A Comprehensive Construction and Demolition Waste Management Model using PESTEL and 3R for Construction Companies Operating in Central Asia

Abstract

:1. Introduction

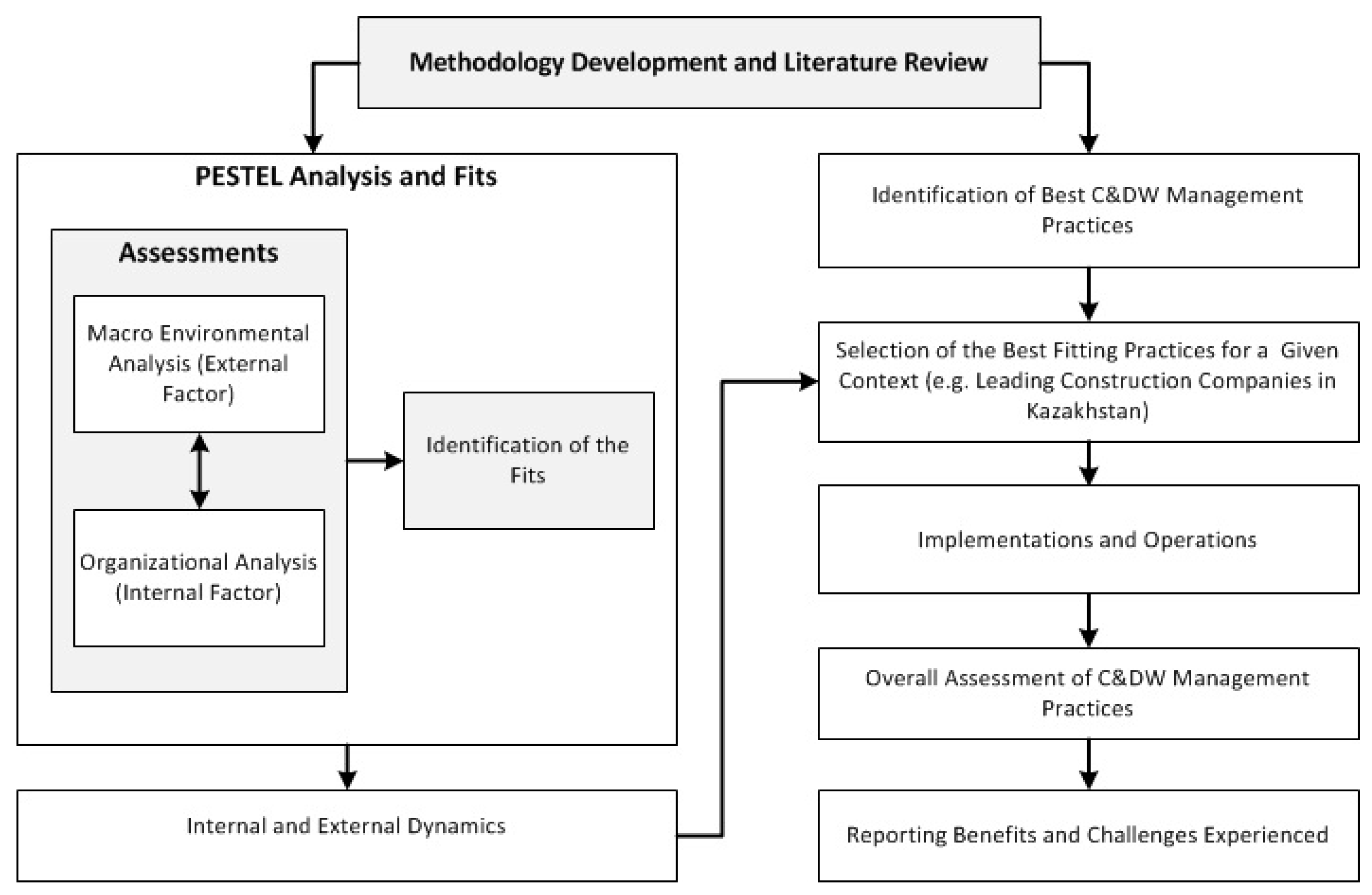

2. Methodology

Case Company (CC)

3. Results and Discussion

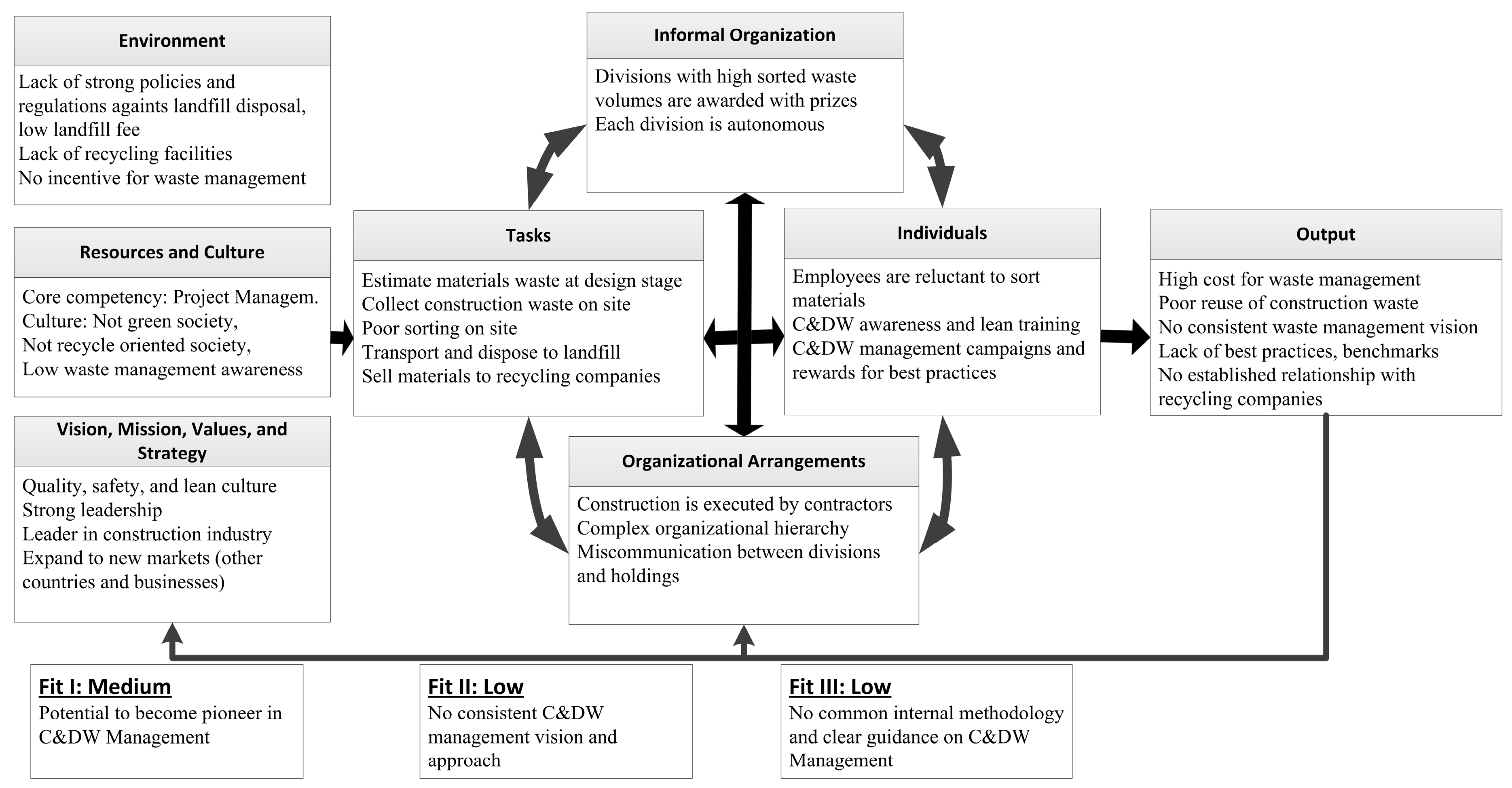

3.1. External and Internal Drivers of C&DW Management in the CC

- An absence of consistent waste management vision and approach

- An absence of common internal waste management methodology

- A lack of experience, best practices and competency in waste management

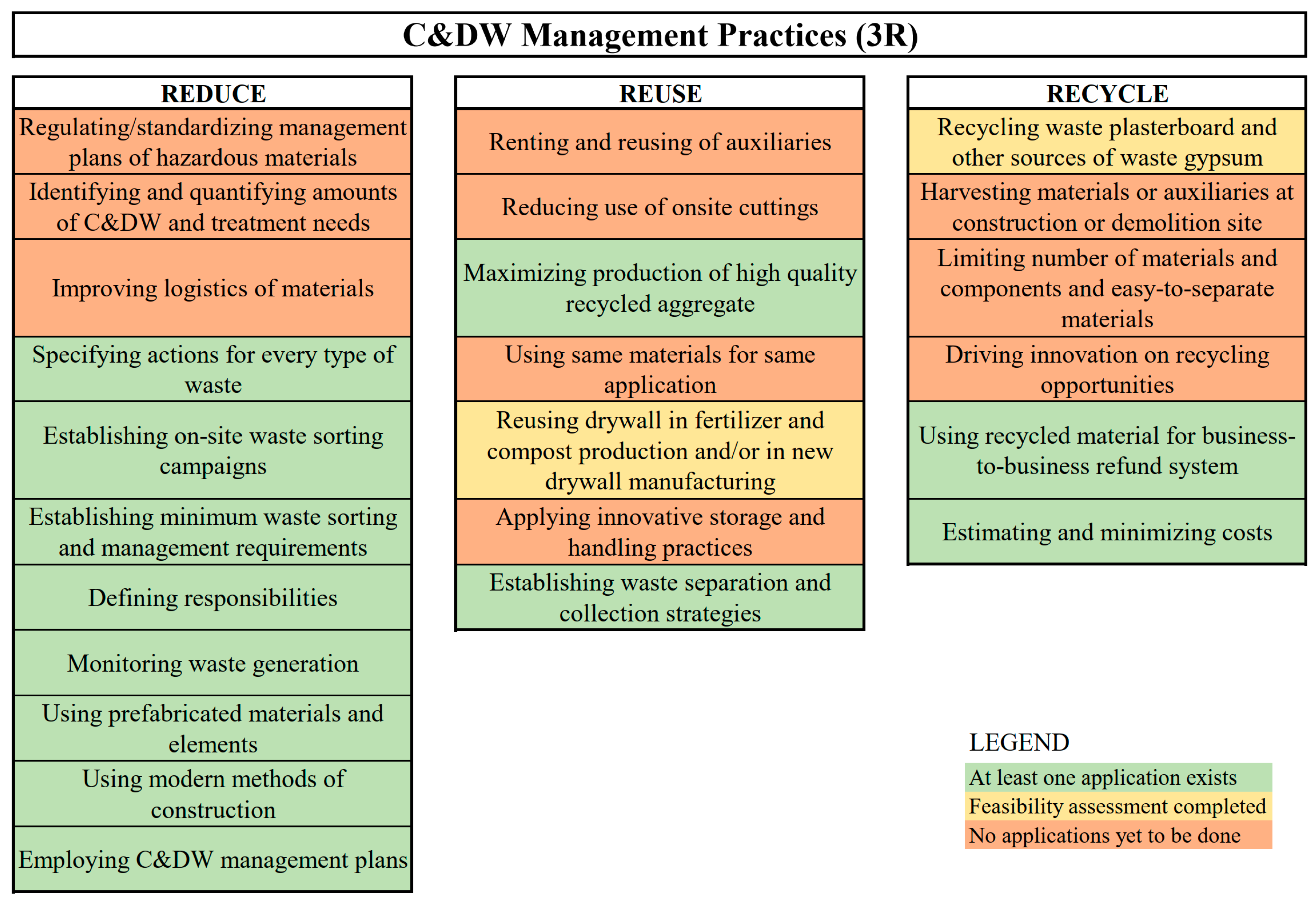

3.2. R-Based C&DW Management Practices and Results

3.2.1. Practices Based on Reduce Strategy

3.2.2. Practices Based on Reuse Strategy

3.2.3. Practices Based on Recycle Strategy

4. Conclusions and Implications

- PESTEL analysis has shown that according to the external and internal drivers analysis, although an “official” vision exists in Kazakhstan towards establishing a waste management guideline, there is still a significant gap in construction industry between the current and the ideal levels of C&DW management practices due to insufficient technological factors prepossessing recycle of waste, a low degree of development of a ‘green culture,’ a lack of awareness and an absolute absence of incentives from legal and economic sides.

- The activities promoting waste reduction seems to have the largest potential to minimize C&DW (compared to reuse and recycling). Since one of the main sources of C&DW is inadequate or faulty design, the BIM technology is highly promising to eliminate related problems early at the design stage.

- The potential of BIM as a reduction strategy is also significant as it already renders some later reuse and recycle activities unnecessary as it leads to reduction at the beginning. Prefabricated construction is also encouraged for waste reduction but its implementation seems less significant than BIM for the moment.

- Though some initial measures successfully and significantly reduced the total C&DW, the generation was still high due to issues discussed in detail in the text, thus further measures in reuse and recycling are also encouraged.

- Concrete was the main material for reuse as it can serve as aggregate to produce new concrete. As the CC already has the crushing equipment, the continuation of its use and applications including alternative applications is recommended (e.g., new concrete, for temporary roads, as backfill, as sub-base). Drywall also has some potential but to a lesser extent than concrete.

- Other materials such as asphalt, wood and metal have significant reuse and/or recycling potential. Especially the off-site recycling potential of metals (i.e., material to be sold to third parties for recycling) is not yet exploited to its full extent of possibility.

- Employee awareness regarding 3R hierarchy and waste management seems low regardless of the level of the employee. Already implemented training programs would likely to be successful and yet needs to be repeated due to high employee turnover in the sector.

Author Contributions

Funding

Conflicts of Interest

References

- UNEP; ISWA. Global Waste Management Outlook; United Nations Environment Programme: Vienna, Austria, 2015. [Google Scholar]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Ferronato, N.; Rada, E.C.; Gorritty Portillo, M.A.; Cioca, L.I.; Ragazzi, M.; Torretta, V. Introduction of the circular economy within developing regions: A comparative analysis of advantages and opportunities for waste valorization. J. Environ. Manag. 2019, 230, 366–378. [Google Scholar] [CrossRef] [PubMed]

- Horvath, A. Construction Materials and The Environment. Annu. Rev. Environ. Resour. 2004, 29, 181–204. [Google Scholar] [CrossRef]

- Thongkamsuk, P.; Sudasna, K.; Tondee, T. Waste generated in high-rise buildings construction: A current situation in Thailand. Energy Procedia 2017, 138, 411–416. [Google Scholar] [CrossRef]

- EC Waste. Available online: http://ec.europa.eu/environment/waste/construction_demolition.htm (accessed on 10 January 2019).

- EPD Statistics Unit. Monitoring of Solid Waste in Hong Kong—Waste Statistics for 2014; Environmental Protection Department: Hong Kong, China, 2015. [Google Scholar]

- Rogers, S. Battling construction waste and winning: Lessons from UAE. Proc. Inst. Civ. Eng. Eng. 2011, 164, 41–48. [Google Scholar] [CrossRef]

- Giannis, A.; Chen, M.J.; Yin, K.; Tong, H.H.; Veksha, A. Application of system dynamics modelling for evaluation of different recycling scenarios in Singapore. J. Mater. Cycles Waste Manag. 2017, 19, 1177–1185. [Google Scholar] [CrossRef]

- Manowong, E. Investigating factors influencing construction waste management efforts in developing countries: An experience from Thailand. Waste Manag. Res. 2012, 30, 56–71. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management. Urban development series. World Bank 2012, 1, 1–116. [Google Scholar]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of Life Cycle Assessment in Municipal Solid Waste Management: A Worldwide Critical Review. J. Clean. Prod. 2018, 209, 630–654. [Google Scholar] [CrossRef]

- Jia, S.; Liu, X.; Yan, G. Dynamic analysis of construction and demolition waste management model based on system dynamics and grey model approach. Clean Technol. Environ. Policy 2018, 20, 2089–2107. [Google Scholar] [CrossRef]

- Kim, J.; Tae, S.; Kim, R. Theoretical Study on the Production of Environment-Friendly Recycled Cement Using Inorganic Construction Wastes as Secondary Materials in South Korea. Sustainability 2018, 10, 4449. [Google Scholar] [CrossRef]

- Ibrahim, M. Estimating the sustainability returns of recycling construction waste from building projects. Sustain. Cities Soc. 2016, 23, 78–93. [Google Scholar] [CrossRef]

- UNEP. Central Asia Waste Management Outlook; ZOI Environment Network: Châtelaine, Switzerland, 2017. [Google Scholar]

- Makhmutova, E.V. Central Asia in Search for Its Own Way of Integration. Mgimo Rev. Int. Relat. 2018, 78–91. [Google Scholar]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Ministry of Justice of the Republic of Kazakhstan. Environmental Code of the Republic of Kazakhstan; ILS Adilet: Astana, Kazakhstan, 2007.

- Inglezakis, V.J.; Moustakas, K.; Khamitovac, G.; Tokmurzin, D.; Rakhmatulina, R.; Serik, B.; Abikak, Y.; Poulopoulos, S.G. Municipal solid waste management in Kazakhstan: Astana and almaty case studies. Chem. Eng. Trans. 2017, 56, 565–570. [Google Scholar]

- Inglezakis, V.J.; Moustakas, K.; Khamitova, G.; Tokmurzin, D.; Sarbassov, Y.; Rakhmatulina, R.; Serik, B.; Abikak, Y.; Poulopoulos, S.G. Current municipal solid waste management in the cities of Astana and Almaty of Kazakhstan and evaluation of alternative management scenarios. Clean Technol. Environ. Policy 2018, 20, 503–516. [Google Scholar] [CrossRef]

- Gi Llespie PESTEL Analysis of the Macro-Environment; Oxford University Press: Oxford, UK, 2011; pp. 1–5.

- Carruthers, H. Using PEST analysis to improve business performance. Practice 2009, 31, 37–39. [Google Scholar] [CrossRef]

- Iacovidou, E.; Busch, J.; Hahladakis, J.N.; Baxter, H.; Ng, K.S.; Herbert, B.M.J. A Parameter Selection Framework for Sustainability Assessment. Sustainability 2017, 9, 1497. [Google Scholar] [CrossRef]

- Buchanan, S.; Gibb, F. The information audit: Methodology selection. Int. J. Inf. Manag. 2008, 28, 3–11. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Australian study. Resour. Conserv. Recycl. 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Wang, J.Y.; Kang, X.P.; Tam, V.W.Y. An investigation of construction wastes: An empirical study in Shenzhen. J. Eng. Des. Technol. 2008, 6, 227–236. [Google Scholar] [CrossRef]

- Peng, C.L.; Scorpio, D.E.; Kibert, C.J. Strategies for successful construction and demolition waste recycling operations. Constr. Manag. Econ. 1997, 15, 49–58. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Memon, M.A. Integrated solid waste management based on the 3R approach. J. Mater. Cycles Waste Manag. 2010, 12, 30–40. [Google Scholar] [CrossRef]

- Shan, N.L.; Wee, S.T.; Wai, T.L.; Chen, G.K. Construction Waste Management of Malaysia: Case Study in Penang. Adv. Sci. Lett. 2018, 24, 4698–4703. [Google Scholar] [CrossRef]

- Osmani, M. Construction Waste. In Waste: A Handbook for Management; Letcher, T.M., Vallero, D.A., Eds.; Elsevier Inc.: Burlington, MA, USA, 2011; pp. 207–218. ISBN 9780123814753. [Google Scholar]

- Rounce, G. Quality, waste and cost considerations in architectural building design management. Int. J. Proj. Manag. 1998, 16, 123–127. [Google Scholar] [CrossRef]

- Keys, A.; Baldwin, A. Designing to encourage waste minimisation in the construction industry. In Proceedings of the CIBSE National Conference, CIBSE2000, Dublin, Ireland, 4–5 September 2000. [Google Scholar]

- Ekanayake, L.L.; Ofori, G. Building waste assessment score: Design-based tool. Build. Environ. 2004, 39, 851–861. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A guide to Building Information Modeling for owners, managers, designers, engineers and contractors, 2nd ed.; Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 9780470541371. [Google Scholar]

- Won, J.; Cheng, J.C.P.; Lee, G. Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.C.P.; Won, J.; Das, M. Construction and Demolition Waste Management using BIM technology. Waste Manag. N. Y. 2015, 27, 159–160. [Google Scholar]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Lawton, T.; Moore, P.; Cox, K.; Clark, J. The gammon skanska construction system. In Proceedings of the International Conference Advances in Building Technology, Hong Kong, China, 4–6 December 2002; Volume 2, pp. 1073–1080, ISBN 978-0-08-044100-9. [Google Scholar]

- Lachimpadi, S.K.; Pereira, J.J.; Taha, M.R.; Mokhtar, M. Construction waste minimisation comparing conventional and precast construction (Mixed System and IBS) methods in high-rise buildings: A Malaysia case study. Resour. Conserv. Recycl. 2012, 68, 96–103. [Google Scholar] [CrossRef]

- Cochran, K.M. Construction and demolition debris recycling: Methods, markets and policy. Diss. Abstr. Int. B Sci. Eng. 2009, 70, 1260. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M. Evaluations of existing waste recycling methods: A Hong Kong study. Build. Environ. 2006, 41, 1649–1660. [Google Scholar] [CrossRef] [Green Version]

- Marvin, E. Gypsum Wallboard Recycling and Reuse Opportunities in the State of Vermont; Vermont Agency of Natural Resources: Montpelier, VT, USA, 2000.

- Tam, V.W.Y.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Taylor, J.; Mann, R.; Reilly, M.; Warnken, M.; Pincic, D.; Death, D. Recycling and End-of-Life Disposal of Timber Products; Forest and Wood Products Research and Development Corporation: Melbourne, Australia, 2005. [Google Scholar]

- Lang, J.C. Zero landfill, zero waste: The greening of industry in Singapore. Green. Ind. New Ind. Econ. Asian-Style Leapfrogging 2014, 4, 189–215. [Google Scholar] [CrossRef]

| Waste Constituent | % | |

|---|---|---|

| Inert reusable/recyclable (total) | 60.0 | |

| Concrete | 18.6 | |

| Bricks | 18.6 | |

| Autoclaved cellular concrete | 4.2 | |

| Façade materials | 3.6 | |

| Decoration materials | 15.0 | |

| Non-inert reusable/recyclable (total) | 35.0 | |

| Metal | 20.3 | |

| Timber | 10.9 | |

| Paper | 1.8 | |

| Plastic | 1.8 | |

| Glass | 0.4 | |

| Other, non-reusable/recyclable (total) | 5.0 | |

| Political Factors | Economic Factors | Socio-Cultural Factors |

|

|

|

| Technological Factors | Environmental Factors | Legal Factors |

|

|

|

| Most Significant Benefits | Challenges | |

|---|---|---|

| Reduce |

|

|

| Reuse |

|

|

| Recycle |

|

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turkyilmaz, A.; Guney, M.; Karaca, F.; Bagdatkyzy, Z.; Sandybayeva, A.; Sirenova, G. A Comprehensive Construction and Demolition Waste Management Model using PESTEL and 3R for Construction Companies Operating in Central Asia. Sustainability 2019, 11, 1593. https://doi.org/10.3390/su11061593

Turkyilmaz A, Guney M, Karaca F, Bagdatkyzy Z, Sandybayeva A, Sirenova G. A Comprehensive Construction and Demolition Waste Management Model using PESTEL and 3R for Construction Companies Operating in Central Asia. Sustainability. 2019; 11(6):1593. https://doi.org/10.3390/su11061593

Chicago/Turabian StyleTurkyilmaz, Ali, Mert Guney, Ferhat Karaca, Zhanar Bagdatkyzy, Aiganym Sandybayeva, and Gulzat Sirenova. 2019. "A Comprehensive Construction and Demolition Waste Management Model using PESTEL and 3R for Construction Companies Operating in Central Asia" Sustainability 11, no. 6: 1593. https://doi.org/10.3390/su11061593

APA StyleTurkyilmaz, A., Guney, M., Karaca, F., Bagdatkyzy, Z., Sandybayeva, A., & Sirenova, G. (2019). A Comprehensive Construction and Demolition Waste Management Model using PESTEL and 3R for Construction Companies Operating in Central Asia. Sustainability, 11(6), 1593. https://doi.org/10.3390/su11061593