1. Introduction

Manufacturing industries account for a large amount of resource consumption and waste generation all over the world [

1]. Stakeholders and regulatory agencies put pressure on manufacturing firms to be sustainable due to the warnings about global warming and social issues [

2,

3,

4]. With increasing demand from stakeholders for firms to be environmentally and socially responsible, firms have become aware of the strategic role of sustainable performance for a competitive advantage [

5,

6]. A number of studies have proposed that the adoption of lean manufacturing can improve firms’ environmental [

7,

8], social [

9,

10], and financial performance [

11,

12].

Lean manufacturing refers to “a methodology designed to lower the costs involved in production with a view to minimizing waste” [

13]. Snee [

14] defined lean manufacturing as “a business strategy and methodology that increases process performance resulting in enhanced customer satisfaction and improved bottom line results.” Research has shown that lean manufacturing significantly improves the operational performance of firms [

15]. Lean manufacturing is formed from different practices [

16]. Researchers and practitioners have tried to find the best lean manufacturing practices. They have suggested various best lean practices for different industries, including the electronics industry [

17], the ceramic industry [

18], the aerospace industry [

19], and the automotive industry [

20]. Panizzolo [

21] categorized lean practices into six main areas, namely process and equipment, manufacturing planning and control, product design, human resources, customer relationships, and supplier relationships, and previous studies have shown that these six areas fit well in various industries [

22].

Several studies have investigated the relationships between overall lean manufacturing and environmental performance [

23,

24] and financial performance [

25,

26]. These studies suffer from two limitations. First, the impact of lean manufacturing on the sustainable performance of firms, including environmental, social, and economic aspects of sustainability simultaneously, has received less attention in the literature. To compete in the current competitive market, manufacturing firms should balance their environmental, economic, and social performance [

27]. As such, these manufacturers need to know the lean practices that have positive effects on all three aspects of sustainability, and not only one aspect. Second, most of the previous studies have tested the impact of overall lean manufacturing on firm performance [

23,

25]. As lean manufacturing practices are diverse in different areas of a firm, investigations of the relationship between these practices and sustainable performance provide a clear picture of the practices that have the best effect on firms’ sustainable performance. Thus, this study investigates the effect of lean manufacturing practices on sustainable performance.

To successfully transform towards lean manufacturing, companies must develop a lean culture, which is a time-consuming process [

20,

28]. Lean culture could be viewed as an organizational culture and refers to the employees’ awareness of lean practices, combined with the real things that are done [

29]. The spread of lean culture among employees can assist management in implementing lean manufacturing practices effectively and efficiently and consequently in achieving lean manufacturing aims. Womack and Jones [

30] found that waste reduction and continuous culture were prerequisite factors for achieving the aim of lean manufacturing. Although previous studies have highlighted the important role of lean culture in the implementation of lean practices, to the best of our knowledge, there is a lack of study on the role of lean culture in strengthening the impacts of lean practices on sustainable performance. As the organizational culture of manufacturing firms varies [

31,

32], testing the moderating effect of lean culture helps to generalize the results and achieve more accurate findings. Furthermore, the results of studies on the impact of lean manufacturing on financial and environmental performance are inconsistent in the literature. For example, although Bergmiller and McCright [

33] and Dues et al. [

34] found a positive relationship between lean practices and environmental performance, Carvalho et al. [

35] found no relationship between these two concepts. Lean culture may explain the difference between success and failure in achieving the sustainability aim of lean implementation. As such, to fill this gap, in the present study the moderating effect of lean culture is investigated.

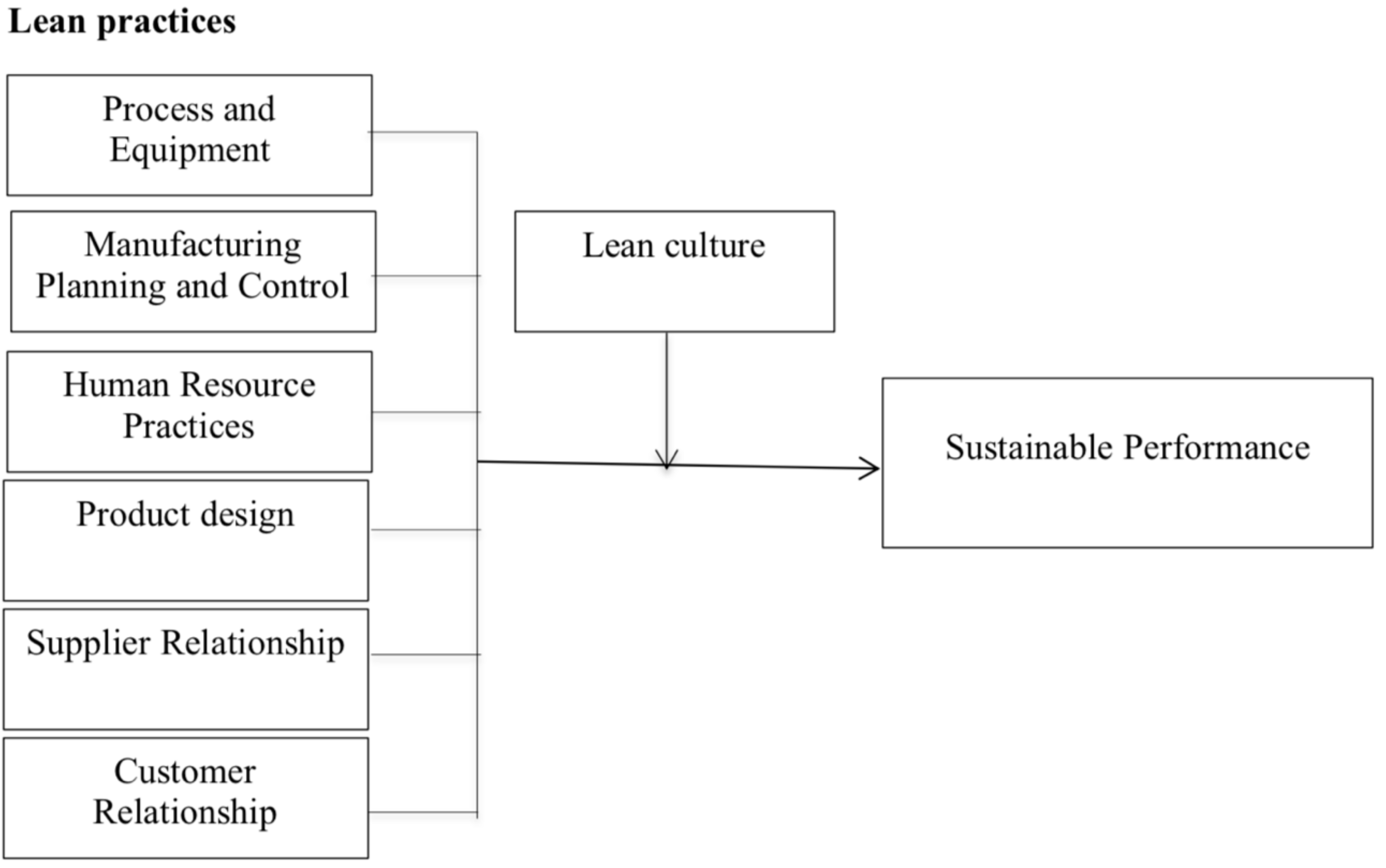

This paper contributes to the literature in two ways. First, a conceptual framework was developed linking the six lean practices and sustainable performance of the manufacturing firms. Second, we empirically assessed the moderating effect of lean culture on the relationship between lean manufacturing practices and environmental performance. Such a moderating effect has not been assessed in the literature and is important to refine our conceptual understanding of the linkage between lean manufacturing practices and sustainable performance. The paper also has a managerial contribution, because its results can guide managers in adopting suitable lean practices to enhance their firms’ sustainable performance.

6. Discussion

The significant impact of process and equipment on sustainable performance is in line with the findings of studies conducted by Panizzolo [

21] and Bergmiller [

22], who claimed that over-processing and the resultant machinery usage results in a waste of energy and resources and also increases the generation of emissions. Some practices, including cycle time reduction, shortening set-up times, order and cleaning (5S approach), and the use of “error proof” equipment are required to create the regular and uniform flow within production processes [

21]. Value stream mapping through fewer defects, lower energy usage, and less scrap across the company increases the environmental benefits of lean manufacturing. The 5S approach provides a methodology for better sustaining, developing, cleaning, and organizing of the work environment, which leads to quicker identification of leaks and spills and reduction in chemicals and materials usage. Furthermore, lowering inventories means that less floor space is needed, which will lead to lower energy usage [

57]. Therefore, manufacturing firms can improve their sustainable performance by implementing process and equipment practices.

The results showed that manufacturing planning and control practices have no significant effect on sustainable performance. One potential reason for this non-significant relationship might be due to some negative impacts of these practices on the environment which trade off against their positive impacts. For example, according to King and Lenox [

43], lot size reduction as a manufacturing and control practice needs frequent changeover, which leads to more disposal of unused process material and also causes higher pressure on employees. According to Biggs [

98], the side-effects of planning and control practices, such as Kanban and visual control, are more than their benefits to the environment. In contrast to the findings of King and Lenox [

43] and Biggs [

98], Fliedner [

57] believes that manufacturing planning and control practices, such as the pull approach, may reduce post-process and in-process inventory, which leads to fewer damaged products and consequently to sustainable performance improvement. Vinodh et al. [

60] also highlighted proper waste management and chemical handling as the consequences of visual control, which contribute to environmental performance. Waste reduction and energy saving can lead to higher financial performance. EPA [

99] also indicated that enhancement of the work environment for employees is one of the consequences of waste reduction goals in lean practices.

The relationship between human resource practices and sustainable performance was not supported. This result is not consistent with King and Lenox’s [

43] findings, which indicated that human resource practices lead to lower pollution and waste generation. The important role of workers in preventing pollution was also highlighted by Florida [

62]. The team approach, comprising engineers, managers, and production workers, can play a critical role in the reduction of wastage and improving environmental outcomes [

62]. Rothenberg et al. [

24] also supported the importance of human resource policies and mentioned that involving employees in environmental practices and providing them with environmental education and training will lead to environmental efficiency. They explained the rationale for this relationship and stated that trained workers have better understanding of materials and have the ability to propose appropriate solutions which will lead to less material wastage. Regarding the social perspective, according to Womack et al. [

100], involving employees in problem-solving activities and work function diversification has a positive effect on the work environment. However, some other studies have shown that human resource practices have a negative effect on employees due to higher work pressure as a result of more responsibility and a higher degree of standardization [

101]. As such, the positive and negative effects of lean human resource practice offset each other and consequently the results show no relationship between lean human resource practice and sustainable performance.

The findings of the study confirmed the positive relationship between product design and sustainable performance. Product design practices with the main aim of eliminating unnecessary process steps and simplifying the production process [

64,

102] can contribute to optimization or resource usage and enhance the levels of quality and efficiency by decreasing non-value-adding activities and wastage throughout the entire process [

66] and may also lead to reduced work pressure. To prevent waste generation, companies implement product design practices [

67] and as King and Lenox [

43] stated, the main focus of methods to reduce environmental impact is on waste elimination.

According to the results, supplier relationship practices also have a positive effect on sustainable performance. This result is consistent with Florida’s [

62] finding of supplier relationship as a driver of environmental performance. According to Shah and Ward [

68], supply management practices eliminate waste of excess capacity and excess inventory by diminishing the variability in supply. Working closely with suppliers from the early stages of product development will help to enhance process quality and reduce waste. The exchange of knowledge through collaboration may enhance suppliers’ capability to meet the requirement of social standards in the industry, especially for those suppliers with limited resources and lack of both knowledge and awareness of social issues. Furthermore, supplier relationships can also enhance firms’ reputation in the eyes of suppliers and customers [

103]. A long-term relationship with suppliers enables the manufacturer and supplier to share technologies, rewards, and risk and consequently to achieve higher operational and financial performance. Involving suppliers in product design and development and paying attention to their concerns and feedback can indicate a firm’s responsibility toward ethical business [

103]. Previous studies have also shown a positive relationship between supplier relationships sand firms’ financial performance [

104,

105].

The results confirm that customer relationships have a positive effect on sustainable performance. Florida [

62] also emphasized the critical role of customers in pushing firms to be environmentally friendly. Florida [

62] showed that the customer relationship is one of the drivers of the adoption and diffusion of environmentally conscious manufacturing practices. A good relationship with customers and meeting their requirements is essential to satisfy them and compete with the firm’s competitors. As such, customer demands for social and environmental practices can explain the relationships between social and environmental strategies and the financial performance of firms [

62]. Meeting customers’ social and environmental demands will enhance customer satisfaction and consequently will lead to higher financial performance.

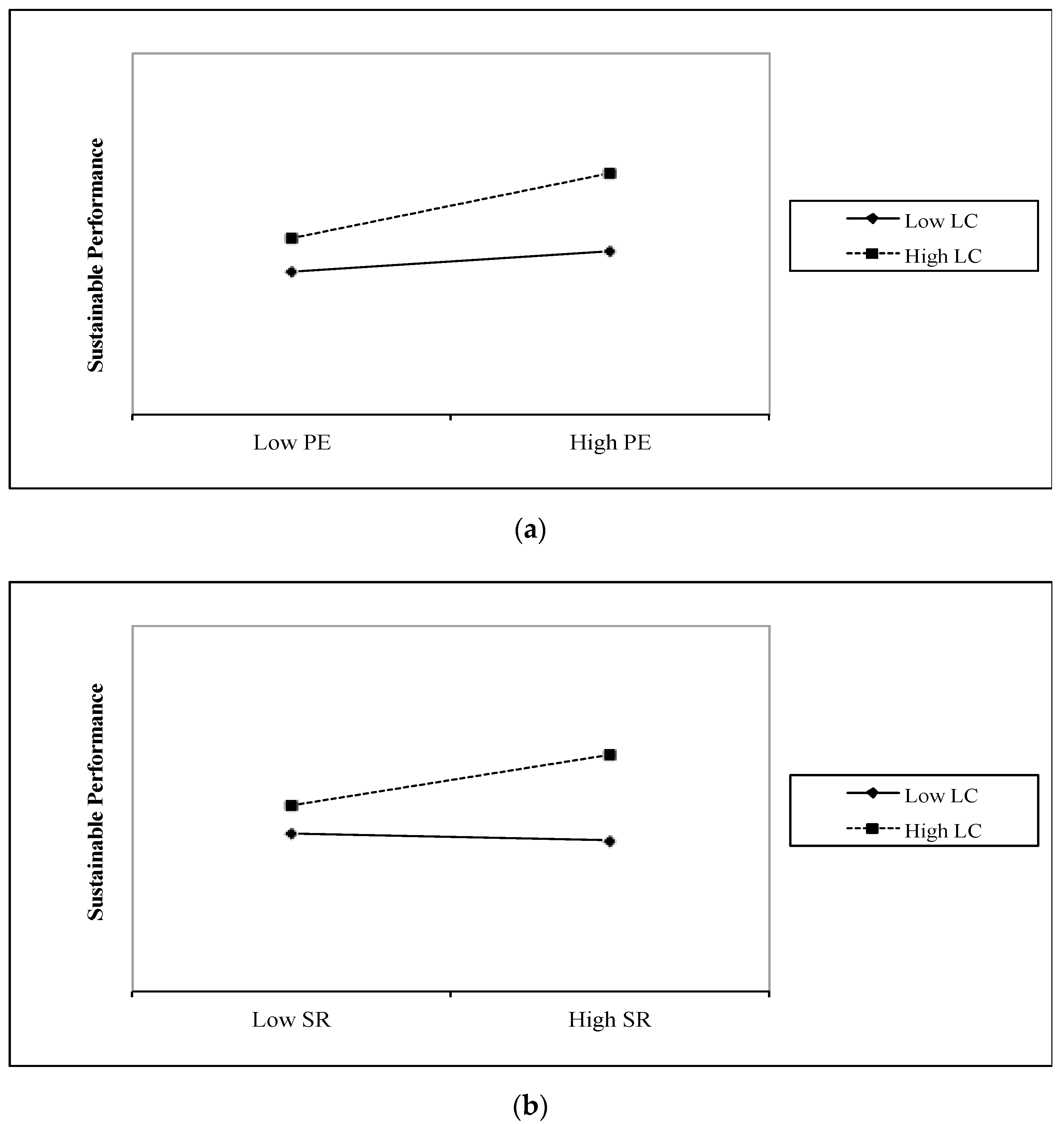

As highlighted by Bhasin and Burcher [

28], in order to successfully implement lean manufacturing practices, the development of a lean culture is needed. Therefore, a lean culture is essential for the implementation of lean manufacturing practices and for better sustainable performance. Thus, the study proposed that lean culture may interact with lean practices and enhance their effects on the sustainable performance of manufacturing firms. The results show that lean culture moderates the relationships between process and equipment practices and supplier relationship practices and sustainable performance. These results imply that, by having a stronger lean culture in the firm, the effects of the process and equipment practices and supplier relationships on sustainable performance will be higher. Hence, it is crucial for managers of manufacturing firms to do the necessary work to enhance their employees’ awareness toward lean practices, to create a lean workplace, and to make lean practices a norm for all employees. The moderating effect of lean culture on the effects of process and equipment practices and supplier relationship practices on sustainable performance was significant because, in comparison to other lean manufacturing practices, implementing process and equipment practices and establishing long-term relationships with suppliers require greater involvement from both top management and employees. Furthermore, another potential reason why most of the hypotheses on the moderating effect of lean culture are not significant could be due to the fact that lean culture is still at a very early stage among manufacturing firms in Malaysia. This is supported by Zailani et al. [

75], who stated that in the early stage of its development, an organizational culture cannot show its real power in successful strategy implementation.

7. Conclusions

The aim of this study was to identify the relationship between lean manufacturing practices and the sustainable performance of manufacturing firms in Malaysia by considering lean culture as a moderator. Our findings suggest that process and equipment, product design, supplier relationships, and customer relationships have a positive and significant effect on sustainable performance. Moreover, the moderating effect of lean culture was confirmed by the effects of process and equipment and supplier relationships on sustainable performance.

The findings of this study have practical contributions for the managers of manufacturing firms. They can understand the lean manufacturing practices that may enhance the sustainable performance of manufacturing firms. The results are especially useful in helping manufacturing firms’ managers to revise the current lean manufacturing model by considering the selected lean manufacturing practices, which make a greater contribution to the sustainable performance of firms. The significant effects of process and equipment, product design, supplier relationships, and customer relationships on environmental performance suggest that these practices should be integrated to improve the current sustainable performance of the firm, as they have positive, significant effects on sustainable performance. In addition, managers should give special attention to lean culture development in order to enhance the impacts of process and equipment practices and supplier relationships on sustainable performance. From an academic perspective, this study extends the literature on lean manufacturing by recognizing the role of lean manufacturing practices in enhancing firms’ sustainable performance. The study also extends the literature by testing the impacts of interactions between lean culture and lean manufacturing practices on sustainable performance.

Although the study meets its objectives, there are certain limitations that need to be considered in terms of generalizing its findings. First, the study is cross-sectional in nature and cannot show the dynamic nature of sustainable performance. As such, a longitudinal study is needed to provide a better picture of the extent to which lean manufacturing practices affect sustainable performance. Furthermore, the study sample is limited to Malaysia and the data were collected from different industries. Future studies can test the conceptual framework of this study in other countries, which will help to generalize the results. Furthermore, future research needs to limit the target population to a specific industry, as the relationship between lean manufacturing practices and sustainable performance may depend on the industry in which manufacturing firms operate.