Circular Economy in Russia: Drivers and Barriers for Waste Management Development

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

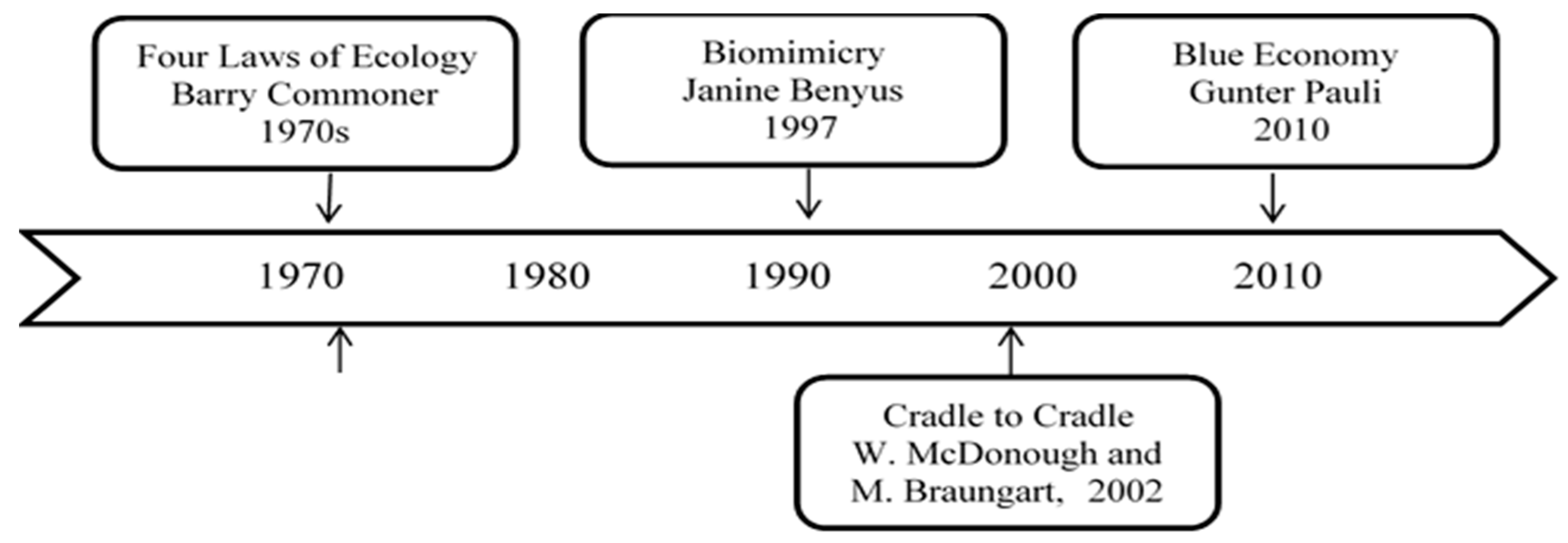

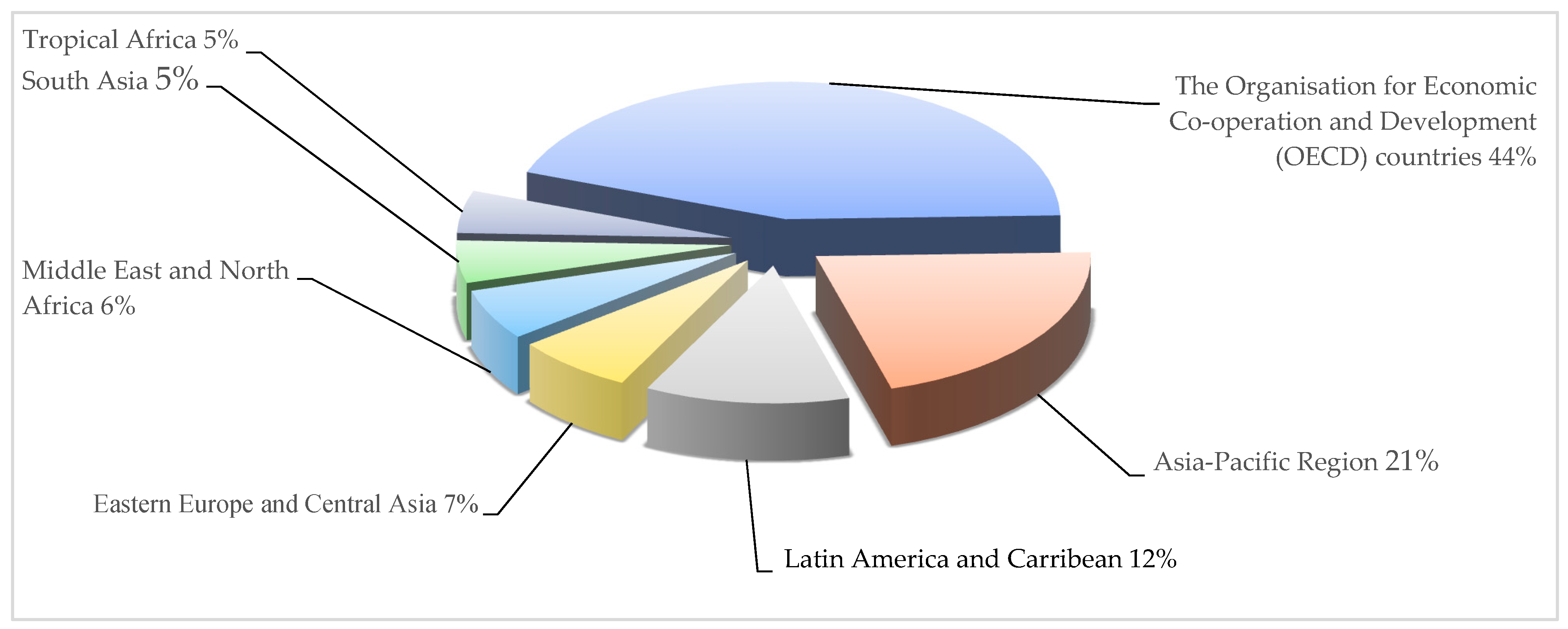

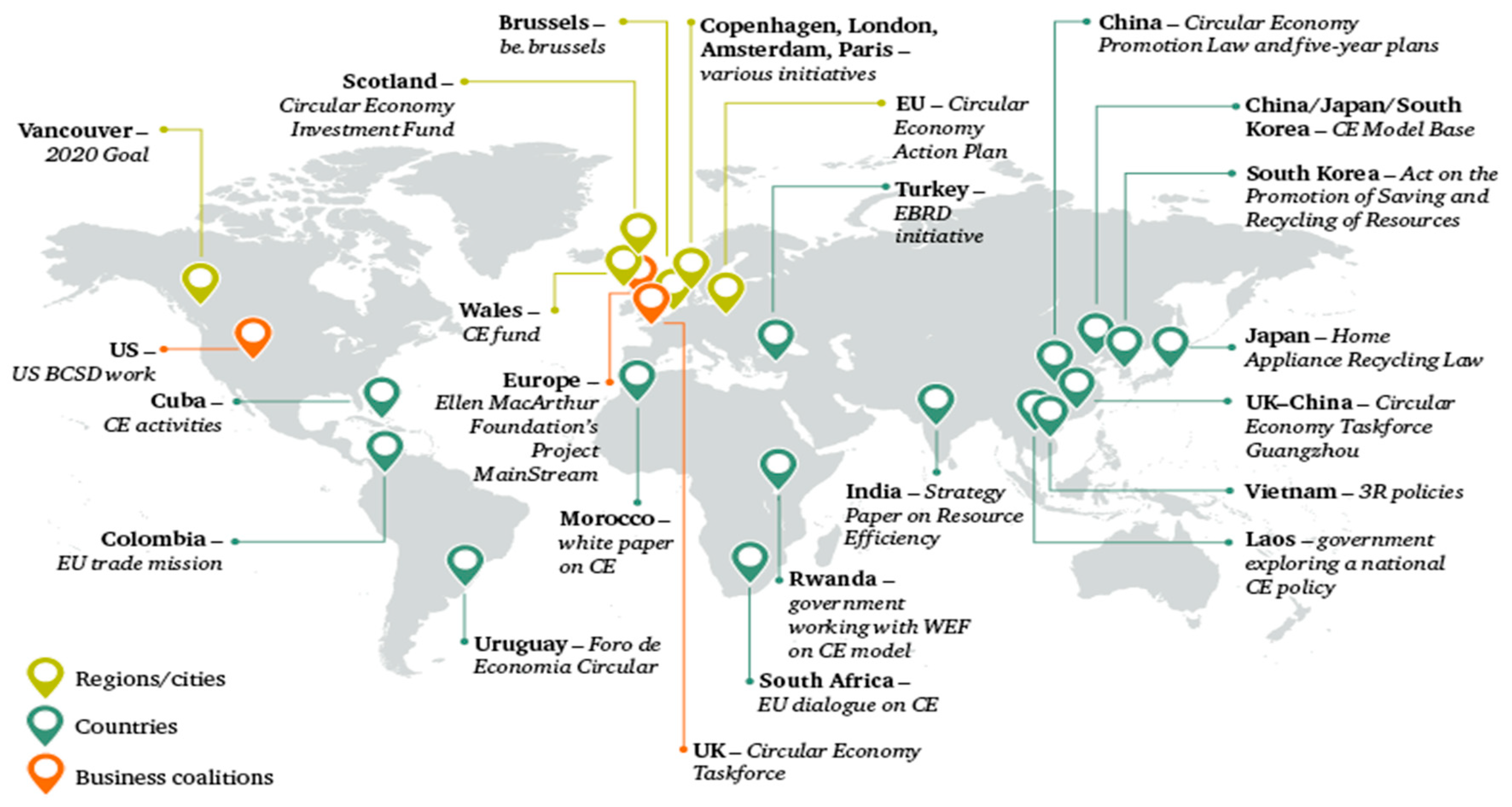

3.1. Global Movement toward the Circular Economy

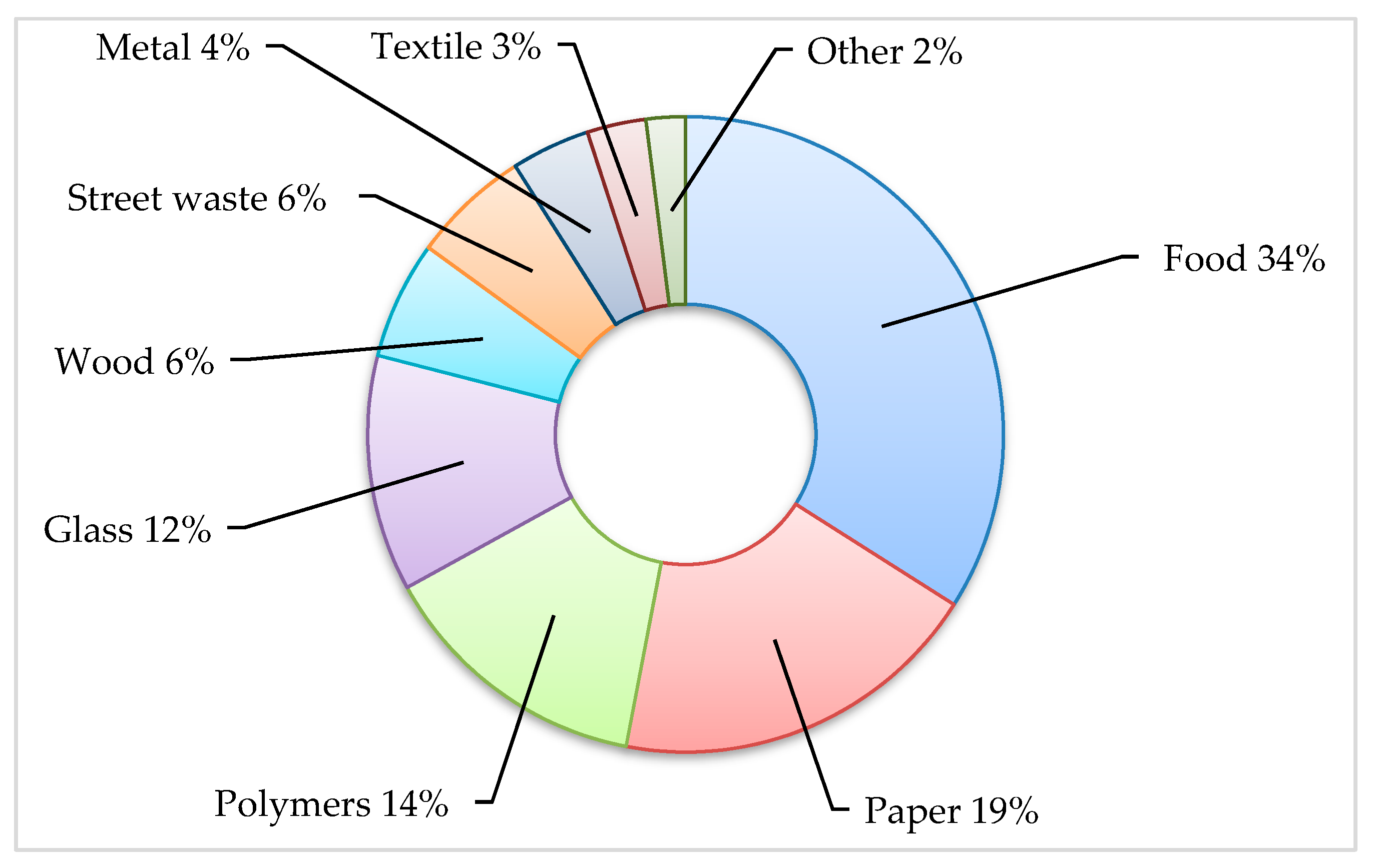

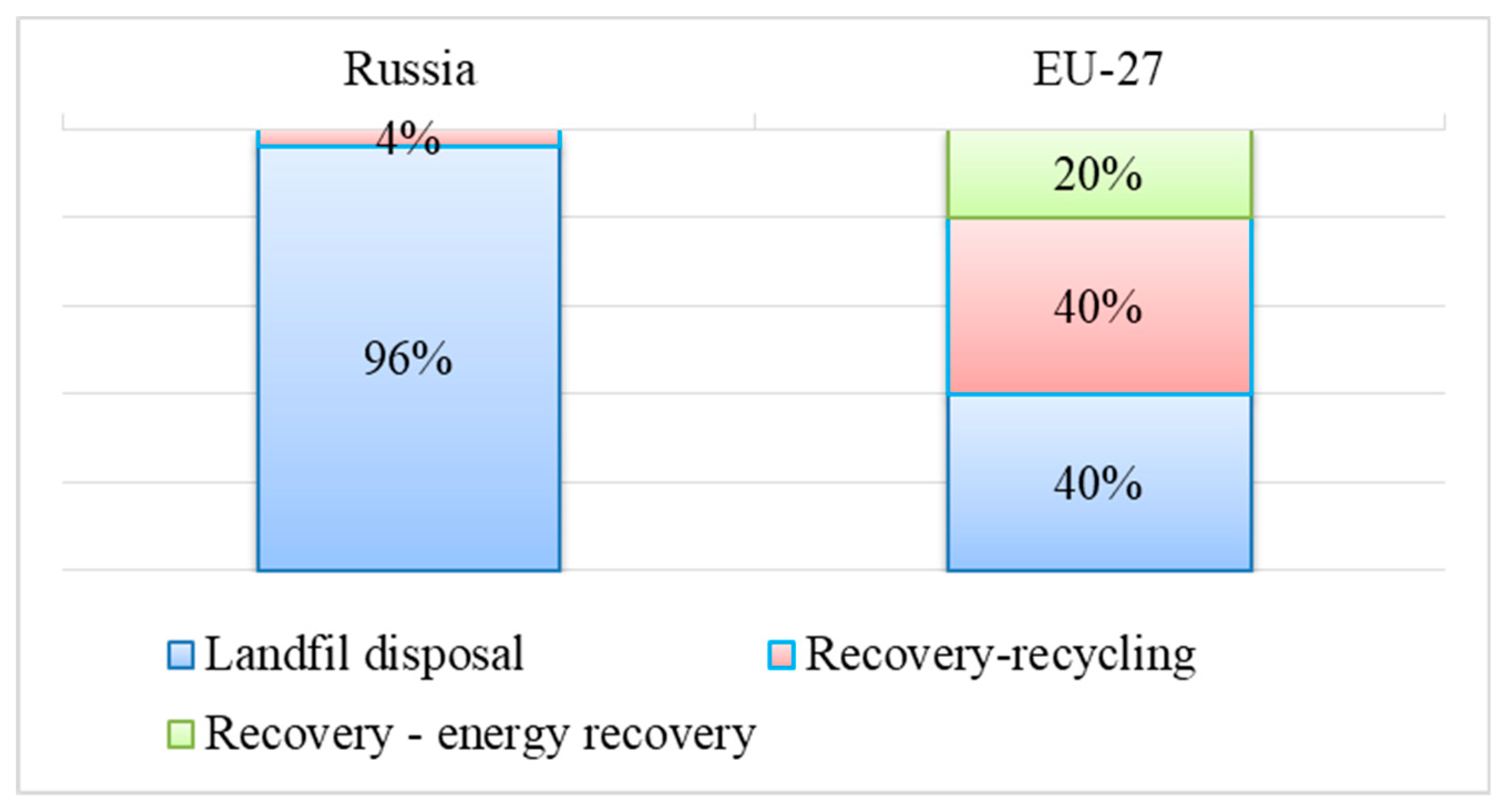

3.2. Current Waste Management Situation in Russia

3.3. Background of CE in Russia

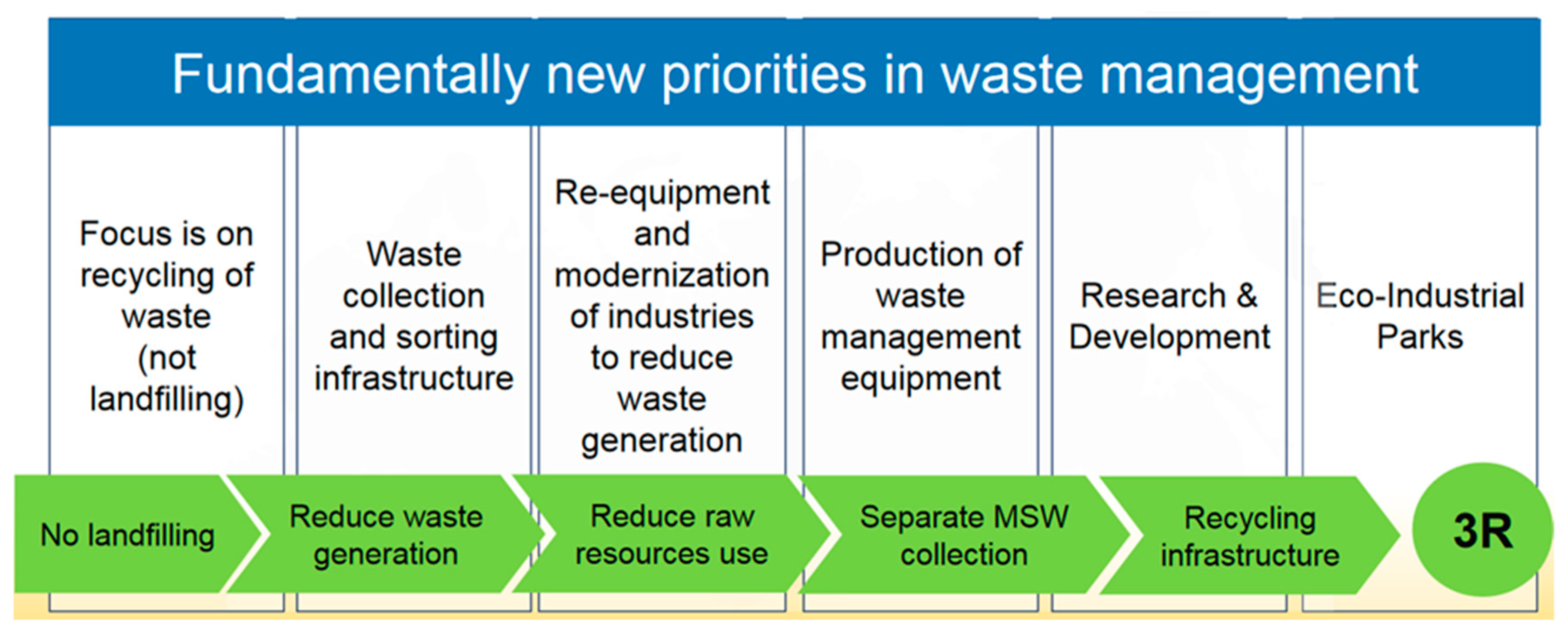

3.4. Reforming Waste Management in Russia

- MSW management based on a closed-cycle economy;

- Stimulate production from secondary material resources;

- Implement a separate collection of MSW;

- Develop eco-industrial parks;

- Create a unified state information system for waste accounting;

- Education of the public for ecological awareness (Figure 6).

Best Available Techniques: A Case Study of Leading Russian Companies

- Identify stakeholders and describe the roles they can play in the waste management system;

- Define the main criteria of the strategy selection and study the specific features of WMS implemented in different organizations;

- Determine the basic WMS business strategies;

- Substantiate general approaches to the choice of WMS business strategies.

- Participation in the Russian national project “Sort It Right”. The purpose of the project is to create an association of public organizations, businesses, government agencies, and municipal authorities, as well as other organizations and citizens of Russia, in order to develop and implement the best new effective practices of separate solid waste collection, and to promote and teach environment protection and the proper disposal of waste for the wider audience;

- Support of initiatives to install containers and automatic machines for separate solid waste collection in Moscow, including the promotion of public initiatives through social networks, the blogosphere, and popular media;

- Membership of the Plastics Europe Association, in which the world’s leading manufacturers pay special attention to the implementation of the CE principles in the field of plastics;

- Membership in the Charter of Responsible Care in 2015, which implies adherence to standards in the field of environmental protection, environmental safety, work with society, and the business environment;

- Implementation of the “green office” concept (separate collection of garbage in public areas, installation of motion sensors in public areas in order to save energy, office stationery made of secondary raw materials, etc.).

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Food and Agriculture Organization (FAO). Guidelines for the Integration of Sustainable Agriculture and Rural Development. The concept of SARD. 2002. Available online: http://www.fao.org/docrep/w7541e/w7541e04.htm (accessed on 19 July 2019).

- Reh, L. Process engineering in circular economy. Particuology 2013, 11, 119–133. [Google Scholar] [CrossRef]

- Birat, J.-P. Life-cycle assessment, resource efficiency and recycling. Met. Res. Technol. 2015, 112, 206. [Google Scholar] [CrossRef]

- Von Bertalanffy, L. An Outline of General System Theory. Br. J. Philos. Sci. 1950, 1, 134–165. [Google Scholar] [CrossRef]

- Boulding, K. The economy of the coming spaceship earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Resources for the Future/Johns Hopkins University Press: Baltimore, MD, USA, 1966; pp. 3–14. [Google Scholar]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment, Italian ed.; Bologna, M., II, Ed.; Harvester Wheatsheaf: Hemel Hempstead, London, UK, 1990. [Google Scholar]

- Erkman, S. Industrial ecology: An historical view. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Chiu, A.S.; Yong, G. On the industrial ecology potential in Asian Developing Countries. J. Clean. Prod. 2004, 12, 1037–1045. [Google Scholar] [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress towards a circular economy: The drivers and inhibitors of eco-industrial initiative. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. 2012. Towards the Circular Economy. Available online: http://www.ellenmacarthurfoundation.org/business/reports (accessed on 21 April 2019).

- The Circularity Gap Report “Closing the Circularity Gap in a 9% World 2019”. Available online: https://docs.wixstatic.com/ugd/ad6e59_ba1e4d16c64f44fa94fbd8708eae8e34.pdf/ (accessed on 17 May 2019).

- Golinska, P.; Kosacka, M.; Mierzwiak, R.; Werner-Lewandowska, K. Grey decision making as a tool for the classification of the sustainability level of remanufacturing companies. J. Clean. Prod. 2015, 105, 28–40. [Google Scholar] [CrossRef]

- Küçüksayraç, E.; Keskin, D.; Brezet, H. Intermediaries and innovation support in the design for sustainability field: Cases from the Netherlands, Turkey and the United Kingdom. J. Clean. Prod. 2015, 101, 38–48. [Google Scholar] [CrossRef]

- George, A.L. Case studies and theory development: The method of structured, focused comparison. In Diplomacy: New Approaches in History, Theory, and Policy; Lauren, P.G., Ed.; Free Press: New York, NY, USA, 1979; pp. 43–68. [Google Scholar]

- Tyshenko, M.; Waste Ranking. Whats’s going on with the waste in Russia and in the world. Available online: https://republic.ru/posts/90408 (accessed on 18 May 2019).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Urban Development: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 License: CC BY 3.0 IGO (accessed on 17 June 2019).

- Preston, F.; Chatham, J.L. House Briefing A Wider Circle? The Circular Economy in Developing Countries. Available online: https://reader.chathamhouse.org/wider-circle-circular-economy-developing-countries#the-circular-economy (accessed on 17 April 2019).

- Official Web-Site of Federal Service for Supervision of Nature Management (Rosprirodnadzor). Available online: http://rpn.gov.ru/ (accessed on 17 April 2019).

- Russia: There Will Be a Change. Global Recycling. Available online: https://global-recycling.info/archives/1023 (accessed on 30 May 2019).

- What Is Solid Waste and How to Treat Them. Available online: https://vtorothody.ru/othody/tko.html (accessed on 30 March 2019).

- Arkharov, I.A.; Simakova, E.N.; Navasardyan, E.S. Landfill gas as feedstock for energy and industrial processes. Chem. Pet. Eng. 2016, 52, 7–8. [Google Scholar] [CrossRef]

- Eurostat. Treatment of Waste. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=env_wastrt&lang=en (accessed on 30 March 2019).

- Semiletov, V.P. Issues of Economic Planning of Education and the Use of Secondary Material Resources. Ph.D. Thesis, Research Institute in Economics of State Planning Agency of Ukrainian Soviet Socialist Republic, Kiev, Ukraine, 1984. [Google Scholar]

- Utkin, E.A. Use of secondary resources: Experience of fraternal countries // Economics and Organization of Production. Know. Publ. House. 1987, 8, 64. [Google Scholar]

- Resolution of the Government of the Russian Federation of 13 September 1996 No. 1098 “On the Federal target Program Waste”. Available online: https://base.garant.ru (accessed on 17 April 2019).

- Federal Law of 24 June 1998 N 89-FZ “On Production and Consumption Waste” (as Amended). Available online: https://base.garant.ru (accessed on 17 April 2019).

- Federal Law “On Amendments to the Federal Law “On Production and Consumption Waste” and Certain Legislative Acts of the Russian Federation” Dated 31 December 2017 N 503-FZ. Available online: http://www.consultant.ru/document/cons_doc_LAW_286766/ (accessed on 23 April 2019).

- Order of the Government of the Russian Federation No84-r from 25 January 2018. Available online: http://static.government.ru (accessed on 23 April 2019).

- Pavlenkov, M.N.; Larionov, V.G.; Voronin, P.M. Approach to predictive modelling of total municipal solid waste removal volumes. Biofuels 2017, 8, 373–376. [Google Scholar] [CrossRef]

- Pavlenkov, M.N.; Larionov, V.G.; Voronin, P.M.; Pavlenkov, I.M. Specifics of monitoring municipal investment projects in the municipal solid waste industry. Espacios 2017, 38, 14. [Google Scholar]

- Pavlenkov, M.N.; Larionov, V.G.; Voronin, P.M. The Method for Evaluation and Selection of Investment Projects in the Field of Municipal Waste Management. Indian J. Sci. Technol. 2016, 9, 151–155. [Google Scholar] [CrossRef]

- Municipal Solid Waste Management: Opportunities for Russia. Summary of Key Findings. Available online: https://www.ifc.org/wps/wcm/connect/a00336804bbed60f8a5fef1be6561834/PublicationRussiaRREP-SolidWasteMngmt-2012-en.pdf?MOD=AJPERES (accessed on 23 April 2019).

- Remchukov, M.K. Sibur–Green Strategy. Implementation of Circular Economy principles in Russia. Round Table “Transition to Circular Economy in Russia” 11 October 2018. Available online: http://www.anspa.ru/linkpics/News/SIBUR.pdf (accessed on 12 May 2019).

- Environmental Policy of GSC Gazprom. Available online: http://www.gazprom.ru/nature/ecology/ (accessed on 12 May 2019).

- Environmental Strategy of JSC RZD until 2017 and with the Forecast till 2030. Available online: http://www.rzdctares.ru/ (accessed on 17 May 2019).

- RZD Placed Green Eurobonds for 500 Million Euro. TASS. Available online: https://finance.rambler.ru/markets/42189010/?utm_content=rfinance&utm_medium=read_more&utm_source=copylink (accessed on 17 May 2019).

- Resource Saving of “KHMAO” Placed a Debut Bond Issue for 1.1 Billion Rubles Vedomosti, 19 December 2018. Available online: https://www.vedomosti.ru/business/articles/2019/05/08/801079-rossiiskaya-kompaniya-vpervie (accessed on 17 May 2019).

- Rational Waste Management. Evraz Sustainable Development Report 2018. Available online: https://sr2018.evraz.com/ru/hse/environmental-stewardship/waste-stewardship (accessed on 10 October 2019).

- Official Web-Site of OPTIKOM Company. Available online: https://www.opti-com.ru/ (accessed on 17 May 2019).

- Sharing Economy in Russia in 2017. Russian Association of Electronic Communication. Available online: https://raec.ru/activity/analytics/9845/ (accessed on 8 May 2019).

- Clean Country Association. Official Web-Site. Available online: https://www.cleancountry.ru/ (accessed on 12 October 2019).

- RusPro Association. Official Web-Site. Available online: https://ruspro.org/ (accessed on 12 October 2019).

- Kurian, J. Stakeholder participation for sustainable waste management. Habitat Int. 2006, 30, 863–871. [Google Scholar] [CrossRef]

- Heidrich, O.; Harvey, J.; Tollin, N. Stakeholder analysis for industrial waste management systems. Waste Manag. 2008, 29, 965–973. [Google Scholar] [CrossRef] [PubMed]

- Isa, M.H.; Asaari, F.A.; Ramli, N.A.; Ahmad, S.; Siew, T.S. Solid waste collection and recycling in Nibong Tebal, Penang, Malaysia: A case study. Waste Manag. Res. 2005, 23, 565–570. [Google Scholar] [CrossRef] [PubMed]

- Pincelli, I.P.; Meireles, S.; de Castilhos, A.B., Jr. Socio-productive Inclusion of Waste Pickers on Segregated Solid Waste Collection in Brazilian Universities as an Instrument for Sustainability Promotion June 2019. In Sustainability on University Campuses: Learning, Skills Building and Best Practices; Springer International Publishing: Berling, Germany, 2019. [Google Scholar] [CrossRef]

- Rai, R.K.; Bhattarai, D.; Neupane, S. Designing Solid Waste Collection Strategy in Small Municipalities of Developing Countries Using Choice Experiment Journal of Urban Management // Journal of Urban Management, January 2019. Available online: https://www.sciencedirect.com/science/article/pii/S2226585617301188?via%3Dihub (accessed on 20 September 2019).

- Salguero-Puerta, L.; Leyva-Diaz, J.C.; Cortes-Garcia, F.J.; Molina-Moreno, V. Sustainability indicators concerning waste management for implementation of the circular economy model on the University of Lome (Togo) Campus. Int. J. Environ. Res. Public Health 2019, 16, 2234. [Google Scholar] [CrossRef] [PubMed]

| Sector of Economy | Number of Employees | Revenue, 2017 Millions of Russian Rubles | |

|---|---|---|---|

| Public Joint Stock Company (PJSC) “Gazprom” | Oil and gas industry | Over 26,000 | 6,524,711 |

| Public Joint Stock Company (PJSC) “Sibur” | Petrochemical industry | Over 26,000 | 454,619 |

| Russian Railways (RZD Holding) | Transport and logistics | Over 735,000 | 1,697,553 |

| OPTICOM Ltd | Production of office supplies | 554 | 7100 |

| EVRAZ plc (public company) | Metallurgy and coal mining | 70,186 | 623,535 |

| Hazard Class | Hazard Description | Waste Stream Project Examples | International Definition |

|---|---|---|---|

| 1 | Extremely hazardous | Fluorescent light bulbs containing mercury, activated carbon contaminated with mercury sulfide | Hazardous |

| 2 | Highly hazard | Concentrated acids, alkalines, halogenated solvents, lead–acid batteries, dry batteries, etc. | |

| 3 | Moderately hazard | Used lubrication oil, oily sludge, oily rags, used oil filters, non-halogenated solvents, paint wastes, etc. | |

| 4 | Low hazard | Domestic trash, nonferrous metal scrap, certain chemicals, certain construction waste, treated sewage sludge, treated medical wastes, water-based drilling mud, etc. | Non-hazardous |

| 5 | Practically non-hazardous | Inert wastes: plastic, ferrous metal scrap, inert construction wastes, food waste, brushwood, non-treated wood waste |

| Specific Features of the Waste Management Evolution | 1970–1990 Soviet Period: Roots of Circular Economy | 1990–2004 Post-Soviet Collapse | 2004–2019 Waste Management Consciousness | 2019 The Emergence of Responsible Waste Management |

|---|---|---|---|---|

| Government policy | Government implements financed state programs of waste collection and recycling | The minimum regulation that does not work | Development of state policy and regulations for waste recycling and environmental protection; focus on infrastructure development | Waste management turns from separate tools to concept with focus on recycling (not landfilling) |

| Municipal administration | No specific role | No specific role | Delegation of responsibility for solid waste management to the municipal level | Regional operators earned the right to control all methods of waste management from a garbage tank to the range or plant on processing |

| Business | Responsible for collection and recycle/re-use of several types of industrial waste | Almost no responsibility and no incentives for the solid waste recycling or re-use; the main practice is landfilling | Extended producer responsibility (EPR)— companies that produce packaged goods should independently engage in its processing or pay an environmental fee to the state budget | Responsible for the management of industrial waste, environmental fees, the active development of business initiatives for solid waste re-use |

| Household | Separate waste collection routine culture | No incentive, no role | Separate waste collection initiatives for the population are introduced in several regions; still little incentive and almost no role | Still little incentive; development of public initiatives for waste reduction and responsible consumption; new high fees for municipal services for waste management |

| Infrastructure | Exists everywhere for collection, sorting, and recycling | Landfills | Landfills, several plants for burning of waste and several recycling plants | Fast development of plants for burning of waste and several recycling plants; still lack of infrastructure for the separate waste collection; emergence of digital infrastructure for waste processing. |

| Limitations | Only part of the waste is recycled such as glass bottles, metal scrap, and scrap paper | Waste management was limited to collection and landfill disposal of solid waste; landfill ownership became a corrupt business | Unstructured policy, investments are not enough, the role of business and people is very low | Incentives for business are still insufficient; infrastructure for separate household waste collection is insufficient |

| WMS Stakeholder Role | Responsibility Assigned to the Role |

|---|---|

| Producer (PR) | A company that produces products that will become solid waste at the end of the lifecycle. The best example is companies that produce packaging or home electronics. The responsibility of the producer is to decrease the environmental impact of the product through different actions like the usage of biodegradable materials or recycled materials or materials that could be recycled, increasing the degree of product recyclability, product service time extension, etc. |

| Generator (G) | Any person or a company producing waste. The industrial generator’s responsibility includes decreasing the amount of waste, collecting and sorting waste, handling waste processing, and/or recycling/reuse of waste. The household generator’s responsibilities include decreasing the amount of waste, collecting and sorting waste, and reusing waste. |

| Collector (C) | A company or a person that collects the waste generated by other persons or companies. Examples are street sweepers in the city or voluntary services cleaning the forests or river banks. The responsibility of the collector is to sort waste and bring it to the official disposal site without burning or burying. Case studies show evidence of high importance of this role in developing countries [47,48]. |

| Transporter (T) | A company that transports waste from the official or non-official disposal sites to the disposer or processor companies. The responsibility of the transporter is to keep the waste sorted in the way it was sorted before the transportation and also to prevent secondary pollution due to the intended or unintended loss of waste. |

| Disposer (D) | A company that accumulates and stores the waste before its processing or without intention to process. Landfills perform the role of the disposer. The responsibility of the disposer is to prevent environmental impact in the process of waste storage. It can also include waste sorting (segregating) or keeping the waste sorted in the way it was done by the collector or the generator. |

| Processor (PS) | A company that processes waste, including recycling. The responsibility of the processor is to increase the level of processing to decrease the amount of waste left after processing, to use technologies with low environmental impact, and to improve the quality of the recycled products. |

| Educator (E) | A person or a company (including non-governmental organizations (NGOs) and media) that teaches waste management tools, principles, and practices to any stakeholders. The responsibility of the educator is to use up-to-date information and relevant training tools to improve the knowledge and skills of stakeholders to be used in WMS. |

| Promoter (PM) | A person or a company (including NGO and media) that promotes the ideas of waste management, shares best practices, involves new participants in WSM, and organizes contests or actions in support of WMS. The responsibility of the promoter is to disclose the up-to-date and true information on WMS, granting full access for everybody to the actions or campaigns without discrimination. The promoter does not use the promotion to garner unfair competition. |

| Regulator (R) | Government or municipal body that produces a strategy of WMS development and relevant legislation for all WMS stakeholders. It can also be a company developing and introducing sectoral standards in waste management. The responsibility of the regulators is to focus on positive environmental, social and economic effects of legislation, create incentives for all stakeholders to take on their responsibilities, provide necessary resources to support legislation, monitor its results, and continuously improve legislation in accordance with changing situation. |

| Inspector (I) | A government or municipal body, NGO, or a private sector company making sure that WMS processes are performed according to the legislation, contract terms, and funding rules. Inspectors may or may not perform punitive functions. The responsibility of an inspector is to focus inspection on environmental, social, and economic effects, to not engage in corrupt and unfair inspecting practices, to seek assistance in WMS development, and to provide transparency and accuracy of inspection results. |

| Funder (F) | A company or a person providing funds to support WMS development, including infrastructure development, education, and promotion actions. It could be an ordinary funder when no other role is performed or an active funder when a company or a person invests funds, as well as performs another role. The responsibility of a funder is to ensure that funds are efficiently used according to the intended purpose, to not engage corrupt and unfair practices in allocating funds, and to measure the efficiency of the funds used for WMS development purposes. |

| Types of WSM Strategies | Passive WMS | Preventive WMS | Active WMS (Sustainable Development Management) |

|---|---|---|---|

| Organization activities | -Purification of emissions and discharges, disposal of waste at the end of the production and technological cycle -Compliance with pollution reduction procedures -Compliance with the requirements of external environmental reporting -environmental service -Emergency action plan | -Preventing environmental pollution by replacing technologies, raw materials, etc. -Waste reduction -Decreasing the amount of waste left after processing -Promoting the ideas of waste management, sharing the best practices | -Implementation of ecological certification programs -Disclosing the up-to-date and important information on WMS -Product lifecycle (cradle-to-grave) system development -Recognition of enterprise importance in the flow of goods, raw materials, and energy |

| State supportive measures | -State environmental control, the establishment of effective standards, taking into account the real technological and financial possibilities, taking into account industry production parameters (for specific industries and agriculture) -Timely informing of a possible tightening of environmental regulations, strict enforcement measures | -Legislative increase of responsibility of top managers and enterprises -Requirements for integration into the regional waste management system -Mandatory provision of environmentally relevant information to the public -Development of incentive programs for energy conservation. | -Discussion and adoption of initiatives in the field of health, environmental safety, and sustainable development at the international level as priorities in relation to the system of free exchange of goods -Strategies for managing and optimizing of the flow of goods, raw materials, and waste |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedotkina, O.; Gorbashko, E.; Vatolkina, N. Circular Economy in Russia: Drivers and Barriers for Waste Management Development. Sustainability 2019, 11, 5837. https://doi.org/10.3390/su11205837

Fedotkina O, Gorbashko E, Vatolkina N. Circular Economy in Russia: Drivers and Barriers for Waste Management Development. Sustainability. 2019; 11(20):5837. https://doi.org/10.3390/su11205837

Chicago/Turabian StyleFedotkina, Olga, Elena Gorbashko, and Natalia Vatolkina. 2019. "Circular Economy in Russia: Drivers and Barriers for Waste Management Development" Sustainability 11, no. 20: 5837. https://doi.org/10.3390/su11205837

APA StyleFedotkina, O., Gorbashko, E., & Vatolkina, N. (2019). Circular Economy in Russia: Drivers and Barriers for Waste Management Development. Sustainability, 11(20), 5837. https://doi.org/10.3390/su11205837