1. Introduction

There are 26 ethnic groups in Yunnan, China, which provides the Province with the most diverse range of minorities in the whole country. Among them, 15 ethnic groups are unique to the Province: Bai, Hani, Dai, Naxi, Lisu, Lahu, Wa, Jing Po, Bulang, Achang, Nu, Pumi, De’ang, Durung and Jinuo. After a long period of evolution and development, all ethnic groups have established rich and unique characteristics that are embodied within their dwellings, culture, and customs [

1,

2,

3,

4]. In recent years, the Chinese Government has recognized the importance of improving the economic vitality of rural areas, and many villages (occupied by particular ethnic groups) have been chosen for focused redevelopment because of the tourist potential arising from the ethnic and cultural features [

5].

The research presented in this paper represents collaboration between teams from different disciplines and countries and led by the need to address, in a holistic way, issues surrounding sustainable development linked to the process of revitalizing rural villages in China, and in particular to those located in the southwest provinces. Aspects of environmental sustainable development in such locations has been described elsewhere [

6], but other technological concerns are important to achieve long lasting preservation, the need for which also impacts on economic and social considerations. Amongst these important other themes that should be addressed, because of geological circumstances, is that of resistance to catastrophic damage caused by earthquakes. As a result, this paper, and the research it represents, is particularly significant during a period of rapid rural redevelopment in China. It also has potential to influence future thinking on how to continue to integrate ethnic minority attributes into dwelling design across large areas of earthquake-prone territory in China and potentially thousands of rural communities.

Disaster resilience is an essential part of sustainable development. To effectively reduce the damage caused by natural disasters is a core task of global and regional sustainable development [

7,

8,

9]. Yunnan is one of the high earthquake risk provinces in China, with a significant number of damaging earthquakes (magnitude 4.5 and above) occurring each year.

Table 1 shows the statistics of the loss caused by earthquakes in Yunnan from 2010–2017. Due to the fact that the construction of rural dwelling houses has mostly used rather basic structures, rural dwellings are one of the most severely damaged building types when earthquakes occur and are often the main cause of casualties. For the preservation and protection of dwellings, it is essential to develop techniques to ensure the modification of the structures so that safety of occupants can be preserved when seismic events occur. The value of the dwelling styles as a tourist attraction and as a means to preserve tangible and intangible heritage associated with the ethnic building cultures of the Province means that balanced alternatives retaining those features should be considered.

In earthquake-prone areas like those in Yunnan province, improving the structural safety of vernacular timber and earth houses is one of three main aims in the sustainability guidance for construction in Yunnan. There is also a broader focus on sustainable environments and adopting technological requirements for safe and clean settlements [

10]. Unsafe ways of construction not only cause damage to the inhabitants and their belongings during the earthquake and flooding but also introduce large volumes of waste into ecological systems. The large amount of repair, redesign and rebuilding that result can have significant impacts on the local economy, thus affecting people’s lives and long-term sustainable planning. During the authors’ field work in villages in Yunnan, they witnessed how damaged homes and environment resulting from earthquakes destroyed villagers’ abilities to pursue sustainable livelihoods, destroyed local self-sufficient economic activity, and also exposed people to other difficulties.

It is difficult to prevent natural disasters, but good guidance based on scientific evidence for safe construction can prepare for or avoid the worst aspects of a disaster situation and ensure that losses are minimal. The government has recognized the importance of safety for building structures in rural areas and invested heavily to improve the situation. For example, during the authors’ field work in Xishuangbanna Prefecture in South Yunnan between 2017 and 2018, they observed that the local government had invested a large amount of funding to send architects from local planning and design institutes into all the villages in the region. They were tasked to identify unsafe structures of houses and making plans to remedy the problems of specific at-risk individual houses. Professional construction teams then followed architects and engineers’ drawings to rectify the structural problems of those unsafe houses. Hundreds of vernacular houses were listed as unsafe structures, which required structural strengthening. Similar investigations, with follow-up design and construction work, are also being carried out in other regions in the province. It became increasingly clear that scientifically supported evidence and knowledge to identify the dangers in the existing structures of rural houses were vital to develop techniques to ensure the buildings achieved safety requirements for preserving and protecting dwellings and the inhabitants.

The Research Institute of Earthquake Resistance of Kunming University of Science and Technology (KUST) has taken a leading role in developing showcase solutions for design and construction. It was a lead collaborator with the Chinese University of Hong Kong (CUHK) in developing and testing a full-scale structure using local materials and labor for the construction of an alternative dwelling form able to withstand earthquakes [

11]. This design has won many accolades and awards, but it does not, however, have the same style or cultural references of those constructed in more traditional ways in line with ethnic group aesthetics.

For more than a decade, the KUST Institute has therefore been involved in studying wider impacts on residential house design and seismic resistance and seeking alternative modifications to traditional design. Researchers have classified the building materials used in the structures and studied the seismic performance of residential houses constructed using various materials including bamboo, wood, earth, and stone structures [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23]. The seismic capacity of residential buildings using traditional construction technologies and the potential for use of improved construction technologies has been determined using an established technique: The seismic simulation vibration table test. This can provide the necessary seismic technical support information for the construction of new residential buildings.

The research reported in this paper is based on the hypothesis that important improvements to performance of dwellings in earthquakes can be achieved whilst retaining the main ethnic and cultural features of the appearance of the buildings. This paper mainly focuses on the seismic study of two types of residential buildings: One using an earth wall structure and one using a wood structure; this paper also proposes construction measures and improvement methods to enhance the earthquake resistance. It should be recognized that the purpose of these studies is not to perform a complete parametric analysis of options in expectation of identifying a form that is resistant to all impacts from earthquakes; it is rather to establish if existing and recognizable forms of traditional ethnic minority designs can withstand typical earthquakes and avoid death or serious injury to dwelling occupants.

The main purpose of the research is therefore to present a qualitative demonstration that the preservation of traditional wooden structures is possible during earthquakes and that modifications can show feasibility to provide excellent seismic resistance. As for the rammed earth wall structure, the research seeks to show that appropriate modification of wall materials and improvements in construction technique can add sufficient strengthening to ensure the safety of the rammed earth wall dwelling structure. These types have so far been regarded as dangerous, as they have exhibited vast damage or collapse in previous earthquakes which have occurred in Yunnan province, China. Meanwhile, key features of ethnic residential buildings can be well preserved.

2. Materials and Methods

The methods of analysis were chosen to assess the capability to withstand earthquakes for two traditional wooden structures and of a modified form of earth wall structure that has in the past been considered a risky option for earthquake areas.

The building damage from earthquakes is mainly caused by ground horizontal vibration, of which the intensity is measured by the peak of ground acceleration (PGA). Usually, the seismic waves used in testing are derived from the records of ground time-history acceleration of earthquakes. In other words, for testing purposes, it is often the case that previously experienced earthquake records are used as the basis for simulation but with varying levels of acceleration amplitudes. A typical seismic wave often used is the El Centro wave recorded on the west coast of the United States in 1940, which is the first well-documented seismic wave. A number of other typical seismic waves were also used for tests, and this will be the case in this study.

2.1. Shaking Table Tests

As for studying the seismic capacity of the building, the most direct way is to reproduce the historical typical seismic waves recorded using the shaking table. In order to test the vibration response performance and the destructive impact on the building (or building model), it is fixed on the seismic simulated shaking table and the seismic wave stimulation is carried out.

The seismic simulation shaking table is composed of a surface (the table); a servo actuator; an oil source; and a control system (

Figure 1). The table is driven by the servo actuators to move according to a predetermined seismic wave. The usual seismic simulation shaker has 6 degrees of freedom (3 line displacements and 3 torsional displacements). The shaking table test of buildings is usually conducted in two directions of horizontal vibration, which typically causes great damage to buildings. Video and sensors are used to record the vibration response of the building model on the shaking table, i.e., displacement, acceleration, stress, and strain, so that the vibration performance and seismic resistance of the building can be analyzed.

The basic parameters of the shaking table used in the test here are: table size 4 m × 4 m; vibration frequency range 0–100 Hz; maximum payload 30 tons; and maximum horizontal acceleration 1.0 g (g is gravitational acceleration 9.8 m/s2).

2.2. Seismic Waves Selecting

All seismic waves are selected according to the Chinese code: The Code for Seismic Design of Buildings (CSDB). According to the requirements of the code, the acceleration response spectrum of the selected natural seismic wave or artificial simulated seismic wave should be consistent with the standard response spectrum (available from CSDB) of the site where the building is located. This means that the value of seismic wave response spectrum should be close to the value of the standard response spectrum, usually with a deviation of no more than 5%. According to this requirement, different structures will use different seismic waves as the excitation of the shaking table test.

3. Shaking Table Test of Wood Structure Dwellings

3.1. Traditional Wa Stilted Wood Structure Dwelling of Weng Ding Ancient Village

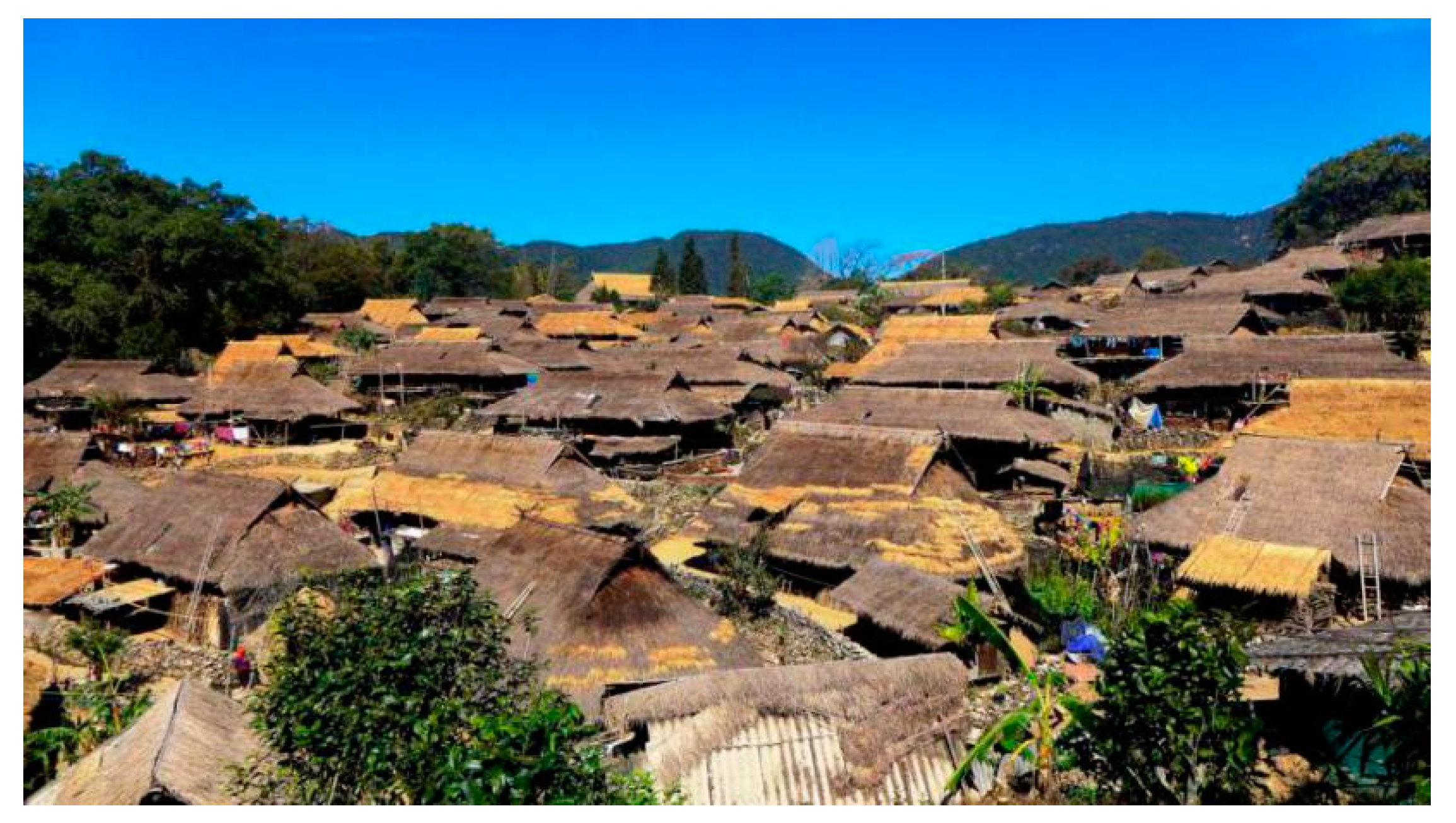

Weng Ding ancient village (

Figure 2 and

Figure 3) is located in Meng Jiao Town, about 40 kilometers from Cangyuan County, Yunnan province; it is a typical hill settlement of the Wa Nationality. The village still retains the original Wa ethnic dwellings of stilted wood structure, architectural style, and the original Wa ethnic customs, and is one of the most well-preserved primitive villages. The basic seismic fortification in this area is for accelerations of 0.3 g. In order to study the seismic performance of this type of dwelling [

11,

12], the actual house structure of an individual household was used as a prototype (

Figure 2 and

Figure 3). Local craftsmen were employed and traditional construction techniques, utilizing previously used timber from Weng Ding village, were used for constructing the full-scale (1:1) experimental model (

Figure 4,

Figure 5 and

Figure 6) in the KUST laboratory. The seismic response and failure modes of the structure were studied by using shaking table tests as previously described. The results provide a basis for establishing the seismic resistance and needs for reinforcement of such dwellings. As such and as mentioned earlier in the paper, the purpose of the testing is to identify initial earthquake response and modifications that ensure the dwelling can remain standing and, thus, support the sustainability of the villages and communities.

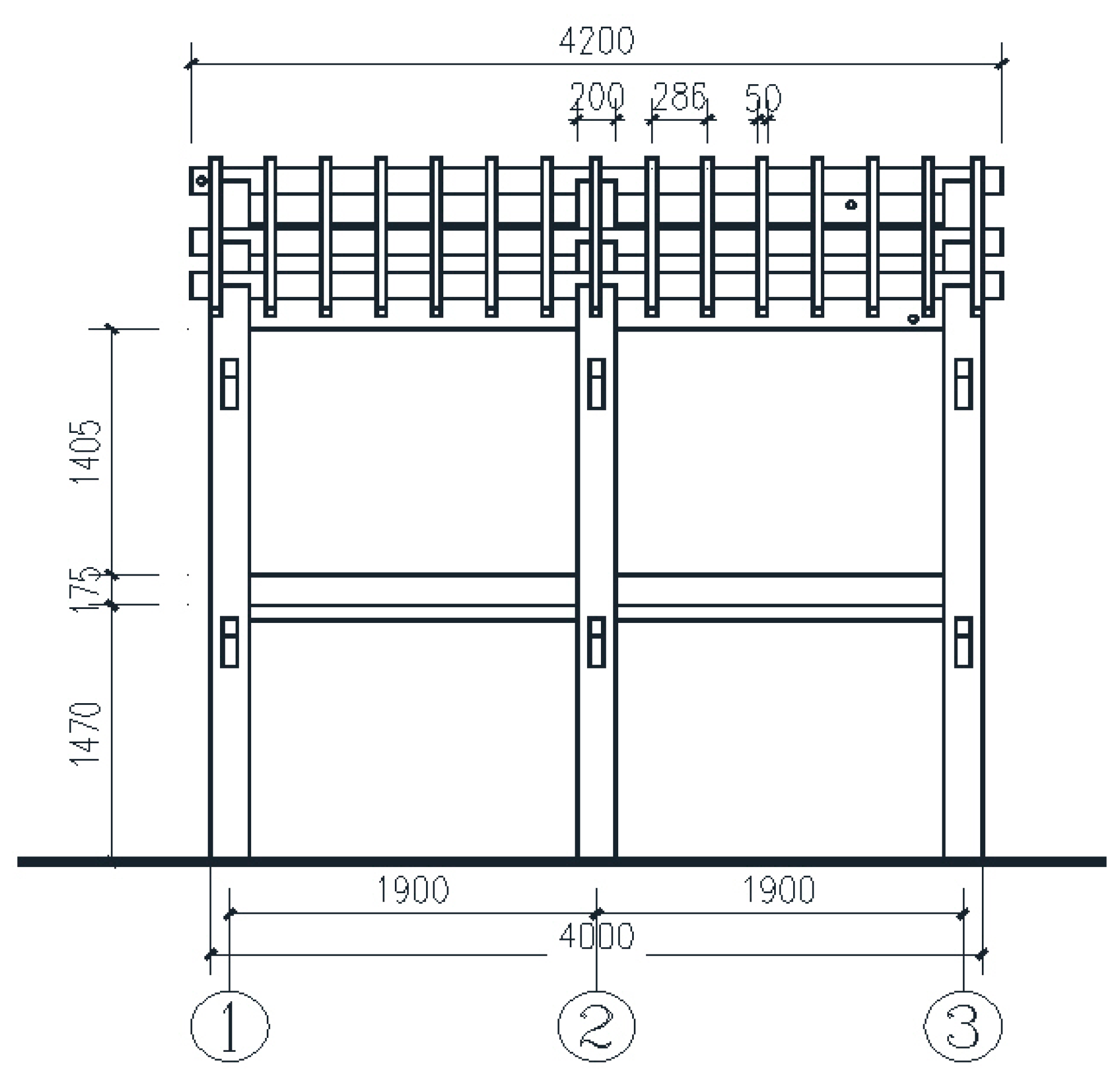

The 1:1 two-story model house was adopted for the prototype of a real timber frame house in the village. The total height is 6.45 m, and the depth and width size is 6.55 m by 5.35 m. For the prototype structure, no enclosure walls were installed as was the case on the lower floor of the actual building. In the real building, the upper floor walls are flat bamboo strips, and the sloping roof is covered with straw. However, for the model, it was concluded that no wall was necessary to be built on the upper floor because the addition of very weak stiffness and light weight of the bamboo strips would have little impact on the test. The timber beams and columns are connected by mortise and tenon joints. In line with the actual dwelling construction, the main section size of the column varied from 120 mm by 120 mm to 200 mm by 200 mm; the main section size of the horizontal member beam in the model was from 100 mm by 100 mm to 100 mm by 150 mm.

According to China’s load code for design of building structures, the standard value of live load on residential floors of civil buildings is 2.0 kNm

−2, and the standard value of live load on the roof is 0.5 kNm

−2. The composite coefficient of the floor live load is 0.5 under earthquake action, and the roof live load is not counted. In the specimen, 1.0 kNm

−2 of live load was applied to the first floor, and 0.45 kNm

−2 of additional constant load was applied to the roof. Stacking and binding sandbags were used to simulate the actual load of floors and roofs [

24,

25,

26]. Construction is illustrated in

Figure 4, and size details are illustrated in

Figure 5.

Due to the simple and relatively imprecise construction technology, the joints of the beam and column may become loose during earthquakes, as observed in previous field examinations. A simple strengthening measure was taken in the test model; this being the use of rake nails fixed at joints (

Figure 7).

Simulated artificial earthquake waves were used as input ground motions for the tests. The artificial earthquake wave was generated according to the acceleration response spectrum of the site the prototype structure was located in. The peaks of acceleration used were 0.11 g, 0.3 g, and 0.51 g, respectively. Results are reported later in the paper.

3.2. Traditional Wood Structure Dwellings Using Mortice and Tenon Joints

The traditional wooden structure houses in Yunnan are mostly constructed with mortise and tenon joints. On the basis of previous studies on the performance of timber members and frame joints, the shaking table test of the whole building was carried out to study its seismic performance. The test model was full-scale (1:1) with two layers of a traditional column-and-tie timber frame. The model referenced the “one seal” style house of Yunnan’s traditional wooden structure. “One seal” is a common form of residential architecture in Yunnan province based on a typical courtyard layout, which in plan has the appearance of a traditional Chinese seal. The overall size was 3.8 m (length) × 3.2 m (width) × 3.9 m (height). The specific dimensions are shown in

Figure 8 and

Figure 9. Connection of beam and column joints was of the mortise and tenon type. The column foots were placed in a box shaped steel plate bearings, and the sand bags were evenly paved on the floor and roof to simulate loads (

Figure 10) [

24].

El Centro and Kobe seismic waves were used as input ground motions. Several peak acceleration input conditions with the structural acceleration and seismic amplification under 0.07 g and 0.4 g peak acceleration cases were analyzed. The results are shown later.

4. Shaking Table Test of Modified Earth Structure Building

Earth building techniques traditionally use raw soil as the base material to build the main structural elements. Since soil is a widely available material, it has been used in construction since prehistoric times. It may be combined with other materials and then compressed and/or baked to add strength. According to the material, structure, and construction technology, earthen buildings are divided into: Mud brick underground courtyard houses (a particular form of earth shelter dwelling common in the Loess Plateau in China’s north), adobe buildings, rammed earth wall buildings, straw-mud wall buildings, and various houses made from earth.

There are still a significant number of earth structure houses in the rural areas of Yunnan, mainly built of raw earth or adobe. The raw soil is taken from the local area, and straw is usually added to increase the strength of the soil. Earth walls are usually artificially compacted.

Earth buildings obtain raw materials locally, are easy to construct and of low cost. They are traditionally considered to be warm in winter and cool in summer, thus saving energy. They are also more integrated with their natural surroundings and conducive to environmental protection and ecological balance. Therefore, this ancient architectural type still has value and a potential role to play in rural construction.

The seismic performance of ordinary earth dwellings (built of raw earth or adobe) is normally considered to be weak, and such buildings often experience considerable destruction and even complete collapse during earthquakes [

25,

26,

27]. This has forced engineers to search for effective improvements, and large numbers of modified walls have been tested and studied [

17]. Examples of modifications include: Small amounts of reinforced fiber and cement being added; mechanical ramming to improve the load-bearing capacity of the wall; and adding of ceramic aggregate to enhance the thermal insulation properties of the wall. Beneficially, the wall thickness of traditional rammed earth dwellings can be reduced from between 400–600 mm to 300 mm whilst also ensuring earthquake resistance and durability (tested in KUST Laboratory [

17]). In order to verify the benefits from these modifications on seismic performance, a seismic simulation shaking table test was performed.

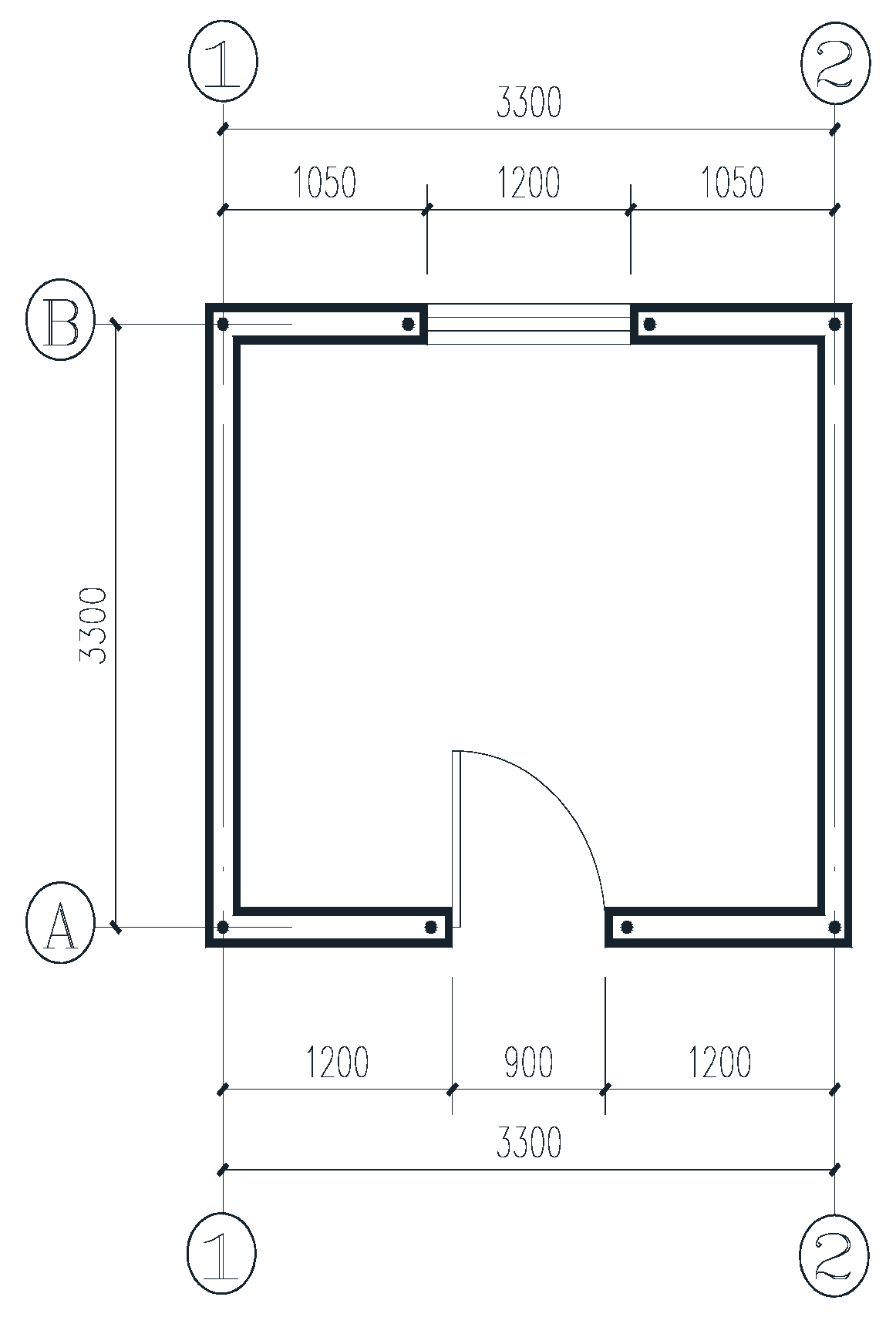

The length and width of the test house were 3 m and 3.6 m respectively, and the height was 2.45 m. The door width was 0.9 m, and its height was 1.8 m; finally, the window width was 1.2 m, and its height was 1.35 m. For basic reinforcement, a vertical steel bar (diameter 14 mm) was arranged on the corner of the wall and both sides of the door and window. The horizontal geo-grid was set up at the height of 0.8 m and 1.7 m along the wall. The flat roof was made of cast-in-place reinforced concrete with 20 MPa strength, and the ring beam of the roof was longitudinally equipped with 4 steel bars with a diameter of 10 mm. The stirrups were 6mm in diameter and 200 mm in spacing; the thickness of the rammed earth wall was 300 mm. The earth wall material had a mixture of 66.7% clay, 25% ceramsite sand (artificial foundry sand originating in China), and 8.3% ceramic sand by volume; in addition, 0.05% reinforcing fiber and 5% cement (dry matter weight ratio) were mixed therein. When the wall was rammed, the soil thickness of each filling was originally 100mm, which was then compacted to 50–70 mm thick. The related drawings are shown in

Figure 11,

Figure 12 and

Figure 13. The construction process and completed model are shown in

Figure 14 and

Figure 15.

El Centro and LuDian seismic waves were used as input ground motions. The peak acceleration input conditions were 0.10 g, 0.22 g, 0.4 g, 0.62 g and 0.90 g, respectively. The structural acceleration and seismic amplification under various input peak acceleration conditions were collated and analyzed. The results are tabulated later in the paper.

5. Results

5.1. Test Results and Analysis—Wa Stilted Wood Structure Dwelling

The results of Wa stilted wood structure are shown in

Table 2,

Table 3 and

Table 4. Through the observation of the vibration response of the structure during the test, the observation of the status of the components and connection between the structural members after the vibration was completed, and the analysis of the test data, the following conclusions can be drawn:

During the earthquake action of 0.3 g and 0.51 g, there was no obvious damage to the component, no obvious distortion, and no obvious damage to the node; the whole structure can be deemed to recover after the earthquake. Therefore, the structure can meet the requirements of China’s seismic precautionary criterion [

28,

29].

The column foot had a certain slip, but the maximum slip of the column foot was only 13% of the column section width, which is acceptable. The sliding of the column foot can provide a certain “isolation” effect and reduce the seismic response of the upper structure [

30]. It is suggested that the width of the plinth stone should be at least twice the width of the column.

The ductility of wood enables the structure to accept a large deformation without damage. The mortise and tenon joints still have the ability to recover even if the deformation is large. The compression between the members at each node under the action of the earthquake increases the frictional damping of the structure, and this can dissipate a portion of the seismic energy, effectively reducing the damage to the superstructure caused by the earthquake.

The dynamic response of the upper structure was obviously smaller due to the slippage of the column foot (the slippage happens even under the smaller peak of acceleration 0.11 g) and the relative deformation energy dissipation of the beam and column in the node area. When the earthquake acceleration was 0.51 g, the acceleration amplification factor on the floor was 0.552 in the X direction and 0.820 in the Y direction, which are each less than 1. This is different from conventional masonry and reinforced concrete structures, where the acceleration amplification factor is usually greater than 1 and acts to magnify the seismic impact.

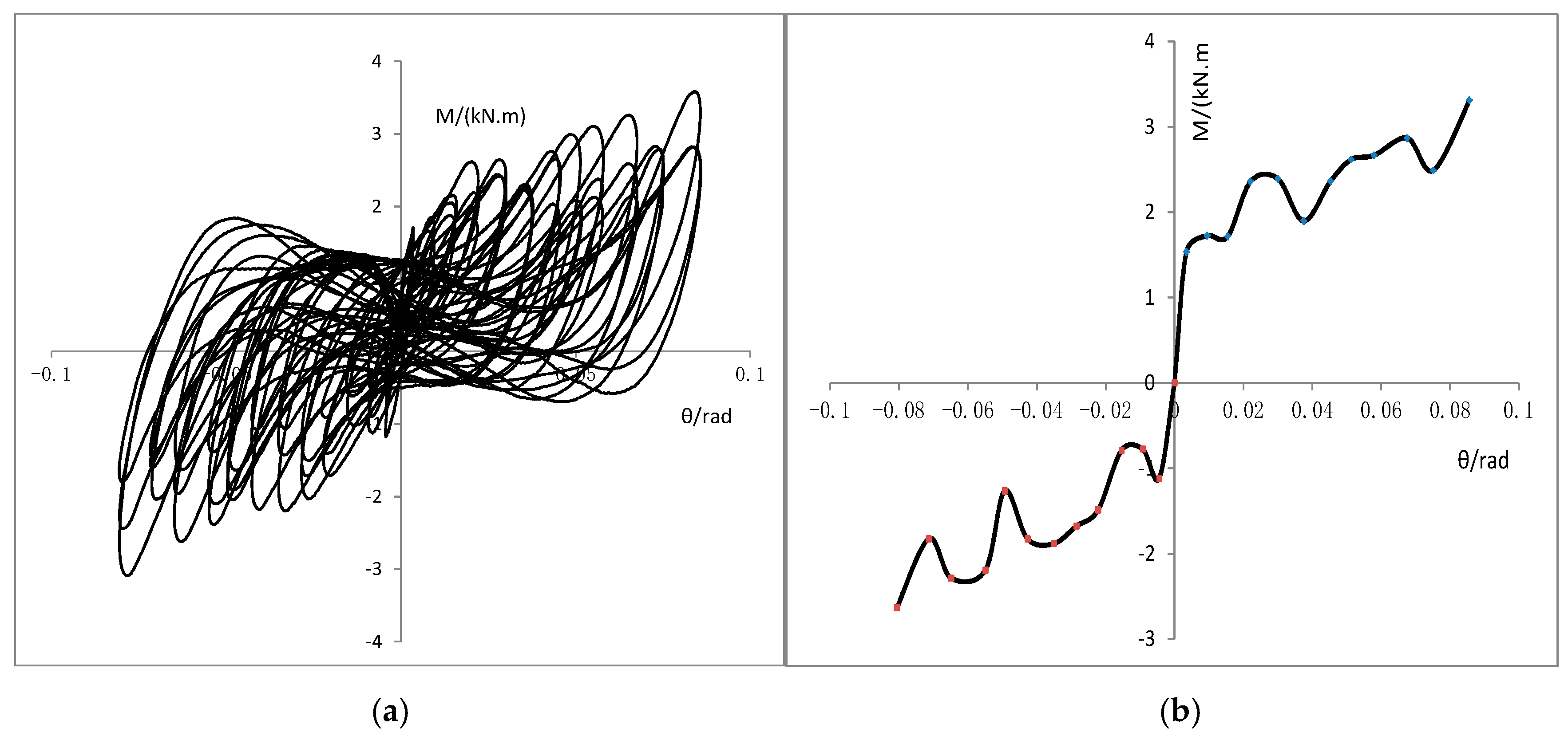

It is feasible to adopt rake nails and other flexible strengthening joints to ensure that the beam-column joints are not too loose at the time of an earthquake while at the same time having a certain rotational energy dissipation capability (

Figure 16), both of which are features that have been demonstrated in previous pseudo-static tests by the authors [

16]. As can be seen from the hysteretic loop curve and skeleton curve in

Figure 16, the area of the hysteretic loop as well as the turning angle increase as its moment

M increases. Even if the turning angle reaches 0.08 (far greater than the deformation requirement under the earthquake), the skeleton curve does not show a sharp decline, which indicates that the node bearing capacity does not significantly decline, and the node can still maintain a stable and satisfactory energy dissipation capacity.

5.2. Test Results and Analysis—Mortise and Tenon Wood Structure Dwellings

El Centro and Kobe seismic waves were used as input ground motions for this aspect of the study. The peak acceleration input conditions were 0.07 g, 0.2 g, 0.4 g, 0.62 g, and 0.95 g, respectively. The structural acceleration and seismic amplification under 0.07 g and 0.4 g peak acceleration cases were analyzed in further detail, and the results are shown in

Table 5 (some sensors are defective and data is incomplete under 0.2 g, 0.62 g, and 0.95 g).

It was observed that when the seismic acceleration is less than 0.4 g, the structure was not damaged and recovers well after vibration. However, under very intense earthquakes, with acceleration peaks of 0.62 g and 0.95 g, there was a slight pulling out/apart phenomenon and very slight splitting at some tenon and mortise joints (

Figure 17). The impact of this can almost be ignored; the structure, on the whole, still recovered well after the test, which means the bearing capacity and stiffness had not obviously declined. The frequency decrease in the direction of weaker structural stiffness mainly occurred in the first loading. After that, the frequency stability indicates that the structural damage was minimal (

Table 6); this is partly due to the rotating friction of the mortise and tenon joints allowing part of the seismic energy to be dissipated (similar to the Weng Ding village wood structures,

Figure 16). As for the acceleration amplification factor, it was generally larger than that of the Weng Ding wood structure. This occurred because the column feet were embedded with high strength mortar in square steel basins which are connected in a rigid way to the shaking table. It restricts the sliding of the column feet when the earthquakes occur, resulting in larger seismic amplification coefficient and a larger structural response [

30,

31].

5.3. Test Results and Analysis—Earth Structure Dwellings

Cracks that occurred were traced and measured (shown in

Figure 18 and

Figure 19). The structural acceleration and seismic amplification outputs occurring under various peak accelerations were collated and analyzed; the results are shown in

Table 7. The following conclusions can be drawn:

The cracks were mainly located on each side of the door and window and at the connection between the base and the wall and the corner of the house. The width of the cracks was between 0.5–3 mm, and the wall was not crushed or in a collapsed state.

When the structure remains intact during the earthquake, the acceleration of the upper part of the structure increases linearly when the seismic acceleration increases. That is, the amplification factor is basically constant. When the structure is damaged, the seismic energy cannot be effectively transferred to the upper part of the structure, and the acceleration growth of the upper structure will be less than the increase of the seismic acceleration, that is, the amplification factor decreases. The trend of amplification factor reflects the damage of structure: As the intensity of earthquake increases, its value generally decreases. It is shown that the vibration has difficulty in passing to the roof due to the structural wall damage. Considering the change of structural frequency (

Table 8), it can be seen that structural damage mainly occurs after the earthquake acceleration of 0.62 g. When the earthquake acceleration was 0.62 g and 0.9 g, the connection parts of the foundation and the wall were greatly damaged, and the relative slip phenomenon occurred (

Figure 20). This had a certain effect of isolation, so the numerical value of the dynamic magnification factor was greatly reduced.

The maximum inter-layer displacement angles in the X and Y directions were 1/423 (Lu Dian wave, 0.9 g) and 1/293 (El Centro wave, 0.62 g), respectively. There was no great damage to the structure after the earthquake. It can therefore meet the seismic fortification requirements of China’s standard which states after “frequent earthquakes buildings are basically intact; after basic earthquakes, buildings can be repaired; and after rare earthquakes, the building is not severely destroyed or collapsed”.

6. Discussion

The diversity of Yunnan’s ethnic minorities has contributed to the diversity of residential buildings. Since 2013, the central government has published an important guidance to improve investment and to accelerate transformation in rural areas in China. From different levels of the government administration system, funding has been allocated to support the development of small towns and villages. The National Standard for Creating Eco and Cultural Villages in China refers to aspects of the rural built environment, which includes: Safety of building structure, environmental air quality, waste water discharge, drinking water quality, and hygiene standards. There arose an important need to provide detailed guidance and scientific evidence to adapt the general generic regulations for the large diversity and variation of design and construction techniques found in rural areas. Key changes in the design briefs for rural developments have offered the opportunity to integrate sustainable building methods into that process.

In this paper, three experimental projects have been reported in relation to seismic performance. Though the number of options is modest, the effort required to build the full scale models is considerable, and, though there are certain limitations, the outcomes can provide an important reference for similar residential buildings. The potential number of village communities to which this might apply and the number of individual dwellings is very significant in this part of China and indicates the value of the research from a practical point of view.

The research direction of earthquake resistance and disaster reduction for dwellings should therefore consider the following key points:

Materials: Most of the materials of traditional dwellings come from natural rough processed materials which are environmentally friendly and renewable but have the disadvantage of poor resistance and ductility. There is a need to investigate how to improve the seismic performance of traditional materials by modifying them with new materials and technologies as well as ensuring that the appearance of materials is consistent with the style of traditional construction. In addition, the construction must be capable of repair and renewal as an essential aspect which requires future development [

12,

15,

17,

20,

22].

Construction technology: Modern construction and processing machinery have had a great impact on traditional dwelling construction methods and the technology used therein. This gives an opportunity to enhance the ability to resist earthquakes, such as the use of dynamic compaction machinery. This can greatly enhance the compactness of the earth wall to enhance the seismic bearing capacity. Therefore, it is necessary to explore and develop the use of modern machinery in the construction of residential buildings to improve the performance of the structure to enhance its seismic performance [

12,

17,

23].

Improvement in design specifications: Traditional dwelling design and construction techniques are mostly “teacher-inherited,” that is they are learned from previous generations. Whilst historically some people had gained some understanding of structural seismic methods from experience of previous earthquakes, this does not form an effective theoretical support mechanism. By using modern testing and analysis, the techniques that must be followed in the design of new residential buildings are perfected, and the executable samples and specifications are established to ensure their seismic capacity.

New seismic technology: The application of new seismic technology is inevitable for social development. For example, the application of new seismic energy dissipation and isolation technology has become much more mature in recent years. It can also be used for reference in the construction of residential buildings. This is a new direction and enables the study of sliding isolation in the foundation of residential buildings as a means to reduce the transmission of seismic forces to the superstructure. There is also the potential to install damping and energy dissipation devices in the superstructure to absorb seismic energy so as to reduce the vibration of the superstructure and protect the safety of buildings [

32].

7. Conclusions

According to the research above, the following conclusions can be drawn:

1. In the Wa nationality, both wooden structure dwellings with poor manufacturing technology and traditional wooden structure residences with better construction technologies have good seismic capacity embedded within their main structures. The results indicate that the main structure does not experience great damage or collapse under the earthquake situations simulated.

2. The joints of wooden structures can dissipate seismic energy well in an earthquake, thus protecting the main structure from significant damage and collapse.

3. The base of a sliding column foundation can introduce the effect of sliding isolation and reduce the vibration of the superstructure. The reason is that sliding equivalently reduces the lateral stiffness of structure, which reduces the earthquake force according to the response spectrum theory. Since the column foundation stone has sufficient size/width, the column will not slide out of position and will provide favorable anti-seismic performance.

4. The tests reported here indicate that appropriate modification of wall material and improvement of construction technique can add sufficient strengthening to ensure the safety of the rammed earth wall dwelling structure. This has so far been regarded as dangerous with large scale damage or collapse identified in previous earthquakes which occurred in Yunnan province. Meanwhile, features of ethnic residential buildings can be preserved, thus maintaining links to culture and history and supporting opportunities for tourism.

Author Contributions

Conceptualization: J.G. and Y.B.; methodology: J.G. and Y.B.; formal analysis: J.G., Y.B., and A.P.; investigation: J.G., Y.B., W.B. and Z.T.; resources: J.G. and Y.B.; data curation: J.G. and Y.B.; writing—original draft preparation: J.G. and Y.B.; writing—review and editing: J.G., Y.B., A.P. and Y.G.; visualization: J.G., Y.B. and Y.G.; administration: J.G., Y.B. and Y.G.; funding acquisition: J.G., Y.B., W.B., A.P., Y.G., Z.T.

Funding

This research was funded by The National Natural Science Foundation of China, grant number 51368027 and 51168025. The UK research aspects in the paper were facilitated through a Research Network funded by the Arts and Humanities Research Council, UK grant number AH/R004129/1.

Acknowledgments

This work was supported in part by Kunming Architectural Design and Research Institute, and Weng Ding Villagers provided the prototype timber frame and built the experimental houses.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, D.Y. From past discovery future, from future discovery past—The study and protection on traditional residence and its culture of Yunnan. J. Huazhong Archit. 2009, 19, 3–11. [Google Scholar]

- Yang, D.Y.; Zhu, L.W. Yunnan Dwellings; China Construction Industry Press: Beijing, China, 2009; Volume 12, pp. 1–11. [Google Scholar]

- Jiang, G.C. Ethnic Housing Culture in Yunnan; Yunnan University Press: Kunming, China, 2016; Volume 4, pp. 3–20. [Google Scholar]

- Gao, Y. The Dai Vernacular House in South China: Tradition and Cultural Development in the Architecture of an Ethnic Minority. Ph.D. Thesis, University of Edinburg, Edinburgh, UK, 1 August 1998. [Google Scholar]

- Gao, Y. Top-Down and Bottom-Up Processes for Rural Development and the Role of Architects in Yunnan, China. J. Build. 2016, 6, 47. [Google Scholar] [CrossRef]

- Pitts, A. Establishing Priorities for Sustainable Environmental Design in the Rural Villages of Yunnan, China. Buildings 2016, 6, 32. [Google Scholar] [CrossRef]

- Shi, P.J.; Guo, W.P.; Li, B.J.; Zheng, J.; Ye, T.; Wang, Y.; Liu, J. Disaster reduction and sustainable development: Adjustment of disaster reduction strategies of China based on “The 2nd World Conference on Disaster Reduction”. J. Nat. Disasters 2005, 14, 1–7. [Google Scholar]

- Uitto, J.I.; Shaw, R. Sustainable Development and Disaster Risk Reduction; Springer Nature: Tokyo, Japan, 2016. [Google Scholar]

- Pearson, L.; Pelling, M. The UN Sendai Framework for Disaster Risk Reduction 2015–2030: Negotiation Process and Prospects for Science and Practice. J. Extreme Events. 2015, 2, 1–12. [Google Scholar] [CrossRef]

- Yunnan Earthquake Prevention and Disaster Reduction. Available online: http://www.yndzj.gov.cn/ (accessed on 2 September 2018).

- Edward, N.; Wan, L.; Chi, X.A.; Bai, W.F. Post-earthquake Reconstruction Demonstration Project of Guangming Village, Zhaotong, China. J. World Archit. 2017, 3, 166. [Google Scholar]

- Bai, W.F.; Su, H.X. The technology about earthquake resisting adobe wall. J. Urbanism Archit. 2014, 25, 41–43. (In Chinese) [Google Scholar]

- Tao, Z.; Pan, X.Q.; Pan, W.; Yang, X.D.; Bai, Y. Mechanics Characteristics of Adobe of Rural Houses in Yunnan Province. J. Earthq. Resistant Eng. Retrofitting 2008, 30, 99–104. [Google Scholar]

- Gao, Z.N.; Yang, X.D.; Tao, Z.; Chen, Z.S.; Jiao, C.J. Experimental Study of Rammed-Earth Wall with Bamboo Cane under Monotonic Horizontal-Load. J. Kunming Univ. Sci. Technol. 2009, 34, 68–70. [Google Scholar]

- Tao, Z.; Tan, G.P.; Cao, J.; Dai, X.Y. Soil Test for Rammed Earth Wall of Rural Houses in Yunnan Province. J. Earthq. Resistant Eng. Retrofitting 2008, 30, 90–93. [Google Scholar]

- Lai, Z.C.; Chu, Q.Q.; Bai, Y.; Liu, Z.Z.; Feng, Y. Experimental investigation on joint seismic performance of the stilted wooden structures in Wengding ancient village. J. Build. Struct. 2016, 3, 39–43. [Google Scholar]

- Su, H.X.; Pan, W.; Bai, W.F.; Bai, Y.; Yang, X.D. Seismic behavior of new adobe walls structure. J. Civ. Archit. Environ. Eng. 2015, 37, 54–61. [Google Scholar]

- He, L.; Pan, W.; Yang, Z.H.; Tao, Z.; Meng, P. Seismic Damage and Seismic Countermeasures of Timber Houses in Villages and Towns. J. Earthq. Resistant Eng. Retrofitting 2006, 28, 94–101. [Google Scholar]

- Gao, Y.L.; Tao, Z.; Ye, L.Y.; Wang, D.; Zhang, L.X. Low-cycle reversed loading tests study on typical mortise-tenon joints of traditional timber building based on friction mechanism. J. Build. Struct. 2015, 36, 139–145. [Google Scholar]

- Xiao, R.; Yang, D.Y.; Li, W. On the Building Materials from Perspective of Residence in Yunnan Seismic Performance. J. New Archit. 2009, 1, 128–131. [Google Scholar]

- Xiao, D.F. The Fabricated Bamboo Building of Design Based on Anti-seismic Bamboo Wall Panel Technology. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 28 May 2015. [Google Scholar]

- Liu, Z.W. Experimental Study on Bamboo Cane Component of Bamboo and Wood Structure Used in Rural Houses of Yunnan Province. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 25 May 2012. [Google Scholar]

- Zhang, N. New Construction Technology of Bamboo Houses Node. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 28 May 2009. [Google Scholar]

- GB 50009—2012 Load Code for Design Building Structures; China Construction Industry Press: Beijing, China, 2012; Available online: https://ebook.chinabuilding.com.cn/zbooklib/bookpdf/probation?SiteID=1&bookID=61020 (accessed on 21 March 2018).

- Shi, Y.C.; Lin, X.W.; Wang, L.M. Earthquake damage characteristics of raw soil buildings in loess areas and disaster prevention counter measures. J. Nat. Disasters 2003, 12, 87–92. [Google Scholar]

- Tong, L.P.; Zhang, Y.X. Seismic response analysis for rammed earth buildings. J. World Earthq. Eng. 2009, 2, 36–40. [Google Scholar]

- Bu, Y.H.; Wang, Y.H.; Yin, Y. Study on seismic performance of raw-soil structure in China. J. Adv. Mater. Res. 2007, 4, 451–456. [Google Scholar] [CrossRef]

- GB 50011—2010 Code for Seismic Design of Buildings; China Construction Industry Press: Beijing, China, 2010; Available online: https://ebook.chinabuilding.com.cn/zbooklib/bookpdf/probation?SiteID=1&bookID=61744 (accessed on 12 July 2018).

- GB 50005—2017 Code for Design of Timber Structures; China Construction Industry Press: Beijing, China, 2017; Available online: https://ebook.chinabuilding.com.cn/zbooklib/bookpdf/probation?SiteID=1&bookID=105038 (accessed on 25 May 2018).

- Yao, K.; Zhao, H.T. Study on the mechanism of sliding friction shock isolation between timber column and plinth in historical buildings. J. Eng. Mech. 2006, 23, 127–131. [Google Scholar]

- Xue, J.Y.; Zhao, H.T.; Zhang, P.C. Study on the seismic behaviors of Chinese ancient wooden building by shaking table test. China Civ. Eng. J. 2004, 37, 6–11. (In Chinese) [Google Scholar]

- Zhou, F.L. Isolation, Energy dissipation and structural control system—The inevitable technical choice to terminate the earthquake disaster in urban and rural areas of China. J. City Disaster Reduct. 2016, 5, 1–10. [Google Scholar]

Figure 1.

Diagrammatic representation of the Shaking table system.

Figure 1.

Diagrammatic representation of the Shaking table system.

Figure 2.

Outlook over Weng Ding Village.

Figure 2.

Outlook over Weng Ding Village.

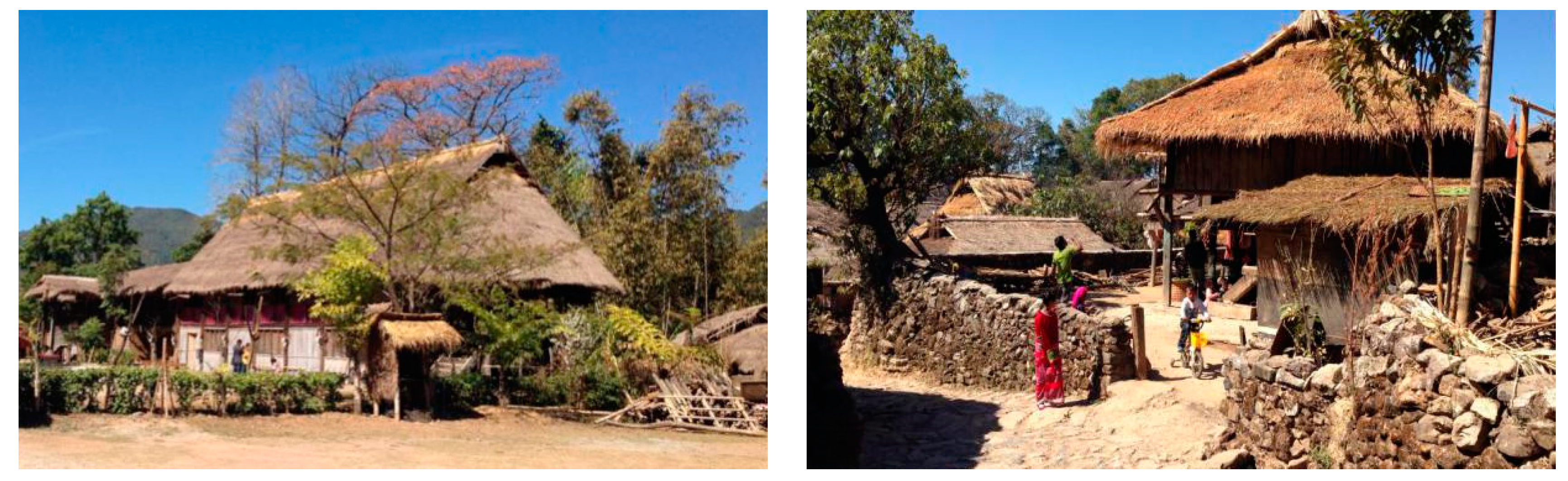

Figure 3.

Wing Ding dwelling view.

Figure 3.

Wing Ding dwelling view.

Figure 4.

Local craftsmen building the model.

Figure 4.

Local craftsmen building the model.

Figure 5.

Stilt building model size.

Figure 5.

Stilt building model size.

Figure 6.

Stilt test model—structure completed.

Figure 6.

Stilt test model—structure completed.

Figure 7.

Strengthened joint with rake nails. Note: (a) Strengthened joint; (b) The nail.

Figure 7.

Strengthened joint with rake nails. Note: (a) Strengthened joint; (b) The nail.

Figure 8.

Mortice and tenon building model—façade view.

Figure 8.

Mortice and tenon building model—façade view.

Figure 9.

Mortice and tenon building model—side elevation view.

Figure 9.

Mortice and tenon building model—side elevation view.

Figure 10.

Mortice and tenon test model—structure completed.

Figure 10.

Mortice and tenon test model—structure completed.

Figure 11.

Earth building test model—section.

Figure 11.

Earth building test model—section.

Figure 12.

Earth building test model—front elevation.

Figure 12.

Earth building test model—front elevation.

Figure 13.

Earth building test model—plan.

Figure 13.

Earth building test model—plan.

Figure 14.

Earth building test model—construction process.

Figure 14.

Earth building test model—construction process.

Figure 15.

Earth building test model—completed construction model.

Figure 15.

Earth building test model—completed construction model.

Figure 16.

The hysteresis curve of the joint moment-rotated angle. Note: (a) Hysteretic loop curve; (b) Skeleton curve.

Figure 16.

The hysteresis curve of the joint moment-rotated angle. Note: (a) Hysteretic loop curve; (b) Skeleton curve.

Figure 17.

Damages of joints. Note: (a) Pulling out; (b) Splitting.

Figure 17.

Damages of joints. Note: (a) Pulling out; (b) Splitting.

Figure 18.

Earth building test model—wall cracks after test (a).

Figure 18.

Earth building test model—wall cracks after test (a).

Figure 19.

Earth building test model—wall cracks after test (b).

Figure 19.

Earth building test model—wall cracks after test (b).

Figure 20.

Foundation sliding and damaged.

Figure 20.

Foundation sliding and damaged.

Table 1.

Earthquakes in Yunnan province of China from 2010–2017 (Data source: Yunnan Earthquake Prevention and Disaster Reduction [

10]).

Table 1.

Earthquakes in Yunnan province of China from 2010–2017 (Data source: Yunnan Earthquake Prevention and Disaster Reduction [

10]).

| Year | Number of Deaths | Number of Injured | Direct Economic Loss (Hundred Million RMB) |

|---|

| 2010 | 0 | 49 | No statistics |

| 2011 | 25 | 326 | 28.13 |

| 2012 | 85 | 1276 | 55.42 |

| 2013 | 3 | 107 | 28.83 |

| 2014 | 619 | 3609 | 298.84 |

| 2015 | 0 | 50 | 10.79 |

| 2016 | 0 | 4 | 1.356 |

| 2017 | 0 | 1 | 3 |

Table 2.

Stilt wood structure dwellings—acceleration and amplification factors.

Table 2.

Stilt wood structure dwellings—acceleration and amplification factors.

| Seismic Acceleration (g) | Floor Level |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor (g) | Acceleration (g) | Amplification Factor (g) |

| 0.11 | 0.0708 | 0.644 | 0.1079 | 0.981 |

| 0.30 | 0.1785 | 0.595 | 0.2406 | 0.802 |

| 0.51 | 0.2815 | 0.552 | 0.4182 | 0.82 |

| Seismic Acceleration (g) | Beam level |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor (g) | Acceleration (g) | Amplification Factor (g) |

| 0.11 | 0.0860 | 0.782 | 0.1352 | 1.229 |

| 0.30 | 0.2076 | 0.692 | 0.2949 | 0.983 |

| 0.51 | 0.3024 | 0.593 | 0.6467 | 1.268 |

| Seismic Acceleration (g) | Roof level |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor (g) | Acceleration (g) | Amplification Factor (g) |

| 0.11 | 0.1132 | 1.029 | 0.1297 | 1.179 |

| 0.30 | 0.2424 | 0.808 | 0.3072 | 1.024 |

| 0.51 | 0.4498 | 0.882 | 0.4947 | 0.97 |

Table 3.

Stilt wood structure dwellings—slip of column foot.

Table 3.

Stilt wood structure dwellings—slip of column foot.

| Seismic Acceleration (g) | 0.11 | 0.3 | 0.51 | 0.11 | 0.3 | 0.51 |

|---|

| Slip Distance | X-direction Slip (mm) | Y-direction Slip (mm) |

|---|

| Column 1 | 3.75 | 15.42 | 19.15 | 2.82 | 8.10 | 13.67 |

| Column 2 | 3.20 | 17.85 | 25.98 | 2.98 | 7.68 | 12.16 |

Table 4.

Structural frequency after each earthquake input.

Table 4.

Structural frequency after each earthquake input.

| Seismic Acceleration (g) | Before Test | 0.11 | 0.30 | 0.51 |

|---|

| X-direction (Hz) | 1.465 | 1.221 | 1.099 | 0.977 |

| Y-direction (Hz) | 1.465 | 1.221 | 1.221 | 1.221 |

Table 5.

Wood structure dwellings—acceleration and amplification factors.

Table 5.

Wood structure dwellings—acceleration and amplification factors.

| Earthquake Wave | Earthquake Acceleration (g) | Column Top of Lower Floor |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor | Acceleration (g) | Amplification Factor |

| El Centro | 0.07 | 0.10110 | 1.474 | 0.06332 | 0.923 |

| 0.4 | 0.48797 | 1.245 | 0.30830 | 0.786 |

| Kobe | 0.07 | 0.10862 | 1.583 | 0.08857 | 1.291 |

| 0.4 | 0.69093 | 1.763 | 0.37693 | 0.962 |

| Earthquake Wave | Earthquake Acceleration (g) | Column Top of Upper Floor |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor | Acceleration (g) | Amplification Factor |

| El Centro | 0.07 | 0.12661 | 1.846 | 0.09862 | 1.438 |

| 0.4 | 0.54028 | 1.378 | 0.52156 | 1.331 |

| Kobe | 0.07 | 0.12777 | 1.863 | 0.13706 | 1.998 |

| 0.4 | 0.46317 | 1.182 | 0.37486 | 0.956 |

| Earthquake Wave | Earthquake Acceleration (g) | Roof Ridge |

| X-direction | Y-direction |

| Acceleration (g) | Amplification Factor | Acceleration (g) | Amplification Factor |

| El Centro | 0.07 | 0.13687 | 1.995 | 0.09920 | 1.446 |

| 0.4 | 0.70398 | 1.796 | 0.55125 | 1.406 |

| Kobe | 0.07 | 0.16966 | 2.473 | 0.14998 | 2.186 |

| 0.4 | 0.86409 | 2.204 | 0.45716 | 1.166 |

Table 6.

Structural frequency after each earthquake input.

Table 6.

Structural frequency after each earthquake input.

| Seismic Acceleration (g) | Before Test | 0.07 | 0.20 | 0.40 | 0.62 |

|---|

| X-direction (Hz) | 2.441 | 2.197 | 2.197 | 2.197 | 2.197 |

| Y-direction (Hz) | 3.662 | 3.662 | 3.662 | 3.418 | 3.418 |

Table 7.

Earth structure dwellings—roof acceleration and amplification factors.

Table 7.

Earth structure dwellings—roof acceleration and amplification factors.

| Earthquake Wave | Earthquake Acceleration (g) | X-direction | Y-direction |

| Acceleration (g) | Amplification Factor | Acceleration (g) | Amplification Factor |

| El Centro | 0.10 | 0.135 | 1.35 | 0.139 | 1.39 |

| 0.22 | 0.2574 | 1.17 | 0.2618 | 1.19 |

| 0.40 | 0.48 | 1.20 | 0.444 | 1.11 |

| 0.62 | 0.7068 | 1.14 | 0.6634 | 1.07 |

| Lu Dian | 0.10 | 0.149 | 1.49 | 0.159 | 1.59 |

| 0.22 | 0.2772 | 1.26 | 0.3234 | 1.47 |

| 0.40 | 0.484 | 1.21 | 0.412 | 1.03 |

| 0.62 | 0.775 | 1.25 | 0.6758 | 1.09 |

| 0.90 | 1.008 | 1.12 | 0.99 | 1.10 |

Table 8.

Structural frequency after each earthquake input.

Table 8.

Structural frequency after each earthquake input.

| Seismic Acceleration (g) | Before Test | 0.100 | 0.220 | 0.400 | 0.620 | 0.900 |

|---|

| X-direction (Hz) | 4.883 | 4.883 | 4.883 | 4.883 | 4.150 | 3.906 |

| Y-direction (Hz) | 6.836 | 6.836 | 6.836 | 6.836 | 5.895 | 5.895 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).