste tires, and those that do are still researching how to increase their life cycle, as succeeded in Poland with the implementation of the urban solid waste law in 2012 [

9]. In Brazil, an urban solid waste law was implemented in 2010 [

10] andTurkey implemented the urban solid waste law in 2014 [

11], Even in countries such as Spain, which implemented such laws in 2005, problems persist concerning the correct final destiny of the waste tires [

12]. In contrast, countries such as USA, Germany, and Japan have been deploying this technology since the 1970s [

13], e.g. New York has usedthe unserviceable tires for the generation of energy and production of gas, fuel oil, and carbon black since 1990 [

14].

The European Union (EU) has prohibited the disposal of tires in landfills since 2009, and the recycling rate is 95% for the manufactured tires, at a cost of 1.78 Euros each. A share of 39% is recycled in retreading and 37% in energy cogeneration. Canada, Japan, and USA disclose that they recycle 89% of the tires produced by means of diversified processes, mainly in energy co-generation systems [

5,

15,

16]. In the 2000s, Korea and Spain also adheredto pyrolysistechnologyforused tires [

16,

17].

According to Nourreddine [

18], an EU draft directive states a goal that, by 2015, only 5% of a vehicle’s weight can be disposed to discharge sites, and that a further 10% can be incinerated. Usually, the recycling of automotive vehicles is focused on recovering metals, while other materials in the form of shredder fluff are disposed to landfills. This material is currently incinerated for energy and carbon black production. The challenge remains because many countries donot have technology to meet the requirements specified in this directive.

The environmental problem caused by used tires is most noticeable in developing countries, as reported by Osahy et al. [

4], who mentioned that 160,000 tons of waste tires are generated in South Africa annually, and up to 28 million used tires are dumped unlawfully or burned. Moreover, this figure is estimated to increase by 9.3 million yearly. The authors proposed the elimination of this waste through pyrolysis of used tires to obtain carbon black.

Banar et al. [

19] reportedthat, in Turkey, while 8 million tires are produced per year, which is equivalent to 285,000 tons/year, the total installed capacity for recovering waste tires is 101 tons/year. In the same country, Aydin and Ilkiliç [

6] were able to obtain a pyrolytic oil thatcan be used as fuel in diesel engines, after removal of excessive sulfur.

In 2012, more than 280 million tires were discarded in China, with a weight of 10.18 million tons. Scrap tires are insoluble and infusible, and are therefore difficult to degrade naturally. A lack of suitable techniques and economic factors over the years has led to scrap tires becoming a serious problem in terms of environmental pollution. At present, most scrap tires aredeposited in open or landfill sites, resulting in disposal problems and the increased risk of fires [

3]. Various recycling methods have been developed over the years, such as retreading, incineration, and crumbling to produce rubber powder, but they all have significant limitations or drawbacks [

3].

Developed countries have been consistently advised to prevent harmful effects to the environment. One of the options for the management of the scrap tires is material recovery. A prevalent alternative to recover scrap tires is rubber crumb, together with the removal of embedded fiberfor the purpose of new products such asplaygrounds and surfacing solutions [

13,

20,

21,

22]. However, according to Banar et al. [

19], Williams [

22], and Martínz et al. [

23], pyrolysis must be regarded asa viable and relevant alternative to recycle the tires because its various derivatives have a greater scope for application and valorization.

1.2. Pyrolysis as an Ecofriendly Solution to the Scrap Tires

Pyrolysis of scrap tires has evolved as a viable alternative to overcome the practices of incorrect disposal of tire waste. Pyrolysis processes can produce tire derived oils that may be used as fuel or added to conventional fuels, producing fuel blends with improved properties at a reduced cost. Pyrolysis is a process that can contribute to overcome the practices of disposal of tire residues from inadequate sites, therefore standing out as a sustainable process to produce alternative fuels [

15].

Roy et al. [

5] defined the vacuum pyrolysis as the combustion of organic substances in the absence of air. It enables the production of large quantities of pyrolysis oils from organic substances. Vacuum minimizes secondary reactions such as thermal cracking, repolymerization and recondensation reactions, gas phase collision, catalytic cracking and redox reactions. If the vapor phase products are quenched, the yield of organic liquids such as pyrolysis oils is increased at the expense of solid residues and gases. The physicochemical properties of the end-products are a function of the pyrolytic temperature [

24]. According to Al-Lal et al. [

25], Martinez et al. [

23] and Raclavská et al. [

26], the pyrolysis processcanbe used to obtain fuel from biomass, coal, lube oil, plastic and tire wastes.

In the last three decades, many products have been derived, thus affirming the interest of pyrolysis for waste tires. For example, Yousefi et al. [

27] developed polymer-modified asphalts prepared by incorporating recycled polyethylene and a used-tire-derived pyrolytic oil residue in asphalt. Its characteristics showed superior properties for the modified asphalts at high temperatures.

At low temperatures, the bitumen becomes brittle and cracks, while, at high temperatures, it softens with the result that the bitumen binder either migrates to the surface or the pavement tends to be put under stress. To solve these problems, Chaala et al. [

28] mixed carbon black with bitumen at levels between 5% and 30%, reaching significant results on the rheological behavior of asphalt obtained.

Canada ranks among the first countries touse tires as a source of energy and of valuable chemical products by thermal decomposition of rubber in a pilot plant. Yields are 55% oil, 25% carbon black, 9% steel, 5% fiber and 6% gas. The maximum recovery of oil isperformed at 415 °C below 2 kPa. The energy obtained from tire pyrolysis has been estimated in 700 kJ/kg, with a mass flow of 200 kg/h [

29].

However, according to Roy et al. [

5], the pyrolysis of scrap tires has been, thusfar, uneconomical due to the absence of an established market for oil and, in particular, for the pyrolytic carbon black product. Therefore, most existing research ontire pyrolysis is more concerned with obtaining pyrolytic oil, which can be used in diesel engines. Several authors showed that the application of pyrolytic oil in engines is feasible, because it hasa quality equivalent to diesel oil [

4,

6,

30,

31,

32,

33,

34,

35,

36]. Mui et al. [

33] also showed that it is possible to use carbon black in the treatment of textile industries effluents. Debek and Walendziewski [

35] showed that, after hydrorefining oil from tire pyrolysis, it is possible to obtain good quality fuels that can be used in passenger carsand vans.

Furthermore, in a survey addressing environmental impacts, Huijbregts et al. [

36] calculated product-specific ecological footprints from consistent and quality-controlled life cycle information of 2630 products and services, including energy, materials, transport, waste treatment and infrastructural processes. They showed that the disposition of tires to a waste incineration process has an ecological footprint of 72 m

2/year, while its disposal in the landfills hasan ecological footprint equal to 113 m

2/year, that is, its impact is reduced by almost 40% when incinerated. In this way, it is evident that the incineration of tires is a greener way than disposal in dumps or landfills.

Currently, this technique ranks among the best to mitigate the contamination from tires discarded inadequately and consequently it concedes a better end-life to the tires [

25,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41].

According to Umeki et al. [

24], the pyrolysis oil of the scrap tires has black coloration, strong odor and specific gravity around 0.93 g/cm

3. In addition, the compositional analysis of tire pyrolytic oil (TPO) describes the liquid as a complex mixture, composed mainly of aromatic compounds and olefins, containing important fuels such as gasoline and diesels. They concluded that the fuel blend’s properties point to a potential viability of using the TPO in mixture with diesel. This would be an alternative fuel for automotive and industrial uses and for the replacement of conventional petroleum fuels.

The energy efficiency of the diesel oil blend with the tire pyrolysis oil was tested on a 440 cm

3 single-cylinder diesel engine. Engine performance, evaluated at different engine speed and loads, showed that the use of 20% of weight (%wt) blend does not cause significant differences in terms of torque, power, specific fuel consumption, and exhaust emissions, compared to those obtained using diesel fuel [

40]. Similar results were obtained by Wang et al. [

2] whotested several diesel oil blends with pyrolysis oil from waste tires on a diesel engine for rotations up to 2500 rpm.

In Iran, Hossain et al. [

41] produced a pyrolysis oil from a mixture of scrap tire and rice husk with characteristics very close to petroleum oil. The highest fuel oil yield was 52 wt% when a mixture of 50 wt% tire and 50% rice husks was used, which was pyrolyzed at 450 °C. The results show that it is possible to obtain liquid products comparable to petroleum fuels, and valuable chemical feedstock from the selected wastes if the pyrolysis conditions are chosen according to the products to be obtained.

Ayanoglu and Yumrutas [

11] producedgasoline- and diesel-like fuels from waste tire oil by using catalytic pyrolysis in a heat reactor. After the distillation processes, the fractions obtained were composed of 18 wt% of light oil (gasoline), 70 wt% of heavy oil (diesel fuel) and 12 wt% of residues. Furthermore, the carbon distribution of GLF (C

4-C

12) and DLF (C

13-C

17) samples was close to the one of standard fuels.

Li et al. [

3] developed a continuous process of pyrolysis from the scrap in the presence and absence of catalysts. The maximum yield of derived oil was up to 55.65 wt% at the optimum temperature of 500 °C. The catalytic pyrolysis was performed using 1.0 wt% (on a scrap tire weight basis) of catalysts. They concluded that the derived oil can therefore be used as a petrochemical feedstock for producing high-value-added chemical products or as fuel oil.

Ahoor and Zandi-Atashbar [

1] obtained pyrolysis oil under an argon atmosphere at 407.3 °C. They achieved 12 wt% of fuel oil, the highest yield. Several works have shown that the derived oil contains variable concentrations of valuable aromatic and aliphatic compounds such as butadiene, D-limonene, benzene, toluene, and xylenes, which could be used directly as substitutes for conventional fuels or petrochemical feedstocks as a potential source of light aromatics [

3,

42].

These tire pyrolysis plants are not yet widespread in underdeveloped countries because of their high cost of deployment. However, researchers have dedicated efforts to enable its implementation as follows.

In Turkey, Ayanoglu and Yumrutas [

11] developed a low-cost tire pyrolysis plant. The main part of pyrolysis unit cost was US

$11,477. The main part can be used for 10 years with a full load production. Amortization of the pyrolysis unit was 0.157 US

$/L, and they realized that the cost of production of the other derivatives was above the price paid for oil products in Turkey.

To minimize the cost of production, Luo and Feng [

43] used the waste heat of blast-furnace slag in the production of fuel oil and combustible gas by catalytic pyrolysis, as a novel waste energy recycling strategy. Their results show that there was an upgrade in the quality of pyrolysis oil.

1.3. Brazilian Situation Regarding the Management of Scrap Tires

According to the National Association of Tire Manufacturers (ANIP), Brazil has 20 companies that manufacture tires, which are responsible for 150,000 jobs [

44]. In 2014, the production reached 68.8 million tires. There was a 26% increase in tire production compared to 2006 and, due to imports, 74.9 million tires were sold that same year [

44].

According to Machin et al. [

10], the production of tires in 2014 by the Brazilian industry totaled 70.8 million units, which was a small reduction compared to 2013, when the sector achieved a historical record. According to the sectorial balance presented by ANIP, Brazil closed 2016 with a fall of 1.1% in total tire production as compared to 2015 [

44]. From 2014 to 2015, the accounts also closed in the red, with a decrease of 1.2%. The ANIP balance sheet presented at the end of December 2017 showed a growth of 2.4% in tire sales, as compared to the same period in 2016, which suggests a slight recovery of the sector, following two years of crisis [

44].

The Normative Instruction N°001/2010, from the National Council of the Environmental of Brazil (CONAMA), regulates the procedure that manufacturers and importers must meet for registration, calculation of goals and confirmation of the allocation. This law states that 100% of the outstanding tires in the country should be recycled, and determines that the companies are responsible for handling the end of life-cycle and end destination of tires [

45].

Manufacturers and tire importers must prepare a management plan to collect, store, and dispose scrap tires within six months after the publication of Resolution No.416/09. The Resolution specifies that, in cities with over 100,000 habitants, at least onecollection point should be installed, within oneyear following the publication of the resolution. The new resolution does not consider the reform of tires as recycling, but as an activity that prolongs tire life [

45].

However, in São Paulo, for instance, only fourcollection pointswhere created when the regulation proposed the creation of 120. In addition, there is no report about the volume of discarded tires in landfills [

16]. Currently, there is no register about the collection points in other cities from Brazil. This demonstrates a disregard of companies towards Brazilian politics, that probably can be explained by the fact that companies want to avoid the costs associated with the collection and implementation of ecologically friendly processes for the end destination of the tires [

5].

According to ANIP in 2016, the goal established by CONAMA was reached and the manufacturers of tires were able to give a correct destination to 404,328.13 tons of waste tires and, from January to September 2017, over 360,000 tons of tires had the correct destination, which corresponds to more than 4.0 million tons of waste tires collected since 2009 [

44]. However, according to Lagaritos and Tenório [

16], Brazil only repairs half of the waste tires at a cost of US

$0.45/tire, which can be proven by the tires in dumps, rivers and lakes that are constantly caught by public inspection entities.

However, according to Roy et al. [

29], all of the tire recycling and treatment processes cited above have some disadvantages. Retreading can only be performed when the carcass is not damaged. When tires are used as solid fuel, polycyclic aromatic hydrocarbons and soot are produced. Therefore, expensive gas cleaning devices are necessary for the removal of potentially hazardous compounds. Tire grinding is very expensive since it is performed at cryogenic temperatures or requires energy-intensive mechanical equipment.

A tire recycling technique, used in many countries, but not yet extensively used in Brazil, is the tire pyrolysis. The outputs of this processing alternative can be used in the preparation of dyes for paints and varnishes, as blends for rubber or asphalt and obtaining some chemicals such as limonene and fuel additives [

27,

28,

46,

47].

As noted, tire pyrolysis is a feasible and ecologically friendly alternative as the end destination of tires [

38], since it produces energy and various chemical products used as fuels (including gasoline), dyes, polymers, asphalts, etc.

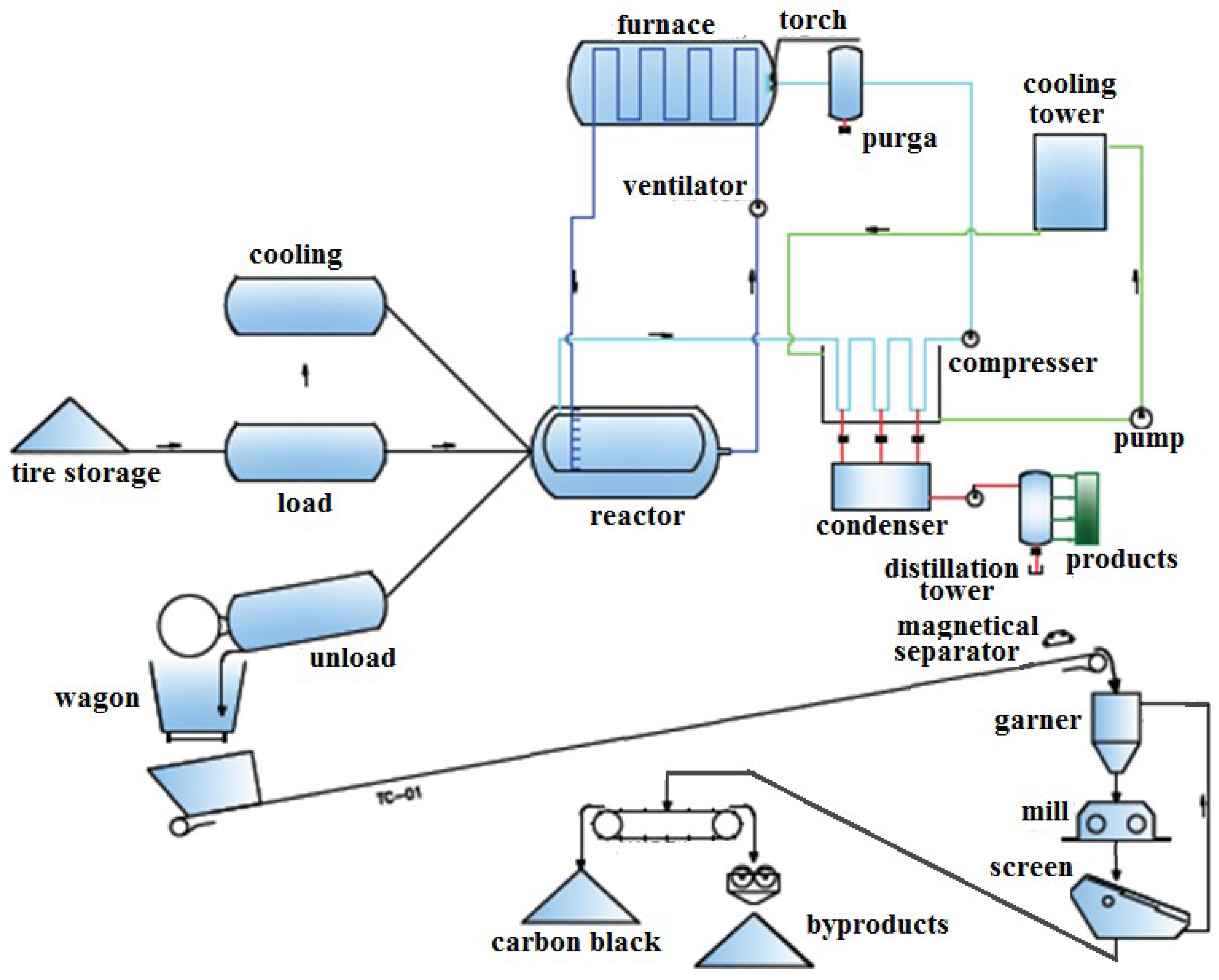

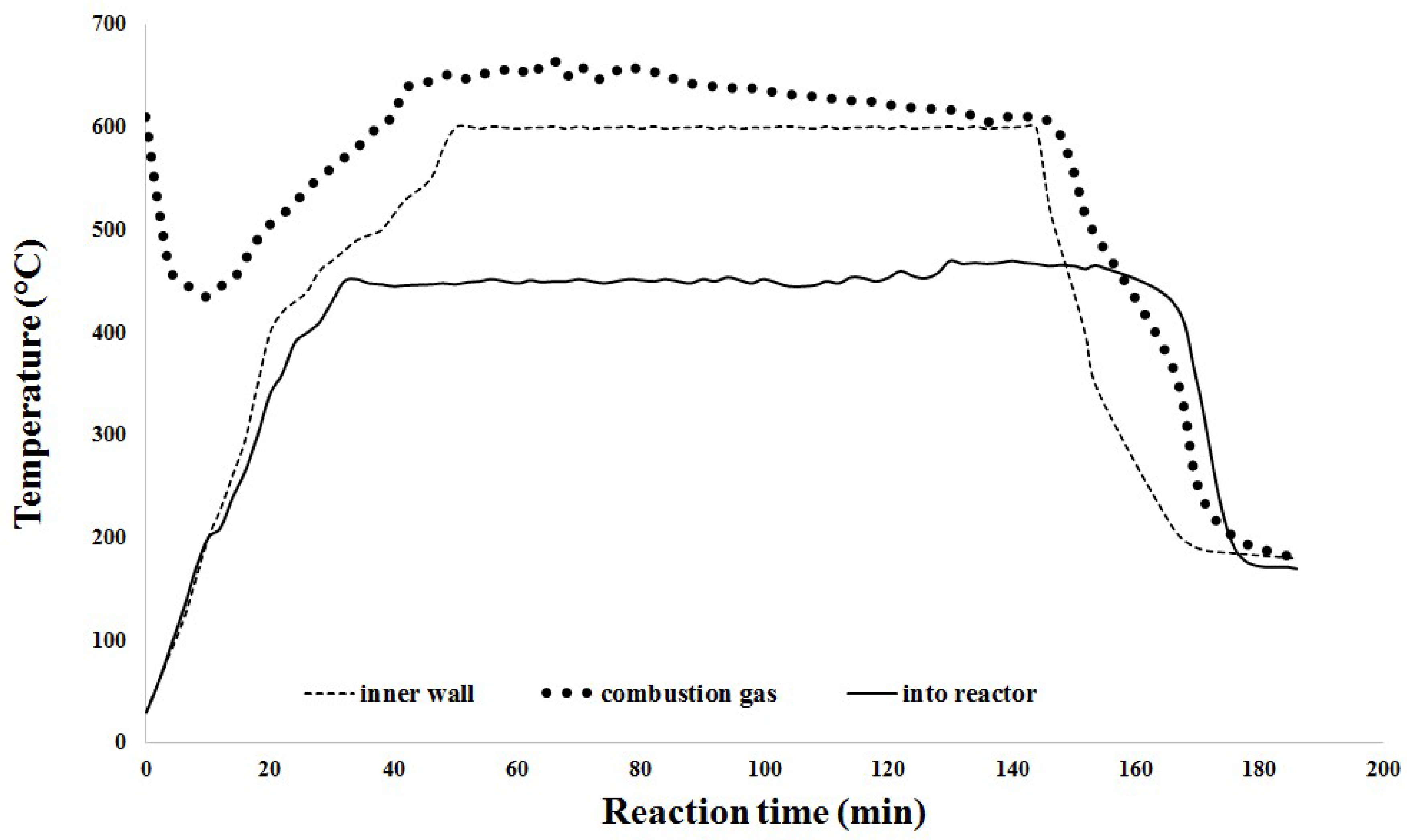

This paper describes a case study in Brazil, which illustrates how to reduce the environmental impacts caused by tire disposal in a sanitary landfill alongside making the process profitable, by vacuum pyrolysis. Moreover, this work aspires to contribute to the development of a market for the pyrolytic oil and carbon black products obtained from a vacuum pyrolysis process, in Brazil. Following a preliminary process of vacuum pyrolysis of used tires conducted in laboratory, the process has been scaled up over the last 10 years from a batch to pilot plant with 100 kg/h capacity.