Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production

Abstract

:1. Introduction

2. Materials and Methods

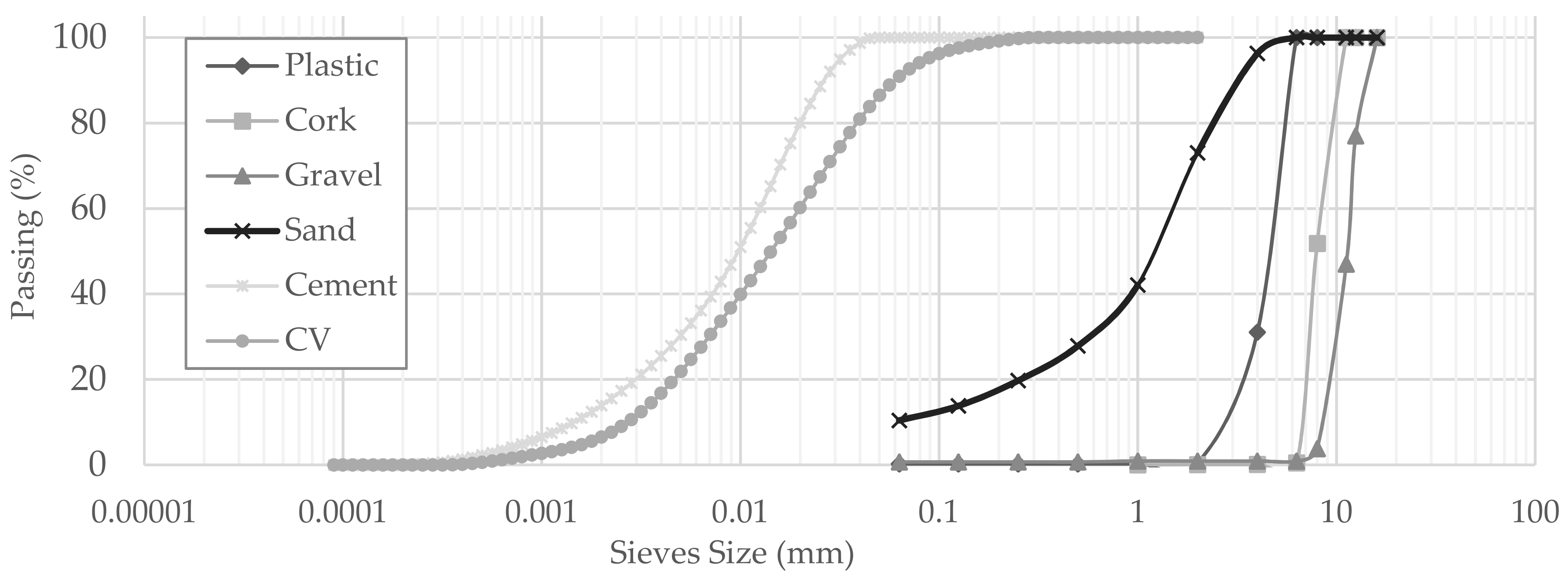

2.1. Materials

2.2. Concrete Mixture, Mixing, and Curing Procedure

2.3. Test Methods

- Before the destructive tests, density was measured by weighing and measuring all the test pieces, by means of a standard scale and a tape measure and working out the average.

- The compressive strength tests were performed according to EN 12390-3 2009. Cylindrical specimens of 150 mm diameter and 300 mm height were used. After the curing period (7, 28, and 90 days) the specimens were removed from the immersion container and polished, then weighed and introduced into an hydraulic press.

- The elasticity modulus was obtained following the ASTM C 469 standard “Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression”. A cylindrical concrete specimen is arranged vertically between uniaxial compression load plates, using two circular steel punches arranged concentrically on top of and underneath the sample to be tested. When performing the test, the applied load produces an increase of the traction on the planes that contain the cylinder axis, thus the sample fractures along these planes. Usually three radial fissures may be observed in the specimen tested, even though 2 or 4 fissures may occur. Under the breaking load, two conical wedges form under the steel punches. The deformation is measured by a wire strain gauge.

- The mercury intrusion porosimetry (MIP) test was performed according to the procedure described by ISO 15901-1 using Quantachrome Poremaster 60 GT, with an approximate pressure of 60.000 psia (414 MPa). Surface tension of mercury; γ = 0.48 Nm-1 and mercury contact angle; θ = 140º. At this pressure, the smallest pore size at which the mercury can be introduced is 3 nm. This test was carried out 60 days after the production of the concrete. After drying 12 hours at 60 ºC, the samples were weighed on a precision scale, placed in the porosimetry equipment and mercury was introduced at low pressure, then the samples were weighed again. Finally, the process was repeated, but at high pressure.

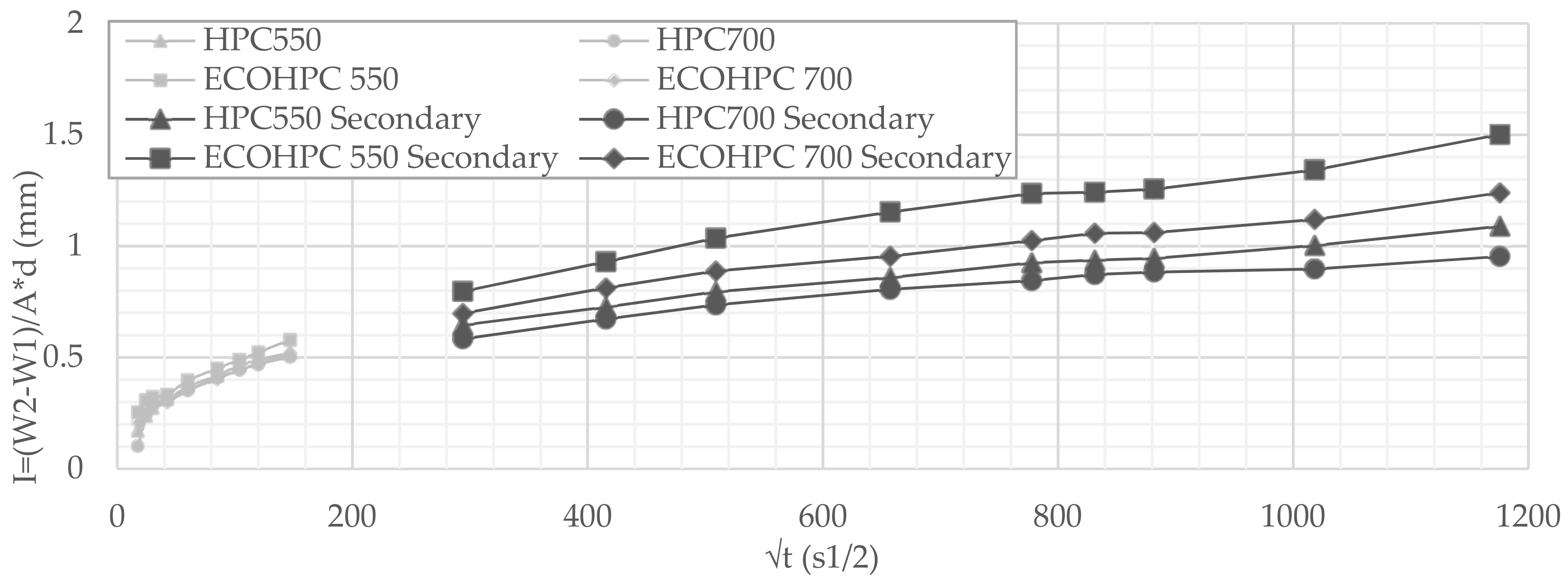

- Sorptivity or absorptivity measures the ability of a medium to absorb water by capillarity. The Faguerlund method (UNE 83982:2008) was used. The samples were dried in an oven at 60 ºC for 48 hours and placed in hermetic bags until the temperature stabilized. Then, the bag was removed and the sample placed in a rectangular plastic container filled with water, sitting on bars. After 6 hours, it was retrieved from the container, excess water was wiped out with absorbent paper and the sample was weighed on standard scales (initial absorptivity). It was then replaced in the container until the next weighing, 24 hours after the first immersion (secondary absorption). The standard requires that both initial and secondary sorptivity are measured because absorption rates differ in these two periods. Sorptivity is measured according to the Equations (1) and (2):S = I/t0.5,where: S = Sorptivity (mm/s2), t = Time (s), W2 = Total weight absorbed (gr), W1 = Weight when leaving the oven (gr), A = Area where water penetrates (mm3), and d = Water density (0.001 gr/mm3).I = (W1 − W2)/(A*d),

- Penetration of water under pressure was assayed according to standard EN 12390-8 2009. Cylindrical specimens with the upper face polished were subjected to a constant pressure of 500 ± 50 kPa for 72 ± 2 hours. To ensure the tightness of the junction between the tube and the device, a rubber O-ring 100 mm in diameter was placed and centered on the polished face of the specimen, so that during the test water pressure acted locally. At the end of the test period, the specimens were cut longitudinally and the boundary between the two zones were marked to enable appropriate measurements of maximum and average depth later on.

- To determine the depth of carbonation (EN 83993-1. 2013), prismatic specimens of 100 mm x 100 mm x 400 mm were introduced in a climatic chamber with 1% CO2 at a temperature of 21 ± 2 °C and relative humidity of 60 ± 10%. After 56 days, the phenolphthalein indicator was atomized by spraying and the depth of attack was measured.

- Accelerated Chloride ion penetration. The immersion method was used to simulate the attack (AASHTO T259). The specimens were subjected to continuous ponding with a sodium chloride solution during 56 days. The attack was measured with the colorimetric method using silver nitrate.

3. Results and Discussion

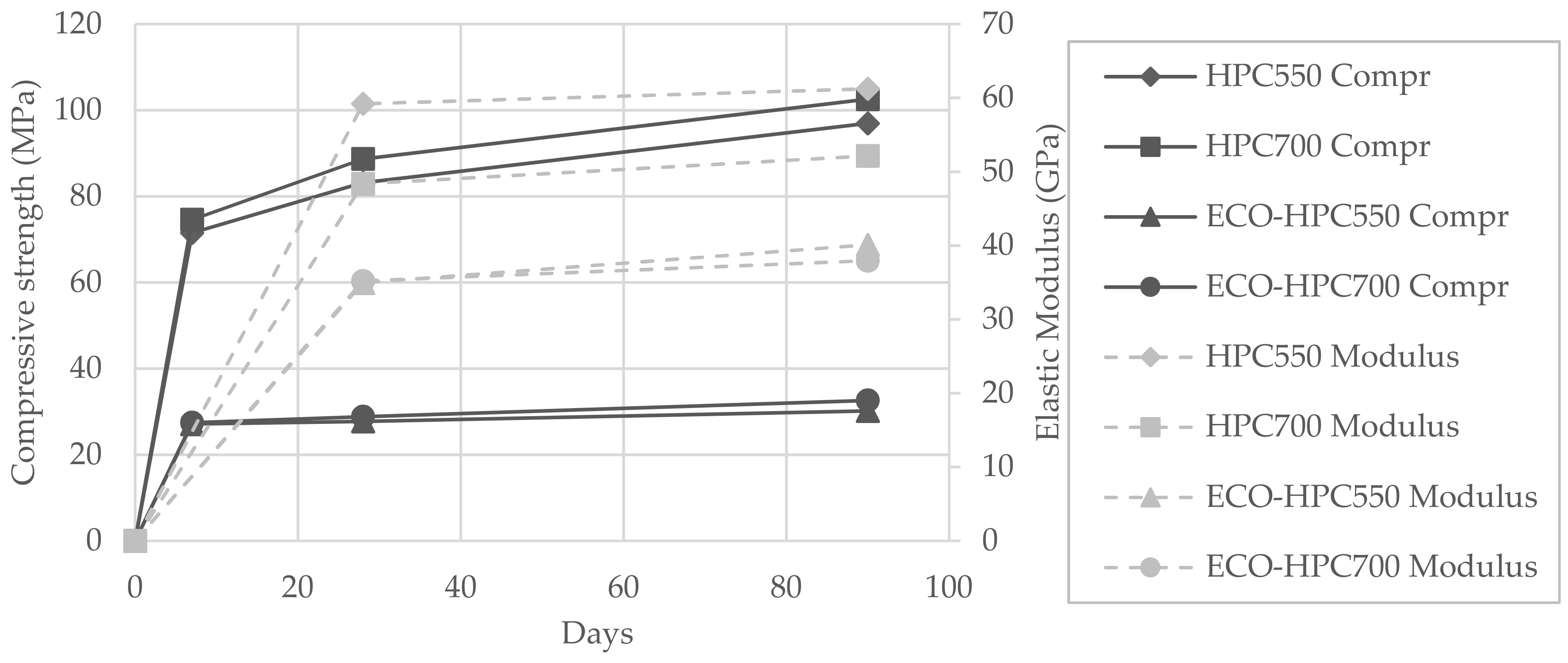

3.1. Compressive Strength

3.2. Elastic Modulus

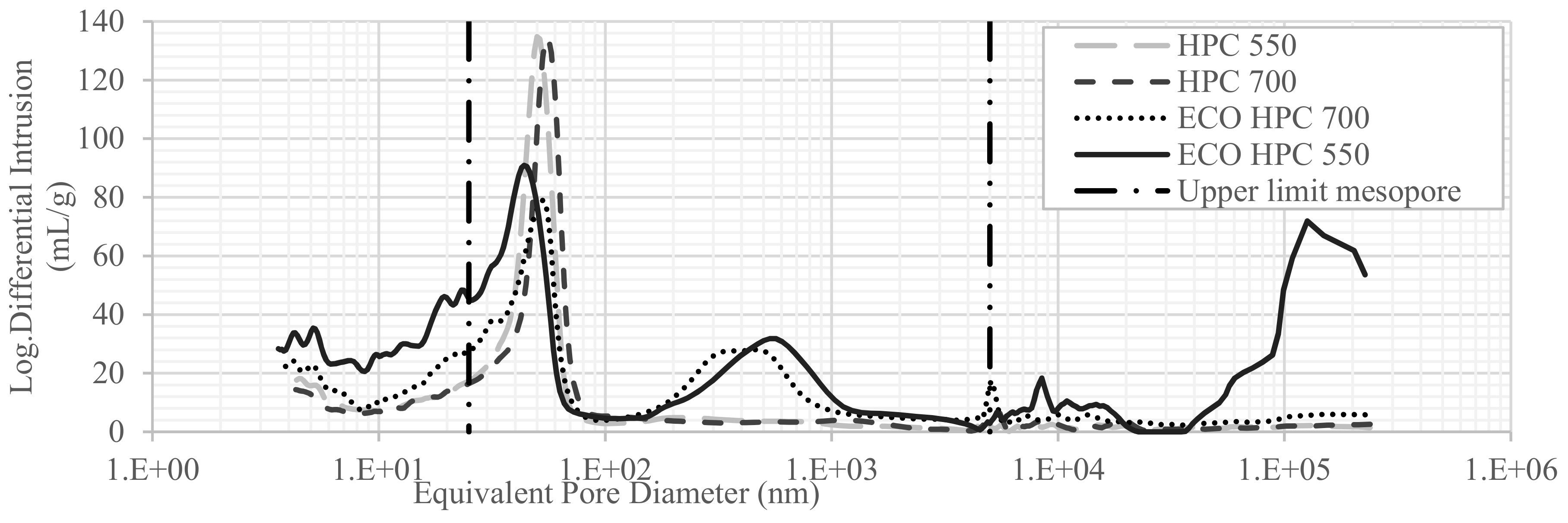

3.3. Mercury Intrusion Porosimetry (MIP)

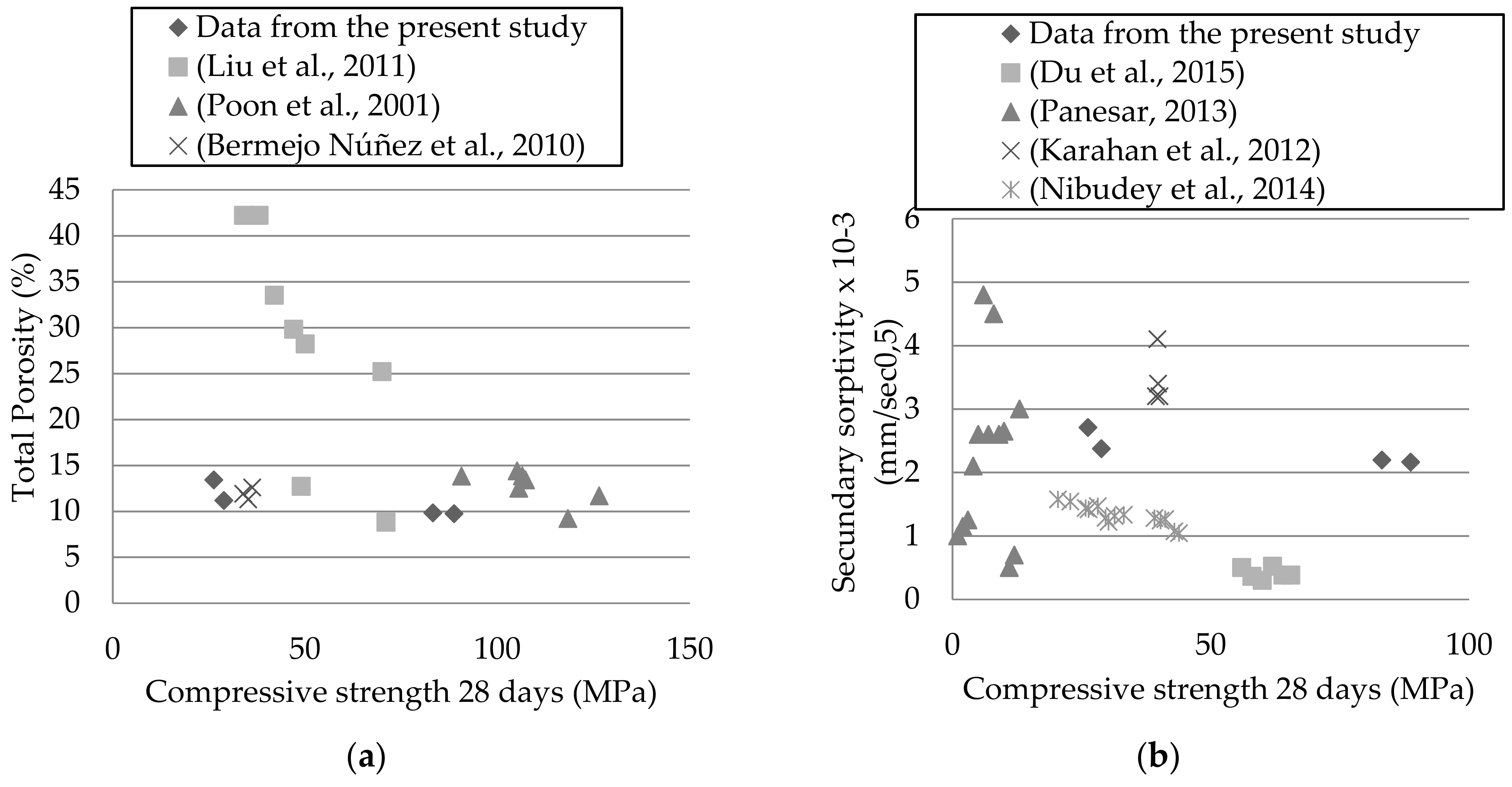

3.4. Sorptivity

3.5. Water Penetration under Pressure

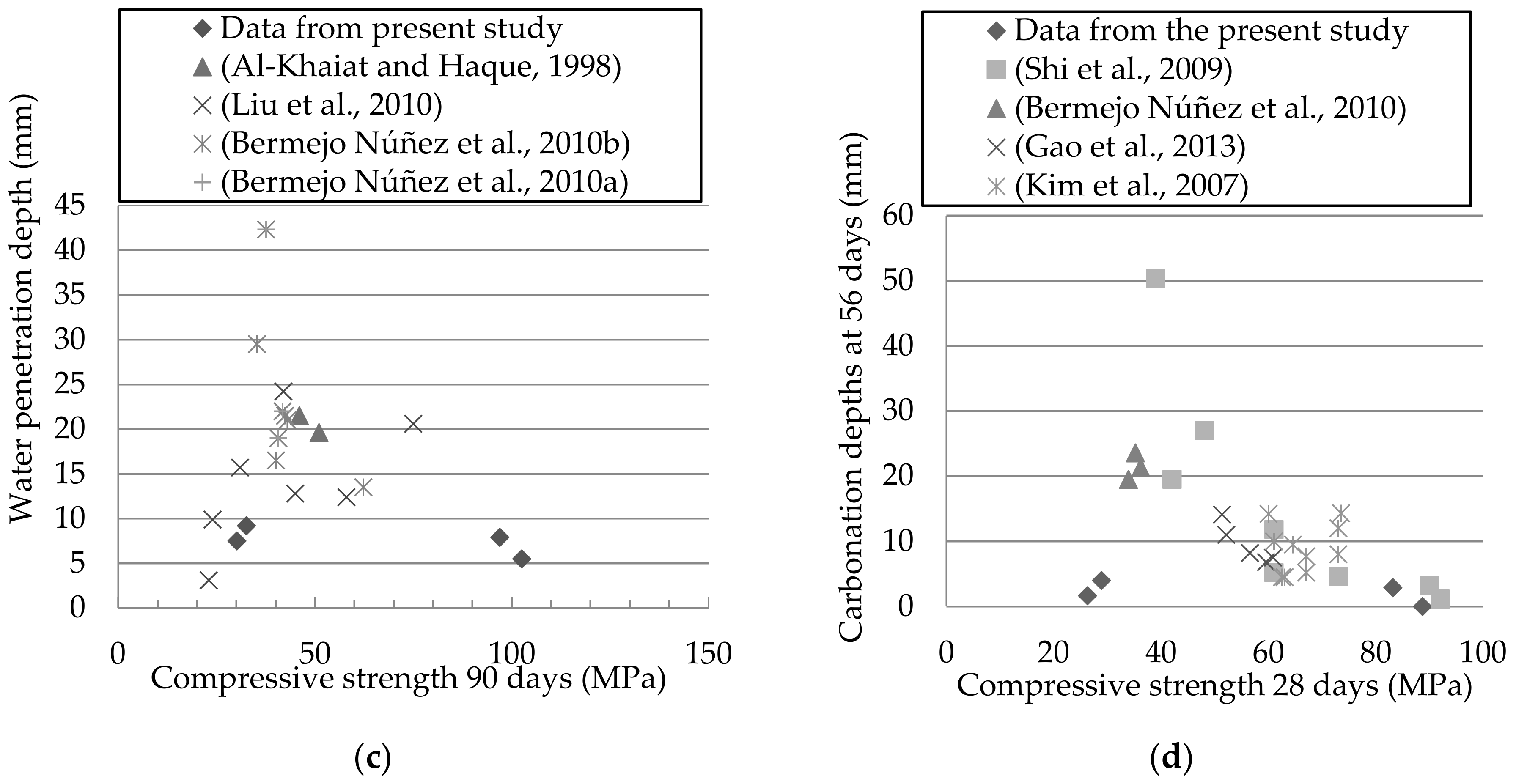

3.6. Carbonation Depth

3.7. Chloride Ion Penetration

4. Conclusions

- The incorporation of recycled aggregates produces a decrease in the compressive strength due to their lower strength and surface characteristics, weakening the ITZ aggregate-cement paste. In this work it has been obtained concrete with light recycled aggregates within the margins of strength established by Eurocode 2, FIB Model code 2010, as well as many of the international codes and standards for structural LWCs.

- Replacing traditional aggregate with plastic does not alter the strength as much as other traditional LWAs, while cork greatly reduces density. The combination of both LWAs allows to balance density and strength to obtain structural LWC. The LWA assayed reduces strength by 68% and density by 19%.

- The elastic modulus is also related to compressive strength, but such relationship is much more diffuse. This is because the modulus is highly influenced by microstructure and shrinkage. A low porosity in the capillary range diminishes the shrinkage capacity of concrete and the stresses caused induce high values of elastic modulus. It is interesting to note how little influence aggregates have on porosity, elastic modulus and shrinkage.

- In all concretes, the volume distribution of the obtained pores follows a similar pattern. It is porosity in the capillary range that affects strength. In this range HPC 700 has the lowest percentage (4.2%), HPC 550 has lower overall porosity (9.83%) but, in a range of finer pores, a greater quantity of smaller pores causes a higher shrinkage due to the loss of humidity by capillary attraction.

- ECOHPCs have greater capillary absorption (58% for those with 550 kg of cement and 50% for the 770 s). The absorption of HPC is much lower than ECOHPC, probably because of the absence of light aggregates. HPC 550 is 8.20% more absorbent than HPC 700, perhaps due to the lower density of its cementitious matrix. ECOHPC 700 is 35% less absorbent than HP and 80% less than ECOHPC 550.

- All the concretes have a very low carbonation depth (below 6 mm at 56 days), with faces of specimens in which the carbonation front has practically no depth, especially in HPC 700. Similar results were obtained from tests of water penetration (below 10 mm) and chloride ion penetration (below 10 mm at 56 days).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mounanga, P.; Gbongbon, W.; Poullain, P.; Turcry, P. Proportioning and characterization of lightweight concrete mixtures made with rigid polyurethane foam wastes. Cem. Concr. Compos. 2008, 30, 806–814. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Ahmed, S.; Lachemi, M. Lightweight concrete incorporating pumice based blended cement and aggregate: Mechanical and durability characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F. Aggregate interlock in lightweight concrete continuous deep beams. Eng. Struct. 2011, 33, 136–145. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.H. Water absorption, permeability, and resistance to chloride-ion penetration of lightweight aggregate concrete. Constr. Build. Mater. 2011, 25, 335–343. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Constr. Build. Mater. 2015, 82, 114–122. [Google Scholar] [CrossRef]

- Henkensiefken, R.; Castro, J.; Bentz, D.; Nantung, T.; Weiss, J. Water absorption in internally cured mortar made with water-filled lightweight aggregate. Cem. Concr. Res. 2009, 39, 883–892. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Rodríguez Martínez, E.D. Efecto de la Incorporación de Materiales Basados en Sílice Sobre las Propiedades de Matrices de Cemento Pórtland y Activadas Alcalinamente. Available online: http://hdl.handle.net/10251/17400. (accessed on 28 March 2019).

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Quercia, G.; Brouwers, H. Application of nano-silica (nS) in concrete mixtures. In Proceedings of the 8th fib PhD Symposium in Kgs, Lyngby, Denmark, 20–23 June 2010; pp. 431–436. [Google Scholar]

- Resíduos Plásticos. Efecto de la Incorporación de Materiales Basados en Sílice Sobre las Propiedades de Matrices de Cemento Pórtland y Activadas Alcalinamente. Available online: http://www.cedexmateriales.es/upload/docs/es_RESIDUOSPLASTICOSDIC2013.pdf (accessed on 28 March 2019).

- Kou, S.C.; Lee, G.; Poon, C.S.; Lai, W.L. Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef] [PubMed]

- Hannawi, K.; Kamali-Bernard, S.; Prince, W. Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manag. 2010, 30, 2312–2320. [Google Scholar] [CrossRef] [PubMed]

- Kan, A.; Demirboga, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Malloy, R.; Desai, N.; Wilson, C.; Swan, C.; Jansen, D.; Kashi, M. High carbon fly ash/mixed thermoplastic aggregate for use in lightweight concrete. In Proceedings of the Society of Plastics Engineering, Annual Technical Conference, Dallas, TX, USA, 6–10 May 2001; pp. 2743–2751. [Google Scholar]

- Panyakapo, P.; Panyakapo, M. Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag. 2008, 28, 1581–1588. [Google Scholar] [CrossRef] [PubMed]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef] [PubMed]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef] [PubMed]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Ben Fraj, A.; Kismi, M.; Mounanga, P. Valorization of coarse rigid polyurethane foam waste in lightweight aggregate concrete. Constr. Build. Mater. 2010, 24, 1069–1077. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Magarinos, O.E.; Alderete, C.E.; Arias, L.E.; Lucca, M.E. Estudio de morteros que contienen escamas de plástico procedente de residuos post-industriales Study of mortars with industrial residual plastic scales. Mater. Constr. 1998, 250, 33–52. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Najim, K.B.; Hall, M.R. Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. 2013, 46, 2029–2043. [Google Scholar] [CrossRef]

- Da Silva, A.M.; De Brito, J.; Veiga, R. Incorporation of fine plastic aggregates in rendering mortars. Constr. Build. Mater. 2014, 71, 226–236. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Coppola, B.; Courard, L.; Michel, F.; Incarnato, L.; Di Maio, L. Investigation on the use of foamed plastic waste as natural aggregates replacement in lightweight mortar. Compos. Part B Eng. 2016, 99, 75–83. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- González, B.; Llamas, B.; Juan, A.; Guerra, I. Tests on concrete containing cork powder admixtures. Mater. Constr. 2007, 57, 83–90. [Google Scholar]

- Fonseca, T.J.; Parresol, B.R. A new model for cork weight estimation in Northern Portugal with methodology for construction of confidence intervals. For. Ecol. Manag. 2001, 152, 131–139. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.; Maher, K. Influence of granule properties and concentration on cork-cement compatibility. Holz Roh Werkst. 2006, 64, 281. [Google Scholar] [CrossRef]

- Moreira, A.; António, J.; Tadeu, A. Lightweight screed containing cork granules: Mechanical and hygrothermal characterization. Cem. Concr. Compos. 2014, 49, 1–8. [Google Scholar] [CrossRef]

- Bachar, M.; Azzouz, L.; Rabehi, M.; Mezghiche, B. Characterization of a stabilized earth concrete and the effect of incorporation of aggregates of cork on its thermo-mechanical properties: Experimental study and modeling. Constr. Build. Mater. 2015, 74, 259–267. [Google Scholar] [CrossRef]

- Panesar, D.; Shindman, B. The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cem. Concr. Compos. 2012, 34, 982–992. [Google Scholar] [CrossRef]

- Freyssinet, E. High-early-strength concrete with Portland cement. Cem. Concr. Manuf. 1936, 9, 71–77. [Google Scholar]

- Roy, D.; Gouda, G. Optimization of strength in cement pastes. Cem. Concr. Res. 1975, 5, 153–162. [Google Scholar] [CrossRef]

- Thorenfeldt, E. Design Criteria of light weight aggregate concrete. In Proceedings of the CEB/FIP International Symposium on Structural Light weight Aggregate Concrete, Sandefjord, Norway, 20–24 June 1995. [Google Scholar]

- Katzer, J.; Kobaka, J. The assessment of fine aggregate pit deposits for concrete production. Kuwait J. Sci. Eng. 2006, 33, 165. [Google Scholar]

- Beushausen, H.; Gillmer, M. The use of superabsorbent polymers to reduce cracking of bonded mortar overlays. Cem. Concr. Compos. 2014, 52, 1–8. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Reichard, T.W. Creep and Drying Shrinkage of Lightweight and Normal-Weight Concretes; Government Printing Office: Washington, DC, USA, 1964; p. 38.

- Li, Y.; Li, J. Capillary tension theory for prediction of early autogenous shrinkage of self-consolidating concrete. Constr. Build. Mater. 2014, 53, 511–516. [Google Scholar] [CrossRef]

- Bermejo Núñez, E.B.; Gálvez Ruíz, J.; Moragues Terrades, A.; Fernández Cánovas, M. Influencia de la estructura porosa en la durabilidad de hormigones autocompactantes de similar resistencia. In Proceedings of the 2nd Iberian Congress on Self-Compacting Concrete (BAC 2010), Guimaraes, Portugal, 1–2 July 2010. [Google Scholar]

- Nibudey, R.; Nagarnaik, P.; Parbat, D.; Pande, A. Compressive strength and sorptivity properties of pet fiber reinforced concrete. Int. J. Adv. Eng. Technol. 2014, 7, 1206. [Google Scholar]

- Karahan, O.; Hossain, K.M.; Ozbay, E.; Lachemi, M.; Sancak, E. Effect of metakaolin content on the properties self-consolidating lightweight concrete. Constr. Build. Mater. 2012, 31, 320–325. [Google Scholar] [CrossRef]

- Panesar, D. Cellular concrete properties and the effect of synthetic and protein foaming agents. Constr. Build. Mater. 2013, 44, 575–584. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.H. Development of lightweight concrete with high resistance to water and chloride-ion penetration. Cem. Concr. Compos. 2010, 32, 757–766. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Algaba, J.; Andrade, C. Corrosion of reinforcing bars in carbonated concrete. Br. Corros. J. 1980, 15, 135–139. [Google Scholar] [CrossRef]

- Francois, R.; Maso, J. Effect of damage in reinforced concrete on carbonation or chloride penetration. Cem. Concr. Res. 1988, 18, 961–970. [Google Scholar] [CrossRef]

- Peter, M.; Muntean, A.; Meier, S.; Böhm, M. Competition of several carbonation reactions in concrete: A parametric study. Cem. Concr. Res. 2008, 38, 1385–1393. [Google Scholar] [CrossRef]

- Valcuende, M.; Parra, C. Natural carbonation of self-compacting concretes. Constr. Build. Mater. 2010, 24, 848–853. [Google Scholar] [CrossRef]

- Hidalgo, A.; Petit, S.; Domingo, C.; Alonso, C.; Andrade, C. Microstructural characterization of leaching effects in cement pastes due to neutralisation of their alkaline nature: Part I: Portland cement pastes. Cem. Concr. Res. 2007, 37, 63–70. [Google Scholar] [CrossRef]

- Lim, S.; Mondal, P. Effects of incorporating nanosilica on carbonation of cement paste. J. Mater. Sci. 2015, 50, 3531–3540. [Google Scholar] [CrossRef]

- Roziere, E.; Loukili, A.; Cussigh, F. A performance based approach for durability of concrete exposed to carbonation. Constr. Build. Mater. 2009, 23, 190–199. [Google Scholar] [CrossRef]

- Shi, H.-S.; Xu, B.-W.; Zhou, X.-C. Influence of mineral admixtures on compressive strength, gas permeability and carbonation of high performance concrete. Constr. Build. Mater. 2009, 23, 1980–1985. [Google Scholar] [CrossRef]

- Wassermann, R.; Katz, A.; Bentur, A. Minimum cement content requirements: A must or a myth? Mater. Struct. 2009, 42, 973–982. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Nadeem, A. Comparison of carbonation of lightweight concrete with normal weight concrete at similar strength levels. Constr. Build. Mater. 2008, 22, 1648–1655. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef] [PubMed]

- Edwin, R.S.; Gruyaert, E.; Dils, J.; De Belie, N. Influence of vacuum mixing on the carbonation resistance and microstructure of reactive powder concrete containing secondary copper slag as supplementary cementitious material (SCM). Procedia Eng. 2017, 171, 534–542. [Google Scholar] [CrossRef]

- Liu, J.; Song, S.; Wang, L. Durability and micro-structure of reactive powder concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 506–509. [Google Scholar] [CrossRef]

- Tragardh, J. Microstructural features and related properties of self-compacting concrete. In Proceedings of the Self-Compacting Concrete: Proceedings of the First International RILEM Symposium, Stockholm, Sweden, 13–14 September 1999; pp. 175–186. [Google Scholar]

- Tam, V.W.; Gao, X.; Tam, C. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Rodhe, M.; X-Betong. Properties of Fresh and Hardened Concrete; Chalmers University of Technology: Goteborg, Sweden, 1986; p. 30. [Google Scholar]

- Konečný, P.; Lehner, P.; Ponikiewski, T.; Miera, P. Comparison of chloride diffusion coefficient evaluation based on electrochemical methods. Procedia Eng. 2017, 190, 193–198. [Google Scholar] [CrossRef]

- Otsuki, N.; Nagataki, S.; Nakashita, K. Evaluation of the AgNO3 solution spray method for measurement of chloride penetration into hardened cementitious matrix materials. Constr. Build. Mater. 1993, 7, 195–201. [Google Scholar] [CrossRef]

- Nyame, B. Permeability of normal and lightweight mortars. Mag. Concr. Res. 1985, 37, 44–48. [Google Scholar] [CrossRef]

- Thomas, M. Chloride diffusion in high-performance lightweight aggregate concrete. Spec. Publ. 2006, 234, 797–812. [Google Scholar]

- Hooton, R.; Titherington, M. Chloride resistance of high-performance concretes subjected to accelerated curing. Cem. Concr. Res. 2004, 34, 1561–1567. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Fapohunda, C.A.; Natale, J. Use of supplementary cementing materials to increase the resistance to chloride ion penetration of concretes cured at elevated temperatures. Mater. J. 1994, 91, 63–66. [Google Scholar]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Zahedi, M.; Ramezanianpour, A.A.; Ramezanianpour, A.M. Evaluation of the mechanical properties and durability of cement mortars containing nanosilica and rice husk ash under chloride ion penetration. Constr. Build. Mater. 2015, 78, 354–361. [Google Scholar] [CrossRef]

| Concrete ID | HPC-550 | HPC-700 | ECOHPC-700 | ECOHPC-550 |

|---|---|---|---|---|

| Cement | 550 | 700 | 550 | 700 |

| Water | 160 | 180 | 160 | 180 |

| FA | 130 | 70 | 150 | 70 |

| Ns | 14 | 14 | 14 | 14 |

| SP | 11 | 11.75 | 11 | 11.75 |

| Sand | 1015.16 (66.7%) 1 | 927.19 (66.7%) 1 | 646.94 (42.7%) 1 | 593.39 (42.7%) 1 |

| Gravel | 507.58 (33.3%) 1 | 463.6 (33.3%) 1 | 142.27 (9.3%) 1 | 129.82 (9.3%) 1 |

| Plastic | - | - | 206.16 (29.5%) 1 | 189.49 (29.5%) 1 |

| Cork | - | - | 21.5 (18.5%) 1 | 19.77 (18.5%) 1 |

| HPC550 | HPC700 | ECO-HPC550 | ECO-HPC700 | ||

|---|---|---|---|---|---|

| Density (kg/m3) | 2291.6 | 2341.4 | 1873 | 1891.2 | |

| Compressive Strength (MPa) | 7 days | 71.5 | 74.59 | 27.12 | 27.46 |

| 28 days | 83.16 | 88.69 | 27.76 | 28.84 | |

| 90 days | 96.96 | 102.57 | 30.19 | 32.61 | |

| Elastic modulus (GPa) | 28 days | 84.8 | 48.4 | 20.9 | 35.2 |

| 90 days | 71.6 | 133.8 | 40.1 | 38 | |

| Mercury intrusion porosimetry (MIP) Test | Total porosity (%) | 9.83 | 9.73 | 13.4 | 11.17 |

| Average pore radius (µm) | 226.7 | 254 | 295.1 | 267 | |

| Porosity in capillary range pores (%) | 5.1 | 4.2 | 8.11 | 5.64 | |

| Sorptivity (mm/s0.5) | S initial x 10-3 | 3.54 | 3.55 | 3.94 | 3.53 |

| S secondary x 10-3 | 2.2 | 2.16 | 2.71 | 2.37 | |

| Water penetration under pressure (mm) | Average penetration | 7.9 | 5.5 | 7.5 | 9.2 |

| Maximum penetration | 17 | 11 | 11.5 | 12.75 | |

| Carbonation depth (mm) | 56 days | 2.88 | 0 | 1.66 | 3.97 |

| 90 days | 3.26 | 0 | 5.89 | 4.88 | |

| Chloride ion penetration (mm) | 28 days | 3.6 | 5.7 | 6.2 | 7 |

| 56 days | 5.9 | 8.6 | 8.2 | 8.6 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parra, C.; Sánchez, E.M.; Miñano, I.; Benito, F.; Hidalgo, P. Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production. Sustainability 2019, 11, 1876. https://doi.org/10.3390/su11071876

Parra C, Sánchez EM, Miñano I, Benito F, Hidalgo P. Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production. Sustainability. 2019; 11(7):1876. https://doi.org/10.3390/su11071876

Chicago/Turabian StyleParra, Carlos, Eva M. Sánchez, Isabel Miñano, Francisco Benito, and Pilar Hidalgo. 2019. "Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production" Sustainability 11, no. 7: 1876. https://doi.org/10.3390/su11071876

APA StyleParra, C., Sánchez, E. M., Miñano, I., Benito, F., & Hidalgo, P. (2019). Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production. Sustainability, 11(7), 1876. https://doi.org/10.3390/su11071876